Inkqubo yoLawulo loMgangatho

Ulawulo lomgangatho ayilogama elichaziweyo ekubumbeni inaliti yeplastiki. Iyinxalenye ebalulekileyo yenkqubo yokuvelisa, kwaye inikwe ingqalelo kwiinkcukacha ezinkulu.

Ukuqinisekisa ukuba inkqubo yokubumba yokuhlola iplastiki iqhutywe ngokufanelekileyo ukudala imveliso yomgangatho ophezulu, iiparitha ezithile ezibalulekileyo zithathelwa ingqalelo. Ungafumana ngakumbi ngezantsi.

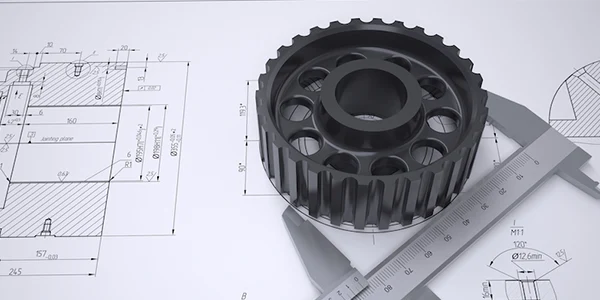

IiParameters zoLawulo loMgangatho kwi-Plastiki ye-Injection Molding

Iiparamitha zenkqubo yimiba ebalulekileyo ebekwe kwaye ilandelwe ukuqinisekisa ukwenziwa komgangatho ophezulu wemveliso. Uluhlu olusisiseko lweeparamitha lubandakanya:

*Inqanaba lonyamezelo

*Iindawo zokufudumeza izinto eziphathekayo

*Uxinzelelo lweCavity

* Ixesha lokutofa, isantya, kunye nesantya

*Ixesha lokuvelisa lilonke

*Ixesha lokupholisa imveliso

Ngaphandle kweeparameters ezikhethiweyo, kuhlala kukho ukubakho kweendawo ezineziphene ezenziweyo. Ukuqinisekisa ukuncitshiswa kweengxenye ezikhatywayo, iiparitha ezikhethiweyo zixhaswa ngezinye iinkqubo zokulawula umgangatho ezichazwe ngezantsi.

*Ulawulo loMgangatho lulonke (TQM)

*Umgangatho woNcedo lweKhompyutha (CAQ)

*UkuCwangciswa koMgangatho oPhezulu (AQP)

*Ulawulo lweNkqubo yoBalo (SPC)

*Ulawulo lwenkqubo eqhubekayo (CPC)

*I-Automation eDityanisiweyo ngokupheleleyo (TIA)

Kungakhathaliseki ukuba yiyiphi inkqubo yokuvelisa, kusoloko kukho ukulawulwa komgangatho omiselweyo ukuze kuqinisekiswe ukuba imveliso engaphantsi ayikhululwa kujikelezo oluqhelekileyo, okanye iimveliso ezingaphantsi zibuyiselwa kumthengi. Xa kuziwa ekubumbeni inaliti, kukho iimvavanyo ezininzi ezahlukeneyo kunye namanqaku olawulo abekwe kuyo yonke inkqubo yokuvelisa ukuqinisekisa ukuba imveliso egqityiweyo ifika kwinqanaba eliphezulu lemigangatho.

UHlolo oluBonakalayo lwamanqaku eSinki

Ukubumba inaliti yeplastiki kunemiba yokubonisa ngokucacileyo enokususwa ngokuhlolwa okubonakalayo. Iingxaki ezahlukeneyo zinokuthi zenzeke kuyo yonke inkqubo yokuvelisa, ngokusekelwe kubushushu, izinto ezisetyenzisiweyo, ixesha lokumisela kunye nezinye izinto ezininzi. Amanqaku e-sink ngawona axhaphakileyo. Oku ngokusisiseko yidimple kwisikhumba sangaphandle seplastiki esenzeka ngelixa iplastiki isathambile kwaye inyibilika. Xa ipholisa izinto eziphathekayo kwaye ibangela i-dimple.

Iimpawu zeGesi kunye nokuTswa

Iimpawu zegesi okanye ukutshisa kunokwenzeka xa iplastiki ishiywe kwindawo yokubumba ixesha elide kwaye itshiswe. Inokuthi yenzeke ukuba umoya oshushu oxinzelelweyo ngaphakathi kwimbumba awukwazi ukubaleka ukubumba, okubangela ukuba wakheke ngaphakathi kwimbumba kwaye utshise iplastiki.

Ukudanyaza kwePlastiki elulwelo

Ukudanyaza kwenzeka xa iindawo ezimbini ezahlukeneyo zokungunda zinyibilika kunye. Ukuba iziqwenga ezibini zeplastiki ezinyibilikisiweyo zidibana ngokukhawuleza, iziqwenga zinokudityaniswa kwaye zingagxothwa. Amaxesha amaninzi kwinkqubo yokwenziwa kwenaliti yokubumba, iimveliso ezimbini zibekwe kunye njengoko nganye iphola, yenze iqhina lethutyana elinokuqhawuka lula kwaye laphuke. Oku kuyilelwe izizathu ezininzi ezahlukeneyo zokupakisha. Nangona kunjalo, ukuba izinto zibekwe kunye kwaye iplastiki ye-liquid isaqina, ezi zimbini zidibanisa kwaye i-detachment ifuna imela okanye ayinakwenzeka konke konke.

IiShots ezimfutshane kunye neMizila ezinithiweyo

Ukudubula okufutshane kwenzeka xa kungasetyenziswanga iplastiki eyaneleyo kubumba. Oku kubangela iikona ezithambileyo, iitshiphusi okanye iindawo zokungunda zingabonakali nje. Imigca edityanisiweyo ibonisa apho iindawo ezimbini ezahlukeneyo zomngundo weplastiki zadibana khona ekuqaleni.

Ngobumba, izinto eziphathekayo kufuneka zigcine ubukeka obudibeneyo ukusuka kwisiqwenga esinye ukuya kwesinye. Nangona kunjalo, iingxaki zinokuthi zenzeke ngamanye amaxesha yiyo loo nto into nganye kufuneka ihlolwe ngaphambi kokuba iphume ukuze ithunyelwe. Le yeyona miba ixhaphakileyo echongiweyo ngokusetyenziswa kokulawulwa komgangatho wokuhlola okubonwayo.

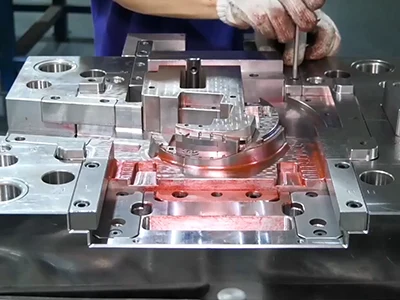

IiParameters zokulawula umgangatho kwi-Plastic Mold Pressing

Kwi-DJmolding, ukuqinisekiswa komgangatho, ulawulo kunye neenkqubo zokubeka iliso njengefilosofi yakhelwe kwinkalo nganye yomsebenzi wethu, equka onke amanyathelo okwenziwa kweplastiki yethu yokubumba (inkqubo yokucofa umngundo);

*Ukulawula umgangatho oNgeniyo: zonke izixhobo zentsimbi kunye nezixhobo zesiko kufuneka zihlolwe ukuze kuqinisekiswe ukuba zonke kufuneka zanelise iimfuno zesixhobo sokubumba iplastiki yesiko ngokungqongqo;

*Ukulawula Kumgangatho wenkqubo: inkqubo yokucoca kunye nokudibanisa yonke into iphantsi kolawulo olungqongqo, iqela le-QC lakhiwe ukuba lijonge kwaye lijonge ukunyamezelana kwesixhobo kunye nomgangatho ocwangcisiweyo ukuze kwaneliswe iimfuno;

*Ukulawula umgangatho wokuGqibela: emva kokugqitywa kwesixhobo sokubumba iplastiki, ukukhangela ngokucokisekileyo kwacutshungulwa ubungakanani obuphambili besampula yeplastiki yovavanyo ukuqinisekisa ukuba akukho nkqubo ilahlekileyo kwaye umgangatho weplastiki ulungile.

Sigcina iinkqubo zokwamkela ubuchule beenkcukacha-manani ukujonga nokulawula iinkqubo zokuqinisekisa ukuba sivelisa isixhobo sokubumba seplastiki esikumgangatho ophezulu, esiza kunye ne-APQP, i-FMEA, i-PPAP, amaxwebhu okulawula umgangatho asemgangathweni. Kwakhona siphakamisa amandla okuxhasa abaxumi abafunwayo ukulungiselela amaxwebhu kunye nolawulo lomgangatho.

Iveki nganye, iqela lethu le-QC linentlanganiso yokuxoxa ngomba ngamnye, kwaye lifuna iindlela malunga nokufumanisa kunye nezisombululo zokuthintela. Iisampulu ezinezitofu ezineziphene ziziswa kwingqalelo yabo bonke abasebenzi kwiintlanganiso zethu ezisemgangathweni, apho uluvo nengcebiso yomntu ngamnye ziqwalaselwa kakuhle kwaye zixatyiswe. Kwaye rhoqo ngenyanga ukusebenza kwangexesha kuboniswa kwaye kuboniswe kwibhodi yebhulethi ukuze abasebenzi babone kwaye bafunde.

U-DJmolding wamkela obona buchwepheshe buntsonkothileyo bokukhangela kunye nokulinganisa obukhoyo. I-micro-scopes echanekileyo ephezulu, i-CMM, i-lapra-scopes, kunye nezixhobo zokulinganisa eziqhelekileyo zisebenza ngomgangatho oqeqeshwe kakhulu weenjineli zabasebenzi be-Q / C.

Kwi-DJmolding, sicinga ukuba iziqinisekiso zethu ezisemgangathweni ezifana ne-ISO 9001: 2008, ukuzibophelela kwethu ekuboneleleni ngezona ndawo zingcono kakhulu kumaxabiso akhuphisanayo. Nangona kunjalo, ukuzibophelela kwethu kudlula ngaphaya kweziqinisekiso. Sinabasebenzi beengcali ezisemgangathweni abagxile kuphela ekuqinisekiseni ukuba sivelisa iinxalenye zeplastiki ezigqibeleleyo kangangoko sinako.

Ukusuka kubasebenzi bethu bolawulo, abasingatha yonke imibuzo ngobuchwephesha kwiinjineli zethu ezihlala zijonge iindlela zokuphucula uyilo kunye nemveliso, inkampani yethu yonke inokuqonda okuyinyaniso kwento efunekayo ukuze ithathelwe ingqalelo njengenye yezona zinto ziphambili zokubumba inaliti yeplastiki eTshayina. . Ludumo esizingca ngalo kwaye sikhuthazwa ukuba siluphucule yonke imihla.