Imeko eOstreliya:

Kutheni iiNkampani zaseOstreliya zangaphandle Isitofu sokubumba ukuya kwi-DJmolding

Ishishini limalunga nokunciphisa iindleko. Kuhlala kukho ukukhangela iindlela zokugcina imali kunye nokwandisa inzuzo kwishishini ngalinye, kungakhathaliseki ubungakanani bayo. Eyona ndlela ixhaphakileyo yokwenza oku namhlanje kukukhuphela ngaphandle.

Ngokwandayo, iinkampani zithengisa iimveliso zazo kwiifektri zaseTshayina ngenxa yesantya esikhawulezayo, ukusebenza kakuhle, kunye namaxabiso aphantsi. Imveliso abayidingayo ngexabiso abakwaziyo ukufikelela kuyo ide yathunyelwa eTshayina ziinkampani zaseOstreliya.

Abanye abavelisi abavela e-Australia, ngenxa yesizathu esifanayo, baye bakhupha i-injection yabo yeplastiki kwi-DJmolding.

Iindleko zokuBumba isitofu kwi-DJmolding

Xa kuthelekiswa namanye amazwe, i-China ineendleko eziphantsi zabasebenzi kunye nempahla ekrwada, esesinye sezizathu zokuba iinkampani zikhuphe isitofu sokubumba kubo. Inzuzo ye-DJmolding inokunyuswa ngokunciphisa iindleko zemveliso.

Iinkampani ezigxile kwimveliso yexabiso eliphezulu kwaye zifuna ukongiwa kweendleko zifanele ukuba zixhamle koku. Inani elikhulu labemi baseTshayina likwathetha ukuba kukho abasebenzi abafumaneka ngokulula abanokwanelisa iimfuno zenkampani yakho. I-DJmolding inokunceda ukunciphisa iindleko zoqeqesho kunye nokwandisa imveliso.

Umgangatho Ngokubonelela nge-DJmolding injeciton

I-DJmolding ityale imali kwizixhobo zokuvelisa eziphambili kwaye baqeqeshe abasebenzi babo kwiindlela zamva nje zokuvelisa, ezinokunceda ukuphucula umgangatho weemveliso zabo. I-DJmolding iphinde ityale imali eninzi kuphando kunye nophuhliso, oku kuthetha ukuba i-DJmolding inokufikelela kubuchwephesha obuphezulu obunokubanceda ukuba bavelise iimveliso ezintsha. Oku kuyinyani ngakumbi kwiinkampani ezisebenza ngobugcisa obuphezulu bokwenza izinto ezifana ne-aerospace, i-electronics kunye nezixhobo zeemoto.

Amaxesha okukhokela:

Ukukhutshwa kwe-DJmolding kaninzi kunokukhokelela kwixesha elifutshane elihamba phambili xa kuthelekiswa nokuveliswa kwekhaya lase-Australia, ngenxa yeziseko eziphuhliswe kakuhle kunye nenyaniso yokuba i-China isondele kwiimarike ezinkulu zase-Asia.

Isantya senkqubo yokwenziwa kwe-DJmolding sikwabalulekile, sinokujika iimveliso kwiiveki nje ezimbalwa. Oku kunokuba luncedo ngakumbi kumashishini ajonge ukusungula iimveliso ezintsha okanye ukwazisa imigca yamaxesha onyaka, eqinisekisa unikezelo olwaneleyo ngaphambi komhla wokukhutshwa.

Amava e-DJmolding I-Injection Molding Industry:

I-DJmolding iqhayisa ngobuchule obuninzi kwicandelo lemveliso, inikezela uluhlu olubanzi lweenkonzo ezibandakanya uyilo, iprototyping, indalo yokubumba, ukubumba inaliti, kunye ne-assembli. Ngaphaya koko, uninzi lwababoneleli baseTshayina banonxibelelwano olusekiweyo nababoneleli basekhaya, okubenza bakwazi ukudibanisa abathengi kunye neefektri ezikhethekileyo zeenkonzo ezinjengokupakisha kunye nokuthumela.

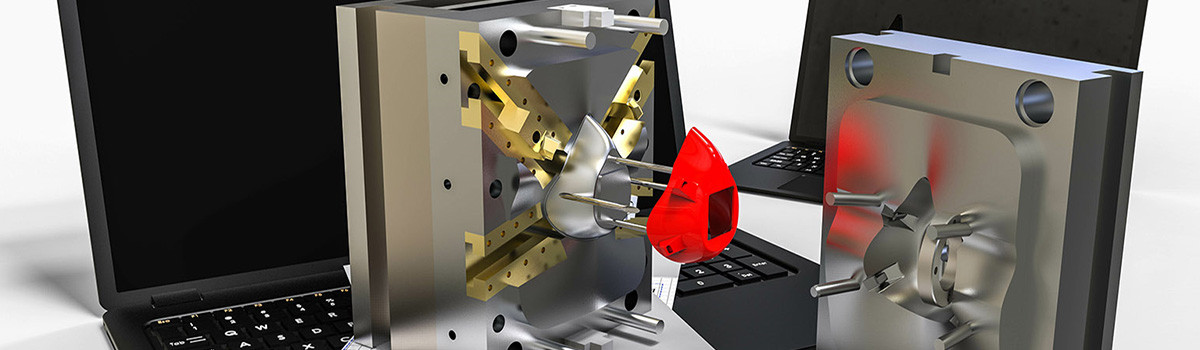

Nantsi isikhokelo senyathelo nenyathelo kwinkqubo yokubumba inaliti ye-DJmolding:

1.Yila ukubumba: Oku kubandakanya ukwenza imodeli ye-3D (iisoftware zoyilo: i-solidworks, ug, pro-e…) yemveliso kunye nokungunda, kuthathelwa ingqalelo izinto ezifana nezinto (PP, PE, ABS, PA…), ubukhulu bodonga, ubungakanani besango, kunye ixesha lokupholisa.

2.Yenza ukungunda: Umngundo udla ngokwenziwa ngentsimbi okanye i-aluminiyam kwaye kufuneka yenziwe ngokweenkcukacha ezichanekileyo. Uluhlu lweentsimbi zokubumba zeplastiki ezinobulukhuni:

*Intsimbi ye-P20 - 28-32 Hrc

* I-420 Steel - 48-52 HRc

*Intsimbi ye-H13 - 48-52 Hrc

* I-S7 Steel - 45-49 HRc

* I-NAK55 Steel - 50-55 HRc

* I-NAK80 Steel - 38-43 HRc

*DC53 Steel - 50-58 HRc

*Intsimbi ye-A2 - 60-64 HRc

* I-D2 Steel - 60-64 HRc

Qaphela: I-HRc ibhekisa kwisikali sobunzima be-Rockwell, esilinganisa ubulukhuni besixhobo.

3.Fakela ukungunda: Umngundo uxhonywe kumatshini wokubumba inaliti kwaye ubotshwe phakathi kweepleyiti ezi-2 kumatshini.

4.Layisha imathiriyeli yeplastiki: Izinto zeplastiki zilayishwa kwi-hopper yomatshini wokubumba inaliti ngokusebenzisa umxhuzulane kwaye enye i-hopper ingazama imathiriyeli yeplastiki ngelixa isitofu sivuliwe.

5. Nyibilikisa iplastiki: Izinto zeplastiki zinyibilikiswa bubushushu kunye noxinzelelo ngaphakathi kombhobho womatshini wokubumba inaliti.

6.Tofa iplastiki kubumba: Iplastiki enyibilikisiweyo ibaleka ingene kumngundo nge nozzle kwaye ihlume phantsi koxinzelelo oluphezulu, kwaye idlule kwimbaleki, isango emva koko ugcwalise imingxuma yokungunda.

7.Cool kwaye uqinise: Umngundo upholisiwe ukuvumela iplastiki ukuba iqine ngaphakathi kumngxuma wokungunda okwethutyana, kwaye ixesha elininzi, ixesha lokupholisa liya kuba yi-2/3 yexesha lomjikelo wonke.

8.Vula umngundo: I-mold ivuliwe kwaye imveliso ebunjiweyo iyasuswa kwi-mold, emva koko i-mold ivale kwaye umjikelezo olandelayo uqala.

Izixhobo eziyimfuneko kunye nemathiriyeli: Isitofu sokubumba umatshini, ukungunda, imathiriyeli yeplastiki, umatshini wokomisa, isilawuli sobushushu (kwimfuno eziphezulu kakhulu nezibanda kakhulu zokubumba inaliti)

Inxalenye ebunjiweyo inokubandezeleka kwimiba eyahlukeneyo ebandakanya izinto ezingaphezulu kwimiphetho (iFlash), enokukhokelela kwisakhiwo esibuthathaka. I-Warping okanye ukuphazamiseka kunokwenzeka xa inxalenye ebunjiweyo ingagcini imilo okanye ubungakanani bayo ngenxa yokupholisa okungalinganiyo. Amabala amnyama kwinqanaba elibunjiweyo liyisiphumo sokucutshungulwa kwezinto ezimbi okanye ukungcoliswa. Ukugqitywa komgangatho ongemhle, obonakaliswe kukuthungwa okungalinganiyo okanye uburhabaxa, kunokubangelwa kuyilo lokungunda olungafanelekanga okanye ukukhetha izinto eziphathekayo. Iimpawu ze-Sink, i-indentations kwinxalenye ebunjiweyo, inokubangelwa ukuzaliswa okungafanelekanga kwesikhunta okanye uxinzelelo olunganeleyo ngexesha lokubumba. Ukongezelela, inxalenye ebunjiweyo inokuba nzima ukuyikhupha, ekhokelela ekunciphiseni ixesha lokuvelisa kunye neendleko ezongeziweyo, okanye inokonakala ngexesha lokukhutshwa.

Ukubaluleka kwamanyathelo okhuseleko akukwazi ukugqithiswa kwinkqubo yokubumba inaliti. Ukuthintela ukwenzakala, abasebenzi kufuneka basebenzise izixhobo zokhuselo ezinje ngeeglavu kunye neeglasi zokhuseleko njengoko iplastiki enyityilisiweyo ifikelela kumaqondo obushushu aphezulu kakhulu, ngamanye amaxesha ukuya kuthi ga kuma-300 degrees, kwaye inamandla okutshiza. Kubalulekile ukuba abaqhubi bafumane uqeqesho olululo kwiinkqubo zokusebenza ezikhuselekileyo.

Yise kude

Kubalulekile ukuqwalasela ngononophelo zonke izinto ezibandakanyekayo ekuthunyelweni kwe-China, kubandakanywa nempahla, iindleko zokuthumela ngenqanawa, kunye nefuthe elinokubakho kwikhonkco lakho lokubonelela.

Ukusebenza neqabane elithembekileyo nelinamava, i-DJmoldnig inokunceda inkampani yakho ukuba iqinisekise amava agudileyo kwaye aphumeleleyo ekukhupheleni ngaphandle.