Ukubunjwa kwesitofu soMqulu ophezulu

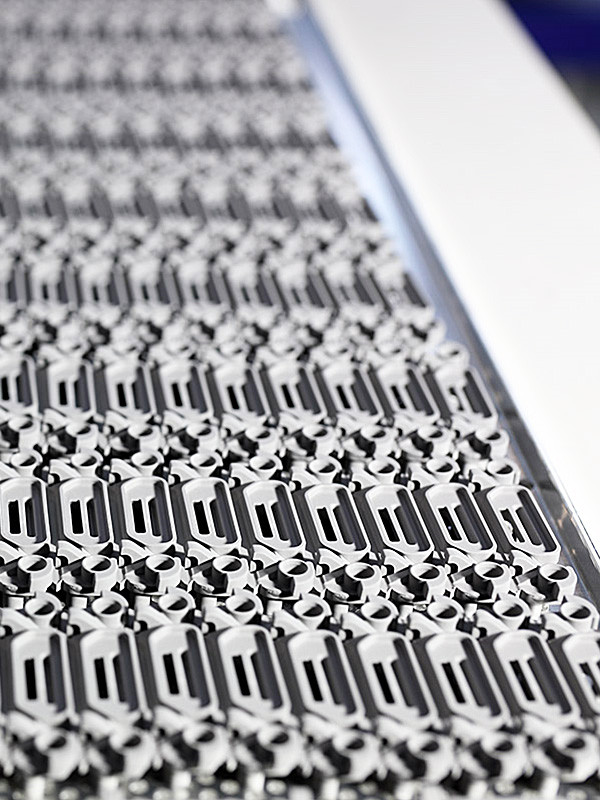

Ukubunjwa kwenaliti yomthamo ophezulu (uMveliso weVolumu ephezulu): I-Plassic Injection Molding

Ngaphezulu kwamawaka ezinto zokubumba iinaliti zeplastiki kunye nezixhobo zokwenza iplastiki ukukhetha kuzo zonke igama, zeziphi ezinye zeempawu eziphezulu ezenza inkampani yokubumba ibonakale? Xa ukhetha umboneleli, izinto ezininzi kufuneka zithathelwe ingqalelo; kubandakanywa amandla, ukuqinisekiswa komgangatho, isidima senkampani, iindleko, kunye nexesha lokuhambisa. Ukufumana i-molder efanelekileyo yeplastiki yokubumba ukuze ihambelane neemfuno zakho kunokubonakala kudla ixesha kodwa ukugqiba iimfuno zakho eziphantsi kunye neziphezulu zevolumu kuqala kunye nendlela ezinokutshintsha ngayo ekuhambeni kwexesha, kuya kunceda ukunciphisa ukhetho lwakho.

Inkonzo yokubumba i-DJmolding ye-High-Volume Injection Molding

Kwi-DJmolding, indawo yethu yokuvelisa iphezulu, isebenza ngokufanelekileyo kunye noomatshini abaninzi kunye nabaqhubi abanezakhono. Ngenxa yezixhobo zethu ezahlukeneyo, singakwazi ukujongana nemisebenzi eyahlukeneyo eyahluke kakhulu kumashishini abo, umgangatho weplastiki, kunye nenani lamaqhekeza avelisiweyo. Imithamo ephantsi kunye nephezulu, ukusuka kuyilo ngokwenziwa kwemveliso, inokugqityezelwa ngaphakathi kwindlu ebonelela abathengi bethu ngeenzuzo zokukhuphisana kwiindleko, umgangatho, kunye namaxesha okukhokela.

Ukubumba inaliti ka-DJmolding yindlela eqinisekisiweyo yenkqubo yokuvelisa umthamo ophezulu. Le yinkonzo ekhethekileyo enikezela ngeenxalenye ezipheleleyo zomgangatho wemveliso ngokwemiqulu ukuya kwizigidi zamaqhekeza ngenyanga. Umthamo omkhulu wokubumba inaliti yeplastiki ivumela ukuchaneka okuphezulu kokunyamezela, ilahleko ephantsi ye-scrap, kunye nokugcinwa kweendleko.

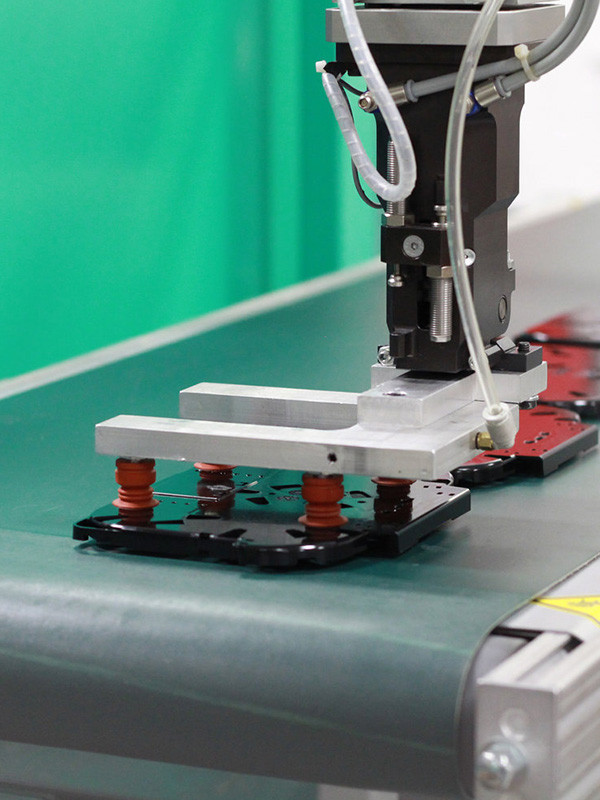

Uninzi lwezixhobo zethu zokubumba ezinomthamo ophezulu zenziwe ngekhompyutha kwaye zisebenzisa iisistim zoomatshini ukongeza ukusebenza kunye nokukhusela umgangatho. Qinisekisa ukujonga "iNkqubo yoLawulo loBulunga" ukuze sibone indlela esiqinisekisa ngayo ukuba ulawulo lomgangatho lubandakanyiwe kuyo yonke imveliso yevolumu ephezulu. Olu hlobo lokuvelisa lufanelekile kumashishini aphakathi kunye nobukhulu obukhulu okanye imveliso yobuninzi.

I-DJmolding's High-Volume Injection Molding Advantages

*Ivelisa iindawo ezininzi ngesantya esikhawulezayo

*Nciphisa iindleko zeyunithi kunye nexesha lokujikela kumenzi

*Ichanekile kwaye ingaguquguquki, imveliso ekumgangatho ophezulu yamalungu

*Imveliso idla ngokuzenzekela ngoomatshini abaqinileyo, abathembekileyo, nangeeyure ezingezizo ezomsebenzi

*Umsebenzi omncinci wasemva kwemveliso

UkuBunjwa koMqulu oPhezulu oSetyenzisiweyo (Iimveliso zesitofu zePlastiki)

Ukubumba kwesiko lika-DJmolding kunye nokubumba umthamo ophezulu kubandakanya yonke into ukusuka kwiiprototypes ukuya kwimveliso epheleleyo. Iimolds zethu zomthamo ophezulu, nokuba zifutshane, ziphezulu, okanye i-multiple-cavity, zibekwe esweni kwaye zilawulwa ukuze uqiniseke ngayo yonke imiba yoyilo kunye nokwakha. Le ngqalelo kwiinkcukacha zemveliso iqinisekisa iinjongo, iinjongo, kunye neziphumo zeprojekthi ezicwangcisiweyo zikwishedyuli kwisigaba ngasinye senkqubo. Konke ukubumba umthamo ophezulu, ukusuka kuyilo ukuya kwimveliso, kugqitywe endlwini kwaye kubonelele abathengi bethu ngezibonelelo zokukhuphisana kwiindleko, umgangatho, kunye namaxesha okukhokela.

I-DJmolding isebenza kunye nomxhasi ukuyila kunye neemveliso zobunjineli, ukuphuhlisa ezona zibumba ziphezulu zexabiso eliphezulu. Sinikezela ngomgangatho obalaseleyo wokubumba umthamo ophezulu okhethekileyo kwishishini lokubumba inaliti yeplastiki, enikezela ngoluhlu olubanzi lweenkonzo. Ukusuka ekubumbeni umthamo ophantsi, ukufaka ukubumba, kunye noshicilelo lwephedi, i-PTI, Inc. luphawu onokuluthemba kwiinkonzo zakho zokubumba inaliti yeplastiki.

I-DJmolding prototype components kubathengi abakwiindawo ezahlukileyo ezifana nezonyango, umbane, isixhobo sesandla, unxibelelwano, kunye namashishini eemoto. Kubandakanya inaliti kunye noxinzelelo loxinzelelo olusuka kwi-85-500 Ton, uninzi lwezixhobo zokubumba zevolumu ephezulu ze-DJmolding zifakwe kwikhompyuter kwaye zisebenzisa iinkqubo zoomatshini ukunyusa ukusebenza kakuhle kunye nokukhusela umgangatho. Kwi-DJmolding sithatha isimo sengqondo sentsebenziswano kuwo onke amalinge, sizisa iminyaka yolwazi lokubumba inaliti yeplastiki kunye nobuchule bobugcisa kwiziko eliyilelwe ukubonelela ngamava abanzi okubumba inaliti yeplastiki.

Ukwakhiwa kokungunda komthamo ophezulu kufuna indibaniselwano yetekhnoloji, izixhobo kunye nabakhi bokubumba abaqeqeshiweyo ukuze benze iinaliti zokungunda ngokukhawuleza ngejiyometri ephantse ingenamda kumacandelo eplastiki.

Ukusuka kuyilo ukuya kuhambiso, i-DJmolding inokulungelelanisa inkqubo yakho yonke yokwakha isixhobo ukusuka ekuqaleni ukuya ekugqibeleni. Incediswa yinkqubo yoqinisekiso lomgangatho wayo, injongo ye-PTI kukubonelela ngeemveliso ezibunjiweyo ezihlangabezana ngokupheleleyo okanye ezingaphezulu kweemfuno kunye nokulindelwe ngabathengi bayo. Ulawulo lwenkampani luzibophelele kuphuculo oluqhubekayo lomgangatho. Ngomgangatho ophezulu kunye neenkonzo zokubumba umthamo ophezulu osebenzayo, qhagamshelana no-DJmolding. namhlanje.

Iinkampani ezininzi azinawo amandla okubonelela ngesiqalo esibanzi ukugqiba amava okwenza umngundo. Nokuba ujonge iiprototypes ezimbalwa ezikhawulezayo, amawaka eeplastiki zabathengi ezilungele ukuthengisa, okanye iinxalenye zemveliso ezisisigidi, i-DJmolding inokubonelela ngento oyifunayo. Okuphantsi kunye nomthamo ophezulu, sigxininisa ngokuzingca ukuba umyalelo ngamnye unomgangatho ofanayo. Qhagamshelana neengcali zethu namhlanje.

Ukusuka kuyilo ukuya kuhambiso, i-DJmolding inokulungelelanisa inkqubo yakho yonke yokwakha isixhobo ukusuka ekuqaleni ukuya ekugqibeleni. Ngomgangatho ophezulu kunye neenkonzo ezisebenzayo, Cela iQuote ngokuthumela ulwazi lwakho ku info@jasonmolding.com

Inkqubo yokwenziwa komthamo ophezulu wokubumba inaliti ivelisa iinxalenye ezininzi zeplastiki ezifanayo. Le nkqubo iyathandwa kuba ibiza imali eninzi, iyasebenza, kwaye ihambisa iziqwenga ezingaguqukiyo, ezikumgangatho ophezulu. Esi sithuba sebhlog siya kuphonononga yonke into oyifunayo malunga nokubumba inaliti yevolumu ephezulu, kubandakanya izibonelelo zayo, izinto ezingeloncedo, usetyenziso, kunye nokunye.

Yintoni i-High Volume Injection Molding?

Ukubumba inaliti yomthamo ophezulu yinkqubo yokuvelisa evelisa iindawo ezininzi zeplastiki ezifanayo. Inkqubo ibandakanya ukutofa izinto zeplastiki ezinyibilikisiweyo kwindawo yokungunda kuxinzelelo oluphezulu kunye nobushushu, ukuyivumela ukuba iphole kwaye iqine kwimilo efunekayo. Le nkqubo izenzekelayo kakhulu inokuvelisa amawaka okanye izigidi zamalungu afanayo kwimveliso enye.

Inkqubo yemveliso encomekayo yeyona nto iphambili kwimpumelelo yokubumba inaliti ephezulu. Le nkqubo ibandakanya ukusebenzisa oomatshini bokubumba inaliti enesantya esiphezulu kunye neenkqubo ezizisebenzelayo ezenza ukuveliswa kwamalungu akhawulezayo nachanekileyo. Ukongeza, abavelisi banokuqinisekisa ukuba benza into nganye kwiinkcukacha ngokusebenzisa imibumbo ekumgangatho ophezulu kunye nokusebenzisa iiparitha ezithile zokutofa.

Olona ncedo lubalulekileyo lokubumba inaliti yomthamo ophezulu kukukwazi ukuvelisa inani elikhulu lamalungu afanayo ngokukhawuleza nangeendleko ezifanelekileyo. Inkqubo yokuvelisa ifanelekile kwiimoto, iimpahla zabathengi, izixhobo zonyango, kunye namashishini ombane.

Enye inzuzo yokubumba inaliti ephezulu kukukwazi ukuvelisa iindawo ezinzima kunye nokunyamezela okuqinileyo. Inkqubo yokubumba isitofu ichanekile kwaye ayiguquguquki, ibangela iinkcukacha ezintsonkothileyo ezinomahluko omncinci phakathi kwamaqhekeza.

Ngaphandle kweenzuzo ezininzi, ukubumba inaliti yevolumu ephezulu kunemida ethile. Ngokomzekelo, kunokubakho ukhetho olungcono lokuvelisa iindawo ezinkulu kakhulu okanye ezincinci, njengoko iindleko kunye nobunzima bokubumba obufunekayo bunokuthintela. Ukongeza, umthamo omkhulu weplastiki unokuba neempembelelo zokusingqongileyo, nto leyo eyenza kube yimfuneko ukuba abavelisi baqwalasele uzinzo kunye neenzame zokurisayikilishwa.

Ukubumba inaliti yevolumu ephezulu yinkqubo yokwenziwa esebenza kakuhle kwaye esebenzayo enokuvelisa izixa ezikhulu zamalungu eplastiki afanayo ngokukhawuleza nangeendleko ezifanelekileyo. Lukhetho olufanelekileyo kuluhlu olubanzi lwamashishini, kwaye ukuchaneka kwayo kunye nokuhambelana kwayo kwenza kube lukhetho oludumileyo lokuvelisa iinxalenye ezinzima kunye nokunyamezela okuqinileyo. Ngelixa inezinto ezithile ezisikelwe umda, izibonelelo zokubumba inaliti yomthamo ophezulu zenza ukuba ibe sisixhobo esixabisekileyo kubavelisi abafuna ukuvelisa izixa ezikhulu zamalungu eplastiki akumgangatho ophezulu.

Isebenza Njani Ukubumba Isitofu seVolumu ephezulu?

Inkqubo ibandakanya amanyathelo abalulekileyo amaninzi, ngalinye libaluleke kakhulu ekuveliseni iindawo ezikumgangatho ophezulu. Esi sithuba sebhlog siya kuchaza indlela ukubumba inaliti yevolumu ephezulu kusebenza ngayo, kubandakanya namanyathelo ayo aphambili kunye nokuqwalaselwa.

Uyilo lokungunda kunye nokuLungisa

Inyathelo lokuqala ekubumbeni inaliti yomthamo ophezulu kukuyila nokulungiselela ukubumba abaza kukusebenzisa ukuvelisa amalungu. Ukusebenzisana nomenzi wokubumba kuyimfuneko ukudala uyilo oluchanekileyo oluhlangabezana nazo zonke iinkcukacha ezibalulekileyo zokwenza iindawo ezifunekayo. Ngokuqhelekileyo, abavelisi benza i-mold kwintsimbi okanye i-aluminium kwaye bayiyile ukuze imelane noxinzelelo oluphezulu kunye nobushushu benkqubo yokubumba inaliti.

Ukulungiselela izinto

Inyathelo elilandelayo lelokuba abavelisi balungiselele imathiriyeli yeplastiki abaza kuyisebenzisa ukuvelisa amalungu. Ukukhetha i-resin yeplastiki efanelekileyo kubalulekile ukudala iimpawu ezinqwenelekayo, njengoko uhlobo lwentlaka esetyenzisiweyo luxhomekeke kwiimfuno ezithile. I-resin ke ifakwe kumatshini wokubumba inaliti, ifudunyezwe, kwaye inyibilike ibe lulwelo.

Inkqubo yokubumba isitofu

Inkqubo yokubumba inaliti iqala xa izinto zeplastiki ezinyibilikisiweyo zitofwa kumgodi wokungunda ngoxinzelelo oluphezulu kunye nobushushu. Isikhunta sibanjwe sivaliwe phantsi koxinzelelo de iplastiki ipholile kwaye iqiniswe; kweli nqanaba, ukubumba kuyavulwa, kwaye inxalenye ikhutshiwe.

Ulawulo lwemeko

Nje ukuba iinxalenye zivelisiwe, zingena kwinkqubo yolawulo lomgangatho ongqongqo ukuqinisekisa ukuba ziyahlangabezana nemigaqo efunekayo. Oku kunokubandakanya ukuhlolwa okubonakalayo, umlinganiselo, kunye novavanyo lokuqinisekisa ukuba inxalenye nganye iyahambelana ngobungakanani, imilo kunye nomgangatho.

Iingqwalasela kwi-High-Volume Injection Molding

Kukho iingqwalasela ezininzi ekufuneka abavelisi bazigcine engqondweni xa besebenzisa ukubumba inaliti yevolumu ephezulu, kubandakanya:

- Ukukhethwa koomatshini: Oomatshini bokubumba inaliti yesantya esiphezulu ngokuqhelekileyo basetyenziselwa ukuveliswa kwevolumu ephezulu, njengoko banokukhawuleza nangokuchanekileyo ukuvelisa iindawo.

- Uyilo lokungunda: Uyilo lokubumba lubalulekile kwimpumelelo yenkqubo yokubumba isitofu, njengoko kufuneka ichaneke kwaye ikwazi ukumelana noxinzelelo oluphezulu kunye nobushushu benkqubo.

- Ukhetho lwezixhobo: Ukukhethwa kwe-resin yeplastiki kunokuchaphazela umgangatho kunye nokusebenza kweendawo eziveliswayo, okwenza kube yimfuneko ukukhetha izinto ezifanelekileyo zomsebenzi.

- Iindleko: Ngelixa i-high-volume injection molding yinkqubo yokuvelisa indleko, kusekho iindleko ezinxulumene noyilo lokubumba, ukukhetha izinto eziphathekayo, kunye nemveliso ekufuneka ithathelwe ingqalelo.

Izinto eziluncedo kwi-High Volume Injection Molding

Ukubunjwa kwenaliti yomthamo ophezulu kuguqule ishishini lemveliso ngokwenza ukuveliswa kweendawo ezifanayo zeplastiki ngobungakanani obukhulu ngesantya esingenakulinganiswa kunye nokusebenza kakuhle. Inkqubo ifumene ukuthandwa kumacandelo awohlukeneyo ngenxa yeenzuzo zayo ezininzi, iyenza ibe yindlela yokuvelisa kwiinkampani ezijonge ukunciphisa iindleko, ukunciphisa inkcitho, kunye nokunyusa imveliso yemveliso.

- Imveliso enexabiso eliphantsi: Ukubunjwa kwenaliti yomthamo ophezulu kuyasebenza kakhulu kwaye kuyazenzekela, kuyenza ingabizi kakhulu xa kuthelekiswa nezinye iinkqubo zokuvelisa. Nje ukuba ukubunjwa kuyilwe kwaye kulungiswe, inkqubo yokuvelisa inokuthi iqhube ngokuqhubekayo, ivelise amawaka okanye izigidi zamalungu afanayo kunye neendleko ezincinci zomsebenzi okanye eziphathekayo.

- Imveliso ePhezulu: Ngoomatshini bokubumba inaliti yesantya esiphezulu, abavelisi banokuvelisa inani elikhulu lamalungu achanekileyo ngexesha elifutshane. Oku kuthetha ukuba imveliso yemveliso inokunyusa ngokukhawuleza okanye iyancipha ukuhlangabezana nemfuno eguqukayo.

- Umgangatho ohambelanayo: Ukuchaneka kunye nokuhambelana kwe-high-volume injection molding kwenza kube yinto efanelekileyo yokuvelisa iindawo ezinokunyamezela okuqinileyo kunye neenkcukacha eziyinkimbinkimbi. Inkqubo ivumela ukuchaneka okuphezulu, ukuqinisekisa ukuba inxalenye nganye eveliswayo iyafana nezinye.

- Ukuguquguquka kwiCandelo loYilo: Ukubumba inaliti yomthamo ophezulu kunokuvelisa iindawo ezinoluhlu olubanzi loyilo kunye neemilo, kubandakanywa nezo zinejiyometri enzima. Oku kuthetha ukuba abavelisi banokuba neempawu ezihlangabezana neemfuno ezithile zabathengi kwaye banokuhlengahlengisa ngokulula ukuyila okanye utshintsho lwenkcazo yemveliso.

- Inkunkuma Ethotyiweyo: Ukusetyenziswa kokungunda okukumgangatho ophezulu kunye neeparamitha zokutofa ezichanekileyo kumthamo ophezulu wokubumba inaliti kunciphisa ubuninzi benkunkuma okanye inkunkuma eveliswayo ngexesha lenkqubo yokuvelisa. Oku kuthetha ukuba abavelisi banokwenza iinxalenye ezinenkunkuma encinci, ukunciphisa iindleko kunye nefuthe lokusingqongileyo.

- UFaneka olwandisiweyo lweMveliso: Ukubunjwa kwenaliti yomthamo ophezulu kuzenzekelayo, oku kuthetha ukuba kufuna umsebenzi omncinci kwaye kunokuqhuba ngokuqhubekayo ngongenelelo oluncinci. Oku kukhokelela ekusebenzeni kakuhle kwemveliso, njengoko abavelisi banokuvelisa iinxalenye ngokukhawuleza nangokufanelekileyo ngaphandle kwesidingo somsebenzi wezandla okanye ukubeka iliso.

Ukungalungi kwi-High-Volume Injection Molding

Ukubumba inaliti yomthamo ophezulu yinkqubo yokuvelisa esetyenziswa ngokubanzi ukuvelisa inani elikhulu lamalungu eplastiki afanayo ngokukhawuleza nangeendleko ezifanelekileyo. Nangona ineenzuzo ezininzi, ezifana neendleko-zokusebenza kunye nomgangatho ongaguqukiyo, kukwakho nokungonakali. Esi sithuba sebhlog siya kuphonononga ezinye zezinto ezingeloncedo zokubumba inaliti yevolumu ephezulu.

- Utyalo-mali oluPhezulu oluPhezulu: Enye yezinto ezingalunganga eziphambili zokubumba isitofu somthamo ophezulu kukunyuka kotyalo-mali lokuqala olufunekayo ukuyila kunye nokwenza umngundo. Ezi ndleko zinokubaluleka, ngakumbi kumashishini amancinci okanye lawo adinga ukubumba okulungiselelwe kwiindawo ezithile.

- Amaxesha AmanqathaInkqubo yokuyila kunye nokuveliswa kokubumba ukubumba kwenaliti ephezulu kunokuthatha iiveki ezininzi okanye iinyanga, okukhokelela kwixesha elide lokukhokela. Oku kunokuba yinto engalunganga kwiinkampani ezifuna ukuvelisa iinxalenye ngokukhawuleza okanye ukuphendula kwiinguqu kwiimfuno.

- Izinto eziNcinane zokuKhetha: Ngelixa uninzi lweentlobo zeentlaka zeplastiki zifumaneka ekubunjweni kwesitofu somthamo ophezulu, ukhetho lunokucuthwa ngokuxhomekeke kwisicelo esithile. Ezinye iirasi zeplastiki zisenokungafaneleki ukuveliswa komthamo omkhulu ngenxa yeempawu zazo, ezinokunqanda ukhetho lwempahla.

- Ukuguquguquka koyilo olunyiniweyo: Ukubunjwa kwenaliti yomthamo ophezulu yinkqubo echanekileyo efuna ukubumba ukuba kuyilwe kunye neenkcukacha ezithile. Oku kuthetha ukuba kunokubakho imida kuyilo lwamalungu avelisiweyo ngale nkqubo, ngakumbi ukuba indawo inejometri ezintsonkothileyo okanye ezinye iimfuno zoyilo ezahlukileyo.

- ULondolozo oluPhezulu kunye neeNdleko zokuLungisa: Izibungu ezisetyenziswe kwi-high-volume injection molding kufuneka zigcinwe kwaye zilungiswe rhoqo ukuze kuqinisekiswe ukusebenza kakuhle. Iindleko zokugcinwa kunye nokulungiswa zinokuba zibalulekileyo, ngakumbi ukuba iimbumba zisetyenziswa rhoqo okanye ixesha elide.

Ngaphandle kwezi zinto zingeloncedo, ukubumba inaliti yevolumu ephezulu kuhlala kuyinkqubo edumileyo nesebenzayo yokuvelisa ukuvelisa izixa ezikhulu zamalungu eplastiki afanayo. Ngokuqwalasela ngononophelo iingenelo kunye nokungonakali kwale nkqubo, abavelisi banokwenza izigqibo ezinolwazi malunga nokuba lukhetho olufanelekileyo kwiimfuno zabo ezithile zemveliso.

Izinto ezisetyenziswa kwi-High-Volume Injection Molding

Ukukhetha izixhobo ezifanelekileyo zokubumba inaliti yomthamo ophezulu kubalulekile ukuqinisekisa umgangatho kunye nokusebenza kwemveliso yokugqibela. Eli nqaku lijonge kwizinto ezisetyenziselwa ukubumba inaliti yevolumu ephezulu, iipropathi zazo, kunye nokusetyenziswa kwazo.

Iipolypropylene (PP)

I-Polypropylene yipolymer ye-thermoplastic esetyenziswa ngokuqhelekileyo ekubunjweni kwenaliti ephezulu ngenxa yeendleko zayo eziphantsi, umlinganiselo wamandla ukuya kubunzima, kunye nokuqina. I-PP iyaguquguquka kwiimoto, ukupakisha, kunye nemveliso yempahla yabathengi. Iingenelo zokusebenzisa i-PP ekubunjweni kwenaliti ibandakanya ubume bayo obukhaphukhaphu, ukuxhathisa kweekhemikhali, kunye nokuzinza kwe-dimensional, ezenza ukuba zilungele iindawo ezichanekileyo.

I-Acrylonitrile Butadiene Isitayile (ABS)

I-ABS yipolymer ye-thermoplastic eyaziwa ngokuba lukhuni kwayo, ukuxhathisa impembelelo, kunye nokugqitywa kweglosi ephezulu. Esi sixhobo siqhele ukusetyenziswa kwizinto zokudlala, iinxalenye zemoto, kunye nezindlu zombane. Ukuchasana kwempembelelo ye-ABS kuyenza ilungele iinkcukacha eziphantsi kwempembelelo okanye ukothuka. Ikwalula ukusetyenzwa kwaye inomphezulu ogqwesileyo ogqityiweyo, iyenza ilungele imveliso yomthamo ophezulu.

IPolycarbonate (PC)

I-Polycarbonate yipolymer ye-thermoplastic ekwazi ukumelana neempembelelo, icacile ngokubonakalayo, kwaye iyakwazi ukumelana nobushushu. Yimathiriyeli eyaziwayo kwimizi-mveliso yeemoto, i-aerospace, kunye ne-electronics. Izibonelelo zePC zibandakanya ukumelana nempembelelo ebalaseleyo, ukucaca okubonakalayo, kunye nokumelana nobushushu, kuyenza ilungele usetyenziso lobushushu obuphezulu, iilensi, kunye nezikrini.

I-Polyethylene (PE)

I-Polyethylene yipolymer ye-thermoplastic eguquguqukayo, eqinile, kunye ne-chemical-resistant. Ngokuqhelekileyo isetyenziselwa ukuvelisa izinto zokupakisha, iingxowa zeplastiki, kunye neefilimu zezolimo. Ukumelana neekhemikhali ze-PE, ukuguquguquka, kunye nendalo ekhaphukhaphu yenza ukuba ilungele izixhobo zokulungisa imichiza, ukupakishwa kweekhemikhali, kunye nosetyenziso olufuna ukuba iindawo zigobe okanye zigobe.

IPolyethylene Terephthalate (PET)

I-PET yipolymer ye-thermoplastic enomlinganiselo ophezulu wamandla-to-ubunzima, ukucaca, kunye neempawu zokuthintela. Ivelisa iibhotile zesiselo, izitya zokutya, kunye nezinto zokupakisha. Izibonelelo ze-PET zibandakanya amandla ayo-kubunzima bokulinganisela, ukucaca, kunye neempawu zokuthintela ezenza ukuba zilungele izicelo apho amandla ayimfuneko, njengeebhotile zesiselo kunye nokupakishwa apho iziqulatho kufuneka zikhuselwe kumswakama kunye ne-oksijini.

Polystyrene (PS)

I-Polystyrene yipolymer ye-thermoplastic ekhaphukhaphu, eneendleko ezifanelekileyo kwaye ineempawu ezilungileyo zokugquma. I-PS iqhele ukusetyenziselwa ukuvelisa iikomityi ezilahlwayo, izinto zokupakisha, kunye nokugquma, kwaye iingenelo zayo ziquka ixabiso eliphantsi, indalo ekhaphukhaphu, kunye neempawu ezilungileyo zokugquma.

Iintlobo zoomatshini bokuBumba be-Injection ezisetyenziselwa ukuveliswa komthamo ophakamileyo

Le nkqubo ibandakanya ukutofa izinto zeplastiki ezinyibilikisiweyo kumngxuma wokungunda, apho uqina kwaye uthatha ubume bomngundo. Oomatshini bokubumba be-injection beza kwiindidi ezahlukeneyo, kwaye nganye ifanele uhlobo oluthile lwemveliso. Nazi iintlobo eziphambili zoomatshini bokubumba benaliti abasetyenziselwa ukuvelisa umthamo omkhulu:

- Oomatshini bokuBumba beSitofu seHydraulic: Aba matshini basebenzisa uxinzelelo lwehydraulic ukuhambisa ukungunda kunye nokutofa iplastiki etyhidiweyo kumngxuma. Ziyaziwa ngemveliso yazo ephezulu kodwa zinexesha elicothayo lomjikelo, zinciphisa ukusetyenziswa kwazo ngokuchanekileyo okuphezulu kunye nezicelo ezikhawulezayo.

- Oomatshini bokuBumba boMbane bokuTofa: Aba matshini basebenzisa i-servo motors zombane ukuqhuba iyunithi yokutofa kunye nokungunda. Banikezela ngokuchaneka okuphezulu kunye nesantya, okubenza balungele amashishini akumgangatho ophezulu njengezixhobo zonyango kunye ne-elektroniki.

- Oomatshini bokuBumba be-Hybrid Isitofu: Aba matshini badibanisa awona mazwe mabini. Basebenzisa i-hydraulic kunye neenkqubo zombane zokuqhuba iyunithi yokutofa kunye nokungunda. Iinjini zeHybrid zisebenza kakuhle kwaye ziyakhawuleza, zinemveliso ephezulu, ezenza zilungele ukuveliswa kwevolumu ephezulu.

- Oomatshini bokuBumba oomatshini bokuTofwa abaDubu-mbini: Aba matshini bavelisa iindawo ezinzima ezifuna izinto ezimbini ezahlukeneyo okanye imibala. Isixhobo sineeyunithi ezimbini zokutofa ezisebenza kunye ukwenza isiqwenga sokugqibela. Oomatshini bokubumba benaliti abadutyulwe kabini bakulungele ukuvelisa iimveliso ezikumgangatho ophezulu ezinamacandelo amaninzi.

- Oomatshini bokuBumba beSitofu esinezinto ezininzi:Aba matshini bavelisa iindawo ezenziwe ngezinto ezahlukeneyo. Baneeyunithi ezininzi zokutofa ezibavumela ukuba basebenzise ezinye izinto ngaxeshanye. Oomatshini bokubumba inaliti yezinto ezininzi balungile ekudaleni amaqhekeza afuna iipropathi ezahlukeneyo, njengamandla, ukuqina, kunye nokuguquguquka.

- Oomatshini bokuBumba beSitofu soLwadi: Aba matshini basetyenziselwa ukuvelisa iindawo ezenziwe ngerabha elulwelo lwe-silicone (LSR). Umatshini ufaka i-LSR kwi-mold cavity, apho iqina kwaye ithatha ubume be-mold. Oomatshini bokubumba inaliti yolwelo balungele ukuvelisa iindawo ezifuna ukuchaneka okuphezulu kunye nokuqina, njengezixhobo zonyango kunye neendawo zemoto.

I-Injection Molding Process Steps for High-Volume Production

Le nkqubo ibandakanya ukutofa izinto zeplastiki ezinyibilikisiweyo kumngxuma wokungunda, apho uqina kwaye uthatha ubume bomngundo. Nanga amanyathelo abandakanyekayo kwinkqubo yokubumba inaliti yokuvelisa umthamo ophezulu:

- Ukhetho lwezixhobo: Isinyathelo sokuqala kwinkqubo yokubumba isitofu kukukhetha izinto ezifanelekileyo zokuvelisa inxalenye. Izinto ezikhethiweyo kufuneka zibe neempawu ezifunekayo, njengamandla, ukuqina, kunye nokuguquguquka, kwaye zihambelane nomatshini wokubumba umjovo.

- Uyilo lokungunda: Inyathelo elilandelayo kukuyila ukungunda xa imathiriyeli ikhethiwe. Umngundo ufanele ulungiswe ngokweenkcukacha zenxalenye eveliswayo, kuquka ukumila kwayo, ubungakanani kunye neempawu zayo. Ukubumba kufuneka kwakhona kuthathele ingqalelo uhlobo lomatshini wokubumba osetyenziswayo kunye neemfuno ezithile zenkqubo yokuvelisa.

- Ukuseta oomatshini: Emva kokuba umngundo uyilwe, umatshini wokubumba wokutofa uyamiselwa. Oku kubandakanya ukufaka isikhunta kwisixhobo, ukuseta ubushushu obufanelekileyo kunye nezicwangciso zoxinzelelo, kunye nokuqinisekisa ukuba yonke into isebenza ngokuchanekileyo.

- Inaliti: Inkqubo yokutofa iqala xa iplastiki etyhidiweyo igalelwe kumgodi wokungunda. Oku kwenziwa ngokusebenzisa iyunithi yokutofa yoxinzelelo oluphezulu olunyanzela izinto ezibonakalayo kwi-mold kwizinga elithile kunye noxinzelelo.

- Ukupholisa:Emva kokuba impahla yeplastiki etyhidiweyo ifakwe kwi-mold cavity, kufuneka ivunyelwe ukuba ipholile kwaye iqine. Oku kwenziwa ngokujikelezisa umoya opholileyo okanye amanzi kumgodi wokungunda ukunciphisa ubushushu bezinto.

- Ukukhutshwa: Emva kokuba izinto zeplastiki zipholile kwaye ziqina, i-mold ivuliwe, kwaye inxalenye iyakhutshwa. Inkqubo yokukhupha ibandakanya ukusebenzisa i-mechanical okanye i-hydraulic system ukutyhala inxalenye ngaphandle kwendawo yokubumba.

- Ulawulo lwemeko: Emva kokuba inxalenye ikhutshiwe, ihlola ukulawulwa komgangatho ukuqinisekisa ukuba ihlangabezana neenkcukacha ezifunekayo. Oku kunokubandakanya ukuhlolwa okubonakalayo, umlinganiselo, kunye novavanyo lokuqinisekisa ukuba inxalenye ikumgangatho ophezulu kwaye ayinaziphene.

Iingqwalaselo zoYilo lokuBumba kweSitofu esiPhezulu

Ukuyila inxalenye yeplastiki yokubunjwa kwenaliti yomthamo ophezulu kufuna uqwalaselo ngononophelo lwemiba emininzi ukuqinisekisa ukuba isiqwenga sinokuveliswa ngokufanelekileyo nangeendleko ezifanelekileyo. Nantsi eminye imiba yoyilo lokubumba inaliti yevolumu ephezulu:

- Ukuqina kweWall: Ubukhulu bodonga lwenxalenye yeplastiki yingqwalasela ebalulekileyo yokubumba inaliti. Ubunzima beendonga kufuneka bufane ukuze kuthintelwe ukupholisa okungalinganiyo kunye ne-warping yesiqhekeza. Iindonga ezibhityileyo zilungele imveliso ephezulu yomthamo njengoko zinciphisa ukusetyenziswa kwezinto kunye nexesha lokujikeleza, ngelixa iindonga ezingqingqwa zilungele iindawo ezifuna amandla angaphezulu.

- Ubungakanani beNdawo kunye noBume: Ubungakanani kunye nokumila kwenxalenye kuya kuba nefuthe kwinkqubo yokubumba inaliti. Izinto ezinkulu kakhulu okanye ezintsonkothileyo zinokufuna amaxesha omjikelo omde okanye izixhobo ezikhethekileyo, ukonyusa iindleko zemveliso. Ukulula, iimilo zejometri zilungele ukuveliswa kwevolumu ephezulu.

- Iiengile zoyilo: I-angle yedrafti yi-angle yodonga lwe-mold cavity evumela ukukhutshwa lula kwenxalenye. Ukubandakanya Ukubandakanya ii-engile zokuyila kuyilo lwenxalenye kubalulekile ukuqinisekisa ukuba isiqwenga sinokukhutshwa ngokukhawuleza kwi-mold. Amanani angenawo ama-angles ayidrafti angabangela imiba yemveliso ebiza kakhulu efana nokuqhekeka okanye ukuguqulwa.

- Indawo yeSango kunye nobukhulu:Indawo kunye nobukhulu besango, apho izinto zeplastiki ezityhidiweyo zingena kumngxuma wokungunda, yinto ebalulekileyo yoyilo oluqwalaselwayo lokubumba inaliti. Indawo yesango kufuneka ibekwe kwindawo engayi kuchaphazela ukunyaniseka kwesakhiwo senxalenye. Ubungakanani besango kufuneka bube bukhulu ngokwaneleyo ukuvumela ukuba impahla ihambe ngokuchanekileyo kodwa ingabi nkulu kangangokuba ibangele iziphene kwindawo.

- Ukhetho lwezixhobo: Ukukhethwa kwezinto eziphathekayo kubalulekile ukuqinisekisa ukuba inxalenye inokuveliswa ngokufanelekileyo kunye neendleko ezifanelekileyo. Ukukhethwa kwezinto eziphathekayo kufuneka kusekelwe kwiimfuno ezithile zeqhekeza, kubandakanywa amandla, ukuqina, kunye nokuguquguquka.

- Isiqhelo sokugqibela: Umphezulu wenxalenye yingqwalasela ebalulekileyo yokubumba inaliti. Ukugqitywa komphezulu wesixa kufuneka kube lula kwaye kungabi naziphene, ezifana ne-warping okanye amanqaku e-sink. Ukubekwa kwesango ngokufanelekileyo, uyilo lokubumba, kunye nokukhethwa kwezinto eziphathekayo kunokufikelela ukugqitywa komphezulu ogudileyo.

- Tolerance: Ukunyamezela yiqondo lokwahluka okuvunyelweyo kwimilinganiselo yenxalenye. Ukunyamezela kufuneka kuthathelwe ingqalelo ngexesha lesigaba sokuyila inxalenye ukuqinisekisa ukuba isiqwenga sinokuveliswa ngokuchanekileyo nangokuchanekileyo.

Imilinganiselo yokulawula umgangatho kwi-High-Volume Injection Molding

Ulawulo lomgangatho luyimfuneko ekubunjweni kwesitofu somthamo ophezulu, njengoko kuqinisekisa ukuba iindawo eziveliswayo ziyahlangabezana nemigaqo efunekayo kwaye azinaziphene. Nanga amanye amanyathelo okulawula umgangatho asetyenziswa ekubumbeni isitofu somthamo ophezulu:

- Ukuhlolwa ngexesha leNkqubo yeMveliso: Ukuphononongwa rhoqo ngexesha lenkqubo yemveliso kunokunceda ukuchonga iziphene kwangethuba kwaye zibathintele ekubeni babe yimiba ebalulekileyo. Oku kunokubandakanya ukuhlolwa okubonakalayo, umlinganiselo, kunye novavanyo ukuqinisekisa ukuba inxalenye yenziwe ngokuchanekileyo.

- Ulawulo lweNkqubo yoBalo (SPC): I-SPC yindlela yamanani esetyenziswa ukujonga nokulawula inkqubo yokuvelisa. Ibandakanya ukuqokelela idatha kwinkqubo yokuvelisa kunye nokuyihlalutya ukuchonga iintsingiselo kunye neepatheni ezinokubonisa imiba ngenkqubo. I-SPC inokunceda ekuboneni nasekulungiseni iingxaki phambi kokuba zibe neziphumo zeendawo ezineziphene.

- Ukusetyenziswa kweZixhobo eziziSebenzisayo: Izixhobo ezizenzekelayo, ezifana neerobhothi kunye neenzwa, zinokunceda ukuphucula ukuhambelana kunye nokuchaneka kwenkqubo yokuvelisa. Izixhobo zoomatshini nazo zinokuwunciphisa umngcipheko weempazamo zabantu, okukhokelela kwiziphene ezimbalwa.

- Ugcino lokungunda:Ukugcinwa ngokufanelekileyo kokungunda kubalulekile ekuqinisekiseni ukuba iindawo eziveliswayo zikumgangatho ophezulu. Oku kubandakanya ukucoca isikhunta rhoqo kunye nokwenza naluphi na ukulungiswa okuyimfuneko okanye ukutshintshwa ukuze kuqinisekiswe ukuba isikhunta sisebenza ngokuchanekileyo.

- Uhlolo lwasemva kweMveliso: Emva kokuba iinxalenye zivelisiwe, zihlolwa okokugqibela ukuqinisekisa ukuba ziyahlangabezana nemigaqo efunekayo. Oku kunokubandakanya uhlolo olubonakalayo, umlinganiselo, kunye novavanyo lokuqinisekisa ukuba amalungu awanaziphene.

- UQeqesho neMfundo: Uqeqesho olufanelekileyo kunye nemfundo yabasebenzi inokuphucula umgangatho wenkqubo yokuvelisa. Abasebenzi kufuneka baqeqeshwe kubuchule obufanelekileyo bokuvelisa kunye nemilinganiselo yokulawula umgangatho ukuqinisekisa ukuba bayakwazi ukuchonga nokulungisa imiba njengoko ivela.

- Uphuculo oluqhubekayo: Ukuphuculwa okuqhubekayo kubalulekile kulawulo lomgangatho kwi-high-volume injection molding. Ngokuphonononga rhoqo inkqubo yemveliso kunye nokuchonga iindawo zokuphucula, abavelisi banokunciphisa iziphene kwaye baphucule umgangatho wamacandelo avelisiweyo.

Uhlalutyo lweendleko ze-High-Volume Injection Molding

Ukubumba inaliti yomthamo ophezulu yinkqubo yokwenziwa kweendleko zokuvelisa izixa ezikhulu zamalungu eplastiki. Nangona kunjalo, iindleko zokuvelisa iinxalenye ngokubumba inaliti inokwahluka ngokusekelwe kwizinto ezininzi. Nazi ezinye zeengcamango zohlalutyo lweendleko zokubumba isitofu somthamo ophezulu:

- Iindleko zezinto: Iindleko zemathiriyeli ekrwada yenye yezona zinto zibalulekileyo ezichaphazela ixabiso lenaliti yokubumba. Uhlobo kunye nomgangatho wemathiriyeli esetyenzisiweyo iya kuba nefuthe kwixabiso, kunye nezinye izixhobo zibiza kakhulu kunezinye. Abavelisi kufuneka bakhethe imathiriyeli efanelekileyo ngokusekelwe kwiimfuno ezithile zenxalenye.

- Iindleko zezixhobo: Iindleko zesixhobo, kubandakanywa ukubumba kunye nezinye izixhobo ezifunekayo ekubunjweni kwenaliti, yenye into ebalulekileyo echaphazela iindleko zemveliso. Iindleko zezixhobo zinokwahluka ngokuxhomekeke kubunzima benxalenye, ubungakanani bemold, kunye nenani lemingxuma ekubumbeni.

- Iindleko zabasebenzi: Iindleko zabasebenzi ziyinto ebalulekileyo ekubunjweni kwenaliti, njengoko inkqubo idinga abasebenzi abanezakhono ukuba basebenzise oomatshini kwaye bajonge inkqubo yokuvelisa. Iindleko zomsebenzi zinokwahluka ngokuxhomekeke kwindawo kunye namava abasebenzi.

- Iindleko eziphezulu: Iindleko ezingaphezulu, kubandakanywa izinto eziluncedo, irenti, kunye nezinye iindleko, zinokuchaphazela iindleko zokubumba inaliti. Ezi ndleko zinokwahluka ngokuxhomekeke kwindawo yokuvelisa kunye nobukhulu bomsebenzi.

- Umthamo weMveliso: Umthamo wemveliso yinto ebalulekileyo echaphazela iindleko zokubumba inaliti. Umthamo ophezulu wemveliso unokukhokelela kwiindleko eziphantsi ngenxalenye nganye ngenxa yoqoqosho lwesikali.

- Uyilo lwenxalenye: Uyilo lunokuchaphazela iindleko zokubumba inaliti. Izinto ezintsonkothileyo okanye ezifuna izixhobo ezikhethekileyo zinokunyusa ixabiso lemveliso.

- Ulawulo lwemeko: Iindleko zamanyathelo okulawula umgangatho, kubandakanywa ukuhlolwa kunye nokuvavanya, kunokuchaphazela iindleko zemveliso. La manyathelo ayimfuneko ukuqinisekisa ukuba iinxalenye eziveliswayo ziyahlangabezana nemigaqo efunekayo kwaye azinasiphako.

Amashishini asebenzisa i-High Volume Injection Molding

Ukubumba inaliti yomthamo ophezulu yinkqubo yokuvelisa esetyenziswa ngokubanzi ekwaziyo ukuvelisa inani elikhulu lamalungu eplastiki ngokukhawuleza nangokufanelekileyo. Nanga amanye amashishini axhomekeke kakhulu ekubunjweni kwesitofu somthamo ophezulu:

- Umzi mveliso weemoto: Umzi-mveliso weemoto ngomnye wabasebenzisi ababalulekileyo bokubumba inaliti ephezulu. Inkqubo yenza amacandelo eplastiki ahlukeneyo afana namalungu edeshibhodi, izibambo zocango, kunye neziqwenga zangaphakathi zokulungisa.

- Ushishino lweeMpahla zabaThengi: Ukubumba inaliti yevolumu ephezulu kuvelisa iimpahla ezahlukeneyo zabathengi, kubandakanya izixhobo zasekhaya, iithoyi, kunye ne-elektroniki. Inkqubo ikhethwa kuba ivumela abavelisi ukuba benze iinxalenye ezinkulu ngexabiso eliphantsi.

- Ishishini lezonyango: Ishishini lezonyango lifuna umgangatho ophezulu kunye namacandelo eplastiki achanekileyo kwizixhobo zonyango ezahlukeneyo, ezifana nezixhobo zokuxilonga, izixhobo zotyando, kunye nezixhobo zonyango ezilahlayo. Ukubunjwa kwesitofu somthamo ophezulu kuyakhethwa kuba kunokuvelisa ezi nxalenye ngokuchanekileyo nangokuqhubekayo.

- Icandelo:Umzi-mveliso wokupakisha uthembele kakhulu ekubunjweni kwenaliti yomthamo ophezulu ukuvelisa iintlobo ngeentlobo zezikhongozeli zeplastiki, izivalo, kunye nokuvalwa. Inkqubo ingabizi kwaye ivumela abavelisi ukuba benze iimilo ezahlukeneyo kunye nobukhulu ngokukhawuleza.

- Ishishini le-Aerospace: Ishishini le-aerospace lifuna amacandelo eplastiki asebenza kakhulu anokumelana neemeko ezinzima, ezifana nobushushu obuphezulu kunye noxinzelelo. Ukubumba inaliti yevolumu ephezulu kuvelisa la malungu, kubandakanywa iindawo zenqwelomoya zangaphakathi nangaphandle, ii-avionics, kunye ne-electronics.

- Ushishino loKwakha: Ishishini lokwakha lisebenzisa isitofu somthamo ophezulu wokubumba ukuvelisa izinto ezahlukeneyo zeplastiki, kuquka iifreyimu zefestile, imibhobho, kunye nokugquma. Inkqubo ikhethwa kuba ivumela ukuveliswa kwezinto ezininzi ezihlala ixesha elide kwaye zixhathisa kwizinto ezisingqongileyo.

- Ishishini lezeMidlalo noLonwabo: Ukubumba inaliti yomthamo ophezulu kuvelisa izinto ezahlukeneyo zeplastiki kushishino lwezemidlalo kunye nolonwabo, kubandakanya izigcina-ntloko, izixhobo zokukhusela, kunye nezinto zokudlala. Inkqubo ikhethwa ngenxa yokuba ivumela ukwenza iindawo ezikhaphukhaphu, ezihlala ixesha elide, kunye nezithandekayo.

Izibonelelo zokuBunjwa kwe-High-Volume Injection kuShishino lwezoNyango

Ishishini lezonyango lelinye lawona mashishini makhulu nakhula ngokukhawuleza ehlabathini. Ngenkqubela phambili yetekhnoloji kunye nemfuno ekhulayo yezixhobo zonyango kunye nezixhobo, kukho imfuneko yeenkqubo zokuvelisa ezisebenzayo ezinokuvelisa izinto ezikumgangatho ophezulu. Ukubumba inaliti yomthamo ophezulu yenye yenkqubo enjalo ebonelela ngeenzuzo ezininzi kushishino lwezonyango. Makhe siphonononge ezinye iingenelo zokubumba inaliti yevolumu ephezulu kushishino lwezonyango.

- Isebenza kakuhle emalini: I-high-volume injection molding yinkqubo yokuvelisa indleko evelisa ubuninzi bezinto zeplastiki ngexabiso eliphantsi kwiyunithi nganye.

- Ukuvumelana: Ukubunjwa kwenaliti yevolumu ephezulu kuvumela ukuvelisa iinxalenye ezine-viscosity ephezulu kunye nokuchaneka, ukuqinisekisa ukuba isiqwenga ngasinye sihlangabezana neenkcukacha ezifunekayo.

- Ngokwezifiso: Inkqubo ivumela uhlengahlengiso lweempawu ukuba zilungele iimfuno ezithile, kubandakanya umbala, ukuthungwa, kunye nemathiriyeli.

- Ukukhawuleza: Ukubunjwa kwenaliti ephezulu kuvumela ukuveliswa ngokukhawuleza kwezikhundla, ukunciphisa ixesha lokukhokela kunye nokwandisa ukusebenza kakuhle.

- umgangatho: Inkqubo yokubumba inaliti ephezulu ivelisa iindawo ezikumgangatho ophezulu ezihlangabezana nemigangatho engqongqo efunekayo kwizixhobo zonyango.

- Ukunyumba: Inkqubo iqhutyelwa kwindawo engcolileyo, iqinisekisa ukuba iindawo eziveliswayo azinangcoliseko kwaye zikhuselekile kwizicelo zonyango.

- Ukuzinza: Amalungu avelisiweyo kusetyenziswa ukubunjwa kwenaliti ephezulu yomthamo womelele kwaye anokumelana nemekobume erhabaxa, eqinisekisa ukuba zihlala ixesha elide kwaye zinciphisa isidingo sokutshintshwa. Ukomelela kubalulekile kwishishini lezonyango, apho izixhobo kunye nezixhobo kufuneka zimelane nokusetyenziswa rhoqo kunye nokuvezwa okunokubakho kwiikhemikhali kunye nezinye izinto ezibukhali.

- Ukutsala nzima: Inkqubo yokubumba inaliti ephezulu ivumela ukuveliswa kwamacandelo anzima kunye noyilo oluyinkimbinkimbi, ukuqinisekisa ukuba izixhobo zonyango zinokwenziwa ukuhlangabezana neemfuno ezichanekileyo zonyango lwanamhlanje. Inkqubo ilungele ukuvelisa amacandelo anzima aneempawu ezizodwa kunye noyilo oluyimfuneko kwizixhobo zonyango kunye nezixhobo.

- Ukuhluka: Ukubunjwa kwenaliti yevolumu ephezulu kunokuvelisa iindawo ezahlukeneyo ezinemilo kunye nobukhulu obahlukeneyo, nto leyo eyenza ukuba ilungele ukwenza amacandelo kwizicelo ezahlukeneyo zonyango.

Ukubunjwa kweTofo yeVolumu ephezulu yoShishino lweZithuthi

Isitofu sokubumba yinkqubo yokuvelisa ebandakanya ukutofa iplastiki enyibilikisiweyo kwindawo yokungunda ukwenza izinto ezahlukeneyo zeplastiki. Le nkqubo isetyenziswa kakhulu kumzi mveliso weemoto ukwenza iindawo ezininzi ezinje ngeepaneli zocango, iideshibhodi, iipaneli zesixhobo, ii-trim zangaphakathi, kunye namalungu omzimba angaphandle. Ukubumba inaliti yomthamo ophezulu yindlela ekhethekileyo eyenza abavelisi bavelise ngokukhawuleza inani elikhulu lamalungu afanayo.

Ukubumba inaliti yomthamo ophezulu yindlela yokuvelisa esebenza kakhulu ebonelela ngeenzuzo ezininzi kumzi mveliso weemoto. Ezinye zezi zibonelelo ziquka:

- Ukwehliswa kweendleko zemveliso - Inkqubo i-automated kakhulu, enciphisa iindleko zabasebenzi, kwaye iimbumba zivumela abavelisi ukuba bavelise iinxalenye ezifanayo ngexabiso eliphantsi.

- Ukuphuculwa kokuhambelana kwenxalenye - I-high-volume injection molding ivumela ukuveliswa kweendawo ezifanayo, ukunciphisa ukuhlukahluka kunye nokuphucula ukuthungwa kwindlela yokuvelisa.

- Amaxesha okuvelisa akhawulezayo - Inkqubo i-automated kakhulu, eyenza abavelisi bavelise izixa ezikhulu zamalungu ngokukhawuleza, ukunciphisa amaxesha okukhokela.

- Amalungu akumgangatho ophezulu- Ukusetyenziswa kwe-molds kuqinisekisa ukuba iindawo eziveliswayo zisemgangathweni ophezulu, zineziphene ezincinci kunye nokungahambelani.

- Ububhetyebhetye boyilo -Ukubumba isitofu kuvumela ukuvelisa ngokukhawuleza iimilo ezintsonkothileyo kunye noyilo, okunika abaqulunqi ukuguquguquka okukhulu kwizicwangciso zabo.

Ukubumba isitofu yeyona ndlela ifanelekileyo yokuvelisa kwishishini leemoto, njengoko ibonelela ngeenzuzo ezininzi eziphucula ukusebenza kakuhle, ukunciphisa iindleko, kunye nokuphucula umgangatho wenxalenye. Ukubumba inaliti yomthamo ophezulu, ngakumbi, bubuchule obukhethekileyo obuvumela abavelisi ukuba bavelise inani elikhulu lamalungu afanayo ngokukhawuleza nangempumelelo.

Umzi-mveliso weemoto uxhomekeke kakhulu kwinaliti yokubumba ukwenza izinto ezahlukeneyo zemoto kunye nezithuthi. Ukusuka kumalungu omzimba angaphandle ukuya kwii-trim zangaphakathi kunye needashbhodi, ukubumba inaliti kube yinkqubo ebalulekileyo yokwenziwa kweshishini leemoto. Ngokubunjwa kwenaliti yomthamo ophezulu, abavelisi banokuvelisa inani elikhulu lamalungu afanayo ngexabiso eliphantsi, kunye nokuphucula ukuhambelana kunye nomgangatho.

Ukubunjwa kweTofo yeVolumu ephezulu kuShishino lweMpahla yoMthengi

Ukubumba inaliti yomthamo ophezulu yinkqubo yokuvelisa eyamkelwa ngokubanzi lishishini lempahla yabathengi ngenxa yokukwazi ukuvelisa inani elikhulu lamalungu akumgangatho ophezulu ngokuchaneka okugqwesileyo kunye nokungaguquguquki. Le nkqubo isetyenziswa ngokuqhelekileyo ekwenzeni iimpahla zabathengi ezifana namathoyizi, i-kitchenware, kunye nezinto zokupakisha, phakathi kwabanye. Esi sithuba sebhlog siza kuphonononga izibonelelo zokubumba inaliti yevolumu ephezulu kwishishini lempahla yabathengi.

Izinto eziluncedo zokuBunjwa kwesitofu soMqulu oPhezulu:

- Isebenza kakuhle emalini: Olunye lolona ncedo luphambili lokubumba inaliti yomthamo ophezulu kukuba yindlela engabizi kakhulu yokwenza izixa ezikhulu zamalungu. Inkqubo i-automated kakhulu, eyanciphisa iindleko zabasebenzi, kwaye i-molds ingaphinda isetyenziswe, okunciphisa iindleko zezinto eziphathekayo.

- Ukungqinelana kunye nokuchaneka:Isitofu sokubumba sinika ukuchaneka okugqwesileyo kunye nokungaguquguquki ekuveliseni iindawo. Oku kungenxa yokuba iimolds ziyilelwe ngokweenkcukacha ezichanekileyo zezinto, ukuqinisekisa ukuba isiqwenga ngasinye sinomgangatho kunye nobukhulu obufanayo.

- Imveliso ekhawulezayo:Ukubumba inaliti yomthamo ophezulu yinkqubo ekhawulezileyo, kwaye izixa ezikhulu zamalungu anokuveliswa ngokukhawuleza. Oku kuyenza ilungele ukwenziwa kwezinto zabathengi ezifuna amaxesha okutshintsha ngokukhawuleza.

- Ngokwezifiso: Ukubumba isitofu kuvumela ukwenziwa kwezinto kusetyenziswa izinto ezahlukeneyo, imibala kunye nokugqitywa komphezulu. Oku bhetyebhetye kwenza kube nokwenzeka ukuvelisa iinxalenye ezihlangabezana neemfuno neemfuno ezithile zabathengi.

Ukusetyenziswa kokuBunjwa kwesitofu soMqulu oPhezulu kuShishino lweMpahla yabaThengi:

- Izinto zokupakisha:Isitofu sokubumba sisetyenziswa ngokubanzi ukuvelisa izinto zokupakisha ezifana neebhotile zeplastiki, iingqayi kunye nezikhongozeli.

- Amathoyizi: Isitofu sokubumba yindlela edumileyo yokwenza amathoyizi njengoko ivumela ukuvelisa ngokukhawuleza inani elikhulu lamalungu.

- Impahla yasekhitshini: Ukubumba isitofu kwenza izinto ezahlukeneyo zasekhitshini ezinjengeekomityi, iipleyiti, kunye nezixhobo.

- ZeWindows: Isitofu sokubumba sisetyenziselwa ukwenza izinto ezahlukeneyo zombane ezifana nezindlu, amaqhosha, kunye nokutshintsha.

UkuBunjwa kweSitofu soMqulu oPhezulu kuShishino lwe-Aerospace

Ishishini le-aerospace lifuna umgangatho ophezulu kunye namacandelo achanekileyo ukuqinisekisa ukhuseleko kunye nokusebenza kakuhle kweenqwelomoya. Ukubunjwa kwenaliti ephezulu kuye kwaba yinkqubo ebalulekileyo kwishishini le-aerospace njengoko libonelela ngesisombululo esineendleko zokuvelisa ubuninzi bezinto eziphezulu eziphezulu kunye nomgangatho ohambelanayo. Esi sithuba sebhlog siyakuxoxa ngomthamo omkhulu wokubumba inaliti kwishishini le-aerospace.

Iinzuzo zokuBunjwa kwesitofu soMqulu oPhezulu kuShishino lwe-Aerospace:

Ishishini le-aerospace lifuna izinto ezikhaphukhaphu, ezomeleleyo ezimelana nobushushu obugqithisileyo kunye noxinzelelo. Ukubumba inaliti yevolumu ephezulu kubonelela ngeenzuzo ezininzi zokuvelisa izinto ezinjalo, kubandakanya:

- Imveliso enexabiso eliphantsi: Ukubunjwa kwenaliti ephezulu kunokuvelisa inani elikhulu lamalungu ngokukhawuleza, okukhokelela ekunciphiseni iindleko zokwenziwa.

- Umgangatho ohambelanayo: Inkqubo ezenzekelayo iqinisekisa ukuba inxalenye nganye eveliswayo ikumgangatho ofanayo ophezulu, obalulekileyo kukhuseleko nokuthembeka kwamacandelo eenqwelo-moya.

- Iijiyometri ezintsonkothileyo: Inkqubo yokubumba inaliti ivelisa iimilo ezintsonkothileyo kunye neejometri, ezinokuba nzima ukufikelela ngeendlela zemveli zokuvelisa.

- Ukhetho lwezixhobo: Ukubunjwa kwenaliti ephezulu kunokusebenza uluhlu olubanzi lwezixhobo, kubandakanywa ii-composites, ezifanelekileyo kwizicelo ze-aerospace.

- Inkunkuma Ethotyiweyo: Inqanaba eliphezulu lokuzenzekelayo kunye nokuchaneka kwinkqubo yokubumba i-injection kubangela inkunkuma yezinto ezincinci kunye ne-scrap, enokukhokelela ekugcinweni kweendleko ezibalulekileyo kunye neenzuzo zokusingqongileyo.

Ukusetyenziswa kokuBunjwa kweSitofu soMqulu oPhezulu kuShishino lwe-Aerospace:

Ukubunjwa kwenaliti ephezulu kusetyenziswa kakhulu kwishishini le-aerospace ukuvelisa amacandelo ahlukeneyo, kubandakanya:

- Imibhobho yomoya kunye neenkqubo zokungenisa umoya

- Iinxalenye zenqwelomoya zangaphakathi nangaphandle

- Izinto zesakhiwo ezifana nezibiyeli, iikliphu, kunye nezindlu

- Amacandelo ombane kunye neengcingo

- Iimpawu kunye neegaskets

Iziphene eziqhelekileyo kwi-High-Volume Injection Molding

Nangona kunjalo, njengayo nayiphi na inkqubo yokuvelisa, ukubumba inaliti ngamanye amaxesha kunokubangela iziphene ezinokuchaphazela umgangatho wemveliso yokugqibela. Esi sithuba sebhlog siza kuxoxa ngezinye iimpazamo eziqhelekileyo ekubumbeni inaliti yevolumu ephezulu kunye nokuba zinokuthintelwa njani.

- Amanqaku eSinki: Iimpawu ze-sink zixinzelelo okanye i-indentations enokuthi yenzeke kumphezulu wecandelo elibunjiweyo. Zibangelwa kukucutheka kwezinto zeplastiki njengoko ziphola, okukhokelela ekusabalazweni okungalinganiyo kwezinto. Ukuthintela amanqaku e-sink, ukuguqula uyilo lwenxalenye kunye nokuqinisekisa ukuba ubukhulu bodonga kulo lonke icandelo kuyimfuneko.

- Warping:I-Warping yi-deformation yecandelo elibunjiweyo ngenxa yokupholisa okungalinganiyo kwezinto zeplastiki. Iphumela kwinxalenye ejijekileyo okanye egobileyo engahambelaniyo nemigaqo efunekayo. I-Warping inokuthintelwa ngokuqinisekisa ukuba ukushisa kwe-mold kuhambelana kwaye ngokubandakanya iimpawu zoyilo ezinciphisa uxinzelelo kwinxalenye ngexesha lokupholisa.

- Flash: I-Flash yimpahla engaphezulu ephuma kwilungu le-mold kwaye ingenzeka xa ukubunjwa kungahambelani ngokuchanekileyo okanye kubambene. I-Flash inokuthintelwa ngokuqinisekisa ukuba i-mold ihambelana ngokufanelekileyo kwaye i-clamping force yanele ukubamba i-mold ivaliwe ngexesha lokutofa.

- IiShots ezimfutshane: Ukudubula okufutshane kwenzeka xa izinto zeplastiki zingazalisi i-mold cavity yonke, okubangela inxalenye engaphelelanga. Oku kunokubangelwa kukungonelanga koxinzelelo lwenaliti, ubushushu obuphantsi bokunyibilika, okanye isango elivaliweyo. Ukudubula okufutshane kunokuthintelwa ngokulungiselela iiparamitha zenaliti kunye nokuqinisekisa ukuba isango lenziwe ngokufanelekileyo kwaye libekwe.

- Imigca yeWeld: Imigca ye-weld yenzeke xa ii-flow fronts ezimbini okanye ngaphezulu zidibana kwaye ziqina, okukhokelela kumgca obonakalayo okanye i-seam kwindawo ebunjiweyo. Imigca ye-weld inokuthintelwa ngokulungisa uyilo lokungunda kunye neeparitha zenaliti zokuqinisekisa ukuba izinto zeplastiki zihamba ngokulinganayo kwaye ngokutyibilikayo kumgodi.

Iingcebiso zokuJonga ingxaki kwi-High-Volume Injection Molding

Ukubumba inaliti yomthamo ophezulu yinkqubo entsonkothileyo efuna ingqwalasela kwiinkcukacha kunye nokujongwa ngononophelo ukuqinisekisa ukuba imveliso yokugqibela ikumgangatho ophezulu. Inani lemiba eqhelekileyo inokuvela ngexesha lenkqubo yokubumba inaliti, enokukhokelela kwiziphene kwimveliso yokugqibela. Esi sithuba siza kuphonononga ezinye iingcebiso eziqhelekileyo zokucombulula iingxaki zokubumba inaliti yevolumu ephezulu.

- Qwalasela Useto lokuBumba loShishino lwesitofu: Enye yezinto zokuqala ekufuneka zijongwe xa ucombulula isitofu sevolumu ephezulu luseto kumatshini wokubumba inaliti. Qinisekisa ukuba iqondo lobushushu, uxinzelelo, kunye nexesha lomjikelo zonke zisetwe ngokuchanekileyo kwizinto ezithile ezisetyenzisiweyo.

- Jonga imiba yokuHamba kwezinto: Imiba yokuhamba kwezinto ngomnye umba oxhaphakileyo ngokubumba inaliti yomthamo ophezulu. Izinto ezininzi, kubandakanywa izicwangciso ezingalunganga kumatshini okanye ukuvaleka kumatshini wokubumba inaliti, kunokubangela oku. Qinisekisa ukuba imathiriyeli ihamba kakuhle kwisixhobo kwaye akukho zithintelo kumatshini wokubumba inaliti.

- Jonga i-Warping kunye ne-Shrinkage: I-Warping kunye ne-shrinkage yimiba eqhelekileyo ngexesha lokubunjwa kwenaliti ephezulu. Le miba idla ngokubangelwa kukupholisa okungalinganiyo kwezinto, nto leyo enokukhokelela ekujikeni okanye ekucuthekeni kwimveliso yokugqibela. Qinisekisa ukuba ixesha lokupholisa limiselwe ngokuchanekileyo kwizinto ezithile ezisetyenziswayo kwaye isistim isebenza ngokufanelekileyo.

- Jonga i-Air Traps: Imigibe yomoya yenye into eqhelekileyo ngexesha lokubumba inaliti yevolumu ephezulu. Oku kwenzeka xa umoya uvaleleka kumgodi wokungunda, onokubangela i-voids okanye amaqamza kwimveliso yokugqibela. Qinisekisa ukuba ukungunda kuvuleleke ngokwaneleyo ukuze kuthintelwe imigibe yomoya ukuba ingenzeki.

- Beka iliso kwinkqubo: Okokugqibela, ukujonga ngokusondeleyo inkqubo yokubumba inaliti kubalulekile ukuqinisekisa ukuba nayiphi na imiba iyabanjwa kwaye iqwalaselwe ngokukhawuleza. Oku kunokwenziwa ngokubeka iliso kwiisethingi zoomatshini, ukuhamba kwezinto, kunye nenkqubo yokupholisa. Ngokubeka iliso elibukhali kwinkqubo, nayiphi na imiba inokuchongwa kwaye iqwalaselwe phambi kokuba ikhokelele kwiziphene kwimveliso yokugqibela.

IiMfuno zoLondolozo lweeMashini zokuBumba ngokutofa

Oomatshini bokubumba be-injection zizinto ezibalulekileyo zezixhobo kwishishini lokuvelisa. Zisetyenziselwa ukuvelisa iimveliso ezahlukeneyo, ukusuka kwiindawo zeplastiki ukuya kwizinto zetsimbi. Nangona kunjalo, njengawo nawuphi na omnye umatshini, oomatshini bokubumba inaliti bafuna ukugcinwa rhoqo ukuqinisekisa ukusebenza kakuhle kunye nokuthintela ukonakaliswa kweendleko. Esi sithuba siya kuphonononga ezinye zeemfuno zolondolozo koomatshini bokubumba inaliti.

- ukuthambisa ajikeleze: Ukuthambisa okufanelekileyo yenye yezona zinto zibalulekileyo zokugcinwa komatshini wokubumba inaliti. Iindawo ezishukumayo zikamatshini, njengenaliti kunye neeyunithi zokubambelela, kufuneka zithanjiswe rhoqo ukuze kuthintelwe ukukhuhlana kunye nokuguga. Ukusebenzisa uhlobo oluchanekileyo lwe-lubricant kunye nokulandela iingcebiso zomenzi ngezithuba zokuthambisa kubalulekile.

- Ukucoca: Enye inkalo ebalulekileyo yokugcinwa komatshini wokubumba umatshini kukucoca rhoqo. Umatshini kufuneka ucocwe rhoqo ukuze kususwe naluphi na uthuli, inkunkuma, okanye iintsalela zeplastiki ezinokuqokelelana kumalungu awo. Oku kuya kunceda ukuthintela ukuvaleka kwemilomo yomatshini kunye nezihluzi, ezinokubangela imiba yokusebenza okanye bonakalise injini.

- ukuhlolwa: Ukuhlolwa rhoqo kuyafuneka ukuqinisekisa ukuba umatshini ukwimeko entle. Uvavanyo kufuneka lubandakanye ukukhangela naziphi na iimpawu zokuguga, ezifana neentanda okanye iindawo ezaphukileyo. Amalungu ombane, anjengezinzwa kunye nezitshixo, nawo kufuneka ajongwe rhoqo ukuqinisekisa ukuba asebenza ngokuchanekileyo.

- NONE Oomatshini bokubumba i-injection nabo bafuna ukulinganisa ukuqinisekisa ukuba basebenza ngaphakathi kweeparamitha ezichanekileyo. Oku kuquka ukujonga ubushushu bomatshini, uxinzelelo, kunye nesetingi zesantya ukuqinisekisa ukuba zingaphakathi kweenkcukacha zomenzi. Ukulinganisa kufuneka kwenziwe rhoqo ukuqinisekisa ukuba isixhobo sisebenza kwinqanaba eliphezulu.

- Ukutshintshwa Kweendawo Ezigugileyo: Okokugqibela, ukutshintshwa kweendawo ezigugileyo okanye ezonakeleyo ngokukhawuleza kubalulekile. Oku kunokunceda ekuthinteleni umonakalo ongakumbi kumatshini nokunciphisa umngcipheko wokophuka kweendleko. Amalungu okutshintshwa kufuneka abe nomgangatho ofanayo kunye namacandelo okuqala kwaye afakwe ngabachwephesha abaqeqeshiweyo.

Ukuzinza kunye nokuBunjwa kweSitofu esiPhezulu

Ukuzinza kuye kwaba yinkxalabo ekhulayo kwishishini lemveliso kwiminyaka yakutshanje. Njengoko ihlabathi lisiya lizazi ngakumbi ifuthe lemeko yendalo esingqongileyo, iinkampani zikhangela iindlela zokunciphisa unyawo lwazo lokusingqongileyo ngelixa zigcina imveliso kunye nengeniso. Ukubunjwa kwenaliti yevolumu ephezulu yindawo enye apho ukuzinza kunokwenza impembelelo ebalulekileyo.

Kukho iindlela ezininzi apho uzinzo lunokuthi ludityaniswe kubumba oluphezulu lwenaliti:

- Ukukhethwa kwezinto:Ukukhetha izixhobo ezifanelekileyo kubalulekile ekufezekiseni ukuzinza kwi-injection molding. Iinketho ezininzi ziquka i-bioplastics, iiplastiki ezisetyenzisiweyo, kunye nezinto ezisekelwe kwi-bio. Ngokukhetha izinto ezihambelana nokusingqongileyo kunye nekhabhoni ephantsi, abavelisi banokunciphisa kakhulu impembelelo yabo kwindalo.

- Ukusebenza kakuhle kwamandla: Ukubumba inaliti yomthamo ophezulu kufuna amandla abalulekileyo ukuze kusebenze. Abavelisi banokunciphisa ukusetyenziswa kwamandla kunye nokukhutshwa kwekhabhoni ephantsi ngokuphumeza iinkqubo kunye nezixhobo ezisebenza ngamandla. Oku kunokufezekiswa ngokusebenzisa oomatshini abasebenzisa amandla, ukwandisa iinkqubo zemveliso, kunye nokutyala imali kwimithombo yamandla ahlaziyekayo.

- Ukunciphisa inkunkuma: Ukubumba isitofu kunokuvelisa inkunkuma ebalulekileyo, ngakumbi iplastiki egqithisileyo. Ngokuphumeza izicwangciso zokunciphisa inkunkuma, abavelisi banokunciphisa inani lenkunkuma eveliswayo kwaye baphucule ukuzinza kwabo. Oku kungaphunyezwa ngokurisayikilishwa, ukuphinda kusetyenziswe imathiriyeli, kunye nokuphucula inkqubo yemveliso ukunciphisa inkunkuma.

- Uhlalutyo lomjikelo wobomi: Ukuqhuba uhlalutyo lomjikelo wobomi kunokunceda abavelisi baqonde ifuthe lemo engqongileyo yeemveliso zabo kubo bonke ubomi babo. Olu hlalutyo lunokunceda ukuchonga iindawo apho uzinzo lunokuphuculwa kwaye lukhokele ukuthathwa kwezigqibo ukwenza iimveliso ezihambelana nokusingqongileyo.

Amaphuzu aphambili:

- Ukukhetha izinto eziphathekayo kudlala indima ebalulekileyo ekufezekiseni uzinzo ekubumbeni inaliti.

- Iinkqubo zokusebenzisa amandla kunye nezixhobo zinokunciphisa ukusetyenziswa kwamandla kunye nokukhutshwa kwekhabhoni ephantsi.

- Ubuchule bokunciphisa inkunkuma, obufana nokurisayikilishwa kunye nokusetyenziswa kwakhona kwemathiriyeli, kunokunciphisa ubungakanani benkunkuma eveliswayo.

- Uhlalutyo lomjikelezo wobomi lunokunceda ukuchonga iindawo apho ukuzinza kunokuphuculwa.

- Ukubandakanya ukuzinza kwi-high volume injection molding kunokunceda abavelisi ngokunciphisa iindleko kunye nokubhenela kubathengi abaqaphela indalo.

- Ikamva le-High-Volume Injection Molding

Ukubumba inaliti yevolumu ephezulu ibiyinkqubo yokwenziwa kwemveliso ebalulekileyo kumashishini amaninzi amashumi eminyaka, kwaye iyaqhubeka ukudlala indima ebalulekileyo ekuveliseni uluhlu olubanzi lweemveliso zeplastiki. Njengoko itekhnoloji ihambela phambili kunye nemfuno yabathengi itshintshela kwiimveliso ezizinzileyo kunye nezinokwenziwa ngokwezifiso, ikamva lenaliti ephezulu yokubumba ibukeka iqaqambile. Nazi ezinye zeendlela kunye nezinto ezintsha ezibumba ukuphela kolu shishino.

- Ukuzinza: Ngokunyuka kwemfuno yabathengi yeemveliso ezihambelana nokusingqongileyo, ukuzinza kuye kwabaluleka ekubunjweni kwenaliti ephezulu. Abavelisi baphonononga izinto ezintsha, ezifana ne-bioplastics kunye ne-bio-based materials, kunye nokuphumeza izicwangciso zokunciphisa inkunkuma ukunciphisa impembelelo yokusingqongileyo kwiimveliso zabo.

- Ngokwezifiso: Abathengi bafuna iimveliso ezihlangabezana neemfuno zabo ezizodwa kunye nezinto abazikhethayo, kwaye ukubunjwa kwenaliti ephezulu kukulungele ukuhlangabezana nale mfuno. Ukuhambela phambili kwezobuchwepheshe, okufana noshicilelo lwe-3D, kwenza kube lula kwaye kungabizi kakhulu ukuvelisa iinxalenye ezilungiselelweyo kunye neemveliso kwimiqulu emikhulu.

- Ukuzenzekelayo: I-automation iya ixhaphake kakhulu kwishishini lemveliso, kwaye ukubunjwa kwenaliti yomthamo ophezulu akukho nto. Iinkqubo ezizenzekelayo, ezinjengeengalo zerobhothi kunye noyilo oluncediswa yikhompyuter, lunokuphucula ukusebenza kakuhle kwemveliso kunye nokunciphisa iindleko.

- Ishishini 4.0: Inguqu yesine yezoshishino, i-Industry 4.0, iguqula ishishini lokuvelisa ngokudibanisa ubugcisa obuphambili obufana nobukrelekrele bokwenziwa, i-Intanethi yeZinto (IoT), kunye nohlalutyo lwedatha enkulu. Ezi teknoloji zenza kube lula ukuba abavelisi basebenzise iinkqubo zokuvelisa kunye nokuphucula umgangatho wemveliso.

- Ishishini lezonyango:Ukubunjwa kwenaliti ephezulu kukulungele ukuvelisa izixhobo zonyango kunye nezixhobo ngenxa yokuchaneka kwayo kunye nokuhambelana. Imfuno yeemveliso zonyango kulindeleke ukuba ikhule, nto leyo eyenza le ndawo ibalulekileyo kwishishini lokubumba inaliti.

- Izithuthi zombane:Ukutshintshela kwiimoto zombane kudala amathuba amatsha kushishino lokubumba inaliti yomthamo ophezulu. Izinto zeplastiki, ezinje ngezindlu zebhetri kunye neziqhagamshelo zombane, zibalulekile kwiimoto zombane, kwaye imfuno yala malungu kulindeleke ukuba ikhule njengoko izithuthi zombane zixhaphake kakhulu.

Isiphelo:

Ukubumba inaliti yevolumu ephezulu kubalulekile ekuveliseni izixa ezikhulu zamalungu eplastiki. Ngokuqonda izibonelelo, izinto ezingeloncedo, izixhobo, oomatshini, iindlela, ingqwalasela yoyilo, amanyathelo olawulo lomgangatho, kunye nokusetyenziswa kokubunjwa kwenaliti ephezulu, amashishini anokuphucula iinkqubo zawo zokuvelisa, anciphise iindleko, kwaye aphucule umgangatho weemveliso zawo. Nokuba ukwishishini lezonyango, iimoto, iimpahla zabathengi, okanye umzi-mveliso we-aerospace, ukubumba inaliti yevolumu ephezulu kunokuzuza ishishini lakho ngokubonelela ngamacandelo angaguqukiyo, akumgangatho ophezulu ngexabiso elingabizi kakhulu.