Ityala eKorea

Izahlulo zesitofu sePlastiki 'Ukutyeba koLwakhiwo lweZakhiwo zeeNkampani zaseKorea

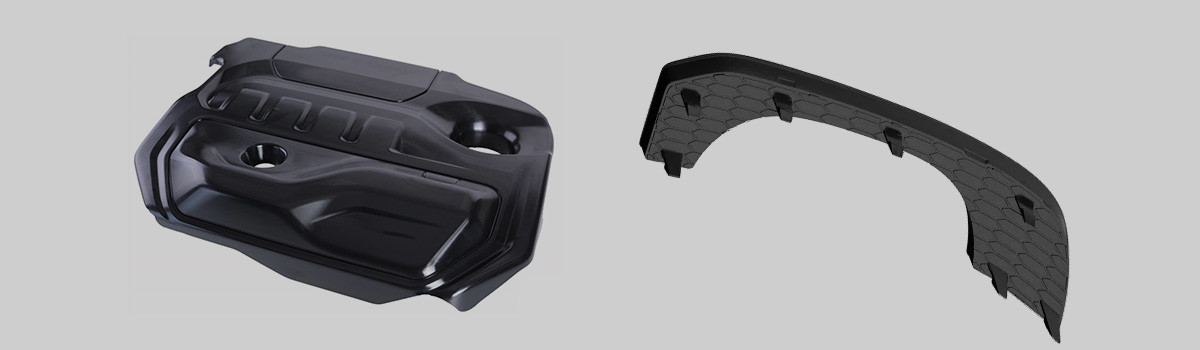

Amalungu eplastiki angenisa kakhulu imoto, kwaye ukuqina kwayo kuya kuba nefuthe kubomi kunye nokuqhuba ngokukhuselekileyo, ke abavelisi baseKorea Auto bathenga iinxalenye zeplastiki zingqongqo kakhulu. Umzi-mveliso we-Auto uza kusebenzisa iinxalenye ezininzi zeplastiki emotweni, iinkampani zaseKorea zasekuhlaleni zokutofa azikwazi ukubonelela ngobonelelo oluninzi, kwaye aba bavelisi be-Auto baya kuthenga iinxalenye zeplastiki phesheya kolwandle, kanye njengo-DJmolding waseTshayina.

Amalungu eplastiki abaluleke kakhulu kwimoto, ke ungayila njani intsimbi yesitofu seplasitiki yolwakhiwo lwesakhiwo sodonga lweenkampani zaseKorea? Ngoku, i-DJmolding iya kukubonisa uyilo lwezahlulo zesitofu seplastiki.

Inkcazo yobukhulu bodonga

Ubukhulu bendonga luphawu olusisiseko lwamalungu eplastiki. Ukuba indawo yangaphandle yeengxenye zeplastiki ibizwa ngokuba ludonga lwangaphandle, indawo yangaphakathi ibizwa ngokuba ludonga lwangaphakathi, ngoko kukho ixabiso lobunzima phakathi kweendonga zangaphandle nangaphakathi. Ixabiso libizwa ngokuba bubunzima bodonga. Ixabiso elingenisiweyo xa iqokobhe litsalwa kwisoftware ngexesha loyilo lwesakhiwo nalo lunokuthiwa bubunzima bodonga.

Umsebenzi wobunzima bodonga

Kudonga lwangaphandle lweemveliso

Udonga lwangaphandle lufana nolusu lwangaphandle. Udonga lwangaphakathi luyi-skeletons yesakhiwo samalungu. Iziphumo ezahlukeneyo zenkangeleko zinokufezekiswa ngonyango lomphezulu wodonga lwangaphandle lwamalungu. Udonga lwangaphakathi ludibanisa nje izakhiwo (iimbambo, imivalo ye-screw, i-buckle njl.) kunye kwaye yenza amandla athile kwiindawo. Okwangoku, ezinye izakhiwo zinokuzaliswa ngexesha lenkqubo yokubumba usulelo. Akukho mfuneko ethile kwiindonga zangaphakathi nangaphandle (ukupholisa, ukuhlanganisana). Ngokuqhelekileyo, lenziwe ngokupheleleyo ukuze amalungu abe namandla aneleyo okukhusela amalungu angaphakathi ekonakalisweni okanye ekuphazamisekeni kokusingqongileyo.

Kwiindawo zangaphakathi zemveliso

Njengombhobho wokuthwala okanye ukudibanisa, akukho mfuneko engqongqo kwiindonga zangaphakathi nangaphandle, ezinokuseka ezinye izakhiwo (iimbambo, i-screw bars, i-buckles njl njl) eludongeni lwangaphandle ngokwemiqathango yangempela. Nangona kunjalo, ngenxa yokwenziwa lula (ikakhulukazi kubhekiselele xa iimbumba zangaphambili kunye nezingasemva zihlulwe, ukuze kugcinwe iinxalenye zeplastiki kwi-mold yangasemva, ubuso obungaphambili bokubumba, apho udonga lwangaphandle kufuneka luyilwe ngokulula kangangoko kunokwenzeka. Ukuba akunjalo, ukulungelelanisa i-engile yokuyila ye-engile yangaphambili kunye ne-mold yangemva, nokuba ne-thmble kwi-mold yangaphambili okanye i-undercut ethile encinci kwi-mold yangemva), kwaye ngokubanzi ukuyila ezinye izakhiwo kudonga lwangaphakathi.

Kungakhathaliseki ukuba ngamalungu eqokobhe okanye angaphakathi, ubukhulu bodonga bubalulekile njengendawo yokufumana i-ejector pin ye-mold, eyenza ukuba iindawo zikhutshwe kakuhle.

Imigaqo yoyilo yobukhulu bodonga:

Ekuqulunqeni iinxalenye zeplastiki, ubukhulu bodonga yinto ephambili, eyimfuneko njengesiseko sesakhiwo. Ezinye izakhiwo kufuneka zakhelwe phezu kwayo. Okwangoku, ikwachaphazela iipropathi zoomatshini, ukumila, inkangeleko, iindleko zamalungu eplastiki. Ngaloo ndlela, ubukhulu bodonga kufuneka busekelwe kwizinto ezingasentla ukuyila.

Ikhankanye ukuba ubukhulu bodonga kufuneka bube lixabiso elithile. Ukuba kukho ixabiso, libhekisa kubukhulu bodonga olulinganayo. Ukuba kukho amaxabiso amaninzi, oko kubhekiselele kukungalingani kodonga. Umahluko phakathi kokudityaniswa okanye ukungalingani uya kwaziswa emva. Ngoku, siza kuthetha malunga nomgaqo woyilo lobunzima bodonga kufuneka ulandelwe.

1. Ngokusekelwe kumgaqo weempawu zomatshini:

Ikhankanye ukuba kungakhathaliseki ukuba ngamalungu eqokobhe okanye amalungu angaphakathi, omabini afuna inqanaba elithile lamandla. Ngaphandle kwezinye izinto, amandla okukhululwa okuchasayo afunekayo xa kuqwalaselwa ukubunjwa kweengxenye. Kulula ukonakala ukuba inxalenye ibhityile kakhulu. Ngokuqhelekileyo, ukuqina kodonga olungqingqwa, kokukhona ukuqina kwamalungu (ubunzima bodonga bunyuka nge-10%, amandla aya kwanda malunga ne-33%). Ukuba ubuninzi bodonga budlula uluhlu oluthile, ukongeza ukuya kwidonga buya kunciphisa amandla amacandelo ngenxa yokunciphisa kunye ne-porosity. Ukwanda kobunzima bodonga kuya kuthoba amandla eenxalenye kunye nokwandisa ubunzima, kwandisa isangqa sokubumba inaliti, iindleko, njl. Kungcono ukusebenzisa iimpawu zejometri ukunyusa ukuqina, njengeembambo, i-curves, i-corrugated surfaces, i-stiffeners, njl.

Akunqunyulwa ukuba ngenxa yokulinganiselwa kwendawo kunye nezinye izinto, amandla amacandelo athile aqondwa ngokukodwa ngodonga lodonga. Ngoko ke, kucetyiswa ukuba unqume ubukhulu bodonga olufanelekileyo ngokuxelisa ukulinganisa oomatshini ukuba amandla yinto ebalulekileyo. Enyanisweni, ixabiso lobunzima bodonga kufuneka kwakhona lihambelane nale migaqo ilandelayo yokusesikweni.

2. Ngokusekelwe kumgaqo wokwakheka:

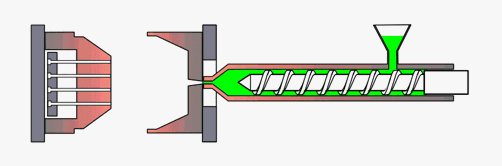

Obona bukhulu bodonga bubungqingqwa bomngxuma wokungunda phakathi kokungunda okungaphambili nangasemva. Xa i-resin etyhidiweyo igcwalisa i-mold cavity kwaye ipholile, ubukhulu bodonga bufunyenwe.

1) I-resin etyhidiweyo ihamba njani ngexesha lokutofa kunye nenkqubo yokuzalisa?

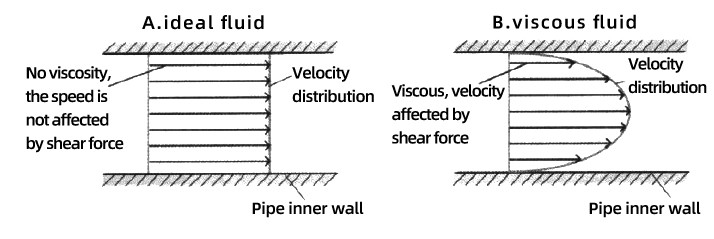

Ukuhamba kweplastiki ngaphakathi kumngxuma kunokubonwa njengokuhamba kwe-laminar. Ngokwethiyori ye-fluid mechanics, i-laminar fluid inokuthathwa njengolwelo olusecaleni komnye olutyibilikayo phantsi kwesenzo sokucheba amandla.

Ngexesha lenkqubo yokubumba, i-resin etyhidiweyo idibanisa kunye nodonga lweembaleki (udonga lomngxuma wokungunda), okwenza iileya zomlambo zibambelele eludongeni lweembaleki (okanye udonga lomngxuma wokungunda) lupholile kuqala. Isantya ngu-zero, kwaye kukho ukuxhathisa ukukhuhlana okuveliswayo kunye nomaleko wayo wolwelo osecaleni. Dlula ngolu hlobo, isantya somgangatho ophakathi womlambo siphezulu. Ifom yokuhamba apho i-laminar velocity iyancipha kufuphi nodonga lomgijimi (okanye udonga lwe-mold cavity) kumacala omabini.

Umaleko ophakathi ngumaleko wolwelo, kwaye umaleko wesikhumba ngumaleko oqinileyo. Njengoko ixesha lokupholisa lihamba, umaleko wesiqalekiso uya kwanda. Ummandla wecandelo lomnqamlezo womaleko wolwelo uya kuba mncinci kancinci kancinci. Ukuqina kokuzaliswa, kokukhona amandla okutofa okukhulu. Ngokwenene, kunzima ngakumbi ukutyhala inyibilika kwisithuba sokungunda ukuzalisekisa inaliti.

Ngoko ke, ubukhulu bodonga lwendonga bunempembelelo enkulu ekuhambeni kunye nokuzaliswa kweengxenye ezibunjiweyo zenaliti ngexesha lenkqubo yokubumba i-injection, kwaye ixabiso layo alikwazi ukuba lincinci.

2) I-viscosity ye-melt yeplastiki nayo inempembelelo enkulu kwi-fluidity

Xa ukunyibilika kuphantsi kwesenzo sangaphandle, kwaye kukho intshukumo ehambelanayo phakathi kweengqimba, kuya kubakho amandla okubetha kwangaphakathi okwenziwa ukuphazamisa intshukumo ehambelanayo phakathi kwemigangatho yamanzi. Amandla okhuhlane angaphakathi oveliswa lulwelo abizwa ngokuba yi-viscosity. Ukuvavanya amandla e-viscosity kunye ne-viscosity eguquguqukayo (okanye i-viscosity coefficient). Ngokwenani umlinganiselo woxinzelelo lokucheba kwisantya sokucheba sokunyibilika.

I-viscosity ye-melts ibonisa iimpawu zokulula apho iplastiki iyancibilika. Ngumlinganiselo wokumelana nokunyibilika kokuhamba. Ukuphakama kwe-viscosity, inkulu ukuchasana kwamanzi, kunzima ngakumbi ukuhamba. Izinto ezinempembelelo zokunyibilika kwe-viscosity azichaphazeli nje kuphela kwisakhiwo semolekyuli, kodwa zihambelana nobushushu, uxinzelelo, izinga lokucheba, izongezo, njl. kunye nezinye izinto ngexesha lenkqubo yokubumba isitofu zinokutshintshwa ukutshintsha ubumanzi beplastikhi kwinkqubo yokubumba inaliti Kwixesha elizayo, siya kubhala inqaku ngesihloko sokungabikho kwamanzi ngokuxhomekeke kwimeko.)

Ngelixa, kwisicelo sokwenyani, i-Melt Index ibonisa ubumanzi bezinto zeplastiki ekusebenzeni. Okukhona ixabiso liphezulu, kokukhona i-fluidity yezinto. Ngokuchasene noko, ukumanzi kwezinto eziphathekayo kuya kuba kubi kakhulu.

Ke ngoko, iplastiki ene-fluidity elungileyo kulula ukuzalisa i-mold cavity, ngakumbi kwiindawo zokubumba iinaliti ezinezakhiwo ezinzima.

Ubumanzi beeplastiki ezisetyenziswa ngokuqhelekileyo bunokwahlulwa ngokweendidi ezintathu ngokweemfuno zoyilo lokungunda:

①Ulwelo olulungileyo: PA, PE, PS, PP, CA, poly(4) methyl pentylene;

②I-fluidity ephakathi: ii-polystyrene series resins (ezifana ne-ABS, AS), i-PMMA, i-POM, i-PPO;

③Ulwelo olubi: IPC, iPVC eqinile, iPPO, iPSF, iPASF, ifluoroplastics.

Njengoko sinokubona kwi-Fig. ngasentla, izinto eziphathekayo ezinobuncwane obunzima kakhulu, iimfuno zobukhulu obuncinane bodonga ziya kuba phezulu. Oku kuye kwaziswa kwithiyori yokuqukuqela kwe-laminar.

Ixabiso elicetyiswayo lobungqingqwa bodonga ngasentla linani nje lolondolozo. Kwisicelo sangempela, ubukhulu bamacandelo bubandakanya amancinci, aphakathi kunye amakhulu, umfanekiso ongentla awukhankanyi uluhlu lwereferensi.

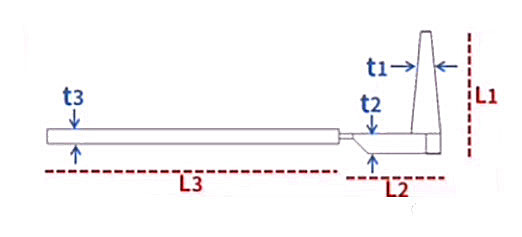

3) Sinokubala ngomlinganiselo wobude bokuhamba

Umlinganiselo wobude bokuqukuqela kweplastiki ubhekisa kumlinganiselo wobude (L) ukuya kubukhulu bodonga (T) lokuhamba kweplastiki yokunyibilika. Oko kuthetha ukuba ubukhulu bodonga olunikiweyo, ukuphakama komlinganiselo wobude bokuhamba, kokukhona inyibilika yeplastiki ibaleka. Okanye xa ubude bokuhamba kweplastiki yokunyibilika buqinisekile, ubukhulu bomlinganiselo wobude bokuhamba, ubuninzi bodonga bunokuba buncinci. Ngaloo ndlela, umlinganiselo wobude beplastiki uchaphazela ngokuthe ngqo inani lokutya kunye nokuhanjiswa kweemveliso zeplastiki. Kwakhona, kuchaphazela udonga lweplastiki.

Ukuchaneka ngakumbi, uluhlu oluthile lwexabiso lobunzima bodonga lunokufumaneka ngokubalwa komlinganiselo wobude bokuhamba. Enyanisweni, eli xabiso lihambelana nobushushu bezinto eziphathekayo, ubushushu bokubumba, iqondo lokupholisa, njl.

Ukubalwa komlinganiselo wobude bokuqukuqela:

L/T (itotali) = L1/T1 (itshaneli engundoqo) + L2/T2 (itshaneli yokwahlula) + L3/T3 (imveliso) Umlinganiselo wobude obaliweyo kufuneka ube ngaphantsi kwexabiso elinikiweyo kwitheyibhile yepropathi ebonakalayo, kungenjalo kunokwenzeka yiba yinto yokuzaliswa kakubi.

Umzekelo

Iqokobhe lerabha, izinto zePC, ubukhulu bodonga yi-2, umgama wokuzalisa yi-200, imbaleki yi-100, ububanzi bembaleki yi-5.

Calculation: L/T(total)=100/5+200/2=120

Ixabiso lereferensi yokulinganisa ubude be-PC yi-90, ngokucacileyo iphezulu kunexabiso lereferensi. Isantya sokutofa kunye noxinzelelo kufuneka sonyuswe njengoko kunzima ukutofa, okanye kufuneke oomatshini bokubumba obuthile bokusebenza okuphezulu. Ukuba wamkela amanqaku amabini okutya okanye utshintshe indawo yokutya, umgama wokuzaliswa kweemveliso ungancitshiswa ube yi-100, eyi-L / T (totali) = 100/5+100/2=70. Umlinganiselo wobude ngoku ungaphantsi kwexabiso lereferensi kwaye kulula ukubumba inaliti. L/T(totali)=100/5+200/3=87 xa ubukhulu bodonga butshintshwa bube yi-3, evumela ukubunjwa kwenaliti eqhelekileyo.

3. Ngokusekwe kumgaqo wembonakalo:

Ukusebenza okuthe ngqo kobunzima bodonga obuchaphazela inkangeleko yamalungu ngolu hlobo lulandelayo:

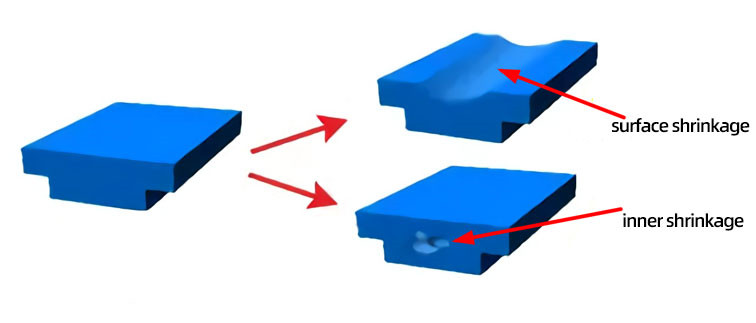

I-1) Ubunzima bodonga olungalinganiyo: ukucutha komphezulu (kubandakanya iziphene zembonakalo ezinje ngokuncipha, imingxunya, iiprinta ezishinyeneyo nezibhityileyo), i-warping deformation, njl.

2) Ubuninzi bodonga olugqithisiweyo: iziphene ezifana nokunciphisa umphezulu kunye nemingxuma yangaphakathi yokunciphisa.

3) Ubukhulu bodonga buncinci kakhulu: iziphene ezifana nokunqongophala kweglue, ukushicilela kwe-thimble, i-warpage kunye ne-deformation.

ukuncipha okanye i-porosity

Ukuncipha okanye ukugoba ngokuqhelekileyo kwenzeka kwiindawo ezishinyeneyo zodonga. Indlela: ngokomgaqo wokuqiniswa kwezinto, i-porosity yangaphakathi kunye nokushwabana komphezulu ngexesha lenkqubo yokubumba inaliti kungenxa yokuxinana rhoqo ngexesha lenkqubo yokupholisa. Xa i-shrinkage igxininiswe kwindawo enomkhenkce ngasemva, kodwa ingenakwenziwa ngokukhawuleza, i-shrinkage kunye ne-porosity kunokwenzeka ukuba yenzeke ngaphakathi.

Imigaqo yokuyila yobunzima bodonga apha ngasentla yaziswa kwimiba emine, eyimpahla yomatshini, ukwakheka, ukubonakala, iindleko. Ukuba sebenzisa isivakalisi esinye ukuchaza uyilo lokutyeba eludongeni, oko lixabiso lobukhulu bodonga lweendawo ezibunjiweyo zesitofu kufuneka zibe zincinci kwaye zibe zifanayo kangangoko kunokwenzeka phantsi kwemeko yokwanelisa iipropati zoomatshini kunye nokusebenza kokucubungula. Ukuba akunjalo, kufuneka iguqulwe ngokufanayo.

I-DJmolding ibonelela ngoyilo lwamalungu eplastiki kunye neenkonzo zokwenziwa kwemarkte yehlabathi, ukuba ufuna ukuqala iprojekthi yakho, nceda uqhagamshelane nathi ngoku.