Inkonzo ye-CNC Machining

Yintoni iCNC Machining

I-CNC imele ukulawulwa kwamanani ekhompyutheni, okuyithekhinoloji yokulawula izixhobo zomatshini ngokuzenzekelayo ngokusebenzisa i-microcomputer encanyathiselwe kwisixhobo. Oomatshini be-CNC babeza kusebenza ngokwemiyalelo ecwangcisiweyo enekhowudi, njengokushukuma koomatshini, izinga lokutya kwezinto, isantya, njalo njalo. Akukho mfuneko yabaqhubi ukulawula umatshini ngesandla, ngoko ke, i-CNC inceda ukuphucula ukusebenza kunye nokuchaneka kumlinganiselo omkhulu.

DJmolding CNC ubuchule bomatshini

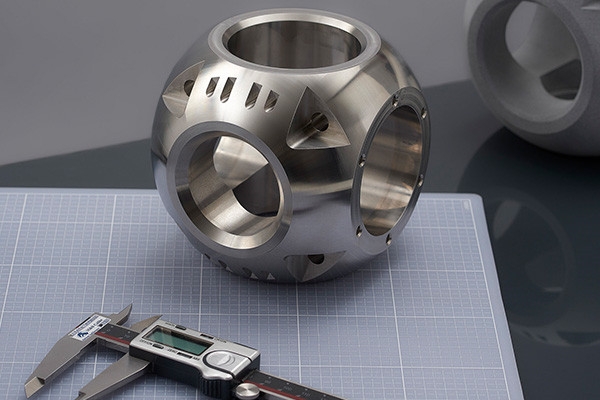

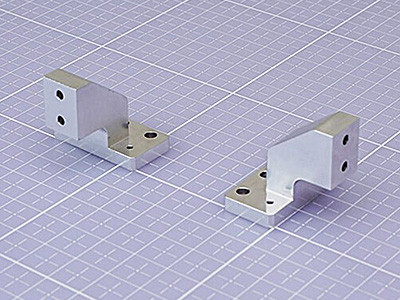

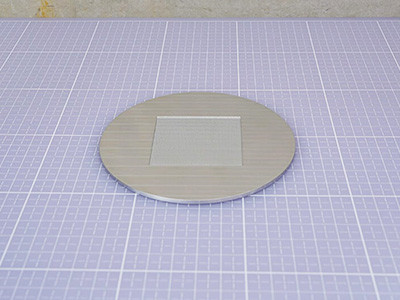

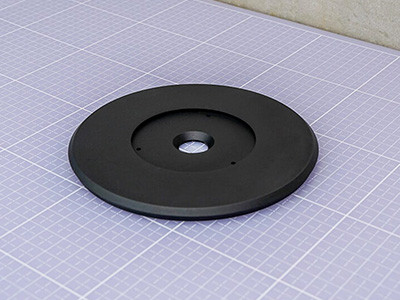

Kwimfuno ye-CNC yomatshini wokwenza umboniso okhawulezayo kunye neenxalenye zemveliso, ezinamava kwaye zihlolwe ngokucokisekileyo iivenkile zoomatshini be-DJmolding CNC.

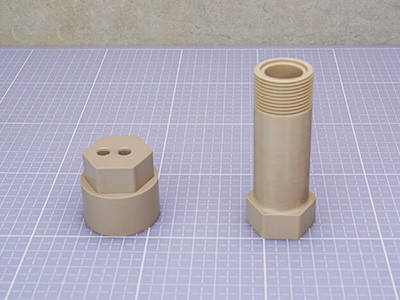

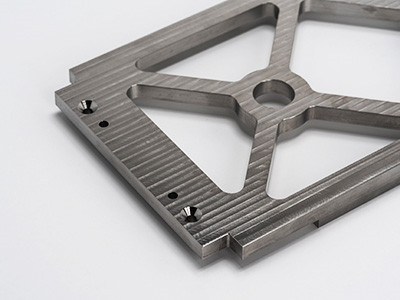

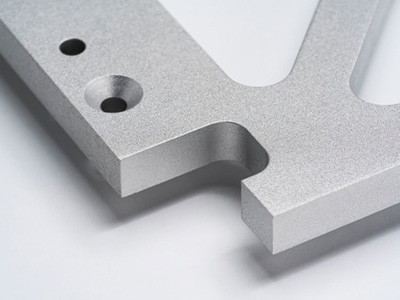

Sisebenza phantse lonke uhlobo lwe-CNC yokusila kunye neziko lokujika, kwaye siyazingca ngokukwazi ukwenza umatshini nantoni na oyifunayo, ukusuka kwizinto ezilula, 'njengoomatshini' ukuya kwizinto ezintsonkothileyo, iijiyometri zendalo ezinokunyamezelana. Ngesicelo, sinokuphinda sivelise iinxalenye nge-EDM kunye ne-grinders. Yakha iimvulophu, ubungakanani obuncinci beempawu kunye nezikhokelo zoyilo ziyahluka ekugayeni nasekujikeni.

Inkonzo yokugaya i-CNC

Ngokweefayile ze-CAD zomthengi, fumana i-CNC milling quote ngoko nangoko kwiiyure ezingama-24.

Inkonzo Yokuvula i-CNC

Ngokweefayile ze-CAD zomthengi, fumana i-CNC yokujika ikhowuti kwiiyure ezingama-24.

DJmolding CNC inkonzo yokusila amandla

Ukusuka kwiprototyping ukuya kwimveliso epheleleyo iyaqhuba. I-3 axis yethu, i-3+2 axis kunye ne-5-axis epheleleyo amaziko okusila aya kukuvumela ukuba uvelise iindawo ezichanekileyo kunye nezisemgangathweni ukuze uhlangabezane neemfuno zakho ezingqongqo.

Igalari yeendawo zoomatshini ze-CNC

Sisebenza ngeeprototypes ezikhawulezayo kunye neodolo yokuvelisa umthamo ophantsi wabathengi kumashishini amaninzi: i-aerospace, i-automotive, i-defense, i-electronics, i-hardware startups, i-industrial automation, oomatshini, imveliso, izixhobo zonyango, i-oyile kunye negesi kunye ne-robotics.

IAluminium 7075-T6

IAluminium 6061-T6

IAluminiyam 6082

IAluminiyam 6063

I-PEEK

Oomatshini abanezakhono basebenzisa umatshini we-CNC ngokucwangcisa iindlela zesixhobo ezisekelwe kwijometri yeendawo zokugqibela zoomatshini. Inxalenye yolwazi lwejiyometri ibonelelwa yi-CAD (uyilo oluncediswa yikhompyutha) imodeli. Oomatshini be-CNC banokusika phantse nayiphi na i-alloy yesinyithi kunye neplastiki eqinile ngokuchaneka okuphezulu kunye nokuphindaphinda, ukwenza iindawo ezinomatshini eziqhelekileyo zilungele phantse yonke imboni, kubandakanywa i-aerospace, unyango, iirobhothi, i-electronics, kunye nemizi-mveliso. I-DJmolding ibonelela ngeenkonzo ze-CNC kwaye inikezela ngeengcaphuno zesiko le-CNC kwizinto ezingaphezulu kwe-40 ukusuka kwi-aluminiyam yempahla kunye ne-acetal ukuya kwi-titanium ephucukileyo kunye neeplastiki zobunjineli ezifana ne-PEEK ne-Teflon.

Ukugqitywa komphezulu okhoyo kumatshini we-CNC

Ukugqitywa komphezulu kusetyenziswa emva komatshini kwaye kunokutshintsha inkangeleko, uburhabaxa bomphezulu, ukuqina kunye nokumelana nemichiza yamacandelo avelisiweyo.

Njengomatshini (Ra 3.2μm / Ra 126μin)

Oku kukugqiba kwethu okusemgangathweni. Iinxalenye zenziwe ngoomatshini kwaye zihlanjululwe, imiphetho ebukhali i-chamfered.

Umatshini ogudileyo (Ra 1.6μm / Ra 63μin)

Umatshini ogudileyo ufana nesiphelo 'Njengomatshini' kodwa onamanqaku omatshini angacacanga kancinci. Izahlulo zenziwe ngoomatshini kwisondlo esisezantsi, akukho kupolishwa kwesandla.

Bead Blasted

Amalungu ngamaso avuswe ngamaso eglasi nto leyo ibangela ukumila okuziinkozo.

Ibrashi exutyiweyo + Electropolished (Ra 0.8μm / Ra 32μin)

Amalungu ahlanjululwa kwaye ahlanjululwe nge-electropolished. Efanelekileyo ukunciphisa i-micro-roughness yenxalenye.

Umnyama oxide

Esebenzayo kwiintsimbi, i-oxide emnyama yingubo yokuguqula esetyenziselwa ukuphucula ukuxhathisa ukubola kunye nokunciphisa ukukhanya kokukhanya.

Ibrashi ebhrashiweyo + neAnodized type II (Ebengezela)

Amalungu ahlanjululwa kwaye emva koko anodized uhlobo II. Efanelekileyo ekunyuseni ukuxhathisa kwe-corrosion yecandelo. Ngokwesiqhelo kubangela umbala omenyezelayo.

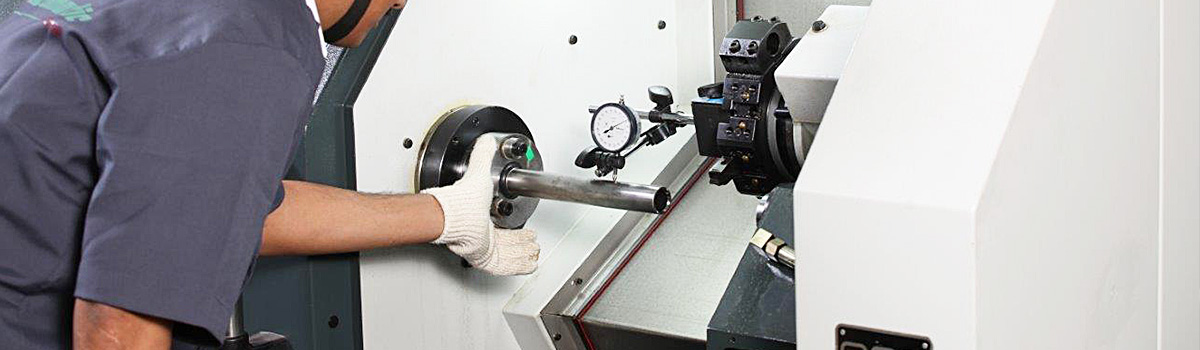

I-CNC (i-Computer Numerical Control) oomatshini yintsika yemveliso yanamhlanje. Baye bayiguqula inkqubo yokuvelisa ngokunikela ngokuchaneka, isantya, kunye nokuguquguquka ukuvelisa iindawo ezinzima kunye namacandelo. Nangona kunjalo, ukuqinisekisa ukuba oomatshini be-CNC basebenza kwinqanaba elilelona lifanelekileyo, bafuna ukugcinwa rhoqo, ukulungiswa, kunye nokusevisa. Ababoneleli benkonzo yomatshini we-CNC banikezela ngeenkonzo ezininzi zokuqinisekisa ukuba aba matshini basebenza ngokufanelekileyo nangempumelelo. Kule post blog, siza kuxubusha iinkalo ezahlukeneyo zenkonzo yomatshini we-CNC kunye nendlela eluncedo ngayo kumashishini okuvelisa.

Yintoni iNkonzo yoMatshini we-CNC?

I-CNC imele iComputer Numerical Control, ebhekisa kumatshini olawulwa yinkqubo yekhompyutha. Oomatshini be-CNC basetyenziselwa imisebenzi eyahlukeneyo, kubandakanya ukusika, ukugrumba, ukugaya, kunye nokujika.

Iinkonzo zoomatshini be-CNC zibandakanya ukusebenzisa aba matshini ukwenza imisebenzi echaneke kakhulu kwaye ephindaphindwayo echanekileyo. Ezi nkonzo zihlala zisetyenziselwa ukuvelisa, zifuna iindawo ezichanekileyo kunye nezihambelanayo.

Ukusebenzisa umatshini we-CNC, inkqubo yenziwa kuqala kusetyenziswa isoftware yoyilo oluncediswa yikhompyutha (CAD). Inkqubo ke ilayishwa kumatshini, esebenzisa imiyalelo ukwenza umsebenzi ofunekayo kwisiqwenga sezinto.

Oomatshini be-CNC bangasetyenziselwa izinto ezahlukeneyo, kubandakanya isinyithi, iplastiki, iinkuni, kunye neengxube. Banikezela ngeenzuzo ezininzi, kubandakanywa amaxesha okuvelisa ngokukhawuleza, ukuchaneka okuphezulu, kunye nokukwazi ukudala iimilo ezinzima kunye neempawu.

Kutheni iNkonzo kaMatshini we-CNC ibalulekile?

I-CNC (i-Computer Numerical Control) oomatshini baye baba yimfuneko kumashishini okuvelisa, ngakumbi kwiimoto, kwi-aerospace, kunye nokuveliswa kwezixhobo zonyango. Aba matshini bazenzekela, ngoko banokusebenza ixesha elide ngaphandle kokungenelela komntu. Oomatshini be-CNC banokuvelisa iindawo ezinzima ngokuchaneka okuphezulu kunye nokuchaneka, okwenza ukuba zibaluleke kakhulu kwimveliso.

Inkonzo yomatshini we-CNC ibalulekile ngenxa yezizathu ezininzi. Okokuqala nokuphambili, iqinisekisa ukuba oomatshini basebenza kwinqanaba elilelona liphezulu. Oomatshini be-CNC baneendawo ezininzi ezihambayo ezifuna ukulungiswa rhoqo ukuze kuthintelwe ukuguga kunye nokukrazula, okunokukhokelela ekuqhekekeni komatshini kunye nokunciphisa ixesha lokuvelisa. Ukugcinwa kwesiqhelo kunye neenkonzo kunceda ukufumanisa nokujongana nemiba enokubakho ngaphambi kokuba ibe yingxaki ebalulekileyo.

Okwesibini, inkonzo yomatshini we-CNC inceda ukuphucula ubomi bomatshini. Ukusetyenzwa rhoqo kuqinisekisa ukuba izixhobo zisebenza ngaphakathi kweeparitha eziyilelweyo, zinciphisa umngcipheko wokuguga ngaphambi kwexesha. Oku kwandisa ubomi bomatshini, konga imali yomvelisi ekutshintsheni nasekulungiseni iindleko.

Okwesithathu, inkonzo yomatshini we-CNC inceda ukugcina umgangatho ongaguqukiyo kwimveliso. Oomatshini be-CNC bacwangciswe ukuba bavelise iinxalenye ezichanekileyo kunye nokuchaneka okuphezulu, okuyimfuneko kwi-aerospace kunye nokuveliswa kwezixhobo zonyango. Ukusetyenzwa rhoqo kuqinisekisa ukuba oomatshini basebenza ngokuchanekileyo, benza iziqwenga ezihlangabezana neenkcukacha ezifunekayo kunye nokugcina umgangatho wemveliso ongaguqukiyo.

Okwesine, inkonzo yomatshini we-CNC inceda ukuphucula ukhuseleko kwindawo yokusebenza. Oomatshini be-CNC zizixhobo ezinamandla ezifuna ukuphathwa ngononophelo ukuthintela iingozi. Unikezelo lwenkonzo rhoqo lunceda ukuchonga iingozi ezinokubakho zokhuseleko, ezinokuthi ziqwalaselwe phambi kokuba zenze umonakalo kubaqhubi okanye umonakalo koomatshini.

Iindidi zoomatshini be-CNC

I-CNC (i-Computer Numerical Control) oomatshini basetyenziswa ngokubanzi kumashishini ahlukeneyo ukwenzela ukuveliswa ngokuchanekileyo. Aba matshini basebenzisa iisistim zolawulo lwekhompyuter ukwenza ngokuzenzekelayo kunye nokwenza imisebenzi yomatshini entsonkothileyo ngokuchaneka okuphezulu kunye nokusebenza kakuhle. Kukho iintlobo ezininzi zoomatshini be-CNC abakhoyo, nganye yenzelwe usetyenziso oluthile. Nazi ezinye zeentlobo eziqhelekileyo:

Oomatshini bokugaya be-CNC

- AmaZiko oMatshini aNgqo (VMC):Aba matshini bane-spindle ejonge ngokuthe nkqo kwaye bafanelekile ukusika kunye nokubumba izinto eziqinileyo.

- Amaziko oMatshini axwesileyo (HMC):Ii-HMCs zinentonga yokusonta ejonge ngokuthe tye kwaye ilungele ukwenza izixhobo zokusebenza ezinkulu nezinzima.

- 5-Oomatshini beAxis:Aba matshini babonelela ngentshukumo ngaxeshanye kwizembe ezintlanu, ivumela imisebenzi entsonkothileyo kunye nentsonkothileyo yomatshini.

Oomatshini be-CNC Lathe

Amaziko okuguqula:Aba matshini basetyenziselwa imisebenzi yokuguqula ngokuchanekileyo, apho i-workpiece ijikeleza ngelixa izixhobo zokusika zibumba izinto.

- Iileyile zohlobo lwaseSwitzerland:Iileyile zohlobo lwase-Swiss ziyilelwe ukuchaneka okuphezulu kunye nezixhobo zokusebenza ezinobubanzi obuncinci. Zibonisa isilayidi sentloko esityibilikayo kunye nesikhokelo sokuhlahla ukuchaneka okuphuculweyo.

CNC Plasma Cutters

- Oomatshini bokusika i-Plasma basebenzisa i-jet yesantya esiphezulu segesi ye-ionized ukusika izinto zombane ezifana nentsimbi, i-aluminium kunye nobhedu. Ngokuqhelekileyo zisetyenziselwa ukwenziwa kwesinyithi kunye nezicelo zoshishino.

CNC Laser Cutting Machines

- Oomatshini bokusika iLaser basebenzisa umqadi welaser ogxile ekunyibilikeni, ukutshisa, okanye ukufunxa izinto, okukhokelela ekusikeni okuchanekileyo nokucocekileyo. Zinezinto ezininzi kwaye ziyakwazi ukuphatha izinto ezahlukeneyo ezifana nentsimbi, umthi, i-acrylic kunye neeplastiki.

Oomatshini bomzila weCNC

- Iirotha ze-CNC zisetyenziselwa ukusika, ukubumba, kunye nezinto zokukrola njengemithi, iplastiki kunye ne-foam. Zisetyenziswa kakhulu ekwenzeni umthi, ukuveliswa kwemiqondiso, kunye neprototyping.

CNC EDM oomatshini

- Oomatshini bokukhutshwa koMbane (EDM) oomatshini basebenzisa ukukhutshwa kombane ukususa izinto ezivela kwindawo yokusebenza. Ngokuqhelekileyo zisetyenziselwa iimilo eziyinkimbinkimbi kunye nezixhobo eziqinileyo njengentsimbi eqinile kunye ne-titanium.

Oomatshini bokuSila be-CNC

- Oomatshini bokugaya basetyenziselwa ukufezekisa ukugqitywa okuphezulu okuphezulu kunye nemilinganiselo echanekileyo. Basebenzisa amavili abrasive ukususa imathiriyeli kwi-workpiece.

CNC Press iziqhoboshi

- Iziqhoboshi zokucofa zisetyenziselwa ukugoba kunye nokubumba isinyithi samaphepha. Iziqhoboshi zokucofa ezilawulwa yi-CNC zinika ulawulo oluchanekileyo kwinkqubo yokugoba, okukhokelela kwiziphumo ezichanekileyo neziphindaphindwayo.

Iingxaki zoomatshini abaqhelekileyo be-CNC

Ngelixa oomatshini be-CNC besebenza kakuhle kwaye bethembekile, basenokufumana imiba ethile enokuchaphazela ukusebenza kwabo kunye nemveliso. Ukuqonda kunye nokulungisa ezi ngxaki ziqhelekileyo kubalulekile ukuze kuqinisekiswe ukusebenza kakuhle. Nazi ezinye zeengxaki zomatshini we-CNC eziqhelekileyo:

Iimpazamo zokucwangcisa

- Imiyalelo yenkqubo engalunganga okanye engaphelelanga inokukhokelela kwiimpazamo kwimisebenzi yomatshini.

- Iindlela zesixhobo ezingafanelekanga okanye ukukhethwa kwesixhobo esingafanelekanga kunokubangela ukugqitywa komphezulu ombi, ukungachaneki kwe-dimensional, okanye ukuphuka kwesixhobo.

Imiba yoomatshini

Izinto ezigugileyo okanye ezonakalisiweyo njengeebheringi, amabhanti, okanye izikrufu zebhola zinokubangela ukudlala ngokugqithisileyo, okukhokelela ekusikeni okungachanekanga kunye nokunciphisa ukuchaneka.

- Ukuthanjiswa okulambathayo okanye ukungonelwa ngokwaneleyo kunokubangela ukungqubana okwandileyo, ukutshisa okugqithisileyo, kunye nokuguga kwangaphambi kwexesha kwamalungu omatshini.

Iingxaki zoMbane neze-Electronic

Ukuguquguquka kwamandla okanye ukuphazamiseka kombane kunokubangela ukuziphatha kakubi koomatshini, njengokuma ngesiquphe, ukusetha ngokutsha, okanye ukubeka ngendlela engeyiyo.

- Abenzi boluvo abangalunganga okanye ukutshintshwa komda kunokukhokelela kwiintshukumo zomatshini ezingachanekanga okanye kufundo lwemposiso yobuxoki.

Iingxaki zezixhobo

- Izixhobo zokusika ezibuthuntu okanye ezingafakelwanga ngokufanelekileyo zinokubangela ukugqitywa komphezulu ombi, ukuncokola, okanye ukunxitywa kwezixhobo ezigqithisileyo.

- Ukunciphisa izixhobo ezingafanelekanga okanye imilinganiselo yobude besixhobo kunokubangela ukungachaneki kobukhulu.

Ukupholisa kunye neMiba yokuSuswa kweChip

- Ukunganelanga kwesipholisi okanye ukukhutshwa kwetshiphu engafanelekanga kunokukhokelela ekwandeni kobushushu, ukufudumeza okugqithisileyo kwesixhobo, kunye nokunciphisa ubomi besixhobo.

- Ukukhutshwa kwe-chip okungonelanga kunokubangela ukuvala i-chip, echaphazela ukugqitywa kwendawo kwaye inokonakalisa i-workpiece okanye umatshini.

Iimpazamo zeSoftware kunye noLawulo lweNkqubo

- Iiglitches zeSoftware okanye imiba yokuhambelana inokuphazamisa ukusebenza komatshini kwaye ibangele iimpazamo ezingalindelekanga okanye ukuphazamiseka.

- Ulungelelwaniso olungachanekanga okanye useto lweparameter engalunganga ngaphakathi kwenkqubo yolawulo kunokukhokelela kwiimpazamo zokubeka okanye iireyithi zokutya ezingachanekanga.

Izinto zendalo

- Ukutshintsha kobushushu, ukufuma, okanye uthuli kunokuchaphazela ukusebenza kunye nokuchaneka koomatshini be-CNC.

- Ufakelo olungafanelekanga okanye ukubeka umatshini ngokubhekiselele kwizinto ezisingqongileyo kunokuchaphazela ukuzinza nokuthembeka kwayo.

ULondolozo loThintelo loomatshini be-CNC

Ukusetyenziswa kwenkqubo yokugcinwa kwenkqubo esebenzayo yokukhusela kubalulekile ekwandiseni ukusebenza, ukuthembeka, kunye nobomi be-CNC (i-Computer Numerical Control) koomatshini. Ukugcinwa rhoqo kunceda ukuchonga imiba enokubakho ngaphambi kokuba ibe yingxaki enkulu, kunciphisa ixesha lokuphumla, kunye nokuqinisekisa ukusebenza komatshini okona kulungileyo. Nazi ezinye iinkalo eziphambili ekufuneka ugxininise kuzo xa usenza ulondolozo lothintelo koomatshini be-CNC:

Lubrication

- Rhoqo thambisa amacandelo oomatshini afana neebheringi, izikrufu zebhola, izilayidi, kunye negiya ngokwemigaqo yomenzi.

- Sebenzisa izithambiso ezifanelekileyo kwaye uqinisekise amaxesha afanelekileyo okuthambisa ukuze unciphise ukukhuhlana, ukunciphisa ukuguga, kunye nokugcina ukusebenza kakuhle.

ukucoca

- Gcina umatshini kunye nendawo ejikelezileyo icocekile kwiitshiphusi, iintsalela zokupholisa, kunye nobutyobo.

- Coca rhoqo izihluzi, iitanki zokupholisa, kunye neetreyi zetshiphu ukugcina ukusebenza okugqibeleleyo kokupholisa kwaye uthintele ukuvaleka.

Ukuhlolwa kunye nokuCalibration

Yenza uhlolo lwesiqhelo lwamacandelo abalulekileyo anje nge-spindles, izixhobo zokubamba izixhobo, kunye nezixhobo zokubona iimpawu zokuguga okanye umonakalo.

- Linganisa kwaye ujonge ukuchaneka kwee-axes zoomatshini, izixhobo zokususa izixhobo, kunye neenkqubo zokubeka ukuze kuqinisekiswe ukwenziwa kwemishini echanekileyo.

Amacandelo oMbane kunye ne-Electronic

- Hlola uqhagamshelo lombane, iintambo, kunye neengcingo ukuba akukho zimpawu zomonakalo okanye uqhagamshelo olukhululekileyo.

- Jonga kwaye uvavanye abenzi boluvo, ukutshintshwa kokunciphisa, kunye nokhuseleko lokudibanisa ukuqinisekisa ukusebenza kakuhle.

Iinkqubo zokupholisa

- Gcina kwaye ucoce izixokelelwano zokupholisa rhoqo ukuthintela ungcoliseko kunye nokuqinisekisa ukupholisa okufanelekileyo.

- Lawula amanqanaba okupholisa, ibhalansi ye-pH, kunye nokugxila, kwaye uzalise okanye ubeke indawo yokupholisa njengoko kuyimfuneko.

Isoftware kunye neNkqubo yoLawulo

- Hlaziya rhoqo kwaye ugcine isoftwe yomatshini we-CNC kunye nenkqubo yolawulo kunye neenguqulelo zamva nje kunye neziqwenga.

- Qinisekisa kwaye ulungelelanise iiparamitha zenkqubo yokulawula, ezifana namazinga okutya kunye nokukhawuleza, ukuqinisekisa umatshini ochanekileyo.

Izixhobo kunye ne-Spindle

- Hlola kwaye ucoce izibambi zezixhobo, iikholethi, kunye ne-spindle tapers rhoqo ukuze uqinisekise ukubamba izixhobo ezifanelekileyo kunye nokunciphisa ukuphuma.

- Jonga kwaye ubeke endaweni yezixhobo zokusika ezigugileyo okanye ezonakalisiweyo ukugcina ukusebenza kakuhle kokusika kunye nokugqitywa komphezulu.

UQeqesho lwabaSebenzisi kunye noXwebhu

- Ukubonelela ngoqeqesho olubanzi kubaqhubi boomatshini ngokusebenza ngokufanelekileyo, iinkqubo zokulondolozwa, kunye nemigaqo yokhuseleko.

- Gcina iirekhodi ezineenkcukacha zemisebenzi yogcino, ukuhlolwa, kunye nokulungiswa kwereferensi kunye nohlalutyo.

Ukuhlolwa rhoqo koomatshini be-CNC

Ukuhlolwa rhoqo kunye nokugcinwa koomatshini be-CNC (Computer Numerical Control) kubalulekile ukuqinisekisa ukusebenza kwabo ngokupheleleyo kunye nokuphila ixesha elide. Ngokwenza uhlolo lwesiqhelo, imiba enokubakho inokuchongwa kwangethuba kwaye amanyathelo okuthintela anokuthathwa ukuthintela ukonakaliswa kweendleko kunye nokulibaziseka kwemveliso. Nanga amanye amanqaku aphambili ekufuneka eqwalaselwe ngexesha lokuhlolwa kwesiqhelo koomatshini be-CNC:

Uvavanyo lokubonakalayo

- Qala ngokujonga umatshini ngokubonakalayo naziphi na iimpawu zokuguga, ukonakala, okanye ukuxengaxenga.

- Qwalasela ukuvuza, okufana ne-oyile okanye into yokupholisa, nto leyo enokubonisa ingxaki kwiinkqubo zolwelo zomatshini.

- Jonga nayiphi na ingxolo engaqhelekanga okanye ukungcangcazela ngexesha lokusebenza komatshini.

Lubrication

- Qinisekisa ukuba zonke iindawo zokuthambisa zithanjiswe ngokwaneleyo ukuqinisekisa ukuhamba kakuhle kwamacandelo omatshini.

- Jonga amanqanaba e-lubricant kwaye uwafake phezulu xa kukho imfuneko.

- Qinisekisa ukuthanjiswa okufanelekileyo kwezikrufu zebhola, iintsimbi zesikhokelo, kunye nezinye izinto ezibalulekileyo.

Ulungelelwaniso lwe-Axis

Qinisekisa ukuchaneka kwee-axes zomatshini ngokwenza iimvavanyo zokulinganisa.

- Khangela nakuphi na ukutenxa kwi-tolerances echaziweyo kwaye ulungelelanise ukuba kuyimfuneko.

- Lungiselela inkqubo yokuhlola yomatshini, ukuba ikhona, ukuqinisekisa umlinganiselo ochanekileyo.

Ukuhlolwa kweSpindle

- Jonga i-spindle ukuze ubone naziphi na iimpawu zokuguga, ukonakala, okanye ukungahambi kakuhle.

- Qwalasela iibheringi zokuphotha kwaye uzibuyisele xa kukho imfuneko.

- Qinisekisa i-spindle runout ukuqinisekisa ukugxila ngexesha lomsebenzi womatshini.

Isixhobo kunye noTshintsho lwesixhobo

- Hlola inkqubo yezixhobo, kuquka abanini, iikholethi, kunye nezixhobo zokusika, naziphi na iimpawu zokuguga okanye umonakalo.

- Jonga isixhobo sokutshintsha isixhobo sokusebenza kakuhle kunye nokulungelelaniswa okufanelekileyo.

- Coca kwaye uthambise izixhobo zokutshintsha izixhobo ngokwezikhokelo zomenzi.

Inkqubo yoLawulo

- Hlola iyunithi yolawulo ye-CNC kwaye ubeke iliso kuyo nayiphi na imiyalezo yemposiso okanye ukungasebenzi kakuhle.

- Qinisekisa ukuba zonke iintambo kunye noqhagamshelo zikhuselekile kwaye zikwimeko entle.

- Hlaziya isoftwe yomatshini, ukuba iyasebenza, kuguqulelo lwamva nje olunikezelwe ngumenzi.

Iimpawu zoKhuseleko

- Qinisekisa ukusebenza kweempawu zokhuseleko, ezifana namaqhosha okumisa ngexesha likaxakeka kunye neziqhagamshelo.

- Jonga imeko yeekhava ezikhuselayo kunye nezithintelo zokuqinisekisa ukhuseleko lwabaqhubi.

- Vavanya inkqubo ye-alam yomatshini ukuze uqinisekise ukusebenza ngokufanelekileyo.

Uxwebhu:

Gcina irekhodi eneenkcukacha zemihla yokuhlolwa, iziphumo, kunye naluphi na ukulungiswa okanye ukulungiswa okwenziwe.

- Landela ishedyuli yogcino ecetyiswayo yomenzi kunye nezikhokelo.

- Gcina ilog yazo naziphi na iindawo ezisetyenzisiweyo kunye neenombolo zazo ezihambelanayo.

Ukulungiswa koomatshini be-CNC

Xa umatshini we-CNC (i-Computer Numerical Control) ufumana imiba okanye ukungasebenzi kakuhle, ukulungiswa ngokukhawuleza kubalulekile ukunciphisa ixesha lokunciphisa nokugcina imveliso. Ukulungisa oomatshini be-CNC kufuna ubungcali kunye nengqalelo kwiinkcukacha zokuqinisekisa ukuba oomatshini babuyiselwa kwimeko yabo yokusebenza ngeyona ndlela ilungileyo. Nanga amanye amanqaku aphambili ekufuneka uwaqwalasele xa ulungisa oomatshini be-CNC:

Diagnostics

- Qala ngokuyixilonga ngokucokisekileyo ingxaki ukuze uchonge oyena nobangela wokungasebenzi kakuhle.

- Jonga amacandelo omatshini, anje ngeenjini, iidrive, izivamvo, kunye nenkqubo yolawulo, ukuze uchonge indawo enempazamo.

- Sebenzisa izixhobo zokuxilonga kunye nesoftware ukunceda ekuchongeni umba ngokuchanekileyo.

Ukutshintshwa kwaMalunga aneempazamo

- Nje ukuba ingxaki ichongiwe, buyisela amacandelo angasebenziyo uwafake amatsha okanye asebenza ngokufanelekileyo.

- Fumana iindawo zokwenyani kubaboneleli abathembekileyo ukuqinisekisa ukuhambelana nokuthembeka.

- Landela izikhokelo zomenzi wokutshintsha amalungu athile kwaye uwalinganise ukuba ayafuneka.

Ukulungiswa koMbane kunye noomatshini

- Ukuqhuba ukulungiswa kombane, kubandakanywa ukulungisa iingcingo eziphosakeleyo, izihlanganisi, okanye iibhodi zesekethe ezonakalisiweyo.

- Lungisa okanye ubuyisele amacandelo awonakeleyo, njengamabhanti, iigiya, iipuli, neebheringi.

- Qinisekisa ukulungelelaniswa okufanelekileyo kwamalungu omatshini ukugcina ukuchaneka nokuchaneka.

Uhlaziyo lweSoftwe kunye noLungiselelo

- Hlaziya isoftwe yomatshini kuguqulelo lwamva nje olunikezelwe ngumenzi.

- Qwalasela iiparamitha zenkqubo yolawulo lwe-CNC kunye nezicwangciso ngokweenkcukacha zomatshini.

- Vavanya kwaye uqinisekise ukusebenza komatshini emva kohlaziyo lwesoftware okanye utshintsho loqwalaselo.

Ulungelelwaniso nolungelelwaniso

Lungiselela ii-axes zoomatshini kwaye uqinisekise ukuba zilungelelaniswe ngokufanelekileyo ukufezekisa umatshini ochanekileyo.

- Qinisekisa i-spindle runout kunye nokulungelelaniswa ukuqinisekisa ukugxila ngexesha lokusebenza.

- Jonga kwaye ulungelelanise i-offsets yesixhobo somatshini kunye nembuyekezo yobude besixhobo sokusika ngokuchanekileyo.

Uvavanyo kunye nokuqinisekiswa

Ukuqhuba uvavanyo olubanzi lomatshini olungisiweyo ukuqinisekisa ukuba usebenza ngokuchanekileyo.

- Qinisekisa ukuchaneka komatshini kunye nokuphindaphinda ngokwenza uvavanyo lokusika okanye ukusebenzisa izinto zakudala zokulinganisa.

- Beka iliso ekusebenzeni komatshini ngexesha lemisebenzi eyahlukeneyo yomatshini ukuqinisekisa ukuzinza nokuthembeka.

Ulondolozo

Cebisa kwaye wenze imisebenzi yogcino lwesiqhelo lokuthintela ukunciphisa ukonakaliswa kwexesha elizayo.

- Coca kwaye uthambise amacandelo omatshini rhoqo ukukhusela ukunxiba kunye nokuphucula ubomi obude.

- Gcina irekhodi yemisebenzi yogcino, kubandakanywa nemihla, imisebenzi eyenziwayo, kunye naziphi na iindawo ezitshintshiweyo.

Uqeqesho kunye neNkxaso

Ukubonelela ngoqeqesho kubaqhubi boomatshini malunga nokusetyenziswa ngendlela eyiyo kunye nokugcinwa kakuhle ukuthintela imiba eqhelekileyo.

- Nikeza ngenkxaso yobugcisa eqhubekayo kunye nesikhokelo sokusombulula iingxaki ezincinci ezinokuvela.

- Ukukhuthaza inkcubeko yokhathalelo lomatshini olusebenzayo kwaye ukhuthaze abaqhubi ukuba baxele nakuphi na ukungaqhelekanga ngokukhawuleza.

Uphuculo lomatshini we-CNC

I-CNC (i-Computer Numerical Control) oomatshini benzelwe ukuba bahlale kwaye bahlale ixesha elide, kodwa ngokuqhubela phambili kwezobuchwepheshe, ukuphuculwa kwabo kunokuphucula ukusebenza kunye nobuchule babo. Ukuphucula oomatshini be-CNC kunokuphucula ukusebenza kwabo kakuhle, isantya, kunye nokuchaneka, ukubonelela amashishini anomdla wokukhuphisana. Nanga amanye amanqaku aphambili ekufuneka uwaqwalasele xa uphucula oomatshini be-CNC:

Ukuvavanywa kwemeko yangoku

Qala ngokuvavanya imeko yangoku yomatshini, kubandakanywa ihardware kunye nesoftware.

- Vavanya ubudala bomatshini, imeko, kunye nokuhambelana nohlaziyo lwamva nje.

- Qinisekisa iziphumo ezinqwenelekayo zohlaziyo, ezifana nokuphuculwa kwesantya, ukuchaneka, okanye ukusebenza okongeziweyo.

Ukuchonga iiNdlela zokuPhucula

- Phanda itekhnoloji yamva nje kunye nokuqhubela phambili ukuchonga ukuphuculwa okufanelekileyo komatshini.

- Qhagamshelana nomenzi womatshini okanye abathengisi beqela lesithathu ukufumanisa olona phuculo lungcono lohlobo oluthile lomatshini.

- Qwalasela iinketho ezifana nezilawuli eziphuculweyo, iinkqubo zokusonta, abaguquli bezixhobo, kunye nezinzwa.

Ukuphucula i-Hardware Components

- Phucula izixhobo zehardware ezinje ngeenjini, iidrive, kunye neenkqubo zokulawula ukuphucula isantya kunye nokuchaneka.

- Faka izixhobo zoluvo ezitsha kunye neeprobes zokuphucula ukuchaneka komlinganiso kunye nokwenza imisebenzi ethile.

- Shintsha iindawo ezigugileyo okanye eziphelelwe lixesha kunye nezintsha ukuphucula ukuqina komatshini kunye nokuphila ixesha elide.

Uphuculo lweSoftware

- Phucula isoftware yomatshini ukuya kuguqulelo lwamva nje ukuphucula ukusebenza kunye nokusebenza.

- Faka iimodyuli ezintsha zesoftware ukwenza imisebenzi eyongezelelweyo okanye uphucule esele ikho.

- Qwalasela isoftware ukuba ihambelane neemfuno zomatshini othile.

Uvavanyo kunye nokuqinisekiswa

- Vavanya umatshini ophuculweyo ukuqinisekisa ukuba usebenza ngokuchanekileyo kwaye uyahlangabezana neziphumo ezifunwayo.

- Qinisekisa ukuchaneka komatshini kunye nokuphindaphinda ngokwenza uvavanyo lokusika okanye ukusebenzisa izinto zakudala zokulinganisa.

- Beka iliso ekusebenzeni komatshini ngexesha lemisebenzi eyahlukeneyo yomatshini ukuqinisekisa ukuzinza nokuthembeka.

Uqeqesho kunye neNkxaso

- Ukubonelela ngoqeqesho kubasebenzi koomatshini kwiimpawu ezintsha kunye nokusebenza komatshini ophuculweyo.

- Nikeza ngenkxaso yobugcisa eqhubekayo kunye nesikhokelo sokusombulula nayiphi na imiba enokuthi ivele.

- Ukukhuthaza inkcubeko yokhathalelo lomatshini olusebenzayo kwaye ukhuthaze abaqhubi ukuba baxele nakuphi na ukungaqhelekanga ngokukhawuleza.

Ulungelelwaniso lomatshini we-CNC

Ulungelelwaniso yinkqubo ebalulekileyo ekugcineni ukuchaneka nokuchaneka koomatshini be-CNC (iComputer Numerical Control). Ukulinganisa rhoqo kuqinisekisa ukuba ii-axes zomatshini, i-spindle, kunye ne-tooling systems zilungelelaniswe ngokuchanekileyo, okukhokelela ekusebenzeni okuchanekileyo komatshini. Nanga amanye amanqaku aphambili ekufuneka uwaqwalasele xa usenza ulungelelwaniso lomatshini we-CNC:

Ulungelelwaniso lwe-Axis

- Ukulinganisa i-axis nganye yomatshini ukuqinisekisa ukuma okuchanekileyo kunye nokunyakaza.

- Sebenzisa izixhobo zokulinganisa ezichanekileyo, ezifana ne-laser interferometers okanye iinkqubo zebar bar, ukulinganisa ukutenxa kunye nokwenza uhlengahlengiso.

- Qinisekisa ukuba umgca womatshini kunye neentshukumo ze-angular zihambelana nokunyamezela okuchaziweyo.

Umlinganiselo wokubaleka weSpindle:

- Ukulinganisa i-spindle runout ukuqinisekisa ukugxila ngexesha lomsebenzi womatshini.

- Sebenzisa isalathisi sokudayela okanye isixhobo esekwe kwi-laser ukulinganisa nayiphi na i-eccentricity okanye ukushukuma kwi-spindle.

- Lungisa izakhi zokusonta okanye utshintshe iindawo ezigugileyo ukunciphisa ukuphuma kunye nokwandisa ukuchaneka.

Ubude beSixhobo kunye neSixhobo sokuJonga i-Offset Calibration

- Lungiselela inkqubo yokulinganisa ubude besixhobo ukuqinisekisa ukubekwa kwesixhobo esichanekileyo.

- Sebenzisa ii-artifacts zokulinganisa okanye iigeyiji zobude ukuze ulinganise ubude besixhobo kwaye uthelekise nemilinganiselo yomatshini.

- Lungisa amaxabiso okulinganisa ubude besixhobo kwinkqubo yolawulo yomatshini ukuhlawula nakuphi na ukungangqinelani.

Imbuyekezo yeDiameter yesixhobo

- Yenza ulungelelwaniso lwembuyekezo yedayamitha yesixhobo ukuze uphendule umahluko kwiidayamitha zesixhobo.

- Ukulinganisa ubungakanani besixhobo esisiso usebenzisa i-micrometer okanye i-caliper kwaye uyithelekise namaxabiso acwangcisiweyo omatshini.

- Lungisa i-offset yesixhobo okanye amaxabiso embuyekezo yesixhobo ukuhlawulela nayiphi na iyantlukwano kunye nokufezekisa ukusikwa okuchanekileyo.

Ukuvavanya ulungelelwaniso lweNkqubo

- Ukuba umatshini unenkqubo yokuhlola, yilinganise ukuze uqinisekise umlinganiselo ochanekileyo wenxalenye kunye nokulungelelaniswa.

- Yenza iinkqubo zokulinganisa ukuqinisekisa ukuchaneka kwenkqubo yokuhlola kwaye ulungelelanise ukuba kuyimfuneko.

- Qinisekisa ukuba isixokelelwano sokuhlola izibhaqa ngokuchanekileyo iindawo kunye nemilinganiselo.

Spindle Speed Calibration

- Linganisa isantya sokusonta ukuqinisekisa ukuba siyahambelana ne-RPM echaziweyo (Ujikelezo ngomzuzu ngamnye).

- Sebenzisa i-tachometer okanye i-spindle speed sensor ukulinganisa isantya sokwenyani sokuphotha ngexesha lokusebenza.

- Lungisa iiparitha zokulawula isantya kwinkqubo yolawulo lomatshini ukufezekisa i-RPM efunwayo.

Amaxwebhu kunye neeRekhodi

- Gcina irekhodi eneenkcukacha zemisebenzi yolungelelwaniso, kubandakanywa imihla, imisebenzi eyenziweyo, kunye naluphi na uhlengahlengiso olwenziwe.

- Landela ishedyuli ecetyiswayo yomenzi kunye nezikhokelo.

- Gcina i-log yazo naziphi na izinto zakudala zokulinganisa ezisetyenzisiweyo kunye neziqinisekiso zabo ezihambelanayo.

Ulungelelwaniso lomatshini we-CNC

Ulungelelwaniso olululo lubalulekile kwi-CNC (Ulawulo lwamanani eKhompyutha) ukuba lusebenze ngokuchaneka nangokuchaneka. Ukulungelelaniswa kakuhle kwamacandelo omatshini, afana ne-spindle, izixhobo ze-tooling, kunye ne-axes, kunokubangela iimpazamo kunye nokungahambelani kwinkqubo yomatshini. Nanga amanye amanqaku aphambili ekufuneka uwaqwalasele xa ulungelelanisa oomatshini be-CNC:

Ukujonga imeko yoMshini

Ngaphambi kokulungelelanisa umatshini, jonga imeko yayo, kubandakanywa nemeko yamacandelo ayo.

- Hlola iindlela zoomatshini, abasebenzi abakhokelayo, kunye nezinye izinto ezisebenza ngoomatshini ukuba zigugile kwaye zonakele.

- Qinisekisa imeko ye-spindle kunye ne-tooling systems.

Ukulungelelaniswa kweSpindle

- I-spindle licandelo elibalulekileyo ekufuneka lilungelelaniswe ngokuchanekileyo.

- Sebenzisa izixhobo zokulinganisa ezichanekileyo, ezifana nesalathisi sokudayela okanye isixhobo esisekelwe kwi-laser, ukulinganisa ukulungelelaniswa kwe-spindle.

- Lungisa indawo yokuphotha kunye namalungu, afana neebheringi, ukuphumeza ulungelelwaniso olufanelekileyo.

Ukujonga izembe

- Khangela ukulungelelaniswa kwe-axis nganye yomatshini ukuqinisekisa ukunyakaza okuchanekileyo kunye nokubeka.

- Sebenzisa izixhobo zokulinganisa ngokuchanekileyo ukulinganisa ukutenxa kwi-axis nganye kwaye wenze uhlengahlengiso.

- Qinisekisa ukuba ii-axes zihamba kumgca othe tye kwaye zihambelane nokunyamezela okuchaziweyo.

Ukulungelelanisa iiNkqubo zeZixhobo

- Iisistim zezixhobo, kuqukwa nezibambi zezixhobo kunye nabatshintshi bezixhobo, kufuneka zilungelelaniswe ngokuchanekileyo ukuqinisekisa ukubekwa kwesixhobo ngokuchanekileyo.

- Sebenzisa izixhobo zokulinganisa ezichanekileyo ukulinganisa ukulungelelaniswa kweenkqubo zezixhobo kwaye wenze uhlengahlengiso xa kukho imfuneko.

- Qinisekisa ukuba izixhobo zokusebenza zilungelelaniswa neeasi zomatshini kunye ne-spindle.

Uvavanyo kunye nokuqinisekiswa

- Emva kokulungelelanisa umatshini, yenza uvavanyo lokuvavanya ukuqinisekisa ukuchaneka nokuchaneka kwayo.

- Sebenzisa izinto zakudala zokulinganisa okanye ezinye izixhobo zokulinganisa ukuqinisekisa ukulungelelaniswa komatshini kunye nokuchaneka.

- Beka iliso ekusebenzeni komatshini ngexesha lemisebenzi eyahlukeneyo yomatshini ukuqinisekisa ukuzinza nokuthembeka kwawo.

Ulondolozo kunye noKhathalelo

- Ukuhlola rhoqo kwaye ugcine amacandelo oomatshini bomatshini ukunqanda ukungahambi kakuhle kunye nokunxiba.

- Ukuqeqesha abaqhubi koomatshini ukuba baxele nakuphi na ukungahambi kakuhle ngoko nangoko kwaye benze imisebenzi yesiqhelo yokulungisa.

- Landela ishedyuli yogcino ecetyiswayo yomenzi kunye nezikhokelo.

Ukulungelelaniswa okufanelekileyo koomatshini be-CNC kubalulekile ekufezekiseni imisebenzi yomatshini echanekileyo kunye nechanekileyo. Ngokubambelela kwiinkqubo zokulungelelaniswa okufanelekileyo kunye nokwenza ukugcinwa rhoqo, abaqhubi banokuqinisekisa ukuba oomatshini babo bahlala bevelisa iindawo eziphezulu eziphezulu kunye neempazamo ezincinci kunye nokusebenza kwakhona.

Ukuthanjiswa koomatshini beCNC

Ukuthambisa okufanelekileyo kubalulekile ekusebenzeni ngokutyibilikayo nangokufanelekileyo koomatshini be-CNC (Ulawulo lwamanani eKhompyutha). Izithambisi zinciphisa ukungqubana, zinciphisa ukuguga nokukrazuka, zichitha ubushushu, kwaye zikhusela izinto zomatshini emonakalweni. Ukugcinwa rhoqo kwe-lubrication kunceda ukwandisa ubomi bomatshini kunye nokuqinisekisa ukusebenza kakuhle. Nanga amanye amanqaku aphambili ekufuneka uwaqwalasele xa kuthambisa oomatshini be-CNC:

Ukukhethwa kweeLubricants

- Khetha izithambiso ezicetyiswa ngumenzi womatshini kumalungu athile kunye neenkqubo.

- Qwalasela izinto ezifana neqondo lobushushu, isantya, umthwalo, nendawo esingqongileyo xa ukhetha izinto zokuthambisa.

- Sebenzisa izithambisi ezifanelekileyo kumacandelo omatshini awohlukeneyo, afana neebheringi zokusonta, iintsimbi zesikhokelo, kunye nezikrufu zebhola.

IShedyuli yokuthambisa

- Landela ishedyuli ecetyiswayo yomenzi yokuthambisa kwilungu ngalinye lomatshini.

- Ukuseka inkqubo yesiqhelo yokuthambisa esekelwe kusetyenziso lomatshini kunye neemeko zokusebenza.

- Thatha ingqalelo izinto ezifana neeyure zokusebenza, ubungakanani bokusetyenziswa, kunye neemeko zokusingqongileyo.

Amanqaku okuthambisa

- Chonga kwaye uphawule zonke iindawo zokuthambisa kumatshini, kubandakanywa amazibuko e-oyile, izifakelo zegrisi, kunye namadama.

- Qinisekisa ukuba zonke iindawo zokuthambisa zifikeleleka lula kwaye ziyabonakala ukuze kuthanjiswe kakuhle.

Iindlela zokuthambisa

- Sebenzisa iindlela ezifanelekileyo zokuthambisa kwicandelo ngalinye, ezifana neebhafu ze-oyile, iinkqubo zenkungu ye-oyile, okanye ukufakwa kwegrisi ngesandla.

- Landela iindlela ezifanelekileyo zokuthambisa, ezifana nokusebenzisa isixa esifanelekileyo sesithambiso kunye nokuqinisekisa ukuba usasazo olulinganayo.

- Sebenzisa iisistim zokuthambisa ezizisebenzelayo, ukuba zikhona, ukwenzela ukuthambisa okungaguquguqukiyo nokuchanekileyo.

Ukusetyenziswa kweLubricant

- Coca iindawo zokuthambisa phambi kokuba ugalele isithambiso ukususa ubumdaka, inkunkuma, kunye neentsalela zezithambisi ezindala.

- Sebenzisa izixhobo zokuthambisa ezicetyiswayo, ezinjengeebhrashi, imipu yegrisi, okanye iinkonkxa zeoyile, ukuze ugalele izithambiso ngokuchanekileyo.

- Qinisekisa ukuba isithambisi sifika kuzo zonke iindawo eziyimfuneko, ezinje ngeebheringi, iigiya, kunye neendawo ezityibilikayo.

Ubungakanani beLubricant

- Faka isixa esifanelekileyo sesithambiso njengoko kuchaziwe ngumvelisi womatshini.

- Kuphephe ukuthambisa ngokugqithisileyo, njengoko i-lubricant egqithisileyo inokubangela ungcoliseko kunye nokuvala izinto ezibalulekileyo.

- Lawula amanqanaba e-lubricant rhoqo kwaye uzalise njengoko kuyimfuneko ukugcina ukuthambisa okufunekayo.

Umgangatho weLubricant

- Sebenzisa izithambiso ezikumgangatho ophezulu ezihlangabezana nemigangatho yoshishino kunye neenkcukacha.

- Jonga imeko yezithambiso, ezifana ne-viscosity, ukucoceka, kunye nenqanaba le-oxidation, kwaye ubeke endaweni yazo xa kuyimfuneko.

- Gcina izithambiso ngokufanelekileyo ukugcina umgangatho kunye nokusebenza kwazo.

Ukugcinwa kweRekhodi

- Gcina irekhodi eneenkcukacha zemisebenzi yokuthambisa, kubandakanywa imihla, izithambisi ezisetyenzisiweyo, kunye neendawo zokuthambisa ezithe zaqwalaselwa.

- Gcina umkhondo wokusetyenziswa kwe-lubricant, kubandakanywa ubuninzi obusetyenzisiweyo kunye nokugcinwa kwakhona.

- Sebenzisa irekhodi njengesalathiso solondolozo lwexesha elizayo kunye nokusombulula ingxaki.

Ukutshintshwa kwezahlulo zoomatshini be-CNC

Ngokuhamba kwexesha, oomatshini be-CNC (Computer Numerical Control) banokufuna ukutshintshwa kwamacandelo athile ngenxa yokuguga, ukonakala, okanye imfuneko yokuphuculwa. Ukutshintshwa ngokukhawuleza kunye nokuchanekileyo kwamalungu omatshini we-CNC kubalulekile ukugcina ukusebenza komatshini kunye nokunciphisa ixesha lokuphumla. Nanga amanye amanqaku aphambili ekufuneka uwaqwalasele xa utshintsha amalungu omatshini we-CNC:

Chonga ingxaki

- Ukuxilonga ngokucokisekileyo umatshini ukuchonga inxalenye ephosakeleyo okanye eyonakeleyo.

- Hlalutya iimpawu, imiyalezo yemposiso, okanye ukuziphatha okungaqhelekanga komatshini ukukhomba ingxaki.

- Sebenzisa izixhobo zokuxilonga kwaye ujonge amaxwebhu omatshini okanye izikhokelo zomenzi wokusombulula ingxaki.

Umthombo waMalungu wokwenyani

- Thenga iindawo ezitshintshileyo kubaboneleli abathembekileyo okanye ngokuthe ngqo kumenzi womatshini.

- Qinisekisa ukuba iindawo ziyinyani kwaye zingqinelane neenkcukacha zamalungu okuqala.

- Qwalasela izinto ezinjengomgangatho, ukuhambelana, kunye newaranti xa ukhetha amalungu okutshintsha.

Disassembly kunye nofakelo

- Landela iinkqubo ezifanelekileyo kunye nezikhokelo zokuqhawula umatshini kunye nokususa inxalenye ephosakeleyo.

- Thatha amanyathelo okhuseleko ayimfuneko ukukhusela amacandelo abuthathaka kunye nokuqinisekisa ukhuseleko lomntu ngexesha lokuqhawula.

- Faka ngononophelo indawo yokutshintsha, ngokulandela imiyalelo yomenzi kunye neenkcukacha ezicetyiswayo zetorque.

Ulungelelwaniso kunye noVavanyo

- Emva kokutshintsha inxalenye, linganisa umatshini ukuqinisekisa ukusebenza ngokufanelekileyo kunye nokulungelelaniswa.

- Yenza uhlengahlengiso oluyimfuneko okanye ulungelelwaniso ukuze uqinisekise ukuchaneka nokuchaneka.

- Yenza uvavanyo olucokisekileyo ukuqinisekisa ukuba indawo yokutshintsha iwusombulule umcimbi kwaye umatshini usebenza ngokuchanekileyo.

Amaxwebhu kunye nokugcinwa kweeRekhodi

- Gcina iirekhodi ezineenkcukacha zamalungu atshintshiweyo, kuquka umhla, inombolo yenxalenye, kunye nolwazi lomthengisi.

- Gcina ilog yembali yokulondolozwa komatshini, kubandakanywa zonke izinto ezitshintshiweyo, ukulungiswa, kunye nokuphuculwa.

- Sebenzisa uxwebhu njengesalathiso solondolozo lwexesha elizayo kunye nokusombulula ingxaki.

Ulondolozo

- Hlola rhoqo kwaye ugcine umatshini ukuze uchonge imiba enokubakho ngaphambi kokuba ikhokelele kwintsilelo ethile.

- Landela ishedyuli yogcino olucetyisiweyo lomenzi kumatshini kunye namalungu awo.

- Tshintsha amalungu ngokuqhubekayo ngokusekelwe kusetyenziso, ubomi obulindelekileyo, okanye ubuthathaka obaziwayo.

Uqeqesho kunye neNkxaso

- Ukubonelela ngoqeqesho kubasebenzi koomatshini kunye nabasebenzi bolondolozo kwiinkqubo ezifanelekileyo zokutshintsha inxalenye.

- Ukubonelela ngenkxaso yobugcisa obuqhubekayo kunye nesikhokelo sokusombulula nayiphi na imiba enokuthi ivele ngexesha okanye emva kokutshintshwa kwenxalenye.

- Ukukhuthaza inkcubeko yolondolozo olukhawulezileyo nokukhuthaza abaqhubi ukuba baxele nakuphi na ukungaqhelekanga ngoko nangoko.

Ngokulandela la manqaku aphambili kunye nokusebenza kunye nabanikezeli abathembekileyo kunye neengcali ezinamava, ukutshintshwa kweengxenye zomatshini we-CNC kunokuqhutywa ngokufanelekileyo. Ukutshintshwa kwenxalenye ngexesha nangexesha elichanekileyo kunceda ukuqinisekisa ukusebenza kakuhle komatshini, kwandisa ubomi bawo, kwaye kucuthe ukuphazamiseka kwiishedyuli zemveliso.

Unikezelo lwe-CNC Machine Spindles

I-CNC (i-Computer Numerical Control) i-spindles yomatshini idlala indima ebalulekileyo ekuchanekeni nasekusebenzeni kwemisebenzi yomatshini. Ukuqinisekisa ukusebenza okugqibeleleyo kunye nokuphila ixesha elide, ukusetyenzwa rhoqo kwee-spindles zomatshini we-CNC kubalulekile. Nanga amanye amanqaku aphambili ekufuneka uwathathele ingqalelo xa kufikwa kwinkonzo yokusonta koomatshini be-CNC:

Ulondolozo

- Ukugcinwa okucwangcisiweyo kubalulekile ukuphepha ixesha elingalindelekanga kunye nokulungiswa kweendleko.

- Yenza ishedyuli yolondolozo ebandakanya ukuhlolwa rhoqo kunye nemisebenzi yokubonelela.

- Landela iingcebiso zomenzi malunga namathuba olondolozo kunye neenkqubo.

Ukucoca kunye nokuthambisa

- Coca i-spindle rhoqo ukususa inkunkuma, uthuli, kunye nentsalela yokupholisa enokuthi ichaphazele ukusebenza.

- Sebenzisa ii-arhente zokucoca ezifanelekileyo kunye nobuchule obucetyiswa ngumenzi.

- Lubricate amacandelo e-spindle ngokwemigaqo echaziweyo ukuqinisekisa ukusebenza kakuhle kunye nokuthintela ukunxiba.

Ukuhlolwa kwebhanti kunye neBhere

- Jonga imeko yebhanti ngeempawu zokuguga, iintanda, okanye umonakalo. Zitshintshe ukuba kuyimfuneko.

- Hlola iibheringi zengxolo egqithisileyo, ukungcangcazela, okanye ukufudumala kobushushu, nto leyo enokubonisa imfuneko yokutshintshwa okanye ukulungiswa.

- Ukulungelelanisa ngokufanelekileyo kunye neebhanti zoxinzelelo ukuze kugcinwe ukuhanjiswa kwamandla aphezulu.

ULondolozo lweNkqubo yokuPholisa

- Coca rhoqo kwaye ugcine isixokelelwano sokupholisa ukuthintela ungcoliseko kunye nokuvala.

- Qwalasela amanqanaba okupholisa, izihluzi, kunye neempompo ukuze zisebenze ngokufanelekileyo.

- Lawula umgangatho wokupholisa kwaye ubeke endaweni yaso xa kukho imfuneko ukugcina iimeko zokusika ezizezona zilungileyo kwaye uthintele umonakalo wokusonta.

I-Spindle Runout kunye neBalance

- Ukulinganisa i-spindle runout usebenzisa izixhobo ezichanekileyo zokuqinisekisa ukugxila kunye nokuchaneka.

- Ukulinganisa i-spindle ukuba ukungcangcazela okugqithisileyo okanye ukusika okungalinganiyo kubonwa.

- Sombulula nayiphi na imiba ngokukhawuleza ukunqanda umonakalo onokuthi ube khona kwi-spindle okanye i-workpiece.

Ukuhlolwa kweNkqubo yoMbane

- Jonga uqhagamshelo lombane, iingcingo, kunye nezivamvo zokubona iimpawu zomonakalo okanye ukungasebenzi kakuhle.

- Vavanya i-spindle motor kunye nokuqhuba ukusebenza ukuze uqinisekise ukusebenza ngokufanelekileyo.

- Ukulinganisa iinkqubo zokulawula isantya ukugcina i-RPM ejikelezayo echanekileyo.

Uncedo lweNgcali

- Ukubandakanya amagcisa aqeqeshiweyo okanye abameli babavelisi kwinkonzo entsonkothileyo okanye ukulungisa.

- Ukuqeqesha rhoqo abaqhubi kunye nabasebenzi bolondolozo kwiindlela zokuphatha nokugcinwa ngokufanelekileyo.

- Funa iingcebiso zobuchwephesha kwimiba yokulungisa ingxaki ngaphaya kolungiso oluqhelekileyo.

UHlolo lweNkqubo yoMbane yoMshini we-CNC

Inkqubo yombane yomatshini we-CNC yinxalenye ebalulekileyo echaphazela ngokuthe ngqo ukusebenza kwayo kunye nokuthembeka. Ukuhlolwa rhoqo kwenkqubo yombane kuyimfuneko ukuqinisekisa ukusebenza okukhuselekileyo kunye nokusebenza kakuhle. Nanga amanye amanqaku aphambili ekufuneka uwaqwalasele xa uqhuba uhlolo lwesixokelelwano sombane koomatshini be-CNC:

Uvavanyo lokubonakalayo

- Qala ngokujonga ngokubonakalayo amalungu ombane ukubona iimpawu zomonakalo, njengeingcingo ezixekileyo, iintambo eziqhawukileyo, okanye izihlanganisi ezitshileyo.

- Khangela naluphi na uqhagamshelo oluxekileyo okanye iitheminali ezinokuchaphazela ukuhanjiswa kombane.

- Jonga ubungqina bobushushu obugqithisileyo, obufana nokutshintsha kombala okanye ukunyibilika kwamalungu.

Ukunikezwa Amandla

- Qinisekisa ukuba umatshini ufumana amandla ombane achanekileyo kwaye unikezelo lwamandla luzinzile kwaye lubekwe ngokufanelekileyo.

- Hlola iintambo zamandla eziphambili kunye nokudibanisa naziphi na iimpawu zokuguga okanye umonakalo.

- Vavanya ukusebenza kwee-breakers zesekethe kunye ne-fuses ukuqinisekisa ukuba babonelela ngokhuseleko olwaneleyo.

IKhabhinethi yoLawulo

- Vula ikhabhinethi yolawulo kwaye uhlole izinto zangaphakathi, ezifana neebhodi zeesekethe, ii-relays, kunye nabafowunelwa.

- Jonga iimpawu zokutshisa kakhulu, ezifana neempawu ezitshileyo okanye ivumba elibi lokugquma kwentsimbi.

- Khangela ukuba zonke iintambo kunye nezihlanganisi zibotshelelwe ngokukhuselekileyo kwaye zibhalwe ngokufanelekileyo.

IiNkqubo zeMoto kunye neDrive

- Jonga iimotor kunye nedrive naziphi na iimpawu zomonakalo, ezinje ngeengcingo ezixekileyo okanye iibrashi ezigugileyo.

- Vavanya ukusebenza kweemoto zokuqhuba kwaye uqinisekise ukuba zibonelela ngolawulo olugudileyo noluchanekileyo lwentshukumo.

- Ukulinganisa i-motor current ukuqinisekisa ukuba ikuluhlu oluchaziweyo lokusebenza ngokufanelekileyo.

Inkqubo yokumisa iNgxakeko

- Vavanya amaqhosha okumisa kaxakeka ukuqinisekisa ukuba asebenza ngokuchanekileyo kwaye unokuwumisa ngoko nangoko umatshini kwimeko kaxakeka.

- Jonga iingcingo kunye noqhagamshelo lwesixokelelwano sokumisa unxunguphalo kuzo naziphi na iimpazamo okanye uqhagamshelo olukhululekileyo.

Iindawo zonxibelelwano

- Hlola i-interfaces zonxibelelwano, ezifana ne-Ethernet okanye izibuko ze-serial, ukuqinisekisa ukuba zisebenza ngokuchanekileyo.

- Vavanya amakhonkco onxibelelwano kunye nezixhobo zangaphandle, ezinjengeekhompyuter okanye abalawuli bengqiqo ecwangcisiweyo (PLCs), ukuqinisekisa ukudluliselwa kwedatha efanelekileyo.

Inkqubo yokuGrounding

- Qinisekisa ukuba inkqubo yokumisa yomatshini ifakwe ngokufanelekileyo kwaye iqhagamshelwe.

- Hlola ukunyaniseka kweengcingo eziphantsi kunye nokudibanisa ukukhusela iingozi zombane kunye nokuqinisekisa ukunciphisa ingxolo yombane.

Ulondolozo rhoqo

- Misela ishedyuli yokugcinwa rhoqo kwenkqubo yombane, kuquka ukucoca, ukuqinisa uqhagamshelo kunye nokuhlola iintambo.

- Landela izikhokelo zomenzi kwiinkqubo ezicetyiswayo zokulondolozwa kunye namathuba.

- Abaqhubi bezoqeqesho kunye nabasebenzi bolondolozo kukhuseleko lombane kunye nokuphathwa ngokufanelekileyo komatshini we-CNC.

UkuLondolozwa kweNkqubo yokuPholisa kwii-CNC Machines

Inkqubo yokupholisa yoomatshini be-CNC (Computer Numerical Control) idlala indima ebalulekileyo ekugcineni amaqondo obushushu afanelekileyo okusebenza, ukwandisa ubomi besixhobo, kunye nokuqinisekisa ukuchaneka komatshini. Ukugcinwa ngokufanelekileyo kwesixokelelwano sokupholisa kubalulekile ukuze kuthintelwe ukufudumeza, ukugcina umgangatho wokupholisa, kunye nokuphepha umonakalo onokuthi ubekho kumatshini. Nanga amanye amanqaku aphambili ekufuneka eqwalaselwe xa kufikwa kulungiso lwenkqubo yokupholisa koomatshini beCNC:

Ukucoca rhoqo

- Coca itanki yokupholisa, izihluzi, kunye nemijelo yokupholisa rhoqo ukususa inkunkuma, iitshiphusi kunye nodaka.

- Sebenzisa ii-arhente zokucoca ezifanelekileyo kunye nobuchule obucetyiswa ngumenzi womatshini.

- Gubha isixokelelwano ngamaxesha athile ukuqinisekisa ukuba ukuhamba kwesipholisi akuthinteleki.

Uxinaniso olupholileyo

- Beka iliso kwaye ugcine ugxininiso olufanelekileyo lwesipholisi kwisixokelelwano ngokweenkcukacha zomenzi.

- Vavanya isixhobo sokupholisa rhoqo usebenzisa i-refractometers okanye iikiti zokuvavanya ukuqinisekisa ukuba siyadibana namanqanaba acetyiswayo.

- Lungisa ugxininiso ngokongeza isipholileyo okanye amanzi amatsha njengoko kuyimfuneko.

Inkqubo yokufotokopa

- Jonga kwaye ucoce izihluzi zokupholisa rhoqo ukuze ususe ungcoliseko kwaye uthintele ukuvaleka.

- Buyisela izihluzi ngokwezithuba ezicetyiswayo okanye xa ziba mdaka kakhulu okanye zonakele.

- Cinga ngokusebenzisa izihluzi ezikumgangatho ophezulu okanye izahluli zemagnethi ukuphucula ukusebenza kakuhle kohluzo.

Umgangatho wokupholisa

- Beka esweni inqanaba le-pH yesisipholisi, i-viscosity, kunye nokwakheka kweekhemikhali ukuqinisekisa ukuba sihlala sikuluhlu olwamkelekileyo.

- Uvavanyo lokukhula kwebhaktiriya okanye ungcoliseko olunokukhokelela kwivumba elibi okanye ukuwohloka kokusebenza kokupholisa.

- Faka indawo yokupholisa ukuba sibonisa iimpawu zokuthotywa okanye iyasilela ukuhlangabezana nemigangatho yokusebenza efunekayo.

Impompo kunye nesantya sokuhamba

- Jonga impompo yokupholisa ukusebenza ngokufanelekileyo, ujonge nakuphi na ukuvuza, ingxolo engaqhelekanga, okanye ukuncipha komyinge wokuhamba.

- Coca okanye ubuyisele i-impeller yempompo ukuba igugile okanye yonakele.

- Qinisekisa ukuba umlinganiselo wokuqukuqela kwesipholisi uphakathi koluhlu olucetyiswayo ukuqinisekisa ukupholisa okusebenzayo.

Ulawulo lobushushu obupholileyo

- Qwalasela inkqubo yokulawula ubushushu, efana ne-chiller okanye isitshintshisi sobushushu, ukugcina ubushushu besipholisi phakathi koluhlu oluxeliweyo.

- Hlola izinzwa, iivalvu, kunye neendlela zokulawula ukuqinisekisa ukulawulwa kobushushu obuchanekileyo.

- Coca okanye utshintshe amaphiko okutshintsha ubushushu ukuba azivalele bubumdaka okanye inkunkuma.

Uqeqesho lwabaSebenzisi

- Ukubonelela ngoqeqesho kubasebenzi boomatshini malunga nokuphatha okupholisayo ngendlela eyiyo, kubandakanywa nokuzalisa kwakhona, ukuhlengahlengisa ukugxila, kunye nokuxela imiba enxulumene nokupholisa.

- Yalela abaqhubi ukuba baqaphele iimpawu zokuthotywa kwesipholisi okanye ukungasebenzi kakuhle kwenkqubo kunye nendlela yokuphendula ngokufanelekileyo.

- Ukukhuthaza inkcubeko yococeko kunye nolondolozo lwenkqubo yokupholisa esebenzayo phakathi kwabaqhubi.

Ukubonelela ngokuLawulwa koomatshini be-CNC kunye neSoftware

Unikezelo lwarhoqo lolawulo lomatshini we-CNC kunye nesoftware kubalulekile ukuqinisekisa ukusebenza kakuhle kunye nokuphepha imiba enokubakho. Nanga amanye amanqaku aphambili ekufuneka uwaqwalasele xa kufikwa kwinkonzo yolawulo lomatshini we-CNC kunye nesoftware:

Uhlaziyo lwesoftware

- Hlaziya rhoqo isoftware yomatshini we-CNC ukuze uxhamle kwizinto zamva nje, ulungiso lwebug, kunye nophuculo lokusebenza.

- Landela izikhokelo zomenzi kunye neengcebiso zokuhlaziya isoftware.

- Yenza i-backups yoguqulelo lwangoku lwesoftware yomatshini phambi kokwenza uhlaziyo.

Ulungelelwaniso nolungelelwaniso

- Ukulinganisa ngamaxesha kwaye ulungelelanise ulawulo lomatshini we-CNC ukugcina ukuchaneka nokuchaneka.

- Jonga kwaye ulungelelanise ulungelelwaniso lwe-axes, izixhobo zokusebenza, kunye nezithuba zero zero.

- Qinisekisa ukuchaneka kweenkqubo zophando, ukuba kufanelekile, kwaye uhlengahlengise ukuba kuyimfuneko.

Ukugcina kunye nokubuyisela

- Rhoqo gcina imilinganiselo yomatshini obalulekileyo, useto, kunye neenkqubo zokuthintela ukulahleka kwedatha.

- Gcina iikopi ezininzi ze-backups kwizixhobo zangaphandle okanye ukugcinwa kwelifu ukwenzela ukhuseleko olongezelelweyo.

- Vavanya inkqubo yokubuyisela ngamaxesha athile ukuqinisekisa ukuba ii-backups zithembekile kwaye ziyafikeleleka.

Uhlolo lwePhaneli yoLawulo

- Jonga ngokubonakalayo iphaneli yokulawula nayiphi na imiqondiso yomonakalo, njengamaqhosha aphukileyo, izihlanganisi ezikhululekileyo, okanye izikhombisi ezingasebenzi kakuhle.

- Coca iphaneli yokulawula kunye namaqhosha rhoqo ukususa uthuli okanye i-debris enokuthi ichaphazele ukusebenza.

- Vavanya ukusebenza kwendawo yolawulo ngokuqinisekisa iqhosha ngalinye, tshintsha, kunye nomboniso.

Ukudityaniswa kombane

- Hlola ukudityaniswa kombane ngaphakathi kwekhabhinethi yolawulo naziphi na iingcingo ezixekileyo okanye ezidlekileyo.

- Qinisa naluphi na uqhagamshelo oluxekileyo kwaye ubuyisele iintambo ezonakalisiweyo okanye izihlanganisi.

- Yenza uhlolo olucokisekileyo lwenkqubo yombane ukuze uqinisekise umhlaba ofanelekileyo kunye nokunciphisa umngcipheko weempazamo zombane.

Ugcino lweZixhobo zokuNgenisa

- Jonga ukusebenza kwezixhobo zongeniso, ezifana nezitshixo, iimpuku, okanye izikrini zokuchukumisa.

- Izixhobo zokungena ezicocekileyo zokususa ukungcola okanye intsalela enokuphazamisana nokusebenza kwazo.

- Faka endaweni yezixhobo ezigugileyo okanye ezingasebenzi kakuhle ukugcina ulawulo olugudileyo noluchanekileyo.

Uqeqesho lwabaSebenzisi

- Ukubonelela abaqhubi ngoqeqesho olubanzi kulawulo lomatshini we-CNC kunye nesoftware.

- Ziqhelanise nabaqhubi ngemisebenzi eyahlukeneyo, iimenyu, kunye neeparamitha zojongano lolawulo.

- Yalela abaqhubi ngokusetyenziswa ngokufanelekileyo kweempawu zesoftware kunye neendlela zokusombulula ingxaki.

Ukujongwa rhoqo kweNkqubo

- Qhuba iitshekhi zenkqubo ngamaxesha athile ukuchonga isoftware enokubakho okanye imiba yolawulo.

- Lawula iilogi zempazamo, ii-alam, kunye nemiyalezo yoxilongo kuyo nayiphi na impazamo.

- Yenza iimvavanyo zokuxilonga kwaye ulandele izikhokelo zomenzi wokusombulula iingxaki kunye nokusombulula imiba.

Iitshekhi zoKhuseleko zoomatshini be-CNC

Ukuqinisekisa ukhuseleko lwabasebenzi kunye nendawo yokusebenza kubaluleke kakhulu xa usebenza noomatshini be-CNC (Computer Numerical Control). Nanga amanye amanqaku aphambili ekufuneka uwaqwalasele xa ujonga ukhuseleko kumatshini we-CNC:

Indawo ebiyelwe ngoomatshini

- Hlola indawo ebiyelweyo yomatshini ukuze uqiniseke ukuba icocekile, ikhuselekile ngokufanelekileyo, kwaye ayinazo iintanda okanye umonakalo.

- Qinisekisa ukuba zonke iingcango zokungena, iiphaneli, kunye nezitshixo zokhuseleko zisebenza ngokuchanekileyo.

- Jonga ukubonakala okufanelekileyo kweempawu ezilumkisayo, iilebhile, kunye namaqhosha okumisa kaxakeka.

Inkqubo yokumisa iNgxakeko

- Vavanya amaqhosha okumisa kaxakeka ukuqinisekisa ukuba amisa ngokukhawuleza ukusebenza komatshini xa ecinezelwe.

- Qinisekisa ukuba inkqubo yokumisa unxunguphalo ikwimeko efanelekileyo yokusebenza kwaye ifikeleleka lula kubaqhubi.

- Qeqesha abaqhubi ekusetyenzisweni okuchanekileyo kwamaqhosha okumisa kaxakeka kunye neendawo zabo.

Ukhuseleko loMbane

- Jonga izixhobo zombane kuzo naziphi na iingcingo eziveziweyo, uqhagamshelo oluxegayo, okanye ukugquma okonakeleyo.

- Qinisekisa ukuba isixokelelwano sombane simiswe ngokufanelekileyo ukunciphisa umngcipheko wokothuka kombane.

- Qwalasela rhoqo ukuba ii-breaker circuit kunye ne-fuses zisebenza kakuhle.

Izixhobo kunye noKhuseleko lweworkpiece

- Hlola izixhobo, ezifana nezixhobo zokusika okanye iziqhoboshi, ukukhangela umonakalo, ukunxiba, okanye ukufakela okungalunganga.

- Jonga izixhobo zokusebenza ukuze zibekwe kwindawo ekhuselekileyo kunye nokubamba ngokufanelekileyo ukunqanda ukufuduswa ngexesha lomatshini.

- Ukubeka iliso kwisixhobo sokunxiba kunye nokutshintsha izixhobo njengoko kuyimfuneko ukugcina ukusika okukhuselekileyo nokusebenzayo.

UkuKhanya okuKhuselekileyo

- Qinisekisa ukuba indawo yokusebenza inezibane ezaneleyo zikaxakeka kwimeko yokucima kombane okanye ezinye iimeko zikaxakeka.

- Vavanya izibane ezingxamisekileyo rhoqo ukuze uqinisekise ukuba zisebenza ngokufanelekileyo kwaye zikhanyisa indawo ngokufanelekileyo.

UKhuseleko loMlilo

- Qinisekisa ubukho kunye nokusebenza kwezicimi-mlilo kwindawo ekufutshane nomatshini we-CNC.

- Ukuqeqesha abasebenzi ngokusetyenziswa ngokufanelekileyo kwezitshizi zokucima umlilo kunye neenkqubo zokufuduka kwimeko yomlilo.

- Coca indawo ejikeleze umatshini we-CNC wazo naziphi na izinto ezinokutsha okanye i-debris.

UQeqesho loMsebenzisi kunye noKwazisa

- Ukubonelela ngoqeqesho olubanzi kubasebenzi kwiinkqubo zokusebenza ezikhuselekileyo kunye neengozi ezinokubakho kumatshini we-CNC.

- Ukukhuthaza inkcubeko yokwazisa ngokhuseleko kwaye ukhuthaze abaqhubi ukuba baxele naziphi na iinkxalabo zokhuseleko ngokukhawuleza.

- Ukuqhuba iintlanganiso zokhuseleko rhoqo okanye iintetho zebhokisi yezixhobo ukujongana nezihloko zokhuseleko kunye nokomeleza izenzo zokhuseleko.

Ukuthotyelwa kweMigangatho yoKhuseleko

- Qinisekisa ukuba umatshini we-CNC uhlangabezana nemigangatho efanelekileyo yokhuseleko kunye nemimiselo kwindawo yokusebenza.

- Hlala uhlaziywa kulo naluphi na utshintsho okanye uhlaziyo lwemigangatho yokhuseleko kwaye ubabandakanye kwiitshekhi zokhuseleko.

- Ukusebenzisana neengcali zokhuseleko okanye abacebisi, ukuba kuyimfuneko, ukuqinisekisa ukuthotyelwa kunye neendlela ezifanelekileyo.

Ukucoca koomatshini be-CNC

Ukucocwa rhoqo kunye nokugcinwa koomatshini be-CNC kubalulekile ekusebenzeni kwabo, ukuchaneka, kunye nobomi babo bonke. Ngokulandela ezi ndlela zokucoca, abaqhubi banokuqinisekisa ukuba oomatshini babo be-CNC bahlala bekwimeko efanelekileyo, ukunciphisa ixesha lokunciphisa kunye nokwandisa imveliso.

- Ukugcina umatshini ococekileyo we-CNC (i-Computer Numerical Control) ucocekile kwaye ugcinwe kakuhle uyimfuneko ekusebenzeni kwayo kunye nokuphila ixesha elide. Ukucocwa rhoqo komtshini kunceda ukuthintela ukwakhiwa kwenkunkuma, uthuli, kunye neechips ezinokukhokelela kwimiba yomatshini kunye nokungachaneki kumatshini.

- Qala ngokucima umatshini kunye nokuwuqhawula kumthombo wamandla ukuze uqinisekise ukhuseleko ngexesha lokucoca.

- Qala ngokususa naziphi na iitshiphusi, inkunkuma, okanye ukusika ulwelo kwindawo yokusebenza usebenzisa ivacuum okanye ibrashi. Nika ingqalelo kwiindawo ekunzima ukufikelela kuzo, njengemingxuma kunye neekona, apho inkunkuma idla ngokuqokelelana khona.

- Sula umphezulu womatshini ngelaphu elicocekileyo, elingena-lint kunye nesisombululo esincinci sesepha. Kuphephe ukusebenzisa izicoci ezirhabaxa ezinokonakalisa ukugqiba komatshini. Ucoca ngokucokisekileyo yonke imiphezulu evelileyo, kubandakanywa itafile, intambo yokusonta, izibambi zezixhobo, kunye nendawo ebiyelweyo.

- Coca itanki yokupholisa kwaye ubuyisele ulwelo lokusika rhoqo. Amanzi amdaka okanye angcolileyo anokuchaphazela ukusebenza komatshini kunye nomgangatho weemveliso ezigqityiweyo.

- Hlola izihluzi kunye nezikrini kwisixokelelwano sokupholisa, inkqubo yokucoca umoya, kunye nenkqubo yokuthambisa. Coca okanye utshintshe la malungu njengoko kuyimfuneko ukuqinisekisa ukuhluzwa okufanelekileyo kunye nokuhamba kwamanzi.

- Nika ingqalelo ekhethekileyo kumatshini wokusonta kunye neendlela zokutshintsha izixhobo. Susa nayiphi na inkunkuma okanye i-buildup enokuphazamisana nokusebenza kwayo okugudileyo. Lubricate la macandelo ngokwezikhokelo zomenzi ukugcina ukusebenza kakuhle.

- Qwalasela isigqubuthelo kunye nemvulo ukuba akukho naziphi na iimpawu zokonakala okanye ukuguga. Zibuyisele endaweni yazo ukuba kuyimfuneko ukukhusela abangaphakathi bomatshini ekungcoleni.

- Okokugqibela, hlola uqhagamshelo lombane, iintambo kunye neengcingo. Qinisekisa ukuba zikhuselekile kwaye akukho monakalo. Coca ipaneli yokulawula kunye namaqhosha ngesicoci esithambileyo ukususa nabuphi na ubumdaka okanye ubumdaka.

- Gcina ishedyuli yokucoca rhoqo kunye nemisebenzi yokugcinwa kwamaxwebhu. Oku kunceda ekulandeleni ukucoca rhoqo kunye nokuchonga nayiphi na imiba enokubakho kwangethuba.

UQeqesho loMatshini we-CNC kunye neNkxaso

Ngokubonelela ngoqeqesho olubanzi kunye nenkxaso eqhubekayo, abaqhubi banokuphuhlisa izakhono eziyimfuneko kunye nokuzithemba ukuze basebenzise oomatshini be-CNC ngokufanelekileyo. Abasebenzi abaqeqeshwe kakuhle banegalelo ekuphuculeni imveliso, ukunciphisa ixesha lokuphumla, kunye neziphumo ezikumgangatho ophezulu.

- Uqeqesho olufanelekileyo kunye nenkxaso eqhubekayo ibalulekile kubaqhubi ukuba basebenzise ngokufanelekileyo i-CNC (i-Computer Numerical Control) oomatshini kunye nokwandisa amandla abo. Iinkqubo zoqeqesho zibonelela abaqhubi ngolwazi kunye nezakhono eziyimfuneko ekusebenzeni, inkqubo, kunye nokusombulula ingxaki koomatshini be-CNC.

- Qala ngokubonelela ngoqeqesho olubanzi kwiziseko zobuchwepheshe be-CNC, kubandakanya ukuqonda amacandelo oomatshini, izixhobo, kunye neziseko zenkqubo. Esi siseko sinceda abaqhubi ukuba babambe iikhonsepthi ezingundoqo kunye nesigama esihambelana noomatshini be-CNC.

- Yazisa abaqhubi kwisoftware yeCAD/CAM esetyenziselwa ukwenza iinxalenye zoyilo kunye nokuvelisa iinkqubo zomatshini. Uqeqesho kwezi zixhobo zesoftware lwenza abaqhubi bakwazi ukucwangcisa ngokufanelekileyo oomatshini be-CNC kunye nokwandisa iinkqubo zomatshini.

- Ukubonelela ngeeseshoni zoqeqesho apho abaqhubi banokuziqhelanisa nokuseta umatshini, ukulayisha izixhobo, kunye nokusebenza ngoomatshini. La mava asebenzayo anceda ukwakha ukuzithemba kunye nokuqhelana nokusebenza komatshini.

- Gxininisa iiprothokholi zokhuseleko kunye neendlela ezifanelekileyo ngexesha loqeqesho. Abaqhubi kufuneka baqeqeshwe kwiinkqubo ezifanelekileyo zokuqalisa kunye nokuvalwa komatshini, ukuphatha izixhobo zokusika, kunye nokusetyenziswa kwezixhobo zokukhusela zomntu (PPE) ukuqinisekisa indawo ekhuselekileyo yokusebenza.

- Ukubonelela ngoqeqesho lokugcinwa koomatshini kunye nokhathalelo lothintelo. Abanini-zithuthi kufuneka bafunde indlela yokuhlola nokugcina izinto ezibalulekileyo, ezinje ngeentambo zokuphotha, izigqubuthelo zeendlela, kunye neenkqubo zokuthambisa, ukugcina umatshini usebenza kakuhle.

- Ukubonelela ngenkxaso eqhubekayo ngeemanyuwali, amaxwebhu, kunye nezixhobo ze-intanethi. Incwadi yesikhokelo yomsebenzisi ebanzi ebandakanya ukusebenza koomatshini, imizekelo yenkqubo, izikhokelo zokusombulula ingxaki, kunye neenkqubo zolungiso zinokusebenza njengereferensi exabisekileyo kubasebenzisi.

- Ukuseka inkqubo yenkxaso apho abaqhubi banokufuna uncedo kunye nesikhokelo xa behlangabezana nemingeni okanye imiba. Oku kunokuba luhlobo lweqela lenkxaso elizinikeleyo, umnxeba woncedo lobugcisa, okanye iiforam ze-intanethi apho abaqhubi banokunxulumana nabasebenzisi abanamava be-CNC.

- Ukuqhuba iiseshoni zoqeqesho lokuhlaziya ukuqinisa ulwazi nezakhono. Itekhnoloji ye-CNC iyaguquka ngokuhamba kwexesha, ngoko ke ukugcina abaqhubi besazi ngenkqubela phambili kunye nobuchule bamva nje kuqinisekisa ukuba banokwenza uninzi lwamandla omatshini.

- Khuthaza abaqhubi ukuba bathathe inxaxheba kwimisitho yoshishino, imiboniso yorhwebo, kunye neendibano zocweyo ukwandisa ulwazi lwabo kunye nothungelwano nabanye abachwephesha endle. Ezi ziganeko zibonelela ngamathuba okufunda malunga nobuchwepheshe obutsha, ukwabelana ngamava, kunye nokufumana ukuqonda kwezona zenzo zingcono.

Iindleko zeNkonzo yoMatshini we-CNC

Ukuqonda iindleko ezinxulumene nenkonzo yomatshini we-CNC kubalulekile kuhlahlo lwabiwo-mali kunye nokucwangcisa.

- Iindleko ze-CNC (uLawulo lwamanani eKhompyutha) inkonzo yomatshini ingahluka ngokuxhomekeke kwizinto ezininzi, kubandakanywa uhlobo lwenkonzo efunekayo, ubunzima bomatshini, kunye namazinga omboneleli wenkonzo. Ukuqonda le miba kubalulekile kuhlahlo lwabiwo-mali nokuqinisekisa isicwangciso sokulondolozwa kweendleko ezonga imali.

- Ukugcinwa rhoqo kokuthintela yinkonzo eqhelekileyo kumatshini we-CNC. Ngokuqhelekileyo ibandakanya imisebenzi efana nokuhlola, ukucoca, ukuthambisa, kunye nokulinganisa. Iindleko zokugcinwa kokuthintela zingavela kumakhulu ambalwa ukuya kwiidola ezingamawaka amaninzi ngonyaka, kuxhomekeke kubukhulu bomatshini kunye nobunzima.

- Ukulungiswa okungxamisekileyo okanye okungacwangciswanga ngomnye umba wenkonzo yomatshini we-CNC onokuchaphazela iindleko. Olu lungiso luhlala lungalindelekanga kwaye lufuna ingqalelo ekhawulezileyo ukunciphisa ixesha lokuphumla. Iindleko ziya kuxhomekeka kubuzaza bomcimbi, ukufumaneka kwamalungu atshintshiweyo, kunye nobuchule obufunekayo ukusombulula ingxaki. Ulungiso olungxamisekileyo lunokusuka kumakhulu ambalwa ukuya kumawaka aliqela eedola.

- Abanye ababoneleli-nkonzo banikezela ngeemvumelwano zenkonzo okanye izicwangciso zolondolozo ezibandakanya zombini ulondolozo lwesiqhelo lothintelo kunye nolungiso olungxamisekileyo. Ezi zivumelwano zinokubonelela ngeendleko zogcino kunye noxolo lwengqondo ngokuqinisekisa inkonzo ekhawulezileyo kunye nokunciphisa umngcipheko weendleko ezingalindelekanga. Iindleko zeekontraka zenkonzo ziyahluka ngokusekelwe kwizinto ezifana nobudala bomatshini, ubunzima, kunye nenqanaba lokhuselo olubonelelweyo.

- Amalungu asetyenzisiweyo kunye nezinto ezisetyenziswayo ziindleko ezongezelelweyo ekufuneka ziqwalaselwe xa kusenziwa inkonzo koomatshini be-CNC. Izinto ezinje ngeenjini, izinzwa, amabhanti, kunye neebheringi zinokufuna ukutshintshwa ngokuhamba kwexesha. Iindleko zala malungu ziya kuxhomekeka kuhlobo lomatshini, imodeli, kunye nokufumaneka. Kunconywa ukugcina uluhlu lwezinto ezisetyenziswa ngokuqhelekileyo ukunciphisa ixesha lokunciphisa kunye nokunciphisa iindleko zokuthumela.

- Utyelelo lwenkonzo kwisiza lusenokubangela iindleko ezongezelelweyo, ezifana neendleko zokuhamba, indawo yokuhlala, kunye neentlawulo zamagcisa. Ezi ndleko zinokwahluka ngokuxhomekeke kwindawo yomatshini kunye nemigaqo-nkqubo yomboneleli wenkonzo. Uxilongo olukude kunye nokhetho lokusombulula ingxaki lunokubakho, olunokunceda ukunciphisa imfuno yokutyelela kwindawo kunye neendleko ezinxulumene nazo.

- Kuyacetyiswa ukuba ufumane iikowuti kubanikezeli benkonzo abaninzi ukuthelekisa iindleko kunye neenkonzo ezibonelelwayo. Qwalasela igama, amava, kunye nobuchule bomboneleli-nkonzo, kunye nexesha labo lokuphendula kunye nokufumaneka kweemeko ezingxamisekileyo.

- Ukutyala imali ekugcinweni rhoqo kunye nokulungiswa kwangexesha kunokunceda ukunciphisa iindleko zexesha elide. Ukungahoyi ulungiso kunokukhokelela ekuqhekekeni rhoqo, ukunciphisa ixesha lokusetyenziswa koomatshini, kunye neendleko zokulungisa ezongeziweyo.

isiphelo

Inkonzo yomatshini we-CNC ibalulekile ukuqinisekisa ukuba aba matshini basebenza ngokufanelekileyo nangempumelelo. Ababoneleli ngenkonzo yomatshini we-CNC banikezela ngoluhlu lweenkonzo zokugcina, ukulungisa, nokuphucula aba matshini ukuqinisekisa ukuba bayahlangabezana neemfuno zamashishini okuvelisa. Ukugcinwa rhoqo, ukuhlolwa, kunye nokulungiswa kubalulekile ukunqanda ixesha lokunciphisa kunye nokunciphisa umngcipheko wokulungiswa okuxabisa kakhulu. Ngotyalo-mali kwinkonzo yomatshini we-CNC, amashishini anokuqinisekisa ukuba akhulisa amandla omatshini wabo we-CNC kwaye aphucule imveliso yawo iyonke.