Isitofu sokwenziwa koMngundo

Iiplastiki zizinto eziqhelekileyo ezisetyenziselwa iimveliso kumashishini ahlukeneyo. Izinto zokudlala, izinto zeemoto, izixhobo zonyango, izixhobo, kunye nokunye konke kwenziwa ngeplastiki. Uninzi lwezinto zeplastiki okanye esidibana nazo kubomi bethu bemihla ngemihla ziveliswa ngokukhohlisa intlaka enyibilikisiweyo kuyilo oluchaziweyo kunye nenkqubo yokuvelisa ebizwa ngokuba yinaliti yeplastiki. Le nkqubo isebenzayo kakhulu inokwenza iinxalenye ngobukhulu kunye neemilo ezininzi kwaye inokuphindaphinda inxalenye efanayo ngamaxesha amaninzi usebenzisa ukubumba okufanayo. Embindini wale nkqubo kukungunda, okwabizwa ngokuba yi-tooling. Inkqubo yokwenziwa komngundo ekumgangatho ophezulu ibalulekile ekuveliseni amacandelo asemgangathweni ngelixa igcina ukusebenza kweendleko. Umgangatho wenxalenye uya kunyuka kwaye iindleko zeprojekthi zizonke ziya kuhla xa utyalo-mali kwimveliso esemgangathweni ophezulu.

Isitofu Molding Amanyathelo

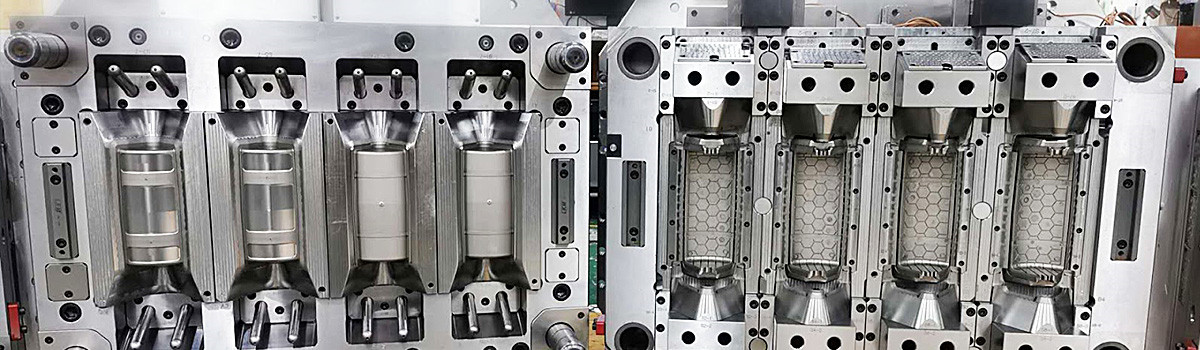

Ukubumba isitofu yenye yezona nkqubo zixhaphakileyo zokuvelisa ezisetyenziselwa ukuvelisa iimpahla zeplastiki. Yinkqubo yemfuno ephezulu enokuthi ivelise kwakhona inxalenye efanayo amawaka amaxesha. Inkqubo iqala ngefayile yeComputer Aided Design (CAD) equlethe ikopi yedijithali yecandelo. Ifayile ye-CAD isetyenziswa njengeseti yemiyalelo yokunceda kwinkqubo yokwenziwa komngundo. Umngundo, okanye isixhobo, ngokuqhelekileyo senziwe ngamaqhekeza amabini esinyithi. Umngxuma okwimilo yenxalenye usikwa kwicala ngalinye lokungunda. Esi sibumba sikholisa ukwenziwa nge-aluminiyam, intsimbi, okanye ingxubevange.

Emva kokuveliswa kokungunda, inyathelo elilandelayo kukukhetha izinto ezifanelekileyo zeplastiki. Ukukhethwa kwezinto eziphathekayo kuya kuxhomekeka kwindlela inxalenye yokugqibela eya kusetyenziswa ngayo. Izinto zeplastiki zineempawu ezahlukeneyo zokuqwalasela. Oku kuquka phezu kwayo yonke inkangeleko kunye nokuziva, kunye nokumelana nemichiza, ubushushu, kunye nokulimala. Thetha neengcaphephe e-DJmolding ukuze ufunde ngakumbi malunga nemathiriyeli yeplastiki ekhoyo yokubumba inaliti.

Izinto ezikhethiweyo ziqala njengepellet yeplastiki efakwe kwi-hopper kumatshini wokubumba inaliti. Iipellets zidlula kwigumbi elishushu apho zinyibilikiswa khona, zixinzelelwe, ze emva koko zitofwe kumgodi wokungunda. Nje ukuba indawo ipholile, iziqingatha ezibini zomngundo zivula ukukhupha inxalenye. Umatshini ke useta ngokutsha ukuqalisa inkqubo kwakhona.

Yeyiphi imathiriyeli esetyenziselwa ukwenza iiMbumba?

Ukuveliswa kokubumba kwenziwa ngentsimbi, i-aluminium, okanye i-alloy. I-DJmolding isebenzisa umgangatho ophezulu wentsimbi yokwenza umngundo. Ukuveliswa kokungunda kwentsimbi kubiza kancinci kunokusebenzisa ialuminiyam okanye ialloyi. Iindleko eziphezulu zidla ngokulungiswa bubude bobomi obude bokungunda kwentsimbi. Iimbumba zeAluminiyam, ngelixa zingabizi kakhulu ukuvelisa, azihlali ixesha elide njengentsimbi kwaye kufuneka zitshintshwe rhoqo. Ukungunda kwentsimbi kuya kuhlala ngaphezulu kwekhulu lamawaka emijikelo. Iimbumba zealuminiyam ziya kufuna ukutshintshwa rhoqo kakhulu. Ukuveliswa kokungunda kwentsimbi kunokuvelisa uyilo oluntsonkothileyo olungenakufezekiswa nge-aluminiyam. Iimbumba zentsimbi nazo zinokulungiswa okanye zitshintshwe nge-welding. Iimbumba ze-aluminiyam ziya kufuneka zenziwe ngoomatshini ukusuka ekuqaleni ukuba ukungunda konakalisiwe okanye ukulungiselela utshintsho. Iimbumba zentsimbi ezikumgangatho ophezulu zinokusetyenziswa amawaka, amakhulu amawaka, kwaye ngamanye amaxesha ukuya kuthi ga kwimijikelo yesigidi.

Isitofu sokungunda Components

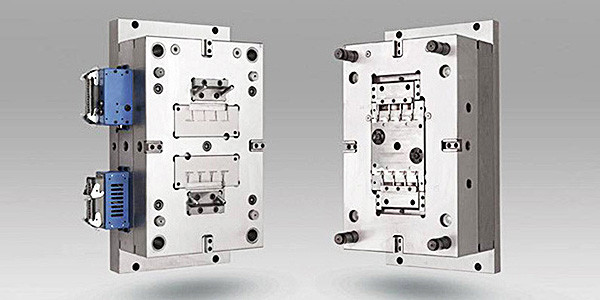

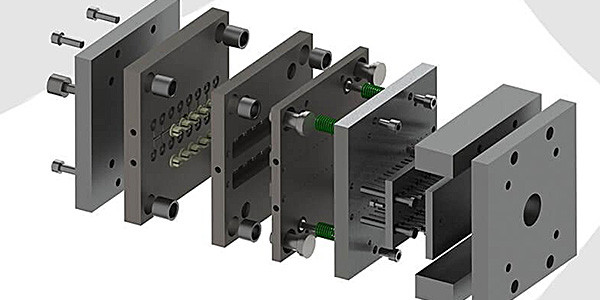

Uninzi lweenaliti zokubumba zenziwe ngamacandelo amabini - icala elingu-A kunye necala lika-B, okanye umngxuma kunye nombindi. Icala lomgodi lelona cala lilungileyo ngelixa esinye isiqingatha, undoqo, siya kuba nokungafezeki okubonakalayo okuvela kwizikhonkwane ze-ejector ezityhala indawo egqityiweyo ngaphandle kokungunda. Isitofu sokungunda siya kubandakanya iipleyiti zenkxaso, ibhokisi ye-ejector, ibha ye-ejector, izikhonkwane ze-ejector, iipleyiti ze-ejector, i-sprue bushing, kunye neringi yokubeka.

I-injection molding yinkqubo yokuvelisa kunye neziqwenga ezininzi ezihambayo. Apha ngezantsi kukho uluhlu lwamagama achaza uninzi lwamaqhekeza ayimfuneko kwimveliso yokungunda kunye nokubumba inaliti. Isixhobo siqukethe iipleyiti ezininzi zentsimbi ngaphakathi kwesakhelo. Isakhelo sokubumba sifakwe kumatshini wokubumba isitofu kwaye sigcinwe kwindawo kunye neeclamps. Ukusikwa kokungunda kwesitofu esijongwe ecaleni kuya kufana nesandwich enomaleko ohlukeneyo. Jonga i-Injection Molding Glossary yethu yoluhlu olupheleleyo lwamagama.

Isakhelo sokungunda okanye isiseko sokungunda: Uluhlu lweepleyiti zentsimbi ezibamba amacandelo okubumba kunye, kuquka i-cavities, ii-cores, i-runner system, inkqubo yokupholisa kunye ne-ejection system.

Ipleyiti: Esinye isiqingatha sobumba besinyithi. Le pleyiti ayinazo iindawo ezihambayo. Ingaqulatha nokuba ngumngxuma okanye umbindi.

B Icwecwe: Esinye isiqingatha sokubumba isinyithi. Ipleyiti iqulethe iindawo ezihambayo okanye indawo yokuvumela iinxalenye ezihambayo ukuba zisebenzisane nenxalenye egqityiweyo - ngokuqhelekileyo izikhonkwane ze-ejector.

Amacwecwe eNkxaso: Iipleyiti zensimbi ngaphakathi kwesakhelo sokubumba esinika uzinzo ngexesha lokubumba.

Ibhokisi ye-Ejector: Iqulethe inkqubo ye-ejector esetyenziselwa ukutyhala inxalenye egqityiweyo ngaphandle kokungunda.

Iipleyiti ze-Ejector: Ipleyiti yentsimbi equlethe ibha ye-ejector. Ipleyiti ye-ejector ihambisa ukukhupha imveliso egqityiweyo emva kokubumba.

Ibha yokukhupha: Inxalenye yepleyiti ejector. Izikhonkwane ze-ejector zixhunyiwe kwi-ejector bar.

Izikhonkwane ze-Ejector: Izikhonkwane zentsimbi ezidibanisa inxalenye egqityiweyo kwaye ziyityhalele ngaphandle kokubumba. Iimpawu ze-Ejector pin ziyabonakala kwezinye izinto ezibunjiweyo zenaliti, ngokuqhelekileyo umfanekiso ojikelezayo ofunyenwe ngasemva kwendawo.

Sprue Bushing: Isiqwenga sokudibanisa phakathi kwesikhunta kunye nomatshini wokubumba isitofu apho i-resin etyhidiweyo iya kungena emgodini.

Sprue: Indawo ekwisakhelo sokungunda apho intlaka etyhidiweyo ingena kumngxuma wokungunda.

Iringi yeNdawo: Intsimbi yentsimbi eqinisekisa ukuba umlomo womatshini wokubumba inaliti udibana ngokufanelekileyo ne-sprue bushing.

Umngxuma okanye Die Cavity: Imbonakalo ye-Concave kwi-mold, ngokuqhelekileyo yenza umphezulu wangaphandle wecandelo elibunjiweyo. Umngundo wonyulwa njengomgodi omnye okanye umngxuma omninzi ngokuxhomekeke kwinani lezo xinzelelo.

Core: Imbonakalo ye-convex kwi-mold, ngokuqhelekileyo yenza indawo yangaphakathi yecandelo elibunjiweyo. Le yinxenye ephakanyisiweyo yokungunda. Yinguqu yomngxuma. I-resin etyhidiweyo ihlala ityhalelwa kwi-cavity, igcwalisa indawo. I-resin etyhidiweyo iya kubumba malunga nombindi ophakanyisiweyo.

Inkqubo yoMbaleki okanye yeMbaleki: Imijelo engaphakathi kokungunda kwentsimbi evumela intlaka etyhidiweyo ukuba impompoze ukusuka kwi-sprue-to-cavity okanye kwicavity-to-cavity.

Isango: Isiphelo sombaleki apho i-resin enyibilikisiweyo ingena kwi-mold cavity. Kukho uyilo lwamasango ahlukeneyo kwisicelo esahlukileyo. Iintlobo zesango ezisetyenziswa ngokuqhelekileyo ziquka iphini, isithethi, i-fan, i-edge, i-disk, i-fan, i-tunnel, ibhanana okanye i-cashew, kunye ne-chisel. Uyilo lwesango kunye nokubekwa yingqwalasela ebalulekileyo ngaphambi kokuqala inkqubo yokuvelisa i-mold.

Inkqubo Yokupholisa: Uluhlu lwemijelo kwiqokobhe langaphandle lokungunda. Le mijelo ijikeleza ulwelo ukunceda inkqubo yokupholisa. Iindawo ezipholiswe ngendlela engafanelekanga zinokubonisa iziphene ezahlukeneyo zomphezulu okanye kwisakhiwo. Inkqubo yokupholisa ngokuqhelekileyo yenza uninzi lomjikelo wokubumba inaliti. Ukunciphisa amaxesha okupholisa kunokuphucula kakhulu ukusebenza kakuhle kokungunda kunye neendleko eziphantsi. IFathom ibonelela ngokuPholisa okuConformal kwiinkqubo ezininzi zokubumba iinaliti eziya kwandisa ukusebenza kakuhle kokungunda ukuya kuthi ga kwi-60%

I-DJmolding Mold Production kwiiNkqubo zokuBumba ezahlukeneyo

Inkqubo yokubumba inaliti yeplastiki inokulungelelaniswa ukuze ihlangabezane neemfuno ezahlukeneyo nezinzima. Ngelixa ilungele ukwenza iimithamo ezinkulu zamalungu alula eplastiki, isenokusetyenziswa ukwenza iindawo ezintsonkothileyo ezintsonkothileyo ngeejometri okanye iindibano.

I-Multi-Cavity okanye i-Family Mold – Lo ngundo unemingxuma emininzi kwisakhelo sokubumba esinye esivelisa amacandelo amaninzi afanayo okanye anxulumeneyo ngomjikelo ngamnye wokutofa. Le yindlela efanelekileyo yokunyusa imiqulu yokuqhuba kunye nokuthoba ixabiso leqhekeza ngalinye.

Ukugcwala – Le ndlela yokubumba inaliti isetyenziselwa ukwenza iinxalenye ezenziwe ngeentlobo ezimbini zeplastiki. Umzekelo omhle wale nto iya kuba ngumzimba ophathwayo we-drill okanye isilawuli somdlalo kunye negobolondo langaphandle elikhuni kunye ne-soft, i-rubberized grips. Inxalenye ebunjiweyo ngaphambili iphinda ifakwe kwi-mold eyenziwe ngokukodwa. Umngundo uvaliwe kwaye umaleko wesibini weplastiki eyahlukileyo yongezwa phezu kwendawo yokuqala. Le yinkqubo efanelekileyo xa kufunwa iindlela ezimbini ezahlukeneyo zokuthungwa.

Faka Ukubumba - Inkqubo yokubumba i-injection evumela ukufakwa kwesinyithi, i-ceramic, okanye iziqwenga zeplastiki kwinxalenye yokugqibela. Iingxenye zetsimbi okanye ze-ceramic zifakwe kwi-mold kwaye emva koko iplastiki enyibilikisiweyo ifakwe kwi-mold ukwenza iqhekeza elingenamthungo elenziwe ngezinto ezimbini ezahlukeneyo. Faka ukubumba ilungele ukusetyenziswa kweemoto njengoko kuyindlela entsha yokunciphisa ubunzima kunye nokunciphisa izinto ezixabisa kakhulu njengentsimbi. Esikhundleni sokwenza yonke into ngentsimbi, kuphela iziqwenga ezidibanisayo kufuneka zibe yintsimbi ngelixa yonke into iya kwenziwa ngeplastiki.

Co-Injection Molding -Iipholima ezimbini ezahlukeneyo zitofwa ngokulandelelana okanye ngaxeshanye kumngxunya. Le nkqubo ingasetyenziselwa ukwenza iinxalenye ngesikhumba solunye uhlobo lweplastiki kunye nombindi womnye.

Ukubunjwa kodonga olunqabileyo -Indlela yokubumba inaliti ejolise kumaxesha amafutshane omjikelezo kunye nemveliso ephezulu ukuvelisa iinxalenye zeplastiki ezinqabileyo, ezilula, kunye nexabiso eliphantsi.

Isitofu serabha – Irabha igalelwe isikhunta kusetyenziswa inkqubo efana nokubumba inaliti yeplastiki. Amalungu erabha afuna uxinzelelo olungakumbi ekubumbeni okuyimpumelelo kwesitofu.

Isitofu seCeramic –Inkqubo yokubumba isitofu kusetyenziswa imathiriyeli yeceramic. I-Ceramic yinto enzima ngokwemvelo, i-inert ye-chemically material esetyenziswa kumashishini ahlukeneyo. Isitofu seCeramic sifuna amanyathelo angaphezulu; kubandakanywa sintering okanye ukunyanga iindawo ezisanda ukubunjwa ukuqinisekisa ukuqina uphawu.

Ukubunjwa kwePlastiki yesitofu soxinzelelo oluphantsi -Iinxalenye zeplastiki eziveliswa kuxinzelelo oluphantsi. Oku kuluncedo kakhulu kwimisebenzi efuna ukubethelwa kwamalungu aethe-ethe, afana nombane.

Qhagamshelana no-DJmolding ngolwazi oluthe kratya malunga nokubumba inaliti yeplastiki. Iqela lethu leengcaphephe linokukunceda ngeprojekthi yakho eyenziwe ngenaliti yeplastiki.