Ukugcwala

Ukugqithisa yinkqubo yokuvelisa apho i-substrate okanye inxalenye yesiseko idibaniswe kunye nenye okanye izinto ezininzi zokudala imveliso yokugqibela kunye nokusebenza okuphuculweyo, ukuqina, kunye nobuhle. Le nkqubo ifumene ukuthandwa kwiminyaka yakutshanje ngenxa yokukwazi ukuphucula umgangatho kunye nokusebenza kweemveliso ngelixa inciphisa iindleko kunye nokwenza lula inkqubo yokuhlanganisa. I-Overmolding ifumana izicelo kumashishini ahlukeneyo, njengeemoto, i-elektroniki, izixhobo zonyango, kunye neemveliso zabathengi. Ukuqonda ngokupheleleyo le nkqubo, eli nqaku liza kuphonononga kwiinkalo ezininzi zokugqithisa, kubandakanya ubuchule bayo, izixhobo kunye nokusetyenziswa.

Inkcazo kunye neMithetho-siseko yokuGqisa

Ukugqithisa kakhulu kukubumba imathiriyeli enye phezu kwenye, ngokuqhelekileyo kusetyenziswa i-thermoplastic elastomers (TPE) okanye irabha ye-thermoset. Le nkqubo idala icandelo elinye elinezixhobo ezimbini okanye ngaphezulu, nganye ineempawu ezizodwa ezisebenza ngenjongo ethile.

Imigaqo yokuGqiba

Kukho imigaqo emithathu ephambili yokugqithisela ekufuneka iqwalaselwe ngabavelisi:

- Ukuhambelana kwezinto:Izinto ezisetyenziselwa ukugqithisa kufuneka zihambelane, kwaye izixhobo kufuneka zikwazi ukudibanisa ukuze zenze icandelo eliqinileyo nelidibeneyo. Ukubambelela phakathi kwezixhobo kubalulekile ukuqinisekisa ukuba into ineempawu ezifunwayo.

- Uyilo lokuGqibela:Ngaphambi kokugqithisa, umntu kufuneka aqwalasele ngokucophelela indlela yecandelo. Uyilo kufuneka luququzelele ukubumba izinto zesibini ngaphezu kweyokuqala ngaphandle kokuphazamiseka. Uyilo lomgca wokuqhawula, apho izinto ezimbini zidibana khona, kufuneka ziqinisekise ngokucophelela ukuba akukho zithuba okanye i-voids phakathi kwezinto ezimbini.

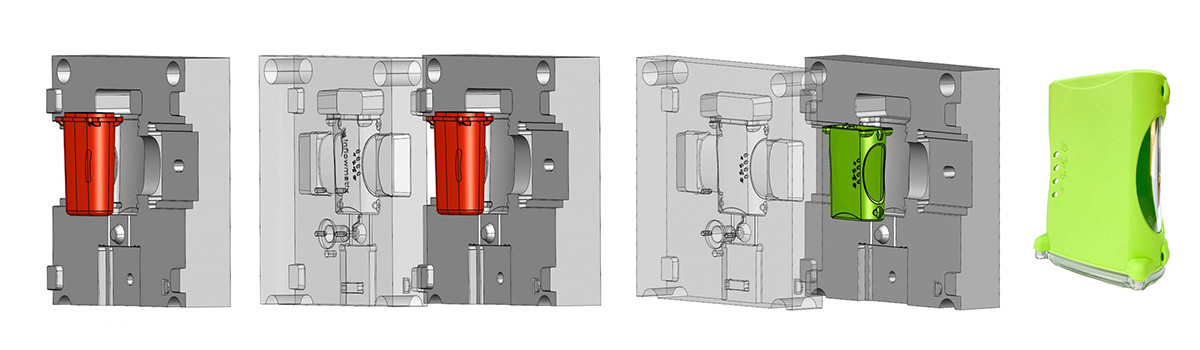

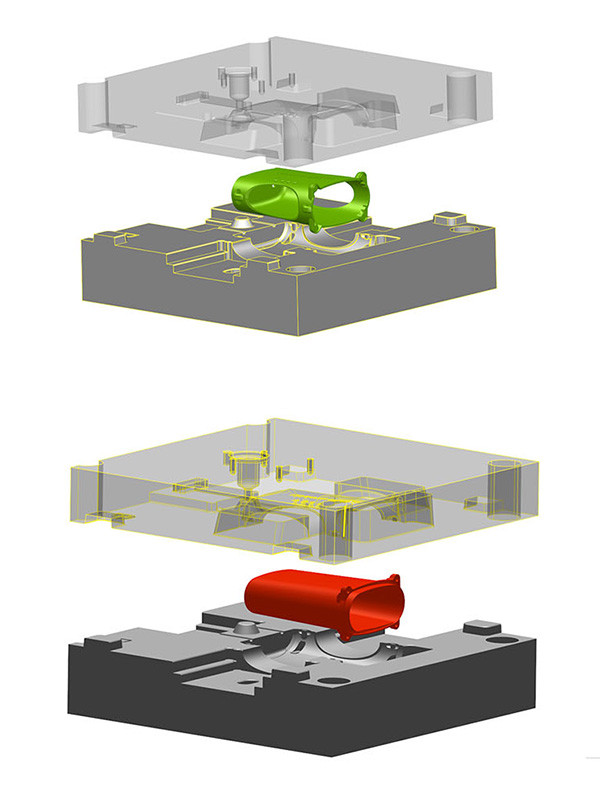

- Inkqubo yeMveliso:Ukugqithisa kakhulu kufuna inkqubo yokuvelisa ekhethekileyo ebandakanya ukubumba enye imathiriyeli kwenye. Indlela isebenzisa iimold ezimbini nangaphezulu, apho ukungunda kokuqala kukhula i-material yokuqala, kwaye ukungunda okwesibini kuvelisa i-material yesibini ngaphezu kweyokuqala. Emva koko, sidibanisa iimbumba ezimbini kunye ukwenza icandelo elinye.

Iingenelo zokuGqiba

I-Overmolding ibonelela ngeenzuzo ezininzi ezenza kube lukhetho oludumileyo kubenzi abaninzi, kubandakanya:

- Ukomelezwa koKuhlala:Ukugqithisa kunokuphucula ukuqina kwecandelo ngokongeza umaleko okhuselayo onokuxhathisa ukugqoka kunye nokukrazula.

- Ukuphuculwa kweAesthetics: Ukugqithisa kunokuphucula i-aesthetics yecandelo ngokongeza umbala okanye ukuthungwa phezulu.

- Ukusebenza okuphuculweyo:Ukugqithisa kunokuphucula ukusebenza kwecandelo ngokongeza iimpawu ezifana nokubamba, amaqhosha, okanye ukutshintsha.

Ukusetyenziswa kokuGqiba

Abavelisi bahlala besebenzisa i-overmolding ukuvelisa iimveliso zombane ezinjengeefowuni eziphathwayo, izilawuli kude, kunye neeperipheral zekhompyuter. Ikwanazo nezixhobo zonyango, izixhobo zemoto, kunye neemveliso zabathengi.

Ukubunjwa kwesitofu vs.

I-injection molding kunye ne-overmolding zisetyenziswa ngokuqhelekileyo iinkqubo zokuvelisa kwiindawo zeplastiki. Ngelixa zombini ezi ndlela zibandakanya ukubumba iplastiki, zineyantlukwano eyahlukileyo. Esi sithuba sebhlog siyakuxoxa ngomahluko phakathi kokubumba inaliti kunye nokugqithisa.

Ukucofa isitya

Isitofu sokubumba yinkqubo yokuvelisa equka ukunyibilika kweepeliti zeplastiki kunye nokutofa iplastiki enyibilikisiweyo kwindawo yokungunda. Iplastiki ke iye ipholiswe kwaye ikhutshwe kwi-mold, ibangele inxalenye yeplastiki eqinile. Abavelisi basebenzisa isitofu sokubumba njengenkqubo echanekileyo nesebenzayo ukuvelisa umthamo ophezulu wamalungu eplastiki. Ezinye izinto eziphambili zokubumba inaliti ziquka:

Uvelisa indawo enye yezinto

- Omnye ugalela i-material kwi-mold cavity kwinqanaba elinye.

- Inkqubo ifumana isicelo ekuveliseni imiqulu ephezulu yamacandelo.

- Ixabiso ngenxalenye nganye liyehla njengoko umthamo wemveliso ukhula.

Ukugcwala

I-Overmolding yinkqubo yokuvelisa ebandakanya ukubumba enye into phezu kwesinye. Inkqubo yongeza into ethambileyo, efana nerabha ngaphezulu kwenxalenye yeplastiki eyomeleleyo ukomeleza ukuqina kwayo kunye nobuhle. Ezinye zeempawu eziphambili ze-overmolding ziquka:

Uvelisa icandelo lezinto ezimbini

- Okokuqala, sibumba izinto zokuqala, kwaye emva koko izinto zesibini ngaphezu kweyokuqala.

- Inkqubo iphakamisa ukuqina kunye nobuhle bento.

- Ixabiso ngenxalenye nganye liphezulu kunobumba lwesitofu ngenxa yendlela eyongeziweyo yokubumba eyesibini ngaphezu kweyokuqala.

- Umahluko phakathi kwe-Injection Molding kunye ne-Overmolding

Umahluko ophambili phakathi kokubunjwa kwesitofu kunye nokugqwesa koku:

- Inani leMathiriyeli:Ukubunjwa kwe-injection kuvelisa inxalenye enye yezinto, ngelixa i-overmolding ivelisa icandelo lezinto ezimbini.

- inkqubo:Isitofu sokubumba sitofa iplastiki etyhidiweyo kwisithuba sokungunda kwinyathelo elinye, ngelixa ukugqithisa kubandakanya ukubumba imathiriyeli yokuqala kuqala kwaye emva koko ukubumba imathiriyeli yesibini phezu kwemathiriyeli yokuqala.

- Injongo: Abavelisi basebenzisa isitofu sokubumba ukuvelisa izixa eziphezulu zamalungu eplastiki, ngelixa besebenzisa ukuhombisa kakhulu ukuqinisa ukuqina kunye nobuhle beqhekeza leplastiki.

- Iindleko: Ukubumba isitofu kudla ngokubiza kancinci kwinxenye nganye kunokugqithisa, ngenxa yenkqubo eyongeziweyo yokubumba imathiriyeli yesibini ngaphezu kweyokuqala.

Usetyenziso lwe-Injection Molding kunye ne-Overmolding

Abavelisi bahlala besebenzisa isitofu sokubumba ukuvelisa iimpahla zabathengi, izixhobo zemoto, kunye nezixhobo zonyango. Bakwasebenzisa i-overmolding ukomeleza ukuqina kunye nobuhle kwiimveliso zombane ezifana neeselfowuni kunye nolawulo olukude.

I-Shot-Shot Overmolding: I-Technique edumileyo

Ukubumba i-two-shot overmolding, ekwabizwa ngokuba kukubumba i-two-shot-shot okanye i-multi-shot-molding, yindlela eyaziwayo esetyenziselwa ukuvelisa iindawo zeplastiki. Le nkqubo ibandakanya ukubumba izinto ezimbini omnye komnye ukwenza imveliso egqityiweyo. Esi sithuba sebhlog siza kuxoxa ngeziseko zokudutyulwa kwe-shot-shot overmolding kunye nezibonelelo zayo.

Izibonelelo zokuBonelwa kweZithonga ezimbini

Ukugqithiswa kweeshot ezimbini kubonelela ngeenzuzo ezininzi kubuchule bemveli bokugqithisa, kubandakanya:

- I-Aesthetics eyomeleziweyo: I-overmolding ye-shot-shot-shot ivumela ukudala iindawo eziyinkimbinkimbi ezinemibala emininzi okanye i-texture. Ukusebenzisa imathiriyeli eyahlukahlukeneyo kunokukhokelela kwimveliso yokugqibela enomtsalane ngakumbi ngokubonakalayo kuneyenziwe ngento enye.

- Ukusebenza okuphuculweyo: I-overmolding ene-two-shot-shot inokwandisa ukusebenza kwemveliso. Umzekelo, i-soft-touch grip phezu kwesiseko esomeleleyo seplastiki inokuphucula i-ergonomics yemveliso kunye namava omsebenzisi.

- Iindleko ezithotyiweyo:Ukugqithisa i-shot-shot overmolding kunokunceda ukunciphisa iindleko ngokuphelisa imfuno yemisebenzi yesibini efana nokupenda okanye ukugubungela. Ukuphumeza oku kunokukhokelela kwinkqubo yokwenziwa ekhawulezayo kunye nokunciphisa iindleko.

- Ukonyuka koKuhlala ixesha elide: I-overmolding ene-two-shot-shot inokuphucula ukuqina kwemveliso. Ngokusebenzisa isiseko seplastiki eqinile kunye ne-soft-touch grip, umzekelo, imveliso ayinakwenzeka ukuba iqhekeze okanye iphule xa iwa.

Ukusetyenziswa kwe-Two-Shot Overmolding

Iintlobo ngeentlobo zemizi-mveliso zihlala zisebenzisa ukuguquguquka okuphindwe kabini, kubandakanya:

- Imoto: I-overmolding ephindwe kabini ivelisa iindawo zemoto, ezifana nezixhobo zedeshibhodi kunye neziqwenga ze-trim zangaphakathi.

- Impahla zomthengi:I-overmolding ephindwe kabini ivelisa iibrashi zamazinyo, iincakuba, kunye nezixhobo zombane.

- Izixhobo zonyango:Ukudubuleka okuphindwe kabini kuvelisa izixhobo zonyango ezifana nezixhobo zotyando kunye nezixhobo zokuhanjiswa kweziyobisi.

Faka Ukubumba: Ukudibanisa amacandelo amabini ahlukeneyo

Faka ukubumba yinkqubo yokuvelisa ebandakanya ukubumba icandelo leplastiki malunga nokufakwa kwangaphambili okanye i-substrate. Ufakelo lwenziwa ngentsimbi okanye iplastiki kwaye lunokuba lufakelo olunemisonto, ucingo, okanye ibhodi yesekethe eprintiweyo. Esi sithuba seblogi siya kuxubusha iziseko zokufaka ukubumba kunye neenzuzo zayo.

UFaka Njani Ukubumba Umsebenzi?

Faka ukubumba yinkqubo enamanyathelo amabini abandakanya oku kulandelayo:

- Sibeka i-insert kwi-mold.

- Iplastiki ijojowe malunga nokufaka, idala icandelo leplastiki elibunjiweyo elifakwe ngokuqinileyo kwi-insert.

- Ufakelo longeza amandla kunye nokuzinza kwinxalenye egqityiweyo, okwenza ukuba ifaneleke kwizicelo ezahlukeneyo.

Iingenelo zokuBumba ngokuFaka

Faka ukubumba inika iingenelo ezininzi ngaphezulu kobuchule bokubumba, kubandakanya:

- Amandla aphuculweyo: Ukufakela ukubumba kudala imveliso egqityiweyo eyomelele kwaye izinzile, njengoko ukufakwa kufakwe ngokuqinileyo kwicandelo leplastiki. Ukuphucula ukuqina kunye nokuphila kwemveliso kunokwenzeka ngale nto.

- Ixesha leNdibano elicuthiweyo: Faka ukubumba kunceda ukunciphisa ixesha lendibano kunye neendleko zabasebenzi ngokudibanisa amacandelo amaninzi kwindawo enye ebunjiweyo.

- Ukwandiswa koButyebi boyilo:Faka ukubumba kwenza kube lula ukwenza iindawo ezintsonkothileyo ezinemathiriyeli ezininzi, ukuthungwa, kunye nemibala, okukhokelela kwisiphumo esijongeka ngcono sokugqibela.

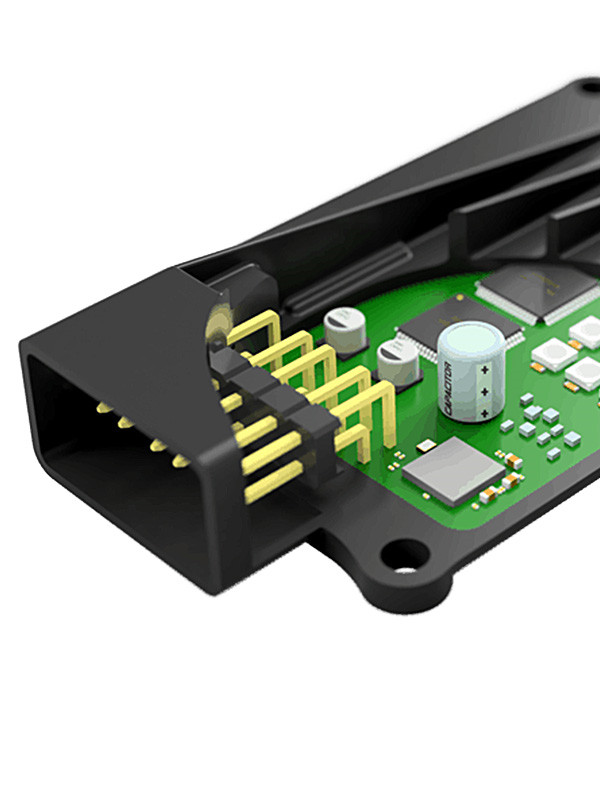

- Ukusebenza okuphuculweyo: Ngokusebenzisa ukubumba okufakelweyo, abavelisi banokuphucula ukusebenza kwemveliso ngokubandakanya iimpawu ezifana nokufaka imisonto okanye uqhagamshelwano lombane.

Usetyenziso lweFaka ukuBunjwa

Faka ukubumba ngokuqhelekileyo kusetyenziswa kumashishini ahlukeneyo, kuquka:

- Imoto: Faka ukubumba kuvelisa iinxalenye zeemoto ezifana nezihlanganisi, izinzwa, kunye nokutshintsha.

- ZeWindows: Faka ukubumba kuvelisa amacandelo e-elektroniki anjengeziqhagamshelo, izindlu, kunye nokutshintsha.

- Izixhobo zonyango:Faka ukubumba kuvelisa i-catheters, izihlanganisi, kunye nezinzwa.

I-Soft Overmolding: Ukuphucula ukubamba kunye nokuThuthuzela

Ukugqithisa okuthambileyo yinkqubo esetyenziswa kwimveliso ukongeza into ethambileyo, ebhetyebhetye kwimathiriyeli esisiseko eyomeleleyo. Ubuchwephesha buvumela ukongeza umaleko wokuthuthuzela kunye nokubambelela kwimveliso, ngaloo ndlela kuphuculwe ukusebenza kwayo kunye nobuhle. Esi sithuba sebhlog siza kuxoxa ngeziseko zokuthambisa ezithambileyo kunye neenzuzo zayo.

Ingaba iSoft Overmolding isebenza njani?

Ukugqithisa okuthambileyo yinkqubo enamanyathelo amabini abandakanya oku kulandelayo:

- Sibumba izinto ezisisiseko eziqinileyo.

- Into ethambileyo, eguquguqukayo ijojowe malunga nesiseko esibunjiweyo, idala indawo ekhululekile kunye ne-tactile.

- Ngokuqhelekileyo, abavelisi benza izinto ezithambileyo ezivela kwi-thermoplastic elastomers (TPE) okanye i-silicone. Imveliso ephumelayo inomgangatho ogudileyo, okhululekileyo onika ukubamba okungcono kunye nokuphucula ukuphatha.

Iingenelo zokuXhuma okuthambileyo

Ukugqithisa okuthambileyo kubonelela ngeenzuzo ezininzi kubuchule bokubumba bendabuko, kubandakanya:

- Intuthuzelo ephuculweyo: Ukugqithisa okuthambileyo kunika umphezulu okhululekileyo owandisa amava omsebenzisi. Izinto ezithambileyo zihambelana nokuma kwesandla somsebenzisi, ukunciphisa iindawo zoxinzelelo kunye nokuphucula ukubamba.

- Ukubamba okomeleziweyo: Izinto ezithambileyo ezisetyenziswe kwi-soft overmolding zinika ukubamba okungcono, ukunciphisa amathuba okulahla okanye ukulahlekelwa yimveliso. Ukuphucula amanyathelo okhuseleko kunokunciphisa umngcipheko womonakalo wemveliso.

- Inomtsalane Ngobuhle: Ukugqithisa okuthambileyo kunokuphucula inkangeleko yemveliso, iyenze ibe nomtsalane ngakumbi. Izinto ezithambileyo zingenziwa ngokwezifiso ukuze zihambelane nombala kunye nokuthungwa kwemveliso, ukudala ukubukeka okuhambelanayo.

- Ihlala: Ukugqithisa okuthambileyo kudala imveliso ehlala ixesha elide enokumelana nokusetyenziswa rhoqo kunye nokunxiba. Izinto ezithambileyo zibonelela ngokhuseleko olongezelelweyo malunga neempembelelo kunye nemikrwelo, ukunciphisa amathuba omonakalo kwimveliso.

Usetyenziso lwe-Soft Overmolding

Iintlobo ngeentlobo zemizi-mveliso zisebenzisa i-soft overmolding, kubandakanya:

- Ii-Electronics zabathengi: Ukugqithisa okuthambileyo kuvelisa izixhobo zombane ezifana nolawulo olukude, ii-headphones, kunye nabalawuli bemidlalo.

- Iimpahla zeMidlalo: Abavelisi basebenzisa i-overmolding ethambileyo ukuvelisa iimpahla zemidlalo ezinje ngokubambisa iiklabhu zegalufa, iirakethi zentenetya, kunye neziphatho zebhayisekile.

- Izixhobo zonyango: Ukugqithisa okuthambileyo kuvelisa izixhobo zonyango ezifana nezixhobo zotyando kunye nezinto ezincedisa ukuva.

Ukugqithisa Okunzima: Ukongeza ukuKhuselwa kunye nokuqina

Ukugqithisa okunzima kwongeza umaleko weplastiki oqinileyo phezu kwezinto ezikhoyo, ezifana nerabha okanye i-silicone, ukudala indawo ehlala ixesha elide kunye nokukhusela. Isiphumo yimveliso enokumelana nemekobume erhabaxa, ukuxhathisa ukonakala, nokunyamezela ukusetyenziswa ngokuphindaphindiweyo.

Nazi ezinye zezibonelelo zokusebenzisa ukugqithisa okunzima kuyilo lwemveliso:

- Ukwanda kokuqina: Ukugqithisa okunzima kunika uluhlu olongezelelweyo lokukhusela olunokwandisa ixesha lokuphila kwemveliso. Ukukhusela imathiriyeli esisiseko ekugugekeni nasekukraleni kwenza ukuba iziphumo zingabi lula ukuphuka okanye ukusilela.

- Ukubamba okuphuculweyo:Ngokudibanisa iplastiki ekhohlisayo kwizinto ezithambileyo, ezifana nerabha okanye i-silicone, abavelisi banokudala ukubamba okungcono kubasebenzisi. Kubalulekile ukuqwalasela lo mba, ngakumbi kwiimveliso ezisetyenziswa kwindawo emanzi okanye emtyibilizi.

- Ukumelana nemiba yokusingqongileyo:Ukugqithisa okunzima kunokukhusela iimveliso ekukhanyeni kwelanga, iikhemikhali, kunye nezinye izinto zokusingqongileyo ezinokubangela umonakalo ekuhambeni kwexesha. Olu lwandiso luphucula ukukwazi kwemveliso ukuziqhelanisa nokumelana neemeko ezahlukeneyo.

- Isibheno sobuhle: Ukugqithisa okunzima kunokuphucula ukubonakala kwemveliso. Ngokudibanisa iplastiki ekhohlisayo, abavelisi banokudala imbonakalo epholileyo, epholileyo engenakwenzeka ngesixhobo esisodwa.

- Ngokwezifiso: Ngokusebenzisa ukugqithisa okunzima, iinkampani zinokwenza iimveliso zazo ngokongeza iilogo, imibala kunye nezinye izinto zoyilo kumphezulu. Esi sicwangciso sophawu sinceda ukwandisa ukubonakala kwindawo yentengiso.

Abavelisi basebenzisa ukugqithisa okunzima kwiimveliso ezahlukeneyo, ukusuka kwizixhobo zemizi-mveliso ukuya kwizinto zombane zabathengi. Nantsi imizekelo embalwa:

- Izixhobo eziphathwayo: Izixhobo ezininzi eziphathwa ngesandla, ezinjengeeselfowuni kunye neetafile, zisebenzisa ukugqithisa okunzima ukwenza umaleko okhuselayo ojikeleze isixhobo. Olu phawu lunceda ukukhusela isixhobo kumonakalo owenziwe ngamathontsi kunye neempembelelo.

- Izixhobo zamandla:Izixhobo zamandla zihlala zidibana nemekobume erhabaxa, efana nothuli nobutyobo. Ukusebenzisa ukugqithisa okunzima kunokukhusela ezi zixhobo kumonakalo kunye nokwandisa ubomi babo.

- Izixhobo zonyango: Izixhobo zonyango zifuna ukuqina okuphezulu kunye nokuchasana nezinto ezisingqongileyo. Ukugqithisa okunzima kunokukhusela ezi zixhobo kwaye kuqinisekiswe ukuba zisebenza ngokuchanekileyo.

I-Thermoplastic Elastomers (i-TPEs): Izinto eziKhethekileyo zokuNxibelela

Xa kufikwa kwi-overmolding, zininzi izinto onokukhetha kuzo, kodwa akukho nanye edume kakhulu kune-Thermoplastic Elastomers (TPEs). Ii-TPE zizixhobo eziguquguqukayo ezibonelela ngeenzuzo ezininzi xa kufikwa kwi-overmolding. Nazi ezinye zezizathu zokuba kutheni i-TPEs ibe yeyona nto ikhethwayo yokwenza izinto ngokugqithisileyo:

- Ukuhluka:Abavelisi banokusebenzisa ii-TPEs ukwenza ngaphezulu izinto ezahlukeneyo, kubandakanya isinyithi, iiplastiki, kunye neerabha. Abavelisi banokuzisebenzisa kwiimveliso ezahlukeneyo ezenziwe ngezinto ezahlukeneyo, bezenza zibe lukhetho oluguquguqukayo.

- Ukuthamba kunye nokuguquguquka: I-TPEs inokwakheka okuthambileyo kunye nokuguquguqukayo, okubenza ukuba balungele iimveliso ezigqithisiweyo ezifuna ukubamba kamnandi. Basenokwenza iimveliso ezifuna ukugoba okanye ukugoba ngaphandle kokuphuka.

- Ukumelana neekhemikhali kunye nemitha ye-UV:Ii-TPE zixhathisa kakhulu kwiikhemikhali kunye nemitha ye-UV, izenza zilungele iimveliso ezivezwe kwindawo enzima.

- Ukuzinza: Ii-TPE zomelele kakhulu kwaye ziyaxhathisa ukunxitywa nokukrazulwa, zizenza zilungele iimveliso ezisetyenziswa rhoqo okanye ziphantsi kokusetyenziswa kakhulu.

- Isebenza kakuhle emalini: Ii-TPE zingabizi kakhulu xa kuthelekiswa nezinye izinto ezisetyenziselwa ukugqithisa, okwenza kube yindlela efikelelekayo kubenzi.

- Kulula ukuqhubekeka:Ii-TPE zinokulungiswa ngokukhawuleza kusetyenziswa ukubumba inaliti, izenze zibe lukhetho oludumileyo kubenzi abafuna ukwenza ubuninzi beemveliso ngokukhawuleza nangokufanelekileyo.

Eminye imizekelo yeemveliso ezisebenzisa i-TPEs ukugqithisa kakhulu ziquka:

- Ukubamba izixhobo zesandla: Abavelisi bahlala besebenzisa ii-TPEs ukuze babambe ngaphezulu kwezixhobo zezandla, ezifana nepliers kunye ne-screwdrivers. Ubume be-TPEs 'ethambileyo kwaye ebhetyebhetye izenza zilungele ukwenza ukubamba okutofotofo okungayi kutyibilika.

- Izixhobo zemidlalo: Abavelisi bahlala besebenzisa ii-TPEs ukugqithisa ngaphezulu izixhobo zemidlalo, ezinje ngokubamba iklabhu yegalufa kunye neziphatho zerakethi yentenetya. Ubume be-TPEs 'ethambileyo kwaye ebhetyebhetye izenza zilungele ukwenza ukubamba okutofotofo okungayi kutyibilika.

- Izixhobo zombane: Ii-TPE zihlala zigqithisa izixhobo zombane ezifana nolawulo olukude kunye neeselfowuni. Ubume be-TPEs 'ethambileyo kwaye ebhetyebhetye izenza zilungele ukwenza umaleko okhuselayo ojikeleze isixhobo esingayi kukrwempa okanye sonakalise umphezulu.

I-Silicone Overmolding: Efanelekileyo kwiZixhobo zoNyango kunye neeMveliso zabaThengi

I-Silicone overmolding yinkqubo ebandakanya inaliti yezinto ze-silicone elulwelo phezu kwe-substrate material. Le nkqubo inokudala iimveliso ezahlukeneyo kumashishini ahlukeneyo kodwa iluncedo ngakumbi kwizixhobo zonyango kunye neemveliso zabathengi. Esi sithuba sebhlog siya kuphonononga iingenelo ze-silicone overmolding kula mashishini.

Izinto eziluncedo zeSilicone Overmolding kwiZixhobo zoNyango

- Biocompatibility:Izixhobo zonyango ezidibana nezicubu zomntu zifuna izixhobo ezikhuselekileyo zomzimba. I-Silicone yinto ehambelana ne-biocompatible engenabungozi okanye eyingozi kwizicubu eziphilayo. Ukusebenzisa le mathiriyeli kwizixhobo zonyango kunenzuzo kakhulu.

- Ukucoceka: Izixhobo zonyango kufuneka zicocwe phambi kokusetyenziswa ukuqinisekisa ukuba azinantsholongwane kunye nezinye izingcolisi eziyingozi. Iingcali zezempilo zinokusebenzisa iindlela ezahlukeneyo zokulungisa i-silicone, kubandakanya umphunga, i-radiation, kunye nokuvalwa kweekhemikhali. Izixhobo zonyango zinokuzuza ngokuguquguquka kwesi sixhobo.

- Ukuzinza: Ukuguquguquka okuphezulu kweSilicone kuvumela ukuyibumba kwiimilo ezahlukeneyo kunye nobukhulu. Ukukwazi kwezinto eziphathekayo ukuhambelana nokumila komzimba kwenza ukuba ilungele izixhobo zonyango.

- Ukuzinza: I-Silicone yinto ehlala ixesha elide enokumelana nokusetyenziswa ngokuphindaphindiweyo kunye nokuvezwa kweekhemikhali ezinoburharha. Ukuqina kwayo kunye nokukwazi ukumelana nokusetyenziswa ngokuphindaphindiweyo kunye nokucoca kwenza kube yinto efanelekileyo yezixhobo zonyango.

Izinto eziluncedo zeSilicone Overmolding kwiiMveliso zabaThengi

- Thuzelo: I-Silicone yinto ethambileyo kwaye eguquguqukayo ekhululekile ukunxiba ngokuchasene nolusu. Iimveliso zabathengi ezinxibelelana nomzimba, njengee-earbuds, iiwotshi, kunye neetraki zokuqina, zifanelekile kwizinto ezinje.

- Ukumelana Namanzi: I-Silicone yinto enganyangekiyo emanzini enokumelana nokuvezwa kumswakama ngaphandle kokuwohloka okanye ukulahleka kwemilo. Iimveliso zabathengi ezisetyenziswa kwiindawo ezimanzi, ezifana nezibuko zokubhukuda kunye nezithethi ezingenamanzi, zenziwe ngokufanelekileyo kule nto.

- Ukuguquguquka koyilo: I-Silicone inokubunjwa kwiimilo ezahlukeneyo kunye nobukhulu, ivumela abaqulunqi ukuba benze iimveliso ezizodwa kunye nezintsha. Le propati yenza i-silicone ifaneleke kwiimveliso zabathengi ezifuna iimilo ezinzima kunye noyilo.

- Ukuzinza:I-Silicone yinto ehlala ixesha elide enokumelana nokuvezwa imitha ye-UV, amaqondo obushushu agqithisileyo, kunye neekhemikhali eziqatha. Eli nqaku liyenza ilungele imveliso yabathengi efuna ukuqina kwaye inokumelana neemeko ezahlukeneyo zemozulu.

I-Polyurethane Overmolding: Iguquguquka kwaye ihlala ixesha elide

I-polyurethane overmolding yinkqubo yokuvelisa esandul 'ukufumana ukuthandwa ngenxa yokuguquguquka kwayo kunye nokuqina. Le nkqubo ibandakanya ukusebenzisa umaleko wemathiriyeli ye-polyurethane phezu kwe-substrate ekhoyo, ukudala umthungo ongenamthungo, ukwambathisa okhuselayo ophakamisa ukomelela kwenxalenye yokuqala, ukuqina, kunye nokusebenza.

Ukugqithisa nge-polyurethane kubonelela ngeenzuzo ezininzi, kuyenza ibe yindlela ekhangayo kubavelisi kuwo wonke amashishini ahlukeneyo. Nazi ezinye zeenzuzo eziphambili:

Ukungafani

Abavelisi banokusebenzisa inkqubo eguquguqukayo kakhulu ye-polyurethane overmolding ene-substrates ezininzi, kubandakanywa iiplastiki, isinyithi, kunye ne-composites.

Oku kuguquguquka kwenza i-polyurethane overmolding isisombululo esifanelekileyo kwizicelo ezifuna ukudibanisa izinto ezahlukeneyo zibe yinxalenye enye.

ukuhlala ixesha elide

I-Polyurethane yimathiriyeli eyomelele kakhulu enokumelana neemeko ezahlukeneyo zokusingqongileyo, kubandakanya ubushushu obugqithisileyo, iikhemikhali ezinoburharha, kunye nokunxiba kunye nokukrazula okukhulu. Izicelo ezifuna ukusebenza okuzinzileyo kunye nokukhuselwa kunokuzuza ekukhetheni oku njengokhetho lwabo olufanelekileyo.

Ngokwezifiso

Abavelisi banokufikelela kwinqanaba eliphezulu lokwenziwa ngokwezifiso kunye ne-polyurethane overmolding, evumela ukuba benze iimilo ezinzima kunye noyilo. Olu phawu lwenza ukuba lube lolona khetho lufanelekileyo kwizinto ezifuna inkangeleko eyodwa okanye uyilo olusebenzayo.

Isebenza kakuhle emalini

I-polyurethane overmolding inokuba sisisombululo esisebenzayo xa kuthelekiswa nezinye iindlela zokuvelisa, ezifana nokubumba inaliti okanye umatshini. Kwakhona kunokunciphisa inani leenxalenye ezifunekayo kwisicelo esinikiweyo, ukunciphisa ixesha lokuhlanganisa kunye neendleko.

Ukubamba okuPhuculweyo kunye neNtuthuzelo

I-polyurethane overmolding inokuphucula ukubamba kunye nokuthuthuzela kweemveliso, ezifana nezixhobo kunye nezibambo, ngokubonelela nge-non-slip surface ekulula ukuyibamba kwaye ikhululekile ukuyibamba.

I-polyurethane overmolding ingasetyenziswa kuluhlu olubanzi lwezicelo, kubandakanya:

- Imoto:kumalungu angaphakathi nangaphandle, njengeziphatho zocango, iinxalenye zedeshibhodi, kunye neziqwenga zokulungisa.

- ZeWindows:ukukhusela izinto ezibuthathaka ze-elektroniki kumonakalo wokusingqongileyo.

- Ezonyango: ukwenza izixhobo zonyango ezihlala zihleli kwaye zicocekile, njengeziphatho zezixhobo zotyando.

- Impahla zomthengi: ukwenza iimveliso zesiko ezinoyilo olulodwa kunye nokusebenza okuphuculweyo, njengempahla yezemidlalo kunye nezixhobo zasekhaya.

Ukugqithiswa kwezicelo zeMoto: Ukuphucula i-Aesthetics kunye nokusebenza

Kwishishini leemoto, ukugqithisa kuye kwanda kakhulu ekuphuculeni i-aesthetics kunye nokusebenza kwezinto zezithuthi. Le nkqubo yokuvelisa idala iindawo ezahlukeneyo zeemoto, ezinje ngokubamba, ukubamba, kunye namaqhina. Apha, siza kuxoxa ngendlela ukugqithisa okusetyenziswa ngayo kwizicelo zeemoto ukuphucula ubuhle kunye nokusebenza.

Ukuphucula iAesthetics

Enye yeenzuzo eziphambili zokugqithisa kakhulu kwishishini leemoto kukukwazi ukuphucula i-aesthetics. I-Overmolding ivumela abaqulunqi ukuba benze iimilo ezintsonkothileyo kunye noyilo oluya kuba nzima ukufikelela kwiinkqubo zokwenziwa kwemveli. Nazi ezinye iindlela zokugqithisela kwandisa umtsalane wobuhle bezinto zemoto:

- Ngokwezifiso: Ukugqithisa kuvumela ukwenziwa ngokwezifiso, okwenza kube lula ukwenza iinxalenye ezinoyilo olulodwa kunye nokudityaniswa kombala ohambelana nengaphakathi lesithuthi okanye ngaphandle.

- Ubume: Ukugqithisa kunokudala iindawo ezahlukeneyo, ukusuka kwi-soft-touch ukuya kwi-high-grip, ukuphucula ukuvakalelwa kwenxalenye ngokubanzi.

- Ukurhweba:Abavelisi banokusebenzisa i-overmolding ukubandakanya izinto zophawu, njengeelogo okanye amagama ebhrendi, kuyilo.

- umgangatho: Ukugqithiswa kwe-overmolding kuvelisa iindawo ezikumgangatho ophezulu kunye nokugqiba okungaguqukiyo, ukuphucula inkangeleko epheleleyo kunye nokuziva.

Ukuphucula ukusebenza

Ukongeza ekuphuculeni i-aesthetics, ukugqithisa kunokuphucula ukusebenza kwezixhobo zemoto. Nazi ezinye iindlela apho abavelisi basebenzisa ukugqithisa ukunyusa ukusebenza:

- Ukubamba: Ukugqithiswa kwe-overmolding kunokudala indawo engatyibilikiyo ephucula ukubamba, okwenza iinxalenye zibe lula ukuzisebenzisa kwaye zikhuseleke kubaqhubi nabakhweli.

- Ukuzinza: I-overmolding inokonyusa ukuqina kwamalungu ngokuwakhusela ekugugeni nasekukraleni kunye nokuvezwa kwiimeko ezirhabaxa zokusingqongileyo.

- Ukunciphisa ingxolo: I-overmolding inokunciphisa ingxolo ngokudala umphumo wokudambisa okunciphisa ukungcangcazela kunye nokufunxa isandi.

- Khuselo:Ukugqithiswa kwe-overmolding kunokukhusela iindawo kumonakalo obangelwa yimpembelelo okanye i-abrasion, enceda ukwandisa ubomi babo.

Ukusetyenziswa kokuGqibelela kuShishino lweeMoto

Abavelisi basebenzisa i-overmolding kwiintlobo ngeentlobo zezicelo zeemoto, kubandakanya:

- Amalungu angaphakathi:Ukugqithisa kakhulu kudala amaqhina, iiswitshi, kunye nezibambo zeempawu zangaphakathi ezinje ngeedeshibhodi, iipaneli zeengcango, kunye neendawo zokumisa iingalo.

- Amalungu angaphandle: I-Overmolding idala iimpawu zangaphandle ezifana nokufakwa kwe-grill, i-headlight surrounds, kunye ne-mirror covers.

- Ngaphantsi kwe-hood: Ukugqithisa kakhulu kudala iindawo ezinje ngee-injini zokunyuswa, izinzwa, kunye nezibiyeli ekufuneka zimelane namaqondo obushushu aphezulu kunye neemeko ezinzima.

Ukugqithiswa kwe-Electronics: Ukuphucula ukusebenza kunye nokuthembeka

Kwishishini le-elektroniki, ukugqithisa kuye kwanda kakhulu ngenxa yokukwazi ukuphucula ukusebenza kunye nokuthembeka kwamacandelo e-elektroniki. Apha, siza kuxoxa ngendlela i-overmolding esetyenziswa ngayo kwi-electronics ukuphucula ukusebenza kunye nokuthembeka.

Ukuphucula uMsebenzi

Enye yeenzuzo eziphambili zokugqithisa kakhulu kwishishini le-elektroniki kukukwazi ukuphucula ukusebenza. Ukugqithisa kunokuphucula ukusebenza kwamacandelo e-elektroniki ngeendlela ezininzi:

- Ukungena emanzini:Ukugqithiswa kwe-Overmolding kwenza ukuba kuthintelwe amanzi amacandelo e-elektroniki, okwenza kube yimfuneko kwizicelo apho inxalenye inokudityaniswa nokufuma okanye olunye ulwelo.

- Ukuxhathisa kwiVibration: Ukugqithisa kunokudala umqobo onceda amacandelo e-elektroniki ukuxhathisa ukungcangcazela, okubaluleke kakhulu kwizicelo apho inxalenye ingaba phantsi komothuko okanye ukungcangcazela.

- Ulawulo lobushushu: I-overmolding inceda ukukhupha ubushushu kude nezinto ze-elektroniki, ngaloo ndlela iphucula ukusebenza kwayo kunye nokwandisa ubomi babo.

- Ukugqunywa koMbane:Ukugqithisa kunokudala i-insulating layer ekhusela amacandelo e-elektroniki ekuphazamisekeni kombane, okunokunceda ukuphucula ukusebenza kwabo.

Ukuphucula ukuthembeka

Ukongeza ekuphuculeni ukusebenza, ukugqithisa kunokunyusa ukuthembeka kwamacandelo e-elektroniki. Nazi ezinye iindlela apho i-overmolding iphucula ukuthembeka:

- Ukukhuselwa kumonakalo: Ukugqithisa kunokukhusela izinto ze-elektroniki kumonakalo womzimba, njengempembelelo okanye i-abrasion, enokunceda ukwandisa ubomi babo.

- Ukumelana neMichiza:Ukugqithisa kunokukhusela amacandelo e-elektroniki kwiikhemikhali ezinokubangela ukubola okanye omnye umonakalo, onokunceda ukuphucula ukuthembeka kwabo.

- Umngcipheko oNcitshisiweyo wokuSilela: Ukugqithisa kakhulu kunokuncedisa ukunciphisa umngcipheko wokungaphumeleli ngokukhusela izinto ze-elektroniki kwizinto ezisingqongileyo ezifana nokufuma, ukungcangcazela, kunye nobushushu obugqithisileyo.

Ukusetyenziswa kokuGqiba kuShishino loMbane

Iintlobo ngeentlobo zezicelo ze-elektroniki zisebenzisa i-overmolding, kubandakanywa:

- Connectors:I-Overmolding idala iziqhagamshelo ezingenamanzi kunye ne-vibration-resistant ezifumana usetyenziso kwizixhobo ezahlukeneyo zombane.

- Iibhodi zeSekethe:Ukugqithisa kunokukhusela iibhodi zeesekethe kumswakama, ukungcangcazela, kunye nezinye izinto zokusingqongileyo ezinokubangela umonakalo okanye ukungaphumeleli.

- Izixhobo: Ukugqithisa kunokukhusela izinzwa kumonakalo obangelwa kukuvezwa kweekhemikhali ezinzima okanye ezinye izinto zokusingqongileyo.

- Izixhobo eziphathwayo:Ukugqithisa kakhulu kudala iimeko ezihlala zihleli kwaye zingangenwa manzi kwizixhobo eziphathwa ngesandla, ezinjengeefowuni eziphathwayo, iikhamera, kunye nezixhobo zeGPS.

Ukugqithiswa kweZixhobo zoNyango: Ukuqinisekisa uKhuseleko kunye neNtuthuzelo

Ukugqithisa kuye kwanda kakhulu kwishishini lezonyango lokuphucula ukhuseleko kunye nentuthuzelo yezixhobo zonyango. Apha, siza kuxubusha indlela i-overmolding esetyenziswa ngayo kwizixhobo zonyango ukuqinisekisa ukhuseleko kunye nentuthuzelo.

Ukuqinisekisa uKhuseleko

Enye yeenzuzo eziphambili zokugqithisa kwishishini lezonyango kukukwazi ukuqinisekisa ukhuseleko. Ukugqithisa kunokwandisa ukhuseleko lwezixhobo zonyango ngeendlela ezininzi:

- Biocompatibility: Ukugqithiswa kwe-overmolding kwenza ukudalwa kwezixhobo zonyango ezihambelana ne-biocompatible, ziqinisekisa ukhuseleko lwazo ukuze zisetyenziswe emzimbeni womntu ngaphandle kokubangela ukusabela okubi.

- Ukucoceka: Ukugqithisa kakhulu kunokudala izixhobo zonyango ezilula ukuba zibulale inzalo, nto leyo ibalulekile ekuthinteleni ukusasazeka kosulelo kwiindawo zokhathalelo lwempilo.

- I-Ergonomics: Ukugqithiswa kwe-overmolding kwenza ukuba kudalwe izixhobo zonyango ezenziwe nge-ergonomically, ezinokukunceda ukunciphisa umngcipheko wokulimala okuphindaphindiweyo kunye nezinye izifo ze-musculoskeletal phakathi kwabasebenzi bezempilo.

- Ukuzinza: Ukugqithisa kunokudala izixhobo zonyango ezihlala ixesha elide, ezinokukunceda ukunciphisa umngcipheko wokungaphumeleli okanye ukungasebenzi ngexesha lokusetyenziswa.

Ukuqinisekisa ukuthuthuzeleka

Ukongeza ekuqinisekiseni ukhuseleko, i-overmolding inokwandisa intuthuzelo yezixhobo zonyango. Nazi ezinye iindlela zokugqithisela kunika intuthuzelo:

- Ubume: Ukugqithisa kunokudala izixhobo zonyango ezinomgangatho owenziweyo onika ukubamba okungcono kunye nokuphucula induduzo.

- Ukuzinza: Ukugqithisa kunokudala izixhobo zonyango eziguquguqukayo, ezinokukunceda ukuphucula induduzo kunye nokunciphisa umngcipheko wokulimala okanye ukuphazamiseka ngexesha lokusetyenziswa.

- Ngokwezifiso: I-Overmolding ivumela ukulungelelaniswa kobume kunye noyilo lwezixhobo zonyango ukuze zihambelane neemfuno ezikhethekileyo zezigulane ezizimeleyo, ukuphucula induduzo kunye nokunciphisa umngcipheko weengxaki.

Izicelo zokuGqiba kuShishino lwezoNyango

Iintlobo ngeentlobo zezicelo zonyango zisebenzisa i-overmolding, kubandakanywa:

- Izixhobo Zotyando: Ukugqithisa kakhulu kunokudala izixhobo zotyando ngokubambelela ngakumbi, i-ergonomics engcono, kunye nokuphucula ukuqina.

- Izinto zokutyala:Ukugqithisa kakhulu kunokudala ukufakelwa kwe-biocompatible ekulula kakhulu kwizigulana kwaye kuncinci ukuba kubangele iingxaki.

- Izixhobo zokuxilonga: Ukugqithisa kunokudala izixhobo zokuxilonga ekulula ukuphatha, ixesha elide, kwaye zikhululekile ngakumbi kwizigulana.

- Izinxibo: I-Overmolding yenza ukuba kwenziwe izixhobo zonyango ezinxitywayo ezinika intuthuzelo eyongeziweyo kunye nokuguquguquka, okwenza kube lula ukuba izigulana zinxibe kwaye zisebenzise.

Ukugqithiswa kweMveliso yoMthengi: Ukongeza ixabiso kunye nesibheno

Apha, siza kuxubusha indlela i-overmolding esetyenziswa ngayo kwiimveliso zabathengi ukongeza ixabiso kunye nesibheno.

Ukuphucula iAesthetics

Enye yeenzuzo eziphambili zokugqithisa kwishishini lemveliso yabathengi kukukwazi ukuphucula ubuhle. Ukugqithisa kunokuphucula inkangeleko kunye nokuziva kweemveliso zabathengi ngeendlela ezininzi:

- Ukuguquguquka koyilo:Ukugqithiswa kwe-Overmolding kuvumela ukuguquguquka okukhulu koyilo, ukwenza iimveliso ezineemilo ezizodwa kunye nokwenziwa lula.

- Ukwenziwa Kwemibala: I-Overmolding yenza imibala emininzi kwimveliso enye, idale uyilo olutsala amehlo olume ngaphandle kwishelufu.

- Ukuchukumisa okuthambileyo:Ukugqithisa kunokudala iimveliso ngokuziva okuthambileyo, ukuphucula amava omsebenzisi kunye nesibheno.

Ukongeza ukusebenza

Ukongeza ekuphuculeni i-aesthetics, ukugqithisa kunokongeza ukusebenza kwiimveliso zabathengi. Nazi ezinye iindlela apho i-overmolding yongeza ixabiso:

- Ukubamba okuphuculweyo: I-Overmolding ivumela ukudalwa kweemveliso ngokubambelela okungcono, ukuphucula ukukhululeka kokusetyenziswa kunye nokuthuthuzela xa ubamba.

- Ukomelezwa koKuhlala:Ukugqithisa kakhulu kunokudala iimveliso ezihlala ixesha elide, ukuphucula ubomi babo kunye nexabiso elipheleleyo.

- Ukungena emanzini: Ukugqithiswa kwe-overmolding kwenza ukudalwa kweemveliso ezingenamanzi, ukwandisa ukuguquguquka kwazo kunye nokubhenela kubathengi.

Izicelo zokuGqiba kuShishino lweMveliso yabaThengi

Iintlobo ngeentlobo zezicelo zemveliso yabathengi zisebenzisa ukugqithisa, kubandakanya:

ZeWindows: Ukugqithisa kakhulu kunokudala iimeko ezinesitayile kunye nezizinzileyo zezixhobo zombane ezinjengeefowuni kunye neetafile.

Izixhobo zeMidlalo: Ukugqithisa kakhulu kunokudala izixhobo eziphuculweyo zokubamba kunye nokuqina, njengezibambo zebhayisekile kunye ne-tennis racket grips.

Impahla yasekhitshini: I-overmolding inokudala i-kitchenware kunye ne-soft-touch-touch kunye nokubamba okuphuculweyo, njengezinto zokupheka kunye nezibambo zeembiza kunye neepani.

Iimveliso zokuKhathalela umntu: Ukugqithisa kakhulu kunokudala iimveliso zokhathalelo lomntu kunye nenkangeleko ekhethekileyo kunye nokuziva, ezifana neebrashi zamazinyo kunye neencakuba.

Uqwalaselo loyilo olugqithisiweyo: Ukusuka kwiPrototyping ukuya kwiMveliso

I-overmolding ibandakanya ukujova into yesibini phezu kwecandelo elenziwe ngaphambili, ukudala imveliso edibeneyo. Ukugqithisa kunokubonelela ngeenzuzo ezibalulekileyo, ezifana nokuphuculwa kobuhle, ukusebenza okongeziweyo, kunye nokuqina okuphuculweyo. Nangona kunjalo, ukuyila kunye nokuvelisa iinxalenye ezigqithisiweyo kufuna ukuqwalaselwa ngenyameko ukuqinisekisa impumelelo.

Nazi ezinye iingqalelo ezibalulekileyo zoyilo lwamalungu agqithisiweyo:

Ukuhambelana kwezinto: Izinto ezisetyenziselwa ukugqithisa kufuneka zihambelane ukuze kuqinisekiswe ibhondi eqinile. Ukubambelela phakathi kwezinto ezimbini kubalulekile ekusebenzeni kwenxalenye. Izinto eziphathekayo ezineempawu ezifanayo kunye namaqondo okushisa anyibilikayo afanelekile ukugqithisa.

Uyilo lwenxalenye: Uyilo lwecandelo elenziwe ngaphambili kufuneka liqwalasele ubungakanani, imilo, kunye nendawo yendawo egqithisiweyo. Inxalenye equlunqwe kakuhle iya kuba nobukhulu bodonga obufanayo kwaye akukho ngaphantsi kokuqinisekisa ukuguqulwa okugudileyo phakathi kwezinto.

Uyilo lwezixhobo: Isixhobo sokubumba ngokugqithisileyo sintsonkothile ngakumbi kunobumba lwesiko lwesitofu. Uyilo lwesixhobo kufuneka lubambe inxalenye esele yenziwe ngaphambili ngexesha lenkqubo yokugqithisa, ukuvumela ukuba izinto zesibini zijikeleze kwaye zijikeleze inxalenye.

Umyili kufuneka kwakhona ayile izixhobo zokunciphisa ukudanyaza kunye nokuqinisekisa ibhondi engaguqukiyo phakathi kwemathiriyeli.

Uphuculo lwenkqubo: Inkqubo yokugqithisa ibandakanya izigaba ezininzi, kubandakanywa ukubumba inxalenye esele yenziwe ngaphambili, ukupholisa, kunye nokufaka into yesibini. Injineli kufuneka yongeze inkqubo yokuqinisekisa eyona nto inokwenzeka phakathi kwezinto ezimbini kunye nokunciphisa iziphene ezinje nge-warping okanye i-sink marks.

Xa usuka kwiprototyping ukuya kwimveliso, kukho izinto ezongezelelweyo ekufuneka uzigcine engqondweni:

Umthamo kunye nexabiso: I-overmolding inokubiza kakhulu kunobumba lwesitofu semveli ngenxa yobunzima benkqubo kunye neendleko zezixhobo. Njengoko umthamo unyuka, ixabiso ngenxalenye nganye linokuhla, okwenza ukuba i-overmolding ibe neendleko ezisebenzayo kwiimveliso ezinkulu.

Ulawulo lwemeko: Ukugqithisa kufuna imilinganiselo engqongqo yokuqinisekisa umgangatho wenxalenye engaguqukiyo kunye nokuthintela iziphene. Iqela lokulawula umgangatho kufuneka lenze ukuhlolwa kunye nokuvavanya kwinqanaba ngalinye lenkqubo yokuvelisa ukuqinisekisa ukuba inxalenye ihlangabezana neenkcukacha.

Ukhetho lomthengisi: Ukukhetha umboneleli ofanelekileyo wokulungisa ngokugqithisileyo kubalulekile kwimpumelelo yeprojekthi. Khangela umthengisi onamava ekugqithiseni kunye nerekhodi yokuvelisa iindawo ezikumgangatho ophezulu. Umboneleli kufuneka akwazi ukubonelela ngoncedo loyilo, ukuphuculwa kwenkqubo, kunye namanyathelo okulawula umgangatho.

Uveliso oluSebenzayo ngeendleko ngokuNxibelela

I-Overmolding yinkqubo yokuvelisa ebandakanya ukujova into yesibini phezu kwecandelo elenziwe ngaphambili ukwenza imveliso enye edibeneyo. Le nkqubo inokubonelela ngeenzuzo ezibalulekileyo, ezifana nokuphuculwa kobuhle, ukusebenza okongeziweyo, kunye nokuqina okuphuculweyo. Ukugqithiswa kwe-overmolding kunokuba sisisombululo esingabizi kakhulu kwiimveliso ezithile.

Nazi ezinye iindlela ezinokuthi ukugqithisa kakhulu kuncede ukunciphisa iindleko zokuvelisa:

Ixesha lokuhlanganisa elincitshisiweyo: Ukugqithisa kunokuphelisa imfuno yamacandelo ahlukeneyo kunye nenkqubo echitha ixesha lokuzihlanganisa. Ukugqithisa kunokunciphisa ixesha lokuhlanganisa kunye neendleko zabasebenzi ngokudala imveliso edibeneyo.

Inkunkuma yezinto ezincitshisiweyo: Ukubumba inaliti yesintu kudla ngokuvelisa inkunkuma ebalulekileyo ngenxa yesprues kunye neembaleki eziyimfuneko ukugcwalisa ukungunda. I-overmolding inokunciphisa inkunkuma ngokusebenzisa icandelo elenziwe kwangaphambili njengengundoqo kunye nokutofa into yesibini kuphela apho kuyimfuneko.

Ukusebenza kwenxalenye ephuculweyo: Ukugqithisa kunokuphucula ukusebenza kwenxalenye kunye nokuqina, ukunciphisa imfuno yokutshintshwa rhoqo okanye ukulungiswa. Ukunciphisa ixesha lokuphumla kunye neendleko zokugcina kunokubangela ukonga okubalulekileyo kwexesha elide.

Iindleko zezixhobo ezicuthiweyo: I-overmolding inokubiza kakhulu kunobumba lwesitofu semveli ngenxa yobunzima benkqubo kunye neendleko zezixhobo. Nangona kunjalo, kwezinye iimeko, ukugqithisa kunokunciphisa iindleko zezixhobo ngokususa imfuno yokubumba okuhlukeneyo kwicandelo ngalinye. Ukugqithisa kunokwenza lula inkqubo yokuvelisa, ngakumbi kwiindawo ezincinci kunye neziyinkimbinkimbi.

Iindleko zokuhamba ezicuthiweyo: I-overmolding ithoba iindleko zothutho ngokuphelisa isidingo sokuthutha kunye nokudibanisa amacandelo ahlukeneyo kamva. Ngokuphumeza oku, kuya kubakho ukunciphisa umngcipheko womonakalo ngexesha lokuthutha, okukhokelela ekunciphiseni kwiindawo ezikhatywayo kunye nenkunkuma.

Xa ucinga ngokugqithisela kwimveliso enexabiso eliphantsi, kubalulekile ukugcina ezi zinto zilandelayo engqondweni:

Ukukhethwa kwezinto: Izinto ezisetyenziselwa ukugqithisa kufuneka zihambelane ukuze kuqinisekiswe ibhondi eqinile. Izinto eziphathekayo ezineempawu ezifanayo kunye namaqondo okushisa anyibilikayo afanelekile ukugqithisa. Ukukhetha izinto ezifanelekileyo kunokuchaphazela ugcino lweendleko zexesha elide ngokuphucula ukusebenza kwenxalenye kunye nokunciphisa iindleko zokulondoloza.

Uphuculo lwenkqubo: Inkqubo yokugqithisa ibandakanya izigaba ezininzi, kubandakanywa ukubumba inxalenye esele yenziwe ngaphambili, ukupholisa, kunye nokufaka into yesibini. Iqela lokuphucula inkqubo kufuneka lenze inkqubo yokuqinisekisa eyona nto ingcono kakhulu phakathi kwezinto ezimbini kunye nokunciphisa iziphene ezifana ne-warping okanye amanqaku e-sink. Ukuphucula inkqubo kunokubangela amaxesha okujikeleza ngokukhawuleza kunye nokwandisa ukusebenza kakuhle, ukunciphisa iindleko zokuvelisa.

Ukhetho lomthengisi: Ukukhetha umboneleli ofanelekileyo wokulungisa ngokugqithisileyo kubalulekile kwimpumelelo yeprojekthi. Khangela umthengisi onamava ekugqithiseni kunye nerekhodi yokuvelisa iindawo ezikumgangatho ophezulu. Umboneleli kufuneka akwazi ukubonelela ngoncedo loyilo, ukuphuculwa kwenkqubo, kunye namanyathelo okulawula umgangatho.

Ukuzinza kokusiNgqongileyo kunye nokuGqibeleka

I-Overmolding yinkqubo yokuvelisa eyaziwayo ebandakanya ukubumba enye impahla phezu kwesinye ukwenza imveliso enye. Le nkqubo inika uluhlu lweenzuzo, kubandakanywa ukuphuculwa kwe-aesthetics, ukusebenza okongeziweyo, kunye nokwanda kokuqina. Kodwa kuthekani ngempembelelo yayo kwimekobume? Ngaba ukugqithisa kakhulu yinkqubo yokuvelisa egcinakeleyo kokusingqongileyo?

Nazi ezinye iindlela zokuthi ukugqithisela kube yinkqubo yokwenziwa kwendalo ezinzileyo:

Inkunkuma yezinto ezincitshisiweyo: I-overmolding inokunciphisa inkunkuma ngokusebenzisa icandelo elenziwe kwangaphambili njengengundoqo kunye nokutofa into yesibini kuphela apho kuyimfuneko. Ukusebenzisa imathiriyeli encinci kwimveliso kunciphisa ubungakanani benkunkuma eyenziwe ngokubanzi.

Ukusetyenziswa kwamandla okucuthiweyo: Ukugqithisa kunokuba namandla ngakumbi kuneenkqubo zokwenziwa kwemveli kuba ukubumba imveliso enye kufuna amandla amancinci kunokuvelisa amacandelo ahlukeneyo kunye nokuzihlanganisa kamva.

Ukusetyenziswa kwemathiriyeli esetyenzisiweyo: Izinto ezininzi ezigudileyo zinokuphinda zisetyenziswe, kuncitshiswe inkunkuma kwiindawo zokulahla inkunkuma. Ukusebenzisa izinto ezisetyenzisiweyo kwakhona kunokunciphisa imfuno yezinto ezinyulu, ukugcinwa kwemithombo yendalo kunye nokunciphisa ukusetyenziswa kwamandla.

Ixesha elide lemveliso: Ukugqithisa kunokuphucula ukusebenza kwenxalenye kunye nokuqina, okukhokelela kwiimveliso ezihlala ixesha elide kwaye zifuna ukutshintshwa okumbalwa. Ukunciphisa inkunkuma eveliswa kubomi bemveliso kunokunciphisa kakhulu ifuthe layo lokusingqongileyo.

Uthutho oluncitshisiweyo: Ngokuphelisa imfuno yohambo olwahlukileyo kunye nokuhlanganiswa kamva kwamacandelo, ukugqithisa kakhulu kunokunciphisa iindleko zothutho. Ukunciphisa umthamo wamafutha asetyenziswa kwisithuthi kunokunciphisa impembelelo yokusingqongileyo kunye nokunciphisa ukukhutshwa okuhambelanayo.

Nangona kunjalo, kubalulekile ukuqaphela ukuba ukugqithisa akusoloko kuyinkqubo yokwenziwa kwendalo ezinzileyo. Nazi ezinye izinto ekufuneka uzigcine engqondweni:

Ukukhethwa kwezinto: Izinto ezisetyenziselwa ukugqithisa kufuneka zikhethwe ngononophelo ukuqinisekisa ukuba zihambelana nokusingqongileyo. Umzekelo, ezinye imathiriyeli zinokuba ngumceli mngeni ukuphinda zisetyenziswe okanye zinokufuna ukusetyenziswa kwamandla amakhulu ukuvelisa.

Uphuculo lwenkqubo: I-overmolding kufuneka iphuculwe ukunciphisa ukusetyenziswa kwamandla kunye nenkcitho. Enye indlela yokunciphisa inkunkuma yezinto kukuphucula oomatshini okanye ukucokisa inkqubo yokubumba ukuze isebenze kakuhle.

Iingqwalasela zokuphela kobomi: Xa ucinga ngesiphelo sobomi bemveliso, abantu okanye imibutho imele icinge ngendlela eza kuyilahla ngayo. Iimveliso ezigqithisiweyo zinokuba ngumngeni ngakumbi ukuphinda zisetyenziswe okanye zinokufuna amandla amaninzi ukulahla kuneemveliso zemveli.

Ukugqithisa kakhulu kunye noShishino 4.0: Izinto ezintsha kunye namaThuba

Ukugqithisa yinkqubo yokuvelisa ebandakanya ukubumba imathiriyeli kwenye into okanye i-substrate. Imizi-mveliso yeemoto, ezonyango, kunye neyombane iyisebenzisa kakhulu. Ngokufika koShishino lwe-4.0, ukugqithiswa kwezinto kuye kwavelisa ngakumbi kwaye kusebenza kakuhle. Apha, siza kuphonononga iinguqulelo ezintsha kunye namathuba okugqithisa kwixesha le-Industry 4.0.

Izinto ezintsha kwi-Overmolding

Ukudibanisa i-Industry 4.0 itekhnoloji efana ne-automation, ubukrelekrele bokwenziwa, kunye ne-Intanethi yeZinto (IoT), iyiguqule inkqubo yokugqithisa. Nazi ezinye zezinto ezintsha ezithe zavela:

- Ii-Smart Molds: Ezi zibumba zixhotyiswe ngeenzwa kwaye ziyakwazi ukunxibelelana noomatshini ukulungelelanisa inkqubo yokubumba. Basenokubona iziphene kwaye baxelele abaqhubi ukuba bathathe amanyathelo okulungisa.

- Iirobhothi:Ukusebenzisa iirobhothi kwi-overmolding kuye kwandisa ukusebenza kakuhle kunye nokunciphisa iindleko zabasebenzi. Iirobhothi ziyakwazi ukusingatha imisebenzi ephindaphindiweyo efana nokulayisha kunye nokukhupha izinto, ukunciphisa ingozi yempazamo yomntu.

- Ushicilelo lwe-3D:Ushicilelo lwe-3D ludale imingundo entsonkothileyo ebikade ingenzeki ngaphambili. Ukonyuka kokuguquguquka koyilo kuye kwakhokelela ekunciphiseni amaxesha okukhokela.

- Ugcino oluqikelelweyo:Ugcino oluqikelelweyo bubuchule obusebenzisa uhlalutyo lwedatha ukuqikelela ukuba oomatshini baya kufuna nini ukulungiswa. Obu buchule bunokunceda ekuthinteleni ixesha lokuphumla kunye nokunciphisa iindleko zokugcina.

Amathuba kwi-Overmolding

Ukugqithisa kunamathuba amaninzi kwi-Industry 4.0, kuquka:

- Ukunciphisa:Ukugqithisa kakhulu kunokudala iindawo ezikhaphukhaphu ngokubumba umaleko omncinci wezinto kwi-substrate ekhanyayo. Ukunciphisa ubunzima bemveliso yokugqibela kuphucula ukusebenza kakuhle kwamafutha kunye nokunciphisa ukukhutshwa.

- Ngokwezifiso: I-Overmolding ivumela ukulungelelaniswa kwamacandelo ngokusebenzisa izinto ezahlukeneyo kunye nemibala. Kumashishini ezonyango kunye nabathengi be-elektroniki, kubonakala kubaluleke kakhulu, kwaye kubalulekile ukuqwalasela le nto.

- Ukuzinza:Ukugqithisa kakhulu kunokuncedisa ukunciphisa inkunkuma ngokusebenzisa izinto ezisetyenzisiweyo njengama-substrates. Ngokunciphisa impembelelo yokusingqongileyo yokwenziwa kwemveliso, iinkampani azinakuphucula kuphela umfanekiso webrand yazo kwaye zibe negalelo kwikamva elizinzileyo.

- Ukonga iindleko: Ukuzenzekela, iirobhothi, kunye nokugcinwa kwangaphambili kunokunciphisa iindleko zabasebenzi kunye nokwandisa ukusebenza kakuhle, okukhokelela ekongeni kweendleko zomenzi.

Ukugqithiswa kwemingeni kunye nezisombululo

Nangona kunjalo, ukugqithisa kakhulu kubangela imiceli mngeni ethile ekufuneka abavelisi bayoyise ukuze bavelise iindawo ezingaphezulu ezikumgangatho ophezulu. Kweli nqaku, siphonononga ezinye zeengxaki ezigqithisileyo kunye nezisombululo.

mngeni

- Ukuncamathela: Ukugqithisa kufuna ukuba izinto ezimbini ezisetyenzisiweyo zihambelana enye kwenye, kwaye ukunamathela kakubi kukhokelela kwi-delamination, cracking, okanye detachment of the overmolded material.

- Warping:Ngexesha lenkqubo yokugqithisa, i-substrate inokukhubazeka ngenxa yokushisa okuphezulu kunye noxinzelelo olusetyenziswayo. I-Warping ichaphazela kakubi umgangatho opheleleyo wecandelo.

- Ukuhambelana kwezinto:Izinto ezisetyenziselwa ukugqithisa kufuneka zihambelane ukuqinisekisa ukunamathela kakuhle kunye nokuthintela ukulwa. Izinto ezingahambelaniyo zinokukhokelela ekudibaneni okubi kunye nokusilela kwezinto.

- Umgca wokwahlulahlula: Umgca wokwahlula kulapho zidibana khona izinto ezimbini. Uyilo olubi lomgca wokuhlula lunokukhokelela kumanqaku abuthathaka kwimveliso egqityiweyo kunye nokunciphisa ukuqina.

- Ukuhamba kwezinto: Inkqubo yokugqithisa idinga into yesibini ukuba ijikeleze i-substrate, igcwalise yonke i-crevice. Ukungahambi kakuhle kwezinto eziphathekayo kunokukhokelela ekugqumeni okungaphelelanga, i-voids, okanye iindawo ezibuthathaka.

izisombululo

- Ukulungiswa komphezulu: Ukulungisa umphezulu we-substrate kubalulekile ekufezekiseni ukunamathela kakuhle. Umphezulu kufuneka ucoceke, wome, kwaye ungabi nazingcolisi ezifana ne-oyile kunye nobutyobo. Ukunyangwa kwangaphambili kwe-substrate kunye nabakhuthazi bokubambelela kunokuphucula ukudibanisa.

- Uyilo olufanelekileyo lwezixhobo: Uyilo kufuneka luthathele ingqalelo izinto ezisetyenzisiweyo kunye nenxalenye yejometri ukuthintela ukulwa nokuqinisekisa ukuhamba kakuhle kwezinto. Ukusebenzisa izixhobo ezikhethekileyo, ezifana nokufaka ukubumba, kunokuphucula ukuqina kunye nokomelela kwenxalenye.

- Ukukhethwa kwezinto: Izinto ezisetyenzisiweyo kwi-overmolding kufuneka zihambelane nokufezekisa ukudibanisa okulungileyo kunye nokuthintela ukulwa. Ukusebenzisa izinto ezinee-coefficients zokwandiswa kwe-thermal ezifanayo kunokunciphisa uxinzelelo lwenxalenye ngexesha lokubumba.

- Uyilo lomgca wokwahlulahlula: Xa uyila imveliso, kubalulekile ukuqwalasela umgca wokwahlula ukuqinisekisa amandla ayo ngononophelo. Ukusebenzisa imigca yokuqhawula engqukuva kuyacetyiswa kakhulu ukunqanda ukuxinana koxinzelelo.

- Ukwandiswa kwenkqubo yokubumba isitofu: Ukuphucula inkqubo kunokuphucula ukuhamba kwezinto kunye nokuthintela i-voids okanye amanqaku abuthathaka. Ukulawula ubushushu, uxinzelelo, kunye nesantya sokutofa kubalulekile ukuze ufumane iziphumo ezilungileyo.

Izalathiso zexesha elizayo zokugqithisela: Iindlela ezisakhulayo kunye neeTekhnoloji

I-Overmolding, inkqubo ebandakanya ukubumba enye imathiriyeli kwenye, ibiyeyona ndlela idumileyo kushishino lokuvelisa amashumi eminyaka. Nangona kunjalo, ngenkqubela phambili yetekhnoloji kunye nokugxila ngakumbi kuzinzo, ukugqithisa ngoku kukufumana ukwanda kokuthandwa. Apha, siza kuxoxa ngemikhombandlela yexesha elizayo yokugqithisa, kubandakanywa neendlela ezivelayo kunye nobuchwepheshe.

Iindlela zokuGqibela:

Ukuzinza: Uzinzo luyiprayorithi ephezulu kwiinkampani ezininzi, kwaye ukugqithisa kunokunceda ukunciphisa inkunkuma kunye nokuphucula ukusebenza kakuhle kwiinkqubo zokuvelisa. Ukusebenzisa imathiriyeli esetyenzisiweyo kunye neepolymers ezinokonakala kwi-overmolding kuya kuxhaphaka ngakumbi, kunciphisa impembelelo yokusingqongileyo.

Iminiaturization: Njengoko itekhnoloji iguquka, imfuno yeemveliso ezincinci, ezikhaphukhaphu, kunye nezintsonkothileyo ziyanda. Ukugqithiswa kwe-overmolding kuvumela ukudala iindawo ezincinci, ezintsonkothileyo ezihlala ixesha elide kwaye zisebenza kakuhle, oko kuyenza ibe lolona khetho lufanelekileyo kwindlela yokwenza i-miniaturization.

Ngokwezifiso: Abathengi bafuna iimveliso ezenzelwe umntu ngakumbi, kwaye ukugqithisa kunika amandla okwenza iimveliso ezinemibala eyahlukeneyo, ukwakheka, kunye nemathiriyeli. Njengoko ukwenza ngokwezifiso kuya kufikeleleka ngakumbi kwaye kufikeleleke, silindele ukuba le ndlela ikhule.

Itekhnoloji kwi-Overmolding:

Ukuhonjiswa koMngundo (IMD): I-In-Mold Decoration yitekhnoloji eyenza umphezulu ohonjisiweyo ngexesha lokugqithisa. Obu buchwephesha buvumela ukwenziwa kweemveliso ezinoyilo oluntsonkothileyo kunye neepateni, nto leyo eyenza ukuba ilungele umkhwa wokwenza ngokwezifiso.

Faka Ukubumba: Faka ukubumba kubandakanya ukugqithisa inxalenye esele ikhona okanye icandelo. Le teknoloji ifanelekile kwi-miniaturization kuba ivelisa izinto ezincinci, ezinzima ngakumbi.

Ii-Multi-Shot Overmolding: I-Multi-shot overmolding ibandakanya ukusebenzisa izinto ezininzi ukwenza inxalenye enye okanye imveliso. Obu buchwephesha buvumela imveliso yendalo enemibala eyahlukeneyo, imibala, kunye nemathiriyeli, iyenza ilungele umkhwa wokwenza ngokwezifiso.

Ukubunjwa kwe-Co-Injection: Ukubumba i-co-injection kubandakanya ukutofa izinto ezimbini okanye ngaphezulu kwi-mold enye. Le teknoloji ivumela ukudalwa kweemveliso kunye nendibaniselwano yepropati, njengamandla kunye nokuguquguquka.

Iinzuzo zokuGqibela:

Inkunkuma Ethotyiweyo: Ukugqithiswa kwe-overmolding kuphelisa imfuno yamacandelo ahlukeneyo kunye namacandelo, okukhokelela kwinkqubo yokuvelisa esebenzayo kunye nezinzileyo.

Ukuphuculwa koKuhlala ixesha elide: Ukugqithiswa kwe-Overmolding kunika ukomelela okwandisiweyo kunye namandla kwiimveliso, okwenza ukuba zixhathise ngakumbi ukunxiba kunye nokukrazula.

Isebenza kakuhle emalini: Ukugqithiswa kwe-overmolding kunokuba yindleko-esebenzayo kwiindlela zokwenziwa kwemveli, ngakumbi xa uvelisa amancinci, iindawo ezintsonkothileyo.

Iinkonzo ezigqithisileyo kunye nababoneleli: Ukukhetha uMlingane oLungileyo

Nangona kunjalo, ukufumana umnikezeli wenkonzo ogqithisayo ochanekileyo kunokuba ngumngeni, ngakumbi xa kunikwa iindidi ezininzi zababoneleli kunye neenkonzo ezikhoyo. Apha, siza kuxoxa ngezinto eziphambili ekufuneka ziqwalaselwe xa ukhetha umboneleli wenkonzo ogqithisayo.

Izinto Emaziqwalaselwe:

amava: Khangela umboneleli wenkonzo onerekhodi eqinisekisiweyo yokugqithisa. Jonga ipotfoliyo yomboneleli ukuba banamava okusebenza kwiiprojekthi ezifana nezakho.

Amandla: Qinisekisa ukuba umboneleli unokuhlangabezana neemfuno zakho ezithile, kubandakanywa ukhetho lwezinto eziphathekayo, ukhetho lokulungelelanisa, kunye nomthamo wemveliso.

umgangatho: Umgangatho ubalulekile ekugqithiseni, njengoko neziphene ezincinci zinokukhokelela ekungaphumeleli kwemveliso. Khangela umnikezeli onenkqubo yokulawula umgangatho oqinileyo oqinisekisiweyo ngamaqumrhu alawulayo afanelekileyo.

Iindleko: Ukugqithisa kunokuba yindleko, ngoko ke ukukhetha umboneleli wamaxabiso okhuphisanayo ngaphandle kokunciphisa umgangatho kubalulekile.

UNxibelelwano: Khangela umboneleli oxabisa unxibelelwano olucacileyo noluselubala. Umboneleli kufuneka aphendule kwimibuzo yakho kwaye akugcine unolwazi kuyo yonke inkqubo yemveliso.

Ixesha lokukhokhela: Qwalasela ixesha elikhokelayo lomboneleli, njengoko ulibaziseko lunokuchaphazela ishedyuli yakho yemveliso. Qinisekisa ukuba umboneleli unokuhlangabezana nemihla yakho ebekiweyo.

Indawo: Ukukhetha umboneleli ngokwejografi kufutshane neshishini lakho kunokunciphisa iindleko zokuhamba kunye namaxesha okukhokela.

Inkonzo eyenzelwe: Khetha umboneleli oxabisa inkonzo yabathengi kwaye uya kusebenza nawe ukusombulula nayiphi na imiba.

Ababoneleli ngeNkonzo:

IiNkampani zokuMbumba ngesitofu: Iinkampani ezininzi zokubumba iinaliti zibonelela ngeenkonzo zokugqithisa njengomnikelo owongezelelweyo. Ezi nkampani zinenzuzo yamava ekubunjweni kwenaliti kwaye zinokubonelela ngoluhlu olupheleleyo lweenkonzo, kubandakanywa ukukhethwa kwezinto kunye nokukhethwa ngokwezifiso.

IiNkampani zokuVelisa ikhontrakthi: Iinkampani ezivelisa ikhontrakthi zibonelela ngeenkonzo zokuvelisa kumashishini ahlukeneyo. Ezi nkampani zihlala zinamava abanzi ekugqithiseni kwaye zinokunika izisombululo ezingabizi kakhulu zokuqhuba imveliso yomthamo omkhulu.

Ababoneleli abakhethekileyo: Ababoneleli abakhethekileyo bagxininise kwiinkalo ezithile zokugqithisa, ezifana nezixhobo okanye ukukhethwa kwezinto eziphathekayo. Aba baboneleli banokunikezela ngobuchule obukhethekileyo obunokuba luncedo kwiiprojekthi ezinzima okanye ezizodwa.

isiphelo

I-Overmolding yinkqubo eguquguqukayo nesebenzayo enokuphucula ukusebenza kwemveliso, ukuqina, kunye nobuhle kumashishini ahlukeneyo. Ngoluhlu lwezinto, ubuchule, kunye nokusetyenziswa, ukugqithisa kunika amathuba amaninzi kubavelisi ukwenza iimveliso ezikumgangatho ophezulu ezihlangabezana neemfuno kunye nezinto ezikhethwa ngabathengi. Abavelisi banokwenza izigqibo ezizizo kwaye bahlale bekhuphisana kwimarike yanamhlanje ngokuqwalasela uyilo, iindleko, ukuzinza, kunye nemiba yokuvelisa izinto ezigqithisileyo. Nokuba ungumyili wemveliso, injineli, okanye umnini weshishini, ukuqonda ingqikelelo yokugqithisa kakhulu kunokukunceda ukuba uthathe iimveliso zakho uzise kwinqanaba elilandelayo.