Iinkonzo zokuBumba ngesitofu sePlastiki

Ukubumba inaliti yeplastiki yinkqubo yokuzalisa isixhobo sokubumba nge-resin yeplastiki engamanzi phantsi koxinzelelo olukhulu. Isixhobo sinokubandakanya umngxuma omnye okanye amakhulu emingxuma ukuze kwenziwe amanani angenammiselo amacandelo.

Zininzi iingenelo zokubumba inaliti yeplastiki. Oku kubandakanya ukukwazi ukwenza umthamo omkhulu wamalungu ngokukhawuleza, umgangatho ophezulu womphezulu, ii-resin ezininzi onokukhetha kuzo, ukuguquguquka kombala, kunye nezixhobo ezihlala ixesha elide ezinokuhlala iminyaka.

* Amawaka eereyini zokukhetha kuzo

* Ezoqoqosho zokukala

* Izinzile kwaye iyaphinda

* Umgangatho ogqwesileyo womphezulu

* Ukugqithisa ngaphezulu kokhetho loyilo olungakumbi

* Imingxunya emininzi kunye nezixhobo zosapho

Ukubumba inaliti yeplastiki yinkqubo yokuvelisa ebandakanya ukunyibilikisa iipeliti zeplastiki kwaye uzitofe kwigodi lokungunda ukwenza into enomacala amathathu. Le nkqubo iqala ngeemveliso ezininzi, ukusuka kwiindawo ezincinci ezichanekileyo ukuya kwizinto ezibalulekileyo zemoto. Ukubumba inaliti yeplastiki kunika iingenelo ezininzi kunezinye iinkqubo zokuvelisa, kubandakanywa amazinga aphezulu emveliso, ukuguquguquka koyilo, kunye nokusebenza kakuhle kweendleko. Esi sikhokelo siya kujonga nzulu kwi-injection yeplastiki yokubumba kwaye iphonononge izicelo zayo ezahlukeneyo, izibonelelo, kunye nemida

Amalungu eplastiki enziwe ngokweenkcukacha zakho kwaye azibonelelwanga kuye nawuphi na omnye umthengi. Ezi zinokuba ziindawo zobunjineli, iikepusi, izinto zokupakisha, iindawo zonyango njl.

Ulwelo lweRubha yeSilicone (LSR) yokuBumba iSitofu

I-injection molding ye-Liquid Silicone Rubber (LSR) yinkqubo esetyenziselwa ukuvelisa iindawo ezithambileyo, ezomeleleyo kwimiqulu ephezulu. Ngexesha lenkqubo, amacandelo amaninzi ayimfuneko: i-injector, i-metering unit, i-drum yokubonelela, i-mixer, i-nozzle, kunye ne-mold clamp, phakathi kwabanye.

Inkonzo yokuKhusela ngokukhawuleza

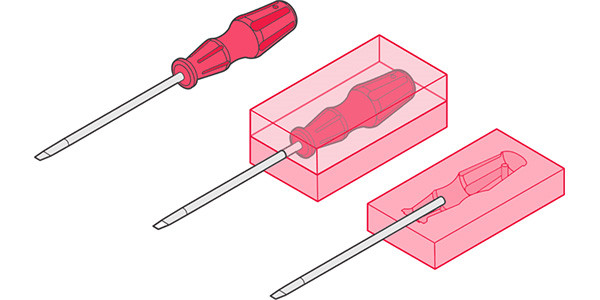

Iprototyping ekhawulezileyo yinkqubo yokuphuhlisa iiprototypes zeemveliso ngokukhawuleza okukhulu. Iprototyping yinxalenye ebalulekileyo yophuhliso lwemveliso. Kulapho amaqela oyilo enza imveliso yovavanyo ukusebenzisa izimvo zabo.

Yinkqubo yokuphuhlisa iiprototypes ngokukhawuleza kangangoko kunokwenzeka ukulinganisa uyilo lokugqibela lwemveliso. Luluhlu lweendlela zobuchule ezisetyenziselwa ukulinganisa iprototype yesikali secandelo lomzimba okanye indibano kusetyenziswa idatha yeCAD.

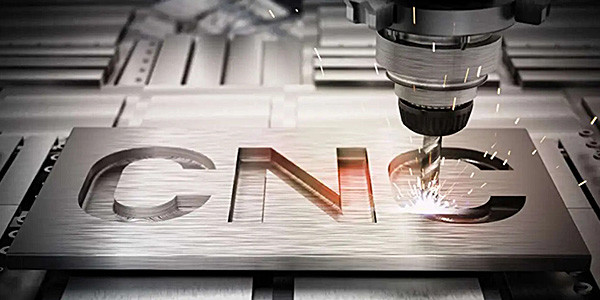

I-CNC imele ukulawulwa kwamanani ekhompyutheni, okuyithekhinoloji yokulawula izixhobo zomatshini ngokuzenzekelayo ngokusebenzisa i-microcomputer encanyathiselwe kwisixhobo. Oomatshini be-CNC babeza kusebenza ngokwemiyalelo ecwangcisiweyo enekhowudi, njengokushukuma koomatshini, izinga lokutya kwezinto, isantya, njalo njalo. Akukho mfuneko yabaqhubi ukulawula umatshini ngesandla, ngoko ke, i-CNC inceda ukuphucula ukusebenza kunye nokuchaneka kumlinganiselo omkhulu.

Automotive Plastic Components Isitofu Molding

Ukusebenza kweemoto eziphezulu kufuna iinxalenye ezizisingatha zonke. Iiplastiki zisebenza ukusuka kwi-injini ukuya kwi-chassis; kuyo yonke ingaphakathi ukuya ngaphandle. Iiplastiki zemoto zanamhlanje zenza malunga ne-50% yomthamo wesithuthi esikhanyayo esitsha kodwa ngaphantsi kwe-10% yobunzima bayo.

Siye saphuhlisa ukungunda kwaye sinemveliso rhoqo yeAutomotive Plastic Parts ezibonelela kushishino lweemoto. Siye sasebenzisana nabavelisi beemoto abaliqela abaziwayo.

I-Recycled Plastic Injeciton Molding

Iiplastiki ezisetyenzisiweyo zibhekiselele kwizinto zeplastiki eziphinda zisetyenziswe. Inokuvela kwezinye iimveliso zeplastiki okanye inkunkuma ephuma kwinkqubo yokubumba inaliti yeplastiki. Ezi mathiriyeli ziphinda zisetyenziswe zinokuba waloluphi na uhlobo okanye umbala, kwaye xa uzisebenzisa ukwenza iimveliso ngokubumba inaliti, akukho lahleko kumgangatho.

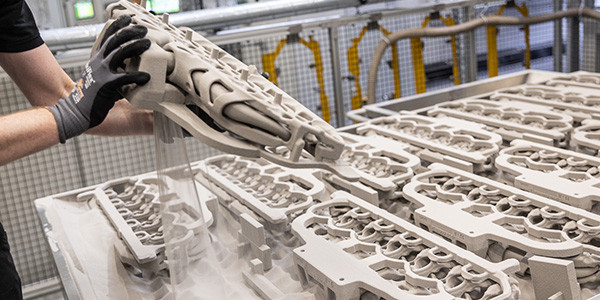

Ukubunjwa kwesitofu soMqulu ophantsi

Kwi-DJmolding, imfuno yethu, imveliso ephantsi yemveliso kunye ne-injection molding-esebenzisa i-aluminium tooling-yindlela ekhawulezayo, eneendleko zokuvelisa amakhulu amawaka eenxalenye ezibunjiweyo zokugqibela.

Inkonzo yokwenziwa komthamo ophantsi

Amashishini amancinci ahlala efuna uncedo ekufumaneni izisombululo zemveliso ezifikelelekayo ezinokuvelisa umthamo ophantsi weemveliso ngaphandle kokufumana iindleko eziphezulu. Amashishini amancinci anezixhobo ezinqongopheleyo ahlala efuna ukoyisa umqobo obalulekileyo ngenxa yemfuno yeendleko zokuyila ubungakanani obukhulu kwiindlela zokwenziwa kwemveli. Nangona kunjalo, ngokuvela kweenkonzo zokuvelisa umthamo ophantsi, amashishini amancinci ngoku anokuvelisa iimveliso ezincinci kwixabiso elincinci leendleko zeendlela zokuvelisa eziqhelekileyo. Eli nqaku liza kuphonononga izibonelelo zeenkonzo zokwenza umthamo ophantsi kunye nendlela abanokunceda ngayo amashishini amancinci ukuba ahlale ekhuphisana.

Ukubunjwa kwesitofu soMqulu ophezulu

Ngaphezulu kwamawaka ezinto zokubumba iinaliti zeplastiki kunye nezixhobo zokwenza iplastiki ukukhetha kuzo zonke igama, zeziphi ezinye zeempawu eziphezulu ezenza inkampani yokubumba ibonakale? Xa ukhetha umboneleli, izinto ezininzi kufuneka zithathelwe ingqalelo; kubandakanywa amandla, ukuqinisekiswa komgangatho, isidima senkampani, iindleko, kunye nexesha lokuhambisa. Ukufumana i-molder efanelekileyo yeplastiki yokubumba ukuze ihambelane neemfuno zakho kunokubonakala kudla ixesha kodwa ukugqiba iimfuno zakho eziphantsi kunye neziphezulu zevolumu kuqala kunye nendlela ezinokutshintsha ngayo ekuhambeni kwexesha, kuya kunceda ukunciphisa ukhetho lwakho.

Thermoplastic Injection Molding

Ukubumba inaliti ye-Thermoplastic yinkqubo yokwenziwa edumileyo esetyenziselwa ukwenza iindawo ezahlukeneyo zeplastiki kumashishini amaninzi. Le nkqubo ibandakanya ukunyibilika iipellet zeplastiki kunye nokutofa kubo kwi-mold ukuvelisa imilo emithathu-dimensional. Ukubumba inaliti ye-Thermoplastic kusebenza kakhulu kwaye kuyabiza kakhulu ekuveliseni umthamo omkhulu wamalungu eplastiki akumgangatho ophezulu anokunyamezelana okuqinileyo. Esi sikhokelo sibanzi siya kuphonononga imiba eyahlukeneyo yokubumba inaliti ye-thermoplastic, kubandakanya izinto eziluncedo kunye nezingeloncedo, iintlobo ze-thermoplastics ezisetyenzisiweyo, inkqubo yokubumba inaliti, ukuqwalaselwa koyilo, kunye nokunye okuninzi.

Faka isitofu sokubumba yinkqubo yokuvelisa esetyenziswa ngokubanzi ekuveliseni iinxalenye zeplastiki ezintsonkothileyo ezinamalungu afakwe ngaphakathi. Obu buchule bubandakanya ukufaka intsimbi okanye iinxalenye zeplastiki kumngxunya wokungunda phambi kwenkqubo yokubumba inaliti. Izinto ezityhidiweyo zihamba zijikeleze into efakiweyo, zenza ikhonkco eliqinileyo phakathi kwezinto ezimbini. Faka isitofu sokubumba kubonelela ngeenzuzo ezininzi, kubandakanya ukuphuculwa kokuguquguquka koyilo, ukunciphisa ixesha lokudityaniswa, kunye nokusebenza kwenxalenye eyongeziweyo. Esi sikhokelo sibanzi siya kuphonononga iindlela ezahlukeneyo, izibonelelo, kunye nokusetyenziswa kokufakwa kwesitofu sokubumba.

Ukugqithisa yinkqubo yokuvelisa apho i-substrate okanye inxalenye yesiseko idibaniswe kunye nenye okanye izinto ezininzi zokudala imveliso yokugqibela kunye nokusebenza okuphuculweyo, ukuqina, kunye nobuhle. Le nkqubo ifumene ukuthandwa kwiminyaka yakutshanje ngenxa yokukwazi ukuphucula umgangatho kunye nokusebenza kweemveliso ngelixa inciphisa iindleko kunye nokwenza lula inkqubo yokuhlanganisa. I-Overmolding ifumana izicelo kumashishini ahlukeneyo, njengeemoto, i-elektroniki, izixhobo zonyango, kunye neemveliso zabathengi. Ukuqonda ngokupheleleyo le nkqubo, eli nqaku liza kuphonononga kwiinkalo ezininzi zokugqithisa, kubandakanya ubuchule bayo, izixhobo kunye nokusetyenziswa.

Ukubunjwa kwesitofu semibala emibini

Ukubumba inaliti yemibala-mibini, okanye ukubumba inaliti yezitofu ezimbini, yinkqubo yokuvelisa esetyenziselwa ukuvelisa iinxalenye zeplastiki ezinemibala emibini eyahlukeneyo okanye imathiriyeli. Le nkqubo ibandakanya ukujova ezinye izinto ezimbini kwi-mold enye ukudala indima kunye nokugqiba iithoni ezimbini okanye iimpawu ezahlukeneyo zokusebenza. Ukubumba inaliti yemibala emibini kunemisebenzi emininzi kumashishini ahlukeneyo, kubandakanya iimoto, ezonyango, kunye neemveliso zabathengi. Eli nqaku liza kuphonononga kwiinkcukacha zokubumba inaliti yemibala emibini, iingenelo zayo, imida, kunye nokusetyenziswa.

Kwihlabathi lanamhlanje elikhawulezayo, imfuno yokusebenza ngokufanelekileyo kunye nokuguquguquka kwimveliso iye yanda. Ngena kwiinkonzo zokuvelisa ezifunekayo, indlela yokuguqula ngokutsha iiparadigms zemveli zemveliso. Eli nqaku lintywila nzulu kumbono, iingenelo, usetyenziso, kunye nethemba leenkonzo zokuvelisa ezifunwayo, lisikhanyisela ngendlela eziguqula ngayo amashishini kwihlabathi liphela.

Ukwazi ngakumbi malunga neemveliso zeplastiki kunye neenkonzo ze-DJmolding, nceda uqhagamshelane nathi nge-imeyile: info@jasonmolding.com