Yintoni ukubumba inaliti yeplastiki

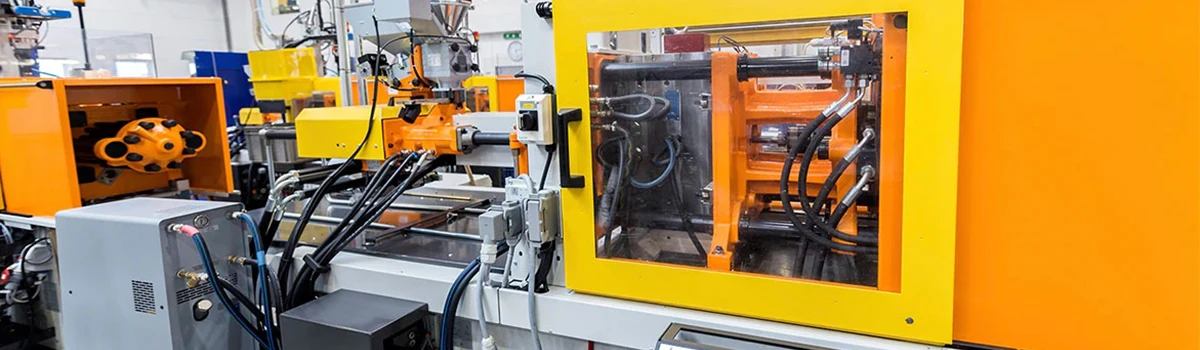

Ukubumba inaliti ye-Thermoplastic yindlela yokwenza iindawo ezinomthamo ophezulu kunye nezixhobo zeplastiki. Ngenxa yokuthembeka kwayo kunye nokuguquguquka kwiinketho zoyilo, ukubumba inaliti kusetyenziswa kumashishini amaninzi, kubandakanya: ukupakisha, abathengi kunye ne-elektroniki, iimoto, unyango, kunye nokunye okuninzi.

Ukubumba isitofu yenye yezona nkqubo zisetyenziswa ngokubanzi kwihlabathi. I-Thermoplastics zi-polymers ezithambileyo kwaye zihamba xa zishushu, kwaye ziqina njengoko zipholile.

izicelo

Isitofu sokubumba yeyona ndlela ixhaphakileyo yanamhlanje yokwenza iinxalenye zeplastiki; ilungele ukuvelisa umthamo ophezulu wento enye. Ukubunjwa kwe-injection kusetyenziselwa ukudala izinto ezininzi, kubandakanywa i-spools yocingo, ukupakishwa, iibhotile, iinqununu zemoto kunye namacandelo, i-consoles yokudlala, i-pocket cobs, izixhobo zomculo, izitulo kunye neetafile ezincinci, izitya zokugcina, iinxalenye zoomatshini kunye nezinye iimveliso zeplastiki.

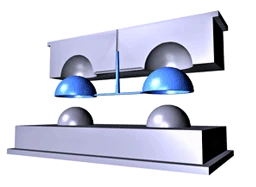

Uyilo lokungunda

Emva kokuba imveliso iyilwe kwiSofthiwe njengepakethe yeCAD, iimbumba zenziwe ngesinyithi, ngokuqhelekileyo intsimbi okanye i-aluminium, kunye nomatshini ochanekileyo ukuze wenze iimpawu zenxalenye efunwayo. Umngundo uqulathe amacandelo amabini aphambili, i-injection mold (A plate) kunye ne-ejector mold (B plate). Intlaka yeplastiki ingena kumngundo nge-sprue, okanye isango, kwaye iqukuqelela kumngxuma wokungunda ngemijelo, okanye iimbaleki, ezenziwe ngoomatshini kubuso beepleyiti zika-A no-B.

Inkqubo yokubumba isitofu

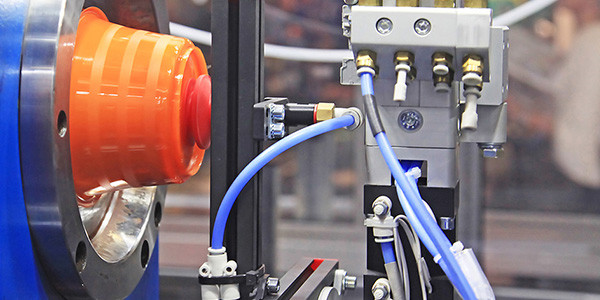

Xa i-thermoplastics ibunjiwe, ngokuqhelekileyo i-pelletized material ekrwada ityiswa nge-hopper kwi-barrel eshushu kunye ne-screw ephindaphindayo. Isikrufu sihambisa imathiriyeli ekrwada phambili, ngevalve yokutshekisha, apho siqokelela ngaphambili kwesikrufu sibe yivolume eyaziwa ngokuba sisityholo.

Isitofu sisixa seresin efunekayo ukuzalisa i-sprue, imbaleki kunye nemingxuma yokungunda. Xa izinto ezaneleyo ziqokelelwe, izinto eziphathekayo zinyanzeliswa kuxinzelelo oluphezulu kunye nesantya kwi-parting forming cavity.

Isebenza Njani Ukubumba Isitofu?

Emva kokuba iplastiki igcwalise i-mold kubandakanywa i-sprues yayo, abagijimi, amasango, njl., i-mold igcinwa kwiqondo lokushisa elimiselweyo ukuvumela ukuqiniswa okufanayo kwezinto kwi-shape shape. Uxinzelelo lokubamba lugcinwa ngelixa ukupholisa kokubini ukuyeka ukubuyisela umva kwi-barrel kunye nokunciphisa imiphumo eyanciphayo. Ngeli xesha, iigranule zeplastiki ezingaphezulu zongezwa kwi-hopper ngokulindela umjikelezo olandelayo (okanye ukudubula). Xa ipholile, i-platen ivula kwaye ivumela inxalenye egqityiweyo ukuba ikhutshwe, kwaye isikrufu sitsalwe kwakhona, sivumela izinto ukuba zingene emgqomeni kwaye ziqale inkqubo kwakhona.

Umjikelezo wokubumba i-injection usebenza ngale nkqubo eqhubekayo-ukuvala isikhunta, ukondla / ukufudumeza iigranules zeplastiki, ukuxinzelela kwi-mold, ukupholisa kwindawo eqinile, ukukhupha inxalenye, nokuvala isikhunta kwakhona. Le nkqubo ivumela ukuveliswa ngokukhawuleza kwamalungu eplastiki, kwaye ngaphezulu kwe-10,000 iinxalenye zeplastiki zingenziwa ngosuku lomsebenzi ngokuxhomekeke kuyilo, ubungakanani kunye nempahla.

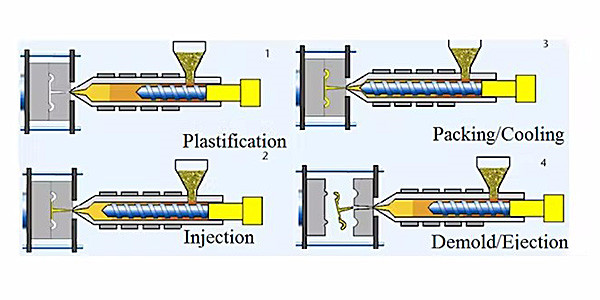

Umjikelo wokubumba isitofu

Umjikelo wokubumba inaliti mfutshane kakhulu, ngokuqhelekileyo phakathi kwemizuzwana emi-2 kunye nemizuzu emi-2 ubude. Kukho izigaba ezininzi:

1.Ukubamba

Ngaphambi kokujova izinto eziphathekayo kwi-mold, ii-halves ezimbini ze-mold zivaliwe, ngokukhuselekileyo, ngeyunithi yokudibanisa. Iyunithi ebambekayo esebenza ngamandla e-hydraulically ityhala iziqingatha zokungunda kunye kwaye isebenzise amandla awoneleyo ukugcina ukungunda kuvaliwe ngelixa izinto zitofwa.

2.Ukutofa

Xa isikhunta sivaliwe, i-polymer shot ifakwe kwi-mold cavity.

3.Ukupholisa

Xa umngxuma ugcwalisiwe, kufakwa uxinzelelo oluvumela ukuba iipolymer ezininzi zingene emngxunyeni ukuze kuhlawulelwe ukucutheka kweplastiki njengoko iphola. Okwangoku, i-screw iyajika kwaye idlise i-shot elandelayo kwisikrufu sangaphambili. Oku kubangela ukuba isikrufu sirhoxe njengoko kulungiselelwa ukudubula okulandelayo.

4.Ukukhutshwa

Xa inxalenye ipholile ngokwaneleyo, isikhunta siyavuleka, inxalenye iyakhutshwa, kwaye umjikelo uqala kwakhona.

eziluncedo

1.Imveliso ekhawulezayo; 2.Design bhetyebhetye; 3.Ukuchaneka; 4. Iindleko zomsebenzi eziphantsi; 5.Inkunkuma ephantsi