Ukubumba inaliti yeplastiki

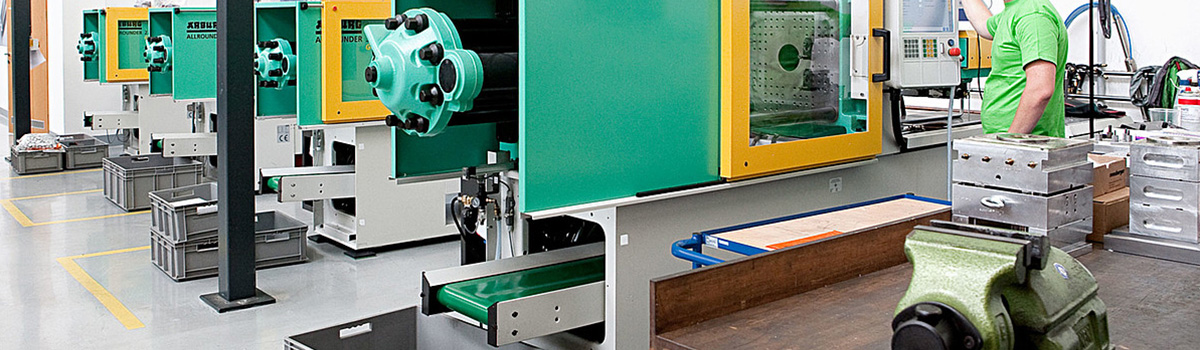

Ukubumba inaliti yeplastiki yinkqubo yokuvelisa ebandakanya ukunyibilikisa iipeliti zeplastiki kwaye uzitofe kumngxunya wokungunda ukwenza into enomacala amathathu. Le nkqubo iqala ngeemveliso ezininzi, ukusuka kwiindawo ezincinci ezichanekileyo ukuya kwizinto ezibalulekileyo zemoto. Ukubumba inaliti yeplastiki kunika iingenelo ezininzi kunezinye iinkqubo zokuvelisa, kubandakanywa amazinga aphezulu emveliso, ukuguquguquka koyilo, kunye nokusebenza kakuhle kweendleko. Esi sikhokelo siya kujonga nzulu kwi-injection yeplastiki yokubumba kwaye iphonononge izicelo zayo ezahlukeneyo, izibonelelo, kunye nemida.

Imbali yokuBunjwa kwesitofu sePlastiki

Ukubumba inaliti yeplastiki yinkqubo yokuvelisa ebandakanya ukutofa iplastiki enyibilikisiweyo kwindawo yokungunda ukwenza imilo ethile. Imbali yokubumba inaliti yeplastiki inokulandelwa emva ekupheleni kweminyaka yoo-1800 xa i-celluloid, uhlobo lweplastiki, yaqala ukuyilwa. Nangona kunjalo, kwakungoo-1940 apho ukubumba inaliti yeplastiki kwasetyenziswa ngokubanzi njengendlela yokwenza.

Ebudeni beMfazwe Yehlabathi II, imfuno yeemveliso zeplastiki eziveliswe ngobuninzi yanda, yaye abavelisi baqalisa ukukhangela iindlela ezintsha nezisebenzayo zokuzivelisa. Ngo-1946, uJames Watson Hendry, umqambi waseMelika, waphuhlisa umatshini wokuqala wokubumba inaliti yesikrufu, owaguqula ishishini lokubumba inaliti yeplastiki. Lo matshini uvumele ulawulo lwenkqubo yokutofa oluchanekileyo kunye noluhambelanayo, okwenza ukuvelisa izixa ezikhulu zeendawo zeplastiki zifikeleleke kwaye zisebenze.

Kuyo yonke iminyaka yoo-1950 kunye no-1960, ukuqhubela phambili kwitekhnoloji yeplastiki kuqhubekile ukuphucula inkqubo yokubumba inaliti yeplastiki. Ukuqaliswa kwezinto ezintsha, ezifana ne-polystyrene kunye ne-polyethylene, zenze iindawo zeplastiki eziyinkimbinkimbi kunye nezizinzileyo. Ukongeza, ukuphuculwa kobuchwephesha bomatshini bokubumba, kubandakanya ukusebenzisa iinkqubo zehydraulic, zenze inkqubo yokubumba inaliti isebenze ngakumbi kwaye ingabizi kakhulu.

Namhlanje, ukubumba inaliti yeplastiki yinkqubo ezenzekelayo esetyenziselwa ukuvelisa uluhlu olubanzi lweemveliso zeplastiki, ukusuka kwizinto zokudlala kunye nempahla yabathengi ukuya kwiindawo zemoto kunye nezixhobo zonyango. Ngophuhliso lwemathiriyeli entsha kunye nobuchwepheshe, inkqubo yokubumba inaliti yeplastiki iyaqhubeka nokuvela kwaye iphucula, iqinisekisa ukuba iya kuhlala iyindlela ebalulekileyo yokwenza iminyaka emininzi.

Izinto eziSisiseko zePlastiki yesitofu sokuBumba

Ukubumba inaliti yeplastiki yinkqubo yokwenza iinxalenye kunye neemveliso ezenziwe ngezinto zeplastiki. Le nkqubo ibandakanya ukutofa iplastiki enyibilikisiweyo kubumba, olupholisa luze lomelele ukuze lube lolo hlobo lufunekayo.

Amanyathelo asisiseko abandakanyekayo kwinkqubo yokubumba inaliti yeplastiki ngala alandelayo:

- Uyilo lokungunda: Inyathelo lokuqala kwinkqubo kukuyila ukubumba okuya kusetyenziswa ukwenza inxalenye efunekayo. Isikhunta ngokuqhelekileyo senziwe ngentsimbi kwaye kufuneka silungiselele ukuphendula ngokushwabana njengoko iplastiki iphola kwaye iqina.

- Ukulungiswa kwezinto: Izinto zeplastiki ezisetyenziselwa inkqubo yokubumba i-injection ziza ngendlela yeepellets okanye i-granules, ekufuneka inyibilikiswe kwaye ilungiselelwe ukutofa kwi-mold. Oku kwenziwa ngokwesiqhelo kwi-hopper, apho iplastiki ifudunyezwa kwiqondo lobushushu elithile kwaye inyibilika ibe yimeko engamanzi.

- Isitofu: Nje ukuba iplastiki inyibilikisiwe, igalelwa kumngundo kusetyenziswa umatshini wokubumba okhethekileyo. Umtshini ufaka uxinzelelo kwiplastiki etyhidiweyo, uyinyanzele kwi-mold cavity, apho ithatha ubume be-mold.

- Ukupholisa kunye nokuqina: Emva kokuba iplastiki ifakwe kwi-mold, inokupholisa kwaye iqine. Oku kungathatha naphi na ukusuka kwimizuzwana embalwa ukuya kwimizuzu emininzi, kuxhomekeke kubukhulu kunye nokuntsonkotha kwenxalenye.

- Ukukhutshwa: Emva kokuba iplastiki ipholile kwaye iqinile, isikhunta siyavulwa, kwaye inxalenye iyakhutshwa. Isikhundla sinokufuna umsebenzi wokugqiba owongezelelweyo, njengokunciphisa okanye ukuthunga, ukususa iplastiki engaphezulu okanye imiphetho erhabaxa.

Ukubumba inaliti yePlastiki yinkqubo echanekileyo nephindaphindwayo, iyenza ilungele iindawo ezivelisa ngobuninzi kunye neemveliso ezinomgangatho ongaguqukiyo. Ikwaguquguquka kakhulu, njengoko inokudala amaqhekeza kunye neemveliso ngobukhulu obahlukeneyo, iimilo kunye nobunzima. Ezinye zezona zicelo zixhaphakileyo zokubumba inaliti yeplastiki ziquka ukuveliswa kweethoyi, iimpahla zabathengi, iindawo zemoto, kunye nezixhobo zonyango.

Inkqubo yokuBumba isitofu sePlastiki: Inyathelo ngenyathelo

Ukubumba inaliti yeplastiki yinkqubo enzima ebandakanya amanyathelo amaninzi. Nantsi isikhokelo senyathelo ngenyathelo kwinkqubo yokubumba inaliti yeplastiki:

- Ukuyila uMbumba: Inyathelo lokuqala kukuyila ukubumba okusetyenziselwa ukwenza inxalenye. Umngundo ngokuqhelekileyo wenziwa ngentsimbi okanye i-aluminiyam kwaye kufuneka ulungele ukuhlalisa i-shrinkage yeplastiki xa iphola.

- Ukudala uMngundo: Nje ukuba uyilo lokungunda lugqityiwe, lwenziwa kusetyenziswa isoftware yoyilo oluncediswa yikhompyuter (CAD) kunye noomatshini abancediswa yikhompyuter (CAM). Umngundo kufuneka ucocwe ngobuchule kwaye upolishwe ukuqinisekisa ukuchaneka nokuphela kwemveliso.

- Ukukhethwa kwezinto: Izinto zeplastiki ze-resin ezisetyenziselwa inkqubo yokubumba isitofu kufuneka zikhethwe ngokusekelwe kwiimfuno zenxalenye, njengamandla ayo, ukuguquguquka, umbala kunye nokuthungwa.

- Ukulungiswa kwezinto: Izinto ezikhethiweyo zeplastiki zifudunyezwa kwiqondo elithile lobushushu kwaye zinyibilike zibe lulwelo. Izinto ke zitofwa kwihopha yomatshini wokubumba.

- I-Injection Molding: Izinto zeplastiki ezityhidiweyo zitofwa kumgodi wokungunda kusetyenziswa umatshini wokubumba okhethekileyo. Umatshini ufaka uxinzelelo kwizinto zeplastiki, zinyanzeliswa kwi-mold cavity, apho ithatha ubume be-mold.

- Ukupholisa: Emva kokuba umgodi wokungunda uzaliswe ngeplastiki, unokupholisa kwaye uqine. Ixesha lokupholisa lichongwa ziimpawu zezinto zeplastiki, ubungakanani kunye nobukhulu benxalenye, kunye nobushushu bokubumba.

- Ukukhutshwa: Emva kokuba iplastiki iqinile, i-mold ivuliwe, kwaye inxalenye ikhutshwe kwi-mold usebenzisa izikhonkwane ze-ejector.

- Ukugqiba: Indawo ekhutshiweyo inokufuna umsebenzi owongezelelweyo wokugqibezela, njengokucheba, ukuthambisa, okanye ukupeyinta, ukususa nayiphi na iplastiki engaphezulu okanye imiphetho erhabaxa.

- Ukulawulwa komgangatho: Inxalenye egqityiweyo ihlolwa ngokucokisekileyo ukuze ihlangabezane neenkcukacha ezifunekayo kunye nemigangatho yomgangatho.

Ukubumba inaliti yeplastiki kunokuvelisa iindawo ezahlukeneyo kunye neemveliso ngobukhulu obuninzi, iimilo kunye nobunzima. Inkqubo isetyenziswa kakhulu kumashishini aliqela, kubandakanya ezemoto, ezonyango, iimpahla zabathengi, kunye nombane.

Iindidi zePlastiki ezisetyenziswa kwi-Injection Molding

Iindidi ezininzi zeplastiki zingasetyenziselwa ukubumba inaliti. Ukukhethwa kwezinto zeplastiki kuya kuxhomekeka kwiimfuno ezithile zemveliso okanye inxalenye eveliswayo, njengamandla, ukuguquguquka, ukuqina, kunye nenkangeleko. Nazi ezinye zezona ntlobo zixhaphakileyo zeplastiki ezisetyenziselwa ukubumba inaliti:

- I-Polyethylene (PE): I-PE yinto esetyenziswa ngokubanzi yeplastiki eyaziwa ngamandla ayo kunye nokuguquguquka. Isetyenziselwa ukuvelisa iimveliso ezahlukeneyo, kubandakanya izinto zokupakisha, iithoyi kunye nezixhobo zonyango.

- I-Polypropylene (PP): I-PP yiplastiki ekhaphukhaphu kwaye ehlala ihleli isetyenziswa ngokuqhelekileyo kwishishini leemoto kwiindawo zangaphakathi, ezifana nedeshibhodi kunye neepaneli zomnyango. Ikwavelisa izinto zokupakisha, ezifana nezikhongozeli kunye neebhotile.

- I-Polycarbonate (i-PC): I-PC yimathiriyeli yeplastiki eqinileyo nengafihliyo edla ngokusetyenziswa ukuvelisa amacandelo e-elektroniki, afana neekesi zekhompyutha kunye neefowuni. Ikwasetyenziselwa iilensi zentloko kunye namalungu edeshibhodi kushishino lweemoto.

- I-Acrylonitrile Butadiene Styrene (ABS): I-ABS yimathiriyeli yeplastiki enemisebenzi emininzi eyaziwayo ngokomelela kwayo, ukuqina, kunye nokumelana nobushushu. Iqhele ukusetyenziswa ukuvelisa iinxalenye zeemoto, ezinje ngedashbhodi, iifender flares, iithoyi, kunye nempahla yabathengi.

- I-Polyamide (PA): I-PA, ekwabizwa ngokuba yinayiloni, yiplastiki eyomeleleyo nekhaphukhaphu imathiriyeli edla ngokusetyenziswa ekuveliseni iindawo zemoto, ezifana nezigqubuthelo zenjini kunye neenkqubo zokungenisa umoya. Ikwavelisa izixhobo zemidlalo, ezifana neebhutsi zokutyibiliza kunye neerekhi zentenetya.

- I-Polystyrene (PS): I-PS yiplastiki ekhaphukhaphu kwaye eqinile esetyenziswa ngokuqhelekileyo kwimveliso yezinto zokupakisha, ezifana neekomityi, iitreyi kunye nezitya zokutya. Ikwavelisa izinto zabathengi, ezifana nezinto zokudlala kunye nezixhobo ze-elektroniki.

- I-Polyethylene Terephthalate (PET): I-PET yinto eyomeleleyo kunye neplastiki ebonakalayo ehlala isetyenziselwa ukuvelisa izinto zokupakisha, ezifana neebhotile kunye nezikhongozeli. Ikwasetyenziswa kushishino lwelaphu ukuvelisa imicu kunye namalaphu.

Ezi zezinye zezona ntlobo zixhaphakileyo zeplastiki ezisetyenziselwa ukubumba inaliti. Ezinye iintlobo ezininzi zeplastiki ziyafumaneka, nganye ineempawu ezizodwa kunye neempawu. Ukukhethwa kwezinto zeplastiki kuya kuxhomekeka kwiimfuno ezithile zenxalenye okanye imveliso eveliswayo.

Iintlobo zoomatshini bokuBumba bokutofa

Oomatshini bokubumba be-injection beza kwiindidi ezahlukeneyo kunye nobukhulu, nganye yenzelwe ukuhlangabezana neemfuno ezithile zokwenziwa. Nazi ezinye zezona ntlobo zixhaphakileyo zoomatshini bokubumba inaliti:

- Umatshini wokubumba we-Hydraulic Injection: Lo matshini usebenzisa amandla e-hydraulic ukuvelisa uxinzelelo lokutofa iplastiki kwi-mold. Oomatshini beHydraulic baqhele ukusetyenziselwa iindawo ezibaluleke ngakumbi ezifuna amandla okubamba okuphezulu.

- Umatshini wokuBumba we-Injection yoMbane: Oomatshini bombane basebenzisa ii-motor zombane ukunika amandla iyunithi yokutofa kunye ne-clamp mechanism. Baziwa ngokuchaneka okuphezulu kunye nokusebenza kakuhle kwamandla, nto leyo eyenza ukuba badume ngokuvelisa iindawo ezincinci, ezintsonkothileyo.

- I-Hybrid Injection Molding Machine: Oomatshini be-Hybrid badibanisa izibonelelo ze-hydraulic kunye nezixhobo zombane, usebenzisa zombini i-hydraulic kunye namandla ombane ukuvelisa uxinzelelo oluyimfuneko kunye namandla. Oomatshini be-Hybrid banika ulungelelwaniso olufanelekileyo lwesantya, ukuchaneka, kunye nokusebenza kakuhle kwamandla.

- Umatshini wokubumba we-Vertical Injection: Oomatshini abamileyo bavelisa iindawo ezifuna ukufaka ukubumba okanye ukubumba ngaphezulu. Baneyunithi yokubambelela ngokuthe nkqo evumela ukufikelela lula kwi-mold, ibenze balungele ukudala iindawo ezincinci okanye ezinzima.

- I-Two-Shot-Shot Molding Molding Machine: Oomatshini abadubula kabini bavelisa iindawo ezinezixhobo ezahlukeneyo okanye imibala. Isixhobo sineeyunithi ezimbini zokutofa, nganye iyakwazi ukutofa izinto zangaphandle kubumba. Olu hlobo lomatshini luqhele ukusetyenziswa ukuvelisa iinxalenye zemoto, njengezibambo kunye namaqhina.

- I-Multi-Shot Injection Molding Machine: Oomatshini abaninzi bavelisa iinxalenye ezinezixhobo ezingaphezu kwezibini okanye imibala. Isixhobo sineeyunithi ezininzi zokutofa, nganye iyakwazi ukutofa izinto ezahlukeneyo kubumba. Olu hlobo lomatshini luqhele ukusetyenziswa ukuvelisa izinto ezithengwayo, ezifana neebhrashi zamazinyo kunye neencakuba.

- Umatshini wokubumba woMbane woMbane woMbane: Bonke oomatshini bombane basebenzisa iimotor zombane ukunika amandla iyunithi yokutofa, i-clamp mechanism, kunye nokungunda. Baziwa ngokuchaneka okuphezulu, isantya, kunye nokusebenza kakuhle kwamandla, nto leyo eyenza ukuba badume ngokuvelisa iindawo ezincinci, ezichanekileyo.

Ezi zezinye zezona ntlobo zixhaphakileyo zoomatshini bokubumba inaliti. Umatshini ngamnye uneempawu ezizodwa kunye neenzuzo, okwenza kube yimfuneko ukukhetha isixhobo esifanelekileyo kwiimfuno ezithile zokwenziwa.

Iinxalenye zoMshini wokuMbumba wokuTofwa

Oomatshini bokubumba be-injection baneendawo ezininzi ezenza iinxalenye zeplastiki kwizinto eziluhlaza. Nanga amacandelo abalulekileyo omatshini wokubumba inaliti:

IHopper: Indawo yokugcina amanzi eplastiki ekrwada phambi kokuba ifakwe kumatshini wokubumba inaliti. Izinto eziphathekayo ngokuqhelekileyo zikwimo yeepellets okanye umgubo.

Umgqomo: Umphanda yinxenye ende, engqukuva yomatshini wokubumba inaliti ogcina isikrufu, esinyibilika kwaye sixube imathiriyeli yeplastiki.

Isikruru: Isikrufu sisixhobo esijikelezayo ngaphakathi komphanda esityhala imathiriyeli yeplastiki ukuya phambili kwaye siyinyibilikise ngokukhuhlana nobushushu.

Iyunithi yokutofa: Iyunithi yokutofa ibandakanya i-hopper, i-barrel, kunye ne-screw kwaye inoxanduva lokunyibilika kunye nokufaka iplastiki kwi-mold.

Iyunithi ye-clamping: Iyunithi ye-clamping inoxanduva lokubamba ngokukhuselekileyo isikhunta kunye nokusebenzisa uxinzelelo oluyimfuneko ngexesha lenkqubo yokubumba i-injection.

Umngundo: Umngundo sisixhobo esenza imilo kunye nobukhulu benxalenye yeplastiki. Umngundo wenziwa ngentsimbi kwaye unesiqingatha ezibini ezidityanisiweyo.

Umbhobho: Umbhobho yinxalenye yeyunithi yokutofa edibanisa umatshini wokubumba inaliti kumngundo. Izinto zeplastiki ezinyibilikisiweyo zitofwa nge-nozzle kunye ne-mold.

Isixokelelwano sokupholisa: Inkqubo yokupholisa inoxanduva lokupholisa inxalenye yeplastiki xa sele itofwe kubumba. Oku kuqinisekisa ukuba isiqwenga siqinisiwe kwaye sinokususwa kwi-mold ngaphandle komonakalo.

Iphaneli yokulawula: Iphaneli yolawulo lujongano oluvumela umqhubi ukuba abeke iliso kwaye ahlengahlengise useto lomatshini wokubumba inaliti, njengobushushu, uxinzelelo kunye nexesha lokujikeleza.

Nganye kwezi nxalenye zidlala indima ebalulekileyo kwinkqubo yokubumba inaliti, kwaye kubalulekile ukugcina kunye nokwandisa iqhekeza ngalinye ukuqinisekisa ukuba iindawo ezikumgangatho ophezulu ziveliswa ngokufanelekileyo.

I-injection Molding Tooling: Uyilo kunye nokuVeliswa

Isitofu sokubumba isixhobo sibhekisa ekuyileni nasekuveliseni imibumba esetyenziswa kumatshini wokubumba inaliti ukuvelisa iinxalenye zeplastiki. Umgangatho kunye nokusebenza kakuhle kwe-molds kuchaphazela ngokuthe ngqo umgangatho kunye nemveliso yenkqubo yokubumba inaliti. Nanga amanyathelo abalulekileyo kuyilo kunye nokwenziwa kwesitofu sokubumba isixhobo:

Uyilo lwemveliso: Inyathelo lokuqala kwisixhobo sokubumba isitofu kukuyila imveliso eza kuveliswa. Uyilo lwemveliso lubandakanya ukumisela ubungakanani benxalenye, imilo, kunye nezinto eziphathekayo, kunye nazo naziphi na iimpawu okanye iimfuno ezithile.

Uyilo lokungunda: Inkqubo yoyilo lokungunda iqala xa uyilo lwemveliso lugqityiwe. Umyili uya kugqiba olona hlobo lokungunda, inani lemingxuma efunekayo, kunye nobukhulu kunye nokumila komngundo.

Ukwakhiwa kwe-Mold: I-mold yakhiwe ngokusekelwe kuyilo lokubumba, usebenzisa izinto eziphezulu ezifana nentsimbi okanye i-aluminium. Ukungunda kwenziwa ngokwesiqhelo kwiziqingatha ezibini, ngasinye sinemingxuma enye okanye ngaphezulu.

Ukudityaniswa kokungunda: Emva kokuba isikhunta senziwe, sidityaniswe kwaye sivavanywe ukuchaneka kunye nokusebenza. Umngundo kufuneka umelane noxinzelelo kunye nobushushu benkqubo yokubumba inaliti.

Uvavanyo kunye nokuqinisekiswa kwe-mold: Emva kokuba i-mold ihlanganiswe, ivavanywa kwaye iqinisekisiwe ukuqinisekisa ukuba ivelisa iindawo eziphezulu ezihambelana neenkcukacha zemveliso. Umngundo unokufuna ukulungiswa okanye ukuguqulwa ukuphucula ukusebenza kwawo.

Ukugcinwa kwesikhunta: Ukugcinwa rhoqo kunye nokulungiswa kwesikhunta kubalulekile ukuqinisekisa ukuba ixesha elide kunye nokusebenza kwalo. Oku kuquka ukucoca, ukuthambisa, kunye nokutshintsha naziphi na iindawo ezigugileyo okanye ezonakeleyo.

Isitofu sokubumba isixhobo sifuna ukuchaneka kunye nobuchule ukuvelisa iindawo ezikumgangatho ophezulu ngokungaguquguqukiyo nangempumelelo. Ngokulandela uyilo olupheleleyo kunye nenkqubo yokuvelisa, abavelisi banokwenza iimbumba ezihlangabezana neemfuno ezizodwa zeemveliso zabo kunye nokwandisa iinkqubo zabo zokubumba inaliti.

Iintlobo zesitofu sokuBumba iZixhobo

Isitofu sokubumba yinkqubo yokuvelisa esetyenziswa ngokubanzi ukuvelisa iinxalenye ngobuninzi. Kubandakanya ukutofa iplastiki enyibilikisiweyo kumngxuma wokungunda kwaye uyivumele ukuba iphole kwaye iqine ibe kukumila okufunayo. I-injection molding tooling yinkqubo yokudala i-molds esetyenziselwa ukubumba inaliti. Kukho iintlobo ezininzi zesixhobo sokubumba inaliti, nganye ineengenelo zayo kunye nokungalunganga.

- IiMbumba zePlate-ezimbini Ukubumba kweepleyiti ezimbini lolona hlobo lulula lwesixhobo sokubumba inaliti. Ziquka iipleyiti ezimbini ezidityanisiweyo ukuze zenze umngxuma wokungunda. Iplastiki etyhidiweyo igalelwa emngxunyeni ngesango kwaye iyekwe ukuba iphole kwaye iqine. Emva kokuba inxalenye idalwe, iiplati ezimbini ziyahlukana, kwaye isixa siyakhutshwa. Iimbumba ezimbini zeepleyiti ziqhele ukusetyenziselwa izinto ezincinci ukuya kweziphakathi kunye neejometri ezilula.

- I-Three-Plate Molds I-molds ye-plate ezintathu ifana ne-plate-plate molds, kodwa ine-plate eyongezelelweyo, eyaziwa ngokuba yi-stripper plate, eyahlula inxalenye ebunjiweyo kwinkqubo yomgijimi. Inkqubo yembaleki ngumnatha womjelo ohambisa iplastiki etyhidiweyo kumgodi wokungunda. Iimold zeplate ezintathu zisetyenziselwa iindawo ezibalulekileyo kunye neejometri ezinzima.

- Ukungunda kweMbaleki eshushu Kungundo lweembaleki ezishushu, iplastiki etyhidiweyo itofwa ngokuthe ngqo kumngxuma wokungunda ngothotho lwemijelo eshushu endaweni yokungena ngesango. Oku kunciphisa izinto ezichithwayo kwi-runner system, okubangela inkqubo esebenzayo. Iifom zomgijimi ezishushu zisetyenziselwa ukuveliswa kwevolumu ephezulu yamacandelo anzima.

- IiMngundo zoSapho Imingundo yosapho ivelisa iindawo ezininzi kumngundo omnye. Zinemingxuma eyahlukeneyo elungiselelwe ngendlela evumela ukuveliswa kwemimandla emininzi ngaxeshanye. Iimbumba zentsapho ziqhele ukusetyenziswa kwiindawo ezinobungakanani obuncinci ukuya kobukhulu obuphakathi.

- Faka ii-Molds Faka ii-molds zivelisa iindawo ezifuna ukufakwa kwentsimbi okanye iplastiki. Izinto ezifakwayo zifakwa kumngxuma wokungunda phambi kokutofa iplastiki etyhidiweyo. Emva kokuba iplastiki ipholile kwaye iqiniswe, inxalenye kunye nokufakwa kufakwe ngokusisigxina. Faka iimolds zisetyenziselwa izikhundla ezifuna ukomelela, ukuqina, okanye ukubhenela ubuhle.

- I-Overmolding Overmolding yinkqubo apho inxalenye ibunjwa ngaphezu kwenye. Ihlala isetyenziselwa izikhundla ezifuna ukubamba okuthambileyo okanye ukubamba okuphuculweyo. Ukugqithisa kubandakanya ukuseta i-substrate okanye inxalenye yesiseko kuqala kunye nokubumba into yesibini phezu kwayo. Isixhobo sesibini sinokuba luhlobo olwahlukileyo lweplastiki, irabha efana nerabha, okanye i-elastomer ye-thermoplastic.

Ukuqukumbela, ukhetho lwesixhobo sokubumba isitofu sixhomekeke kuhlobo lwenxalenye eveliswayo, umthamo ofunekayo wemveliso, kunye nenqanaba lobunzima obubandakanyekayo kuyilo lwenxalenye. Ukukhetha izixhobo ezifanelekileyo kubalulekile ukuqinisekisa ukuba inkqubo iyasebenza kwaye ayinandleko.

Izikhokelo zoYilo lwesitofu sokubumba

Isitofu sokubumba yinkqubo yokuvelisa esetyenziswa ngokubanzi ukuvelisa iinxalenye zeplastiki. Ukuyila iinxalenye zokubumba inaliti kufuna ukuqonda kakuhle inkqubo, izixhobo, kunye nezikhokelo zoyilo ekufuneka zilandelwe ukuqinisekisa ukuba iinkcukacha zinokwenziwa ngempumelelo. Nazi ezinye izikhokelo zoyilo lokubumba lokutofa ekufuneka uzigcine engqondweni:

Ukutyeba kweendonga, Ubukhulu bodonga lwenxalenye kufuneka bufane kwaye bube mncinci ngokusemandleni ngelixa ugcina amandla afunekayo kunye nokusebenza. Oku kunceda ukunciphisa ixesha lokupholisa kunye nomjikelo kunye nokunciphisa umngcipheko we-warping kunye namanqaku e-sink.

Iimbambo kunye neeBosi Iimbambo kunye nabaphathi zingasetyenziselwa ukunyusa amandla kunye nokuqina kwenxalenye. Iimbambo kufuneka zingabi ngaphezu kwe-60% yobukhulu bodonga oluqhelekileyo, kwaye abaphathi kufuneka babe ngamaxesha angama-1.5 ubukhulu bodonga.

I-Angle eyidrafti, i-angle eyidrafti yobuncinci i-1-2 degrees kufuneka isetyenziswe kuzo zonke iindawo ezithe nkqo ukuququzelela ukukhutshwa kwenxalenye kunye nokukhusela umonakalo kwi-mold.

Iifillet kunye neRadii Iikona ezibukhali kunye nemiphetho kufuneka zigwenywe ukukhusela uxinzelelo lwengqondo, olunokubangela ukuqhekeka kunye nokungaphumeleli. Endaweni yoko, iifillet kunye neradii kufuneka zisasaze uxinzelelo kwaye ziphucule amandla enxalenye.

Iigeyithi kunye neeMbaleki Indawo kunye noyilo lwamasango kunye neembaleki zibalulekile ekuphumezeni umgangatho olungileyo. Amangeno kufuneka abe mancinci kangangoko kwindawo engqindilili yenxalenye. Iimbaleki kufuneka ziyilelwe ukunciphisa uxinzelelo kunye nokwandisa ukuhamba.

Umphezulu Ukugqibezela Umphezulu wecandelo kufuneka ucaciswe ngokusekelwe kwiimfuno zesicelo. Ukugqitywa komgangatho ophezulu kunokufuneka kwiinqununu ezibonakalayo, ngelixa ukugqiba umgangatho ophantsi kunokwamkeleka kwiindawo ezifihlakeleyo.

Ukukhethwa kwezinto eziphathekayo Izinto ezikhethiweyo zenxalenye kufuneka zilungele ukubumba inaliti kwaye zihlangabezane nezixhobo ezifunekayo zomatshini, i-thermal, kunye neekhemikhali.

Imisebenzi yeSekondari kwi-Injection Molding

Isitofu sokubumba yinkqubo yokwenza izinto ezininzi esetyenziselwa ukuvelisa iindawo ezahlukeneyo zeplastiki. Ukongeza kwinkqubo yokubumba ephambili, izikhundla ezininzi zifuna imisebenzi yesibini ukufezekisa imilo efunekayo, ukugqiba, okanye ukusebenza. Nantsi imisebenzi yesibini yemihla ngemihla yokubumba inaliti:

- Ukucheba kukususa imathiriyeli engaphezulu kwindawo ebunjiweyo emva kokuba ikhutshiwe kumngundo. Oku kuqhele ukwenziwa kusetyenziswa i-trim press okanye umatshini we-CNC. Ukucheba kudla ngokufuneka ukuphumeza imilo yokugqibela kunye nobukhulu benxalenye.

- I-Welding idibanisa iiplasitiki ezimbini okanye ngaphezulu usebenzisa ubushushu, uxinzelelo, okanye indibaniselwano yazo zombini. Oku kudla ngokusetyenziswa ukwenza izinto ezinkulu okanye ezintsonkothileyo ezingenakuveliswa kubumba olunye.

- Ukuhlobisa yinkqubo yokongeza iimpawu ezibonakalayo okanye ezisebenzayo kumphezulu wecandelo elibunjiweyo. Oku kunokubandakanya ukupeyinta, ukuprinta, ukuleyibheli, okanye ukusebenzisa ukuthungwa okanye ipateni.

- INdibano yinkqubo yokudibanisa iinxalenye ezininzi ukwenza imveliso epheleleyo. Oku kunokwenziwa ngokusebenzisa iziqhoboshi, izinto zokuncamathelisa, okanye ezinye iindlela zokuhlanganisa.

- Faka ukubumba Ukubumba iplastiki yokubumba intsimbi esele yenziwe ngaphambili okanye ifake iplastiki. Oku kudla ngokusetyenziswa ukwenza iinxalenye ezinomgangatho ophezulu wamandla okanye ukuqina.

- I-Overmolding Overmolding yinkqubo yokubumba into yesibini phezu kwenxalenye eyenziwe ngaphambili. Oku kunokongeza i-soft-touch surface, ukuphucula ukubamba, okanye ukudala ithoni ezimbini okanye i-multi-material piece.

- I-coating isebenzisa umaleko wezinto ezincinci kumphezulu wenxalenye ukuphucula inkangeleko yayo, ukuqina, okanye ezinye iipropathi. Oku kunokubandakanya iingubo ezifana ne-chrome, i-nickel, okanye i-powder coatings.

Izinto eziluncedo zeplastiki Inaliti Ukubumbela

Ukubumba inaliti yeplastiki yinkqubo yokuvelisa esetyenziswa ngokubanzi ukuvelisa iinxalenye zeplastiki ngokuchaneka okuphezulu, ukungaguquguquki, kunye nomgangatho. Kubandakanya ukutofa iplastiki enyibilikisiweyo kwindawo yokungunda kwaye uyivumele ukuba iphole kwaye yomelele. Nazi ezinye iingenelo zokubumba inaliti yeplastiki:

- UkuSebenza okuPhezulu kunye neMveliso yokubumba inaliti yePlastiki yinkqubo esebenza kakhulu kwaye izenzekelayo enokuthi ivelise umthamo omkhulu wamacandelo kunye nokuhambelana okuphezulu kunye nomgangatho. Ngetekhnoloji ye-automation ephezulu, ixesha lomjikelezo wemveliso lingancitshiswa libe yimizuzwana, evumela ukuveliswa kwevolumu ephezulu yamacandelo anzima kunye anzima.

- Ukuchaneka okuphezulu kunye nokuchaneka kwe-Injection ukubumba kwandisa ukuchaneka kunye nokuchaneka ekuveliseni iindawo ezinzima kunye neziyinkimbinkimbi. Oomatshini abalawulwa yikhompyuter kunye nesoftware ephucukileyo yenza ukunyamezelana okuqinileyo kunye nokuphindaphindwa okuphezulu kunye nokuchaneka.

- I-Versatility Isitofu sokubumba yinkqubo eguquguqukayo enokuvelisa uluhlu olubanzi lweengxenye zeplastiki ezinobukhulu obahlukeneyo, iimilo kunye nobunzima. Inkqubo ingasetyenziselwa ukwenza yonke into ukusuka kumaqhekeza amancinci kunye neenkcukacha eziyinkimbinkimbi ukuya kwiimali ezinkulu kunye neejometri eziyinkimbinkimbi.

- I-Material Flexibility Isitofu sokubumba unokusebenzisa uluhlu olubanzi lwezinto zeplastiki, kubandakanywa i-thermoplastics, i-thermosets, kunye ne-elastomers. Oku kuvumela ukuvelisa iinxalenye ezinomatshini, i-thermal, kunye neekhemikhali ezahlukeneyo.

- Ukwenziwa kweNkunkuma ePhantsi Ukubumba Isitofu yinkqubo yokuvelisa inkunkuma ephantsi njengoko ivelisa inkunkuma encinci ngexesha lemveliso. Nayiphi na imathiriyeli engaphezulu inokuphinda isetyenziswe ngokulula kwaye iphinde isetyenziswe kwimveliso, oko kuyenza ibe yinkqubo yokwenziwa kwendalo ehambelana nokusingqongileyo.

- Iindleko eziNcitshisiweyo zeMisebenzi Iqondo eliphezulu lokuzisebenzela ekubumbeni inaliti linciphisa imfuno yeenkqubo ezifuna abasebenzi abaninzi, linciphisa kakhulu iindleko zabasebenzi. Oku kwakhona kunciphisa umngcipheko wempazamo yomntu, ukuphucula umgangatho wemveliso yokugqibela kunye nokuhambelana.

- Ukuncitshiswa kweMisebenzi ye-Post-Production I-injection molding ivelisa iinxalenye ngokuchaneka okuphezulu kunye nokuhambelana, ukunciphisa imfuno yemisebenzi ye-post-production efana ne-trimming, i-drilling, okanye i-milling. Oku kunciphisa ixesha lokuvelisa kunye neendleko zemveliso yokugqibela.

- Ukuhambelana kunye nokubumba kwe-Injection yoMgangatho kuvelisa iindawo ezinomgangatho ophezulu wokuhambelana kunye nomgangatho. Itekhnoloji ephezulu kunye noomatshini abalawulwa yikhompyuter baqinisekisa ukuba zonke iinkcukacha ziyafana ngokumila, ubungakanani kunye nomgangatho.

- Uyilo lokubumba lokutofa lokutofa lubonelela ngenqanaba eliphezulu lokuguquguquka koyilo, njengoko livumela ukuvelisa iinxalenye ezinejometri ezintsonkothileyo, ii-undercuts, kunye neenkcukacha ezintsonkothileyo. Oku kuya kwenza ukuba abaqulunqi benze iziqwenga ezinemilo ekhethekileyo kunye nemisebenzi engenakwenziwa ngokusebenzisa ezinye iinkqubo zokuvelisa.

- Indleko-esebenzayo kwi-High-Volume Production Injection molding yinkqubo eneendleko zokuvelisa iinxalenye zeplastiki. Iindleko zokuqala zezixhobo zinokuba phezulu, kodwa ixabiso ngenxalenye liyancipha njengoko umthamo wemveliso usanda. Oku kuyenza ibe yinkqubo efanelekileyo yokuvelisa izixa ezikhulu zamalungu.

Ukubumba inaliti yeplastiki inika iingenelo ezininzi, iyenza ibe lukhetho oludumileyo lokuvelisa iinxalenye zeplastiki. Ukusebenza kwayo okuphezulu, ukuchaneka, ukuguquguquka kwezinto, ukuguquguquka kwezinto eziphathekayo, ukuveliswa kwenkunkuma ephantsi, ukunciphisa iindleko zabasebenzi, kunye nokuhambelana kunye nomgangatho kwenza kube yinkqubo efanelekileyo kwizicelo ezahlukeneyo. Ukukwazi ukuvelisa iinxalenye ezinzima kunye neziyinkimbinkimbi kunye nokuguquguquka okuphezulu koyilo kunye neendleko-zokusebenza kwimveliso ephezulu yenza kube yinkqubo yokuvelisa efunwa kakhulu.

Ukungalungi kwePlastiki yeSitofu sokuBumba

Ukubumba inaliti yeplastiki yinkqubo yokuvelisa esetyenziswa ngokubanzi ebandakanya ukutofa iplastiki etyhidiweyo kwindawo yokungunda ukuvelisa uluhlu olubanzi lwamalungu eplastiki kunye neemveliso. Nangona ukubumba inaliti yeplastiki kuneenzuzo ezininzi, kukwakho nezinto ezingeloncedo. Nazi ezinye zezinto ezingalunganga zokubumba inaliti yeplastiki:

- Iindleko eziphezulu zokusebenzisa izixhobo: Iindleko zokuyila kunye nokuvelisa i-mold yokubumba inaliti yeplastiki ingaba phezulu kakhulu. Oku kungenxa yokuba umngundo kufuneka wenziwe ngezinto ezikumgangatho ophezulu kwaye zenziwe ngoomatshini ngokuchanekileyo ukwenza indawo efunwayo. Ukongeza, iindleko zokuyila kunye nokuvelisa ukungunda zinokuba zithintelo kwimveliso encinci yokuqhuba, ukwenza ukubumba inaliti yeplastiki kungabi naqoqosho kwimveliso enevolumu ephantsi.

- Amaxesha amade okukhokela: Inkqubo yokuyila kunye nokuvelisa ukubumba ukubumba inaliti yeplastiki kunokuthatha ixesha elide, elinokulibazisa ukuveliswa kwamalungu eplastiki. Oku kunokuba yingxaki ngakumbi kumashishini afuna ukuphendula ngokukhawuleza kwiinguqu kwimfuno yemarike okanye ukuphuhlisa ngokukhawuleza iimveliso ezintsha.

- Ukuguquguquka okulinganiselweyo: Nje ukuba umngundo uyilwe kwaye uveliswe, kulula kwaye kunexabiso eliphantsi ukutshintsha uyilo okanye ukuguqula inkqubo yemveliso. Oku kunokunciphisa ukuguquguquka kokubumba inaliti yeplastiki kwaye kuyenze ingalungeli kakhulu ukuvelisa isiko okanye imveliso enye yohlobo.

- Iinkxalabo zokusingqongileyo: Ukubumba inaliti yeplastiki kuxhomekeke kwisixa esikhulu seplastiki, esinokuba neempembelelo ezimbi kwindalo. Inkunkuma yePlastiki ngowona mba uphambili wokusingqongileyo, kwaye ukubumba inaliti yeplastiki kunokuba negalelo kule ngxaki. Ukongezelela, inkqubo yokuvelisa iimveliso zeplastiki idinga ukusetyenziswa kwamandla kunye nemithombo yendalo, enokuthi ibe nefuthe ngakumbi kwindalo.

- Amazinga aphezulu okulahlwa: Ukubumba inaliti yeplastiki kunokuvelisa izinto ezilahliweyo ezibalulekileyo, ezinokubiza ukulahla okanye ukuphinda zisetyenziswe. Ukongezelela, ukuveliswa kwezinto ezilahliweyo kunokunyusa iindleko zokuvelisa ngokubanzi kunye nokunciphisa ukusebenza kakuhle kwenkqubo yokuvelisa.

- Iinketho zemathiriyeli ezilinganiselweyo: Ukubumba inaliti yeplastiki kusetyenziswa ikakhulu ukuvelisa iinxalenye kunye neemveliso ezivela kwimathiriyeli ye-thermoplastic, eneempawu ezilinganiselweyo xa kuthelekiswa nezinye izinto ezinjengeentsimbi okanye iiseramikhi. Oku kunokwenza ukubunjwa kwenaliti yeplastiki kungafanelekanga kakhulu kwizicelo ezifuna amandla aphezulu, ukumelana nobushushu, okanye ezinye iipropathi eziphambili.

Unyino lwePlastiki yokuTofa yokuBumba

Ngelixa ukubumba inaliti yeplastiki kubonelela ngeenzuzo ezininzi, imida ethile ikwanxulunyaniswa nenkqubo. Nantsi imida yokubumba inaliti yeplastiki:

Iindleko zokuQala eziPhezulu zokuSebenza: Iindleko zokuqala zokuyila kunye nokuvelisa ukungunda kunokunyuswa. Umngundo kufuneka uchaneke kwaye womelele ukuze umelane nenkqubo yokubumba inaliti ephindaphindiweyo, kwaye oku kunokufuna utyalo-mali lwangaphambili, ngakumbi kubumba obunzima okanye obukhulu.

Ixesha lokukhokela: Ixesha elikhokelayo lokuvelisa i-mold inokubaluleka, ukusuka kwiiveki ukuya kwiinyanga, kuxhomekeke kubunzima kunye nobukhulu bombumba. Oku kunokubangela ulibaziseko kwixesha lemveliso, ngakumbi kwiiprojekthi ezithatha ixesha.

Izithintelo zoyilo: I-injection molding inemida ethile yoyilo ekufuneka iqwalaselwe. Umzekelo, ukufezekisa ubukhulu bodonga obufanayo kuyo yonke indawo kubalulekile ukuqinisekisa ukuzaliswa nokupholisa okufanelekileyo. Ukongeza, ii-engile zokuyila ziyafuneka kumphezulu othe nkqo ukuze ukhuphe ngokulula kwimold.

Icandelo lokulinganiselwa kobungakanani: I-injection molding ifaneleke kakhulu ukuvelisa iindawo ezincinci ukuya kweziphakathi. Amalungu amakhulu anokufuna izixhobo ezikhethekileyo kunye nokubumba okukhulu, okongeza kwiindleko kunye nobunzima.

Ukukhetha izinto eziphathekayo: Ngelixa ukubunjwa kwenaliti kuvumela uluhlu olubanzi lwezixhobo zeplastiki, ukhetho lwempahla lusenomda xa kuthelekiswa nezinye iinkqubo zokuvelisa. Izinto eziphathekayo ezinamaqondo aphezulu okunyibilika okanye iimpawu zokuhamba kakubi zisenokungafaneleki ukubumba inaliti.

Ukugqitywa komphezulu: Inkqubo yokubumba inaliti inokubangela imigca edityanisiweyo ebonakalayo okanye imigca yokwahlula kumphezulu wenxalenye. Ukufezekisa ukugqiba umgangatho ophezulu kunokuba ngumngeni, kwaye ezinye iindlela, ezifana nokupholisa okanye ukugquma, kunokufuneka.

Ii-Undercuts ezilinganiselweyo: Ii-Undercuts ziimpawu okanye iinkcukacha kwinxalenye ethintela ukuba isuswe ngokulula kumngundo. Ii-Undercuts zinokwenza nzima inkqubo yokukhupha kwaye ifune iimpawu ezongezelelweyo zokubumba okanye imisebenzi yesibini ukufezekisa inxalenye efunekayo yejometri.

Izinketho zokuLungisa okulinganiselwe: Ukuba isikhunta sonakaliswe okanye sifuna ukuguqulwa, sinokubiza kunye nexesha elide ukulungisa okanye ukuguqula ukubumba okukhoyo. Ngamanye amaxesha, umngundo omtsha ngokupheleleyo unokufuna ukuveliswa, okukhokelela kwiindleko ezongezelelweyo kunye nokulibaziseka.

Ngaphandle kwale mida, ukubumba inaliti yeplastiki kuhlala kuyinkqubo eguquguqukayo kwaye isetyenziswa ngokubanzi ukuvelisa iinxalenye zeplastiki. Ngokuqwalasela ngononophelo le mida ngexesha loyilo kunye nenqanaba lokucwangcisa imveliso, kunokwenzeka ukunciphisa impembelelo yabo kunye nokuphucula ngokufanelekileyo izibonelelo zokubumba inaliti.

Usetyenziso lwePlastiki yokuTofa isitofu

Ukubumba inaliti yeplastiki yinkqubo yokwenza izinto ezininzi ezinokuvelisa uluhlu olubanzi lwamalungu eplastiki. Nazi ezinye zezicelo zokubumba inaliti yeplastiki:

- Iimveliso zabathengi: Isitofu sokubumba sisetyenziswa ngokubanzi ukuvelisa iimveliso ezahlukeneyo, ezifana nezinto zokudlala, izixhobo zasekhitshini kunye nezixhobo zombane. Inkqubo inokuvelisa iindawo ezikumgangatho ophezulu ezinejometri entsonkothileyo kunye nemilinganiselo echanekileyo, iyenza ilungele iimveliso ezifuna ukunyamezelana okuqinileyo kunye neemilo ezinzima.

- Amacandelo ezeMoto: Izinto ezininzi zeplastiki zemoto, ezinje ngezixhobo zedeshibhodi, izibambo zocango, kunye nezibane, ziveliswa kusetyenziswa isitofu sokubumba. Inkqubo ivumela umthamo ophezulu wemveliso kunye nomgangatho ohambelanayo, okwenza kube yinto engabizi kakhulu kubenzi beemoto.

- Izixhobo zonyango: Isitofu sokubumba ngokuqhelekileyo sisetyenziselwa ukuvelisa izixhobo zonyango, njengesirinji, ii-inhalers, kunye nezixhobo zokuxilonga. Inkqubo inokuvelisa iinxalenye ngokuchaneka okuphezulu kunye nokuhambelana, ukuqinisekisa umgangatho kunye nokuthembeka kwezixhobo.

- Ukupakishwa: Isitofu sokubumba sisetyenziswa ngokubanzi ukuvelisa ukupakishwa kweplastiki, njengezikhongozeli, iziciko, kunye neminqwazi. Inkqubo ingaba neengxenye ezinobungakanani obuhambelanayo kunye nokugqitywa komgangatho ophezulu, okwenza kube yinto efanelekileyo yokupakisha ngenkangeleko ekhangayo kunye nokugcinwa okukhuselekileyo.

- I-Aerospace kunye noKhuseleko: I-injection molding ivelisa i-aerospace eyahlukeneyo kunye nezixhobo zokukhusela, ezifana neendawo zangaphakathi zenqwelomoya, ukukhanya, kunye neenkqubo zonxibelelwano. Inkqubo ingaba neengxenye ezinobunzima, izinto ezihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala khona.

- Ulwakhiwo: Isitofu sokubumba sinokuvelisa izinto ezahlukeneyo zokwakha, ezinjengeethayile zeplastiki, ukufulela, kunye necala. Inkqubo ingaba neengxenye ezinobungakanani obuhambelanayo kunye nokugqitywa komgangatho ophezulu, okwenza kube yinto ekhangayo kwiinkampani zokwakha.

- Ezemidlalo noLonwabo: Isitofu sokubumba sisetyenziswa kakhulu ekuveliseni izixhobo zemidlalo, njengeeklabhu zegalufa, iirakethi zentenetya, kunye namacandelo ebhayisekile. Inkqubo inokuvelisa iinxalenye ezinezixhobo ezilula kunye neejometri ezichanekileyo, ukuqinisekisa ukusebenza kunye nokuqina kwezixhobo.

Lilonke, ukubumba inaliti yeplastiki yinkqubo yokwenza izinto ezininzi kwaye isetyenziswa ngokubanzi enokuvelisa iinxalenye zeplastiki ezikumgangatho ophezulu kwizicelo ezahlukeneyo. Inkqubo inokulungelelaniswa ukuhlangabezana neemfuno ezithile zoyilo kunye nemveliso, okwenza kube yindlela ekhangayo kubavelisi kumashishini amaninzi.

Ishishini leeMoto kunye nePlastiki yokuTofa isitofu

Umzi-mveliso weemoto ungumsebenzisi obalulekileyo weteknoloji yokubumba inaliti yeplastiki. Inkqubo yokubumba inaliti yeplastiki iguqule ukuveliswa kwamalungu eemoto kunye namacandelo, okwenza kube lula ukuvelisa iimilo eziyinkimbinkimbi ngokuchaneka okuphezulu kunye nokuchaneka. Nazi ezinye zeendlela zokubumba inaliti yeplastiki esetyenziswa kushishino lweemoto:

- Amalungu angaphakathi: Ukubumba inaliti yeplastiki kuvelisa izinto ezininzi zangaphakathi, kubandakanywa amacandelo edeshibhodi, iipaneli zocango, iziqwenga ze-trim, kunye nokunye. La malungu anokuthi ayilwe ngeemilo ezintsonkothileyo kunye nokwakheka kwaye alungele ukuhambelana nesitayile semoto nganye kunye neemfuno zokusebenza.

- Amalungu angaphandle: Isitofu seplastiki sokubumba sikwasetyenziselwa ukuvelisa iimpawu ezahlukeneyo zangaphandle, kuquka ii-bumpers, i-grilles, izibuko ezisecaleni kunye nokunye. Ezi nxalenye zinokuthi ziyilwe ukumelana neemeko zemozulu ezigqithisileyo kwaye zenziwe ngemibala emininzi kunye nokugqitywa.

- Amacandelo angaphantsi kwe-hood: I-injection yeplastiki yokubumba ivelisa izinto ezininzi eziphantsi kwe-hood, kubandakanywa izigqubuthelo zenjini, iinkqubo zokungenisa umoya, kunye neendawo zokupholisa. Ezi zixhobo zifuna ukushisa okuphezulu kunye nokuchasana kweekhemikhali, ezinokufezekiswa ngezinto ze-thermoplastic.

- Amalungu ombane kunye ne-elektroniki: Isitofu seplastiki sokubumba sivelisa izinto ezahlukeneyo zombane kunye ne-elektroniki, kubandakanywa izihlanganisi, izindlu, kunye nezinzwa. Ezi zixhobo zifuna ukuchaneka okuphezulu kunye nokuthembeka, okunokuthi kufezekiswe ngokuchaneka kunye nokuhambelana kweplastiki yokubumba inaliti.

- I-Lightweighting: I-injection yeplastiki yokubumba isetyenziselwa ukuvelisa iindawo ezilula ezinceda ukunciphisa ubunzima besithuthi, ukuphucula ukusebenza kakuhle kwamafutha kunye nokunciphisa ukukhutshwa. Ukukhanya okulula kunokuphucula ukuphathwa kunye nokusebenza kwesithuthi.

Ishishini lezoNyango kunye nokuBunjwa kwesitofu sePlastiki

Ukubumba inaliti yeplastiki isetyenziswa ngokubanzi kushishino lwezonyango ukuvelisa izixhobo zonyango ezahlukeneyo kunye namacandelo. Inkqubo yokubumba inaliti yeplastiki ivumela ukuveliswa kweemilo eziyinkimbinkimbi ngokuchaneka okuphezulu kunye nokuchaneka, okwenza kube yindlela efanelekileyo yokuvelisa kwizicelo ezininzi zonyango. Nazi ezinye zeendlela zokubumba inaliti yeplastiki esetyenziswa kushishino lwezonyango:

- Izixhobo zonyango: Isitofu seplastiki sokubumba sivelisa izixhobo ezahlukeneyo zonyango, kubandakanywa izixhobo zotyando, izixhobo zokuxilonga, iinkqubo zokuhanjiswa kweziyobisi, njl. Ezi zixhobo zihlala zifuna ukuchaneka okuphezulu kunye nokuchaneka, kunye nokubumba kweplastiki yeplastiki kunokuhlangabezana nezi mfuno.

- Ukufakelwa: Ukufakelwa kwesitofu seplastiki kukwasetyenziselwa ukuvelisa iintlobo ezahlukeneyo zokufakelwa, kubandakanywa ukutshintshwa kwamalungu, ukufakelwa kwamazinyo, kunye nokunye. Ezi zihlomelo zinokuyilwa ukuba zihambelane ne-anatomy yesigulana kwaye ziveliswe ngezinto ezihambelana ne-biocompatible.

- Izixhobo zaselabhoratri: Ukubumba inaliti yeplastiki kuvelisa iipayipi, ii-microplates, kunye neetyhubhu zokuvavanya. La macandelo afuna ukuchaneka okuphezulu kunye nokuchaneka ukuqinisekisa iziphumo ezithembekileyo.

- Ukupakishwa: Isitofu seplastiki sokubumba sisetyenziselwa ukuvelisa ukupakishwa kwezixhobo zonyango, kubandakanywa neenkqubo zokuthintela iintsholongwane kunye nokupakishwa kwesiko kwimveliso nganye. Ezi zisombululo zokupakishwa zinokunceda ukugcina ubucwebe kunye nokuthembeka kwesixhobo sonyango.

- Izixhobo ezisetyenziswa kanye: Isitofu seplastiki sisoloko sivelisa izixhobo ezisetyenziswa kanye njengesirinji, iinaliti neecatheter. Ezi zixhobo zingenziwa ngomthamo ophezulu ngexabiso eliphantsi kwaye zinokunceda ukuthintela ukusasazeka kwezifo kwiindawo zempilo.

IiMveliso zoMthengi kunye nokuBunjwa kwesitofu sePlastiki

Ukubumba inaliti yePlastiki isetyenziswa kakhulu kwimveliso yeemveliso zabathengi ngenxa yokuguquguquka kwayo, ukusebenza kakuhle, kunye nokusebenza kakuhle kweendleko. Inkqubo yokubumba inaliti yeplastiki ivumela ukuveliswa kweemilo eziyinkimbinkimbi ngokuchaneka okuphezulu kunye nokuchaneka, okwenza kube yindlela efanelekileyo yokuvelisa kwizicelo ezininzi zabathengi. Nazi ezinye zeendlela zokubumba inaliti yeplastiki esetyenziswayo kwimveliso yeemveliso zabathengi:

- Izinto zokudlala: Ukubumba inaliti yeplastiki kuvelisa uluhlu olubanzi lweethoyi, ukusuka kwimifanekiso emincinci ukuya kwiiseti ezinkulu zokudlala. Inkqubo ivumela ukuyila uyilo oluntsonkothileyo kunye neenkcukacha kunye nokwenza amathoyizi ngemibala eyahlukeneyo kunye nemathiriyeli.

- Izinto zasekhaya: Isitofu seplastiki sokubumba sivelisa iimpahla zasekhaya ezahlukeneyo, eziquka izinto zasekhitshini, izitya zokugcina, nezinto zokucoca. Ezi mveliso zinokuyilwa ukuba zomelele, zibe khaphukhaphu, kwaye kube lula ukuzisebenzisa.

- I-Electronics: Ukubumba inaliti yeplastiki kuvelisa izinto ezininzi zombane, kubandakanywa izindlu zekhompyutha, iikesi zefowuni, kunye neetshaja. Ukuchaneka kunye nokuchaneka kwenkqubo kuqinisekisa ukuba la macandelo enziwe ngeqondo eliphezulu lokuhambelana nokuthembeka.

- Iimveliso zokuzinyamekela: Ukubumba inaliti yeplastiki kuvelisa imveliso ekhethekileyo yokunyamekela, kuquka ibhrashi yamazinyo, iincakuba, neebrashi zeenwele. Ezi mveliso zifuna ukuchaneka okuphezulu kunye nokuchaneka ukuqinisekisa ukukhululeka kokusetyenziswa kunye nokhuseleko.

- Izixhobo zemoto: Ukubumba inaliti yeplastiki kuvelisa uluhlu lwezixhobo zemoto, kubandakanywa amacandelo edeshibhodi, abaphethe iikomityi, kunye nokunye. Ezi zixhobo zinokuyilwa ukuba zibe khaphukhaphu, zomelele, kwaye zixhathise ukunxitywa kunye nokukrazula kokusetyenziswa kwemihla ngemihla.

Iingqwalasela zokusiNgqongileyo kwiPlastiki yesitofu sokuBumba

Ukubumba inaliti yeplastiki yinkqubo yokuvelisa esetyenziswa ngokubanzi kodwa ineempembelelo ezibalulekileyo zokusingqongileyo. Nazi ezinye zeengqwalasela ze-ikholoji ekubumbeni inaliti yeplastiki:

- Ukukhetha izinto eziphathekayo: Ukukhethwa kwezinto zeplastiki ezisetyenziselwa ukubumba inaliti kunokuchaphazela kakhulu okusingqongileyo. Ezinye izinto ziyakwazi ukubola okanye ziphinde zisetyenziswe, ngelixa ezinye azinjalo. Ukusebenzisa imathiriyeli enokubola okanye enokuphinda isetyenziswe kunokunceda ukunciphisa impembelelo yokusingqongileyo yokubumba inaliti yeplastiki.

- Ukusetyenziswa kwamandla: Ukubumba inaliti yeplastiki kufuna amandla abalulekileyo ukunyibilikisa iplastiki kunye nokuyitofa kwi-mold. Izixhobo ezisebenza ngamandla kunye neenkqubo, ezifana noomatshini bombane kunye neenkqubo ezivaliweyo, zinokunciphisa ukusetyenziswa kwamandla kunye nefuthe lokusingqongileyo.

- Ulawulo lweNkunkuma: Ukubumba inaliti yeplastiki kuvelisa inkunkuma kwizinto ezigqithisileyo, iindawo ezineziphene, kunye nokupakishwa. Imisebenzi yokulawula inkunkuma eyiyo, efana nokurisayikilisha kunye nokusetyenziswa kwakhona kwenkunkuma, kunokunceda ukunciphisa impembelelo yokusingqongileyo yokubumba inaliti yeplastiki.

- Ukusetyenziswa kweekhemikhali: Ezinye iikhemikhali ezikwizitofu zeplastiki, ezifana nezixhobo ezikhupha umngundo kunye nezinyibilikisi zokucoca, zinokuyonakalisa indalo esingqongileyo. Ukusebenzisa ezinye iindlela zokusingqongileyo okanye ukunciphisa ukusetyenziswa kwezi khemikhali kunokunceda ukunciphisa impembelelo yokusingqongileyo.

- Iingqwalasela zokuphela kobomi: Iimveliso zeplastiki eziveliswe ngokubumba inaliti zihlala ziphelela kwiindawo zokulahla inkunkuma, ezinokuthatha amakhulu eminyaka ukuthotywa. Ukuyila iimveliso zokuphinda zisetyenziswe okanye ukonakaliswa kwezinto eziphilayo kunokunciphisa impembelelo yokusingqongileyo yokubumba inaliti yeplastiki.

Ikamva lePlastiki yokuBonda isitofu

Ikamva lokubumba inaliti yeplastiki lijongeka lithembisa, njengoko inkqubela phambili yetekhnoloji kunye nemathiriyeli kulindeleke ukuba yenze inkqubo isebenze ngakumbi, ingabizi kakhulu, kwaye igcineke. Nazi ezinye zeendlela kunye nophuhliso olunokuthi lumise ikamva lokubumba inaliti yeplastiki:

- Imveliso eyongeziweyo: Imveliso eyongeziweyo, ekwabizwa ngokuba yi-3D yoshicilelo, bubuchwephesha obuvelayo obunokuthi buguqule ukubumba inaliti yeplastiki. Ngokusebenzisa ushicilelo lwe-3D ukwenza iimbumba, abavelisi banokunciphisa kakhulu ixesha kunye neendleko ezinxulumene nobuchule bokwenza umngundo.

- Ukwenziwa ngobuchule: Ukwenziwa ngobuchule, okubandakanya ukuzenzela, uhlalutyo lwedatha, kunye nokufunda koomatshini, kulindeleke ukuba kuguqule ukubumba inaliti yeplastiki. Abavelisi banokuphucula ukusebenza kakuhle, ukunciphisa inkunkuma, kunye nokwandisa imveliso ngokusebenzisa i-sensor kunye ne-analytics yedatha ukuphucula iinkqubo.

- Iimathiriyeli ezizinzileyo: Izinto ezigcinakalayo, ezifana ne-bioplastics kunye neeplastiki ezisetyenzisiweyo, ziya zithandwa kakhulu kushishino lokubumba inaliti yeplastiki. Ezi zixhobo zibonelela ngeenzuzo zokusingqongileyo kwaye zinokunceda abavelisi ukuba bahlangabezane neenjongo zokuzinza.

- Ukubumba iMicro: Ukubumba okuncinci, okubandakanya ukuvelisa iinxalenye ezincinci ngokuchaneka okuphezulu, kuya kubaluleka ngakumbi kumashishini afana nezempilo kunye ne-elektroniki. Ukuqhubela phambili kwitekhnoloji kunye nezixhobo kulindeleke ukuba zenze ukubumba okuncinci kufikeleleke ngakumbi kwaye kungabizi kakhulu.

- Ukwenziwa ngokwezifiso: Njengoko abathengi bafuna iimveliso ezenzelwe umntu ngakumbi, ukubunjwa kwenaliti yeplastiki kulindeleke ukuba kube bhetyebhetye kwaye kwenziwe ngokwezifiso. Inkqubela phambili kwitekhnoloji, njengengxelo yexesha langempela kunye nokufunda koomatshini, kuya kwenza ukuba abavelisi bavelise iimveliso zesiko ngokukhawuleza nangokufanelekileyo.

Isiphelo:

Ukubumba inaliti yePlastiki yinkqubo yokwenza izinto ezininzi ezininzi nesebenzayo ethe yaguqula ukuveliswa koluhlu olubanzi lweemveliso. Ukusuka kwizixhobo zonyango ukuya kumacandelo eemoto, ukubumba inaliti yeplastiki kunika iingenelo ezininzi ngaphezu kwezinye iinkqubo zokuvelisa, kubandakanya amazinga aphezulu emveliso, ukuguquguquka koyilo, kunye nokusebenza kakuhle kweendleko. Ngenkqubela phambili eqhubekayo kwitekhnoloji kunye nezixhobo, ikamva lokubumba inaliti yeplastiki likhangeleka liqaqambile, kwaye le nkqubo iya kudlala indima ebaluleke ngakumbi kushishino lwemveliso kwiminyaka ezayo.