Automotive Plastic Components Isitofu Molding

Amacandelo ePlastiki yeeMoto namhlanje

Ukusebenza kweemoto eziphezulu kufuna iinxalenye ezizisingatha zonke. Iiplastiki zisebenza ukusuka kwi-injini ukuya kwi-chassis; kuyo yonke ingaphakathi ukuya ngaphandle. Iiplastiki zemoto zanamhlanje zenza malunga ne-50% yomthamo wesithuthi esikhanyayo esitsha kodwa ngaphantsi kwe-10% yobunzima bayo.

Safety

Inkqubela phambili yokhuseleko kwizinto zanamhlanje isindisa abantu abaninzi. Iingxowa zomoya, iifestile zomoya, ii-sunroofs kunye nezinto ezintsha ezifunxa amandla zinciphisa ukufa kwezithuthi. Iimodyuli zeplastiki zangaphambili, izihlalo zemodyuli kunye neebhampa ezifunxa amandla zinceda ukusindisa ubomi minyaka le.

Izakhiwo zeplastiki ezidibeneyo zinokunceda izithuthi ezikhaphukhaphu ngelixa zigcina iimpawu zokhuseleko. Xa isithuthi sintlitheka, iinjineli zifuna ukuba isakhiwo sityumke ngendlela eqikelelwayo. Izinto zeemoto kufuneka zifunxe, zingadluliseli, "amandla empembelelo" ebantwini. Ishishini likubiza oku "kukutyumza okulawulwayo."

Imihlanganisela yepolymer eyomelezwe ngeFayibha ifunxa ngokuphindwe kane amandla okutyumza entsimbi. I-B-intsika sisithuba senkxaso esidibanisa uphahla lwesithuthi nomzimba wayo. Isemva komnyango wangaphambili kwaye ibonelela ngowona mthombo omkhulu wokuchasana nokungena ngexesha longquzulwano.

ULawulo lweSizwe loKhuseleko lweNdlela ePhakamileyo kutshanje luxhase ngemali isifundo kwiintsika ze-B. Uphononongo lujonge ngokukodwa kwidizayini ye-carbon fiber thermoplastic B-pillar eyi-composite. Injongo ibikukuqinisekisa ukonga ubunzima boyilo kunye nokhuseleko kwingozi yemoto xa kuthelekiswa nesiseko sesinyithi. I-B-intsika wabonisa 60 ekhulwini ukonga ubunzima, kunye neemfuno zaneliseka side-impembelelo yokuwa. Izixhobo zokubala ziyimodeli yempembelelo eguqukayo kunye nokutyumza impendulo ye-B-iintsika.

Iiplastiki zinceda ukusindisa ubomi ngexesha leempembelelo zabahambi ngeenyawo nazo. Iibhampa zePolycarbonate-blend zinceda ukukhusela abakhweli kwiingozi. Iiplastiki zikwavumela ukusasazwa ngokukhawuleza kukhuseleko olukhulu lwabahambi ngeenyawo kwiimoto zakwaFord. Inaliti yesibiyeli sokhuselo olubhetyebhetye olunyuswe ngokuthe ngqo kwisivamvo sokhuselo olubunjwe ngeplastiki. Bona ngakumbi "kwiBlog Zone yeCrumple" kunye nokhenketho lwethu lweBMW i3 Carbon Fiber Chassis Safety Components.

Iifestile zomoya, iiWindows kunye nee-Sunroofs

Iifestile zomoya zaseMntla Melika ziza njengeyunithi enamaleko amaninzi. Yiba nomfanekiso umaleko obhityileyo weplastiki phakathi kwamacwecwe amabini eglasi. Inhlanganisela ingaba yincinci, ilula kwaye yomelele kuneglasi epholileyo yodwa. Umaleko weplastiki okwaziyo ukukrazuka unceda ukunqanda ukuphuma komhlali. Ngapha koko, i-NHTSA iqikelela ukuba ezi maleko zinceda ukuthintela ukufa kwabantu abangaphezu kwama-300 ngonyaka.

Izixhobo zeplastiki ezikhaphukhaphu zophahla zehlisa umbindi womxhuzulane zinciphisa ukubakho kwetiphu-ngaphaya ngexesha lokuqhuba kwengozi ezikoneni. I-polycarbonate ecacileyo engagqwethekiyo ngoku inokumelana ne-UV kwaye inciphise ubunzima kakhulu. Iindibano zophahla lonke zinokuthi zenziwe ngepolymer.

DJmolding's Automotive Plastic Components Isitofu Molding

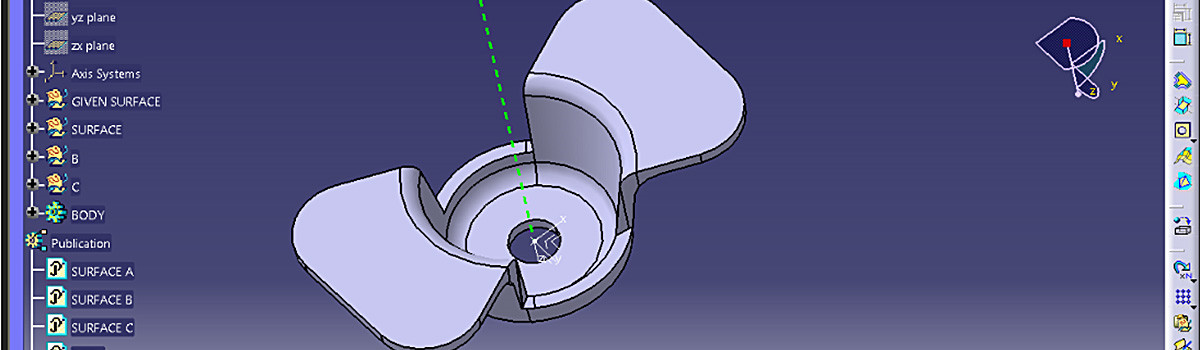

I-Djmolding yinkampani yokubumba inaliti yeplastiki yemoto ene-ISO/TS 16949:2009, sinikezela ngesixovulelo seplastiki yesixovulelo esiqhelekileyo, umyili kunye nomvelisi wokubumba isitofu esichanekileyo kusetyenziswa iireyini zebakala lobunjineli, iglasi, itungsten, ikhabhoni kunye nentsimbi ezaliswe izixhobo zemoto, i-aerospace, i-elektroniki, elwandle, ezonyango kunye nezicelo ze-telecom.

Amashumi amabini ekhulwini ezinto ezisetyenziselwa ukwenziwa kweemoto ziquka iinxalenye zeplastiki zeempawu ezahlukeneyo. Kwi-DJmolding sibonelela ngoluhlu olupheleleyo lwamalungu eplastiki kwiinkampani zeemoto, ngaphakathi nangaphandle kwezithuthi, kunye nezixhobo zezithuthi. Sisebenza ngobuchwephesha bamvanje bokutofwa kwamalungu eplastiki kunye nezixhobo zobunjineli bokwenziwa kweendawo ezisetyenziswa ziimpawu endaweni yentsimbi, ezixhathisayo, zikhaphukhaphu ngakumbi kwaye kulula ukuzisebenzisa kwakhona.

I-DJmolding njengomenzi wokubumba inaliti yeplastiki kunye nomthengisi, igxile kwitekhnoloji yokubumba inaliti ye-thermoplastic. Ukwazi kwethu kukwabandakanya itekhnoloji yokubumba inaliti yerhasi, iglosi ephezulu kunye nokubumba i-e. Isitofu sethu esibunjiweyo sangaphandle nangaphakathi semoto kushishino lweemoto zenziwa ikakhulu kwezi zixhobo zilandelayo: - polystyrene (PS), - polypropylene (PP), - ABS, - PC, - PC / ABS, - PC / PMMA.

Isitofu sangaphakathi esibunjiweyo samalungu emoto

Kwishishini leemoto eliguqukayo siliqabane elithembekileyo ekuveliseni iintlobo ngeentlobo zenaliti ezibunjiweyo zangaphakathi. Kwiifektri zethu ezivunyiweyo ze-ISO IATF siqhuba iiprojekthi zecandelo langaphakathi kubenzi beemoto abahamba phambili. Sinamava e-OEM, iTier 1 umthengisi weemoto kunye nomvelisi wezinto zangaphakathi zeemoto kunye nezangaphandle. Ipotfoliyo yethu yemveliso yamacandelo okubumba inaliti yangaphakathi iquka iinxalenye zeplastiki zemoto ezifana nezi: izinto zedeshibhodi (umzekelo: igumbi leglavu, iintsika zocango kunye nefestile), iikholamu zokuqhuba, izibambo zocango, iindawo zokuvula umoya, izikhonkwane zamaziko, iimodyuli zophahla, njl.

Isitofu sangaphandle esibunjiweyo samalungu emoto

Isitofu sokubumba yeyona ndlela ifanelekileyo yokwenza uluhlu olubanzi lwamacandelo emoto angaphandle. Iqela lethu leengcali zokubumba iinaliti ezinamava zisebenza ngokusondeleyo nee-OEM zemoto kunye nabathengi be-Tier 1 ukuvavanya nokuchaza zonke iimfuno zobugcisa kwaye ke ngoko bandise imveliso yezinto ezingaphandle zemoto. Singabenzi bokubumba inaliti yeplastiki yeendawo zangaphandle zemoto umz.: ii-mudguards (iifenda), ii-arches zamavili, iigrili, izibambi zoluvo, iileyile zomgangatho, ii-trunk trim ngaphambili kunye nezigqubuthelo zangasemva, iibumpers kunye nocango lwemoto lwangaphandle, iipaneli zamacango. Iinxalenye zethu zeplastiki zokutofa kwiimoto zifumaneka kwiimodeli ezahlukeneyo zehlabathi.

Injongo yethu kukubonelela ngexabiso elikhulu kubathengi bethu. Ngaphandle kokwenza iinxalenye zeplastiki, i-DJmolding ibonelela ngoyilo lokubumba inaliti kunye neenkonzo zokwenza. Sinceda abathengi bethu bafumane iinxalenye zeplastiki kwifom elungele ukuhanjiswa kwimarike. Sigubungela yonke inkqubo ukusuka kumbono, ngokubumba inaliti, ukuhanjiswa kweemveliso ezigqityiweyo kumashishini amacandelo eplastiki.

Njengoko ubona, i-DJmolding ayibashiyi abathengi bayo bodwa. Kwinyathelo ngalinye, sikhona ukunceda abathengi bethu ngokubonelela ngendlela ebanzi. Sinokujika ngokulula oko kubonakala kuyinkqubo entsonkothileyo ekuqaleni ibe yintsebenziswano enempumelelo evelisa iziphumo ezinkulu.

Ishishini leemoto libone inkqubela phambili ebalaseleyo kule minyaka idlulileyo, igxininisa ngamandla izinto ezilula kunye nezisebenzayo. Izinto zePlastiki zibalulekile ekwenzeni iimoto zale mihla, zibonelela ngokuqina, ukuguquguquka koyilo, kunye nokusebenza kakuhle kweendleko. Phakathi kweenkqubo ezahlukeneyo zokwenziwa kwezixhobo zeplastiki zemoto, ukubumba inaliti kusetyenziswa kakhulu. Esi sithuba sebhlog siza kuphonononga izinto zeplastiki zokutofa, izibonelelo zayo, usetyenziso, kunye neendlela ezivelayo. Makhe sihlolisise ihlabathi elinomdla lokubumba izinto zeplastiki zemoto!

Ukuqonda i-Injection Molding kwi-Automotive Industry

Umzi-mveliso weemoto usebenzisa isitofu sokubumba ukuvelisa amacandelo ahlukeneyo, kubandakanywa iideshibhodi, ii-bumpers, iipaneli zesixhobo, njl.

Nantsi eminye imiba ephambili ekufuneka uyiqwalasele xa uqonda ukubumba inaliti kumzi mveliso weemoto:

Izinto ezisetyenziselwa ukubumba inaliti

Isitofu sokubumba sisebenzisa uluhlu olubanzi lwezixhobo ze-thermoplastic kunye ne-thermosetting, kubandakanya:

- Iipolypropylene (PP)

- I-Polyethylene (PE)

- I-Polyvinyl chloride (PVC)

- I-Acrylonitrile-butadiene-styrene (ABS)

- IPolycarbonate (PC)

- I-Polyamide (PA)

- Lyu (DB)

Isixhobo ngasinye sineempawu ezizodwa kunye neempawu, ezifana nokuguquguquka, amandla, ukuqina, kunye nokuchasana nokushisa kunye neekhemikhali. Ukukhethwa kwezinto kuxhomekeke kwiimfuno ezithile zenxalenye okanye imveliso eveliswayo.

Izinto eziluncedo zokubumba inaliti kushishino lweemoto

- Ukusebenza okuphezulu kwemveliso: Ukubumba i-injection kunokuvelisa amanani amakhulu eenxalenye ngokukhawuleza nangokufanelekileyo, ukunciphisa ixesha lokuvelisa kunye neendleko.

- Ukuchaneka kunye nokuhambelana: I-injection molding ivelisa iindawo ezichanekileyo kunye nezihambelanayo kunye nokwahluka okuncinci phakathi kwamaqhekeza.

- Ububhetyebhetye boyilo: Ukubumba ukutofa kuvumela ukuba iijiyometri ezintsonkothileyo kunye neenkcukacha ezintsonkothileyo zidityaniswe zibe ziinxalenye, okwenza abaqulunqi benze iziqwenga ezihlangabezana neemfuno ezithile zokusebenza kunye nobuhle.

- Ukusebenza kweendleko: Ukubunjwa kwe-injection kunokuvelisa iinxalenye ngexabiso eliphantsi kunezinye iindlela zokuvelisa, ezifana nomatshini okanye ukuphosa.

Imingeni yokubumba inaliti kushishino lweemoto

- Iindleko zesixhobo: Isitofu sokubumba sifuna indalo yokungunda, enokubiza kakhulu ukuyila nokuvelisa.

- Ukukhetha izinto eziphathekayo: Ukukhetha izinto ezifanelekileyo kwinxalenye okanye imveliso kunokuba ngumngeni, njengoko izinto ezahlukeneyo zineepropati ezahlukeneyo kwaye zinokufuna iimeko ezongezelelweyo zokucubungula.

- Ukugcinwa kunye nokulungiswa: Izixhobo zokubumba i-injection zifuna ukugcinwa rhoqo kunye nokulungiswa ukuqinisekisa ukusebenza kakuhle kunye nokuthintela ixesha lokuphumla.

- Impembelelo yokusingqongileyo: Ukulahlwa kwenkunkuma yeplastiki eveliswe kwinaliti yokubumba kunokuba neziphumo ezibi zokusingqongileyo.

IiNzuzo zeMithombo yePlastiki yeMicimbi yokuBunjwa kwesitofu

Izixhobo zeplastiki ezizihambelayo zokubumba isitofu yinkqubo ebandakanya ukudalwa kwamalungu antsonkothileyo ngokusetyenziswa kokungunda kunye neepeliti zeplastiki. Le ndlela isetyenziswa kakhulu kushishino lweemoto ngenxa yeenzuzo ezininzi. Esi sithuba sebhlog siyakuxoxa ngezinto eziluncedo zokubumba iinxalenye zeplastiki zemoto.

Ixabiso-Ngempumelelo: Enye yezona nzuzo zibalulekileyo zemoto yeplastiki yento yokubumba isitofu kukuba yindlela eneendleko zokuvelisa iinxalenye. Oku kungenxa yokuba inkqubo inokudala iinxalenye ezinzima ngobuninzi ngokukhawuleza nangempumelelo. Oku kunciphisa iindleko zokuvelisa, okwenza kube sisisombululo esifanelekileyo kwishishini leemoto, apho iindleko zihlala zixhalabile.

Ikhaphukhaphu: Enye inzuzo ebalulekileyo yokubumba inaliti yeplastiki kumzi mveliso weemoto kukuba izinto zeplastiki zikhaphukhaphu. Oku kubalulekile kuba kuphucula ukusebenza kakuhle kwamafutha ezithuthi, eyona nto ibalulekileyo kubavelisi beemoto ekuhlangabezaneni nemigaqo yokusingqongileyo kunye nolindelo lwabathengi.

Ukomelela kunye noKuhlala ixesha elide: Amalungu eplastiki aveliswa ngokubumba inaliti anamandla abalaseleyo kunye nokuqina. Oku kungenxa yokuba inkqubo ivumela ukudalwa kweengxenye ezinodonga olungaguquguqukiyo kunye nokulwa okuncinci. Ngenxa yoko, izinto zeplastiki eziveliswe ngokubumba inaliti zinokumelana nobunzima bemeko yemoto, njengamaqondo obushushu aphezulu kunye nokungcangcazela.

Ngokwezifiso: Isitofu sokubumba sivumela ukudalwa kweengxenye ngobukhulu obuhlukeneyo kunye neemilo. Oku kuyenza ibe sisisombululo esifanelekileyo kushishino lweemoto, apho ukwenziwa ngokwezifiso kubalulekile. Ngokubumba inaliti, abavelisi beemoto ngokulula banokwenza iinxalenye ezihlangabezana neemfuno ezithile, ezinjengobukhulu, ukumila nombala.

Inkunkuma Ethotyiweyo: Ukubumba inaliti yeplastiki kuvelisa inkunkuma encinci kuneendlela zokuvelisa zemveli. Inkqubo isebenza kakuhle kwaye inokudala iinxalenye kunye ne-scrap encinci. Ngenxa yoko, umzi-mveliso weemoto unokunciphisa unyawo lwekhabhoni ngokusebenzisa isitofu sokubumba ukuvelisa amacandelo eplastiki.

Imveliso eKhawulezayo: Isitofu sokubumba yindlela ekhawulezayo nesebenzayo yokuvelisa amacandelo eplastiki. Inkqubo inokudala iinxalenye ngemizuzwana, iyenza ibe sisisombululo esifanelekileyo kushishino lweemoto, apho amaxesha okuvelisa ngokukhawuleza abaluleke kakhulu.

Umgangatho ophuculweyo: Amalungu eplastiki avelisiweyo ngokubumba inaliti anomgangatho ongaguqukiyo. Oku kungenxa yokuba inkqubo ivumela ulawulo oluchanekileyo phezu kweeparamitha zokubumba, ezifana nobushushu, uxinzelelo, kunye nexesha lokupholisa. Ngenxa yoko, izinto zeplastiki eziveliswe ngokubumba inaliti zinokuchaneka okugqwesileyo komgangatho kunye nokugqitywa komphezulu.

Ukuphonononga iiPlastiki ezisetyenziswa ngokuqhelekileyo kwi-Injection Molding

Ukubumba isitofu kubandakanya ukunyibilika iipeliti zeplastiki kunye nokuzitofa kumgodi wokungunda ukwenza imilo ethile. Ukuguquguquka kwale nkqubo kuvumela abavelisi ukuba benze iinxalenye ezinzima ngokuchaneka okuphezulu kunye nokuhambelana. Izinto ezahlukeneyo zeplastiki zisetyenziselwa ukubumba inaliti ukufezekisa iipropati ezifunwayo. Esi sithuba sebhlog siya kuphonononga iiplastiki ezisetyenziswa ngokuqhelekileyo ekubumbeni inaliti kunye neempawu zazo.

- I-Acrylonitrile Butadiene Styrene (ABS): I-ABS yipolymer ye-thermoplastic esetyenziswa ngokubanzi ekubunjweni kwenaliti ngenxa yempembelelo yayo enkulu, ukuqina, kunye nokumelana nobushushu. Iqhele ukusetyenziswa kwiindawo zemoto, iithoyi, kunye nezindlu zombane.

- I-Polycarbonate (iPC): I-PC yinto eqinile, ecacileyo yeplastiki esetyenziswa ekubunjweni kwesitofu kwiimveliso ezifuna ukuxhathisa impembelelo kunye nokucaciswa kwamehlo, njengeeglasi zokhuseleko, izinto ze-elektroniki, kunye neendawo zemoto.

- I-Polypropylene (PP): I-PP yimathiriyeli yeplastiki eguquguqukayo esetyenziselwa ukubumba inaliti kwiimveliso ezifuna ukuguquguquka, amandla, kunye nokuxhathisa imichiza. Ngokuqhelekileyo isetyenziselwa ukupakisha, iinxalenye zemoto, kunye nempahla yabathengi.

- I-Polyethylene (PE): I-PE yinto yeplastiki ekhaphukhaphu esetyenziselwa ukubunjwa kwenaliti kwiimveliso ezifuna ukuguquguquka kunye nokuqina. Ngokuqhelekileyo isetyenziselwa ukupakisha, izinto zendlu kunye nezinto zokudlala.

- I-Polyoxymethylene (i-POM): I-POM yinto eqinileyo kunye neqinileyo yeplastiki esetyenziswa ekubumbeni isitofu kwiimveliso ezifuna uzinzo lwe-dimensional kunye nokumelana nokunxiba. Isetyenziswa ngokuqhelekileyo kwiigiya, iibheringi, kunye namanye amalungu oomatshini.

- I-Polystyrene (PS): I-PS yimathiriyeli yeplastiki ekhaphukhaphu kwaye eqinile esetyenziswa ekubumbeni inaliti kwiimveliso ezifuna uzinzo olulungileyo kunye neempawu zokugquma. Ngokuqhelekileyo isetyenziselwa ukupakishwa kokutya, izitya ezilahlayo, kunye neemeko zeCD.

- I-Polyethylene Terephthalate (PET): I-PET yinto eyomeleleyo kunye nekhaphukhaphu yeplastiki esetyenziswa ekubumbeni inaliti yeemveliso ezifuna ukucaca okuphezulu, ukuqina, kunye nokumelana neekhemikhali. Isetyenziswa ngokuqhelekileyo kwiibhotile zesiselo, ukupakishwa kokutya, kunye nezixhobo zonyango.

- Inayiloni (PA): Inayiloni sisixhobo seplastiki esomeleleyo nesomeleleyo esisetyenziswa ekubumbeni inaliti yeemveliso ezifuna ukomelela okuphezulu, ukumelana nobushushu, kunye nokumelana neekhemikhali. Isetyenziswa ngokuqhelekileyo kwiindawo zeemoto, izixhobo ze-elektroniki, kunye noomatshini bemizi-mveliso.

Iingqwalaselo zoYilo lweMicimbi yePlastiki yeeMoto

Esi sithuba sebhlog siza kuxoxa ngengqwalasela ebalulekileyo yoyilo lwezixhobo zeplastiki zemoto.

Ukukhethwa kwezinto:

- Amacandelo eplastiki angenziwa kwizinto ezahlukeneyo, kuquka i-polypropylene, i-polycarbonate, i-ABS, kunye nokunye.

- Isixhobo ngasinye sineempawu ezizodwa, njengamandla, ukuqina, ukuzinza kwe-thermal, kunye nokuchasana neekhemikhali kunye nemitha ye-UV.

- Kubalulekile ukukhetha imathiriyeli ehlangabezana neemfuno ezithile zosetyenziso olucetywayo kunye nemigangatho yolawulo.

Indlela yokuvelisa:

- Amalungu ePlastiki anokuveliswa kusetyenziswa iindlela ezininzi, kubandakanya ukubumba inaliti, ukubumba ukuvuthela, i-thermoforming, kunye nokubumba okujikelezayo.

- Indlela nganye ineengenelo kunye nezingeloncedo ngokweendleko, isantya semveliso, ukuntsonkotha, kunye nomgangatho wenxalenye.

- Indlela yokuvelisa kufuneka ikhethwe ngokusekelwe kwiimfuno ezithile zenxalenye, ezifana nobukhulu bayo, imilo, kunye nomthamo, kunye nenqanaba elifunwayo lokuchaneka kunye nokuhambelana.

Ukusebenza kwenxalenye:

- Umsebenzi wecandelo leplastiki kufuneka uqwalaselwe ngononophelo xa uyilo.

- Amalungu anokufuna ukuyilwa ukumelana noxinzelelo lomatshini, ukuguquguquka kobushushu, ukuvezwa kweekhemikhali, kunye nezinye izinto zokusingqongileyo.

- Kufuneka kuqwalaselwe kwakhona ukufaneleka kwelungu, imo, kunye nomsebenzi kunye nazo naziphi na iimfuno zobuhle.

Uyilo lwendibano:

- Amacandelo eplastiki kufuneka ayilwe ngokulula ukuhlanganisana engqondweni.

- Amacandelo anzima okanye achitha ixesha ukudibanisa anokunyusa iindleko zemveliso kwaye akhokelela kwimiba yomgangatho.

- Amalungu kufuneka ayilwe ukuba ahlangane ngokulula kwaye ngokukhuselekileyo, kunye nesidingo esincinci se-hardware eyongezelelweyo okanye izibophelelo.

Uyilo lokwenziwa kwezinto:

- Uyilo lwamacandelo eplastiki kufuneka kwakhona luthathele ingqalelo inkqubo yokuvelisa kunye nayo nayiphi na imida okanye imiqobo.

- Iimpawu zoyilo ezinje ngee-engile zokuyila, ubukhulu bodonga, kunye nemigca yokwahlulahlula zinokuchaphazela kakhulu umgangatho wemveliso kunye neendleko.

- Ukusebenzisana nomenzi kunokunceda ukuqinisekisa ukuba uyilo lulungiselelwe imveliso.

Uvavanyo kunye nokuqinisekiswa:

- Emva kokuba uyilo lwecandelo leplastiki ligqityiwe, kufuneka livavanywe kwaye liqinisekiswe ukuqinisekisa ukuba lihlangabezana neemfuno ezifunekayo zokusebenza kunye nokhuseleko.

- Uvavanyo lunokubandakanya uvavanyo lomatshini, iikhemikhali, kunye ne-thermal kunye novavanyo lokufaneleka kunye nokusebenza.

- Ukuqinisekiswa kufuneka kuqhutywe kuyo yonke inkqubo yophuhliso, ukusuka kuyilo lokuqala ukuya kwimveliso yokugqibela.

Indima yePrototyping kwi-Injection Molding

Iprototyping idlala indima ebalulekileyo kwihlabathi lokubumba inaliti. Linyathelo elibalulekileyo kwimveliso, evumela abaqulunqi kunye neenjineli ukuba basulungekise uyilo lwabo, ukuvavanya ukusebenza, kunye nokuchonga imiba enokubakho ngaphambi kokuqhubela phambili nemveliso epheleleyo. Apha, siza kuphonononga ukubaluleka kweprototyping ekubumbeni inaliti kunye nezibonelelo zayo ezininzi.

Ukuqinisekiswa koYilo:

Iprototyping yenza abaqulunqi baqinisekise uyilo lwemveliso yabo kwaye bavavanye ukwenzeka kwabo kwihlabathi lokwenyani. Ngokwenza iprototype yomzimba, abaqulunqi banokuvavanya izinto ezinje ngejometri yenxalenye, kufanelekile, kunye nokuhlanganisa. Inceda ekuchongeni iziphene zoyilo, iqinisekisa ukuba imveliso yokugqibela ihlangabezana nemigaqo efunekayo kwaye yenza njengoko kucetyiwe.

Uphuculo oluphindaphindiweyo:

Iprototyping ivumela ukuphuculwa okuphindaphindwayo kuwo wonke umjikelo wophuhliso lwemveliso. Ngokwenza iiprototypes ezininzi kunye nokuzivavanya, abaqulunqi banokuqokelela ingxelo ebalulekileyo kwaye benze uhlengahlengiso oluyimfuneko. Le nkqubo yokuphindaphinda inceda ukucokisa uyilo, ukongeza ukusebenza kakuhle, kunye nokuphucula ukusebenza kwemveliso yokugqibela.

Iindleko kunye nokugcinwa kwexesha:

Ukuchonga iziphene zoyilo okanye imiba yokusebenza ngexesha lokwenziwa kweprototyping kubaluleke kakhulu kunokonga kwaye konga ixesha kunokuzifumana ngexesha lemveliso yobuninzi. Ukwenza utshintsho kuyilo kwangethuba kunciphisa imfuneko yokulungiswa kwakhona kwexabiso eliphezulu kwaye kwehlisa umngcipheko wokulibaziseka kwemveliso. Iprototyping ivumela ukusonjululwa kwengxaki okusebenzayo kunye nokwenza ngcono phambi kokuzinikela kwizixhobo ezibiza kakhulu kunye neenkqubo zokuvelisa.

Ukhetho lwezixhobo:

Iprototyping iququzelela ukhetho lwezixhobo ezifanelekileyo zokubumba inaliti. Ngokuvavanya izixhobo ezahlukeneyo, iinjineli zinokuvavanya iipropathi zazo, kubandakanya amandla, ukuguquguquka, kunye nokumelana nobushushu, kwaye ukhethe ezona zinto zifanelekileyo kwisicelo esifunwayo. Ngokwenza oku, siqinisekisa ukuba umphumo uhlangabezana nemigangatho efunekayo yokusebenza kunye nokuqina.

Ukuqinisekiswa kweNkqubo yokuVelisa:

Iiprototypes zisebenza njengendlela yokuqinisekisa ukwenzeka kunye nokusebenza kwenkqubo yokuvelisa ekhethiweyo. Ngokuvelisa iiprototypes zisebenzisa izinto ezifanayo kunye neendlela ezijoliswe kwimveliso yobuninzi, iinjineli zinokuchonga nayiphi na imingeni okanye imida kwangethuba. Le nkqubo yokuqinisekisa inceda ukulungelelanisa imveliso, ukunciphisa iziphene, kunye nokuqinisekisa umgangatho ohambelanayo kwimveliso yokugqibela.

UNxibelelwano kunye neNxulumano namahlakani:

Iiprototypes luphawu olubambekayo lwengcamango yemveliso, ukuququzelela unxibelelwano olusebenzayo kunye nokuzibandakanya kwabachaphazelekayo. Nokuba inikezela ngombono woyilo kubathengi okanye iqokelela ingxelo evela kubasebenzisi bokugqibela, iiprototypes zenza kube lula kuye wonke umntu obandakanyekayo ukuba abone ngeso lengqondo imveliso, abonelele ngegalelo, kwaye enze izigqibo ezinolwazi. Intsebenziswano ephuculweyo ikhokelela ekungaqondani okumbalwa kunye nokwaneliseka ngokubanzi.

Amanyathelo abalulekileyo kwiNkqubo yokuMonda i-Injection

Esi sithuba sebhlog siza kuxoxa ngamanyathelo abalulekileyo kwinkqubo yokubumba inaliti.

Inyathelo 1: Ukukhetha izinto eziphathekayo

Isinyathelo sokuqala kwinkqubo yokubumba isitofu kukukhethwa kwezinto eziphathekayo.

Izinto ezahlukeneyo zeplastiki zineempawu ezizodwa, njengamandla, ukuguquguquka, kunye nokuxhathisa imichiza.

Ukukhethwa kwezinto eziphathekayo kuya kuxhomekeka kwiimfuno ezithile zenxalenye kunye nokusetyenziswa kwayo.

Inyathelo 2: Ukulungiswa kwePellet

Iipilisi zeplastiki zilungiselelwe ngokumisa kunye nokuxuba kwiinkcukacha ezifunekayo.

Eli nyathelo liyimfuneko ekuqinisekiseni ukuba iplastiki ayinakufuma kunye nezinto ezingcolisayo ezinokuchaphazela umgangatho wemveliso yokugqibela.

Inyathelo lesi-3: Ukunyibilikisa iplastiki

Iipellet zeplastiki ziye zinyibilike kumatshini wokubumba inaliti.

Ubushushu kunye noxinzelelo lwenkqubo yokunyibilika kuya kuxhomekeka kuhlobo lwezinto zeplastiki ezisetyenzisiweyo.

Inyathelo lesi-4: Isitofu

Iplastiki enyibilikisiweyo ithi ke itofwe kwisingundo.

Ukungunda ngokuqhelekileyo kwenziwa ngentsimbi kwaye yenzelwe ukudala imilo efunekayo yemveliso yokugqibela.

Inyathelo lesi-5: Ukupholisa kunye nokuqinisa

Emva kokuba iplastiki ifakwe kwi-mold, ipholisa kwaye iqina kwimo efunekayo.

Ixesha lokupholisa liya kuxhomekeka kubunzima kunye nobunzima benxalenye.

Inyathelo lesi-6: Ukukhutshwa

Emva kokuba iplastiki ipholile kwaye iqinile, isikhunta siyavulwa, kwaye inxalenye iyakhutshwa.

Kwezinye iimeko, izikhonkwane ze-ejector zisetyenziselwa ukunceda ukususa inxalenye kwi-mold.

Inyathelo 7: Ukucheba kunye nokugqiba

Emva kokuba inxalenye ikhutshwe kwi-mold, inokufuna ukucutshungulwa okongeziweyo kunye nokugqiba ukususa nayiphi na into engaphezulu kwaye igudise imiphetho.

Inyathelo lesi-8: Ulawulo lomgangatho

Ulawulo lomgangatho linyathelo elibalulekileyo kwinkqubo yokubumba inaliti.

Imveliso yokugqibela ihlolwe iziphene, ezifana nokujika, ukuqhekeka, okanye ukungahambelani kombala okanye ukuthungwa.

Ubuchwephesha bokuphucula amandla kunye nokuqina kwezixhobo zePlastiki

Nangona kunjalo, bahlala bejongana nemingeni ngamandla kunye nokuqina, ngakumbi xa bevezwe kuxinzelelo oluphezulu okanye iimeko ezinzima zokusingqongileyo. Kule post yebhlog, siza kuxoxa ngeendlela ezithile zokuphucula amandla kunye nokuqina kwamalungu eplastiki.

Ukuqiniswa kunye nezongezo

- Izongezo zinokuphucula amandla kunye nokuqina kwamacandelo eplastiki ngokuziqinisa ngeefiber, iifayili, okanye i-nanoparticles.

- Izongezo eziqhelekileyo ziquka iifayili zeglasi, iifayili zekhabhoni, i-silica, i-talc, kunye nodongwe.

Ukudibanisa nezinye izinto

- Ukudibanisa iiplastiki kunye nezinye izinto, ezifana nerabha okanye i-elastomers, kunokwandisa amandla kunye nokuqina kwazo.

- Ngokomzekelo, ukongeza inani elincinci lerabha kwi-polypropylene kunokuphucula ukuchasana kwayo neempembelelo.

unyango ubushushu

- Ukunyanga ukushisa kunokunyusa amandla kunye nokuqina kweentlobo ezithile zamacandelo eplastiki.

- Oku kubandakanya ukubeka iplastiki kubushushu obuphezulu ukuguqula iikhemikhali zayo kunye neempawu zayo.

I-Annealing

- I-Anealing yindlela yonyango lobushushu olubandakanya ukufudumeza iplastiki kwiqondo lobushushu elithile kwaye emva koko uyipholise kancinane.

- Le ndlela inokunciphisa uxinzelelo lwangaphakathi kwiplastiki, iphucula amandla ayo kunye nokuqina.

Ukulungiswa kwenkqubo yokubumba isitofu

- Ukuphucula inkqubo yokubumba inaliti kunokomeleza amandla kunye nokuqina kwezinto zeplastiki.

- Oku kubandakanya ukulawula ubushushu, uxinzelelo, kunye nezinga lokupholisa ngexesha lokubumba.

Unyango oluphezulu

- Ubuchule bonyango obuphezulu, obufana ne-corona, iplasma, okanye unyango lomlilo, lunokuphucula ukunamathela phakathi kweplastiki kunye nezinye izinto.

- Oku kunokomeleza amandla kunye nokuqina kwecandelo leplastiki kwizicelo apho ukudibanisa kubaluleke kakhulu.

Imikhosi

- Iingubo zinokuphucula amandla kunye nokuqina kwamacandelo eplastiki ngokubonelela ngoluhlu olongezelelweyo lokukhusela.

- Ngokomzekelo, i-coating-resistant-resistant coating inokukhusela amacandelo eplastiki kumonakalo kwiindawo ezinzima.

Imilinganiselo yoLawulo loMgangatho kwi-Automotive Injection Molding

Ukubumba inaliti yemoto yinkqubo ebaluleke kakhulu ekuvelisweni kwamalungu emoto akumgangatho ophezulu. Inkqubo ibandakanya ukusetyenziswa koomatshini abakhethekileyo kunye nokubumba ukuvelisa iindawo ezihlangabezana nomgangatho ongqongqo kunye nemigangatho yokusebenza. Amanyathelo olawulo lomgangatho ayimfuneko ukuqinisekisa ngokuthe rhoqo ukuba iinxalenye zemoto ezenziwe ngale nkqubo ziyahlangabezana nale migangatho. Nanga amanye amanyathelo abalulekileyo olawulo lomgangatho athi aphunyezwe ekubumbeni inaliti yemoto:

Ukuhlolwa kwezinto: Isinyathelo sokuqala ekulawuleni umgangatho kukuhlolwa kwezinto eziphathekayo. Iimathiriyeli ekrwada ziyahlolwa ukuqinisekisa ukuba ziyahlangabezana nemigaqo efunekayo. Oku kubandakanya ukujonga ukubunjwa kwezinto, ubunyulu, kunye nokungaguquguquki.

UkuJonga iNkqubo yokuBumba: Inkqubo yokubumba ijongwa ngokuqhubekayo ukuqinisekisa ukuba iinxalenye ziveliswa ngokweenkcukacha ezifunekayo. Oku kubandakanya ukubeka esweni ubushushu bezinto ezisetyenzisiweyo, uxinzelelo, kunye nesantya sokuhamba.

Uhlolo lweCandelo: Iinxalenye zihlolwa emva kokuveliswa ukuhlangabezana nemigangatho efunekayo. Oku kuquka ukujonga iziphene ezifana ne-warping, i-sink marks, kunye nokudanyaza.

Ulawulo lweNkqubo yoBalo (SPC): I-SPC sisixhobo samanani esibeka iliso kwaye silawule inkqubo yemveliso. Ibandakanya ukusetyenziswa kobuchule beenkcukacha-manani ukuhlalutya idatha kunye nokuchonga iintsingiselo okanye iipatheni ezibonisa iingxaki ezinokubakho kwinkqubo.

Uqinisekiso loMgangatho (QA): I-QA ibandakanya ukusebenzisa uluhlu lweenkqubo kunye nezikhokelo zokuqinisekisa ukuba imveliso yokugqibela ihlangabezana nemigangatho yomgangatho ofunekayo. Oku kubandakanya ukuhlola nokuvavanya imveliso egqityiweyo ukuqinisekisa ukuba iyahlangabezana neenkcukacha ezifunekayo.

Ukulandeleka: Ukulandeleka kukukwazi ukulandelela imveliso emva komthombo wayo. Ekubunjweni kwenaliti yemoto, ukulandeleka kubalulekile ukuze kuqinisekiswe ukuba naziphi na iziphene okanye imiba yomgangatho inokulandwa ibuyele kumthombo wayo kwaye ilungiswe.

Uphuculo oluqhubekayo: Ukuphuculwa okuqhubekayo yinkqubo eqhubekayo ebandakanya ukuchonga iindawo zokuphucula kunye nokuphumeza utshintsho ukuphucula umgangatho wemveliso. Oku kubandakanya ukuhlalutya idatha, ukuchonga iintsingiselo, kunye nokuphumeza utshintsho kwinkqubo yokuphucula umgangatho wemveliso kunye nokungaguquguquki.

Uhlalutyo lweendleko: I-injection Molding vs. Iindlela zokuVelisa ngokweMveli

Kwishishini lemveliso, uhlalutyo lweendleko luyinkalo ebalulekileyo yokwenza izigqibo. Abavelisi kufuneka bavavanye iindleko zokuvelisa iimveliso zabo besebenzisa iindlela ezahlukeneyo ukumisela eyona ndlela ingabizi kakhulu. Isitofu sokubumba kunye neendlela zemveli zokuvelisa zimbini ezisetyenziswa ngokuqhelekileyo, kwaye abavelisi kufuneka bathathe isigqibo sokuba yeyiphi eyona ndlela ingabizi kakhulu kwiimveliso zabo. Nalu uhlalutyo lweendleko zenaliti yokubumba ngokuchasene neendlela zokuvelisa zemveli.

Ukubunjwa kwesitofu:

Isitofu sokubumba yindlela yokuvelisa ebandakanya ukutofa iplastiki etyhidiweyo kwisingundo ukuvelisa iindawo. Nazi ezinye zezibonelelo kunye nokungalunganga kokubumba inaliti:

eziluncedo:

- Umthamo wemveliso ephezulu:Isitofu sokubumba sikulungele ukuvelisa iincwadi eziphezulu zamalungu afanayo.

- Iindleko zomsebenzi eziphantsi:Ukubumba isitofu kufuna umsebenzi omncinci xa kuthelekiswa neendlela zokuvelisa zemveli.

- Ukuvumelana: Ukubumba isitofu kwenza iindawo ezihambelanayo ezifanayo enye kwenye.

- Inkunkuma yezinto ezisezantsi: I-injection yokubumba inenkunkuma encinci kuneendlela eziqhelekileyo zokuvelisa.

Ilishwa:

- Iindleko eziphezulu zangaphambili:Iindleko zokumisela isitofu sokubumba ziphezulu xa kuthelekiswa neendlela zokuvelisa zemveli.

- Ububhetyebhetye obulinganiselwe: Ukubumba ukutofa akuguquguquki kancinci kuneendlela zokwenziwa kwesiqhelo, kuyenza ilunge kakhulu ukuvelisa iinxalenye zesiko.

Iindlela zesiNtu zokuVelisa:

Iindlela zokwenziwa kwemveli zibhekisa kubuchule bokuvelisa obuqhelekileyo obusetyenziswa amashumi eminyaka. Ezi ndlela ziquka ukungqusha, ukugrumba, kunye nokujika. Nazi ezinye iingenelo kunye nobubi beendlela zokwenziwa kwemveli:

eziluncedo:

- Ixabiso eliphantsi, langaphambili:Iindlela zokwenziwa kwemveli zifuna iindleko ezincinci zangaphambili, zizenze zilungele ukuvelisa umthamo ophantsi wamalungu.

- Ukuzinza:Iindlela zokwenziwa kwemveli zibhetyebhetye ngakumbi kunobumba lwesitofu, nto leyo ebenza ukuba balungele ukuvelisa iindawo eziqhelekileyo.

- Iindleko zokusebenza ezisezantsi:Iindlela zokwenziwa kwemveli zifuna iindleko eziphantsi zezixhobo kunokubumba inaliti.

Ilishwa:

- Iindleko eziphezulu zabasebenzi:Iindlela zokwenziwa kwemveli zifuna umsebenzi omninzi kunokubumba inaliti, okukhokelela kwiindleko eziphezulu zabasebenzi.

- Inkunkuma yezinto eziphezulu:Iindlela zokwenziwa kwemveli zivelisa inkunkuma ngaphezu kokubumba inaliti.

- Amalungu angangqinelaniyo:Iindlela zokwenziwa kwemveli zivelisa izixa ezinokuthi zibe nokwahluka kancinci kwenye.

Uzinzo kunye neMpembelelo yokusiNgqongileyo yokuBunjwa kwesitofu

Uzinzo kunye neempembelelo zokusingqongileyo zizinto ezibalulekileyo ekufuneka amashishini kunye nabavelisi baziqwalasele kwiinkqubo zabo zemveliso. I-injection molding, indlela yokuvelisa eyaziwayo, ineempembelelo ezilungileyo nezimbi zokusingqongileyo. Kule post yebhlog, siza kuxoxa ngozinzo kunye nefuthe le-ikholoji yokubumba inaliti.

Ukuzinza:

Uzinzo lubhekisa ekuhlangabezaneni neemfuno zangoku ngaphandle kokubeka esichengeni amandla ezizukulwana ezizayo ukuhlangabezana neemfuno zabo. Isitofu sokubumba sineenzuzo ezininzi zozinzo:

- Ukusebenza kakuhle kwezinto:Ukubunjwa kwe-injection kuvelisa iindawo ezinenkunkuma encinci, ukunciphisa izinto ezifunekayo ukwenza iindawo.

- Ukusebenza kakuhle kwamandla:Ukubumba isitofu kufuna amandla amancinci ukuvelisa iinxalenye kunezinye iindlela zokuvelisa, ezifana nomatshini kunye nokuphosa.

- Ixesha elide lokuphila: Amalungu avelisiweyo ngokubumba inaliti ahlala ixesha elide kwaye ahlala ixesha elide, ukunciphisa imfuno yokutshintshwa rhoqo.

Impembelelo yokusingqongileyo:

Ukubumba ngesitofu nako kuneempembelelo zokusingqongileyo ekufuneka ziqwalaselwe. Nazi ezinye zeziphumo ezilungileyo nezingalunganga ze-ikholoji zokubumba inaliti:

Impembelelo entle yokusiNgqongileyo:

- NoKwenziwa ngokutsha kwezinto ebesezisetyenzisiwe: Izinto ezininzi zokubumba iinaliti, ezinje ngeeplastiki, ziyaphinda zisetyenziswe, zinciphisa inkunkuma ethunyelwa kwiindawo zokulahla inkunkuma.

- Umgangatho ophantsi wekhabhoni:Ukubumba isitofu kuvelisa ukukhutshwa kwegesi encinci ye-greenhouse kunezinye iindlela zokuvelisa ezifana nomatshini kunye nokuphosa.

Impembelelo embi yokuSingqongileyo:

- Ukusetyenziswa kwemithombo engahlaziyekiyo:I-injection molding isebenzisa izinto ezisekelwe kwi-petroleum ezifana neplastiki ephuma kwizinto ezingenakuhlaziyeka.

- Ukuveliswa kwenkunkuma:Nangona isitofu sokubumba sivelisa inkunkuma encinane kunezinye iindlela zokuvelisa, isavelisa inkunkuma, enjengezinto ezilahliweyo kunye nenkunkuma yokupakisha.

ImiSebenzi eZinzileyo ekuBumbeni ngesitofu:

Ukunciphisa impembelelo embi yokusingqongileyo yokubumba inaliti, abavelisi banokusebenzisa iindlela ezizinzileyo ezifana nezi:

- Ukusetyenziswa kwemathiriyeli esetyenzisiweyo:Abavelisi banokusebenzisa imathiriyeli ehlaziyiweyo kwiinkqubo zabo zokutofa, ukunciphisa inkunkuma ethunyelwa kwiindawo zokulahla inkunkuma.

- Ukusetyenziswa kwamandla ahlaziyekayo:Abavelisi banokusebenzisa imithombo yamandla ahlaziyekayo efana nelanga okanye amandla omoya ukunika amandla oomatshini babo bokubumba inaliti, ukunciphisa ukukhutshwa kwegesi yendlu yokushisa.

- Ukunciphisa inkunkuma:Abavelisi banokusebenzisa iindlela zokunciphisa inkunkuma ezifana nokusebenzisa ukupakishwa okuphinda kusetyenziswe kunye nokunciphisa ubuninzi bezinto ezilahliweyo eziveliswayo.

UkuziSebenzisa iiNkqubo zokuBumba isitofu ngokuSebenzayo

Kwishishini lemveliso, ukusebenza kakuhle kubalulekile ukuze uhlale ukhuphisana kwaye unengeniso. Isitofu sokubumba yindlela edumileyo yokuvelisa ebandakanya ukuvelisa iinxalenye ngokutofa izinto ezinyibilikisiweyo zibe ngundo. Iinkqubo zokubumba iinaliti ezizenzekelayo zinokuphucula kakhulu ukusebenza kakuhle kunye nemveliso. Kule post yebhlog, siza kuxoxa ngeenzuzo zokuzenzela isitofu sokubumba iinkqubo zokusebenza ngempumelelo.

Izibonelelo zokuziSebenzisa kwiiNkqubo zokuBumba isitofu:

Nazi ezinye zezibonelelo zeenkqubo zokubumba inaliti:

- Isantya esongeziweyo:I-automation inokunyusa kakhulu isantya seenkqubo zokubumba inaliti. Oomatshini abazenzelayo banokuvelisa iinxalenye ngesantya esikhawulezayo kunoomatshini abazandla.

- Ukuvumelana:Oomatshini bokubumba benaliti ngokuzenzekelayo bavelisa iinxalenye ezihambelanayo kunye nokuhluka okuncinci, ukuqinisekisa umgangatho kunye nokuthembeka.

- Ukuchaneka okuphuculweyo:Oomatshini abazenzekelayo banokuchaneka okuphezulu kunye nokuchaneka, ukuvelisa iindawo ezinokunyamezela okuqinileyo kunye neejometri ezinzima.

- Iindleko zabasebenzi ezicuthiweyo:Iinkqubo zokubumba inaliti ngokuzenzekelayo kunokunciphisa imfuno yomsebenzi wezandla, ukunciphisa iindleko zabasebenzi.

- Ukhuseleko oluphuculweyo:Oomatshini abazenzekelayo banokwenza imisebenzi enobungozi kubantu, ukuphucula ukhuseleko kwindawo yokuvelisa.

- Inkunkuma yezinto ezincitshisiweyo:Oomatshini abazenzekelayo banokuvelisa iindawo ezinobuncwane obuncinci bezinto eziphathekayo, ukunciphisa iindleko zempahla kunye nefuthe lokusingqongileyo.

Iinkqubo zokuBumba isitofu ngokuzenzekela:

Nazi ezinye zeendlela zokusebenzisa inkqubo yokubumba inaliti:

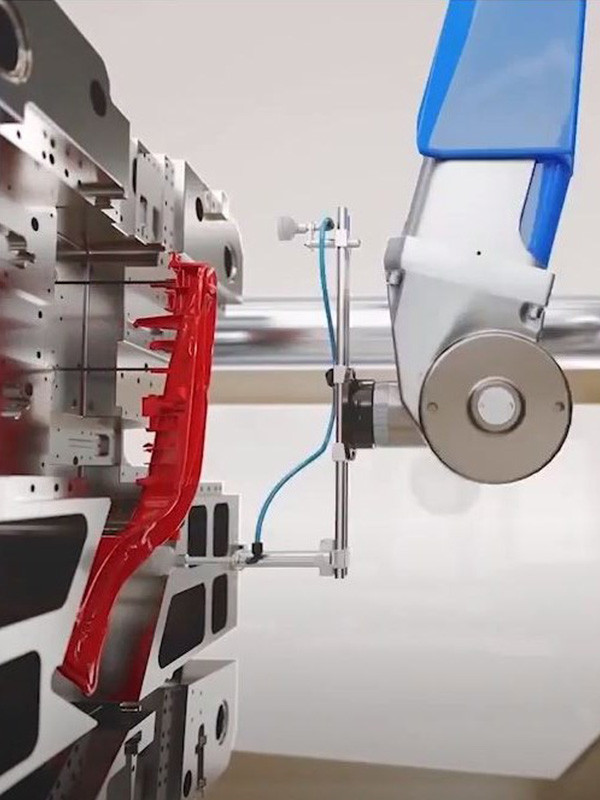

- I-Automation yeRobhothi:Iirobhothi zinokwenza imisebenzi efana nokulayisha kunye nokukhulula iindawo, ukuhlola iindawo, kunye nokupakisha iimveliso ezigqityiweyo. I-Robotic automation inokunyusa kakhulu isantya kunye nokuchaneka kweenkqubo zokubumba inaliti.

- Ukuphathwa kwezinto ezizenzekelayo:Iinkqubo zokuphatha izinto ezizenzekelayo zinokuthutha izinto kumatshini wokubumba inaliti, ukunciphisa imfuno yomsebenzi wezandla.

- Ulawulo lomgangatho oluzenzekelayo:Iinkqubo zokulawula umgangatho ngokuzenzekelayo zinokuhlola iindawo zokukhubazeka kunye nokuphambuka, ukuqinisekisa umgangatho ohambelanayo kunye nokunciphisa imfuno yokuhlolwa ngesandla.

- Esweni Real-ixesha: Ezi nkqubo zinokulandelela ukusebenza komatshini kwaye zichonge imiba yexesha langempela, ukunciphisa ixesha lokuphumla kunye nokuphucula ukusebenza kakuhle.

Imiceli mngeni yokuZisebenzela kwiiNkqubo zokuBumba isitofu:

Nangona iinkqubo zokubumba inaliti ngokuzenzekelayo zineenzuzo ezininzi, zikwanika imingeni ethile:

- Iindleko eziphezulu zangaphambili:Iinkqubo zokubumba inaliti ngokuzenzekelayo zinokubiza ngenxa yeendleko zezixhobo kunye nokuphunyezwa.

- Ukonyuka kobunzima:Iisistim ezizisebenzelayo zintsonkothe ngakumbi kunezixokelelwano zezandla, zifuna uqeqesho olukhethekileyo nololongo.

- Ukunciphisa ububhetyebhetye:Iinkqubo ezizenzekelayo aziguquguquki kakhulu kuneenkqubo zezandla, okwenza kube nzima ukulungelelanisa utshintsho kwiimfuno zemveliso.

Imingeni kunye neMida yeMicimbi yePlastiki yeMoto yeZinto zokuSebenza

Nangona kunjalo, eminye imiceli mngeni kunye nemida kufuneka ithathelwe ingqalelo xa usebenzisa isitofu sokubumba izinto zeplastiki zemoto. Kule posi yebhlog, siza kuxoxa ngeminye yemiceli mngeni kunye nemida yokubumba izinto zeplastiki zemoto.

Imicelimngeni yokuBunjwa kweZinto zePlastiki yeZithuthi:

Nantsi eminye yemiceli mngeni yokwenziwa kwentolo yeplastiki yemoto:

- Ukukhethwa kwezinto:Ukukhetha imathiriyeli echanekileyo yokubumba iintsimbi zeplastiki yemoto kunokuba ngumngeni. Izinto eziphathekayo kufuneka zomelele, zomelele, kwaye zimelane namaqondo obushushu agqithisileyo kunye neemeko ezirhabaxa zokusingqongileyo.

- Iindleko zezixhobo:Iindleko zesixhobo sokubumba inaliti zinokubiza, ngakumbi kwiindawo ezintsonkothileyo ezinoyilo oluntsonkothileyo.

- Uyilo lwenxalenye:Ukuyila iinxalenye zokubumba inaliti kunokuba ngumceli mngeni, njengoko uyilo kufuneka luthathele ingqalelo izinto ezinjengokubumba, ukushwabana, kunye ne-warping.

- Ulawulo lwemeko:Ukuqinisekisa umgangatho ongaguquguqukiyo kunye nokusebenza kwezinto zeplastiki ezenziwe ngenaliti yemoto kunokuba ngumngeni ngenxa yemathiriyeli, inkqubo, kunye nokwahluka kwezixhobo.

Unyino lokuBunjwa kweMithombo yePlastiki yeMoto:

Nantsi eminye imida yokwenziwa kwentolo yeplastiki yemoto:

- Ubungakanani bomlinganiselo:Ukubumba isitofu kunomlinganiselo wobungakanani, kwaye akunakukwazi ukuvelisa amacandelo amakhulu eplastiki yemoto usebenzisa ukubumba inaliti.

- Umthamo wemveliso:I-injection molding ifaneleke kakhulu kwimveliso yomthamo ophezulu kwaye ingabi neendleko ezisebenzayo kwimveliso ephantsi.

- Ukutsala nzima:Isitofu sokubumba asifaneleki kumalungu anejometri entsonkothileyo okanye uyilo olufuna izixhobo ezininzi okanye indibano.

- Impembelelo yokusingqongileyo:I-injection molding ivelisa inkunkuma kwaye isebenzisa izixhobo ezingahlaziyekiyo, ezinokulimaza indalo.

Ukoyisa imingeni kunye neMida:

Nazi ezinye iindlela zokoyisa imiceli mngeni kunye nezithintelo zokubumba izinto zeplastiki zemoto:

- Ukukhethwa kwezinto:Ukukhetha imathiriyeli efanelekileyo yokubumba inaliti kufuna ukuba kuqwalaselwe ngononophelo iimfuno zecandelo kunye nokusebenza. Abavelisi banokusebenza kunye nababoneleli ukukhetha izixhobo ezihlangabezana neemfuno ezithile zenxalenye.

- Iindleko zezixhobo:Ukutyalomali kwizixhobo ezikumgangatho ophezulu kunokunciphisa iindleko kwixesha elide ngokunciphisa ixesha lokunciphisa kunye nokwandisa imveliso.

- Uyilo lwenxalenye:Ukuphucula uyilo lwenxalenye yokubumba inaliti kufuna intsebenziswano phakathi kwabayili, iinjineli, kunye neengcali zokuvelisa ukuqinisekisa ukuba inxalenye inokuveliswa ngokufanelekileyo nangokufanelekileyo kusetyenziswa isitofu sokubumba.

- Ulawulo lwemeko:Ukusebenzisa iinkqubo zokulawula umgangatho ezizenzekelayo kunokuphucula ukungaguquguquki kunye nokunciphisa ukuguquguquka kwinqanaba lomgangatho.

Izinto ezintsha kwiTekhnoloji yokuBumba isitofu

Isitofu sokubumba yinkqubo yokuvelisa esetyenziswa ngokubanzi ukuvelisa iinxalenye zeplastiki ezinzima. Kubandakanya ukutofa imathiriyeli yeplastiki etyhidiweyo kwisingundo esiphantsi koxinzelelo oluphezulu kunye nokuyipholisa ukuze yenze ubume obufunekayo. Ngokukhula kwemfuno yokuchaneka kunye nokusebenza kakuhle kwishishini lemveliso, izinto ezintsha kwitekhnoloji yokubumba inaliti idlale indima ebalulekileyo ekufezekiseni ezi mfuno. Kwesi sithuba sebhlog, siza kuphonononga ezinye zezinto zamva nje kubugcisa bokubumba inaliti.

- Ukubumba isitofu esincinci: Ubuchwephesha buvumela ukuveliswa kwamalungu amancinci kakhulu, kunye nokunyamezela okuphantsi njenge-microns ezimbalwa. Ukubunjwa kwe-Micro-injection kubaluleke kakhulu kumashishini ezonyango kunye ne-electronics, apho imfuno yezinto ezincinci, eziyinkimbinkimbi zisanda.

- Ukubumba amacandelo amaninzi: Le nkqubo ibandakanya ukutofa izinto ezahlukeneyo kwisikhuseli esifanayo, ukuvumela ukuveliswa kwamalungu anemibala emininzi okanye izinto. Le teknoloji iqhele ukusetyenziswa kwimizi-mveliso yeemoto kunye nempahla yabathengi.

- Ukuhombisa okungaphakathi komngundo:Le teknoloji ibandakanya ukongeza imizobo, ukuthungwa, kunye neepateni kwiindawo ezibunjiweyo ngexesha lokubumba. Umhlobiso we-in-mold yindlela engabizi kakhulu yokufezekisa ukugqitywa komgangatho ophezulu ngaphandle kokucubungula okongeziweyo.

- Ukubumba ngokufakwa ngokudibeneyo: Le teknoloji ifaka izinto ezimbini ngaxeshanye, idala inxalenye ngesikhumba kunye neyona nto ingundoqo. Ukubumba i-co-injection luncedo ekudaleni iinxalenye ezine-soft-touch feel okanye iipropathi eziphuculweyo zomatshini.

- Ukubumba isitofu esincediswa yigesi:Le teknoloji ibandakanya ukutofa irhasi, ngokuqhelekileyo initrogen, kwimold ngexesha lokubumba inaliti. Irhasi yenza imijelo ngaphakathi kwenxalenye, ukunciphisa ukusetyenziswa kwezinto kunye nokuphucula ukusebenza kwemveliso.

- Ukubumba inaliti yesantya esiphezulu:Le teknoloji ivumela ukukhawuleza kwesantya sokutofa kunye namaxesha okujikeleza, ukwandisa ukusebenza kakuhle kwemveliso kunye nokunciphisa iindleko. Ukubunjwa kwenaliti yesantya esiphezulu kubaluleke kakhulu ekuveliseni iindawo ezinodonga olubhityileyo.

- Ukubumba ngobukrelekrele: Le teknoloji isebenzisa i-sensor kunye ne-analytics yedatha ukulungiselela inkqubo yokubumba inaliti. Ukubumba ngobukrelekrele kunokuphucula umgangatho wemveliso kunye nokunciphisa inkunkuma ngokubeka iliso kwizinto ezifana nobushushu, uxinzelelo, kunye nokuhamba kwezinto.

Ukukhanya kweSicelo: Izixhobo zePlastiki zangaphakathi

Kwishishini leemoto, uyilo lwangaphakathi kunye nokusebenza kubalulekile ukuhambisa amava okuqhuba aphezulu. Amacandelo eplastiki angaphakathi adlala indima ebalulekileyo ekufezekiseni le njongo, ebonelela ngentuthuzelo, isimbo, kunye nokuqina. Esi sithuba sebhlog siya kuphonononga ezinye zezona zinto zisetyenziswa ngokuqhelekileyo kwiplastiki ngaphakathi kweemoto.

- I-Dashboard: Ideshibhodi luphawu lwangaphakathi olubalaseleyo olubandakanya iigeyiji, iiventi zomoya, iinkqubo zeinfotainment, kunye nolunye ulawulo olubalulekileyo. Amalungu ePlastiki aqhele ukusetyenziswa ukwenza iidashbhodi ngenxa yokuqina kwazo, ukuguquguquka koyilo, kunye nokucutshungulwa ngokulula.

- Iiphaneli zeengcango:Iipaneli zomnyango ziyimfuneko kuyilo lwangaphakathi, ukubonelela ngokukhusela nokuthuthuzela. Amacandelo eplastiki ahlala esetyenziselwa ukwenza iipaneli zeengcango ngenxa yokukwazi ukumelana neempembelelo, ukunciphisa ingxolo, kunye neempawu ezilula.

- Izihlalo:Izihlalo zeemoto zifuna izinto eziphezulu zokusebenza ezinika induduzo kunye nenkxaso. Amacandelo eplastiki asetyenziselwa ukudala izihlalo zokuhlala, iindawo zokuhlala, kunye nezinye iindawo zokuhlala. Ezi zixhobo zinika amandla kunye nokuguquguquka kwaye zinokubunjwa ngokulula ukuze zihambelane noyilo olwahlukileyo.

- Ikhonsoli yombindi:Icentre console liziko lolawulo olubalulekileyo olufana nolawulo lwemozulu, iinkqubo zeaudio, kunye nokugcinwa. Amalungu ePlastiki aqhele ukusetyenziswa ukwenza iziko lokuthuthuzela ngenxa yokukwazi ukumelana nobushushu, ukufuma, kunye nezinye izinto zokusingqongileyo.

- Iiphaneli zokunquma: Iipaneli ze-Trim zisetyenziselwa ukugubungela iindawo zangaphakathi zesithuthi, njengeentsika, i-headliners, kunye nezihlalo zokuhlala. Amacandelo eplastiki asetyenziselwa ukwenza ezi panels ngenxa yokuguquguquka koyilo, iindidi zemibala, kunye nokulula ukusetyenzwa.

I-Spotlight Spotlight: Izixhobo zePlastiki zangaphandle

Izinto zeplastiki zangaphandle ziye zaxhaphaka ngakumbi kwishishini leemoto. Ngemfuno yezinto ezikhaphukhaphu, ukuphuculwa kokusebenza kwepetroli, kunye noyilo oluyilayo, izinto zeplastiki ziye zaba lukhetho oludumileyo ekwenzeni iindawo ezahlukeneyo zangaphandle zezithuthi. Kule post yebhlog, siza kuphonononga ezinye zezona zinto ziqhelekileyo zisetyenziswa ngaphandle kweplastiki kushishino lweemoto.

- Iibhampa: Iibhampa ziyinxalenye ebalulekileyo yangaphandle ekhusela isithuthi xa kukho ukungqubana. Amalungu ePlastiki ahlala esetyenziselwa ukwenza ii-bumpers kuba zikhaphukhaphu, ziyakwazi ukumelana nefuthe, kwaye azibizi.

- Iigrile: Igrille luphawu olubalaseleyo lwangaphandle lwesithuthi, kwaye idlala indima ebalulekileyo kuyilo lwaso ngokubanzi kunye ne-aerodynamics. Amacandelo eplastiki asetyenziswa ngokuqhelekileyo ukwenza iigrille ngenxa yokuguquguquka koyilo kunye nokukwazi ukubunjwa kwiimilo ezinzima.

- Izilungisi zangaphandle:Izixhobo zangaphandle ziquka ukubumba, ukuvutha kweefender, kunye nezinye izinto zokuhombisa eziphucula ukubonakala kwesithuthi. Amacandelo eplastiki ahlala esetyenziselwa ukuvelisa ezi ngqungquthela kuba zinokuba nemibala kwaye zenziwe, zibonelela ngeendlela ezininzi zokuyila.

- Izibuko: Izibuko ziyinxalenye ebalulekileyo yayo nayiphi na isithuthi, ebonelela ngokubonakala kunye nokhuseleko. Amacandelo eplastiki ahlala esetyenziselwa ukwenza izindlu zesipili ngenxa yeempawu zazo ezikhaphukhaphu, ukuchasa impembelelo, kunye nokuguquguquka koyilo.

- Abaphangi: I-Spoilers yongezwa okudumileyo kwizithuthi ezininzi, ukuphucula i-aerodynamics kunye nokuphucula ukubonakala ngokubanzi. Amacandelo eplastiki ahlala esetyenziselwa ukwenza abaphangi ngenxa yobunzima babo kunye nokuguquguquka koyilo.

Ikamva le-Automotive Plastic Components Ukubunjwa kwesitofu

Izinto zeplastiki eziziimoto zokubumba inaliti iye yaba yinto ebalulekileyo kushishino lweemoto. Njengoko iteknoloji iqhubela phambili, ikamva lale nkqubo libonakala lithembisa. Nazi ezinye iindlela kunye noqikelelo lwekamva lezinto zeplastiki zemoto zokubumba inaliti:

- Ukusetyenziswa okongeziweyo kweZixhobo eziKhala: Izinto ezilula ezifana ne-carbon fiber kunye ne-thermoplastics ziya zithandwa kakhulu kwishishini leemoto. Oku kungenxa yeenzuzo zabo ngokubhekiselele ekusebenzeni kakuhle kwamafutha, ukusebenza, kunye nokunciphisa ukukhutshwa. Ngenxa yoko, izinto zeplastiki zemoto zokubumba isitofu ziya kudlala indima ebalulekileyo ekuveliseni ezi mathiriyeli zikhaphukhaphu.

- Ukudityaniswa kweMveliso eyoNgezelelweyo:Imveliso eyongezelelweyo, eyaziwa ngokuba yi-3D yoshicilelo, iya ixhaphake kakhulu kushishino lweemoto. Obu buchwephesha buvumela ukuyilwa kweejometri ezintsonkothileyo kunye neemilo eziya kuba nzima okanye zingenzeki ukuvelisa kusetyenziswa ukubumba inaliti yesintu. Kwixesha elizayo, izinto zeplastiki zemoto zokubumba isitofu zinokudibanisa imveliso eyongezelelweyo kwimveliso ukwenza uyilo oluntsonkothileyo.

- Ukwandiswa kokuzenzekela: Njengoko itekhnoloji ihambela phambili, sinokulindela ukubona i-automation ngakumbi kwinkqubo yokubumba inaliti. Oku kuya kukhokelela ekwandeni kobuchule kunye nokuncipha kwamaxesha emveliso. Ukongeza, i-automation inokunciphisa ukubakho kwempazamo yomntu, okukhokelela kwiimveliso ezikumgangatho ophezulu.

- Izinto eziZinzo ngakumbi: Uzinzo luba ngumba okhulayo obaluleke ngakumbi kushishino lweemoto. Izinto zeplastiki eziziimoto zokubumba isitofu ziya kufuna ukuziqhelanisa nale ndlela ngokusebenzisa imathiriyeli ezinzileyo. Ngokomzekelo, iiplastiki ezisekelwe kwi-bio kunye nezixhobo ezihlaziyiweyo zingasetyenziselwa inkqubo yokubumba inaliti ukunciphisa inkunkuma kunye nokukhutshwa kwekhabhoni.

- Ukwandiswa koLungiso:Abathengi baya besiba nesidingo ngakumbi malunga nokwenziwa ngokwezifiso kunye nobuntu. Kwixesha elizayo, izinto zeplastiki eziziimoto zokubumba isitofu zinokubandakanya itekhnoloji evumela ukwenziwa ngokwezifiso okukhulu kweemveliso. Oku kunokubandakanya ukukwazi ukwenza uyilo, umbala, kunye nokuthungwa kwezinto zeplastiki.

- Ukudityaniswa kwe-Smart Technologies: Itekhnoloji ye-Smart efana ne-sensor kunye ne-Intanethi yeZinto (IoT) izixhobo ziya zixhaphake ngakumbi kushishino lweemoto. Kwixesha elizayo, izinto zeplastiki eziziimoto zokubumba isitofu zinokubandakanya obu buchwepheshe kwimveliso. Oku kunokuvumela ukudala amacandelo anokunxibelelana namanye amalungu esithuthi kunye nomqhubi.

Uphononongo oluyiNyaniso: UkuPhunyezwa okuFanelekileyo kokuBunjwa kwesitofu kuShishino lweziThuthi

I-injection molding yinkqubo yokuvelisa esetyenziswa ngokubanzi eye yanda kakhulu kwishishini leemoto. Kule posi yebhlog, siza kuxoxa ngesifundo somzekelo wokuphunyezwa ngempumelelo kwenaliti yokubumba kwishishini leemoto.

Ityala: UkuKhanya kweeMoto

Enye indawo apho ukubunjwa kwenaliti kuye kwaphumelela ngakumbi kushishino lweemoto kukuveliswa kwezinto zokukhanyisa iimoto. Kulo mzekelo, siza kugxila ekuphumezeni isitofu sokubumba ukuvelisa i-taillight lens yemodeli ethandwayo ye-sedan.

Iingxaki:

I-taillight lens kwafuneka ihlangabezane nezi mfuno zilandelayo:

- Ukumelana nokukhanya kwe-UV kunye nemozulu

- Ukucaca kakuhle kwe-optical

- ukuhlala ixesha elide

- Uyilo olukholisa ukubukeka

- Ixesha elisebenzayo lokuvelisa

isisombululo:

Emva kokuhlalutya iimfuno kunye nemiceli mngeni, umenzi wokukhanyisa iimoto wakhetha ukubumba inaliti njengesisombululo esona sisombululo sokuvelisa i-taillight lens. Umenzi ubambisene nenkampani yokubumba inaliti enamava enerekhodi yokuvelisa amacandelo emoto akumgangatho ophezulu.

Inkqubo yokubumba inaliti ibandakanya la manyathelo alandelayo:

- Ukukhethwa kwezinto:Isixhobo sepolycarbonate esinganyangekiyo kwi-UV sakhethwa kwilensi yokukhanya.

- Uyilo lokungunda:Inkampani yokubumba isitofu yenzelwe ukubumba isiko ukuvelisa ilensi yomsila ukuhlangabezana neenkcukacha ezifunekayo.

- Ukubumba ukutofa:Umngundo ke wasetyenziswa kwinkqubo yokubumba inaliti ukuvelisa ilensi yomsila.

- Ulawulo lwemeko:I-taillight lens yayiphantsi kwemilinganiselo engqongqo yokulawula umgangatho ukuqinisekisa ukuba ihlangabezana nemigangatho efunekayo.

iziphumo:

Ukuphunyezwa kwesitofu sokubumba kwimveliso ye-taillight lens kubonakalise ukuba yimpumelelo. Umenzi wokukhanyisa iimoto uvelise i-lens yomgangatho ophezulu we-taillight edibana nazo zonke iinkcukacha ezifunekayo.

Iinzuzo zokusebenzisa isitofu sokubumba kwesi sicelo ziquka:

- Umgangatho ohambelanayo:Ukubunjwa kwe-injection kuqinisekise umgangatho ohambelanayo we-taillight lens, edibana nemigangatho efunekayo.

- Imveliso esebenzayo: Inkqubo yokubumba i-injection ivumele ukuveliswa ngokufanelekileyo kwe-taillight lens, okukhokelela ekunciphiseni ixesha lokuvelisa kunye neendleko.

- Uyilo oluthandekayo:Isitofu sokubumba sivumeleke ekudaleni uyilo lobuhle obukholisayo kwi-taillight lens.

- Ihlala: Ilensi yomsila eveliswe ngokubumba inaliti yomelele kwaye imelana nokukhanya kwe-UV kunye nemozulu.

Iingcamango ezingezizo eziQhelekileyo malunga nokuBunjwa kwesitofu

Isitofu sokubumba yinkqubo yokuvelisa esetyenziswa ngokubanzi ebandakanya ukutofwa kwemathiriyeli enyibilikisiweyo ibe ngumngundo ukwenza ubume obunqwenelekayo. Nangona kunjalo, ezininzi iingcamango eziphosakeleyo malunga nokubunjwa kwenaliti kunokukhokelela ekungaqondani malunga nenkqubo. Esi sithuba sebhlog siza kuxoxa ngezinye iingcamango ezingalunganga malunga nokubumba inaliti.

Ubuxoki 1: Ukubunjwa kwe-injection kulungele kuphela ukuvelisa ubuninzi beemveliso.

Uninzi lukholelwa ukuba ukubumba inaliti kufanelekile kuphela ukuvelisa inani elikhulu leemveliso. Ngelixa ukubunjwa kwenaliti kunokuvelisa inani elikhulu leemveliso, kunokusetyenziselwa ukuqhuba okuncinci kwemveliso. Isitofu sokubumba sinokusebenza kakuhle kwaye singabizi kakhulu ukuvelisa imveliso encinci ukuya kwephakathi.

Ubuxoki 2: Isitofu sokubumba yinkqubo ecothayo.

Enye impazamo eqhelekileyo malunga nokubumba inaliti kukuba yinkqubo ecothayo. Ngelixa kuyinyani ukuba ukubumba inaliti kufuna ubungakanani bexesha lokuseta, yakuba inkqubo iphezulu kwaye iqhuba, inokuvelisa inani elikhulu leemveliso ngokukhawuleza nangokufanelekileyo. Ukongeza, ukuqhubela phambili kwetekhnoloji kuvumele ukukhawuleza koomatshini bokubumba kunye neenkqubo.

Ubuxoki 3: Ukubunjwa kwe-injection kulungele kuphela ukuvelisa iimilo ezilula.

Ukubumba isitofu kuhlala kunxulunyaniswa nokuvelisa iimilo ezilula, kodwa oku akuyonyani. Ukuqhubela phambili kuyilo lokubumba kunye nokukhethwa kwezinto eziphathekayo kuye kwavumela ukuveliswa kweemilo ezinobunzima kunye noyilo ngokubumba inaliti. Ukongeza, ukudityaniswa koshicilelo lwe-3D kunye nezinye iitekhnoloji ziye zandisa amathuba okubumba inaliti ngakumbi.

Ubuxoki 4: Isitofu sokubumba asiyongozi kwendalo.

Isitofu sokubumba sisoloko sigxekwa ngokungakhathaleli indalo esingqongileyo. Ngelixa kuyinyani ukuba ukubumba inaliti kuyayidala enye imathiriyeli eyinkunkuma, ukuqhubela phambili ekukhetheni imathiriyeli kunye nobuchwepheshe bokurisayikilisha kuvumele ukuveliswa kweemveliso ezihambelana nokusingqongileyo ngokubumba inaliti. Ukongeza, ukubunjwa kwenaliti kuvumela ukuveliswa kwezinto ezikhaphukhaphu kunye nezizinzileyo ezinokunceda ukunciphisa i-carbon footprint yeemveliso.

Ubuxoki 5: Ukubumba isitofu kuyabiza.

Abantu abaninzi bakholelwa ukuba ukubumba inaliti yinkqubo yokuvelisa ebiza imali eninzi. Ngelixa kuyinyani ukuba kukho iindleko ezingaphambili ezinxulumene nokubumba inaliti, njengexabiso lokuyila kunye nokuvelisa imibumbo, ixabiso ngeyunithi liyancipha njengoko umthamo wemveliso unyuka. Ukongeza, ukuqhubela phambili kwetekhnoloji kwenze ukuba isitofu sisebenze kakhulu kwaye sisebenze ngokufanelekileyo kunangaphambili.

Ukucombulula iingxaki kwiMiba eQhelekileyo kwi-Injection Molding

Isitofu sokubumba yinkqubo yokuvelisa esetyenziswa ngokubanzi evelisa amacandelo eplastiki ekumgangatho ophezulu kumashishini ahlukeneyo. Nangona kunjalo, njengayo nayiphi na inkqubo yokuvelisa, ukubumba inaliti kunokufumana imiba eqhelekileyo enokuchaphazela kakubi imveliso yokugqibela. Kule post yebhlog, siza kuxoxa ngemiba eqhelekileyo ekubumbeni inaliti kunye nendlela yokuyicombulula.

Umba 1: Amanqaku atshisiweyo

Amanqaku okutshisa anokuvela kumphezulu wamalungu abunjiweyo enaliti ngenxa yokutshisa okugqithisileyo, okubangela ukuthotywa kwentlaka kunye nokuguquka kombala. Lo mbandela unokubangelwa luluhlu lwezinto, eziquka:

- Ubushushu obuphezulu bokunyibilika

- Ixesha elide lokuhlala

- Ixesha lokupholisa elingafanelekanga

- Isantya esiphezulu sokutofa

Ukulungisa iingxaki zokutsha, abavelisi kufuneka baqwalasele la manyathelo alandelayo:

- Yehlisa ubushushu obunyibilikayo

- Ukunciphisa ixesha lokuhlala

- Yandisa ixesha lokupholisa

- Nciphisa isantya sokutofa

Umba 2: Ukulwa

I-Warping yinto eqhelekileyo ekubunjweni kwenaliti enokuthi yenzeke ngenxa yokupholisa okungalinganiyo kwezinto. Oku kunokubangela ukuba imveliso yokugqibela igqwethwe okanye igqwethwe, enokuthi ichaphazele kakubi ukusebenza kwayo. Lo mcimbi unokubangelwa zizinto ezininzi, eziquka:

- Ukupholisa okungalinganiyo

- Uxinzelelo lokupakisha olunganelanga

- Uyilo lokungunda olungafanelekanga

Ukusombulula ingxaki, abavelisi kufuneka baqwalasele la manyathelo alandelayo:

- Qinisekisa nokuba kuyaphola kulo lonke ubumba

- Ukwandisa uxinzelelo lokupakisha

- Lungisa uyilo lokungunda ukuphucula inxalenye yejometri

Umba 3: Amanqaku eSinki

Amanqaku eSinki luxinzelelo olunokuthi lwenzeke kumphezulu wamalungu abunjiweyo ngenxa yokupholisa okungalinganiyo okanye ukupakishwa. Lo mcimbi unokubangelwa zizinto ezininzi, eziquka:

- Isantya esiphezulu sokutofa

- Uxinzelelo lokupakisha olunganelanga

- Ubushushu obuphezulu bokunyibilika

- Ixesha elide lokuhlala

Ukusombulula ingxaki yamanqaku e-sink, abavelisi kufuneka baqwalasele la manyathelo alandelayo:

- Nciphisa isantya sokutofa

- Ukwandisa uxinzelelo lokupakisha

- Yehlisa ubushushu obunyibilikayo

- Ukunciphisa ixesha lokuhlala

Umba 4: Ukudanyaza

Ukudanyaza ngumba oxhaphakileyo ekubumbeni inaliti eyenzeka xa imathiriyeli engaphezulu icudiswa ngaphandle kokungunda. Oku kunokubangela ukuba izinto ezingaphezulu zibonakale zijikeleze imiphetho yemveliso yokugqibela, enokuthi ichaphazele kakubi ubuhle kunye nokusebenza kwayo. Lo mcimbi unokubangelwa zizinto ezininzi, eziquka:

- Amalungu okungunda agugileyo

- Amandla okubamba anganelanga

- Ixesha lokupholisa elingafanelekanga

Ukusombulula ingxaki yokudanyaza, abavelisi kufuneka baqwalasele la manyathelo alandelayo:

- Tshintsha amalungu okungunda agugileyo

- Yandisa amandla okubamba

- Yandisa ixesha lokupholisa

Ulwazi lweNgcali: Udliwano-ndlebe kunye naBachwephesha boShishino kwi-Automotive Injection Molding

Ukubumba isitofu yinkqubo ebalulekileyo kushishino lweemoto, ukuvelisa izinto zeplastiki ezikumgangatho ophezulu kwiindawo ezahlukeneyo zezithuthi. Siye sathetha neengcali zeshishini ezabelana ngezimvo zabo zobuchwephesha kunye nokuqonda malunga nokubumba inaliti yemoto ukufumana ulwazi malunga neshishini kunye nemeko yalo yangoku.

Ingcali 1: UJohn Doe, i-CEO yeNkampani yokuBumba i-Injection

- U-Doe wabelane ukuba ukusetyenziswa kwe-bioplastics kwishishini leemoto kuya kuthandwa kakhulu. Ezi plastiki zinobuhlobo nokusingqongileyo kwaye zinokunciphisa i-carbon footprint yesithuthi, ibenze ibe yindlela ekhangayo kubenzi beemoto.

- Ukwaphawule ukuba inkqubela phambili yoshicilelo lwe-3D ivumele ukuyilwa kokungunda okuntsonkothileyo, okukhokelela kwiimveliso ezikumgangatho ophezulu.

- Ngokumalunga nemingeni, ukhankanye ukunqongophala kwabasebenzi abanezakhono njengomba obalulekileyo kwishishini, okukhokelela kwiindleko eziphezulu zabasebenzi.

Ingcaphephe yesi-2: uJane Smith, iNjineli yoYilo kwiNkampani yeeMoto

- USmith wabelane ukuba kukho ukukhula okukhulayo kwishishini kwizinto ezilula, ezifana ne-composites kunye neeplastiki, ukuphucula ukusebenza kakuhle kwamafutha kunye nokunciphisa ukukhutshwa.

- Uye waphawula ukuba ukusebenzisa isoftware yokulinganisa kwinkqubo yoyilo kuye kwanda ukuthandwa, oku kuvumela uphuhliso lwemveliso olusebenzayo kunye nexabiso eliphantsi.

- Ngokuphathelele imiceli mngeni, ukhankanye ukwanda kokuntsonkotha kwamacandelo eemoto kunye nesidingo seenkqubo zokwenziwa ezichanekileyo.

Ingcali ye-3: UBob Johnson, uMphathi woLawulo loMgangatho kwiNkampani yokuBumba i-Injection

- UJohnson wabelane ngokuba ulawulo lomgangatho lubalulekile kwishishini leemoto. Nokuba iziphene ezincinci zinokubeka esichengeni ukhuseleko kunye nokusebenza.

- Waphawula ukuba ukuqhubela phambili kwezobuchwepheshe, njengeenkqubo zokuhlola ngokuzenzekelayo, ziye zavumela iinkqubo zokulawula umgangatho ochanekileyo kunye nochanekileyo.

- Ngokubhekiselele kwimingeni, ukhankanye imfuno ekhulayo yamaxesha okuvelisa ngokukhawuleza ngelixa egcina imigangatho ephezulu.

Ingcali ye-4: USarah Lee, uMmeli weNtengiso kwiNkampani yokuBumba i-Injection

- U-Lee wabelane ngokuba iimfuno zabathengi zihlala zivela, ngokugxila okukhulayo kuzinzo kunye nokusebenza kakuhle kweendleko.

- Uqaphele ukuba unxibelelwano kunye nentsebenziswano phakathi kwabavelisi kunye nabathengi kubalulekile ukuqinisekisa ukuba imveliso yokugqibela ihlangabezana nemigangatho efunekayo kunye nokulindelweyo. Ngokumalunga nemiceli mngeni, ukhankanye ukwanda kokhuphiswano kwishishini kunye nesidingo seenkampani zokubumba iinaliti ukuba zizahlule ngokwenza izinto ezintsha kunye nomgangatho.

isiphelo

Njengoko ishishini leemoto liqhubeka nokuvela, ukubumba inaliti kuhlala kuyinkqubo ebalulekileyo yokuvelisa ukuvelisa izinto zeplastiki ezikumgangatho ophezulu. Nokuba iinxalenye zangaphakathi okanye zangaphandle, ukubumba inaliti kunika inkululeko yoyilo olumangalisayo, ukusebenza kakuhle, kunye nozinzo. Abavelisi banokuvula amathuba amatsha okudala iimoto ezintsha nezithembekileyo ngokuqonda ubucukubhede bezinto zeplastiki zemoto zokubumba inaliti. Hlala ubukele le bhlog ukuze ufumane ulwazi oluthe kratya kwihlabathi lokubumba inaliti kunye nefuthe layo kushishino lweemoto.