Ukubunjwa kwe-Low Volume Injection - Inkonzo yokuVelisa uMqulu ophantsi

Ukusetyenziswa njani ukuBunjwa kwesitofu esinomthamo ophantsi (Inkonzo yokwenziwa koMqulu ophantsi)

Sebenzisa imveliso efunwayo ukunciphisa iindleko zemveliso kunye nokunciphisa ukuguquguquka kwemfuno

Nokuba uyila isixhobo sonyango esisindisa ubomi okanye idrone ebhabhayo, ukutyala imali eyi-100,000 yeedola okanye ngaphezulu-kaninzi kakhulu-kwisixhobo sentsimbi esinomthamo ophezulu ngumngcipheko wemali okhoyo oza nokufudukela kwimveliso enkulu. Ukudibanisa umngcipheko ziinyanga zexesha elingasebenziyo njengoko ulinda isixhobo sakho sentsimbi ukuba silungele xa unokuphinda uyilo okanye uvelise iimveliso ezivelisa ingeniso. Kukho indlela engcono: ukwenziwa kwemfuno.

Yintoni i-On-Demand Manufacturing(inaliti yomthamo ophantsi wokubumba)?

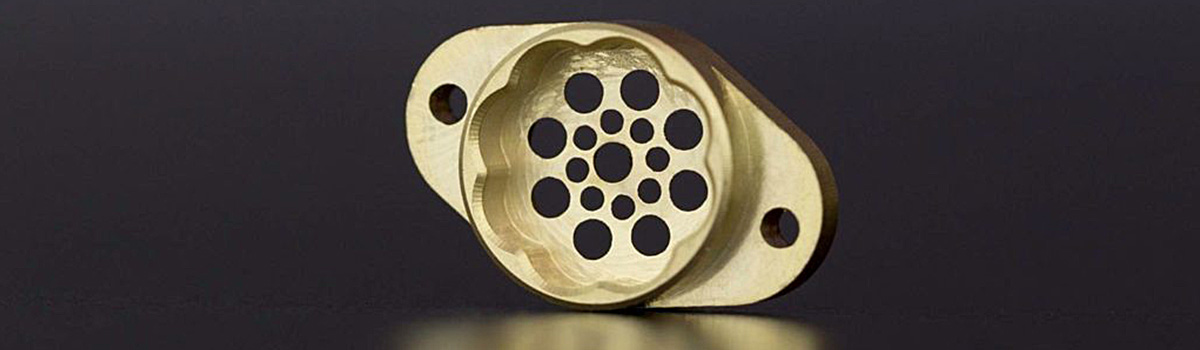

Kwi-DJmolding, imfuno yethu, imveliso ephantsi yemveliso kunye ne-injection molding-esebenzisa i-aluminium tooling-yindlela ekhawulezayo, eneendleko zokuvelisa amakhulu amawaka eenxalenye ezibunjiweyo zokugqibela.

Sebenzisa le nkqubo njengeyona ndlela iphambili yemveliso yeemveliso zakho. Imveliso efunwayo ikwayindlela ebalaseleyo yokuhamba ukusuka kwiprototyping ukuya kwimveliso enomthamo ophantsi weendawo ezibunjiweyo. I-DJmolding eneneni ngumboneleli wokwenza inkonzo epheleleyo. Ukuqhutywa kwevolyum ephantsi kunokukunceda ukuba uqinisekise uyilo lwenxalenye kwaye ulawule uluhlu lwempahla kunye nemveliso yamacandelo kuphela xa imfuno iyalela. Ukongeza, nokuba kufuneka ekugqibeleni utshintshe kwimveliso yobuninzi yamalungu eplastiki, usengasebenzisa izixhobo zethu ze-aluminiyam ezinexabiso elisebenzayo njengebhulorho ngaphambi kokuba uzibophelele kwindleko enkulu ngezixhobo zentsimbi. Okokugqibela, le ndlela ifunwayo yongeza ikhonkco lakho lonikezelo, iyenze ibe nobuchule ngakumbi bokulawula ukuguquguquka kwemfuno.

Biza Iimpawu eziBalulekileyo-kuMgangatho

Xa usebenzisa ukhetho lwethu lokwenziwa kwemfuno, uya kuba nakho ukubonisa kwinxalenye yakho uyilo imilinganiselo ebaluleke kakhulu kumsebenzi wenxalenye. Ngokubiza ezi zinto zibalulekileyo kwi-Critical-to-Quality (CTQ) kwimodeli yakho ye-3D CAD, unokuqiniseka ukuba iinxalenye eziyalelweyo ziyahambelana nemodeli. Ukongeza, oko kuthetha ukuba kwixesha elizayo xa u-odola loo malungu, sinokulandela la manyathelo achanekileyo ukwenza iindawo ezingaguquguqukiyo, eziphinda-phindayo ezihambelana neenkcukacha zakho ze-CTQ.

Ukuhlolwa zizinto eziphambili zale nkqubo yeCTQ. Ngokufanelekileyo, iqela lethu lobunjineli bezicelo liya kuphonononga imodeli yakho kwaye likuthumelele i-imeyile kwiNgxelo yoHlolo yoMsebenzi (ISOW), ekwazisa ukuba naziphi na iimpawu ozibiyele ngesangqa zinemiba yokunyamezela kunye nokubumba. Nje ukuba sithumele i-ISOW, senza kwaye sihlole iodolo yakho.

Nje ukuba sigqibe uphuhliso lwenkqubo yokubumba, eqinisekisa ukuba sinenkqubo engaguqukiyo nephindaphindwayo yokuvelisa iinxalenye ezisemgangathweni, siya kuhlola izithonga ezintathu zokuqala kwisixhobo, sisebenzisa umatshini wokulinganisa ulungelelwaniso oluzenzekelayo (CMM), kwaye sikunikeze ezintathu. -inxalenye yeNgxelo yokuQala yoHlolo lweNgxelo (FAI) ingxelo, kunye neNgxelo yokuXhobisa ngeNkqubo.

Fumana ukuguquguquka kwekhonkco lonikezelo kwinkonzo yokubumba inaliti ye-DJmolding umthamo ophantsi

Kwezi ntsuku, njengoko sonke siqhubeka nokujonga ubhubhani wehlabathi, uqwalaselo lokubonelela lubalulekile. Indlela yokwenza okufunwayo inokukunceda wenze isixokelelwano sobonelelo esinamandla ngoku:

* Ukufumana iinxalenye kwimfuno ngaphandle kobuncinci boMyinge woMyalelo (MOQ)

* Ukwehliswa kweendleko ze-inventri kunye neendleko zogcino-mpahla kunye ne-on-demand sourcing

* Ukulawula ukunyuka kwemfuno yokuguquguquka ngaphandle kokubuyela emva

* Ukunciphisa umngcipheko wokulibaziseka kweenqanawa zasekhaya kunye nehlabathi jikelele

* Ukunciphisa ixesha lokuphumla kunye nokunciphisa umngcipheko wokuphela kwamayeza xa izixhobo ezinkulu zilungiswa

Ukuveliswa kweVolumu ephantsi ka-DJmolding

Le yinkonzo ekhethekileyo enikezela ngamacandelo apheleleyo akumgangatho wemveliso kodwa ngokwemiqulu edla ngokukhawulelwa kumaqhekeza ali-10,000 okanye ngaphantsi, kuxhomekeke kwinkqubo esetyenziswayo. Ukubumba kwethu okunomthamo ophantsi, okukwabizwa ngokuba kukubaleka okufutshane, kujongwe kwaye kulawulwe ukuze uqiniseke ngayo yonke imiba yoyilo lokubumba kunye nokwakha. Olu hlobo lwemveliso lufanelekile kumashishini amancinci naphakathi okanye amashishini amancinci amancinci.

Ukwenziwa komthamo ophantsi yintsimi entsha ngokufanelekileyo kwishishini lemveliso elimalunga nokukhupha iinxalenye, iimveliso kunye nezixhobo kumaqela esithathu.

Oku kuvumela inkampani yakho ukuba igxile ngakumbi kwimveliso ngelixa amashishini amancinci ephethe uyilo kunye nophawu lweemveliso. Lo mkhwa okhulayo uya kuxhaphaka kwishishini ngalinye njengoko amashishini amancinci ejonge ukukhulisa ishishini lawo ngokukhuphela ngaphandle kwezinye iinkampani kunye nokugcina iindleko ziphantsi.

I-DJmolding's Small Volume Injection Molding

Uninzi lwabantu luva amagama athi "iTshayina" kunye "nobumba" kwisivakalisi esifanayo kwaye bacingela okubi kakhulu. Bacinga ngeemveliso ezinexabiso eliphantsi, ezikumgangatho ophantsi ezenziwe kusetyenziswa iindlela ezikumgangatho ophantsi ezibeka ubomi babasebenzi emngciphekweni.

Kodwa oko akusoloko kunjalo.

I-DJmolding evela eChina inembali ende yokuvelisa iimpahla ezisemgangathweni ezithunyelwa ngaphandle. Ngapha koko, ezinye zeemveliso ezenziwe kakuhle kwihlabathi zivela eTshayina! Kwaye xa kuziwa ekubumbeni inaliti yeplastiki, iTshayina lelinye lawona mazwe anobunkunkqele emhlabeni.

Isitofu sokubumba yindlela edumileyo yokwenza iinxalenye zeplastiki kunye nezixhobo. I-DJmolding ngumvelisi olungileyo wokufumana ukubumba kwenaliti yevolumu ephantsi eyenziwe ngenxa yokuba iindleko zabasebenzi zingaphantsi kakhulu kune-United States okanye eYurophu. I-DJmolding inemilinganiselo encinci ye-odolo (MOQs) yeenqununu ze-1,000 kuphela kunye namaxesha ahamba phambili njengeeveki ze-3-4. Oku kunokuba luncedo kakhulu kwiinkampani ezincinci ezifuna ukuqalisa ngomgca wazo wemveliso kodwa ezingafuni ukutyala imali eninzi ekusebenziseni izixhobo kunye neendleko zemveliso ngaphambili.

Ngoko wazi njani ukuba usebenzisana nomthengisi othembekileyo? Kufuneka ujonge iinkcukacha

Ubuncinci boMyinge weodolo (MOQ) -Umthengisi othembekileyo akayi kukucela iodolo enkulu phambi kokuba abe nethuba lokudibana nawe okanye abone imveliso yakho. Endaweni yoko, siya kufuna ukuqiniseka ukuba uzimisele ngeprojekthi yakho ngaphambi kokuchitha ixesha elininzi okanye imali kuyo.

Ixesha lokukhokela - Abona baboneleli abalungileyo baya kuba namaxesha okukhokela ngokukhawuleza ukuze bakwazi ukuhambisa imveliso yakho ngokukhawuleza (kwaye bahlangabezane nemigangatho yomgangatho).

Ukubumba isitofu yinkqubo edumileyo yokuvelisa iimveliso zeplastiki ezivelisa ngobuninzi, kodwa kuthekani ukuba ufuna inani elincinci lamalungu kwiprojekthi yakho? Kulapho ukubunjwa kwenaliti yevolumu ephantsi kungena khona. Yindlela enexabiso eliphantsi yokuvelisa ibhetshi encinci yeenxalenye zeplastiki ngaphandle kokuphula ibhanki. Kule post yebhlog, siza kuntywila kwizibonelelo kunye nokusetyenziswa kokubumba inaliti yevolumu ephantsi, ukuba yahluke njani ekubunjweni kwenaliti yomthamo ophezulu, kunye nendlela enokulizuzisa ngayo ishishini lakho.

Ukuqonda i-Low Volume Injection Molding

Ukubumba inaliti yevolumu ephantsi yinkqubo yokuvelisa evumela ukuvelisa iindawo ezincinci zeplastiki. Sisisombululo esisebenzayo kunye neendleko ezisebenzayo kwiinkampani ezifuna ukuqhuba imveliso encinci okanye uhlahlo lwabiwo-mali olulinganiselwe.

- Inkqubo yokubumba inaliti yomthamo ophantsi iqala ngokudala isikhunta. Ngokuqhelekileyo, abavelisi benza i-mold kwintsimbi okanye i-aluminium kwaye bayiyile ukuze bafezekise uhlobo olufunwayo lwenxalenye yeplastiki. Ngexesha lenkqubo yokubumba, abavelisi babamba kunye iziqingatha ezibini zokubumba: i-cavity kunye ne-core.

- Ngaphambi kokuba ukubunjwa kwenaliti kwenzeke, izinto zeplastiki ziyafudunyezwa kwaye zinyibilike kwigumbi elahlukileyo. Abavelisi bafaka iplastiki kwi-mold phantsi koxinzelelo oluphezulu xa ifikelele kwiqondo lokushisa elifunekayo. Iplastiki igcwalisa umngxuma kwaye ithatha ubume besikhunta.

- Emva kokuba iplastiki ipholile kwaye yomelela, abavelisi bavula i-mold baze bakhuphe inxalenye egqityiweyo. Ixesha lomjikelo lokubumba inaliti yomthamo ophantsi lifutshane, livumela ukuveliswa ngokukhawuleza kunezinye iinkqubo zokuvelisa.

- Ukubumba inaliti yevolumu ephantsi kunika iingenelo ezininzi. Okokuqala, iya kwenza ukuveliswa kweendawo ezintsonkothileyo nezintsonkothileyo ngokuchaneka okuphezulu kunye nokuphindaphinda. Amashishini afuna amacandelo antsonkothileyo, njengeemoto, i-elektroniki, kunye nezixhobo zonyango, kuya kuba luncedo ukukhetha olu khetho.

- Ukongeza, ukubunjwa kwenaliti yomthamo ophantsi kubonelela ngeendleko zokonga xa kuthelekiswa neendlela zemveli zokuvelisa umthamo omkhulu. Ekubeni utyalo-mali lokuqala kwi-tooling luphantsi, lufikeleleka ngakumbi kumashishini amancinci okanye aqalayo. Ikwavumela ixesha elikhawulezayo ukuya kwintengiso, njengoko ixesha elikhokelayo lezixhobo lifutshane.

- Enye inzuzo yokubumba inaliti yevolumu ephantsi kukuguquguquka kwayo. Ivumela ukuguqulwa koyilo kunye nokuphindaphinda ngaphandle kokufumana iindleko ezongezelelweyo ezibalulekileyo. Yiyo loo nto utshintsho loyilo olulindelekileyo ngexesha lamanqanaba okuqala lunceda kakhulu uphuhliso lwemveliso kunye neprototyping.

- Ngaphandle kweenzuzo zayo, ukubumba inaliti yevolumu ephantsi kunemida ethile. Njengoko igama libonisa, ayifanelekanga kwimveliso ephezulu. Iindleko ngenxalenye nganye ingaba phezulu kuneendlela zokuvelisa ngobuninzi ngenxa yeendleko eziphezulu zezixhobo kunye nokusekwa. Ngoko ke, ifaneleke ngakumbi kwimveliso emincinci ukuya kwephakathi.

- Ukukhethwa kwezinto eziphathekayo kukwaqwalaselwa ekubunjweni kwenaliti yomthamo ophantsi. Izinketho zezinto eziphathekayo ezilinganiselwe zikhoyo xa kuthelekiswa neenkqubo zokuvelisa umthamo ophezulu. Nangona kunjalo, izixhobo ezininzi ze-thermoplastic, ezibandakanya i-ABS, i-polycarbonate, inayiloni, kunye ne-polypropylene, zisenokusetyenziswa.

- Ukusebenza nomenzi wokubumba inaliti onamava kunye nolwazi kubalulekile kwimveliso yomthamo ophantsi. Banokukhokela ukhetho lwempahla, uyilo lokubumba, kunye nokulungiswa kwenkqubo ukuqinisekisa iziphumo ezilungileyo.

Izinto eziluncedo kwi-Low Volume Injection Molding

Ukubumba inaliti yevolumu ephantsi kubonelela ngeenzuzo ezininzi kwiinkampani ezineemfuno ezincinci ukuya kweziphakathi zemveliso. Ezinye zezibonelelo eziphambili zale nkqubo yokuvelisa ziquka:

Imveliso enexabiso eliphantsi

- Utyalo-mali olusezantsi kwizixhobo zokusebenza xa kuthelekiswa neendlela zemveli zokuvelisa umthamo omkhulu.Ukufikelela kumashishini amancinci okanye aqalwayo.

- Ixesha elikhawulezayo ukuya kwimarike ngenxa yexesha elifutshane lokukhokela izixhobo, ukunciphisa iindleko zemveliso.

Iindawo ezintsonkothileyo nezichanekileyo

- Inkqubo yenza ukuba kuveliswe iindawo ezintsonkothileyo nezintsonkothileyo ngokuchaneka okuphezulu kunye nokuphinda-phinda. Ilungele amashishini afana neemoto, ombane, kunye nezixhobo zonyango ezifuna amacandelo anzima.

- Inkqubo ivumela ukunyamezela okuqinileyo kunye nokufakwa kweenkcukacha ezintle kuyilo.

Ukuguquguquka koyilo

- Inkqubo ivumela ukuguqulwa koyilo olulula kunye nokuphindaphinda ngaphandle kweendleko ezibalulekileyo ezongezelelweyo.

- Eyona nto iluncedo kuphuhliso lwemveliso kunye neprototyping, apho uhlengahlengiso loyilo kunye nokulungiswa kusemgangathweni ngexesha lamanqanaba okuqala.

Ukuguquguquka kwezinto

- Inkqubo ibonelela ngezinto ezahlukeneyo ze-thermoplastic, kubandakanya i-ABS, i-polycarbonate, inayiloni, kunye ne-polypropylene.

- Ihlangabezana neemfuno ezithile kunye neempawu ezifunwayo zemveliso yokugqibela.

Imijikelo yemveliso ekhawulezayo

- Inkqubo iqhayisa ngamaxesha omjikelezo omfutshane, okwenza imveliso ikhawuleze kunezinye iinkqubo zokuvelisa.

- Iluncedo ekuhlangabezaneni nexesha elibekiweyo leprojekthi okanye ukuphendula kwiimfuno zentengiso ngokukhawuleza.

- Yandisa imveliso kwaye ibonelela ngamaxesha okutshintsha ngokukhawuleza.

Ukuncitshiswa kwenkunkuma kunye neempembelelo zokusingqongileyo

- Inkqubo inciphisa inkunkuma yezinto ngokusebenzisa kuphela isixa esiyimfuneko seplastiki.

- Inkqubo inciphisa ukusetyenziswa kwamandla kunye nokukhutshwa kwamandla xa kuthelekiswa neendlela zokuvelisa umthamo ophezulu.

- Inketho yokwenziwa kwemeko-bume.

Umgangatho kunye nokuhambelana

- Inkqubo iqinisekisa iindawo eziphezulu kunye nemilinganiselo ehambelanayo kunye neempawu.

- Inkqubo ibonelela ngolawulo olubalaseleyo kubushushu, uxinzelelo, kunye nokuguquguquka kokupholisa.

- Ukuthembeka kumashishini apho ukusebenza kwemveliso kunye nokuthembeka zizinto ezibalulekileyo.

Ukwenza ngokwezifiso kunye nobuntu

- Inkqubo inika ithuba lokwenziwa ngokwezifiso kunye nobuntu beemveliso.

- Ukuveliswa kweendawo ezizodwa ezilungiselelwe iimfuno ezithile zabathengi.

- Inkqubo yonyusa ulwahlulo lwemveliso kunye nokwaneliseka kwabathengi.

Ukunciphisa umngcipheko kunye novavanyo lwemarike

- Inkqubo lukhetho olunomngcipheko ophantsi wophuhliso lwemveliso entsha okanye uvavanyo lwemarike.

- Inkqubo ivelisa iindawo ezilinganiselweyo zokuvavanya, ukuqinisekiswa, kunye nengxelo yentengiso.

- Yehlisa umngcipheko wotyalo-mali kwizixa ezikhulu zamalungu anokufuna uhlengahlengiso okanye angahlangabezani neemfuno zemarike.

Umthamo ophantsi vs. Ukubunjwa kwesitofu soMqulu oPhezulu

Unokuziqhelanisa nokubumba inaliti, inkqubo yokwenza izinto ezininzi, ukuze ihambelane neemfuno ezahlukeneyo zemveliso. Iinguqu ezimbini eziqhelekileyo zokubunjwa kwenaliti ngumthamo ophantsi kunye nomthamo ophezulu. Makhe sithelekise ezi ndlela zimbini kwaye siphonononge umahluko wazo:

Ukubunjwa kwesitofu soMqulu ophantsi

- Ilungele iinkampani ezineemfuno zemveliso ezincinci ukuya kweziphakathi.

- Inikezela ngemveliso enexabiso eliphantsi, eyenza ukuba ifikeleleke kumashishini amancinci okanye aqalwayo.

- Inkqubo idinga utyalo-mali olusezantsi olusezantsi kwizixhobo zokusebenza xa kuthelekiswa nemveliso ephezulu.

- Ivumela ixesha elikhawulezayo ukuya kwimarike ngenxa yexesha elifutshane lokukhokela kwisixhobo, ukunciphisa iindleko zemveliso.

- Inkqubo yenza ukuba kuveliswe iindawo ezintsonkothileyo nezintsonkothileyo ngokuchaneka okuphezulu kunye nokuphinda-phinda.

- Ibonelela ngokuguquguquka koyilo, ukuvumela ukuguqulwa koyilo olulula kunye nokuphindaphinda ngaphandle kweendleko ezibalulekileyo ezongezelelweyo.

- Ixhasa ukuguquguquka kwezinto, inika uluhlu olubanzi lwezixhobo ze-thermoplastic ukuhlangabezana neemfuno ezithile.

- Ibonelela ngemijikelo yemveliso ekhawulezayo xa kuthelekiswa nezinye iinkqubo zokwenziwa kwemveliso, inegalelo ekwandeni kwemveliso kunye namaxesha amafutshane okuguqula.

- Ukunciphisa inkunkuma yezinto eziphathekayo ngokusebenzisa kuphela inani elifunekayo leplastiki, ukunciphisa impembelelo yokusingqongileyo.

- Ukuqinisekisa iindawo ezikumgangatho ophezulu ezinemilinganiselo ehambelanayo kunye neepropati kubalulekile kumashishini apho ukusebenza kwemveliso kunye nokuthembeka kubaluleke kakhulu.

- Ibonelela ngokwenziwa ngokwezifiso kunye neenketho zobuntu, ezivumela ukuveliswa kweendawo ezizodwa ezilungiselelwe iimfuno ezithile zabathengi.

- Inciphisa imingcipheko ngexesha lophuhliso lwemveliso entsha kunye novavanyo lwemarike, ivumela iinkampani ukuba zivelise inani elilinganiselweyo lamalungu ukuze kuqinisekiswe kunye nengxelo phambi kokuzinikela kwimveliso epheleleyo.

Ukubunjwa kwesitofu soMqulu ophezulu

- Ilungele iinkampani ezinemfuno ezinkulu zemveliso.

- Umthamo ophezulu wemveliso ubandakanya utyalo-mali oluthe kratya kwizixhobo zokusebenza kunye nokubumba.

- Ifuna ixesha elide lokukhokela kwisixhobo, elinokwandisa ixesha lokuthengisa.

- Inika inzuzo yeendleko ngenxa yoqoqosho lwesikali, njengoko umthamo ophezulu usasaza iindleko ezisisigxina kwiiyunithi ezinkulu.

- Inkqubo yenza ukuba ukuveliswa ngokufanelekileyo kwamacandelo amakhulu ngexesha elifutshane.

- Ilungele amashishini aneemveliso ezifunwa kakhulu kunye nobukho obusekiweyo bemarike.

- Inokubonelela ngoluhlu oluncinci lwezinto onokukhetha kuzo xa kuthelekiswa nokubumba kwesitofu somthamo ophantsi.

- Ifuna ukucwangciswa ngocoselelo kunye noqikelelo lwengqikelelo ukwandisa impumelelo yemveliso kunye nokunciphisa inkcitho.

- Inkqubo ixhasa ukulawulwa komgangatho ongaguqukiyo kunye nokubambelela kwiinkcazo kuyo yonke inkqubo yokuvelisa umthamo ophezulu.

- Inikezela ngobubhetyebhetye boyilo olulinganiselweyo, njengoko utshintsho loyilo lunokuba neendleko ezongezelelweyo.

Usetyenziso lwe-Low Volume Isitofu sokuBumba

Ukubumba inaliti yevolumu ephantsi yinkqubo yokwenza izinto ezininzi efumana izicelo kuwo wonke amashishini ahlukeneyo. Ikhono layo lokubonelela ngemveliso engabizi kakhulu, ukuguquguquka koyilo, kunye nokukhethwa ngokwezifiso kwenza ukuba ifaneleke kwizicelo ezininzi. Makhe siphonononge ezinye iinkqubo eziqhelekileyo zokubumba inaliti yevolumu ephantsi:

Industry Automotive

- Ukuveliswa kwamacandelo anzima kunye achanekileyo kwizinto zangaphakathi zeemoto, zangaphandle, kunye nezicelo ezingaphantsi kwe-hood.

- Ukwenziwa kweephaneli zedeshibhodi yesiko, iziqwenga zokunquma, amaqhina, kunye nokutshintsha.

- Iprototyping kunye nokuveliswa kweendawo ezikhethekileyo zeemoto ezineempawu ezithile zezinto.

- Ukudalwa kweendawo zomoya zomoya, imigudu, kunye neziqhagamshelo kwiinkqubo zeHVAC zesithuthi.

Ishishini le-Electronics kunye noMbane

- Ukuveliswa kwezinto ezintsonkothileyo kubathengi be-elektroniki njengee-smartphones, iitafile kunye neelaptops.

- Ukwenziwa kweziqhagamshelo, izindlu, kunye neendawo ezivaliweyo zezixhobo zombane.

- Ukwenza ngokwezifiso iiphedi zamaqhosha, amaqhosha, kunye nokutshintsha ngeendlela ezahlukeneyo zemibala kunye nemibala.

- Ukuveliswa kwezixhumi zombane kunye neziseko zezixhobo zoshishino.

- Iprototyping kunye nokuveliswa kwezixhobo ze-microelectromechanical systems (MEMS).

Ishishini lezonyango kunye neMpilo

- Ukuvelisa izixhobo zonyango ezifana nemigqomo yesirinji, izihlanganisi ze-IV, kunye nezixhobo zotyando.

- Ukuveliswa kweengxenye ezilungiselelwe izixhobo zonyango kunye nezixhobo zokuxilonga.

- Iprototyping kunye nokuveliswa kweendawo ezihambelana ne-biocompatible zokufakelwa kwezonyango kunye neprosthetics.

- Ukuveliswa kwezixhobo zokuhanjiswa kweziyobisi kunye namacandelo okupakisha.

- Ukuvelisa iimveliso zamazinyo ezifana neetreyi zesiko, ii-orthodontic aligners, kunye nezikhokelo zotyando.

Impahla zomthengi

- Ukwenziwa ngokwezifiso kweemveliso zabathengi njengezinto zokudlala, izixhobo zasekhaya, kunye nezinto zokhathalelo lomntu.

- Ukuveliswa koyilo lokupakisha olulodwa oluneempawu zophawu.

- Ukwenziwa kwemveliso yezinga elincinci kuqhutywa kwiimveliso zoshicilelo olunyiniweyo okanye iimarike ze-niche.

- Ukuveliswa kwezinto eziyinkimbinkimbi kunye nezihombise izinto zokuhombisa ikhaya.

- Ukwenziwa kweemveliso zokuthengisa ezilungiselelweyo kunye nezipho.

Izixhobo zeShishini

- Iprototyping kunye nokuveliswa kwamacandelo akhethekileyo koomatshini boshishino kunye nezixhobo.

- Ukwenziwa kwezixhobo zokusebenza, iijigs, kunye nezixhobo.

- Ukwenziwa ngokwezifiso kwezixhobo zemizi-mveliso ukuhlangabezana neemfuno ezithile.

- Ukuveliswa kwamacandelo ahlala ixesha elide kunye nokusebenza okuphezulu kwizicelo ezinzima.

- Ukwenziwa kwezigqubuthelo zokhuselo, oonogada, kunye nezixhobo zokukhwela koomatshini.

Imidlalo noLonwabo

- Ukuveliswa kwezixhobo zezixhobo ezifana nezibambo, ukubamba, kunye nezixhobo zokukhusela.

- Ukwenziwa kwamalungu esiko kwiibhayisekile, iikayak, kunye nezinye izinto zemidlalo.

- Ukudalwa kwamacandelo akhethekileyo kwizixhobo zokufaneleka.

- Iprototyping kunye nokuveliswa kwamacandelo kwiimveliso zokuzonwabisa zangaphandle.

Imizi-mveliso eNzuzwayo kwi-Low Volume ephantsi yokuBunjwa kwesitofu

Ukubumba inaliti yomthamo ophantsi kunika izibonelelo ezibalulekileyo kumashishini amaninzi, kubandakanya izixhobo zonyango, i-aerospace, iimoto, izinto zombane, iimpahla zabathengi, izixhobo zamashishini, iprototyping, iimveliso ezizodwa, kunye neendawo ezitshintshileyo. Le nkqubo yokwenza izinto ezininzi iququzelela imveliso enexabiso eliphantsi lezinto ezincinci, ezivumela ukwenziwa ngokwezifiso, ukuveliswa kwezinto ezintsha, kunye nophuhliso olusebenzayo lwemveliso.

- Izixhobo zonyango:Ukubumba inaliti yevolumu ephantsi ilungele ukuvelisa izixhobo zonyango ezilungiselelweyo kunye namalungu anengcaciso echanekileyo. Ivumela ukuveliswa kwexabiso elincinci lezinto ezincinci, okwenza ukuba abavelisi bezonyango bahlangabezane neemfuno ezahlukeneyo zezigulane.

- I-Aerospace:Ishishini le-aerospace lifuna iindawo ezintsonkothileyo ezichaneke kakhulu kunye nemigangatho engqongqo yobulunga. Ukubumba inaliti yevolumu ephantsi kuvumela ukuveliswa kwezinto ezikhaphukhaphu, ezihlala ixesha elide, ukunciphisa ubunzima kunye nokuphucula ukusebenza kakuhle kwamafutha kwinqwelomoya.

- Imoto:Ukubumba inaliti yevolumu ephantsi ibalulekile kwiprototyping kunye nokuvelisa iindawo ezikhethekileyo zeemoto. Ivumela abavelisi ukuba baphindaphinde ngokukhawuleza kwaye baphucule uyilo, baqinisekise ukusebenza kakuhle kunye nokusebenza ngaphambi kokuveliswa ngokupheleleyo.

- ZeWindows:Ishishini le-elektroniki lixhamla ekubumbeni inaliti yevolumu ephantsi ukuze kuveliswe iindawo ezintsonkothileyo, ezinjengeziqhagamshelo kunye neecasings. Le nkqubo ivumela ukuveliswa okusebenzayo kweebhetshi ezincinci, ezihambelana nendalo ekhawulezayo yokuvelisa i-electronics.

- Impahla zomthengi: Ukubumba inaliti yevolumu ephantsi kunenzuzo ekudaleni iimpahla zabathengi ezilungelelanisiweyo ezinoyilo kunye neempawu ezizodwa. Ivumela ukuveliswa ngokukhawuleza kwezinto ezincinci, ukuququzelela uvavanyo lweemarike kunye nokwenza ngokwezifiso ukuhlangabezana nokukhethwa kwabathengi.

- Izixhobo Zoshishino: Ukubumba inaliti yevolumu ephantsi kuvelisa izixhobo zemizi-mveliso, ezinjengeegiya, iivalvu, kunye nezindlu. Le nkqubo ivumela ukuveliswa kwexabiso elincinci lamanani amancinci, ukuhlangabezana neemfuno ezithile zezicelo zoshishino.

- iPrototyping kunye noPhuhliso lweMveliso: Iinkampani zisebenzisa kakhulu isitofu esinomthamo ophantsi wokubumba kwiprototyping kunye nenqanaba lophuhliso lwemveliso. Inika indlela enexabiso eliphantsi yokuvelisa iiprototypes ezisebenzayo, ukuvumela ukuqinisekiswa koyilo, ukuvavanywa, kunye nokucokisa phambi kokuveliswa kobuninzi.

- Iimveliso ezikhethekileyo: Amashishini amaninzi e-niche afuna iindawo ezikhethekileyo ezingaveliswanga ngobuninzi. Ukubumba inaliti yevolumu ephantsi kunika isisombululo esisebenzayo sokwenza la macandelo ahlukileyo ngokufanelekileyo, ukubonelela iimfuno ezithile zentengiso.

- Icandelo lokuTshintsha:Ukubumba inaliti yevolumu ephantsi kuluncedo ekwenzeni iindawo ezitshintshileyo kumashishini ahlukeneyo. Ivumela ukuveliswa kweemfuno zemilinganiselo emincinci, iqinisekisa ukubonelelwa ngokuzinzileyo kwamacandelo abalulekileyo ngaphandle kokufuna uluhlu olukhulu.

Iintlobo zezinto ezisetyenziswayo kwi-Low Volume Injection Molding

Ukubumba inaliti yomthamo ophantsi kusebenzisa izixhobo ezahlukeneyo ukulungiselela iimfuno ezahlukeneyo zokwenziwa.

- Thermoplastics: I-Thermoplastics zezona zinto zisetyenziswa ngokuqhelekileyo ekubunjweni kwenaliti yomthamo ophantsi. Zinokunyibilika, zipholile, kwaye ziphinde zinyibilike izihlandlo ezininzi ngaphandle kokutshintsha kakhulu iipropathi zazo. Imizekelo ye-thermoplastics ibandakanya i-polyethylene (PE), i-polypropylene (PP), i-polystyrene (PS), kunye ne-polycarbonate (PC).

- Iilastomers:Ii-elastomers, ezikwabizwa ngokuba zizixhobo ezifana nerabha, zivelisa izinto eziguquguqukayo kumthamo ophantsi wokubumba inaliti. Banikezela nge-elasticity ebalaseleyo, ukomelela, kunye nokumelana nempembelelo. I-elastomers eziqhelekileyo ziquka i-silicone, i-polyurethane (PU), kunye ne-thermoplastic elastomers (TPE).

- IiPlastiki zobuNjineli:Iiplastiki zobunjineli zizixhobo zokusebenza eziphezulu ezibonisa iimpawu ezikhethekileyo zoomatshini, ezishushu, kunye neekhemikhali. Imizi-mveliso izisebenzisa ngokubanzi iindawo zayo ezomeleleyo kunye nezomeleleyo. Ezinye iiplastiki zobunjineli ezisetyenziswa ngokuqhelekileyo kwi-low volume injection molding i-acrylonitrile butadiene styrene (ABS), inayiloni (PA), i-polyethylene terephthalate (PET), kunye ne-polyoxymethylene (POM).

- Izinto eziBonekayo neziZinzileyo: Ngokukhula kogxininiso lokuzinza, ukubumba inaliti enomthamo ophantsi nako kusebenzisa imathiriyeli enokubola kunye nezinzileyo. Ezi zixhobo zinokufunyanwa kwimithombo evuselelekayo kwaye zibonelele ngeenzuzo zokusingqongileyo. Imizekelo ibandakanya i-polylactic acid (PLA), i-bio-based polyethylene (PE), kunye ne-bio-based polypropylene (PP).

- Isinyithi kunye nomgubo weCeramic: Ukongeza kwiiplastiki, ukubumba inaliti yevolumu ephantsi kunokubandakanya isinyithi kunye nomgubo weceramic ukuvelisa isinyithi okanye iindawo ze-ceramic. Inkqubo, eyaziwa ngokuba yi-metal injection molding (MIM) okanye i-ceramic injection molding (CIM), ibandakanya ukuxuba i-powders kunye ne-binder kwaye ifakwe kwi-molds. Emva koko, iinxalenye ziphantsi kwe-debinding kunye ne-sintering ukufezekisa iipropathi zazo zokugqibela.

- Izinto ezidityanisiweyo:Izinto ezidibeneyo zidibanisa izinto ezahlukeneyo ukuze zifezekise izinto ezifunwayo. Izinto ezixubeneyo zinokomeleza amandla, ukuqina, okanye ukuxhathisa ubushushu kwinaliti ephantsi yokubumba. Imizekelo ibandakanya i-carbon fiber-reinforced polymers (CFRP), i-glass fiber-reinforced polymers (GFRP), kunye neepolima ezizaliswe ngamaminerali.

- Irabha yeSilicone elulwelo (LSR): I-LSR sisixhobo esikhethekileyo sokuvelisa iinxalenye eziguquguqukayo, ezikwaziyo ukumelana nobushushu, kunye ne-biocompatible. Ilungele kakhulu izicelo ezifuna iipropathi ezibalaseleyo zokutywina, njengakumashishini ezonyango kunye neemoto.

Isebenza njani i-Low Volume I-injection Molding

Ukubumba inaliti yevolumu ephantsi yinkqubo yokuvelisa enceda amashishini ahlukeneyo kwaye ivumela ukuvelisa amanani amancinci eendawo ezilungiselelwe. Ibandakanya ukuyila kunye nokuqulunqwa kwesikhunta kunye nokulungiswa kwezinto eziye zancibilika kwaye zifakwe kwi-mold cavity phantsi koxinzelelo oluphezulu.

- Uyilo lokungunda:Inkqubo iqala ngokuyila kunye nokwenza umngundo ohambelana nenxalenye efunekayo yejometri. Umngundo uqulathe iziqingatha ezibini, umngxuma kunye nombindi, ezenza ubume benxalenye yokugqibela xa zidityanisiwe.

- Ukulungiswa kwezinto: Izinto ezikhethiweyo, ngokuqhelekileyo ngendlela yeepellets, zilayishwa kwi-hopper kwaye zondliwe kumatshini wokubumba inaliti. Emva koko amaqokobhe ayafudunyezwa aze anyibilike anyibilike.

- Inaliti:Izinto ezityhidiweyo zifakwe kwi-mold cavity phantsi koxinzelelo oluphezulu usebenzisa i-screw ebuyiselayo okanye i-plunger. Olu xinzelelo luqinisekisa ukuba izinto eziphathekayo zigcwalisa zonke iinkcukacha eziyinkimbinkimbi ze-mold kwaye zigcina ukuma kwayo ngexesha lokuqina.

- Ukupholisa kunye nokuqinisa:Emva kokuzalisa i-mold cavity, izinto ezityhidiweyo zivumelekile ukuba zipholile kwaye ziqiniswe ngaphakathi kwesikhunta. Imijelo yokupholisa edibeneyo kwi-mold ichitha ubushushu kwaye ikhawulezise inkqubo yokuqinisa.

- Ukuvulwa kokungunda kunye nokuKhutshwa:Umngundo uvula emva kokuba i-material iqiniswe ngokwaneleyo, yahlula iziqingatha ezibini. Izikhonkwane zejector okanye iipleyiti zityhala inxalenye ngaphandle komngundo, ukuya kumgqomo wokuqokelela, okanye kwibhanti lokuhambisa.

- Ukugqiba:Indawo ekhutshiweyo inokungena kwiinkqubo ezahlukeneyo ukufezekisa umphezulu ofunwayo kunye nokuchaneka komda. Le misebenzi inokuquka ukucheba imathiriyeli engaphezulu, ukususa ifleshi okanye iibhara, kunye nokwenza imisebenzi yesibini efana nomatshini okanye ukupeyinta.

- Phinda inkqubo:Umngundo uyavala, kwaye umjikelo uyaphinda ukuvelisa inxalenye elandelayo. Ukubunjwa kwenaliti yevolumu ephantsi kuvumela ukuphindaphinda okuninzi kunye nohlengahlengiso kubumba kunye nenkqubo, okwenza kube lula kwimveliso kunye nokuphuculwa koyilo.

- Ulawulo lwemeko:Amanyathelo olawulo lomgangatho aphunyezwa kuyo yonke le nkqubo ukuqinisekisa ukuba iindawo eziveliswayo ziyahlangabezana nemigaqo efunekayo. Le misebenzi inokubandakanya ukuhlolwa rhoqo, imilinganiselo yobukhulu, kunye novavanyo olusebenzayo.

- Ukusabalala:Ukubunjwa kwenaliti yevolumu ephantsi kugxininise ekuveliseni amanani amancinci, kodwa kunokusebenza njengelitye lokunyathela kwimveliso enkulu.

Iindidi zoomatshini bokuBumba beSitofu esisezantsi

Oomatshini bokubumba benaliti enomthamo ophantsi bayafumaneka kwaye bayilelwe ukujongana neemfuno ezahlukeneyo zokwenziwa. Izinto ezinjengezinto ezisetyenzisiweyo, ubunzima bokuvelisa inxalenye, kunye nokuchaneka okufunwayo kunye nokusebenza kakuhle kumisela ukhetho lomatshini. Ukukhetha uhlobo oluchanekileyo lomatshini kubalulekile ekufezekiseni iziphumo ezinqwenelekayo kunye nokuqinisekisa ukusebenza kakuhle kweendleko kwimveliso.

- Oomatshini beHydraulic:Oomatshini bokubumba inaliti yomthamo ophantsi weHydraulic basebenzisa iimpompo zehydraulic ukuvelisa uxinzelelo olufunekayo lokutofa izinto kumgodi wokungunda. Banokuvelisa iindawo ezichanekileyo kunye nokuphindaphinda kwaye baphathe izinto ezahlukeneyo.

- Oomatshini boMbane:Oomatshini bokubumba inaliti yombane ephantsi basebenzisa iimotor zombane endaweni yeempompo zehydraulic ukuqhuba inkqubo yokutofa. Banikezela ukusebenza kakuhle kwamandla, ukugcinwa okuncitshisiweyo, kunye nokusebenza okuthe cwaka kunoomatshini bamanzi.

- Oomatshini abaHybrid:Oomatshini bokubumba inaliti yomthamo ophantsi weHybrid badibanisa izibonelelo zezixhobo zombini zehydraulic kunye nombane. Badibanisa i-hydraulic kunye ne-electric drives, ukuphucula ukuchaneka, ukusebenza kakuhle kwamandla, kunye nokunciphisa amanqanaba engxolo.

- Oomatshini abathe nkqo:Oomatshini bokubumba inaliti yomthamo ophantsi othe nkqo basebenzisa umxhuzulane ukondla imathiriyeli kumgodi wokungunda, kwaye ukungunda kuxhonywe ngokuthe nkqo. Zikulungele ukuvelisa iinxalenye ezinejometri ezintsonkothileyo kwaye zinokugcina indawo yomgangatho kwiindawo zokuvelisa.

- Oomatshini bokuMbumba abancinci:Umatshini wokubumba we-Micro-molding low volume low umthamo we-injection zenzelwe ngokukodwa ukuvelisa iindawo ezinomlinganiselo omncinci kunye nokuchaneka okuphezulu. Basebenzisa izixhobo ezikhethekileyo ukufezekisa iziphumo ezifunwayo, kubandakanywa iiyunithi ze-micro-injection kunye ne-micro-mold cavities.

- Oomatshini bokuDubula okuninzi:Oomatshini bokubumba inaliti yomthamo ophantsi othotyiweyo basebenzisa iiyunithi ezininzi zokutofa ukuvelisa iinxalenye ezinezixhobo ezahlukeneyo okanye imibala. Esi sixhobo sivumela ukudala iindawo ezinzima ezinokwakheka okungafaniyo kunye nokugqiba.

- Oomatshini begumbi lokucoca:Abaqulunqi benza oomatshini bokubumba benaliti ephantsi-ivolumu ephantsi ukuze basetyenziswe kwindawo engenanto, njengendawo yokuvelisa amayeza okanye amayeza. Abavelisi bazenza ngemathiriyeli ekulula ukuyicoca, ukuyicoca, kunye nokubandakanya iimpawu zokunciphisa ungcoliseko.

Izinto ezichaphazela ukuBunjwa kwesitofu soMqulu ophantsi

Izinto ezininzi zinempembelelo kwisiphumo kunye nokusebenza kakuhle kwenaliti yomthamo ophantsi wokubumba. Ukuthathela ingqalelo ezi zinto kunye nokwandisa inkalo nganye yenkqubo inceda ekuqinisekiseni ukuba yimpumelelo kwemveliso yokubumba inaliti enomthamo ophantsi.

- Iingqwalasela zoyilo:Uyilo lwenxalenye ludlala indima ebalulekileyo ekubumbeni inaliti yevolumu ephantsi. Izinto ezifana nobukhulu bodonga, ii-engile zedrafti, kunye nobukho bee-undercuts 'zichaphazela ukubunjwa kwenxalenye kunye nomgangatho jikelele. Iimpawu ezilungiselelwe kakuhle kunye nejometri efanelekileyo zinokunceda ukufezekisa iziphumo ezingcono.

- Ukhetho lwezixhobo:Ukhetho lwemathiriyeli yokubumba inaliti yomthamo ophantsi lubalulekile. Izixhobo ezahlukeneyo zineempawu ezahlukeneyo, ezifana neempawu zokunyibilika kokunyibilika, amazinga okuncipha, kunye nobuthathaka bobushushu. Izinto ezifanelekileyo eziye zahlangabezana neemfuno zokusebenza kunye nobuhle obufunwayo buyimfuneko ekubunjweni okuphumelelayo.

- Uyilo lokungunda kunye noKwakha:Uyilo kunye nokwakhiwa kwesikhunta sichaphazela ngokuthe ngqo umgangatho kunye nokuba nokwenzeka kokubunjwa kwenaliti yomthamo ophantsi. Ukuqinisekisa ukugcwaliswa kwenxalenye efanelekileyo, ukupholisa, kunye nokukhupha, umntu kufuneka acinge ngononophelo izinto zokungunda, imijelo yokupholisa, i-venting kunye nenkqubo yokungena.

- Iiparamitha zeNkqubo:Ukubumba inaliti yevolumu ephantsi, umntu kufuneka asebenzise iiparamitha ezininzi zenkqubo, kubandakanya isantya sokutofa, ubushushu, uxinzelelo, kunye nexesha lokupholisa. Ukufumana ulungelelwaniso olululo lwezi parameters lubalulekile ekuphumezeni eyona nxalenye yomgangatho, ukunciphisa iziphene, kunye nokuqinisekisa imveliso engaguqukiyo.

- Ulawulo lwemeko:Ukuphumeza imilinganiselo yokulawula umgangatho kuyo yonke inkqubo yokubumba inaliti yomthamo ophantsi kubalulekile. Ukuhlolwa rhoqo, ukutshekishwa komgangatho, kunye novavanyo olusebenzayo lunceda ukuchonga nokujongana nayo nayiphi na imiba okanye iziphene kwangethuba, ukuqinisekisa ukuba iindawo eziveliswayo ziyahlangabezana nemigaqo efunekayo.

- Izixhobo kunye noLondolozo lweZixhobo:Ukugcinwa rhoqo kunye nokugcinwa kwe-injection yomatshini wokubumba kunye nokubunjwa kuyimfuneko kwimveliso ehambelanayo kunye nokusebenzayo. Ukucoca ngokufanelekileyo, ukuthambisa, kunye nokuhlolwa kwezixhobo kunye nokubumba kunceda ukukhusela ukuphuka, ukunciphisa ixesha lokunciphisa, kunye nokuqinisekisa ixesha elide lezixhobo.

- Umthamo weMveliso:Nangona abavelisi beyila ukubumba inaliti yevolumu ephantsi yomthamo omncinci, umthamo wemveliso usenakho ukuphembelela izinto ezinje ngexabiso ngenxalenye nganye, ixesha lokukhokela, kunye nokukhethwa kwezixhobo. Ukuqonda umthamo wemveliso olindelweyo kubalulekile ekuphuculeni inkqubo kunye nokukhetha isicwangciso esifanelekileyo sokwenziwa kwemveliso.

- Ukuqwalaselwa kweendleko: Ixabiso lokubumba inaliti yevolumu ephantsi ibandakanya izinto ezahlukeneyo, kubandakanya iindleko zempahla, iindleko zokwenziwa komngundo, ukusetwa komatshini kunye neendleko zokusebenza, kunye neendleko zasemva kokulungiswa. Ukulungelelanisa ukusebenza kakuhle kweendleko kunye nomgangatho ofunekayo kunye nokusebenza kwamalungu kubalulekile kwimveliso yomthamo ophantsi oyimpumelelo.

Iingqwalaselo zoYilo lokuBunjwa kwesitofu soMqulu ophantsi

Ukuyila iinxalenye zokubumba inaliti yomthamo ophantsi kufuna uqwalaselo ngononophelo lwemiba eyahlukeneyo. Ezi ziquka:

Uluhlu lweNdonga

- Ukugcina udonga olungaguquguqukiyo nolufanelekileyo lubalulekile

- Iindonga ezishinyeneyo zinokukhokelela kumaxesha amade okupholisa kunye nokungqubana okunokwenzeka.

- Iindonga ezibhityileyo zinokubangela ukomelela kwenxalenye ethile.

- Ukuyila kunye nobukhulu bodonga obufanayo kuqinisekisa ukuhamba kwezinto ezifanelekileyo kunye nomgangatho ophezulu wenxalenye.

Iiengile zoyilo

- Ukubandakanya ii-engile zedrafti kuyilo kubalulekile kwi-ejection yenxalenye elula

- Ii-engile zokuyila zivumela ukususwa okugudileyo kwenxalenye ngaphandle kokwenza umonakalo.

- Ii-angles eziyidrafti ezaneleyo zinceda ukukhusela ukunamathela kunye nokuququzelela imveliso esebenzayo.

Iindlela ezisezantsi kunye neentshukumo ezisecaleni

- Ukunciphisa ii-undercuts kunye nezenzo zecala kuyacetyiswa

- Ii-undercuts zenza ukukhutshwa kube ngumngeni kwaye kunokufuna uyilo olunzima lokungunda okanye imisebenzi yesibini.

- Ukwenza lula inxalenye yejometri kunye nokuphepha iimpawu ezinzima kuphucula ukubumba kunye nokunciphisa iindleko.

Ukubekwa kweSango

- Ukubekwa kwesango ngendlela eyiyo kubalulekile ekusebenzeni kakuhle kwezinto kunye nokunciphisa iziphene

- Indawo yesango ichaphazela inkangeleko yenxalenye, amandla, kunye ne-warpage.

- Ukubeka amasango kwiindawo ezifanelekileyo kuphucula umgangatho wenxalenye kunye nobuhle.

Umgca wokwahlula kunye noMphezulu woKwahlula

- Ukuchaza umgca wokuhlula ofanelekileyo kunye nomphezulu kuyimfuneko kwi-mold design kunye nendibano

- Umgca wokuqhawula ococekileyo kunye ochazwe kakuhle uququzelela ukwakhiwa kwesikhunta kunye nokunciphisa umngcipheko weziphene.

Iimbambo kunye neeBoss

- Ukubandakanya iimbambo kunye nabaphathi kuphucula imfezeko yesakhiwo kunye nokusebenza

- Iimbambo zinika amandla kunye nokuqina kumacandelo amancinci.

- Abaphathi basebenza njengendawo yokuncamathela okanye ufakelo lwemisebenzi yesibini.

UkuGqiba komphezulu kunye nokuThungwa

- Ukuqwalasela ukugqiba umgangatho ofunekayo kunye nokuthungwa kubalulekile

- Unyango lokungunda okanye ukuthungwa komngxunya kunokufikelela kwindawo egudileyo okanye eyenziweyo.

- Ukukhethwa okufanelekileyo kunye nokunxibelelana kweemfuno zokugqiba umphezulu negalelo kwi-aesthetics efunwayo kunye nokusebenza.

Ukunyamezela kunye nokuchaneka koMda

- Ukucacisa ukunyamezela okufanelekileyo kunye nokuchaneka kobukhulu kubalulekile

- Ukuqonda ubuchule bokubumba inaliti yomthamo ophantsi kubalulekile.

Ngokuthathela ingqalelo le miba yoyilo, abavelisi banokukhulisa ukubumba inaliti yevolumu ephantsi, okukhokelela kwiindawo ezikumgangatho ophezulu, imveliso esebenzayo, kunye nokusebenza kakuhle kweendleko.

Ukulawulwa koMgangatho kwi-Low Volume Injection Molding

Ulawulo lomgangatho lubalulekile ekubunjweni kwesitofu somthamo ophantsi ukuqinisekisa ukuveliswa kweendawo ezikumgangatho ophezulu ezihlangabezana neenkcukacha ezifunekayo. Nazi ezinye izinto eziphambili ekufuneka ziqwalaselwe kulawulo olusebenzayo lomgangatho wokubumba inaliti yevolumu ephantsi:

- Ukuhlolwa noVavanyo:Ukuhlolwa rhoqo kunye novavanyo kuyo yonke imveliso inceda ukuchonga iziphene okanye imiba kwangethuba. Ukuqinisekisa ukuba iinxalenye ziyahlangabezana neenkcukacha, umntu kufuneka enze iitshekhi zobukhulu, uhlolo olubonakalayo, kunye novavanyo olusebenzayo.

- Ukuqinisekiswa kwezinto: Ukuqinisekisa umgangatho kunye nokungaguquguquki kwezinto ezisetyenziselwa ukubumba inaliti yomthamo ophantsi kubalulekile. Ukuqinisekiswa kwezinto kubandakanya ukujonga izinto eziphathekayo, ezifana ne-melt flow, i-viscosity, kunye nombala, ukuqinisekisa ukuba zihambelana neenkcukacha ezifunwayo.

- Ugcino lokungunda:Ukugcinwa ngokufanelekileyo kunye nokugcinwa kwe-molds kubalulekile kwimveliso ehambelanayo kunye nekhwalithi ephezulu. Ukucocwa rhoqo, ukuthambisa, kunye nokuhlolwa kokungunda kunceda ukuthintela iziphene, ukunciphisa ixesha lokuphumla, kunye nokwandisa ixesha lokuphila kwe-molds.

- Ukubeka iliso kwinkqubo:Ukubeka iliso okuqhubekayo kwiiparameters zenkqubo yokubumba i-injection kubalulekile ekugcineni umgangatho. Kuyimfuneko ukubeka iliso izinto eziguquguqukayo ezifana nobushushu, uxinzelelo, kunye nexesha lomjikelo ukuze kuqinisekiswe ukuba ziphakathi koluhlu oluchaziweyo kunye nokufumanisa ukutenxa okanye ukungaqhelekanga.

- Ulawulo lweNkqubo yoBalo (SPC):Ukusebenzisa ubuchule be-SPC kunceda ukubeka iliso kunye nokulawula ukuhluka kwinkqubo yokuvelisa. Kubandakanya ukuqokelela kunye nokuhlalutya idatha kwinkqubo yokuvelisa ukuchonga iintsingiselo, iipatheni, kunye nemithombo enokubakho yokwahluka, ukuvumela uhlengahlengiso olusebenzayo kunye nokuphuculwa.

- Amanyathelo oLungiso kunye noThintelo:Ukuphumeza amanyathelo okulungisa nokuthintela kubalulekile ekujonganeni nemiba esemgangathweni okanye ukungathotyelwa. Emva kokuchonga iziphene okanye ukuphambuka, iqela ngokukhawuleza lenza umzamo wokuzilungisa kunye nokuthintela ukuphindaphinda kwabo, ukuqinisekisa ukuphuculwa okuqhubekayo kwinkqubo yokuvelisa.

- Amaxwebhu kunye nokulandelelwa:Ukugcina amaxwebhu afanelekileyo kunye nokulandeleka kwenkqubo yokuvelisa kubalulekile kulawulo lomgangatho. Ukuququzelela ukulandelelwa kunye nokuqinisekiswa komgangatho, iiparamitha zenkqubo yokurekhoda, iziphumo zokuhlola, kunye nolwazi lwempahla, kunye nokulandelela imbali yecandelo ngalinye eliveliswayo, kubalulekile.

- Ulawulo loMgangatho woMboneleli:Ukuqinisekisa umgangatho wamacandelo kunye nemathiriyeli efunyenwe kubaboneleli kubalulekile. Ukuseka iinkqubo zolawulo oluluqilima lwababoneleli, kubandakanywa isiqinisekiso, uvavanyo, kunye nokubeka iliso okuqhubekayo, kunceda ukuqinisekisa ukusetyenziswa kwegalelo elikumgangatho ophezulu kuphela kwimveliso.

Ngokuphumeza amanyathelo okulawula umgangatho asebenzayo, abavelisi banokuvelisa umgangatho ophezulu, ongaguqukiyo, kunye namalungu athembekileyo ngokubumba inaliti yomthamo ophantsi.

Isixhobo sokuBumba isitofu soMqulu ophantsi

Isixhobo sokubumba isitofu somthamo ophantsi kufuna uqwalaselo olucokisekileyo lokukhetha izinto zokubumba, uyilo, ulwakhiwo, ukugcinwa, ukulungiswa, ukufakwa, uvavanyo kunye nokugcinwa.

Ukukhethwa kwezinto zokungunda

Ukukhetha imathiriyeli yokubumba efanelekileyo kubalulekile ekubumbeni inaliti enomthamo ophantsi. Qwalasela imiba efana nokuqina, ukumelana nobushushu, kunye nokuhambelana xa ukhetha imathiriyeli. Izinto eziqhelekileyo zokubumba ziquka i-alloys yensimbi, i-aluminium alloys, kunye nezixhobo ezidibeneyo.

Uyilo loMngundo

Ukuyila ukubumba ukubumba inaliti yomthamo ophantsi kufuna uqwalaselo ngononophelo lwemiba efana nenxalenye yejometri, inkqubo yokungena, itshaneli zokupholisa, kunye nesixhobo sokukhupha.

- Inxalenye yejometri efanelekileyo iququzelela ukuzaliswa ngokufanelekileyo, ukupholisa, kunye nokukhupha inxalenye.

- Inkqubo yokungena eyilwe kakuhle iqinisekisa ukuhamba kakuhle kwezinto kunye nokunciphisa iziphene.

- Iitshaneli zokupholisa eziyilwe ngokufanelekileyo zinceda ukulawula amaxesha omjikelezo kunye nokuqinisekisa umgangatho ohambelanayo wenxalenye.

- Indlela yokukhupha i-ejection esebenzayo ivumela ukukhutshwa lula kwenxalenye kwi-mold.

Ukwakhiwa kokungunda

Yenza ulwakhiwo lokungunda ngokuchanekileyo kunye nengqalelo kwiinkcukacha.

- Abenzi bezixhobo zezakhono basebenzisa umatshini, i-CNC milling, kunye ne-EDM (i-Electrical Discharge Machining) ubuchule bokudala i-mold components.

- Ukudityaniswa ngononophelo kunye nokulungelelaniswa kwamacandelo okubumba kubalulekile ekusebenzeni kakuhle kunye nomgangatho wenxalenye.

ULondolozo lokungunda kunye nokulungiswa

Ukugcinwa rhoqo kunye nokulungiswa ngexesha lokubumba kubalulekile ukuqinisekisa ukuhlala ixesha elide kunye nokusebenza okungaguqukiyo.

- Abanini-zithuthi kufuneka baqhube ukucoca rhoqo, ukuthambisa, kunye nokuhlola ukuthintela imiba kunye nokwandisa imveliso.

- Ukulungiswa ngokukhawuleza kwanoma yimuphi umonakalo okanye ukunxiba kumacandelo okubumba kunceda ukuphepha iziphene kunye nokuphazamiseka kwemveliso.

Ukufakwa kokungunda kunye neMixholo eTshintshwayo

Ukusebenzisa i-mold inserts kunye namacandelo aguquguqukayo kuvumela ukuguquguquka kunye nokuphumelela kweendleko kwi-low volume volume injection molding.

- Abaqhubi banokuguqula okanye bafake endaweni yokufakela ukulungelelanisa utshintsho loyilo okanye ezinye iimfuno-iinguqu zenxalenye.

- Amacandelo atshintshiselanayo avumela utshintsho olukhawulezayo lokungunda, ukunciphisa ixesha lokuphumla kunye nokwandisa ukusebenza kakuhle kwemveliso.

Uvavanyo lokungunda kunye nokuqinisekiswa

Uvavanyo olucokisekileyo kunye nokuqinisekiswa kokungunda kubalulekile ngaphambi kokuba uqalise imveliso.

- Senza ulingo lokungunda ukwandisa iiparamitha zenkqubo, siqinisekise umgangatho wenxalenye, kwaye sichonge uhlengahlengiso oluyimfuneko.

- Sisenokwenza uhlalutyo lokuhamba komngundo kunye nokulinganisa ikhompyuter ukuqikelela nokwandisa inkqubo yokubumba.

Ukugcinwa kokungunda kunye noLondolozo

Ukugcinwa ngokufanelekileyo kunye neendlela zokulondoloza zibalulekile ukugcina umgangatho kunye nokusebenza xa ukubunjwa kungasetyenziswanga.

- Umngundo kufuneka ugcinwe kwindawo elawulwayo ukunqanda umonakalo osuka kukutshintsha kobushushu, ukufuma, kunye nezinto ezingcolisayo.

- Nangexesha lokungasetyenziswa, abaqhubi kufuneka baqhube uhlolo kunye nokugcinwa rhoqo.

IiNdlela zokuSebenza eziSebenzayo zokuBumba isitofu soMqulu ophantsi

Ukwamkela izicwangciso ezingabizi kakhulu zokubunjwa kwenaliti yomthamo ophantsi kufuna indlela epheleleyo ebandakanya uyilo lokubumba, ukukhetha izinto eziphathekayo, ukuphuculwa kwenkqubo, ukuzenzekelayo, kunye nentsebenziswano yababoneleli. Ngokuphumeza ezi zicwangciso, iinkampani zinokufikelela kwiziphumo ezikumgangatho ophezulu ngelixa zinciphisa iindleko kunye nokwandisa ukusebenza kakuhle kwimisebenzi yazo yokuvelisa umthamo ophantsi.

- Uyilo lokungunda olusebenzayo:Ukuyila ngokufanelekileyo isikhunta sokubumba isitofu esisezantsi kunokunciphisa kakhulu iindleko. Ukwenza lula uyilo lokungunda kunye nokunciphisa inani leentsimbi kunokunciphisa iindleko zesixhobo kunye nokunciphisa ixesha lokuvelisa.

- Ukukhethwa kwezinto:Ukukhetha imathiriyeli efanelekileyo kubalulekile ekubumbeni inaliti enexabiso eliphantsi. Ukukhetha iintlaka ezingabizi kakhulu okanye ukujonga imathiriyeli ezizezinye ezihlangabezana nemigaqo efunekayo kunokukhokelela kugcino lweendleko ezinkulu ngaphandle kokubeka esichengeni umgangatho.

- Ukuzenzekela kunye nerobhothi:Ukusebenzisa i-automation kunye nerobhothi ekubunjweni kwenaliti kunokuphucula ukusebenza kakuhle kunye nokunciphisa iindleko zabasebenzi. Iinkqubo ezizenzekelayo ziyakwazi ukusingatha imisebenzi ephindaphindiweyo, ukunciphisa iimpazamo, kunye nokwandisa imveliso yemveliso, ezenza zilungele ukuveliswa kwevolumu ephantsi.

- Uphuculo lwenkqubo:Ukulungisa kakuhle inkqubo yokubumba inaliti kunokubangela ukongiwa kweendleko. Ukuhlalutya kunye nokwenza ngcono iiparamitha ezinje ngeqondo lobushushu, uxinzelelo, kunye namaxesha okujikela kunokunciphisa inkunkuma yezinto, ukuphucula umgangatho wenxalenye, kunye nokwandisa imveliso.

- Ukwenziwa kwemfuno:Ukwamkela ukuveliswa kweemfuno kuvumela ukuguquguquka okungakumbi kunye neendleko-zokusebenza kwi-injection ye-volume ephantsi yokubumba. Ngokuvelisa iinxalenye kuphela xa zifuneka, iinkampani zinokunqanda iindleko ezigqithisileyo zoluhlu kunye nokunciphisa umngcipheko wokuphelelwa lixesha.

- Ezinye iindlela zokusebenzisa izixhobo:Ukuphonononga ezinye iindlela zokusebenzisa izixhobo, ezifana ne-3D-printed molds okanye i-soft tooling, inokuba yindleko-esebenzayo kwimveliso yomthamo ophantsi. Ezi zikhetho zihlala zineendleko zangaphambili ezisezantsi kunye namaxesha amafutshane okukhokela kunobumba bentsimbi.

- Ubambiswano lwababoneleli:Ukusebenzisana ngokusondeleyo nababoneleli bokubumba inaliti ethembekileyo nabanamava kunokuncedisa ukwandisa iindleko. Ababoneleli abanobuchule bokuvelisa umthamo ophantsi banokunika ulwazi oluxabisekileyo, bacebise amanyathelo okonga iindleko, kwaye babonelele ngamaxabiso akhuphisanayo kwizinto kunye nezixhobo.

- Emva kokwenziwa komsebenzi:Ukulungelelanisa imisebenzi yasemva kokulungiswa, njengokulungisa, ukuhlanganisa, kunye nokugqiba, kunokunciphisa iindleko. Utyalo-mali kwizixhobo ezisebenzayo zasemva kokulungiswa kunye nobuchule kunokunciphisa iimfuno zabasebenzi kunye nokunciphisa iindleko zokusebenza kwesibini.

IiNzuzo zokuSebenzisa i-3D yoShicilelo kwi-Molding ye-Low Volume ye-Low

Ukusebenzisa ushicilelo lwe-3D lokubumba inaliti yevolumu ephantsi kubonelela ngeenzuzo ezininzi. Ivumela iprototyping ekhawulezayo, ivumela ukuphindaphinda okukhawulezayo kunye nokuncipha kweempazamo zoyilo. Ushicilelo lwe-3D lunciphisa ukuveliswa kwenkunkuma kwaye lunceda ukunciphisa umngcipheko ngokuvumela uvavanyo kunye nokuqinisekiswa ngaphambi kokuzinikela kwimveliso epheleleyo.

- Ukuchwetheza ngokukhawuleza: Ushicilelo lwe-3D lubonelela ngenzuzo yeprototyping ekhawulezayo, evumela abaqulunqi ukuba baphindaphinde kwaye basulungekise uyilo lwemveliso yabo ngokukhawuleza. Le ndlela yenza ukuba iinkampani zikwazi ukuzisa iimveliso kwimarike ngokukhawuleza kwaye zithintele iimpazamo zoyilo ezibizayo.

- Izixhobo ezingabizi kakhulu:Ushicilelo lwe-3D lunokuba yinto engabizi kakhulu kwisixhobo sokubumba inaliti enomthamo ophantsi. Ngokusebenzisa ii-molds eziprintiweyo ze-3D okanye ezifakelwayo, iinkampani zinokugcina kwiindleko zangaphambili zokubumba zensimbi zendabuko, ngakumbi kwiimveliso ezincinci.

- Ububhetyebhetye boyilo: Ushicilelo lwe-3D luvumela uyilo oluntsonkothileyo noluntsokothileyo olunokuthi lungenzeki ngeendlela zakudala zobutshixo. Oku kuguquguquka kwenza ukuveliswa kwamacandelo alungelelanisiweyo kunye neyodwa, ukulungiselela iimfuno ezithile zabathengi.

- Ukuncitshiswa kwamaxesha okukhokela: Ngokusebenzisa ushicilelo lwe-3D, abavelisi banokunciphisa kakhulu amaxesha okukhokela xa kuthelekiswa neendlela zemveli zokuvelisa. Ukungabikho kwezixhobo kunye nokukwazi ukuvelisa iinxalenye kwimfuno kukhawuleza inkqubo yokuvelisa, okwenza kube lula ukuhanjiswa kwabathengi.

- Izinto ezahlukeneyo:Ukuprintwa kwe-3D kunika uluhlu olubanzi lwezixhobo, kubandakanya i-thermoplastics, i-resins, kunye ne-composites. Oku kuguquguquka kwezinto kuvumela ukuvelisa iinxalenye ezineempawu ezahlukeneyo, ukulungiselela iimfuno ezithile zokusebenza kunye nobuhle.

- Ukunciphisa inkunkuma:Ushicilelo lwe-3D yinkqubo yokuvelisa okongeziweyo, okuthetha ukuba isebenzisa kuphela imathiriyeli efunekayo ukwakha inxalenye, ekhokelela ekuveliseni inkunkuma encinci. Ukunciphisa iindleko zezinto eziphathekayo nako kunceda ekukhuthazeni iinzame zokuzinza.

- Ukunciphisa umngcipheko: Ukusebenzisa ushicilelo lwe-3D lokubumba inaliti yomthamo ophantsi kuvumela iinkampani ukuba zithobe umngcipheko onxulumene notyalo-mali kwizixhobo ezibiza imali eninzi kuyilo olungangqinwanga okanye imfuno yemarike engaqinisekanga. Iyakwenza ukuba kuvavanywe imarike ngemithamo emincinci yemveliso phambi kokuba izibophelele kwimveliso epheleleyo.

- Ibhulorho ukuya kwimveliso:Ushicilelo lwe-3D lunokusebenza njengebhulorho kwimveliso, evumela iinkampani ukuba ziqinisekise ngokukhawuleza uyilo lwazo kwaye zivavanye ukusebenza kwamalungu ngaphambi kokuba zenze utyalo-mali kwisixhobo sokubumba inaliti ebiza kakhulu. Ukuchonga iziphene zoyilo kwangethuba kunokonga iindleko ekuhambeni kwexesha.

Uzinzo lokuBumba kweSitofu soMqulu ophantsi

Ukubumba isitofu somthamo ophantsi kunokuba lukhetho oluzinzileyo lokwenziwa kwemveliso xa usondelelwa nezenzo zokukhathalela indalo esingqongileyo.

- Ukusebenza kakuhle kwezinto:Ukubumba inaliti yevolumu ephantsi kukhuthaza ukusebenza kakuhle kwezinto ngokuvelisa kuphela iindawo ezifunekayo, ukunciphisa ukuveliswa kwenkunkuma. Le ndlela inceda ukunciphisa impembelelo yokusingqongileyo ehambelana nokusetyenziswa okugqithisileyo kwempahla.

- Ugcino lwamandla:Xa kuthelekiswa neendlela zokuvelisa umthamo ophezulu, ukubunjwa kwenaliti yomthamo ophantsi kudla amandla amancinci ngenxa yemveliso emfutshane kunye nokunciphisa ixesha lokusebenza komatshini. Ngokwenza oku, sinokuwonga amandla kunye nokunciphisa ukukhutshwa kwegesi ye-greenhouse.

- Ukunciphisa inkunkuma:Ukubumba inaliti yevolumu ephantsi kuvumela ubungakanani bemveliso obuchanekileyo, ukunciphisa imfuno yoluhlu olugqithisileyo kunye nokunciphisa inkunkuma. Iinkampani zinokunciphisa ukuveliswa kwenkunkuma kunye neendleko zokuyilahla ngokunyusa ucwangciso lwemveliso kunye nemfuno yoqikelelo.

- Amathuba okuhlaziya:Ukubumba inaliti yevolumu ephantsi kaninzi kusebenzisa izixhobo ezinokuphinda zisetyenziswe ezifana ne-thermoplastics. Singaphinda sisebenzise imathiriyeli kwaye sinciphise ukuthembela kwimithombo enyulu ngokuhlanganisa izenzo zokurisayikilishwa kwinkqubo yokuvelisa. Ukudibanisa izenzo zokurisayikilisha kwinkqubo yemveliso kuvumela ukusetyenziswa kwakhona kwezinto kunye nokunciphisa ukuthembela kwimithombo esulungekileyo.

- Ukhetho oluzinzileyo lwemathiriyeli:Iinkampani zinokubeka phambili ukusebenzisa izinto ezizinzileyo kunye ne-eco-friendly ekubumbeni inaliti yevolumu ephantsi. Iiplastiki ezisekwe kwibhayoloji, izinto ezisetyenzisiweyo, kunye neentlaka ezibolayo zibonelela ngeendlela ezinokusetyenziswa ezinokuthi zinciphise impembelelo yokusingqongileyo kwaye zikhuthaze uqoqosho olujikelezayo.

- Imveliso yendawo:Ukubunjwa kwenaliti yomthamo ophantsi kuvumela ukuveliswa kwendawo, ukunciphisa imigama yokuhamba kunye nokukhutshwa kwekhabhoni ehambelanayo. Ngokuvelisa kufutshane nemarike yokugqibela, iinkampani zinokunciphisa indawo engqongileyo yekhonkco labo lokubonelela.

- Uyilo lozinzo:Ukubunjwa kwenaliti yevolumu ephantsi kuvumela umntu ukuba abandakanye imigaqo yoyilo oluzinzileyo. Ukuyila iinxalenye ezinezakhiwo ezikhaphukhaphu, iijiyometri eziphuculweyo, kunye nokusetyenziswa kakuhle kwemathiriyeli kunokuphucula ngakumbi ukuzinza kwenkqubo yokuvelisa.

- UVavanyo lomjikelo woBomi:Ukuqhuba uvavanyo lomjikelo wobomi beenkqubo zokubumba inaliti yomthamo ophantsi kunceda ukuchonga iindawo zokuphucula kunye nokuzinza. Ukuhlalutya iimpembelelo zokusingqongileyo kwinqanaba ngalinye, ukusuka ekutsalweni kwezinto ezikrwada ukuya ekulahlweni kokuphela kobomi, kwenza ukuba iinkampani zenze izigqibo ezinolwazi kwaye ziphumeze izenzo ezizinzileyo.

Imimiselo kunye neMigangatho yokuBunjwa kwe-Low Volume Injection

Ukuthobela imimiselo kunye nemigangatho ekubunjweni kwenaliti yomthamo ophantsi kubalulekile ukuqinisekisa ukhuseleko lwemveliso, uxanduva lokusingqongileyo, ukhuseleko emsebenzini, kunye nokuthotyelwa kwemithetho kunye neemfuno zeshishini. Iinkampani kufuneka zihlale zinolwazi malunga nemimiselo kunye nemigangatho esebenzayo kwaye zibadibanise kwiinkqubo zabo zokuvelisa.

- Imigangatho yokhuseleko lwemveliso:Ukubumba inaliti yevolumu ephantsi kufuneka kuhambelane nemigangatho efanelekileyo yokhuseleko lwemveliso ukuqinisekisa ukuba iindawo eziveliswayo ziyahlangabezana neemfuno zomgangatho kunye nokhuseleko. Le migangatho inokwahluka ngokuxhomekeke kushishino, njengemoto, unyango, okanye iimpahla zabathengi.

- Imimiselo yezinto eziphathekayo:Ukulandela imigaqo ethile kunye nemigangatho ekukhetheni nasekusebenziseni izinto zokubumba isitofu somthamo ophantsi kuyimfuneko ukuqinisekisa iinkqubo ezifanelekileyo zokuvelisa. Le mimiselo ilawula ukwakheka kwezinto, amanqanaba etyhefu, kunye nefuthe lokusingqongileyo. Ukuthotyelwa kwemithetho efana ne-REACH (uBhaliso, uVavanyo, uGunyaziso, kunye noThintelo lweMichiza) kubalulekile ekuqinisekiseni ukusetyenziswa kwezinto ezikhuselekileyo nezizinzileyo.

- Imigaqo yokusingqongileyo:Imisebenzi yokubumba inaliti yomthamo ophantsi kufuneka ihambelane nemigaqo yokusingqongileyo ukunciphisa ifuthe labo kwi-ikholoji. Le migaqo ijongana nemiba efana nokukhutshwa komoya, ulawulo lwamanzi amdaka, ukulahlwa kwenkunkuma, kunye nokusetyenziswa kwamandla. Ukuthobela imida efana ne-ISO 14001 (IiNkqubo zoLawulo lokuSingqongileyo) ibonisa ukuzibophelela kuxanduva lokusingqongileyo.

- Imigangatho yempilo nokhuseleko emsebenzini:Ukuqinisekisa indawo yokusebenza ekhuselekileyo kubalulekile kwiindawo zokubumba inaliti enomthamo ophantsi. Ukuthotyelwa kwemigangatho yezempilo kunye nokhuseleko lomsebenzi, njenge-OSHA (i-Occupational Safety and Health Administration) imithetho, inceda ukukhusela abasebenzi kwiingozi ezinokubakho ezinxulumene noomatshini, izixhobo kunye neenkqubo.

- Iinkqubo zolawulo lomgangatho:Ukusebenzisa iinkqubo zolawulo lomgangatho, ezifana ne-ISO 9001, kubalulekile kwimisebenzi yokubumba inaliti enomthamo ophantsi. Ezi nkqubo zibonelela ngesakhelo sokuzisa rhoqo iimveliso ezihlangabezana neemfuno zabathengi kwaye zithobela imigaqo nemigangatho esebenzayo.

- Iimfuno zokulandelelwa kunye nokuleyibhelishwa:Amanyathelo okulandeleka anokuba yimfuneko ekubunjweni kwesitofu somthamo ophantsi ukulandelela imvelaphi yezinto kunye namacandelo asetyenziswa kwimveliso. Iimfuneko zokuleyibhile, ezifana nokuchongwa kwemveliso, iinombolo zebhetshi, kunye nezilumkiso zokhuseleko, ziqinisekisa unxibelelwano olucacileyo kunye nokuthotyelwa kwemimiselo efanelekileyo.

- Iingqwalasela zepropathi enomgangatho ophezulu wokuqonda:Ukukhusela amalungelo epropathi enomgangatho ophezulu wokuqonda kubalulekile ekubumbeni inaliti yomthamo ophantsi, ngakumbi xa kusenziwa iinxalenye zeemveliso zobunini. Iinkampani kufuneka zihloniphe amalungelo elungelo elilodwa lomenzi wechiza kwaye ziqinisekise ukuba inkqubo yazo yokuvelisa ayiphazamisi ipropathi enomgangatho ophezulu wokuqonda.

- Imigaqo yorhwebo lwamazwe ngamazwe:Ukuba ubandakanyeka kurhwebo lwamazwe ngamazwe, imisebenzi yokubumba isitofu somthamo ophantsi kufuneka ihambelane nemigaqo yorhwebo kunye nemigangatho ethe ngqo kumazwe abandakanyekayo. Ukulandela imimiselo yezithethe kunye nezithintelo zokungenisa/ukuthumela ngaphandle kunokuba yimfuneko ukuqinisekisa ukuthotyelwa kwezivumelwano zorhwebo zamazwe ngamazwe.

Ukukhetha uMboneleli weNkonzo yokuBumba iSitofu esiLungelo esiPhantsi

Iqabane elithembekileyo nelinobuchule liya kuba negalelo kwimpumelelo yemizamo yakho yokuvelisa umthamo ophantsi.

- Ubungcali kunye namava:Khangela umboneleli wenkonzo oyingcali ekubumbeni inaliti yevolumu ephantsi, onolwazi kunye namava okuphatha iiprojekthi zesikali esifanayo kunye nobunzima. Umnikezeli onerekhodi eqinisekisiweyo unokunika ulwazi oluxabisekileyo, iinkqubo ezisebenzayo, kunye neziphumo eziphezulu.

- Ubunakho bokwenza ngokwezifiso: Vavanya ukukwazi komnikezeli ukunika izisombululo ezilungelelanisiweyo ezihambelana neemfuno zeprojekthi yakho. Jonga ukuguquguquka kwabo ukulungiselela ukuguqulwa koyilo, ukhetho lwezinto eziphathekayo, kunye nomthamo wemveliso ukuqinisekisa indlela elungiselelwe.

- Ukuqinisekisa umgangatho:Qinisekisa ukuba umboneleli-nkonzo uneenkqubo zokuqinisekisa umgangatho owomeleleyo. Ukuqinisekisa ukuthembeka kunye nokuhambelana kwamacandelo, sithobela imigangatho yoshishino kunye neziqinisekiso (ezifana ne-ISO 9001) kwaye siqhuba uhlolo olucokisekileyo kunye novavanyo.

- Umthamo wemveliso kunye nokukala:Vavanya amandla omboneleli wenkonzo kunye nokwandiswa ukuhlangabezana neemfuno zakho zokwenziwa komthamo ophantsi. Kufuneka bakwazi ukuphatha umthamo wakho wemveliso owunqwenelayo, nokuba uncinci okanye uphakathi, kwaye unyuse ukuba kuyimfuneko.

- Itekhnoloji kunye nezixhobo:Vavanya amandla obuchwepheshe bomboneleli kunye nezixhobo zanamhlanje abazisebenzisayo. Oomatshini bokubumba obuphezulu benaliti kunye netekhnoloji iphucula ukusebenza kakuhle kwenkqubo, ukungaguquguquki kwenxalenye, kunye nemijikelo ekhawulezayo yemveliso.

- Ubuchwephesha bezinto eziphathekayo:Qwalasela ubuchule bomboneleli-nkonzo ekusebenzeni ngoluhlu olubanzi lwemathiriyeli elungele ukubumba inaliti yomthamo ophantsi. Bamele bazi iirasi ezahlukeneyo kunye neempawu zabo kwaye babe nakho ukucebisa izinto eziphathekayo ezihlangabezana neemfuno zakho zeprojekthi.

- Iinkonzo ezongeziweyo ngexabiso:Vavanya iinkonzo ezongezelelweyo ezibonelelwa ngumboneleli, ezifana nokulungiswa kwangemva, ukuhlanganisa, kunye nokugqiba. Iinkonzo ezongeziweyo zexabiso ziyakwazi ukulungelelanisa inkqubo yakho yokuvelisa, ukunciphisa ubunzima bezinto eziphathekayo, kunye nokubonelela ngesisombululo esibanzi ukusuka ekuqaleni ukuya ekupheleni.

- Ulawulo lwekhonkco lonikezo:Vavanya amandla olawulo lwesixokelelwano sobonelelo, kubandakanywa imathiriyeli yokukhangela kunye namacandelo. Ikhonkco lonikezelo elilawulwa kakuhle liqinisekisa ukufumaneka kwangethuba kwemathiriyeli, kunciphisa ukulibaziseka kwemveliso, kunye nokwandisa iindleko ezifanelekileyo.

- Inkxaso yabathengi kunye nonxibelelwano:Qwalasela inkxaso kubathengi kunye nenqanaba lonxibelelwano lomniki-nkonzo. Unxibelelwano oluchanekileyo noluphendulayo, uhlaziyo lweprojekthi rhoqo, kunye nendlela yokusebenzisana ibalulekile kwintsebenziswano eyimpumelelo.

- Ukusebenza kweendleko:Ngelixa iindleko zingafanelanga ukuba yiyo yodwa into emiselayo, ukuvavanya ubume bexabiso lomnikezeli kunye nokusebenza kakuhle kweendleko kubalulekile. Thelekisa iikowuti, uvavanye ixabiso lemali, kwaye uqinisekise ukungafihli malunga nayo nayiphi na imirhumo okanye iintlawulo ezongezelelweyo.

Imingeni eqhelekileyo kwi-Low Volume Injection Molding

Ukujongana nale mingeni ekubumbeni inaliti yomthamo ophantsi kufuna ukuqonda ngokucokisekileyo iimfuno zeprojekthi, intsebenziswano esondeleyo nababoneleli kunye namahlakani, kunye nokuphuculwa okuqhubekayo kweenkqubo.

- Iindleko zezixhobo:Ukubumba inaliti yevolumu ephantsi kudla ngokubandakanya ukuqhuba okuncinci kwemveliso, okwenza iindleko zokuxhobisa kwangaphambili zibe ngumngeni omkhulu. Ukuyila kunye nokuvelisa i-molds ingaba phezulu ngokulinganayo kwinxalenye yemveliso ephezulu, efuna uhlalutyo olucokisekileyo lweendleko kunye nokulungiswa.

- Ubunzima boyilo:Ukwenziwa komthamo ophantsi kunokubandakanya uyilo oluntsonkothileyo noluntsonkothileyo. Umceli mngeni uxhomekeke ekuqinisekiseni ukuba indlela yokwenziwa kwesitofu inokwenzeka kwaye umngundo unokuvelisa ngokuchanekileyo ijometri efunwayo. Uhlengahlengiso loyilo kunye nophindaphindo kunokuba yimfuneko ukufikelela kwiziphumo ezizezona zilungileyo.

- Ukukhethwa kwezinto:Ukukhetha imathiriyeli efanelekileyo yokubumba inaliti yevolumu ephantsi kunokuba ngumngeni. Kufuneka siqwalasele ixabiso, ukusebenza, ukuqina, kunye nokufumaneka. Ukufumana ibhalansi phakathi kwezinto eziphathekayo kunye neemfuno zeprojekthi kubalulekile ukufezekisa umgangatho ofunekayo kunye nokusebenza.

- Ukuhambelana komgangatho wenxalenye:Ukugcina umgangatho wenxalenye engaguqukiyo kuyo yonke imveliso yevolumu ephantsi kunokuba ngumngeni. Ukwahluka kwiiparamitha zenkqubo, ukunxiba kokungunda, kunye neempawu zemathiriyeli zinokuchaphazela imilinganiselo yenxalenye, ukugqiba komphezulu, kunye neempawu zoomatshini. Amanyathelo olawulo lomgangatho ongqongqo kunye nokubekwa kweliso okuqhubekayo kuyafuneka ukuze kuncitshiswe iiyantlukwano.

- Amaxesha okukhokela:Ukubumba inaliti yevolumu ephantsi kudla ngokufuna amaxesha amafutshane okukhokela kunemveliso yomthamo ophezulu. Ukucwangcisa okusebenzayo kunye nolungelelwaniso lubalulekile ekwandiseni iishedyuli zemveliso, ukunciphisa ixesha lokuphumla, kunye nokuqinisekisa ukuhanjiswa kwangethuba kwamalungu. Unxibelelwano olusebenzayo nababoneleli kunye namaqabane lubalulekile ukuhlangabezana namaxesha anzima.

- Izithintelo zokwaleka:Iinkqubo zokubumba inaliti yevolumu ephantsi zinokuba nemida xa kufikwa kwi-scalability. Ukutshintsha ukusuka kwivolumu ephantsi ukuya kwimveliso ephezulu kunokufuna izixhobo, izixhobo kunye nohlengahlengiso lwenkqubo. Ukulindela imiceli mngeni yokulinganisa kunye nokucwangciswa kweemfuno zemveliso yexesha elizayo kubalulekile.

- Iindleko ngenxalenye:Iindleko ngenxalenye ekubunjweni kwenaliti yevolumu ephantsi ithande ukuba phezulu xa kuthelekiswa nokuveliswa kwevolumu ephezulu kuba sisasaza iindleko zezixhobo kwiziqwenga ezincinci. Ukulungelelaniswa kweendleko ngelixa ugcina imigangatho yomgangatho kunye nokuhlangabezana neemfuno zeprojekthi kubalulekile.

- Umngcipheko wokuphelelwa lixesha:Umthamo ophantsi wemveliso uqhuba rhoqo ukujongana neemarike ze-niche okanye iintlobo ezahlukeneyo zemveliso. Umngcipheko wokuba amalungu aphelelwe lixesha okanye afune ukuguquguquka angabangela imingeni. Uhlalutyo olucokisekileyo lwemarike, uqikelelo lwemfuno, kunye nezicwangciso zolawulo lwe-inventri ziyimfuneko ukunciphisa umngcipheko wokuphelelwa lixesha.

Ikamva lokuBumba kweSitofu soMqulu ophantsi

Ikamva lokubunjwa kwenaliti yomthamo ophantsi liqaqambile, kunye namathuba amatsha avela kwinkqubela phambili ye-automation, imveliso eyongezelelweyo, izixhobo ezizinzileyo kunye neenkqubo, ukwenziwa ngokwezifiso, kunye nedijithali. Abavelisi abamkela le mikhwa kwaye batyala imali kubuchwepheshe obutsha kunye neenkqubo baya kuba kwindawo efanelekileyo yokuphumelela kwimarike eguqukayo ngokukhawuleza.

- Ukuzenzekela kunye noShishino 4.0:Ukubumba inaliti yevolumu ephantsi ikulungele ukuxhamla kwi-automation kunye ne-Industry 4.0 iteknoloji efana nerobhothi, ubukrelekrele bokwenziwa, kunye ne-IoT. Ukuzenzekela kunokunceda ukunciphisa amaxesha okukhokela, ukuphucula ukungaguquguquki komgangatho, kunye nokwandisa imveliso ngelixa unciphisa iindleko zabasebenzi.

- Uveliso oloNgezelelweyo kunye neeNkqubo zeHybrid: Ukuphucula ngakumbi amandla okuvelisa umthamo ophantsi, ukuveliswa okongeziweyo kunye neenkqubo ezixubileyo, ezinjengokudibanisa ukuprintwa kwe-3D kunye nokubumba inaliti, kunokuqeshwa. Ezi teknoloji zinokwenza iprototyping ekhawulezayo, inkululeko enkulu yoyilo, kunye nokuphuculwa komgangatho wenxalenye.

- Izinto eziZinzo kunye neeNkqubo:Uzinzo lujoliso olukhulayo kwimisebenzi yokuvelisa. Ikamva lokubumba inaliti yomthamo ophantsi lilele ekwamkeleni izinto ezizinzileyo kunye neenkqubo. Izinto eziguquguqukayo kunye nezixhobo ezivuselelekayo zinokunciphisa impembelelo yokusingqongileyo, ngelixa iindlela zokulungisa i-eco-friendly zinokunciphisa inkunkuma kunye nokusetyenziswa kwamandla.

- ULungiselelo kunye noKwakho:Imfuno yabathengi yokwenziwa ngokwezifiso kunye nobuntu buqhuba inguqulelo kwinaliti ephantsi yokubumba. Isoftware ephucukileyo kunye netekhnoloji ye-automation inokwenza uhlengahlengiso oluninzi kunye neendleko ezincinci zesixhobo, ukuvula amathuba amatsha kwiimarike ze-niche.

- Ukwenziwa kweDijithali kunye noQhagamshelwano:Ukwenziwa kwedijithali kunye noqhagamshelo likamva lokubumba inaliti yomthamo ophantsi. Abavelisi banokwandisa imveliso, baphucule umgangatho, kwaye baphucule ukucaca kwekhonkco lokubonelela ngokunyusa uhlalutyo lwedatha kunye namaqonga asekwe kwilifu. Ezi teknoloji zinokuvumela ukubeka iliso kude kunye nokugcinwa kwangaphambili.

isiphelo

Ukubumba inaliti yevolumu ephantsi kunika iingenelo ezibalulekileyo kwimiba emincinci yemveliso. Itekhnoloji yoshicilelo ye-3D yenza iprototyping ekhawulezileyo, izixhobo ezineendleko ezisebenzayo, kunye nokuguquguquka koyilo. Ivumela amashishini ukuba anciphise amaxesha okukhokela, akhethe kuluhlu olubanzi lwezixhobo, ukunciphisa inkunkuma, kunye nokunciphisa umngcipheko. Ngokwamkela ezi zibonelelo, amashishini amancinci anokwandisa iinkqubo zawo zokuvelisa, ahlangabezane neemfuno zabathengi, kwaye agcine umda wokhuphiswano kwimarike. Ukubumba inaliti yevolumu ephantsi kubonelela ngesisombululo esisebenzayo, esinexabiso eliphantsi esixhobisa imveliso encinci ukubaleka ukuphumelela kumhlaba wokuvelisa wanamhlanje.