Ityala eIndiya

U-DJmolidng's Faka uMngundo kwiNkonzo yokuBumba isitofu kwiiNkampani zaseIndiya

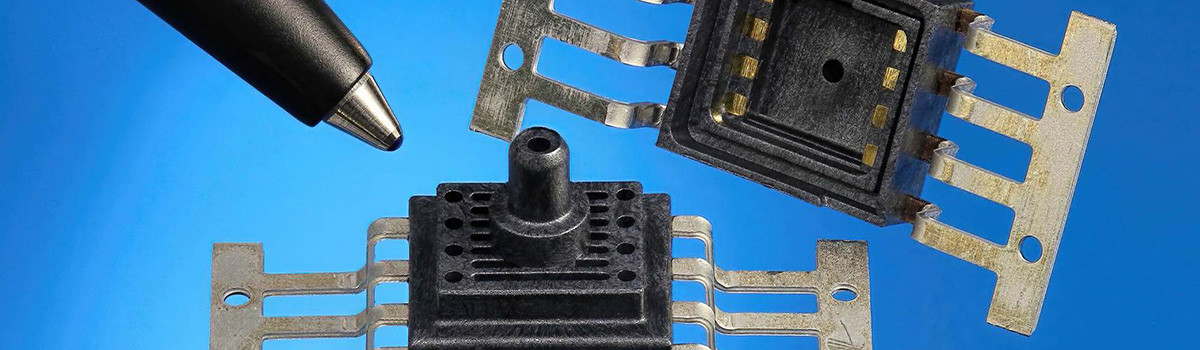

Faka ukungunda ngokubanzi luhlobo lokungunda elenza amandongomane, iinxalenye zentsimbi okanye iinxalenye zeplastiki eziqinileyo ezimiliselwe ngaphakathi kwimingxuma yokubumba inaliti.

I-DJmolding ibonelela ngenkonzo yokubumba inaliti ye-mlod kwimakethi yaseIndiya, kwaye sivelisa iindawo ezininzi zeplastiki zokubumba kumashishini ahlukeneyo, ngakumbi abenzi bezixhobo zasekhaya. Abanye abavelisi bezixhobo zasekhaya zaseIndiya bathenga iinxalenye zeplastiki zokubumba ixesha elide i-DJmolding. Sinobudlelwane obuhle kakhulu nezi nkampani zaseIndiya.

Faka isitofu sokubumba amantongomane: izinto zamandongomane zinokuba yintsimbi engatyiwa, ubhedu, ubhedu kunye nentsimbi, ngokuqhelekileyo kusetyenziswa amandongomane obhedu. Ubhedu kulula ukugquma, nto leyo enceda amandongomane kunye neeplastiki zidibanise kakuhle. Ukunyamezelana kwe-nut bores yangaphakathi kufuneka kulawulwe ngaphakathi kwe-0.02mm, kungenjalo kubangele ukukhanya ukuba ukunyamezela ngaphaya kwe-0.02mm. Ekufakeni isikhunta, kufuneka udibanise amantongomane kwizikhonkwane zokufaka ukuvavanya. Ukuba iqinile phakathi kwamantongomane kunye nezikhonkwane, kuya kuba nzima ukukhupha inxalenye kwaye kubangele amanqaku okukhupha okanye iingxaki zokuncamathela. Ukuba ayilunganga, inokubangela ukukhanya.

Faka intsimbi yokubumba isitofu:

Amalungu esinyithi anokuba yintsimbi engatyiwa, ialuminiyam, ubhedu, intsimbi ... njl. Ukunyamezela kweengxenye zetsimbi kufuneka kulawulwe ngaphakathi kwe-0.02mm, ngaphandle koko kunzima ukutywina izinto kwaye kulula ukuba ne-flash. I-acreage yeendawo zetsimbi ayinakuyilwa ibe nkulu kakhulu.

Ukuba i-acreage yokuzalisa yamalungu esinyithi inkulu kakhulu, kuya kuba nzima kakhulu ukufikelela ngokujovwa ngokupheleleyo njengomahluko omkhulu wobushushu phakathi kwamalungu esinyithi. Iindawo zentsimbi zidla ngokuyilwa emngxunyeni njengoko umngxuma ungashukumi, nto leyo enceda ukunqanda isiphumo sodanyazi olusuka kumalungu esinyithi aphumayo xa ehamba (kwimeko embi kakhulu, inokonakalisa ukungunda). Kwiimeko ezithile, izikhundla zeengxenye zetsimbi zinokuthi ziyilwe kuphela kwindawo engundoqo okanye kwicala lemveliso.

Faka ukubumba ngenaliti yeplastiki eqinile:

Ngokuqhelekileyo khetha iiplastiki eziqinileyo ezinezinga eliphezulu lokunyibilika, njenge-PEEK, PA66+30GF, PP+30GF, PA12+30GF, PPS….etc. Ukunyamezela kwezi plastiki ezinzima kufuneka kuchaneke. Iziphene ezifana nokushwabana, ukubola, kunye nokonakala akunakubakho kwindawo yokutywina. Ekufakeni umngundo, iplastiki eqinileyo kufuneka ifakwe ngaphakathi ekubumbeni ukuze ivavanywe, kwaye ishiywe yi-0.05-0.1mm yokucinezela kwangaphambili kwindawo yokutywina ukufikelela ukutywinwa okungcono.

Inxalenye yeplastiki eqinileyo akufuneki iyilwe iacreage enkulu kakhulu, eya kubangela umahluko wobushushu kwaye yenze kubenzima ukuzalisa imathiriyeli kwinaliti. Ngokwesiqhelo yenza indawo eqinileyo yeplastiki ibekwe ecaleni komngxuma, kuba umngxuma awushukumi, ukunqanda ukukhanya okanye ukonakalisa umngundo ekunyakazeni kokungunda. Kwiimeko ezithile, izikhundla zeengxenye zetsimbi zinokuqulunqwa kuphela kwindawo engundoqo okanye kwicala lemveliso.

Yila amanqaku aphambili

I-1.Design shrinkage yeemveliso ezinokufakwa kwamantongomane, ngelixa kungekho mfuneko yokuyila i-shrinkage yeemveliso ezineengxenye zetsimbi kunye nokufakwa kweplastiki enzima. Kwiindawo ezifuna unyamezelo olungqongqo, guqula ubungakanani bokunyamezela kweemveliso ukuya kwi-median.

2. Ngokuqhelekileyo yamkela isiseko sokubumba kunye nesango eliqhelekileyo le-pin-point kuyilo lokubumba, kunye nenaliti yesibini, ubeke iindawo zokufakela emngxunyeni kangangoko kunokwenzeka. Kwimeko yokwenza izinto ezifakwe kwi-cavity, qwalasela indlela yokwenza inxalenye ekhohlo kwi-core emva kokubunjwa kwenaliti, ngale ndlela, inxalenye ingakhutshwa. Ngokwesiqhelo yongeza iibhloko ezilastiki kumngxunya kunye neglue elastiki ukwenza indawo ihlale kumbindi. Umgama phakathi kweebhloko ze-elastic kunye ne-glue awukwazi ukuba mkhulu kakhulu, ngaphandle koko amandla e-elastic aya kubangela iplastiki enzima okanye i-deformation yeendawo zetsimbi. Umgama udla ngokuyilwa ngaphakathi kwe-2mm, kwaye ngokufanelekileyo wandise ubuninzi beebhloko ezilastiki kunye neglue elastiki xa isinyithi okanye ukufakwa kweplastiki eqinile kune-acreage enkulu.

I-3.Ubukhulu bezinto eziphathekayo bungcono kakhulu ngaphakathi kwe-1.3-1.8mm (malunga ne-1.5mm iyona nto ibhetele), ukuba akunjalo, kufuneka uhlolisise imizobo yemveliso kwaye ucebise umthengi ukuba ayiguqule. Ukuba ubukhulu bezinto eziphathekayo buncinci kune-1.3mm, kunzima ukuzaliswa kwezinto eziphathekayo, ngelixa ubukhulu bezinto eziphathekayo bukhulu kune-1.8mm, ukushwabana kulula ukwenzeka kwimveliso.

4.Ukugawula kubaluleke kakhulu kubumba. Ukulungelelaniswa kwezinto zokuzaliswa kwendawo yesango kufuneka kuqwalaselwe ngokupheleleyo.Xa izinto zibaleka kwindawo apho iintsimbi zentsimbi okanye iiplastiki ezinzima ziqinisiwe, isantya sokuzaliswa kwezinto kunye noxinzelelo luya kuncipha ngenxa yokuba ukufakwa kokuchasana kunye nokuhluka kweqondo lokushisa.

5.Kwinkqubo ye-mold ejector, Ibhalansi yokukhupha kufuneka ithathelwe ingqalelo okanye i-deformation iya kwenzeka emva kokukhutshwa. Kuba iinxalenye azinakukhutshelwa kwibhalansi, kufuneka kuqwalaselwe ukudilika ukuphucula ingxaki yebhalansi kuyilo lwesakhiwo.

6.Ukuqinisekisa ukufaneleka kwembonakalo yamalungu emva kokuba ikhutshwe kwi-injection molding, isixhobo se-ejector kufuneka sibe yintlama yeplastiki enzima efakwe kunye ne-ABS okanye i-PMMA. Ukuba ngaphezulu komngundo kukho ukutywinwa kwesilayidi, yila izilayidi kwicango kangangoko, kuba izilayidi ezikumngxuma ziququzelela ukufakwa kokungunda.

7.Ukuqinisekisa ukomelela kokutywinwa kwe-SA(isibonelelo somthungo), kwimveliso eyenziwe ngokubumba inaliti kabini, ububanzi bokutywina iSA kufuneka bube yi-0.8mm ubuncinane. Kwimathiriyeli yesinali yesibini yiplastiki eqinileyo, ububanzi bokutywina iSA kufuneka bube yi-1.0mm, kungenjalo, kufuneka ucebise umthengi ukuba aguqule imveliso.

8.Kuyilo lokubumba, kufuneka sithathele ingqalelo oomatshini bokubumba inaliti kwimveliso ukuze babone ukuba loluphi uhlobo lomatshini olwamkelayo, oluthe nkqo okanye oluthe tye. Kucetyiswa ukuba musa ukuyila imingxunya emininzi kakhulu, ngakumbi umngundo oneembaleki ezibandayo njengoko imingxunya emininzi yenza imbaleki ibe nde, imoshe imathiriyeli kwaye iyingozi ekufumaneni inaliti yobuchule obuphezulu. Ukutshatisa umatshini wokubumba inaliti, kufuneka siqwalasele ukuba ibumbene kwaye isengqiqweni na ukulungiselela imveliso. Enye indlela yinkqubo yokusabela yoyilo ukuze ilumkise ukuba inxalenye ayikho kwindawo efanelekileyo ngaphambi kokuvalwa komngundo, okunceda ukuyeka ukuvala ukungunda. Ngale ndlela, iinxalenye zikwimeko efanayo kubumba, nto leyo ephakamisa amaxabiso afanelekileyo kunye nokusebenza kakuhle kwemveliso ekubumbeni inaliti.

I-9.Inkxaso yensimbi kufuneka iqulunqwe njengoko indawo ye-injection ye-mold ithwala uxinzelelo olukhulu kwi-injection (kufuneka ibe yi-5-10 mm enkulu kuneyo nxalenye yobume kunye nobukhulu). Makungawushiyi umsantsa phakathi kwamalungu ajikeleze indawo yokubumba ngaphezulu, kungenjalo indawo iya kuba ingekho kwimeko emva kwesitofu sesibini. Amacandelo angenayo i-SA(isibonelelo somthungo) kuya kufuneka kuqwalaselwe ngakumbi kulo mba.

10.Uhambo lwasemoyeni lula Uhambo lomoya lwenzeka lula ekubumbeni inaliti, ngoko ke kufuneka kuqwalaselwe ngokupheleleyo ukungena kuyilo lokungunda. Kuzo zonke ii-engile ezingaboniyo kunye neendawo zomgama omde womgca wamanzi, kufuneka uyile imingxunya yokukhupha umoya kwindawo eqinileyo yeplastiki njengoko kunzima kakhulu ukugcwalisa imathiriyeli kwii-engile ezingaboniyo.

11.Ukuqinisekisa ukuba izinto ezitofelweyo kunye nokutyhalwa okufanelekileyo zizaliswe ngokupheleleyo, enye indlela kukuyila i-undercuts kwiikona zenxalenye yokuphucula isiphumo sokubambelela kwaye emva koko ukwenza iinxalenye zibambelele ngokuqinileyo.

12. Kwindawo yokutywina kunye nendawo yomgca wokwahlula, akufuneki sidilize ukusuka kumngxuma kunye nasembindini, kuba imigca ebambekayo kwisingundo kunye nokudilizwa kwedrafti kuya kubangela ukudanyaza kokulingana kokungunda. Zama ukudiliza nge-LISS-OFF.

Iintlobo zenqaku lesango lokufaka umngundo

Indawo yesango yofakelo lokungunda inokuyilwa ukuze iqondise isango levalvu yesprue eshushu, isango lentsimbi yesprue eshushu, isango lendawo yokukhonkxa, isango elincinane, isango lomphetho…njl.

Isango levalve ye-sprue eshushu: umbane olungileyo, indawo yokukhetha ebhetyebhetye, indawo yesango encinci. Iisuti zemveliso enkulu kunye neemveliso ezinodonga olungqingqwa. Inokunceda ukugcina imathiriyeli, akukho nkunkuma yezinto eziphathekayo kwisango, ixesha elifutshane lokukhokela, kunye nomgangatho ophezulu. Ekuphela kwesiphako kukulandela umkhondo omncinci wokungena.

Isango lephini lesprue elishushu: ukusetyenzwa kakuhle, indawo yokukhetha eguquguqukayo, indawo yesango elincinci. Iisuti zemveliso enkulu kunye neemveliso ezinodonga olungqingqwa. Inokunceda ukugcina imathiriyeli, akukho nkunkuma yezinto eziphathekayo kwisango, ixesha elifutshane lokukhokela, kunye nomgangatho ophezulu. Kodwa kukho iziphene, ezinje nge-0.1mm imathiriyeli eshiywe kufutshane nendawo yesango, kwaye kulula ukuyibhuqa. Kufuneka wenze iigrooves ukugquma izinto ezisekhohlo ezijikeleze indawo yesango.

Isango lendawo yokukhonkotha: indawo yokukhetha eguquguqukayo, ubuthathaka bemali, umgama wembaleki omde, indawo yesango elincinci. Iisuti zokuvelisa ibhetshi encinci. Inkunkuma eninzi ejikeleze indawo yesango. Kufuneka iingalo zomatshini ukuze ubambe indawo yesango kwimveliso. Ixesha elide lokuhamba. Isiphene yi-0.1-0.2mm imathiriyeli eshiyekileyo ejikeleze indawo yesango, kufuneka wenze iigrooves ukugquma imathiriyeli esekhohlo ejikeleze indawo yesango.

Isango elingaphantsi: inokuthi iyilwe kwiimbambo kwindawo, umbindi, iindonga ezisecaleni, kunye nezikhonkwane ze-ejector. Unokukhetha indawo yesango ngokuguquguqukayo, isango lokugalela lahlula inxalenye ngokuzenzekelayo, umkhondo omncinci wokungena. Iziphene: kulula ukukhupha izinto ezijikeleze isango, kulula ukwenza amanqaku omile kwindawo yokungena, kufuneka kucinywe izinto ngesandla, ilahleko enkulu yocinezelo ukusuka kwindawo yesango ukusuka kwimingxuma.

Isango lomda: iplastiki etyhidiweyo ihamba ngesango, ibekwe ecaleni ngokulinganayo, iyancipha uxinzelelo; nciphisa amathuba okungena komoya emngxunyeni, kunqande ukubangela imijelo kunye namaqamza. Iziphene: isango lokugalela alikwazi ukwahlula inxalenye ngokuzenzekelayo, amanqaku e-sprue ashiywe kwimida yenxalenye, kufuneka izixhobo zokusebenza ukugalela isango elisicaba. Isango lomda linokunceda inaliti yomlinganiso kunye nokubamba uxinzelelo, kwaye ilungele ukubamba uxinzelelo kunye nokutyisa, ngale ndlela, kungcono ekuphuculeni imigca yomoya, amanqaku okuhamba…njl.

Ukulungiswa kunye nokufakwa kokungunda

1.Ngaphambi kokucubungula, sebenzisa itekhnoloji yokulungiswa kokungunda. Khetha oomatshini bokulungisa abachanekileyo, umatshini ohamba ngesantya esiphezulu, ukondla kancinci umatshini wokusika i-NC, isibuko se-EDM (umatshini wokukhupha umbane) njl.

2.Uyilo 0.05-0.1mm ekhohlo kwindawo yokucofa kwangaphambili.

I-3.Qaphela iimfuno ezichanekileyo kwi-mold base processing, hlola ukunyamezela emva kokufumana isiseko sokubumba kwaye ungayisebenzisi ukuba ukunyamezela akufanelekile.

4.Beka amantongomane, iinxalenye zetsimbi kunye neenxalenye zeplastiki eziqinileyo ngaphakathi kwesikhunta ukulungiselela ukubumba. Ukuba ufumana iingxaki ekufakeni umngundo, jonga ngamandongomane, iindawo zentsimbi, iinxalenye zeplastiki eziqinileyo kunye nokungunda ukubona ukuba yeyiphi engalunganga. Inkqubo inxalenye ngokomzobo kangangoko kunokwenzeka, okunceda ukulandelela idatha kwixesha elizayo.

5.Ayikwazi ukusebenzisa igrinder yokufaka umngundo. Jikela koomatshini ukulungisa apho ukufakwa kokungunda kungalunganga.

6.Yenza uvavanyo lwesenzo phambi kokuvavanywa, kunqande ukuphoswa kokudibanisa kunye nokudibanisa ngempazamo. Ukudibanisa ngempazamo kuya kubangela umonakalo wesiseko sokungunda.

Uvavanyo lokungunda lokufaka ukungunda

1.Kuvavanyo lokubumba, umntu kufuneka azi ngokucacileyo malunga nokulandelelana kokuvula, ukuvala kunye nokukhupha i-mold. Qonda iimpawu zesakhiwo kunye neempawu zeendawo zentsimbi kunye neendawo zeplastiki ezinzima.

2.Yazi ngokucacileyo malunga nobuninzi beesampuli ezifunwa ngumthengi, lungiselela amantongomane aneleyo, iinxalenye zetsimbi kunye neeplastiki ezinzima, kuba zifuna iisampuli ezininzi ekuvavanyeni isikhunta.

3.Qaphela ukuba unokuvavanya ukungunda ngaphandle kokufaka amantongomane, iinxalenye zentsimbi okanye iiplastiki eziqinileyo. Ukuba fakela amandongomane, iindawo zentsimbi kunye neeplastiki eziqinileyo azidityaniswanga kubungu, inxalenye inokuba neziphene ezifana nokuncamathela kumngundo okanye ishot emfutshane.

4. Kwiimeko ezininzi, kufuneka ulungelelanise i-waterline plate kwi-mold, kodwa ngamanye amaxesha ayinako ukuhlengahlengisa ipleyiti yomgca wamanzi kwindawo ethile yokufaka i-mold ngokusekelwe kwisakhiwo sabo, okanye ngakumbi, ukubunjwa kugxininiswe kakhulu kwaye kufuna ukulungiswa, okanye ukubunjwa kubonakaliswe kwi-mold. ukuvula.

I-5.Iingxaki zinokuthi zenzeke kuvavanyo lokungunda, njengokudubula okufutshane, ukuhamba emoyeni, ukukhanya, okanye ukunamathela kwi-mold. Ukuba iingxaki zinokuqinisekiswa kumatshini wokubumba inaliti, kungcono ukuyisombulula.

I-DJmolding ineminyaka engaphezu kwe-10 + faka amava okubumba, ukuba unombuzo, nceda uqhagamshelane nathi.