Faka Ukubumba Isitofu

Faka isitofu sokubumba yinkqubo yokuvelisa esetyenziswa ngokubanzi ekuveliseni iinxalenye zeplastiki ezintsonkothileyo ezinamalungu afakwe ngaphakathi. Obu buchule bubandakanya ukufaka intsimbi okanye iinxalenye zeplastiki kumngxunya wokungunda phambi kwenkqubo yokubumba inaliti. Izinto ezityhidiweyo zihamba zijikeleze into efakiweyo, zenza ikhonkco eliqinileyo phakathi kwezinto ezimbini. Faka isitofu sokubumba kubonelela ngeenzuzo ezininzi, kubandakanya ukuphuculwa kokuguquguquka koyilo, ukunciphisa ixesha lokudityaniswa, kunye nokusebenza kwenxalenye eyongeziweyo. Esi sikhokelo sibanzi siya kuphonononga iindlela ezahlukeneyo, izibonelelo, kunye nokusetyenziswa kokufakwa kwesitofu sokubumba.

Yintoni Ukubumba Isitofu sokuFaka?

Ukubumba i-injection yinkqubo yokuvelisa esetyenziselwa ukudala iinxalenye ezahlukeneyo kunye neemveliso. Faka isitofu sokubumba luhlobo lwesitofu sokubumba esivumela ukufakwa kwezinto ezenziwe kwangaphambili, okanye ukufakwa, kwi-mold ngaphambi kokuba inkqubo yokubumba iqale. Obu buchule buvumela ukudalwa kweenxalenye ezifuna iimpawu ezithile ezinokuthi iindlela zokubumba zenaliti zemveli azikwazi ukufikelela.

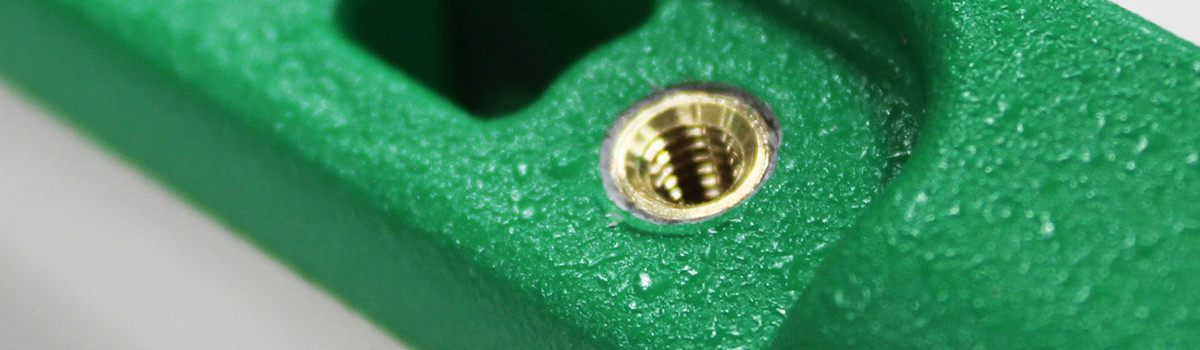

Faka umsebenzi wokubumba inaliti ngokubeka isifakelo esenziwe kwangaphambili kumgodi wokungunda phambi kokuba inkqubo yokubumba iqale. Ufakelo lunokuba nezinto ezahlukeneyo, kubandakanywa isinyithi, iplastiki, kunye neeseramikhi. Inkqubo yokubumba iqala njengesiqhelo, ngeplastiki enyibilikisiweyo itofelwe kumgodi wokungunda. Njengoko iplastiki ipholile kwaye iqina, idibanisa kunye nokufakwa, idala inxalenye enye, edibeneyo.

Zininzi iingenelo zokusebenzisa isitofu sokubumba. Enye yeenzuzo eziphambili zolu buchule kukuba ivumela ukudala iinxalenye ezineempawu ezithile ezinokuthi iindlela zokubumba zenaliti zendabuko azikwazi ukufikelela kuzo. Umzekelo, faka isitofu sokubumba singasetyenziswa ukuba umsebenzi ufuna ukufaka intambo okanye icandelo lesinyithi ukuqinisa. Obu buchule buvumela kwakhona ekudalweni kweengxenye kunye nendibaniselwano yezinto eziphathekayo, njengenxalenye yeplastiki kunye nokufakwa kwesinyithi.

Enye inzuzo yokubumba isitofu sokufaka kukonga ixesha kunye nemali. Endaweni yokudibanisa amacandelo amaninzi, faka isitofu sokubumba senze iqhekeza elinye, elidibeneyo. Ngokwenza njalo, iinkampani zinokunciphisa ixesha kunye neendleko ezifunekayo kwindibano.

Faka isitofu sokubumba kukwaluncedo ekwenzeni iindawo ezinzima. Ngenxa yokuba ukufakwa kunokubekwa kumngxunya wokungunda phambi kokuba inkqubo yokubumba iqale, kuyenzeka ukuvelisa iinxalenye ezinejiyometri entsonkothileyo kunye neempawu ezinokuba nzima ukufikelela kuzo ngeendlela zokubumba zenaliti zesintu.

Isebenza Njani Ukubumba Isitofu?

Luhlobo lwenkqubo yokubumba i-injection evumela ukufakwa kwamacandelo angaphambili, okanye ukufakwa, kwi-mold ngaphambi kokuba inkqubo yokubumba iqale. Obu buchule buvumela ukwenza iziqwenga ezineempawu ezithile ezinokuthi iindlela zokubumba zenaliti zemveli zingakwazi ukufikelela kwaye ziluncedo ngakumbi ekudaleni iindawo ezinzima. Apha siza kuxoxa ngendlela yokufaka isitofu sokubumba imisebenzi.

Inkqubo yokubumba yokufaka inaliti ibandakanya la manyathelo alandelayo:

- Faka indawo yokubeka:Inyathelo lokuqala kwinkqubo yokubumba inaliti yokufaka kukubeka i-preformed ifake kwi-mold cavity. Abavelisi banokuvelisa olu fakelo kwizinto ezahlukeneyo, njengentsimbi, iplastiki, okanye iiseramikhi.

- UkuBamba uMngundo:Umngundo uyavalwa kwaye ubotshwe uvale xa kufakwe indawo. Injongo kukugcina ukufakwa kwindawo ngexesha lokubumba.

- Isitofu sePlastiki etyhidiweyo:Inkqubo yokubumba isitofu ifaka iplastiki etyhidiweyo kwindawo yokungunda. Abavelisi bakholisa ukufudumeza iplastiki kwiqondo lobushushu eliphakathi kwama-200 kunye nama-300 degrees Celsius, beyimisela ngokusekelwe kwiplastiki ethile esetyenzisiweyo.

- Ukupholisa kunye nokuqinisa: Njengoko iplastiki ipholile kwaye iqina, idibanisa kunye nokufakwa, idala inxalenye enye, edibeneyo. Ixesha lokupholisa kunye nokuqina lixhomekeke kwiplastiki ethile esetyenzisiweyo kunye nobunzima bokuvelisa iqhekeza.

- Ukuvulwa kokungunda kunye nokuKhutshwa: Emva kokuba inxalenye ipholile kwaye iqinile, umqhubi uvula i-mold kwaye ayikhuphe into. Isiqwenga sinokugqitywa kwaye silungiselelwe ukusetyenziswa.

Zininzi iingenelo zokusebenzisa isitofu sokubumba. Ezinye zezi zibonelelo ziquka:

- Ukukwazi ukwenza iinxalenye ezineempawu ezithile ezinokuthi iindlela zokubumba zenaliti zemveli azikwazi ukufikelela

- Izinto zingenziwa njengeqhekeza elilodwa, elidibeneyo, elibangela ukunciphisa ixesha lokudibanisa kunye neendleko

- Ukukwazi ukwenza iindawo ezinzima kunye neejometri ezinzima kunye neempawu

- Ukukwazi ukusebenzisa izinto ezahlukeneyo, kubandakanya isinyithi, iplastiki kunye neekeramics

- Isitofu sokubumba yinkqubo esebenza kakuhle kwaye ephindaphindwayo enokuvelisa inani elikhulu lamalungu ngokuchaneka okuphezulu kunye nokuchaneka.

Iindidi zoFakelo eziSetyenzisiweyo kwi-Injection Molding

Abavelisi banokusebenzisa izinto ezahlukahlukeneyo, kuquka isinyithi, iplastiki, kunye neeseramikhi, ukwenza izinto ezifakwayo. Olu fakelo luvumela ukudalwa kwamalungu aneempawu ezithile ezinokuthi iindlela zokubumba zesitofu zesintu zingakwazi ukufikelela kuzo. Apha siza kuxoxa ngeentlobo ezahlukeneyo zofakelo olusetyenziswa ekubumbeni inaliti.

- Izinto zentsimbi:Ukufakwa kwesinyithi ngokuqhelekileyo kusetyenziselwa ukubunjwa kwenaliti ukunika amandla okongeziweyo kunye nokuzinza kwiindawo zeplastiki. Ngokuqhelekileyo zenziwe ngobhedu, intsimbi, okanye i-aluminiyam kwaye inokudityaniswa okanye ingafundwanga, kuxhomekeke kwisicelo. Abavelisi banokusebenzisa ukufakwa kwesinyithi ukwenza iinxalenye ezinejometri ezintsonkothileyo kunye nezinto ezifuna amandla aphezulu kunye nokuqina.

- Izinto zePlastiki: Ukufakwa kweplastiki ngokuqhelekileyo kusetyenziselwa ukubumba inaliti ukuxhasa kunye nokomeleza iinxalenye zeplastiki. Ngokuqhelekileyo zenziwe nge-nayiloni, i-ABS, okanye izixhobo ze-polycarbonate kwaye zinokwenza iziqwenga ezineempawu ezithile ezifana nokudityaniswa kwe-snap-fit okanye imingxuma enemisonto. Abavelisi baxabisa ukufakwa kweplastiki ngokukwazi kwabo ukubonelela ngezisombululo ezikhaphukhaphu, ezingabizi kakhulu kunye nokubumba ngokulula kwiimilo ezahlukeneyo kunye nobukhulu.

- Izinto zeCeramic: Ukufakwa kweCeramic kusetyenziselwa ukubumba inaliti ukwenza iindawo ezifuna amandla aphezulu kunye nokuchasana nokugqoka kunye nokukrazula. Ngokuqhelekileyo zenziwe ngezinto ezifana ne-zirconia okanye i-alumina kwaye zinokusetyenziselwa ukuvelisa iinxalenye zeemoto, i-aerospace, kunye namashishini ezonyango. Ufakelo lweCeramic luxhathisa kakhulu kumaqondo obushushu aphezulu, ukubola, kunye ne-abrasion, ezenza zilungele indawo ezingqongileyo.

- Iifakelo ezidityanisiweyo: Abavelisi badibanisa izinto ezimbini okanye ngaphezulu, ezifana nentsimbi kunye neplastiki, kwaye zibumbe ukuze zenze ukufakwa okudibeneyo, okubangelwa inxalenye enye, edibeneyo. Abavelisi banokusebenzisa izifakelo ezixutyiweyo ukuphuhlisa iziqwenga ezineempawu ezithile ezingenakufikelelwa ziindlela zokubumba zenaliti zesintu. Ngaphaya koko, banokwenza ngokwezifiso ezi zinto zifakelweyo ukuhlangabezana neemfuno ezizodwa zezicelo ezithile.

- Ufakelo olugqithisiweyo: Ngexesha lenkqubo yokubumba, abavelisi bafaka i-mold kwinxalenye yeplastiki, okukhokelela kwinto eyaziwa ngokuba yi-over-molded inserts. Le nkqubo ibandakanya ukuphuhlisa i-shot yokuqala yeplastiki ejikeleze i-insert kwaye emva koko ibeka okwesibini ngaphezu kokudubula kokuqala ukwenza inxalenye enye, edibeneyo. Abavelisi bahlala besebenzisa ii-investi ze-molded over-molded ukuze benze iziqwenga ezidibanisa izinto, ezifana nokufaka intsimbi yentsimbi kwinxalenye yeplastiki.

Ukufakwa kwesinyithi vs. Ukufakwa kwePlastiki

Le nkqubo ibandakanya ukusetyenziswa kwamalungu asele elungisiwe, okanye afakelweyo, afakwe kwisingundo ngaphambi kokuba inkqubo yokubumba inaliti yeplastiki iqale. Abavelisi banokwenza izinto ezifakwe kwizinto ezahlukeneyo, kubandakanywa isinyithi kunye neplastiki, kwaye uhlobo ngalunye lubonisa izinto eziluncedo kunye nokungalunganga. Eli nqaku liza kuthelekisa ukufakwa kwesinyithi kunye neplastiki kwaye kukuncede unqume olona khetho lufanelekileyo kwisicelo sakho.

Metal Insert

Abavelisi ngokuqhelekileyo basebenzisa ukufakwa kwesinyithi ekubumbeni ngenxa yamandla abo aphezulu kunye nokuqina. Ngokuqhelekileyo zenziwe ngobhedu, intsimbi, okanye i-aluminiyam kwaye inokudityaniswa okanye ingafundwanga, kuxhomekeke kwisicelo. Ukufakwa kwesinyithi kudla ngokusetyenziswa kwi-injection yokubumba ukunika amandla okongeziweyo kunye nokuzinza kwiindawo zeplastiki.

Izinto eziluncedo zeMetal Insert

- Amandla aphezulu kunye nokuqina

- Ukumelana nokunxiba kunye nokukrazula

- Inokubonelela ngokusebenza okongezelelweyo ngokudibanisa

- Ilungele iindawo ezinoxinzelelo oluphezulu okanye iimfuno zokuthwala umthwalo

Ububi beMetal Insert

- Iindleko eziphezulu kunokufakwa kweplastiki

- Kunzima kakhulu ukubumba kunokufaka iplastiki

- Inzima, enokuthi ibe yinkxalabo kwizicelo ezithile

Iiplastiki zePlastiki

Ukufakwa kweplastiki kudume ngokubumba ngenxa yokuguquguquka kunye nokusebenza kakuhle kweendleko. Abavelisi bazenza ngokwemathiriyeli efana nenayiloni, i-ABS, okanye i-polycarbonate, kwaye banokuzibumba ngokulula kwiimilo ezahlukeneyo kunye nobukhulu. Izifakelo zeplastiki zikhaphukhaphu kwaye zinokwenza iinxalenye ezineempawu ezithile, ezinje ngoqhagamshelo lwe-snap-fit okanye imingxunya enemisonto.

Izinto eziluncedo zokufakwa kwePlastiki

- Isebenza kakuhle emalini

- KDEName

- Ukubunjwa ngokulula kwiimilo ezahlukeneyo kunye nobukhulu

- Ilungele iindawo ezinoxinzelelo oluphantsi okanye iimfuno zokuthwala umthwalo

Ukungalungi kokufakwa kwePlastiki

- Ihlala ingaphantsi kokufakwa kwentsimbi

- Ayilunganga kwiindawo ezinoxinzelelo oluphezulu okanye iimfuno zokuthwala umthwalo

- Kunokuba lula ukunxiba kunye nokukrazula ekuhambeni kwexesha

Unokukhetha nini iziFakelo zeMetal

Ukufakwa kwesinyithi kugqwesa kwiindawo ezifuna amandla aphezulu kunye nokuqina, njengoko zixhathisa ukuguga kunye nokukrazula kwaye zibonelela ngokusebenza okongeziweyo kokuthotywa. Ukufakwa kwesinyithi kukwafanelekile kwimisebenzi enoxinzelelo oluphezulu okanye iimfuno zomthwalo. Nangona kunjalo, zibiza kakhulu kunokufakwa kweplastiki kwaye kunokuba nzima ukubumba.

Izicelo ezinokuthi zifune ukufakwa kwentsimbi zibandakanya

- Izithuthi kunye nezixhobo ze-aerospace

- Izixhobo zonyango

- Izixhobo zeshishini

- Izixhobo zombane zabathengi

Unokukhetha Nini Izixhobo zePlastiki

Ukufakwa kwePlastiki kuneendleko-zokusebenza kwaye ziguquguqukayo kumacandelo anoxinzelelo oluphantsi okanye iimfuno zokuthwala umthwalo. Babonisa iimpawu ezikhaphukhaphu; abavelisi bangazibumba ngokwemilo kunye nobukhulu obahlukeneyo. Ukufakwa kweplastiki kukwafanelekile kwizikhundla ezifuna iimpawu ezithile ezifana nokudityaniswa kwe-snap-fit okanye imingxuma enentambo. Nangona kunjalo, banokufuna ukuba bafaneleke ngakumbi kwiinkcukacha ezinoxinzelelo oluphezulu okanye iimfuno zokuthwala umthwalo.

Izicelo ezinokuthi zifune ukufakwa kweplastiki kubandakanyiwe

- Impahla zomthengi

- Izixhobo zekhaya

- Izinto zokudlala kunye nemidlalo

- Electronics

Izibonelelo zokuBumba isitofu sokuFaka

Faka isitofu sokubumba yinkqubo yokwenziwa edumileyo ebandakanya iindawo ezenziwe kwangaphambili okanye ukufakwa kubumba phambi kokuba inkqubo yokubumba inaliti yeplastiki iqale. Le ndlela yobugcisa ibonelela ngeenzuzo ezininzi kwiindlela zokubumba zemveli, iyenza ibe lukhetho oludumileyo kwizicelo ezahlukeneyo. Eli nqaku liza kuxubusha ezinye zeenzuzo eziphambili zokufaka isitofu sokubumba.

- Isebenza kakuhle emalini: Faka isitofu sokubumba sinokuba sisisombululo esisebenzayo sokuvelisa ngenxa yokuba kuphelisa isidingo sokuhlanganisana emva kokubunjwa kwamacandelo ahlukeneyo. Ngokudibanisa ukufakwa ngexesha lokubumba, abavelisi banokunciphisa iindleko zabasebenzi kunye nendibano ngelixa besandisa ukusebenza kakuhle kwemveliso.

- Amandla enxalenye aphuculweyo: Faka isitofu sokubumba kunokwandisa ukomelela kunye nokuqina kwamalungu ngokusebenzisa izixhobo ezahlukeneyo kwiindawo ezahlukeneyo zeqhekeza. Olu phawu lunokuba luncedo ngakumbi kwizicelo ezifuna iinkcukacha zokunyamezela uxinzelelo oluphezulu okanye iimfuno zomthwalo.

- Ukonyuka kokuguquguquka koyilo: Faka isitofu sokubumba inika ukuguquguquka okukhulu koyilo, njengoko isenza iindawo ezinzima ezineempawu ezininzi kunye nemisebenzi. Le nkqubo ifaneleke kakuhle kuyilo oluntsonkothileyo kunye nejometri, iyenza ibe lukhetho olufanelekileyo kwezo nkcukacha.

- Ukungqinelana kunye nokuchaneka: Faka isitofu sokubumba kunika ukuhambelana okugqwesileyo kunye nokuchaneka kwinxalenye yemveliso. Sibeka ngokuchanekileyo ukufakwa kwangaphambili kwi-mold, siqinisekisa ukubekwa kwazo ngokuchanekileyo ngokweemfuno zecandelo ngalinye. Ngenxa yoko, sifezekisa imilinganiselo efanayo kunye nokulawulwa komgangatho okhethekileyo kwiziqwenga eziveliswayo.

- Ixesha lomjikelo elincitshisiweyo: Faka isitofu sokubumba kunokunciphisa ixesha lomjikelo ngokudibanisa amanyathelo amaninzi kwinkqubo enye. Le ndlela inokonga ixesha kwaye iphucule imveliso, ngakumbi xa ujongana nemveliso yomthamo ophezulu.

- Izinto ezahlukeneyo: Faka inaliti yokubumba ingasetyenziswa ngezinto ezahlukeneyo, kubandakanya iplastiki, isinyithi, kunye neceramic. Abavelisi ngoku banokukhetha eyona mathiriyeli ifanelekileyo kuso nasiphi na isicelo ngokuqwalasela amandla, ukuqina, kunye neendleko.

- Iinzuzo zokusingqongileyo: Faka ukubumba inaliti kunokubonelela ngeenzuzo zokusingqongileyo ngokunciphisa inkunkuma kunye nokunciphisa ukusetyenziswa kwemathiriyeli. Ngenxa yokuba sibeka ngokuchanekileyo ukufakwa kwi-mold, sifumana inkunkuma encinci kuneendlela zokubumba zendabuko. Ukuphumeza oku kunokukhokelela ekwehleni kweempembelelo zokusingqongileyo kunye nokwehliswa kweendleko zemveliso.

Iingqwalasela zoyilo lokuFaka ukuBunjwa

Faka ukubumba yinkqubo yokwenziwa edumileyo ebandakanya ukuhlanganiswa kwezinto ezifakwe ngaphambili kwinkqubo yokubumba inaliti yeplastiki. Le ndlela yobugcisa ibonelela ngeengenelo ezininzi, kubandakanya ukomelela kwenxalenye ephuculweyo, ukuncitshiswa kweendleko zokuhlanganisa, kunye nokunyuka kokuguquguquka koyilo. Nangona kunjalo, iinxalenye zokuyila zokufaka ukubumba zifuna ukuqwalaselwa ngononophelo kwizinto ezininzi zokuqinisekisa ukuveliswa okuyimpumelelo kunye nokusebenza kakuhle. Eli nqaku liza kuxubusha ezinye zeengqwalasela eziphambili zoyilo lokufaka ukubumba.

- Faka indawo yokubeka: Ukufakwa kokufaka ngaphakathi kwesikhunta kubaluleke kakhulu kwimpumelelo yenkqubo yokubumba yokufaka. Ufakelo kufuneka lubekwe ngokuchanekileyo kwi-mold ukuqinisekisa ukuba izinto zeplastiki ziyifake ngokupheleleyo ngexesha lokubumba. Abaqulunqi kufuneka kwakhona baqinisekise ukuba ukufakwa akuphazamisi ukuhamba kwezinto zeplastiki okanye kubangele nayiphi na imiba yomgca wokuqhawula.

- Ukuhambelana kwezinto: Ukukhethwa kwezinto zokufaka kunye nezinto zeplastiki kubalulekile kwimpumelelo yenkqubo yokubumba. Izinto eziphathekayo kufuneka zihambelane ukukhusela imiba yokudibanisa okanye ukungahambelani kwezinto. Abaqulunqi kufuneka baqwalasele ngokucophelela izinto eziphathekayo, ezifana ne-melting point, i-shrinkage, kunye ne-coefficient yokwandiswa kwe-thermal, ukuqinisekisa ukuphumelela kokufaka ukubumba.

- Icandelo leJiyometri: Ijiyometri yenxalenye yenye ingqwalasela ebalulekileyo yokubumba ukubumba. Uyilo kufuneka luvumele ukuzaliswa ngokufanelekileyo kunye nokupakishwa kwezinto zeplastiki ezijikeleze ukufakwa ukuze kuqinisekiswe ukuba zifake ngokupheleleyo. Inxalenye yejiyometri kufuneka ivumele umoya owaneleyo kunye nokupholisa ukuthintela nayiphi na imiba nge-warping, shrinkage, okanye i-sink marks.

- Ii-engile zoyilo kunye nee-Undercuts: Ubukho bee-angles zedrafti kunye ne-undercuts kunokuchaphazela ukubunjwa kwenxalenye ekufakeni ukubumba. Abaqulunqi kufuneka baqwalasele ngokucokisekileyo ukubekwa kunye nejometri yee-angles zedrafti kunye ne-undercuts ukuqinisekisa ukuba banokususa ngokulula ukufaka kwi-mold ngaphandle kokwenza umonakalo kwinxalenye okanye kwi-mold.

- Iingqwalasela zesiXhobo: Isixhobo esifunekayo sokufaka ukubumba kunokuba nzima kuneendlela zokubumba zendabuko. Abaqulunqi kufuneka baqwalasele ngononophelo uyilo lokubumba, kubandakanywa ukubekwa kunye nejometri yokufaka, i-gating kunye ne-venting, kunye naziphi na izenzo ezifunekayo zecala. Ukongeza, izixhobo kufuneka zikwazi ukugcina ukunyamezelana okuqinileyo ukuqinisekisa ukufakwa ngokufanelekileyo kokufaka kunye nokuthintela nayiphi na imiba enomgangatho wenxalenye.

Izinto ezisetyenziswa kwi-Faka i-Injection Molding

Faka isitofu sokubumba yinkqubo ekhethekileyo kakhulu evelisa iindawo ezintsonkothileyo ngokuchanekileyo nangokungaguquguqukiyo. Le nkqubo ibandakanya ukusetyenziswa kweempawu ezenziwe kwangaphambili ezibizwa ngokuba zii-inserts, ezifakwe kumngundo phambi kokuba isitofu sibumbe. Ezi zifakelo zingenziwa kwizinto ezahlukeneyo, nganye ineempawu ezizodwa kunye neenzuzo. Apha siza kuxoxa ngezona zinto zixhaphakileyo ezisetyenziswa ekufakeni isitofu sokubumba kunye neenzuzo zazo.

Metals

Isitofu sokubumba sisebenzisa ngokubanzi izifakelo ezenziwe ngesinyithi njengentsimbi, ialuminiyam kunye nobhedu. Ezi zixhobo zinika amandla abalaseleyo kunye nokuqina, zizenza zilungele iindawo ezifuna ukunxiba okuphezulu kunye nokumelana nokukrazula. Ukongeza, ukufakwa kwesinyithi kunokumelana nobushushu obuphezulu, kubenze balungele ukusetyenziswa kwizicelo ezifunwayo ezifana ne-aerospace kunye nemizi-mveliso yeemoto. Ezinye zezibonelelo ezithile zokusebenzisa izifakelo zetsimbi ekubumbeni inaliti ziquka:

- Amandla aphezulu kunye nokuqina

- Ukumelana nobushushu obugqwesileyo

- Ukuxhatshazwa

- Ukukwazi ukumelana noxinzelelo oluphezulu kunye noxinzelelo

iiplastiki

Ufakelo lwePlastiki lukwasetyenziswa ngokuqhelekileyo ekubumbeni inaliti, kunye nemathiriyeli efana ne-PEEK, PTFE, kunye ne-UHMW ibe lukhetho oludumileyo. Ezi zixhobo zibonelela ngeqondo eliphezulu lokumelana nobushushu, ukuxhathisa imichiza, kunye neempawu eziphantsi zokukhuhlana. Ezi zixhobo zilungele ukusetyenziswa kwizixhobo zonyango kunye nokuveliswa kwe-semiconductor ngenxa yokuchaneka okuphezulu kunye nokucoceka, okuyizinto ezibalulekileyo kwezo zicelo. Ezinye zezibonelelo ezithile zokusebenzisa ukufakwa kweplastiki ekubumbeni inaliti ziquka:

- Ukumelana neekhemikhali eziphezulu

- Ukumelana nobushushu obugqwesileyo

- Iimpawu zokukhuhlana okuphantsi

- Kulula kumatshini kunye nokumila

ukubumba

Ekubunjweni kwenaliti, ukufakwa kwe-ceramic zifumana ukusetyenziswa ngenxa yokuqina kwazo okuphezulu, ukuqina, kunye nokumelana nokunxiba. Ezi zixhobo zilungele ukusetyenziswa kwizicelo apho inxalenye idinga ukumelana nokushisa okuphezulu okanye iindawo ezinzima. Ukongeza, ukufakwa kwe-ceramic kunika uzinzo olubalaseleyo lwe-dimensional, lubenza bafanelekele izicelo zobunjineli ezichanekileyo. Ezinye zezibonelelo ezithile zokusebenzisa ukufakwa kwe-ceramic kwisitofu sokubumba kubandakanya:

- Amandla aphezulu kunye nobunzima

- Ukulwa okungahambelani kakuhle

- Ukumelana nokushisa okuphezulu

- Ukuzinza okuzinzileyo

Iindibano

Iimathiriyeli ezidityanisiweyo, ezifana ne-carbon fiber okanye i-fiberglass, zisetyenziswa ekubumbeni inaliti kumlinganiselo wabo ophezulu wobunzima bobunzima. I-aerospace kunye nemizi-mveliso yeemoto ihlala isebenzisa ezi zixhobo apho ukunciphisa ubunzima kubaluleke kakhulu. Ukufakwa okuhlanganisiweyo kunika ubunzima obuphezulu kunye namandla, okwenza kube lula kwiiinjini zomoya kunye nezicelo zezixhobo zemidlalo eziphezulu. Ezinye zezibonelelo ezithile zokusebenzisa izinto ezidityanisiweyo zokubumba isitofu ziquka:

- Umlinganiselo wamandla aphezulu ukuya kubunzima

- Ukuqina okuphezulu kunye namandla

- Ukuchasana kwempembelelo elungileyo

- Ukwanda komlingani okwandisiweyo kwe-thermal

IRubber

Izixhobo zerabha, ezifana ne-silicone okanye i-neoprene, zisetyenziselwa ukubumba inaliti ngenxa yokuguquguquka kunye nokutywinwa kwazo. Ezi zixhobo zisetyenziswa ngokuqhelekileyo kumashishini ezonyango kunye neemoto apho ukutywinwa kunye ne-cushioning kubalulekile. Ukufakwa kweerabha kunika ukuchasana okugqwesileyo kwiikhemikhali kunye namaqondo obushushu aphezulu, okwenza kube yinto efanelekileyo yokusetyenziswa kwiindawo ezinzima. Ezinye zezibonelelo ezithile zokusebenzisa irabha ekufakeni isitofu sokubumba ziquka:

- Iimpawu zokutywina ezigqwesileyo

- Bhetyebhetye High

- Ukumelana neekhemikhali kunye nobushushu

- Ukungcangcazela kakuhle

amagwebu

Izixhobo zogwebu, ezinje nge-polyurethane okanye i-polystyrene, zisetyenziselwa ukubumba inaliti ngenxa yobunzima bazo kunye neempawu zabo ezifunxayo. Ezi zixhobo zihlala zisetyenziselwa ukupakisha kunye nemizi-mveliso yeemoto apho ukugcinwa kunye nokuchasana kwempembelelo kubalulekile. Ukufakwa kwe-foam kunika ukugquma okuphezulu, okwenza ukuba kube yinto efanelekileyo kwizicelo ezinobushushu bobushushu. Ezinye zezibonelelo ezithile zokusebenzisa ukufakwa kwegwebu ekubumbeni inaliti ziquka:

- Ikhaphukhaphu kwaye ibhetyebhetye

- Ukufunxa ukothuka okugqwesileyo

- Iimpawu ezilungileyo zokugquma

- Ukukwazi ukubumba kwiimilo ezintsonkothileyo

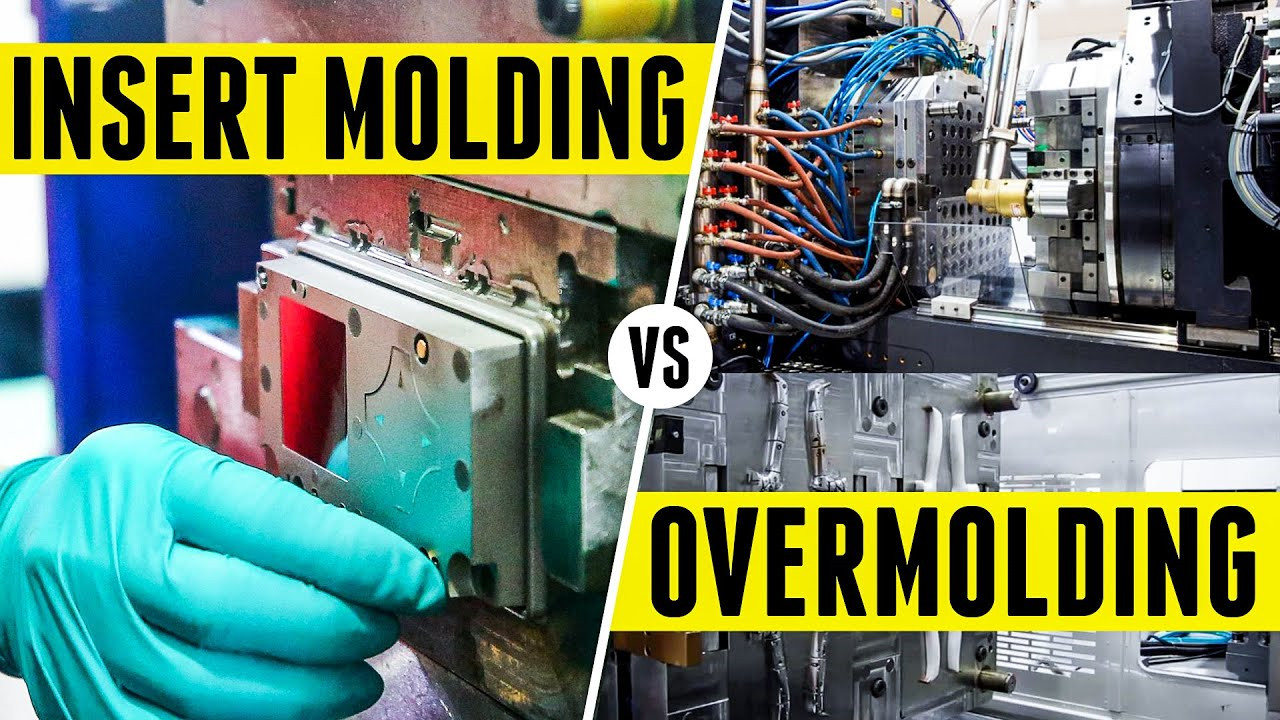

Faka Ukubumba vs. Ukubumba ngaphezulu: Yintoni Umahluko?

Faka ukubumba kunye nokugqithisa zimbini iinkqubo eziqhelekileyo ezisetyenziswayo ekubunjweni kwenaliti ezibandakanya izinto ezininzi. Nangona ezi nkqubo zinokubonakala zifana, zinomohluko othile osisiseko. Apha siza kuxoxa ngomahluko phakathi kokufaka ukubumba kunye nokubumba ngaphezulu.

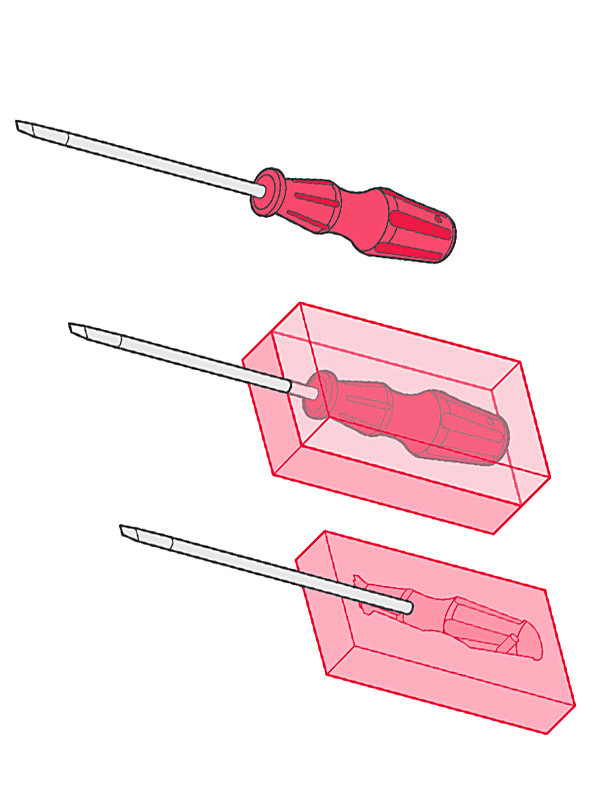

Faka Ukubumba

I-Insert molding yinkqubo ebandakanya ukufakwa kweendawo ezenziwe ngaphambili, ezaziwa ngokuba zifakela, kwi-mold ngaphambi kokuba inkqubo yokubumba i-injection yenzeke. Izinto zeplastiki emva koko zijojowe malunga nokufakwa, ukudala umkhiqizo ogqityiweyo odibanisa iimpawu zokufaka kunye neplastiki. Le nkqubo iqhele ukusetyenziswa kwimizi-mveliso yeemoto, ezonyango, kunye ne-aerospace ukwenza iinxalenye ezinomgangatho ophezulu wokuchaneka.

Izinto eziluncedo zokubumba ifake

- Ukuchaneka okuphezulu kunye nokuchaneka

- Ukuphuculwa kwamandla enxalenye kunye nokuqina

- Ixesha lendibano elincitshisiweyo kunye neendleko

- Ukukwazi ukudibanisa izinto ezineempawu ezahlukeneyo

Ukugcwala

I-Overmolding yinkqubo ebandakanya ukubunjwa kwenaliti yezinto zesibini ngaphezu kwendawo esele ikhona. Abavelisi basebenzisa le nkqubo ukwenza izibambo ezithambileyo, ukubamba, kunye nezinye iimveliso zabathengi. Izinto ezibunjiweyo ezingaphezulu ngokuqhelekileyo zithambile kwaye zifana ne-rubber, zibonelela ukubamba okuphuculweyo kunye nokuthuthuzela. Ngokuxhomekeke kubunzima benxalenye, sinokwenza ukubumba ngaphezulu kwi-single-shot okanye inkqubo yokudubula kabini.

Izinto eziluncedo zokubumba ngaphezulu

- Ukuphuculwa kwe-ergonomics kunye ne-aesthetics

- Ukuphucula ukubamba kunye nentuthuzelo

- Ixesha lendibano elincitshisiweyo kunye neendleko

- Ukukwazi ukudibanisa izinto ezineempawu ezahlukeneyo

Umahluko phakathi kokufakwa kokubumba kunye nokubumba ngaphezulu

- Ukufakwa kwe-insert molding kubandakanya ukufakwa kweengxenye ezenziwe ngaphambili, ngelixa i-overmolding ibandakanya ukubunjwa kwe-injection yezinto zesibini kwinxalenye esele ikhona.

- Sisebenzisa ukubumba okufakelweyo ukwenza iziqwenga ezinomgangatho ophezulu wokuchaneka, ngelixa sisebenzisa ukubumba okungaphezulu ukomeleza i-ergonomics kunye nobuhle bemveliso.

- Ukufakela ukubumba kubandakanya ukudibanisa izinto ezineempawu ezahlukeneyo, ngelixa ukubunjwa ngokugqithisileyo kubandakanya ukusebenzisa i-soft, i-rubber-efana ne-rubber yesahlulo esiphezulu.

- Ukufakwa kokubumba kudla ngokusetyenziswa kwimizi-mveliso yeemoto, ezonyango, nakwi-aerospace, ngelixa ukubumba okungaphezulu kudla ngokusetyenziswa kwiimveliso zabathengi ezifana nezixhobo, i-elektroniki, kunye nezinto zokhathalelo lomntu.

Ubuchwephesha boFakelo loFakelo

Faka ukubumba yinkqubo apho iindawo ezenziwe ngaphambili, okanye ukufakwa, zifakwe kwi-mold phambi kokuba inkqubo yokubumba inaliti yenzeke. Izinto zeplastiki zijojowe malunga nokufakwa ukuze zenze imveliso egqityiweyo. Ukubeka ukufakwa kubalulekile kwimpumelelo yenkqubo yokubumba yokufaka. Apha siza kuxubusha ezinye iindlela zobuchule bokufakwa kokufaka.

- Ukubekwa ngesandla: Umsebenzisi ubeka ngesandla izinto ezifakelwayo kumngundo kobu buchule. Abavelisi baqhele ukusebenzisa obu buchule kumalungu amancinane okanye athe ngqo afuna nje ukufakwa okumbalwa. Nangona kunjalo, kunokuthatha ixesha kunye nomsebenzi onzima, kwaye kukho umngcipheko ophezulu wempazamo ngenxa yokubekwa ngesandla.

- Ubeko oluzenzekelayo: Kobu buchule, izinto ezifakwayo zifakwa kumngundo kusetyenziswa inkqubo yekhompyutha, njengerobhothi okanye umatshini wokuchola-ubeka. Obu buchule bukhawuleza kwaye buchanekile ngakumbi kunokubekwa ngesandla, okwenza ukuba bufanelekele ukuqhutywa kwemveliso enkulu okanye iindawo ezinzima. Nangona kunjalo, ifuna utyalo-mali lokuqala kwizixhobo kwaye inokufuna ukuba neendleko ezisebenzayo kwimveliso encinci.

- Faka ukubumba ngaphezulu kokubumba: Sifaka izinto ezifakwe kwisibini, inxalenye edibeneyo kwaye siyibeke kwi-mold primary. Abavelisi baqhele ukusebenzisa obu buchule kumabango anejiyometri entsonkothileyo okanye iindawo ekunzima ukufikelela kuzo. Isenokudibanisa izixhobo ezineempawu ezahlukeneyo, ezifana neplastiki eqinile yokufaka kunye nezinto ezibunjiweyo ezithambileyo.

- Izinto ezincamathelayo ezincamathelayo:Kulo buchule, sifake kwangaphambili ukufakwa ngokubambelela kwi-adhesive, kusivumela ukuba sibeke kwi-mold ngaphandle kokufuna ukufakwa kwe-manual okanye ngokuzenzekelayo. I-adhesive backing inyibilika ngexesha lokubumba i-injection, idibanisa ukufakwa kwizinto zeplastiki. Obu buchule busetyenziswa ngokuqhelekileyo kwiindawo ezincinci, ezilula kwaye zinokunciphisa ixesha lokuvelisa kunye neendleko.

- Ufakelo olunemisonto: Kulo buchule, ukufakwa kwentambo kufakwe kwi-mold kwaye kusetyenziselwa ukudala imicu kwimveliso egqityiweyo. Abavelisi ngokuqhelekileyo basebenzisa obu buchule ekwenzeni iimveliso ezifuna ukufaka isikrufu okanye ibholithi, njengezixhobo zombane okanye iinxalenye zemoto.

Iindidi zoFaka oomatshini bokuBumba bokuTofa

Enye yezinto eziphambili zenkqubo yokubumba isitofu ngumatshini wokubumba inaliti. Aba matshini beza kwiindidi ezahlukeneyo, ngamnye uneempawu ezizodwa kunye neenzuzo. Apha siza kujonga kwiindidi ezahlukeneyo zomatshini wokubumba inaliti.

Okokuqala, makhe sichaze ukuba yintoni na umatshini wokubumba wofakelo. Umatshini wokubumba wokufaka inaliti ngumatshini wokubumba wokutofa owenza ukuba kufakwe amacandelo asele elungisiwe, afana nokufakwa kwentsimbi okanye iplastiki, kumngundo phambi kokutofa imathiriyeli yeplastiki. Ngobu buchule, kuba yinto enokwenzeka ukwenza iinxalenye ezintsonkothileyo ezifuna iimpawu ezongezelelweyo ezinje ngemingxuma enemisonto okanye izixhaso zentsimbi.

Nazi iintlobo ezahlukeneyo zoomatshini bokubumba isitofu:

- Oomatshini bokubumba inaliti emi nkqo:Aba matshini banoyilo lokujongwa ngokuthe nkqo, apho bafaka umngundo ngokuthe nkqo. Zikulungele ukufaka ukubumba ngenxa yokuba zivumela ukufakwa lula kokufakwa kwi-mold ukusuka phezulu. Olu hlobo lomatshini nalo luthatha indawo encinci yomgangatho kwaye lufaneleka ngcono ukuqhubela imveliso encinci.

- Oomatshini bokubumba inaliti ethe tye:Aba matshini banoyilo lokuqhelaniswa tyaba, apho baxhoma ukungunda ngokuthe tye. Banikezela ngeyona ndlela ifanelekileyo yokuqhuba imveliso enkulu, kwaye abavelisi baqhele ukuzisebenzisa ukwenza iindawo ezibalulekileyo. Ngoomatshini abanqamlekileyo, ukufakwa kunokulayishwa ukusuka kwicala, okwenza kube nzima kakhulu ukuqinisekisa ukulungelelaniswa okufanelekileyo.

- Oomatshini bokubumba inaliti yetafile:Aba matshini banetafile ejikelezayo evumela ukuba iimolds ezininzi zifakwe kwaye zijikelezwe kwiyunithi ye-injection yokuvelisa. Olu hlobo lomatshini lulungele ukufaka ukubumba ngenxa yokuba luya kwenza ukufakwa okuhlukeneyo kwi-mold, ukudala iindawo ezinzima ngakumbi.

- Oomatshini bokubumba inaliti yesitshixo: Aba matshini bane-shuttle ehambisa ukungunda emva naphambili phakathi kweyunithi yokutofa kunye nendawo yokubumba. Zifaneleke kakhulu kwiimveliso ezincinci kwaye zilungele ukufaka ukubumba ngenxa yokuba zivumela ukulayishwa lula kunye nokukhulula izinto ezifakiweyo.

Iiparamitha zeNkqubo yokuFaka ukuBunjwa

Imveliso ephumayo inamandla amakhulu kunye nokuqina xa kuthelekiswa nokubunjwa kwenaliti yendabuko. Iiparamitha zenkqubo yokubunjwa kokufaka zibalulekile ekufezekiseni umgangatho ophezulu kunye neziphumo ezihambelanayo. Apha siza kujonga iiparameters zenkqubo yokufaka ukubumba.

- Ukhetho lwezixhobo: Ukukhethwa kwezinto eziphathekayo yiparameter yenkqubo ebalulekileyo yokufaka ukubumba. Izinto zeplastiki kufuneka zihambelane nezinto zokufaka kunye nesicelo. Ukuhambelana kuqinisekisa ukuba ukufakwa kunye nezinto zeplastiki zihambelana kakuhle, okubangelwa imveliso eyomeleleyo kunye neyomelele.

- Ukushisa: Ubushushu budlala indima ebalulekileyo kwinkqubo yokubumba ifake. Kufuneka sibeke ubushushu bokubumba ngokuchanekileyo ukuqinisekisa ukuba izinto zeplastiki zihamba ngokufanayo kwaye zizalise i-cavity ngaphandle kwe-voids okanye i-deformations. Kufuneka kwakhona siqwalasele ubushushu bokufaka ukuqinisekisa ukuba izinto zeplastiki zibambelela kakuhle kwi-insert ngaphandle kokubangela umonakalo we-thermal.

- Uxinzelelo lokutofa: Uxinzelelo lwenaliti yenye iparameter ebalulekileyo yokufaka ukubumba. Kufuneka sibeke uxinezeleko ngokuchanekileyo ukuze siqinisekise ngokufana nangokukhawuleza sitofe izinto zeplastiki kumgodi wokungunda. Uxinzelelo oluphezulu lwe-injection lunokubangela ukuguqulwa kokufakwa okanye isikhunta, ngelixa i-injection ephantsi ye-injection inokukhokelela ekuzalisweni okungaphelelanga kwe-mold cavity.

- Isantya sokutofa: Isantya sokutofa sikwayiparameter ebalulekileyo yokufaka ukubumba. Kufuneka sibeke umlinganiselo ngokuchanekileyo ukuqinisekisa ukuba izinto zeplastiki zizalise ngokulinganayo i-mold cavity ngaphandle kwe-voids okanye i-deformations. Isantya esiphezulu sokutofa singakhokelela kwisiphithiphithi kwizinto zeplastiki, ezikhokelela kwiziphene kwimveliso egqityiweyo.

- Ixesha lokupholisa: Ixesha lokupholisa liyafuneka ukuze izinto zeplastiki ziqine kwaye zenze imilo yokugqibela yemveliso. Kufuneka sibeke ixesha lokupholisa ngokuchanekileyo ukuqinisekisa ukuba sifezekisa imilo efunekayo kunye nobukhulu bemveliso egqityiweyo. Ukupholisa ixesha elifutshane kunokukhokelela ekuguquleni okanye ekunciphiseni, ngelixa ixesha elide lokupholisa lingabangela amaxesha omjikelo omde kunye nokunciphisa imveliso.

- Ixesha lokukhupha: Sifuna ixesha lokukhupha ukukhupha imveliso egqityiweyo kwi-mold. Kufuneka sibeke ixesha lokukhupha ngokuchanekileyo ukususa imveliso egqityiweyo ngaphandle kokubangela umonakalo okanye ukuguqulwa. Ixesha elifutshane lokukhupha lingakhokelela kwi-ejection engaphelelanga okanye umonakalo kwimveliso, ngelixa ixesha elide lokukhupha lingabangela ixesha elide lokujikeleza kunye nokunciphisa imveliso.

Faka iziphene zokubumba eziqhelekileyo kunye nendlela yokuziphepha

Faka ukubumba yinkqubo yokuvelisa eyaziwayo ebandakanya ukubeka izinto ezenziwe kwangaphambili, ezinje ngentsimbi okanye ukufakwa kweplastiki, kubumba ngaphambi kokutofa izinto zeplastiki. Le nkqubo iphumela kwiimveliso ezibambekayo nezihlala ixesha elide kunentolo yokubumba yemveli. Nangona kunjalo, njengayo nayiphi na inkqubo yokuvelisa, ukufaka ukubumba kunokuba neziphene ezichaphazela umgangatho kunye nokuhambelana kwemveliso yokugqibela. Apha siza kujonga ngokusondeleyo kwiziphene zokubumba zofakelo eziqhelekileyo kunye nendlela yokuziphepha.

Flash: Ukubaleka sisiphako esenzeka xa imathiriyeli yeplastiki egqithisileyo ivuza kumngundo kwaye yenza umaleko obhityileyo kumphezulu wemveliso egqityiweyo. Esi siphene sinokuchaphazela ukubonakala kunye nomsebenzi wemveliso. Ukunqanda iflash, unokuthatha la manyathelo alandelayo:

- Yehlisa uxinzelelo lwenaliti

- Yandisa amandla okubamba ngundo

- Sebenzisa i-arhente yokukhulula ukungunda

- Yandisa ixesha lokupholisa

Umfanekiso omfutshane: Ukudubula okufutshane sisiphene esenzekayo xa izinto zeplastiki zingazalisi i-mold cavity, okukhokelela kwimveliso engaphelelanga okanye engaphantsi. Ukunqanda ukudubula okufutshane, unokuthatha la manyathelo alandelayo:

- Yandisa uxinzelelo lwenaliti

- Yandisa isantya sokutofa

- Yandisa ubushushu bezinto eziphathekayo

- Yandisa iqondo lobushushu lokungunda

Iphepha lemfazwe: I-Warpage sisiphene xa imveliso egqityiweyo ikhubazeka okanye ijijekile ngenxa yokupholisa okungalinganiyo okanye ukushwabana. Ukunqanda iWarpage, unokuthatha la manyathelo alandelayo:

- Yandisa iqondo lobushushu lokungunda

- Yandisa ixesha lokupholisa

- Ukwandisa uxinzelelo lokupakisha

- Sebenzisa inkqubo yokupholisa elungeleleneyo

Amanqaku eSinki: Iimpawu ze-Sink zixinzelelo okanye i-indentations eyenzekayo kumphezulu wemveliso egqityiweyo ngenxa yokupholisa okungalinganiyo okanye ukuncipha. Ukunqanda amanqaku e-sink, unokuthatha la manyathelo alandelayo:

- Yandisa iqondo lobushushu lokungunda

- Yandisa ixesha lokupholisa

- Ukwandisa uxinzelelo lokupakisha

- Sebenzisa iindonga ezityebileyo okanye iimbambo ukomeleza imveliso

Ukulahla I-Delamination iyisiphene eyenzeka xa izinto zeplastiki kunye nezinto ezifakelwayo zingadibanisi ngokufanelekileyo, okubangela ukuhlukana okanye ukuxobula. Ukuthintela i-delamination, unokuthatha la manyathelo alandelayo:

- Sebenzisa imathiriyeli yeplastiki ehambelanayo kwaye ufake itoti

- Yandisa uxinzelelo lwenaliti kunye nesantya

- Yandisa ubushushu bokufaka

- Yandisa iqondo lobushushu lokungunda

Imisebenzi ye-Post-Molding ye-Insert Molding

Nangona kunjalo, emva kokugqiba inkqubo yokubumba yokufaka, kufuneka senze imisebenzi emininzi emva kokubumba ukuqinisekisa ukuba umkhiqizo wokugqibela udibana neenkcukacha ezifunwayo. Apha siza kujongisisa imisebenzi yasemva kokubumba yokubumba.

- Ukunciphisa:I-Deflashing yinkqubo esusa nayiphi na into engaphezulu, efana ne-flash okanye i-burrs, kwimveliso egqityiweyo. Le nkqubo inokwenziwa ngesandla okanye ngokuzenzekelayo, kuxhomekeke kubukhulu kunye nobunzima bemveliso.

- Ukucheba:Ukunquma yinkqubo esusa nayiphi na into engaphezulu okanye i-protrusions kwimveliso egqityiweyo. Le nkqubo inokwenziwa ngokusebenzisa izixhobo ezahlukeneyo zokusika okanye iindlela, kuxhomekeke kwimilo kunye nobukhulu bemveliso.

- Ukucoca: Ukucoca yinkqubo esusa nayiphi na inkunkuma, i-debris, okanye i-debris kwimveliso egqityiweyo. Le nkqubo inokwenziwa ngokusebenzisa iindlela ezahlukeneyo zokucoca okanye iindlela, kuxhomekeke kuhlobo lwezinto ezisetyenzisiweyo kwinkqubo yokubumba yokufaka.

- Ndibano:INdibano yinkqubo ebandakanya ukudibanisa amacandelo amaninzi kunye nokwenza imveliso egqityiweyo. Le nkqubo inokwenziwa ngokusebenzisa iindlela ezahlukeneyo, ezifana ne-ultrasonic welding, i-hot stamping, okanye i-adhesive bonding, kuxhomekeke kuhlobo lwezinto eziphathekayo kunye nemveliso yokugqibela efunekayo.

- Uvavanyo: Ukuvavanya yinkqubo eqinisekisa ukuba imveliso egqityiweyo ihlangabezana neenkcukacha ezifunwayo kunye nemigangatho yomgangatho. Le nkqubo inokubandakanya iimvavanyo ezahlukeneyo, ezifana nokuhlolwa komatshini, umbane, okanye ukujonga, kuxhomekeke kuhlobo lwemveliso kunye nokusetyenziswa kwayo.

Ukongeza kule misebenzi emva kokubumba, kukho izinto ezininzi ekufuneka ziqwalaselwe xa kuyilwa inkqubo yokubumba yokufaka eya kunciphisa imfuno yeenkqubo zokubumba. Ezi ziquka:

- Ukukhetha izinto ezifanelekileyo zokufaka kunye nenxalenye ebunjiweyo

- Ukuqinisekisa ukuba ukufakwa kufakwe ngokufanelekileyo kwaye kubanjwe ngexesha lokubumba

- Ukulungelelanisa iiparamitha zokubumba, ezifana nobushushu kunye noxinzelelo, ukunciphisa iziphene kunye nezinto ezingaphezulu

- Ukusebenzisa i-molds ephezulu kunye nezixhobo zokuqinisekisa ukuhambelana kunye nokuchaneka kwimveliso egqityiweyo

Usetyenziso lwe-Faka ukuBunjwa kwesitofu

Faka isitofu sokubumba yinkqubo yokwenza izinto ezininzi ezininzi ezisetyenziswa kumashishini amaninzi ukuvelisa umgangatho ophezulu, iindawo ezintsonkothileyo ezinamandla amakhulu kunye nokuqina. Apha siza kujonga ngakumbi kwizicelo zokubumba inaliti kunye nezibonelelo zayo kumashishini ahlukeneyo.

- Umzi mveliso weemoto:Ushishino lweemoto ngomnye wabasebenzisi ababalulekileyo bokufakela isitofu sokubumba. Ifumana ukusetyenziswa ekuveliseni amacandelo ahlukeneyo, kubandakanywa izindlu ze-airbag, amabhanti ezihlalo, kunye nezixhobo ze-injini. Inkqubo ivumela ukubunjwa okuchanekileyo kunye nokuchanekileyo kwamalungu anokumelana neemeko ezinzima zokusetyenziswa kweemoto.

- Ishishini le-Electronics:Umzi-mveliso wombane uxhomekeke kakhulu ekufakeni isitofu sokubumba ukuvelisa amacandelo ezixhobo ezifana nee-smartphones, iilaptops, kunye nezinye izixhobo zombane. Inkqubo ifumana ukusetyenziswa ekudaleni izinto ezifana nezihlanganisi, iiswitshi, kunye nezindlu zamacandelo e-elektroniki. Inkqubo isebenza kakuhle kwaye inokuvelisa umthamo ophezulu wamacandelo ngokukhawuleza kwaye ingabizi.

- Ishishini lezonyango: Ishishini lezonyango nalo lizuza kakhulu ngokufaka isitofu sokubumba. Inkqubo ifumana ukusetyenziswa ekuveliseni amacandelo ahlukeneyo, kubandakanywa izixhobo zotyando, izixhobo zokuhanjiswa kweziyobisi, kunye nokufakelwa kwezonyango. Indlela ivumela ukubunjwa okuchanekileyo kwezinto ezinokumelana nobunzima bokusetyenziswa kwezonyango kwaye ivumela ukuveliswa komthamo omkhulu.

- Ishishini le-Aerospace: Ishishini le-aerospace lelinye ishishini elisebenzisa isitofu sokubumba kakhulu. Inkqubo ifumana isicelo ekuveliseni amacandelo afana nemigudu yomoya, izibiyeli, kunye nezindlu zamacandelo eenqwelomoya. Inkqubo ivumela ukudala amacandelo anamandla aphezulu anokumelana noxinzelelo oluphezulu kunye namaqondo okushisa aphezulu okusetyenziswa kwe-aerospace.

- Ushishino lweeMpahla zabaThengi: Umzi-mveliso wempahla yabathengi usebenzisa ukubumba inaliti yokufaka kakhulu ukuvelisa uluhlu olubanzi lweemveliso ezifana nezinto zokudlala, izixhobo zasekhaya, kunye nezixhobo zemidlalo. Inkqubo ivumela ukudalwa kwemigangatho ephezulu, ehlala ixesha elide, ekhaphukhaphu, kunye namacandelo amnandi.

Ukongeza kule mizi-mveliso, ukufaka isitofu sokubumba kuyasetyenziswa nakwezinye izinto ezininzi, kubandakanya:

- Ishishini lokuPakisha: ukuvelisa iikepusi, ukuvalwa, kunye nezinye izinto zokupakisha

- Ushishino loKwakha: ukuvelisa imibhobho, izifakelo, kunye nezinye izinto zokwakha

- Ishishini loMkhosi: ukuvelisa iinxalenye zeenqwelo zomkhosi kunye nezixhobo

Izicelo zoShishino lweemoto

Umzi-mveliso weemoto ngomnye wabasebenzisi ababalulekileyo bokubumba inaliti yeplastiki, njengoko iyindlela engabizi kakhulu kwaye esebenzayo yokwenza izinto ezintsonkothileyo zesithuthi. Apha siza kujonga ngakumbi kwiinkqubo ezahlukeneyo zokubumba inaliti yeplastiki kushishino lweemoto.

- Amacandelo Angaphakathi: Ingaphakathi lesithuthi liqukethe izinto ezininzi zeplastiki eziyimfuneko kubuhle obupheleleyo kunye nokusebenza kwemoto. La malungu aquka ideshibhodi, iipaneli zamacango, iiventi zomoya, kunye nezixhobo zamavili okuqhuba. Ukubunjwa kwe-injection kwenza ukuveliswa kwezi nxalenye kwimiqulu ephezulu ngokukhawuleza kunye neendleko ezifanelekileyo ngelixa kugcinwa izinga eliphezulu lokuchaneka.

- Amacandelo Angaphandle: Umphandle wesithuthi unezixhobo ezininzi zeplastiki, kubandakanywa izigqubuthelo zebhampa, iindibano zezibane zentloko, kunye neendibano zokukhanya. Ukubunjwa kwe-injection kuvelisa la macandelo kumanqanaba aphezulu okuchaneka, ukuqinisekisa ukuba bahlangabezana nokhuseleko olungqongqo kunye nemigangatho yomgangatho ofunekayo kwishishini leemoto.

- Amacandelo eNjini: Isitofu sokubumba sikwafumana ukusetyenziswa ekuveliseni amacandelo enjini aliqela, kubandakanywa ii-manifolds zokungenisa umoya, izigqubuthelo zenjini, kunye nezihluzo zeoyile. Kufuneka sivelise la macandelo ekunyamezelweni okungqongqo kunye nemigangatho, kunye nokubumba isitofu kwenza ukuba kuveliswe izithako ezikumgangatho ophezulu ezihlangabezana nezi mfuno.

- Amacandelo oMbane: Izinto zombane kwisithuthi, ezifana neziqhagamshelo, iiswitshi, kunye nezindlu zenzwa, nazo zenziwe kusetyenziswa isitofu sokubumba. La macandelo kufuneka ahlale ehlala kwaye amelane neemeko zokusebenza ezinzima, kunye nokubumba isitofu kuvumela ukuvelisa izithako eziphezulu ezinokumelana nale miqathango.

- Amacandelo e-HVAC:I-injection molding ivelisa amacandelo amaninzi asetyenziswa kwinkqubo ye-HVAC yesithuthi, kubandakanywa nemibhobho yomoya kunye neendawo zokukhupha umoya. La macandelo kufuneka enziwe ngokunyamezela okuchanekileyo ukuqinisekisa ukuhamba komoya okufanelekileyo kunye nokungena komoya emotweni.

Ukongeza kwezi zicelo, abavelisi basebenzisa isitofu sokubumba ukuvelisa amanye amacandelo emoto, aquka amafutha, iziqhoboshi, kunye neenkqubo zokunqunyanyiswa.

Izibonelelo zokusebenzisa isitofu sokubumba kwishishini leemoto zininzi, kubandakanya:

- Ukusebenza ngokuphezulu:Ukubunjwa kwe-injection kuvumela ukuvelisa ngokukhawuleza amacandelo aphezulu kwimiqulu emikhulu, ukunciphisa amaxesha okuvelisa kunye neendleko.

- Ulungelelaniso:Ukubunjwa kwe-injection kuvumela ukudala amacandelo ngokuchaneka okuphezulu kunye nokuhambelana, ukuqinisekisa ukuba bahlangabezana nemigangatho engqongqo yomgangatho.

- Ngokwezifiso: Ukubunjwa kwe-injection kuvumela ukuveliswa kweemilo eziyinkimbinkimbi kunye noyilo, okuvumela abavelisi ukuba benze amacandelo ukuba ahlangabezane neemfuno ezithile zoyilo.

Izicelo zoShishino lwezoNyango

Ishishini lezonyango licandelo apho ukuchaneka kunye nokuthembeka kubaluleke kakhulu, ukwenza ukubumba inaliti yeplastiki ibe yinkqubo efanelekileyo yokuvelisa ukuvelisa amacandelo onyango. Apha siza kujonga ngakumbi kwiinkqubo ezahlukeneyo zokubumba inaliti yeplastiki kushishino lwezonyango.

- Izixhobo Zotyando: Isitofu sokubumba sivelisa izixhobo ezininzi zotyando, kubandakanywa iiforcep, iiclamps, kunye neescalpels. Abavelisi kufuneka benze la macandelo ukuba anyamezele ngokungqongqo kunye nemigangatho yokuqinisekisa ukuchaneka okuphezulu kunye nokuchaneka.

- Izixhobo zonyango:Abavelisi bakwasebenzisa isitofu sokubumba ukuvelisa izixhobo zonyango, ezinjengeecatheter kunye nezinto zokuphefumla. Ukuqinisekisa ukhuseleko nokuthembeka kwezigulana, abavelisi kufuneka benze la malungu ngokwemigangatho engqongqo.

- Amacandelo oxilongo: Abavelisi basebenzisa isitofu sokubumba ukuvelisa izinto ezininzi ezisetyenziswa kwizixhobo zokuxilonga, ezinje ngeepayipi, iisirinji, kunye neetyhubhu zovavanyo. La macandelo kufuneka enziwe ngendlela echanekileyo yokunyamezela ukuqinisekisa iziphumo zovavanyo ezichanekileyo.

- Ukupakisha: Ukubumba isitofu kuvelisa ukupakishwa kweemveliso zonyango, ezifana neetreyi ezinyumba, izikhongozeli, kunye nezinto zokupakisha. La macandelo kufuneka enziwe ngokwemigangatho engqongqo ukuqinisekisa ubunyumba kunye nokhuseleko lweemveliso zonyango.

- Amacandelo Amazinyo: Isitofu sokubumba sivelisa amacandelo amaninzi amazinyo, kuquka imilomo, iitreyi, kunye neziqwenga zamazinyo. La malungu kufuneka enziwe ngokunyamezela okuchanekileyo ukuqinisekisa ukufaneleka okufanelekileyo kunye nokuthuthuzela isigulana.

Ukongezelela kwezi zixhobo, abavelisi basebenzisa isitofu sokubumba ukuze bavelise ezinye iinxalenye zonyango, kuquka iiprothetics, izixhobo zokuva nezixhobo zaselabhoratri.

Izibonelelo zokusebenzisa isitofu sokubumba kwishishini lezonyango zininzi, kubandakanya:

- Ukuchaneka okuphezulu:Ukubunjwa kwe-injection kuvumela ukuvelisa amacandelo anamanqanaba aphezulu okuchaneka kunye nokuhambelana, ukuqinisekisa ukuba bahlangabezana nemigangatho engqongqo yomgangatho.

- Ngokwezifiso:Ukubunjwa kwe-injection kuvumela ukuveliswa kweemilo eziyinkimbinkimbi kunye noyilo, okuvumela abavelisi ukuba benze amacandelo ukuba ahlangabezane neemfuno ezithile zoyilo.

- Isebenza kakuhle emalini: Ukubunjwa kwe-injection yinkqubo yokuvelisa indleko evelisa amacandelo aphezulu kwinani elikhulu, ukunciphisa amaxesha okuvelisa kunye neendleko.

Izicelo zoShishino loMbane

Ishishini le-elektroniki licandelo elixhomekeke kakhulu kwiinkqubo zokwenziwa ezichanekileyo nezisebenzayo. Ukubumba inaliti yeplastiki yinkqubo efanelekileyo yokuvelisa izinto zombane ngenxa yokuchaneka kwayo, ukuguquguquka, kunye nesantya. Apha siza kujonga ngakumbi kwiinkqubo ezahlukeneyo zokubumba inaliti yeplastiki kushishino lombane.

- Connectors: Ukubunjwa kwe-injection kuvelisa uluhlu olubanzi lweziqhagamshelo ezisetyenziswa kwishishini le-elektroniki, kubandakanywa izixhumi ze-USB, izixhumi ze-HDMI, kunye neejekhi zomsindo. La macandelo kufuneka enziwe alungele ukunyamezelana okuchanekileyo ukuqinisekisa ukusebenza okufanelekileyo kunye nokuhambelana.

- Izindlu kunye neendawo ezibiyelweyo: Ukubumba isitofu kuvelisa izindlu kunye neendawo ezivaliweyo zezixhobo zombane, kubandakanya iiselfowuni, iilaptops, kunye nezinye izixhobo zombane zabathengi. Abavelisi kufuneka benze la macandelo ngokweenkcukacha ezichanekileyo ukuqinisekisa ukufaneleka nokusebenza ngokufanelekileyo.

- Ukutshintsha: Ukubumba isitofu kuvelisa iintlobo ezininzi zolawulo olusetyenziswa kwizixhobo zombane, kubandakanywa iiswitshi zerocker, iqhosha lokutyhala, kunye nokutshintsha isilayidi. La macandelo kufuneka enziwe ngokunyamezela okuchanekileyo ukuqinisekisa umsebenzi othembekileyo.

- Amacandelo e-LED:Isitofu sokubumba sivelisa izinto ezininzi ezisetyenziswa ekukhanyeni kwe-LED, kubandakanywa iilensi, izibonisi, kunye ne-diffusers. Abavelisi kufuneka benze la macandelo ngokweenkcukacha ezichanekileyo ukuqinisekisa ukuhanjiswa kokukhanya okufanelekileyo kunye nokusebenza kakuhle.

- Amacandelo oBonelelo boMbane: Isitofu sokubumba sivelisa amacandelo amaninzi asetyenziswa kwiiyunithi zobonelelo lwamandla, kubandakanywa iisokethi, iiplagi, kunye nezihlanganisi zentambo. La macandelo kufuneka enziwe ngokunyamezela okuchanekileyo ukuqinisekisa ukusebenza okukhuselekileyo nokuthembekileyo.

Ukongeza kwezi zicelo, abavelisi basebenzisa isitofu sokubumba ukuvelisa ezinye izinto ze-elektroniki ezininzi, kubandakanya ikhibhodi, iimpuku zekhompyuter, kunye nolawulo olukude.

Izibonelelo zokusebenzisa isitofu sokubumba kwishishini le-elektroniki zininzi, kubandakanya:

- Ukuchaneka okuphezulu: Ukubunjwa kwe-injection kuvumela ukuvelisa amacandelo anamanqanaba aphezulu okuchaneka kunye nokuhambelana, ukuqinisekisa ukuba bahlangabezana nemigangatho engqongqo yomgangatho.

- Ngokwezifiso: Ukubunjwa kwe-injection kuvumela ukuveliswa kweemilo eziyinkimbinkimbi kunye noyilo, okuvumela abavelisi ukuba benze amacandelo ukuba ahlangabezane neemfuno ezithile zoyilo.

- Ukukhawuleza:Ukubunjwa kwe-injection yinkqubo yokuvelisa ngokukhawuleza kwaye esebenzayo evumela ukuvelisa amacandelo aphezulu kwimiqulu emikhulu, ukunciphisa amaxesha okuvelisa kunye neendleko.

Aerospace Industry Applications

Ishishini le-aerospace licandelo elifuna inqanaba eliphezulu lokuchaneka, ukuchaneka, kunye nokuqina kuwo onke amacandelo alo. Ukubumba inaliti yeplastiki kumzi-mveliso we-aerospace iye yaxhaphaka ngenxa yokukwazi ukuvelisa iijiyometri ezintsonkothileyo, ukunciphisa ubunzima, kunye nokuphucula imfezeko yesakhiwo. Apha siza kujonga ngakumbi kwiinkqubo ezahlukeneyo zokubumba inaliti yeplastiki kwishishini le-aerospace.

- Amacandelo Angaphakathi: Isitofu sokubumba sivelisa uluhlu lwamacandelo angaphakathi kwinqwelomoya, kubandakanywa umva wezihlalo, iitafile zetreyi, kunye namagumbi aphezulu. Ezi zixhobo kufuneka zibe khaphukhaphu kwaye zomelele, zikwazi ukumelana noxinzelelo oluphezulu kunye nokunxiba kunye nokukrazula.

- Amacandelo oLwakhiwo: Isitofu sokubumba sivelisa amacandelo esakhiwo senqwelomoya, kubandakanywa neencam zamaphiko, ii-fairings, kunye namacandelo e-fuselage. Ezi zixhobo kufuneka zibe khaphukhaphu, zomelele, kwaye zomelele ukuze kuqinisekiswe ukhuseleko nokusebenza kakuhle kwenqwelomoya.

- Amacandelo eNjini:Ukubumba isitofu kuvelisa amacandelo amaninzi eenjini zenqwelomoya, kuquka iiblade zeinjini yomoya, imilomo yepetroli, kunye nezindlu. La malungu kufuneka enziwe ngokweenkcukacha ezichanekileyo ukumelana namaqondo obushushu aphezulu, uxinzelelo kunye noxinzelelo.

- Amacandelo oMbane: Isitofu sokubumba sivelisa izinto zombane zenqwelomoya, kubandakanywa izihlanganisi, iiswitshi, kunye neentambo zokubopha. La macandelo kufuneka enziwe alungele ukunyamezelana okuchanekileyo ukuqinisekisa ukusebenza okufanelekileyo kunye nokuthembeka.

- Amacandelo ezixhobo:Ukubunjwa kwe-injection kuvelisa amacandelo ezixhobo zenqwelomoya, kubandakanywa iipaneli zokulawula kunye nezindlu zezixhobo. Ezi zixhobo kufuneka zomelele kwaye zimelane namaqondo obushushu aphezulu, uxinzelelo kunye nokungcangcazela.

Ukongeza kwezi zicelo, abavelisi basebenzisa isitofu sokubumba ukuvelisa ezinye izinto ezininzi kwishishini le-aerospace, kubandakanya izibiyeli, iziqhoboshi, kunye neegesi.

Izibonelelo zokusebenzisa isitofu sokubumba kwishishini le-aerospace zininzi, kubandakanya:

- Ukunciphisa Ubunzima: Isitofu sokubumba sivumela ukuveliswa kwezinto ezilula ezinciphisa ubunzima benqwelo-moya, okukhokelela ekusetyenzisweni okuphantsi kwamafutha kunye nokwandisa ukusebenza kakuhle.

- Ulungelelaniso:Ukubunjwa kwe-injection kuvumela ukuvelisa iinxalenye ngokuchaneka okuphezulu kunye nokuhambelana, ukuqinisekisa ukuba bahlangabezana nemigangatho engqongqo yomgangatho.

- Ngokwezifiso:Ukubunjwa kwe-injection kuvumela ukuveliswa kweemilo eziyinkimbinkimbi kunye noyilo, okuvumela abavelisi ukuba benze amacandelo ukuba ahlangabezane neemfuno ezithile zoyilo.

- Ukuqina: Iukubumba i-njection ivelisa iindawo ezihlala ixesha elide kwaye zikwazi ukumelana namanqanaba aphezulu oxinzelelo, ubushushu, kunye noxinzelelo, ukuqinisekisa ukhuseleko kunye nokuthembeka kwenqwelomoya.

Izicelo zoShishino lweeMpahla zabaThengi

Ishishini lempahla yabathengi lelinye lawona macandelo abalulekileyo kuqoqosho lwehlabathi. Impahla yabathengi ziimveliso ezisetyenziswa ngabantu mihla le, kubandakanya izinto zasekhaya, izinto zombane, iithoyi, kunye neemveliso zokhathalelo lomntu. Ukubumba inaliti yeplastiki kwishishini lempahla yabathengi kuye kwanda ukuthandwa ngenxa yokukwazi ukuvelisa izinto ezikumgangatho ophezulu ngokuchaneka nokuchaneka. Apha siza kujonga ngakumbi kwiinkqubo ezahlukeneyo zokubumba inaliti yeplastiki kushishino lwempahla yabathengi.

- Ukupakisha: I-injection molding isetyenziswa kakhulu ekuveliseni izinto zokupakisha zempahla yabathengi, kubandakanywa ukupakishwa kokutya, iibhotile zesiselo, kunye nezitya zokuthambisa. Ukubunjwa kwe-injection kuvumela ukuveliswa kweemilo eziyinkimbinkimbi kunye noyilo, ukuqinisekisa ukuba izinto zokupakisha ziyasebenza kwaye zikhangeleka.

- Izinto Zasekhaya: Ukubunjwa kwe-injection kuvelisa uluhlu lwezinto zendlu, kubandakanywa izitya zasekhitshini, izitya zokugcina, kunye nezinto zokucoca. Ezi zinto kufuneka zomelele, zibe khaphukhaphu, kwaye zimelane nokusetyenziswa kwemihla ngemihla.

- Amathoyizi: Isitofu sokubumba sivelisa izinto zokudlala ezahlukeneyo, kubandakanya amanani entshukumo, oonodoli, kunye nemidlalo yebhodi. Ezi zinto zokudlala kufuneka zenziwe ngokweenkcukacha ezichanekileyo ukuqinisekisa ukuba zikhuselekile kwaye zihlala ixesha elide.

- Iimveliso zokuKhathalela umntu: Ukubumba isitofu kuvelisa iimveliso zokhathalelo ezizodwa, kubandakanya iibrashi zamazinyo, iincakuba, kunye neebhotile zeshampu. Ezi mveliso kufuneka zithandeke ngobuhle, zisebenze, kwaye zimelane nokusetyenziswa rhoqo.

- ZeWindows: Isitofu sokubumba sivelisa amacandelo amaninzi ezixhobo zombane, kuquka iimeko, amaqhosha, kunye nezihlanganisi. La malungu kufuneka ahlale eqinile, alula, kwaye amelane namaqondo aphezulu kunye noxinzelelo.

Ukongeza kwezi zicelo, abavelisi basebenzisa isitofu sokubumba ukuvelisa ezinye izinto ezininzi kumzi mveliso wempahla yabathengi, kubandakanya iimoto, izixhobo zonyango, kunye nezixhobo zamashishini.

Izibonelelo zokusebenzisa isitofu sokubumba kwishishini lempahla yabathengi zininzi, kubandakanya:

- Isebenza kakuhle emalini:Ukubunjwa kwe-injection kuvumela ukuvelisa amacandelo aphezulu ngexabiso eliphantsi kunezinye iinkqubo zokuvelisa.

- Ukwenziwa ngokwezifiso: Iukubumba njection kuvumela ukudala izinto ezineemilo ezintsonkothileyo kunye noyilo, okuvumela abavelisi ukuba benze izinto ngokusesikweni ukuhlangabezana neemfuno zoyilo ezithile.

- Ulungelelaniso: Isitofu sokubumba sineenkcukacha ezichanekileyo nezingaguquguqukiyo ezihlangabezana nemigangatho engqongqo yobulunga.

- Ukuzinza: Ukubunjwa kwe-injection kwenza iindawo zomelele kwaye zikwazi ukumelana namanqanaba aphezulu oxinzelelo, ubushushu, kunye noxinzelelo, ukuqinisekisa ukhuseleko kunye nokuthembeka kweemveliso.

IiNdlela zexesha elizayo kwi-Faka i-Injection Molding

Njengoko itekhnoloji ihambela phambili kunye neemfuno zabathengi zitshintsha, imboni yokubumba yokufaka inaliti ihlala iguquka. Abavelisi bahlala bekhangela iindlela zokuphucula ukusebenza kakuhle, ukunciphisa iindleko, kunye nokuvelisa iimveliso ezikumgangatho ophezulu. Apha siza kujonga ezinye iindlela zexesha elizayo zokufaka ukubumba isitofu.

- Ukuzenzekelayo: I-automation iya isanda kakhulu kwishishini lokuvelisa, kwaye ukufaka isitofu sokubumba akukho nto. Iinkqubo ezizenzekelayo zinokunciphisa iindleko zabasebenzi, zandise isantya semveliso, kwaye ziphucule ulawulo lomgangatho.

- Ukuzinza: Ngokukhula kwenkxalabo yokusingqongileyo, abavelisi bafuna iindlela zokunciphisa inkunkuma kunye nokuphucula ukuzinza. Ukusebenzisa imathiriyeli esetyenzisiweyo kunye nokuyila iimveliso ezinokuphinda zisetyenziselwe okanye ziphinde zisetyenziswe ziindlela nje ezimbalwa abavelisi bajongana nalo mba.

- Ushicilelo lwe-3D: Eminye imiba yokubumba inaliti yokufaka sele isebenzisa ushicilelo lwe-3D, kodwa inamandla okuba ixhaphake ngakumbi kwixesha elizayo. Ukukwazi ukwenza ngokukhawuleza iiprototypes kunye nokuvelisa amacandelo alungiselelweyo yinzuzo enye yoshicilelo lwe-3D.

- Izixhobo ezikwinqanaba eliphezulu: Abaphandi nabavelisi benza izinto ezintsha ezikwaziyo ukumelana namaqondo obushushu awahlukahlukeneyo, iingcinezelo noxinezeleko.

- Ukwenziwa kobuchule:Ukuveliswa kwe-Smart kubandakanya ukusebenzisa itekhnoloji ukuqokelela kunye nokuhlalutya idatha ngexesha langempela, ukuvumela ukuthathwa kwezigqibo ngokukhawuleza kunye nemveliso esebenzayo. Le teknoloji inokuphucula ulawulo lomgangatho, ukunciphisa ixesha lokunciphisa, kunye nokwandisa imveliso.

isiphelo

Faka i-injection molding yinkqubo yokwenza izinto ezininzi kwaye ingabizi kakhulu evumela ukudala iinxalenye ezinzima kunye namacandelo afakwe ngaphakathi. Iingenelo zayo ngaphezulu kweendlela zokuhlanganisana zemveli ziyenza idume kumashishini ahlukeneyo, kubandakanya iimoto, ezonyango, ezombane, i-aerospace, kunye nempahla yabathengi. Ngokuqonda iindlela ezahlukeneyo zobuchule, izixhobo, kunye neengqwalasela zoyilo ezibandakanyekayo ekufakeni isitofu sokubumba, abavelisi banokuphucula iinkqubo zabo zemveliso kwaye bazise iimveliso ezikumgangatho ophezulu kubathengi babo. Njengoko itekhnoloji ihambela phambili, sinokulindela ukubona usetyenziso oluyintshayo lokubumba inaliti.