Isitofo sePlastiki yokuBumba

Ukubumba inaliti yesiko ifanelekile kwiindawo zeplastiki apho impumelelo ixhomekeke ekuphumezeni izinto ezithile zoomatshini okanye zobuhle. I-DJmolding yokubumba inaliti yeplastiki iqhutywa yinjongo esisiseko yokunceda abathengi bavelise ezona nxalenye zeplastiki zibalaseleyo. Akukho mntu wasemzini kubunzima, imiceli mngeni yoyilo iwuthintele ngokwenene umnqweno wethu wokukwenzela izinto ezintsha. Ukusibandakanya kwangethuba kusenza songeze ixabiso kwinkqubo yoyilo.

Iinzuzo zokuBumba isitofu sePlastiki

Iimpawu ezinenkcukacha

Qwalasela iinkcukacha zobuhle okanye umsebenzi wokuphucula ibhrendi yakho: umbhalo oshicilelweyo, izinto zokuthambisa okanye umphezulu owenziweyo, ukuhombisa okukwimold, ukufakwa kwesnap, iihenjisi ezibhetyebhetye, ubunzima obahlukeneyo.

UkuPhumelela okuPhezulu

Ukusebenza kakuhle kokubumba inaliti yeplastiki akuhambelani. Thina injineli iindleko ezingeyomfuneko ngaphandle kwenxalenye yakho kunye nesixhobo. Iinjineli zethu zoyilo ekudala zihleli kunye nababumbi abanobuchule bayagqwesa koku.

Ukuphuculwa kweNtsebenzo

Sisebenza nzima ukuqonda umsebenzi ocetywayo wenxalenye yakho kwaye sifezekise iinjongo zakho eziphambili ngokusebenzisa isayensi yezinto, imigaqo yoyilo, izixhobo zohlalutyo, kunye nolawulo lwenkqubo.

Izinto Ezahlukeneyo

Khetha kwizinto ezingaphezu kwama-200, imveliso kunye neereyini zobunjineli. Siza kukunceda ulungelelanise ukusebenza kunye nexabiso kwaye uchonge ezinye izinto ezilinganayo ukunciphisa iindleko.

Inkqubo yokubumba isitofu

Ukubumba inaliti yeplastiki yenye yezona ndlela zindala zokwenza iiplastiki kunye nenyathelo elibalulekileyo kuphuhliso lwamalungu abavelisi bemveliso. Kwakhona sisisombululo esikhulu kubavelisi abafuna ukuguqula iintsimbi ezinzima zibe zeplastiki. Icaciswe ngeyona ndlela ilula, inkqubo isebenzisa iipolymers okanye iiresin zeplastiki ezithi xa zishushu, zinyibilike kwaye zitofwe phantsi koxinzelelo oluphezulu kwimold yesiko, ziya kuvelisa iinxalenye zeplastiki eziza kusetyenziswa ekwenzeni imveliso.

Ngelixa loo nkqubo ibonakala ngathi ithe ngqo, inokuntsonkotha kakhulu kwaye ifuna inqanaba eliphezulu lamava avela kwiqabane elingumyili wenaliti elinokujongana neemfuno zakho zoshishino ezizodwa, iinkcukacha, ukusetyenziswa kokuphela kunye nexesha / imiqobo yohlahlo lwabiwo-mali. Indawo efanelekileyo yokuqalisa kukufumana ulwazi olusisiseko lwenkqubo yokubumba iplastiki kunye noyilo lwezona ndlela zilungileyo.

Ukubumba kwezeNzululwazi

Indlela yokubumba yesayensi inceda ukuveliswa kwamalungu abalulekileyo afuna ukusebenza okuthe ngqo kunye nokuchaneka okuphezulu. Itekhnoloji yethu yokubumba ephucukileyo iqinisekisa ukuphinda-phinda kunye nokungaguquguquki. Oko kuthetha ukuba imveliso esikwenzela yona namhlanje, yimveliso esikwenzela yona ngomso.

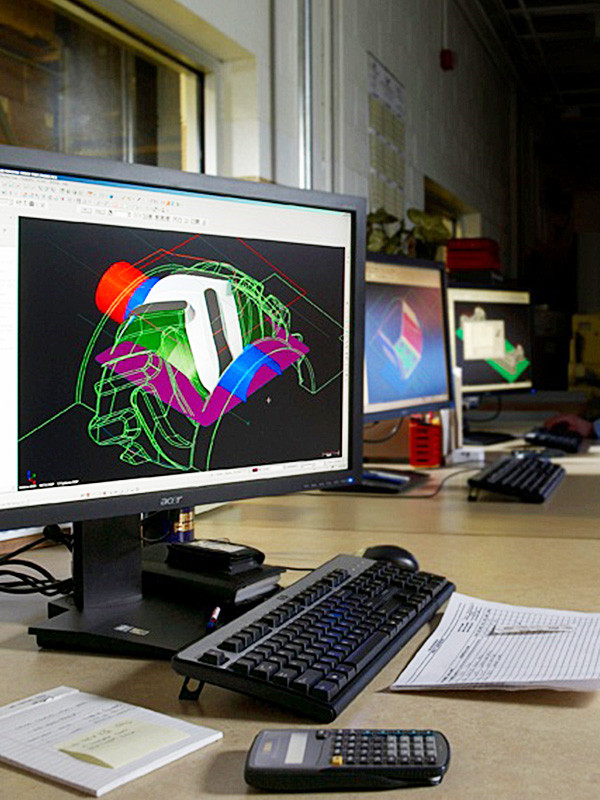

Ukubumba inaliti yenzululwazi iqala ngexesha lophuhliso lwezixhobo. Izinto ezinje ngoxinzelelo, ubushushu, ixesha lokuzalisa i-cavity ziyalungiswa ukuze uyilo lokubumba lunciphise amathuba okuguquguquka. Uhlalutyo lokuhamba kwe-mold lubonisa iindawo zokugqibela zecandelo lokuzalisa, indlela izinto eziza kuhamba ngayo kunye ne-mold, kwaye iveze i-warp enokubakho kunye namanqaku oxinzelelo. Linyathelo elisebenzayo elibonelela ngohlalutyo loqikelelo lobunjineli kunye nomlinganiselo kwaye livumela ukumiselwa lula kwempumelelo okanye ukungaphumeleli kwenxalenye okanye iprojekthi.

Iinkqubo zemveliso ezomeleleyo zikwasebenzisa indlela yenzululwazi ngokubeka iliso kunye nolawulo lwenkqubo oluzenzekelayo olucutha izinto ezilahliweyo kunye nexesha lokucubungula. Ukuba kukho utshintsho okanye ukungasebenzi kakuhle, ichongiwe ngokukhawuleza kwaye ibekwe yodwa phambi kokuba amalungu angahambelaniyo enziwe.

Ukugcwala

Izinto ezimbini (okanye ngaphezulu) zinokudibaniswa zibe yinxalenye enye kunye ne-overmolding. Le nkqubo isoloko isetyenziselwa indawo ebambekayo eyahlukileyo, njengendawo yokubamba ethambileyo. Ukugqithisa kunokuba yiplastiki phezu kwe-substrate yeplastiki okanye irabha phezu kwe-substrate yeplastiki, ngokuqhelekileyo kufezekiswa yinkqubo yokubumba inaliti ezimbini. Ukuqulunqwa kwe-resin kunye nemibala inokwahluka. Iinzuzo zobuhle bokugqithisa kulula ukuzibona, kodwa ziphinda zisuse imisebenzi yesibini. I-Overmolding ifanelekile kwizixhobo ezinezandla, izinto ezibanjwe ngesandla, iirobhothi apho i-rubber grips iyadingeka, okanye ukunyusa ukubonakala kwenxalenye enemibala eyahlukileyo.

Faka Ukubumba

Faka ukubumba kuyafana nokungunda ngokugqithisileyo kodwa kubandakanya into ebekwe ngaphakathi kumgodi wokungunda. Faka iibhondi zokubumba zeplastiki kwizinto ezifakelwayo, ngokuqhelekileyo isinyithi okanye iplastiki. Ufakelo olunemisonto luxhaphakile. Oku kuphelisa umsebenzi xa isetyenziswa njengenye into yokuqhobosha, izinto zokuncamathelisa, okanye ukubambisa ubushushu. Ukufakwa kwakhona komeleza inxalenye. Ukufakwa kulayishwa ngesandla okanye ngerobhothi ezenzekelayo.

Inxalenye yokuHombisa kunye nokuFakwa kweeLebhile

Ukuhonjiswa kwe-in-mold (IMD) kunye ne-in-mold labeling (IML) isetyenziselwa ukudala inkangeleko ephawulekayo ebonakalayo kunye nemizobo okanye iilebhile. Iququzelelwa yi-robotics kunye ne-electrostatic okanye i-vacuum grip, ifilimu eprintiweyo yokwalekayo yongezwa kwi-mold cavity ngaphambi kokutofwa kwe-resin yeplastiki etyhidiweyo. Le nkqubo idala ibhondi esisigxina phakathi kweleyibhile kunye nenxalenye egqityiweyo, ngokuqhelekileyo isusa nayiphi na imfuneko yokusebenza emva kokulungiswa. Uluhlu olubanzi lokuthungwa, umbala, kunye nokhetho lokugquma umphezulu lushiya ucango luvulekile kumathuba okudala. Siyakukhuthaza ukuba uthethe nomphathi weprojekthi yakho malunga nezinto onokukhetha kuzo zokuphucula ibhrendi yakho.

Inkonzo yokuBumba yesitofu yePlastiki yaseTshayina

DJmolding Operating ukususela 2010 | I-AFAQ ISO/TS 16949, UL kunye nezatifikethi ze-ISO, ingakumbi ibonelela kwiiNkampani ezininzi zoShicilelo ze-3D Ehlabathini Ngoku.

E-Djmolding sisebenza ngokukhethekileyo ekuveliseni iindawo ezibunjiweyo zeplastiki ezinomgangatho ophezulu kunye nezixhobo zokungunda. Ubukhulu becala sibonelela ngokwenza inaliti yeplastiki kwiinkampani ezininzi zoshicilelo lwe-3D ehlabathini. Sinemishini ye-55 yerobhothi kunye ne-automatic plastic injection-injection.Sinikezela zonke iinkonzo zokucoca kunye nokugqiba ukwenza izixhobo ezivela kwizinto ezahlukeneyo, kwaye unokuvelisa i-100 ukuya kwi-200k + iinxalenye ezigqityiweyo kuzo zonke iiplastiki ezinkulu. Eyona nto isahlulayo kukuqinisekiswa kwezinto eziphambili, ukuhlolwa kunye nokuvavanya ukuqinisekisa ukuba iinxalenye zakho ziyahlangabezana kwaye zigqithise oko ukulindeleyo. Qhagamshelana neengcali zethu zokubumba iinaliti zamazwe ngamazwe ukuze ufumane isicatshulwa sasimahla namhlanje.

DJmolding Plastic Injection Molding Process

Nje ukuba izixhobo zakho zokubumba inaliti yeplastiki sele zilungile, inkqubo yokubumba inala manyathelo alandelayo asisiseko:

Inyathelo 1. I-resin yeplastiki ifika kwiipellets ezikrwada. Ezi zomiswa kumxholo wokufuma ofanelekileyo, kwaye ke ukuba kuyimfuneko zinokudityaniswa nee-pigments okanye ii-master batch colorants.

Isinyathelo 2. Iipelisi ezomileyo zigalelwa kwi-hopper yomatshini wokubumba. Isikrufu esibuyiselanayo ngaphakathi kumbhobho womatshini siya kuthutha ezi pellet zisingise kumngundo.

Isinyathelo sesi-3. Ngaphakathi kwe-barrel, iipelisi zixutywe kwaye zifudumeze de zinyibilike ngokupheleleyo, zenze i-resin ye-liquid.

Inyathelo 4. Isikhunta esivuthayo sivala ngokuzenzekelayo kwaye i-resin, phantsi koxinzelelo olukhulu, ifakwe ngesango kunye ne-mold cavity.

Inyathelo 5. Isikhunta sipholile ukuqinisa inxalenye ngaphakathi.

Inyathelo 6. Ukubumba kuyavula kwaye inxalenye ikhutshiwe ukuqalisa umjikelo omtsha.

Ukunyamezelwa kokuBumba kwesitofu sePlastiki

Zonke izinto zeplastiki ziya kwanda kunye nenkontileka phantsi kwefuthe lobushushu kunye nokufuma. Isikhokelo sethu sonyamezelo siya kunika ulwazi ngokubanzi ngokubanzi kwiimpawu zezona ntlobo zixhaphakileyo zeresin kwiimpawu zenxalenye eqhelekileyo.

Siza kusebenza ngokusondeleyo nawe ukukhulisa uyilo lwakho lokuvelisa. Siya kubonisa naziphi na iindawo apho uyilo olulambathayo lunokuvelisa uxinzelelo lwe-thermal, ukucutheka, ukugoba, njl.

Ngaphandle kokuba kucaciswe ngenye indlela, sithobela i-DIN 16742 yokunyamezelana okusemgangathweni kwizitofu zeplastiki. Funda ngemigangatho yomgangatho wokubonwayo esiyisebenzisayo kumalungu abunjiweyo.

Izixhobo zokuBumba isitofu sePlastiki

I-Djmolding yenza izixhobo zokubumba inaliti kwaye ifa kwi-Aluminiyam 7075, i-P20 kunye ne-NAK80 i-semi-hardened steels kunye ne-H13 eqinile ngokupheleleyo. Ukongezelela, sinikezela ngokugqitywa kwe-SPI esemgangathweni, i-EDM yokubhaliweyo kunye noluhlu lwezinto eziqingqiweyo.

Nganye kwezi ntlobo zezinto eziphathekayo ziya kuba neenzuzo ezikhethekileyo kwizicelo ezithile. *Iingqwalasela ziquka:

*Ixabiso lemathiriyeli ekrwada

*Ukomelela kunye nokuxhathisa umhlwa okanye ukukrala

*Ubuchule

*Ukukwazi ukuthatha ipolishi ephezulu

*Ixesha elifunekayo kunyango lobushushu

*Ubomi besixhobo obulindelekileyo

Qhagamshelana neengcali zethu zobugcisa ukufunda ngakumbi malunga nokuba yeyiphi ekulungeleyo.

Iinxalenye zePlastiki ezitofwayo

Kukho amawaka eeplastiki ze-thermoforming kunye ne-thermosetting ongakhetha kuzo kwiprojekthi yakho. Ukongeza, iimpawu zoomatshini kunye neekhemikhali zinokuthi ziphuculwe ngezongezo ezifana neentsinga zeglasi, izizinzi ze-UV kunye nezithambiso. Iphepha lethu lezinto eziphathekayo liya kukunika ulwazi oluthe kratya malunga neentlobo ezisemgangathweni kunye nokunyamezela okulindelekileyo ngakunye.

Ukukhetha kwakho i-resin kunokuxhomekeka kwingcinga enye okanye ngaphezulu kwezi zilandelayo:

*I-UV, iikhemikhali, ukukrazuka kunye nokuxhathisa impembelelo

*Ixabiso lemathiriyeli ekrwada

*Amandla oomatshini

*Ubunzima kunye nobuninzi

*Ukuba bhetyebhetye

*Ukwenziwa elubala

*Ukuphinda kusetyenziswe

Qhagamshelana nenye yeengcali zethu zobugcisa ukufunda ngakumbi malunga neempawu zezinto eziphathekayo.

DJmolding ivenkile yokutofa:

Umngundo okhokelayo wenaliti yeplastiki kunye nomenzi wenkonzo yeprototyping ekhawulezayo

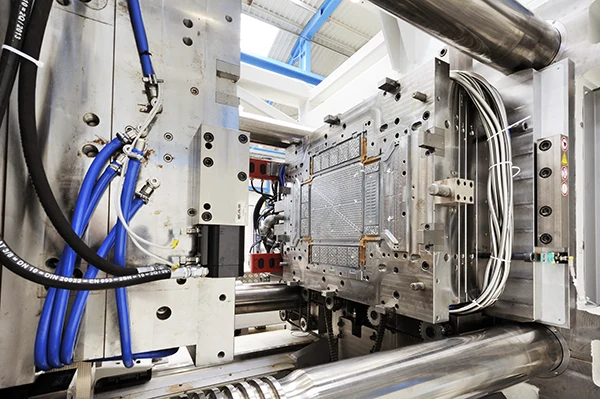

I-Djmolding yenye yeenkampani zokubumba iinaliti zeplastiki ezaziwa ngakumbi eTshayina. Ivenkile yethu yokubumba inaliti ixhotyiswe ngeeseti ezingama-50 zoomatshini bokubumba benaliti abachanekileyo, ukusukela kwiitoni ezingama-30 ukuya kwiitoni ezingama-800, ubukhulu becala basuka eTaiwan naseJapan, ivenkile yethu yokutofa iqhuba iiyure ezingama-24 ngosuku, iintsuku ezisi-7 ngeveki, kwaye ibonelela ngemveliso. iinkonzo.

Sinamava ngeemveliso zeplastiki ezahlukeneyo kumashishini amaninzi, kubandakanywa: iimoto, unyango, izibane, izixhobo zemidlalo, izixhobo zasekhaya, kunye nezolimo. I-Djmolding iphumelele i-AFAQ ISO/TS 16949, UL kunye ne-ISO 9001 Certifications ukususela ngo-2010, Sikwanayo nabantu abali-15 be-IPQC abahlala bebukele imveliso yethu kwaye bajonge umgangatho wenxalenye, oku kuqinisekisa ukuba imveliso yethu igcina umgangatho ophezulu womgangatho. Kwiminyaka eyi-9 edlulileyo, i-Djmolding iseke igama eliqinileyo lokuvelisa isixhobo somgangatho ophezulu kunye nenxalenye ngexabiso elifanelekileyo.Sigcina ubudlelwane obuqinileyo beshishini kunye ne-appx. Abathengi abangama-50, ngakumbi abavela e-USA naseYurophu.

Isitofo sePlastiki yokuBumba

Isiko lokubumba inaliti yeplastiki yindlela entsha nesebenzayo yokuvelisa iinxalenye zeplastiki ezikumgangatho ophezulu. Le nkqubo yokuvelisa isebenzisa ukubumba ukubumba izinto zeplastiki kwiimilo ezintsonkothileyo kunye nobukhulu, iyenza ibe sisisombululo esifanelekileyo kumashishini ahlukeneyo. Esi sithuba sebhlog siya kuntywila nzulu kwisiko lokubumba inaliti yeplastiki kwaye iphonononge izibonelelo zayo, usetyenziso, kunye nezona zinto zilungileyo.

Ukuqonda inkqubo yokubumba isitofu yesiko

Ukubumba inaliti yesiko yinkqubo yokuvelisa esetyenziselwa ukuvelisa iinxalenye zeplastiki kwimiqulu emikhulu. Kubandakanya ukunyibilikisa iipeliti zeplastiki okanye iigranules kunye nokuzifaka kwi-mold phantsi koxinzelelo oluphezulu, apho zipholisa kwaye ziqiniswe ukwenza imo efunekayo. Nantsi indlela esebenza ngayo inkqubo yokubumba inaliti:

- Ukubamba: Iziqingatha ezibini zomngundo, ezibizwa ngokuba “sisixhobo,” zibotshelelwe kunye ngamandla awoneleyo ukuze zimelane noxinzelelo lwenaliti.

- I-injection: Iipelisi zeplastiki ziyancibilika kwi-barrel evuthayo kwaye zifakwe kwi-mold ngokusebenzisa inkqubo yokugijima phantsi koxinzelelo oluphezulu. Iplastiki igcwalisa umngxuma wokungunda kwaye ithatha ubume bomngundo.

- Ukupholisa: Iplastiki inokupholisa kwaye yomelele ngaphakathi kwesikhunta ukugcina imilo efunekayo.

- Ukukhutshwa: Umngundo uvula emva kokuba iplastiki ipholile kwaye inxalenye egqityiweyo ikhutshiwe.

- Phinda: Inkqubo iphinda iphindwe ukwenza iindawo ezininzi ezifanayo.

Isitofu sokubumba sivelisa iimveliso zeplastiki, ukusuka kwizinto ezincinci ukuya kwizinto ezinkulu ezifana nezixhobo zemoto kunye nezixhobo zasekhaya. Inkqubo isebenza kakuhle kakhulu kwaye inokuvelisa iinxalenye ezinejiyometri ezintsonkothileyo kunye nokunyamezelana okuqinileyo, kwaye ichanekile, kunye nenkunkuma encinci kunye namazinga asezantsi okulahlwa.

Inkqubo idinga izixhobo ezikhethekileyo, kubandakanywa i-mold, i-injection yomshini wokubumba, kunye nenkqubo yokulawula ukuqinisekisa iziphumo ezichanekileyo nezihambelanayo. Isikhunta ngokuqhelekileyo senziwe ngentsimbi kwaye sinokuyilwa ukuvelisa iindawo ezininzi zisebenzisa i-multi-cavity molding.

Isitofu sokubumba sinokusetyenziswa ngezinto ezahlukeneyo, kubandakanya i-thermoplastics, i-thermosets, kunye ne-elastomers. Isixhobo ngasinye sineempawu ezizodwa kwaye zinokuthi zilungelelaniswe kwizicelo ezithile.

Lilonke, ukubumba inaliti yinkqubo yokwenza izinto ezininzi ezahlukeneyo kwaye esebenzayo esetyenziswa kumashishini amaninzi.

Izinto ezilungileyo zokubumba inaliti yeplastiki yesiko

Isiko lokubumba inaliti yeplastiki yinkqubo yokuvelisa esetyenziselwa ukwenza iinxalenye zeplastiki zesiko kwimiqulu emikhulu. Nazi ezinye iingenelo zale nkqubo:

Ukusebenza okuphezulu kunye nemveliso: Isiko lokubumba inaliti yeplastiki yinkqubo esebenza kakuhle kakhulu enokuvelisa umthamo omkhulu wamalungu afanayo ngokukhawuleza nangokungaguquguqukiyo. Oku kwenza kube lukhetho olufanelekileyo kwimveliso yobuninzi yamalungu eplastiki.

Ukuhluka: Inkqubo inokusetyenziselwa uluhlu olubanzi lwezinto zeplastiki, kuquka i-thermoplastics, i-thermosets, kunye ne-elastomers. Oku kuvumela iintlobo ezininzi ezahlukeneyo zoyilo kunye nokusetyenziswa.

Ukungqinelana kunye nokuchaneka: Ukubunjwa kwe-injection kunika iziphumo ezihambelanayo nezichanekileyo, kunye nokunyamezela okuqinileyo kunye nokuhluka okuncinci phakathi kwamalungu. Oku kuqinisekisa ukuba isiqwenga ngasinye siyafana nesilandelayo, esiyimfuneko kwizicelo ezininzi.

Indleko-esebenzayo: Isiko lokubumba inaliti yeplastiki inokuba yindleko-esebenzayo kwimiba yemveliso ephezulu. Iindleko zokuqala zezixhobo zingaba phezulu, kodwa ixabiso ngenxalenye liyancipha njengoko umthamo unyuka.

Ukutsala nzima: Ukubumba isitofu kunokuvelisa iinxalenye ezinemilo entsonkothileyo kunye neejometri, kubandakanywa neendonga ezibhityileyo kunye neempawu ezintsonkothileyo. Oku kuvumela ukuguquguquka okukhulu koyilo kwaye kwenza ukuveliswa kwezinto ezinokuba nzima okanye akunakwenzeka ukuvelisa usebenzisa ezinye iindlela.

Inkunkuma encinci: Ukubumba isitofu kuvelisa inkunkuma encinci xa kuthelekiswa nezinye iinkqubo zokwenza, njengoko nayiphi na iplastiki engaphezulu inokuphinda isetyenziswe kwaye isetyenziswe kwakhona.

Ekupheleni kokuphela: Ukubunjwa kwe-injection kunokuvelisa iinxalenye ezinomgangatho ophezulu wokugqiba umgangatho ngaphandle kwemisebenzi eyongezelelweyo emva kokulungiswa okanye ukugqiba. Oku kuyenza ibe sisisombululo esinexabiso eliphantsi lokudala iziqwenga ezinomda ogudileyo kunye nopolishiweyo.

Ukuzenzekelayo: Ukubumba i-injection kungenziwa ngokulula, kunye neerobhothi ezilayishwayo kunye nokukhupha iindawo ezivela kwi-mold kunye nokuhlola kunye nokuhlelwa kwezinto. Oku kunciphisa imfuno yomsebenzi wezandla kwaye kwandisa ukusebenza kakuhle.

Isiko lokubumba inaliti yeplastiki yinkqubo yokwenza izinto ezininzi ezahlukeneyo kwaye isebenzayo ebonelela ngeenzuzo ezininzi kunezinye iindlela. Ukukwazi ukuvelisa ngokukhawuleza nangokuchanekileyo izixa ezikhulu zamalungu afanayo kwenza ukuba ilungele amashishini amaninzi, kubandakanya iimoto, i-aerospace, unyango kunye nempahla yabathengi.

Ukusetyenziswa kwenaliti yokubumba

Isitofu sokubumba yinkqubo yokuvelisa esetyenziswa ngokubanzi ukwenza iimveliso zeplastiki zamashishini ezahlukeneyo. Nazi ezinye zezona zicelo eziqhelekileyo zokubumba inaliti:

- Umzi-mveliso weemoto: Isitofu sokubumba sivelisa iindawo ezahlukahlukeneyo zemoto, kuquka ingaphakathi nangaphandle, iinxalenye zedeshibhodi, izibambo zocango, kunye neenxalenye zenjini. Ikhethwa ngenxa yokuba inokuba neempawu ezinamandla aphezulu kunye nokuchaneka kwe-dimensional.

- Impahla yabathengi: Isitofu sokubumba sidala iimveliso ezahlukeneyo zabathengi, kubandakanya izinto zokudlala, izixhobo zasekhaya kunye nezixhobo zombane. Ivumela ukuvelisa iimilo ezintsonkothileyo kunye neejometri kunye nomgangatho ophezulu wokugqitywa komphezulu.

- Izixhobo zonyango: I-injection molding isetyenziselwa ukuvelisa izixhobo zonyango ezahlukeneyo, kubandakanywa iisirinji, amacandelo e-IV, kunye nezixhobo zokuxilonga. Ibonelela ngokuchaneka okuphezulu, ukuveliswa okucocekileyo, kunye nokukwazi ukuvelisa iindawo ezinejometri ezintsonkothileyo, eziyimfuneko kwishishini lezonyango.

- Umzi-mveliso wokupakisha: Isitofu sokubumba sivelisa izinto zokupakisha, kuquka iibhotile, iingqayi, kunye neziciko. Ivumela ukwenza izikhongozeli ezikhaphukhaphu nezihlala ixesha elide kunye nokwenza ngokwezifiso imibala, ukuthungwa, kunye neemilo.

- Umzi-mveliso we-aerospace: I-injection molding isetyenziselwa ukuvelisa amacandelo ahlukeneyo amacandelo e-aerospace, kubandakanywa izinto zesakhiwo kunye nezixhobo zangaphakathi. Ivumela ukudala izinto eziphezulu zokusebenza ezinokumelana nokushisa okukhulu kunye noxinzelelo.

- Umzi-mveliso wokwakha: Isitofu sokubumba sivelisa izinto ezahlukeneyo zokwakha, kuquka imibhobho yePVC, iinkqubo zegutter, kunye nezinto zokufulela. Inika ukuqina okuphezulu, ukumelana nemozulu kunye neekhemikhali, kunye nokukwazi ukuvelisa iinxalenye kwimiqulu emikhulu.

- Ishishini le-Electronics: Isitofu sokubumba sivelisa izinto ezahlukeneyo ze-elektroniki, kuquka izindlu, izihlanganisi, kunye nokutshintsha. Inika ukuchaneka okuphezulu, ukufana, kunye nokukwazi ukuvelisa iindawo ezinejometri ezintsonkothileyo, eziyimfuneko kwishishini le-elektroniki.

Lilonke, ukubumba inaliti yinkqubo yokwenza izinto ezininzi ezinokuvelisa iindawo ezininzi zeplastiki kumashishini amaninzi. Ukukwazi ukuvelisa iinxalenye ezinejiyometri ezintsonkothileyo, ukuchaneka okuphezulu, kunye nomgangatho ongaguqukiyo kwenza ukuba ibe lukhetho oludumileyo kubenzi abaninzi.

Iindidi zezinto ezisetyenziselwa ukubumba inaliti

Isitofu sokubumba yinkqubo yokuvelisa ebandakanya ukutofa iplastiki enyibilikisiweyo kwindawo yokungunda ukwenza imo ethile. Izinto ezahlukeneyo zingasetyenziselwa ukubumba inaliti, kuxhomekeke kwiipropati ezifunwayo zemveliso yokugqibela. Nazi ezinye zezona ntlobo zixhaphakileyo zemathiriyeli ezisetyenziswa ekubumbeni inaliti:

- I-Thermoplastics: Ezi zezona zixhobo zisetyenziswa kakhulu ekubumbeni inaliti. Ziluhlobo lweplastiki ethi ithambile kwaye ibumbeke xa ishushu kwaye iqine xa ipholile. I-Thermoplastics inokubunjwa kwaye ihlaziywe ngamaxesha amaninzi ngaphandle kokulahlekelwa iipropati zabo. Ii-thermoplastics eziqhelekileyo ezisetyenziselwa ukubumba inaliti ziquka i-polypropylene, i-polyethylene, i-polystyrene, kunye neyiloni.

- Thermosets: Ezi iiplastiki ezinokubunjwa kube kanye kuphela. Ziyafudunyezwa kwaye ziphuhliswe kwimilo ethile, kwaye emva kokuba ziqiniswe, azikwazi ukuphinda zibunjwe. I-Thermosets isetyenziselwa izicelo apho amandla aphezulu kunye nokuqina kuyadingeka. Ii-thermosets eziqhelekileyo ezisetyenziselwa ukubumba inaliti ziquka i-epoxy, i-melamine, kunye ne-phenolic resins.

- Elastomers: Ezi zixhobo zineempawu ezinwebekayo kwaye zinokuzolula zibuyele kubume bazo bokuqala. Ii-elastomers zisetyenziselwa izicelo apho ukuguquguquka kunye nokufunxa ukothuka kuyadingeka. Ii-elastomers eziqhelekileyo ezisetyenziselwa ukubumba inaliti ziquka irabha, i-silicone, kunye ne-polyurethane.

- Izinto eziguquguqukayo ze-Biodegradable: Ezi zinokuqhekeka ngokwendalo kwindawo ngaphandle kokushiya iintsalela ezinobungozi. Zisetyenziselwa izicelo apho uzinzo lwendalo luyinkxalabo. Izinto eziqhelekileyo ezinokuboliswa kwe-biodegradable ezisetyenziswa ekubumbeni inaliti ziquka i-polylactic acid (PLA) kunye ne-polyhydroxyalkanoates (PHAs).

- I-Composites zizinto ezenziwe ngokudibanisa izinto ezimbini okanye ngaphezulu ezahlukeneyo ukwenza izinto ezintsha kunye neempawu ezithile. Ii-Composites zisetyenziselwa izicelo apho amandla aphezulu kunye nokuqina kuyadingeka. Iikhompositi ezisemgangathweni ezisetyenziselwa ukubumba inaliti ziquka iiplastiki zeglasi zefiber-reinforced (GRP) kunye ne-carbon fiber-reinforced plastics (CFRP).

- Iiplastiki ezizaliswe ngeentsimbi ziyiplastiki ezifakwe ngamasuntswana esinyithi ukwenza izinto ezinombane ophezulu kunye ne-thermal conductivity kunye nezinye iimpawu ezithile. Iiplastiki ezizaliswe ngesinyithi zisetyenziselwa izicelo ezinombane ofunekayo okanye ukuhanjiswa kwe-thermal. Iiplastiki eziqhelekileyo ezizaliswe ngesinyithi ezisetyenziselwa ukubumba i-injection ziquka iiplastiki ezizaliswe lubhedu kunye neeplastiki ze-nickel.

Lilonke, ukhetho lwemathiriyeli yokubumba inaliti ixhomekeke kwiimfuno ezithile zemveliso yokugqibela, kubandakanya amandla, ukuguquguquka, ukuqhuba, kunye nokuqina. Abavelisi bahlala bekhetha izinto ezisekelwe kwindleko, ukufumaneka, ukukhululeka kokulungiswa, kunye neempawu ezifunekayo kwimveliso yokugqibela.

Izinto ekufuneka ziqwalaselwe xa ukhetha imathiriyeli yokubumba inaliti

Ukukhetha imathiriyeli efanelekileyo kubalulekile xa kufikwa kwisitofu sokubumba, njengoko kunokuchaphazela iipropati kunye nokusebenza kwemveliso yokugqibela. Nazi ezinye zezinto ekufuneka uziqwalasele xa ukhetha imathiriyeli yokubumba inaliti:

- Iimpawu zoomatshini: Enye yezona zinto zibalulekileyo ekufuneka ziqwalaselwe xa ukhetha imathiriyeli ziimpawu zayo zomatshini. Oku kuquka ukomelela kwayo, ukuqina, ukuqina, kunye nokumelana nokuguga nokukrazuka. Iimpawu zomatshini ezifunekayo kwimveliso yokugqibela ziya kuxhomekeka kwisicelo kunye noxinzelelo apho imveliso iya kuvezwa khona.

- Iimpawu ze-Thermal: Iimpawu ze-thermal ze-material nazo zibalulekile, ngakumbi ukuba imveliso yokugqibela iya kuboniswa kumaqondo obushushu aphezulu okanye i-thermal cycling. Oku kubandakanya indawo yokunyibilika kwesixhobo, i-thermal conductivity, kunye ne-coefficient yokwandiswa kwe-thermal.

- Ukumelana neekhemikhali: Ukuba imveliso yokugqibela ibonakaliswe kwimichiza, ukukhetha into enokumelana nokuthotywa kweekhemikhali kubalulekile. Izinto eziphathekayo kufuneka zimelane nokuvezwa kwe-acids, iziseko, i-solvents, kunye nezinye iikhemikhali ngaphandle kokuphula okanye ukulahlekelwa iimpawu zayo.

- Imiba yokusingqongileyo: Imiba yokusingqongileyo, efana nokufuma kunye nokuvezwa kwe-UV, inokuchaphazela iipropati kunye nokusebenza kwempahla. Kubalulekile ukuqwalasela iimeko zokusingqongileyo zemveliso yokugqibela kwaye ukhethe imathiriyeli enokumelana nazo.

- Iindleko: Ixabiso lezinto eziphathekayo likwayingqwalasela ebalulekileyo, ngokukodwa kwimiba yemveliso ephezulu. Ixabiso lezinto eziphathekayo kufuneka lilinganiswe malunga nokusebenza kwayo kunye neempawu zokuqinisekisa ukuba lukhetho olungabizi kakhulu kwimveliso yokugqibela.

- Iimfuno zokucubungula: Iimfuno zokucubungula izinto eziphathekayo zinokuchaphazela inkqubo yokhetho. Ezinye izixhobo zinokufuna izixhobo ezithile zokusetyenzwa okanye ubuchule, kwaye ezinye zinokuba nzima ngakumbi ukuqhubekeka. Iimfuno zokucubungula kufuneka ziqwalaselwe ukuqinisekisa ukuba izinto eziphathekayo zingasetyenziswa ngempumelelo kwinkqubo yokubumba inaliti.

- Ukuthotyelwa kwemigaqo: Okokugqibela, kubalulekile ukuqwalasela naziphi na iimfuneko zolawulo ekufuneka imveliso yokugqibela ihlangabezane nazo. Amanye amashishini, njengemizi-mveliso yezonyango neyokutya, anemigaqo engqalileyo yezinto ezisetyenziswa kwiimveliso zawo. Ukukhetha imathiriyeli ehlangabezana nezi mfuno zolawulo kubalulekile ukuqinisekisa ukuba imveliso yokugqibela ikhuselekile kwaye iyathotyelwa.

Ngokubanzi, ukukhetha imathiriyeli efanelekileyo yokubumba inaliti kufuna ukuba kuqwalaselwe ngononophelo izinto ezahlukeneyo, kubandakanya iipropathi zoomatshini kunye ne-thermal, ukumelana neekhemikhali, iimeko zokusingqongileyo, iindleko, iimfuno zokusetyenzwa, kunye nokuthotyelwa komgaqo. Abavelisi kufuneka balinganise le miba omnye komnye ukuze bakhethe imathiriyeli eyona ifanele imveliso yokugqibela.

Ukubaluleka koyilo lokungunda ekubumbeni inaliti

Uyilo lokungunda luyinkalo ebalulekileyo yenkqubo yokubumba inaliti. Uyilo lokubumba lunokuchaphazela umgangatho wemveliso yokugqibela, kunye nokusebenza kakuhle kunye nokuphumelela kweendleko zenkqubo yokuvelisa. Nazi ezinye zezizathu zokuba uyilo lokungunda lubalulekile ekubumbeni inaliti:

- Umgangatho wemveliso: Uyilo lokungunda lunokuchaphazela umgangatho wemveliso yokugqibela. Ukuba ukungunda akwenziwanga ngokufanelekileyo, kunokubangela iziphene ezifana ne-warping, i-sink marks, kunye ne-flash. Ezi ziphene zingenza imveliso yokugqibela ingasebenziseki, inciphise ukusebenza, kwaye inyuse amazinga e-scrap kunye neendleko zokuvelisa.

- Ukusebenza kakuhle kwemveliso: Uyilo lokubumba lunokuchaphazela ukusebenza kakuhle kwenkqubo yokuvelisa. Ukuba isikhunta ayenzelwanga ukuhamba kakuhle kunye nokupholisa, kunokubangela amaxesha omjikelo omde, ukwanda kokusetyenziswa kwamandla, kunye nokunciphisa umthamo. Uyilo lokungunda oluphuculweyo lunokuphucula ukusebenza kakuhle kunye nokunciphisa iindleko zemveliso.

- Ukusebenza kweendleko: Uyilo lokungunda lunokuchaphazela indleko-ukusebenza kwenkqubo yokubumba inaliti. Umngundo owenziwe kakuhle unokunciphisa inkunkuma yezinto eziphathekayo, uphucule umgangatho wenxalenye, kunye nokwandisa umthamo, ukunciphisa iindleko zemveliso. Ukongezelela, i-mold eyenzelwe ukuveliswa kwevolumu ephezulu inokunciphisa iindleko ngenxalenye kwaye yandise imbuyekezo kutyalo-mali.

- Ukwenza ngokwezifiso: Uyilo lokungunda ludlala indima ebalulekileyo ekwenzeni imveliso yokugqibela. Ngokuyila ukungunda kwiimilo ezithile kunye neempawu, abavelisi banokudala iimveliso ezilungiselelwe iimfuno zabathengi babo. Oku kuvumela ukuguquguquka okukhulu kunye nokwahlula kwiimarike, okukhokelela ekwanelisekeni kwabathengi kunye nokunyaniseka.

- Ukukhetha izinto eziphathekayo: Uyilo lokubumba lunokuchaphazela ukhetho lwezinto ezisetyenziselwa ukubumba inaliti. Indlela yokubumba inokuchaphazela ukuhamba kwezinto kunye nokupholisa, okunokuchaphazela i-mechanical and thermal properties of the final product. Ngokukhetha uyilo lokubumba olufanelekileyo, abavelisi banokwandisa ukhetho lwempahla kwaye baqinisekise ukuba imveliso yokugqibela ihlangabezana neemfuno zokusebenza ezinqwenelekayo.

Ngokubanzi, uyilo lokungunda luyinto ebalulekileyo kwinkqubo yokubumba inaliti. Umngundo owenziwe kakuhle unokuphucula umgangatho wemveliso, ukusebenza kakuhle kwemveliso, ukuphumelela kweendleko, ukulungelelanisa, kunye nokukhethwa kwezinto eziphathekayo. Abavelisi kufuneka batyale ixesha kunye nezibonelelo ekuyileni ukubumba okulungiselelwe iimfuno zabo ezithile ukuphumeza ezona ziphumo zibalaseleyo kwinkqubo yokubumba inaliti.

Iindidi ezahlukeneyo zokubumba ezisetyenziselwa ukubumba inaliti

Isitofu sokubumba yinkqubo yokwenza izinto ezininzi ezinokuvelisa iimveliso ezahlukeneyo zeplastiki. Enye into ebalulekileyo emisela umgangatho kunye nokusebenza kakuhle kwenaliti yokubumba luhlobo lokubumba olusetyenzisiweyo. Nazi ezinye zeentlobo ezahlukeneyo zokubumba ezisetyenziselwa ukubumba inaliti:

- Ukubumba iipleyiti ezimbini: Ukubumba kweepleyiti ezimbini zezona ziqhelekileyo zisetyenziselwa ukubumba inaliti. Ziquka amacwecwe amabini ahlulwe ngumngxuma wokungunda. Izinto zeplastiki zifakwe kwi-cavity, zidibanisa amacwecwe amabini ukwenza imveliso yokugqibela.

- Ukubumba kwamacwecwe amathathu: Iimbumba zeepleyiti ezintathu zifana nezibunjwa zeplati ezimbini kodwa zinepleyiti eyongezelelweyo eyahlula inkqubo yembaleki ukusuka kwindawo ebunjiweyo. Oku kuvumela ukukhutshwa okulula kwenxalenye kwaye kunokunciphisa ixesha lokujikeleza.

- Isikhunta somgijimi oshushu: Iimboli zembaleki ezishushu zisetyenziselwa ukuveliswa komthamo ophezulu, njengoko zinokunciphisa ixesha lokujikeleza kunye nenkunkuma yezinto eziphathekayo. Umngundo uqulethe inkqubo yembaleki efudumeleyo ehambisa iplastiki etyhidiweyo ngokuthe ngqo kumngxuma wokungunda, isusa imfuneko yembaleki ebandayo.

- Umngundo wembaleki ebandayo: Imingundo yembaleki ebandayo lolona hlobo lusisiseko lokungunda kwaye lubandakanya i-sprue, iimbaleki, kunye nomngxuma wokungunda. Iplastiki etyhidiweyo igalelwa kwi-sprue, ethi ifake iplastiki kwiimbaleki kwaye emva koko ingene kumgodi wokungunda.

- Ukungunda kwintsapho: Iimbumba zentsapho zivelisa iindawo ezininzi kumjikelo omnye. Umngundo unemingxuma emininzi, nganye inenxalenye eyahlukileyo. Iimbumba zentsapho zihlala zisetyenziselwa izinto ezincinci, ezinomthamo ophezulu.

- I-stack mold: I-stack mold ivelisa iileya ezininzi zeplastiki kumjikelo omnye. Umngundo unemiqolo emininzi, ebekwe phezu komnye. Iplastiki itofwa emingxunyeni, ize iileya zidityaniswe ndawonye zenze imveliso enye, enemaleko amaninzi.

- Faka i-mold: Faka ii-molds zisetyenziselwa ukufaka isinyithi okanye amacandelo eplastiki kwindawo ebunjiweyo ngexesha lokubumba. Isifakelo sifakwa kumgodi wokungunda phambi kokuba iplastiki itofwe, ize iplastiki ijikeleze loo nto ifakiweyo.

Ngokubanzi, uhlobo lokubumba olusetyenziswa ekubumbeni inaliti luxhomekeke kwiimfuno ezithile zemveliso eveliswayo. Ngokukhetha uhlobo oluchanekileyo lokungunda, abavelisi banokwandisa ukusebenza kakuhle kwenkqubo yokubumba inaliti, umgangatho, kunye nokusebenza kakuhle kweendleko.

Eyona ndlela ilungileyo yokubumba inaliti

Ukubunjwa kwe-injection yinkqubo yokuvelisa eyinkimbinkimbi efuna ukucwangciswa ngokucophelela kunye nokuphunyezwa ukufezekisa iziphumo ezifunwayo. Nazi ezinye zeendlela ezilungileyo zokubumba inaliti ezinokunceda ukuqinisekisa umgangatho ophakamileyo, ukusebenza kakuhle, kunye neendleko-zokusebenza:

- Uyilo lokwenziwa kwemveliso: Uyilo lwemveliso kufuneka lulungiselelwe ukubumba inaliti. Oku kubandakanya ukunciphisa inani lamalungu, ukuqinisekisa ubukhulu bodonga obufanayo, kunye nokuphepha ii-undercuts kunye nezinye iimpawu ezenza nzima ukubumba.

- Ukukhethwa kwezinto eziphathekayo: Izinto ezisetyenziselwa ukubunjwa kwenaliti kufuneka zikhethwe ngokusekelwe kwiimfuno zemveliso. Izinto ezinjengeepropathi zomatshini, iipropathi ze-thermal, kunye nokumelana nokusingqongileyo kufuneka kuthathelwe ingqalelo.

- Uyilo lokungunda: Uyilo lokungunda kufuneka lulungiselelwe imveliso ethile. Oku kubandakanya ukuqinisekiswa kokupholisa okufanelekileyo, ukukhupha umoya, kunye nokungena, kunye nokukhetha uhlobo olufanelekileyo lokungunda.

- Iiparamitha ze-injection: Iiparamitha ze-injection, ezifana noxinzelelo lwe-injection, ubushushu, kunye nesantya, kufuneka zilawulwe ngononophelo kwaye zibekwe esweni ukuze kuqinisekiswe umgangatho ophezulu kunye nokuhambelana.

- Ukugcinwa: Umatshini wokubumba umjovo oqhelekileyo kunye nokugcinwa kwesikhunta kubalulekile ekuqinisekiseni ukusebenza kakuhle kunye nokuthintela ixesha lokuphumla.

- Ulawulo lomgangatho: Ukulawulwa komgangatho kufuneka kuphunyezwe kuyo yonke inkqubo yokubumba inaliti, ukusuka ekuhlolweni kwezinto ezingenayo ukuya ekuhlolweni kokugqibela kwemveliso. Oku kuquka iziphene esweni ezifana warpage, amanqaku isinki, kunye flash.

- Ukulungiswa kwenkqubo: Ukuphuculwa kwenkqubo eqhubekayo kufuneka ibe yingqwalasela ephambili yemisebenzi yokubumba inaliti. Oku kubandakanya iimethrikhi zenkqubo yokubeka iliso njengexesha lokujikeleza, izinga le-scrap, kunye nokusetyenziswa komatshini kunye nokwenza uhlengahlengiso njengoko kuyimfuneko ukuze kuphuculwe ukusebenza kakuhle kunye nomgangatho.

Ngokubanzi, ukubunjwa kwesitofu kufuna ingqalelo enononophelo kwiinkcukacha kunye nokugxila ekuphuculeni okuqhubekayo. Ngokulandela ezona ndlela zilungileyo zokubumba inaliti, abavelisi banokuqinisekisa umgangatho ophezulu, ukusebenza kakuhle, kunye neendleko ezifanelekileyo kwaye bavelise iimveliso zeplastiki ezikumgangatho ophezulu ezihlangabezana neemfuno zabathengi babo.

Amanyathelo okulawula umgangatho wokubumba inaliti

Ulawulo lomgangatho lubalulekile ekubumbeni inaliti, njengoko iqinisekisa ukuba imveliso yokugqibela ihlangabezana neenkcukacha ezifunekayo kunye nemigangatho. Nanga amanye amanyathelo okulawula umgangatho wokubumba inaliti:

- Ukuhlolwa kwezinto ezingenayo: Inkqubo yokulawula umgangatho kufuneka iqale ngokuphononongwa kwezinto ezisetyenziselwa ukubumba inaliti. Oku kubandakanya ukuqinisekisa ukuba imathiriyeli luhlobo oluchanekileyo, ibakala, kunye nombala kwaye ihlangabezana nemilinganiselo efunekayo yomatshini kunye neempawu ze-thermal.

- Ukuhlolwa kwenkqubo: Ngexesha lokubumba inaliti, abasebenzi bokulawula umgangatho kufuneka bahlole rhoqo imveliso ukuqinisekisa ukuba ibunjwe ngokuchanekileyo. Oku kubandakanya ukubeka esweni iziphene ezifana namanqaku e-sink, warping, kunye ne-flash kunye nokuqinisekisa ukuba imveliso iyahlangabezana nokunyamezela okufunekayo.

- Ukuhlolwa kwemveliso yokugqibela: Emva kokuba inkqubo yokubumba isitofu igqityiwe, imveliso yokugqibela kufuneka ihlolwe ukuqinisekisa ukuba iyahlangabezana neenkcukacha ezifunekayo kunye nemigangatho. Oku kubandakanya ukuqinisekisa ukuba imveliso ayinaziphene, ezinje ngeentanda, amaqamza, kunye ne-voids kwaye iyahlangabezana nokunyamezela okufunekayo.

- Ulawulo lwenkqubo yamanani: Ulawulo lwenkqubo yobalo (Statistical process control) (SPC) yindlela yokubeka iliso nokulawula inkqubo yokuqinisekisa ukuba ivelisa iziphumo zomgangatho ophezulu rhoqo. I-SPC ibandakanya ukuqokelela idatha kwiiparameters zenkqubo ebalulekileyo, njengoxinzelelo lwe-injection kunye nokushisa, kunye nokusebenzisa uhlalutyo lwamanani ukuchonga iindlela kunye neepatheni ezibonisa ukuguquguquka kwenkqubo.

- Ukuphuculwa okuqhubekayo: Ulawulo lomgangatho kufuneka lube yinkqubo eqhubekayo yokuphucula rhoqo. Oku kubandakanya ukuhlalutya idatha malunga nokusebenza kwenkqubo, ukuchonga iindawo zokuphucula, kunye nokwenza utshintsho kwinkqubo yokwandisa umgangatho kunye nokusebenza kakuhle.

- Amaxwebhu kunye nokulandeleka: Abasebenzi bolawulo lomgangatho kufuneka bagcine amaxwebhu aneenkcukacha zenkqubo yokubumba inaliti, kubandakanywa iiparamitha zenkqubo, iziphumo zokuhlolwa, kunye nezenzo zokulungisa. Olu xwebhu lubonelela ngokulandeleka kwaye lunceda ukuqinisekisa ukuba nayiphi na imiba esemgangathweni inokuchongwa kwaye ilungiswe ngokukhawuleza.

Ngokubanzi, ukulawulwa komgangatho ngumba obalulekileyo wokubumba inaliti kwaye kufuneka kudityaniswe kuzo zonke iinkalo zenkqubo yokuvelisa. Ngokuphumeza la manyathelo okulawula umgangatho, abavelisi banokuvelisa iimveliso zeplastiki eziphezulu ezihlangabezana neemfuno zabathengi babo.

Iziphene eziqhelekileyo ekubumbeni inaliti kunye nendlela yokuthintela

Isitofu sokubumba yinkqubo entsonkothileyo enokubangela iziphene ukuba ayiphunyezwanga ngokufanelekileyo. Nazi ezinye iziphene eziqhelekileyo ekubumbeni inaliti kunye nendlela yokuzikhusela:

- Amanqaku e-sink kukudandatheka okanye ukubola kumphezulu wemveliso. Zibangelwa kukupholisa okungalinganiyo okanye ukungonelanga koxinzelelo lokupakisha. Qinisekisa uyilo lokungunda lubandakanya ubukhulu bodonga obufanayo kunye nee-engile eziyidrafti ezaneleyo zokuthintela amanqaku e-sinki. Ukulungelelanisa uxinzelelo lokupakisha kunye nexesha lokupholisa kunokunceda ukuthintela amanqaku e-sink.

- I-Warpage: I-Warpage kukugqwethwa kwemveliso emva kokuba isusiwe kubumba. Kubangelwa ukupholisa okungalinganiyo okanye uxinzelelo lwangaphakathi kwimveliso. Ukuthintela i-warpage, qinisekisa uyilo lokungunda lubandakanya ubukhulu bodonga olufanayo kunye nexesha elaneleyo lokupholisa. Gwema iikona ezibukhali okanye utshintsho ngokukhawuleza kwijometri yemveliso, enokudala amanqaku oxinzelelo.

- Ifleshi: I-Flash yiplastiki egqithileyo ephumela ngaphaya kwemida yemveliso, eyenzeka ngokujikeleze imiphetho yokungunda. Ibangelwa luxinzelelo olugqithisileyo lwenaliti, amandla angonelanga okubamba, okanye ukungunda okugugileyo. Ukuthintela iflash, hlengahlengisa uxinzelelo lwenaliti kunye namandla okubamba kwaye ujonge rhoqo ukungunda ngeempawu zokuguga.

- Izithonga ezimfutshane: Izithonga ezimfutshane zenzeka xa ukungunda kugcwele iplastiki. Oku kunokubangelwa kukungonelanga koxinzelelo lwenaliti okanye ubushushu okanye umjelo ovalekileyo okanye othintelweyo. Ukuthintela ukudubula okufutshane, lungisa uxinzelelo lwenaliti kunye nobushushu, kwaye uqinisekise ukuba umjelo wokuhamba ucacile kwaye awuphazamiseki.

- Amanqaku atshileyo: Amanqaku atshileyo kukutshintsha kwemibala emnyama kumphezulu wemveliso okubangelwa kubushushu obugqithisileyo okanye ukukhuhlana okugqithisileyo ekubumbeni. Ukuthintela iimpawu zokutsha, qinisekisa ukuba umngundo upholiswe ngokwaneleyo kwaye uthanjiswe, kwaye ulungelelanise isantya sokutofa kunye noxinzelelo njengoko kuyimfuneko.

- I-Voids kunye namaqamza: I-Voids kunye namaqamza ziindawo zemveliso ezilahlekileyo okanye zineepokotho zomoya. Zibangelwa ngumoya ovalelweyo okanye igesi ekubumbeni okanye ukuhamba kwezinto ezinganeleyo. Ukuthintela i-voids kunye namaqamza, qinisekisa ukuba isikhunta siphuma ngokuchanekileyo kwaye isantya sokutofa kunye noxinzelelo lwanele ukuqinisekisa ukuhamba kwezinto ezifanayo.

Iingcebiso zogcino lwezixhobo zokubumba inaliti

Isixhobo sokubumba isitofu lutyalo-mali olubalulekileyo kubavelisi, kwaye ukugcinwa okufanelekileyo kubalulekile ukuze kuqinisekiswe ukusebenza kakuhle kunye nokuphila ixesha elide. Nanga amanye amacebiso olondolozo lwezixhobo zokubumba inaliti:

- Yenza uhlolo rhoqo: Zihlole rhoqo izixhobo ukuze uchonge nakuphi na ukuguga, umonakalo, okanye eminye imiba. Jonga imibhobho yehydraulic, itywina, kunye nezinye izinto ezibalulekileyo ukuqinisekisa ukuba zikwimeko entle.

- Coca kwaye uthambise izixhobo: Coca kwaye uthambise izixhobo rhoqo ukuthintela ukubola kunye nokuguga. Sebenzisa iimveliso ezicetyiswayo zokucoca kunye nokuthambisa, kwaye ulandele imiyalelo yomenzi.

- Beka iliso kwaye ugcine ioyile yehydraulic: Yibeke iliso rhoqo ukuze uqinisekise ukuba icocekile kwaye ikwi-viscosity echanekileyo. Tshintsha ioli njengoko kuyimfuneko, kwaye usebenzise uhlobo lweoli olucetyiswayo.

- Gcina iibhanti zesifudumezi: Zijonge rhoqo ukuqinisekisa ukuba zikwimeko entle kwaye zifudumeza ngendlela eyiyo. Faka kwakhona naziphi na iibhanti zesifudumezi ezonakeleyo okanye ezigugileyo ngoko nangoko.

- Ukubeka iliso kwaye ugcine inkqubo yokupholisa: Ibalulekile ekubumbeni inaliti, njengoko ithintela ukufudumeza kunye ne-warpage. Beka iliso kwisixokelelwano sokupholisa rhoqo ukuqinisekisa ukuba sisebenza ngokuchanekileyo, kwaye ucoce amajelo okupholisa njengoko kufuneka.

- Abaqhubi boololiwe: Ukuqeqesha abaqhubi malunga nokusebenza kwezixhobo ezifanelekileyo kunye neenkqubo zokulondoloza ukukhusela umonakalo kunye nokuqinisekisa ukusebenza kakuhle.

- Cwangcisa ulungiso oluthe gqolo: Misela ishedyuli yokulungisa uze unamathele kuyo. Cwangcisa imisebenzi yogcino lwesiqhelo, efana nokuthanjiswa nokutshintshwa kwe-oyile, kwaye ubhale yonke imisebenzi yogcino.

- Gcina izixhobo ezisecaleni zisesandleni: Zibonelele ngezinto ezisecaleni, ezinje ngamabhobho oxinzelelo lwehydraulic, izitywini kunye neebhanti zesifudumezi. Oku kuya kutshintsha ngokukhawuleza iindawo ezonakalisiweyo okanye ezigugileyo kunye nokunciphisa ixesha lokuphumla.

Ukugcinwa ngokufanelekileyo kwezixhobo zokubumba inaliti kubalulekile ukuqinisekisa ukuba zisebenza ngokufanelekileyo, zivelisa iimveliso ezikumgangatho ophezulu, kwaye ziphila ixesha elide. Ngokulandela ezi ngcebiso zokulondoloza, abavelisi banokugcina izixhobo zabo zikwimeko ephezulu kunye nokunciphisa ixesha lokunciphisa kunye neendleko zokulungisa.

Indlela yokukhetha umenzi wesitofu esifanelekileyo sokubumba

Ukukhetha umenzi wesitofu esifanelekileyo sisigqibo esibalulekileyo esinokuchaphazela kakhulu umgangatho kunye neendleko zeemveliso zakho. Nazi ezinye izinto ekufuneka uziqwalasele xa ukhetha umenzi wokubumba inaliti:

- Amava kunye nobuchule: Khangela umenzi onamava kunye nobuchule bokubumba inaliti. Buza ngeenkqubo zabo zokuvelisa, imilinganiselo yokulawula umgangatho, kunye neziqinisekiso.

- Itekhnoloji kunye nezixhobo: Khangela umenzi osebenzisa ubuchwepheshe bale mihla kunye nezixhobo. Oku kunokunceda ukuqinisekisa umgangatho ongaguqukiyo, amaxesha amafutshane okukhokela, kunye nokusebenza kakuhle kweendleko.

- Izixhobo kunye nobuchule: Qwalasela iintlobo zemathiriyeli umvelisi anokusebenza ngayo kunye nobuchule babo. Khangela umenzi onokujongana noluhlu olubanzi lwezixhobo, kubandakanywa izinto ezikhethekileyo, kwaye unokuvelisa iintlobo ezahlukeneyo zobukhulu kunye neemilo.

- Amanyathelo olawulo lomgangatho: Khangela umenzi ogxile kakhulu kulawulo lomgangatho. Buza malunga nemilinganiselo yabo yokulawula umgangatho, efana nokuhlolwa kunye neenkqubo zokuvavanya, kunye nazo naziphi na iziqinisekiso abanokuba nazo.

- Inkonzo yabathengi: Khangela umenzi obonelela ngenkonzo yomthengi ebalaseleyo. Cinga ngokuphendula, unxibelelwano, kunye nokuzimisela ukusebenza nawe ukuhlangabezana neemfuno zakho ezithile.

- Iindleko kunye nexesha lokukhokela: Qwalasela iindleko zomenzi kunye nexesha lokukhokela kwiprojekthi yakho. Jonga umenzi obonelela ngamaxabiso akhuphisanayo kunye namaxesha okukhokela afanelekileyo ahlangabezana neemfuno zakho.

- Iireferensi kunye nophononongo: Buza iimbekiselo kwaye ujonge uphononongo lwe-intanethi lomenzi. Oku kunokukunceda ufumane ingqiqo engcono yegama labo kunye namava abanye abathengi.

Unokukhetha umenzi wokubumba inaliti efanelekileyo yeprojekthi yakho ngokuqwalasela ezi zinto kwaye uqhube uphando olunzulu. Umenzi ohloniphekileyo onamava afanelekileyo, amandla, kunye nokuzinikela kumgangatho unokunceda ekuqinisekiseni ukuba iimveliso zakho ziveliswa ngokufanelekileyo, ngeendleko ezifanelekileyo, kunye neenkcukacha zakho ezichanekileyo.

IiNgqwalasela zeendleko kwisiko lokubumba inaliti yeplastiki

Isiko lokubumba inaliti yeplastiki yinkqubo yokwenza izinto ezininzi ezinokuvelisa izinto ezinzima, ezikumgangatho ophezulu kwisikali. Nangona kunjalo, ukuqwalaselwa kweendleko kungumba obalulekileyo ekusebenziseni le nkqubo yokuvelisa. Nazi ezinye zeendleko eziphambili zokubumba inaliti yeplastiki:

- Iindleko zezinto eziphathekayo: Uhlobo kunye nobuninzi bezinto ezisetyenziselwa inkqubo yokubumba i-injection iya kuchaphazela ixabiso. Ezinye izinto, ezifana neeplastiki zobunjineli ezisebenza kakhulu, zibiza kakhulu kunezinye. Iindleko zemathiriyeli zinokuchatshazelwa kukuphazamiseka kwekhonkco lokubonelela, imfuno yemarike, kunye nokunyuka kwamaxabiso.

- Iindleko zezixhobo: Iindleko zesixhobo, okanye ukubumba okusetyenziselwa ukuvelisa amalungu, yindleko ebalulekileyo ekubunjweni kwesiko leplastiki yesitofu. Ubunzima benxalenye, inani leemingxuma ekubumbeni, kunye nezinto ezisetyenziselwa ukudala ukubumba zonke ziya kuchaphazela iindleko zezixhobo. Ukusetyenziswa kwezixhobo kungabiza kakhulu ngaphambili kodwa kunokunceda ukunciphisa iindleko zeyunithi ngokuhamba kwexesha ngokunyusa ukusebenza kakuhle kwemveliso.

- Umthamo wemveliso: Umthamo wamacandelo avelisiweyo uya kuba nefuthe kwixabiso lokubumba inaliti. Ukuveliswa kwevolumu ephezulu kunokuncedisa ukunciphisa iindleko zeyunithi, ngelixa ukuveliswa kwexabiso eliphantsi kunokuba neendleko eziphezulu zeyunithi ngenxa yesidingo sezixhobo ezininzi kunye nexesha lokucwangcisa.

- Iindleko zabasebenzi: Iindleko zabasebenzi zingumba obalulekileyo wokubumba inaliti, ngakumbi kwiindawo ezinzima kakhulu ezifuna umsebenzi wezandla. Umgangatho wezakhono zabaqhubi kunye nobunzima benxalenye iya kuchaphazela iindleko zokuhanjiswa.

- Iindleko zokulawula umgangatho: Ukugcina ulawulo lomgangatho kubalulekile ukuqinisekisa ukuthembeka kwamalungu. Ixabiso lokulawula umgangatho lingabandakanya izixhobo zokuhlola, uvavanyo, kunye nomsebenzi.

- Iindleko zokuthumela ngenqanawa: Ukuthumela iinxalenye kumthengi okanye kwezinye iindawo kunokuba yindleko enkulu, ngakumbi kwiinkcukacha ezinkulu okanye ezinzima.

Abavelisi banokuvelisa iindawo ezikumgangatho ophezulu ngexabiso eliphantsi ngokuqwalasela ezi ndleko kunye nokuphucula inkqubo yokubumba inaliti. Oku kunokufezekiswa ngokunciphisa inkcitho yezinto eziphathekayo, ukwandisa ukusebenza kakuhle kwemveliso, kunye nokunciphisa ukuseta kunye namaxesha okutshintsha. Ukusebenza nomenzi wokubumba inaliti onamava kunye nolwazi kunokunceda ukwandisa inkqubo kunye nokunciphisa iindleko.

Iimpawu kunye nezinto ezintsha kwiteknoloji yokubumba inaliti

Itekhnoloji yokubumba isitofu ikhona iminyaka emininzi, kodwa kusekho izinto ezintsha ezininzi kunye neendlela ezibumba ikamva lale nkqubo yokuvelisa. Nazi ezinye zeendlela eziphambili kunye nezinto ezintsha kwitekhnoloji yokubumba inaliti:

- Ushicilelo lwe-3D kunye nokuveliswa okongeziweyo: Ushicilelo lwe-3D kunye nokuveliswa okongeziweyo kuya kuthandwa kakhulu kwishishini lokubumba inaliti. Obu buchwephesha buvumela ukudalwa kweemilo ezintsonkothileyo kunye neejometri ekunzima okanye engenakwenzeka ukuba ziphunyezwe ngokubumba isitofu sesintu.

- Ukubunjwa kwenaliti yezinto ezininzi: Ukubumba inaliti yezinto ezininzi kuvumela ukudala iinxalenye ezinezixhobo ezininzi okanye imibala kwishothi enye. Le nkqubo inokunciphisa ixesha lokuvelisa kunye neendleko kunye nokudala imisebenzi eneempawu ezizodwa kunye nokubonakala.

- I-Automation kunye ne-Industry 4.0: I-Automation kunye ne-Industry 4.0 iteknoloji, njenge-sensors ze-IoT kunye neerobhothi, ziyadityaniswa kumatshini wokubumba inaliti kunye neenkqubo. Oku kunokuphucula ukusebenza kakuhle kwemveliso, ukunciphisa iindleko zabasebenzi, nokuphucula ulawulo lomgangatho.

- Izinto ezizinzileyo kunye neenkqubo: Njengoko iinkampani zifuna ukunciphisa impembelelo yazo yendalo esingqongileyo, izinto ezizinzileyo kunye neendlela ziya zibaluleke ngakumbi kushishino lokubumba inaliti. Oku kubandakanya ukusebenzisa izinto ezinokubola okanye ezisetyenzisiweyo kunye neenkqubo ezinciphisa inkcitho kunye nokusetyenziswa kwamandla.

- Ukwenziwa ngobuchule kunye nokulungiswa kwangaphambili: Itekhnoloji yokuvelisa ngobuchule, njengokufunda koomatshini kunye nokulungiswa kwangaphambili, zisetyenziselwa ukwenza iinkqubo zokubumba inaliti kunye nokunciphisa ixesha lokuphumla. Oku kunokuphucula ukusebenza kakuhle kunye nokunciphisa iindleko zokugcina.

- Izinto zokusebenza eziphezulu: Izinto ezintsha zokusebenza okuphezulu ziphuhliswa ukubumba inaliti, kubandakanywa izinto ezinamandla aphuculweyo, ukuqina, kunye nokumelana nobushushu. Ezi zixhobo zinokusetyenziswa kwizicelo ezahlukeneyo, ukusuka kwiindawo zeemoto ukuya kwizixhobo zonyango.

Ngokuhlala usexesheni kule mikhwa kunye nezinto ezintsha, abavelisi bokubumba inaliti banokuhlala bekhuphisana kwaye baqhubeke nokubonelela ngamacandelo akumgangatho ophezulu kubathengi babo. Njengoko itekhnoloji entsha kunye nezixhobo ziphuhliswa, ishishini lokubumba inaliti liya kuqhubeka nokuvela kwaye lilungele ukuhlangabezana neemfuno eziguqukayo zabathengi kunye namashishini.

Uzinzo ekubumbeni inaliti: ukunciphisa inkcitho kunye nokusetyenziswa kwamandla

Uzinzo luya lubaluleka ngakumbi kwishishini lokubumba inaliti njengoko iinkampani zifuna ukunciphisa impembelelo yazo yokusingqongileyo kunye nokuhlangabezana nemfuno ekhulayo yeemveliso ezilungele indalo. Nazi ezinye iindlela abenzi bokubumba inaliti abanokunciphisa inkcitho kunye nokusetyenziswa kwamandla:

- Sebenzisa imathiriyeli ezinzileyo: Ukhetho lwemathiriyeli yinto ebalulekileyo ekuzinzeni. Abavelisi bokubumba be-injection banokusebenzisa izinto ezinokubola okanye ezisetyenzisiweyo ukunciphisa impembelelo yokusingqongileyo. Iiplastiki ze-Biodegradable, umzekelo, ziyakwazi ukuphuka ngokwemvelo ngokuhamba kwexesha kwaye zinciphise ubuninzi benkunkuma kwiindawo zokulahla. Izinto ezisetyenzisiweyo, ezifana neeplastiki ezisetyenziswe ngokutsha, zinokunceda ukunciphisa inkunkuma kunye nokusetyenziswa kwamandla.

- Ukunciphisa inkunkuma yezinto eziphathekayo: Abavelisi bokubumba i-injection banokunciphisa inkunkuma yezinto ngokulungisa uyilo lwenxalenye kunye nokungunda. Oku kubandakanya ukunciphisa inani lezinto ezigqithisiweyo ezisetyenzisiweyo, ukunciphisa inani leemigodi kwi-mold, kunye nokunciphisa ubunzima obupheleleyo benxalenye. Ngokunciphisa inkunkuma yezinto eziphathekayo, abavelisi banokugcina iindleko zempahla kunye nokunciphisa impembelelo yabo yokusingqongileyo.

- Ukwandisa ukusebenza kakuhle kwemveliso: Abavelisi bokubumba i-injection banokwandisa iinkqubo zabo zokuvelisa ukunciphisa ukusetyenziswa kwamandla. Oku kubandakanya ukusebenzisa iimatshini zokubumba iinaliti eziphezulu, ukulungelelanisa iiparamitha zenkqubo yokubumba, kunye nokunciphisa ixesha lokuphumla. Ngokunciphisa ukusetyenziswa kwamandla, abavelisi banokugcina kwiindleko zamandla kunye nokunciphisa i-carbon footprint.

- Ukuphumeza izenzo ezizinzileyo: Abavelisi bokubumba isitofu banokuphinda baphumeze izenzo ezizinzileyo kwimisebenzi yabo, njengokuphinda kusetyenzwe kunye neenkqubo zokunciphisa inkunkuma, ukusebenzisa imithombo yamandla ehlaziyekayo, kunye nokukhuthaza ukuzinza phakathi kwabasebenzi kunye nabanikezeli babo. Ngokukhuthaza izenzo ezizinzileyo kulo lonke ikhonkco lokubonelela, abavelisi banokunceda ukudala ishishini elizinzileyo ngokubanzi.

- Sebenzisa ukupakishwa okuzinzileyo: Okokugqibela, abavelisi bokubumba inaliti banokusebenzisa izinto zokupakisha ezizinzileyo kunye noyilo lokunciphisa inkunkuma kunye nefuthe lokusingqongileyo. Oku kuquka ukusebenzisa izinto zokupakisha ezinokonakala okanye ezinokuphinda zisetyenziswe, ukunciphisa inkunkuma yokupakisha, kunye nokuyila ukupakishwa okunokuphinda kusetyenziswe okanye ukuphinda kuzaliseke.

Ngokuphumeza ezi zenzo ezizinzileyo, abavelisi bokubumba inaliti banokunciphisa ifuthe labo lokusingqongileyo kwaye benze ishishini elizinzileyo ngokubanzi. Njengoko uzinzo lusiya lubaluleke kakhulu kubathengi nakumashishini, abavelisi bokubumba inaliti ebeka phambili ukuzinza baya kubekwa kakuhle ukuhlangabezana nemfuno ekhulayo yeemveliso ezilungele indalo.

Indlela yesiko lokubumba inaliti yeplastiki ithelekisa nezinye iinkqubo zokuvelisa

Isiko lokubumba inaliti yeplastiki yinkqubo yokwenziwa edumileyo yokuvelisa iinxalenye zeplastiki ezikumgangatho ophezulu ngobuninzi. Nangona kunjalo, ezinye iinkqubo ezininzi zokuvelisa zinokusetyenziselwa ukwenza iinxalenye zeplastiki, nganye ineengenelo kunye nokungonakali. Nalu uthelekiso lwesiko lokubumba inaliti yeplastiki kunye nezinye iinkqubo zokwenza:

- Ushicilelo lwe-3D: Ushicilelo lwe-3D bubuchwepheshe obukhula ngokukhawuleza obuvumela ukudalwa kweemilo ezintsonkothileyo kunye neejometri. Ngelixa ushicilelo lwe-3D lungasetyenziselwa imveliso encinci, ukubumba inaliti ngokuqhelekileyo akubizi ndleko kwaye kusebenza kakuhle kunokubumba inaliti ukuvelisa iindawo ezinkulu.

- Ukubumba ukuvuthela: Ukubumba ukuvuthela yinkqubo yokuvelisa eyenza iindawo zeplastiki ezingenanto, ezifana neebhotile kunye nezikhongozeli. Ngelixa ukubumba ukuvuthela kukulungele ukuvelisa umthamo ophezulu weempawu, ukubumba inaliti ayichanekanga kancinane kunokubumba inaliti kwaye isenokungalungeli ekudaleni iimilo ezintsonkothileyo kunye neejiyometri.

- I-CNC Machining: I-CNC machining yinkqubo yokuvelisa i-subtractive ebandakanya ukusika kunye nokubumba iinxalenye kwibhloko eqinileyo yezinto. Ngelixa umatshini we-CNC ufanelekile ukuvelisa iindawo ezichanekileyo kwimilinganiselo emincinci, ngokuqhelekileyo ayibizi kakhulu okanye isebenze ngokufanelekileyo njengokubumba inaliti.

- Ukubunjwa okujikelezayo: Ukubumba okujikelezayo yinkqubo yokuvelisa ebandakanya ukujikeleza i-mold ejikeleze i-axes ezimbini ze-perpendicular ngelixa uyifudumeza. Ngelixa ukubumba okujikelezayo kunokuvelisa iindawo ezinkulu ezinejometri ezintsonkothileyo, ukubumba inaliti ayichanekanga ngokuqhelekileyo kunokubumba inaliti kwaye isenokungafaneleki ukwenza iindawo ezincinci.

- I-Thermoforming: I-Thermoforming yinkqubo yokuvelisa ebandakanya ukufudumeza ishidi leplastiki kwaye emva koko uyilonge phezu kokungunda. Ngelixa i-thermoforming inokuvelisa iinxalenye ezinkulu ezinejiyometri ezilula, ukubumba inaliti ayichanekanga kangako kunokubumba inaliti kwaye isenokungafaneleki ekudaleni iimilo ezintsonkothileyo kunye neejometri.

Isiko lokubumba inaliti yeplastiki yinkqubo yokwenza izinto ezininzi ezininzi kwaye ineendleko ezifanelekileyo ukuvelisa iinxalenye zeplastiki ezikumgangatho ophezulu ngobuninzi. Ngelixa ezinye iinkqubo zokuvelisa zinokufaneleka ngakumbi kwizicelo ezithile okanye umthamo wokuvelisa, ukubumba inaliti ngokuqhelekileyo lukhetho olukhethwayo kubakhiqizi abaninzi ngenxa yesantya, ukuchaneka, kunye nokusebenza kakuhle kweendleko. Ekugqibeleni, ukhetho lwenkqubo yokuvelisa luya kuxhomekeka kwizinto ezahlukeneyo, kubandakanya uyilo lwenxalenye, umthamo wemveliso, kunye nohlahlo lwabiwo-mali.

Iinzuzo kunye neengozi zokubumba isitofu sangaphandle

Ukubumba inaliti yangaphandle yinto eqhelekileyo kwiinkampani ezijonge ukuvelisa iinxalenye zeplastiki ngaphandle kokutyala imali kwizixhobo zabo zokubumba inaliti okanye ubuchule. Ngelixa ukukhutshwa komsebenzi wangaphandle kunokubonelela ngeenzuzo ezininzi, kukwanezinye iingxaki ezinokubakho. Nazi ezinye iingenelo kunye neengozi zokubumba isitofu sangaphandle:

eziluncedo:

- Ugcino lweendleko: Ukubumba inaliti ye-Outsourcing kudla ngokuba neendleko eziphezulu kunokuseka indawo yokuvelisa ngaphakathi endlwini. Oku kuyinyani ngakumbi kwiinkampani ezincinci ukuya kweziphakathi ezifuna imali eninzi okanye umthamo wokuxhasa utyalo-mali kwizixhobo ezibiza imali eninzi kunye nabasebenzi.

- Ubungcali: Iinkampani zokubumba ii-injection zisebenza ngokukhethekileyo kwimveliso kwaye zinobuchule bokuqinisekisa ukuba iinxalenye ziveliswa kumgangatho ophezulu. Ngokukhupha isitofu sokubumba, iinkampani zinokuxhamla kubuchwephesha beengcali ezinamava.

- Umthamo: Iinkampani zokubumba i-injection zinokuvelisa inani elikhulu lamalungu ngokukhawuleza nangempumelelo. Oku kuluncedo ngakumbi kwiinkampani ekufuneka zenze imiqulu emikhulu yeempawu rhoqo.

- Ukuguquguquka: Ukubumba inaliti yangaphandle kuvumela iinkampani ukuba zibe bhetyebhetye ngakumbi kwiishedyuli zazo zemveliso. Iinkampani zinokuhlengahlengisa umthamo wazo wemveliso okanye zitshintshele kwiindawo ezahlukeneyo ngaphandle kokukhathazeka ngeendleko ezinkulu zokutshintsha izixhobo kunye nokubumba.

bendlela:

- Unxibelelwano: Ukubumba inaliti yangaphandle kunokudala imingeni yonxibelelwano phakathi komthengi kunye nenkampani. Ukungaqondi kakuhle okanye ukulibaziseka kunxibelelwano kunokubangela iimpazamo okanye ukulibaziseka kwimveliso.

- Ulawulo loMgangatho: Ukubunjwa kwenaliti yangaphandle kuthetha ukuthembela kwinkampani yangaphandle ukuvelisa iinxalenye kwimigangatho yomgangatho ofunekayo. Ukulawulwa komgangatho kunokuba ngumngeni xa usebenza nenkampani yangaphandle, kwaye kuhlala kukho umngcipheko wokufumana iimpawu ekufuneka zihlangabezane neenkcukacha ezifunekayo.

- Ukuxhomekeka: Ukubumba inaliti yangaphandle kuthetha ukuxhomekeka kwinkampani yemveliso yangaphandle. Oku kunokudala imingcipheko malunga nokuthembeka komthengisi, uzinzo, kunye namaxesha okuhanjiswa.

- Ubunini boBukrelekrele: Ukukhutshwa kwesitofu sokubumba kunokudala imingcipheko yokukhusela ipropathi enomgangatho ophezulu wokuqonda. Iinkampani kufuneka ziqinisekise ukuba uyilo kunye nobuchwepheshe bazo zikhuselwe ngamanyathelo asemthethweni afanelekileyo.

Amathuba exesha elizayo okubumba inaliti yeplastiki yesiko

Isiko lokubumba inaliti yeplastiki ibe yinkqubo yokwenziwa ethembekileyo neguquguqukayo kangangamashumi eminyaka. Kwiminyaka yakutshanje, ukuqhubela phambili kwetekhnoloji kunye nezixhobo kuye kwaqhubeka ukukhulisa amandla kunye nokubanakho kokubumba inaliti. Nanga amanye amathemba ekamva lokubumba inaliti yeplastiki yesiko:

- Ukwamkelwa kobuchwephesha boShishino lwe-4.0: Ukudityaniswa kobuchwephesha be-Industry 4.0, obufana nobukrelekrele bokwenziwa, ukufundwa koomatshini, kunye ne-Intanethi yeZinto (IoT), kulindeleke ukuba yonyuse i-automation, iphucule ulawulo lomgangatho, kwaye yandise iinkqubo zemveliso ekubumbeni inaliti.

- Ukwanda kokusetyenziswa kwemathiriyeli enokubola: Iinkxalabo zokusingqongileyo ziqhuba ukwamkelwa kwemathiriyeli enokubola ekubumbeni inaliti. Izinto eziguquguqukayo ze-Biodegradable zinika enye indlela ezinzileyo kwiiplastiki zemveli kwaye zinokunceda ukunciphisa inkunkuma kunye nefuthe lokusingqongileyo.

- Imfuno ekhulayo yokwenziwa kwezixhobo zonyango: Imfuno yezixhobo zonyango iyanda ngenxa yokuguga kwabantu kunye nenkqubela phambili yetekhnoloji yezonyango. Isitofu sokubumba yinkqubo yokwenziwa kwezixhobo zonyango edumileyo ngenxa yokuchaneka kwayo, isantya, kunye nokusebenza kakuhle kweendleko.

- Ukwandiswa kwezakhono zoshicilelo ze-3D: Ukuphuhliswa kobugcisa bokushicilela be-3D kwenze ukuba ukuveliswa kweendawo ezintsonkothileyo nezintsonkothileyo ebezikade zingenakwenzeka ngaphambili ukwenziwa kusetyenziswa isitofu sokubumba. Nangona kunjalo, ushicilelo lwe-3D lusecotha kwaye lubiza kakhulu xa kuthelekiswa nokubumba inaliti, kwaye ezo teknoloji zimbini ziya kuqhubeka zincedisana kunokuba zitshintshe enye kwenye.

- Ukwandisa ukubunjwa kwenaliti yezinto ezininzi: Ukubumba inaliti yezinto ezininzi kubandakanya ukusebenzisa izinto ezimbini okanye ngaphezulu ezahlukeneyo kwinkqubo yokubumba enye. Le teknoloji ibonelela ngeenzuzo ezininzi, kubandakanywa ukusebenza kwenxalenye ephuculweyo, ubunzima obuncitshisiweyo, kunye nokugcinwa kweendleko.

- Ukuqhubela phambili kwitekhnoloji yezixhobo: Uphuhliso lwezixhobo ezitsha kunye noyilo kulindeleke ukuba lonyuse isantya, ukusebenza kakuhle, kunye nokuchaneka kokubumba inaliti. Umzekelo, amajelo okupholisa ngokusesikweni kwisixhobo anokuphucula amaxesha omjikelezo kunye nokunciphisa ukusetyenziswa kwamandla.

Isiphelo:

Isiko lokubumba inaliti yeplastiki yinkqubo yokuvelisa eyomeleleyo eyenza ukuveliswa kwezixhobo zeplastiki ezikumgangatho ophezulu ngokuchaneka okukhulu kunye nokusebenza kakuhle. Ngokuqonda inkqubo yokubumba inaliti, ukukhetha imathiriyeli efanelekileyo kunye noyilo lokungunda, kunye nokuphumeza ezona ndlela zilungileyo zolawulo lomgangatho kunye nokugcinwa kwezixhobo, amashishini anokuphucula imisebenzi yawo yokubumba inaliti kwaye azuze impumelelo enkulu. Njengoko iintsingiselo ezintsha kunye nezinto ezintsha zivela kushishino, ukuhlala usexesheni kwaye uphonononga amathuba amatsha okuphucula uzinzo, ukusebenza kakuhle, kunye nenzuzo yokubumba inaliti yeplastiki yesiko kubalulekile.