Uphuhliso olutsha kwi-Plasstiki yokuBonda isitofu

Ukubumba inaliti yeplastiki njengendlela yokuvelisa sele ikhona amashumi eminyaka. Nangona kunjalo, iindlela ezintsha zokubumba inaliti ziqhubela le ndlela phambili, izisa izibonelelo ezintsha nezingazange zibonwe ngaphambili kwiinkampani ezikhethayo.

Fumana ukuba zeziphi iindlela zokubumba iinaliti ezintsha zeminyaka ezayo kunye nendlela inkampani yakho enokuxhamla ngayo ngokuyisebenzisa.

Kuvele njani ukubumba inaliti yeplastiki?

Ngelixa iiplastiki bezikho ukusukela ngeminyaka yoo-1850, akuzange kube ngowe-1870 apho kwaveliswa iintlobo eziguquguqukayo zeeplastiki. Ngenxa yoko, iinkqubo zokubumba iinaliti zaphuhliswa. Ukusukela ngoko, inani lenkqubela phambili liye latyhala amathuba okubumba inaliti yeplastiki ngakumbi:

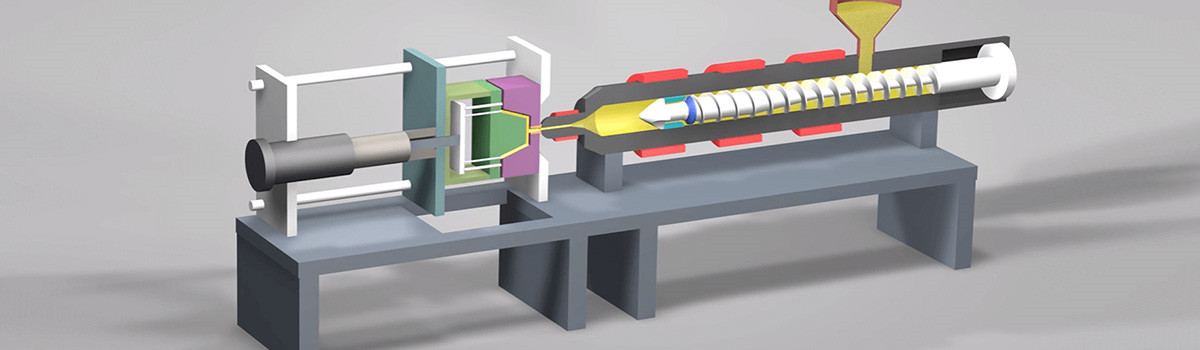

Ukuveliswa koomatshini bokubumba inaliti yesikrufu kuthetha ukuba isantya sokutofa sasilawulwa ngokulula ukuze imveliso yokugqibela ibonise umgangatho ophezulu. Le nkqubo ikwavumela ukusetyenziswa kwezinto ezixubeneyo, ukuvula umnyango wokuba kusetyenziswe iiplastiki ezinemibala kunye nezakhiwe ngokutsha.

Oomatshini be-screw abancediswa ngerhasi nabo baye benza ukuba kuveliswe iimveliso ezintsonkothileyo, ezibhetyebhetye nezinamandla. Le ndlela ikwathetha ukuba iindleko zoqoqosho ziye zahla, njengoko ixesha lemveliso, inkcitho, kunye nobunzima bemveliso zonke zincitshisiwe.

Ukungunda okuntsokothileyo kukho ngoku enkosi kwimveliso encediswa yikhompyuter, abayili ngoku banokuvelisa iimilo ezintsonkothileyo (zinokuba namacandelo amaninzi okanye zibe neenkcukacha ngakumbi kwaye zichaneke).

Ukubumba inaliti yokuncedisa igesi

Kolu hlobo lwesitofu sokubumba, isitofu seplastiki esinyibilikisiweyo esiqhelekileyo sincediswa kukutofa kwerhasi enoxinzelelo kumngundo - initrogen iqhele ukusetyenziswa kule nkqubo. Irhasi ivelisa iqamza elityhala iplastiki ukuya ekupheleni kokungunda; ngoko, njengoko iqamza lisanda, amacandelo ahlukeneyo ayazaliswa. Kukho iindlela ezininzi zokubumba ezisetyenziswa kwishishini leplastiki elahlulwe ngendawo apho irhasi itofwayo xa iphosa ipolymer.

Ngokukodwa ngakumbi, irhasi inokutofwa ngombhobho kumatshini, okanye ngokuthe ngqo kumgodi wokungunda phantsi koxinzelelo olungagungqiyo okanye umthamo. Ezinye zezi ndlela zikhuselwe ngamalungelo awodwa abenzi; ke ngoko, izivumelwano ezifanelekileyo zeelayisenisi kufuneka kungenwe kuzo ukuze zisetyenziswe.

Ukubunjwa kwesitofu sogwebu

Obu buchule bubonelela ngendlela esebenzayo, efikelelekayo yokufezekisa ukuchasana okuphezulu kunye nokuqina kwiindawo zesakhiwo. Ukongeza kolu ncedo, iinxalenye ze-foam zesakhiwo zinokwahlulwa okuphezulu kwe-thermal, ukuxhathisa okukhulu kweekhemikhali, kunye neempawu eziphuculweyo zombane kunye ne-acoustic. La malungu abandakanya i-foam core phakathi kweeleya ezimbini; le ngundoqo ifunyenwe ngokunyibilikisa igesi ye-inert kwi-resin kwaye ivumele ukuba yandise xa ijova isisombululo se-gas-plastiki kwi-cavity ye-mold. Singazifumana phi iinxalenye ezenziwe ngokubumba inaliti yogwebu? Le nkqubo isetyenziswe kwiipaneli zezithuthi njengenye indlela yokunciphisa ubunzima benxalenye.

Thin-wall Isitofu Molding

Ubutsha obuphambili bezobuchwepheshe kule meko buhambelana nesiphumo sokugqibela: icandelo elineendonga ezincinci kakhulu.

Ubunzima obukhulu bale nkqubo kukuthatha isigqibo malunga nokuba ububanzi bodonga kufuneka buthathwe ngokuba "ludonga oluncinci". Njengomgaqo jikelele, xa iinxalenye zecandelo ezinobubanzi obungaphantsi kwesiqingatha semilimitha (1/50 ye-intshi) zenziwe, zithathwa njengeendonga ezincinci.

Iinzuzo ezinxulumene nokucuthwa kobubanzi bodonga zixatyiswa kakhulu kwaye ziyafunwa kule mihla.

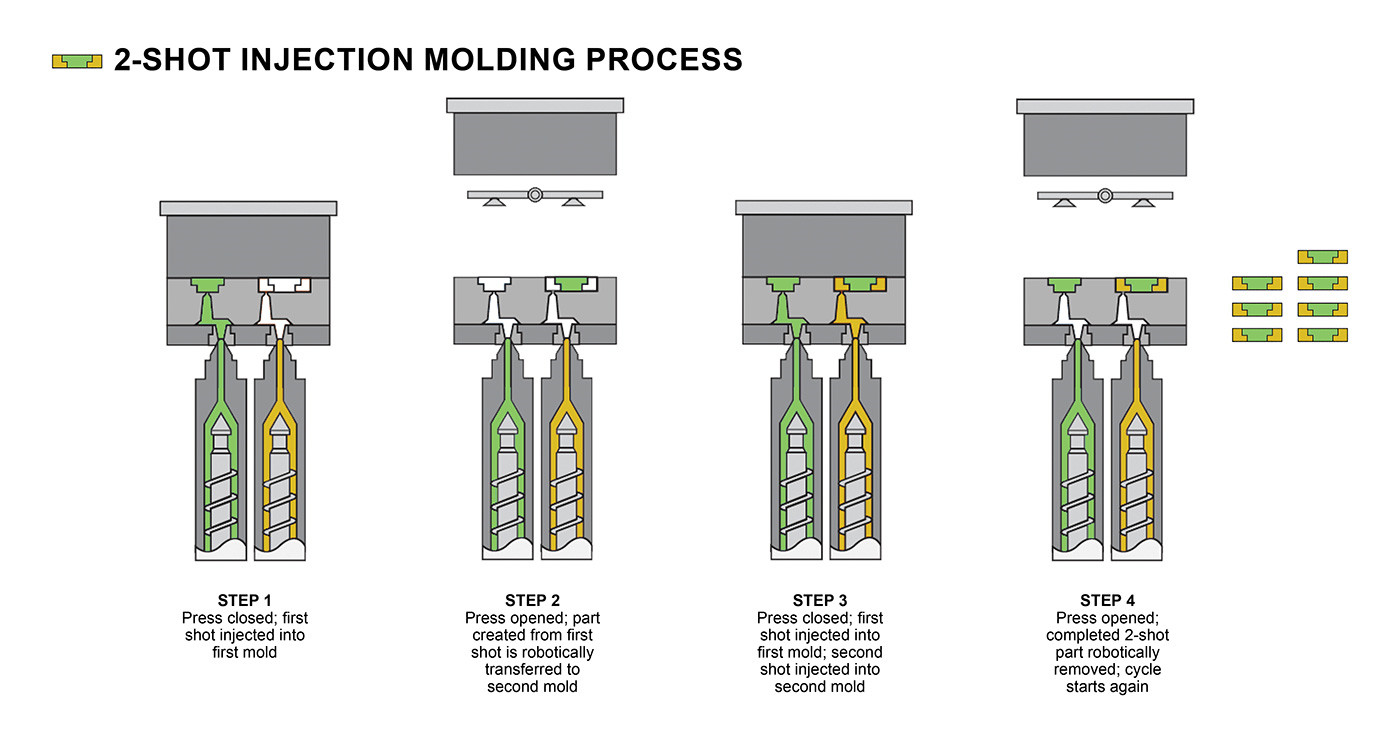

Multi Component Isitofu Molding

Ikwabizwa ngokuba sisitofu ngokugqithisileyo okanye i-injection engaphezulu, kuba le projekthi ibandakanya ukugqithisa i-polymer eqinile okanye ethambileyo phezu kwesiseko semathiriyeli (i-substrate), eyiplastiki okanye icandelo lesinyithi.

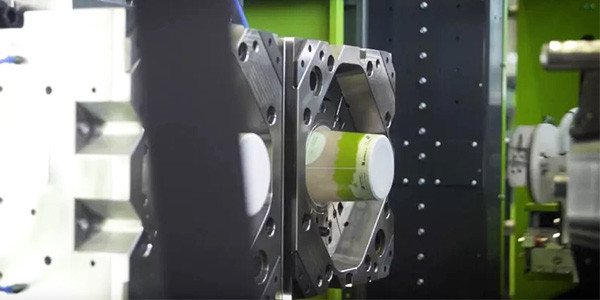

Ngokubanzi, le teknoloji inokuchazwa njengenaliti yecandelo elingaphezulu kwesinye okanye izinto eziphathekayo ngaphakathi kokubumba okufanayo kunye nenxalenye yenkqubo enye, evumela ukudibanisa kwezinto ezimbini, ezintathu okanye ngaphezulu ezinemibala eyahlukeneyo, ukuthungwa kunye nemilo.

Ziziphi iingenelo zokubumba inaliti yezinto ezininzi?

Ukubumba inaliti yezinto ezininzi kunceda ukuveliswa kweendawo ezintsonkothileyo ezinokuthi zenziwe ngeentlobo ezahlukeneyo zeeplastiki. Inzuzo ephambili yale nkqubo yokutofa kweplastiki kukuba iinxalenye ezinomatshini ophezulu, ukuchasana nokushisa kunye neekhemikhali kunokufumaneka.

Iindlela zokubumba inaliti yeplastiki kunyaka ozayo

Isitofu seplastiki sokubumba ukuzinza

Umzi-mveliso wokubumba inaliti yeplastiki ngokukhawuleza ulungelelanisa amaxabiso amatsha okuzinza kunye nemimiselo, ngakumbi ngexesha apho ishishini leplastiki lisanda kubekwa iliso kwaye lilawulwa. Ke ngoko, iindlela ezintsha zokubumba inaliti zikhomba:

Ukusetyenziswa kwe-100% yezixhobo zeplastiki ezinokuphinda zisetyenziswe kwakhona zikhuselekile kwaye zingathathi hlangothi kokusingqongileyo.

Ukujonga ezinye iindlela zokunciphisa i-carbon footprint ngexesha lokuvelisa. Oku kunokubandakanya ukusebenzisa imithombo yamandla ehlaziyekayo kunye nokusebenza ekunciphiseni ilahleko yamandla ngexesha leenkqubo zokuvelisa

Kwangaxeshanye, iinkampani kufuneka ziqinisekise ukuba utshintsho oluya kwiimodeli ezizinzileyo alubeki esichengeni kumgangatho wemveliso, kubandakanywa neempawu zoomatshini nezobume bemveliso.

Ukunyuka kwemfuno yezinto ezilula

Izinto ezikhaphukhaphu zihlala ziguqulela kwiindleko ezingaphantsi kwezoqoqosho (ezifana nezo zibandakanyeka kuthutho), kunye neendleko zamandla ezincinci (umzekelo, kwiindawo zemoto). Izinto ezikhaphukhaphu kwizixhobo zonyango zinokuphucula iziphumo zezigulane.

Isitofu seplastiki sokubumba izisombululo zesiko

Ukukhangela iindlela ezingabizi kakhulu zokubumba inaliti yeplastiki kuye kwakhokelela ekubekeni phambili izisombululo zesiko, njengoko iinkampani ezininzi ziqaphela ukunyuka kwazo kwe-ROI xa iinxalenye zabo zobugcisa zenziwe ukuba zilungele iimfuno zabo ezithile.

I-automation yokubumba inaliti yeplastiki kunye nobuchwepheshe obutsha

Iinketho ezahlukeneyo zesoftware ezenzekelayo, kunye nokwaziswa kwe-AI, ukuFunda koomatshini, kunye nohlalutyo oluphambili, zityhala amathuba okubumba inaliti yeplastiki ngakumbi.

Ezi teknoloji zivumela ukunciphisa ixesha lokunciphisa kunye nokungasebenzi kakuhle kwisixhobo, ukuphuhlisa iinkqubo zokulondoloza kwangaphambili, kunye nemijikelezo ekhawulezayo yemveliso. Kwangaxeshanye, isoftware entsha ivumela iinkampani ukuba zilingise imijikelo yokubumba inaliti ngexesha lenkqubo yoyilo, uvavanyo lwemiba efana neepateni zokuzalisa ezingaqhelekanga. Oku kuguqulela ekulungiseni imiba ngaphambi kokudlulela kwinkqubo yokuvelisa, ngaloo ndlela konga ixesha nemali.