Isitofu sokuLungisa uMngundo

Ukulungiswa kokungunda kunye noLungiso

Silungisa zonke iimolds ezenziwe sithi okanye abanye abavelisi phakathi kweentsuku ezi-5.

Izixhobo zokusebenza

Kwimveliso kunye nenkonzo yokubumba i-DJmolding isebenzisa ngaphandle koomatshini abaqhelekileyo abanje ngelathe, oomatshini abangqukuva nabasicaba, oomatshini bokugaya kunye noomatshini bokungqusha kunye namaziko omatshini ochwephesha.

Ukulungiswa kokungunda kusebenza njani

Sinikezela ngenkonzo yokubumba nakuwuphi na umenzi. Ingaba unalo ukungunda okuntlithekayo? Sihlola umonakalo, siyile isisombululo esiya kuthi sichaphazele ubomi bobungunda, kwaye sisebenze. Ulungiso olungeyomfuneko kangako lugqitywe ngeentsuku ezi-5. Nangona kunjalo, sinokulungisa ukungunda ngokukhawuleza, umzekelo ngempelaveki ukuba umonakalo wokungunda ubangele ukwehla kwexesha lokuvelisa. Qhagamshelana nathi, siya kufumana isisombululo.

Ukulungiswa komphezulu wokubumba umphezulu liqela lethu apha e-DJmoldng kuya kukuqinisekisa owona mdlalo ubalaseleyo.

Iingcibi zethu ezinamava kunye neengcali ziya kubuyisela nayiphi na ipateni eyonakalisiweyo. Konke ukulungiswa komngundo kwahlukile nokuba kuya kuba:

*Weld ukusuka ekulungiseni umonakalo omkhulu okanye utshintsho lobunjineli.

*Ukulungiswa komhlwa kunye neglosi

*Iscuff yokwakheka ukusuka kwidrafti encinci

*Uhlaziyo lwesimo

*Izahlulo zomgca wokwahlula okanye ii-dings

Ukuba i-welding iyafuneka, landela la macebiso alandelayo okulungisa kakuhle:

Weld ngezinto ezifanayo ukungunda yenziwe; oko kukuthi i-P-20, i-S-7, i-H-13 okanye isinyithi esingenasici. Ukuba into efanayo ayisetyenziswanga, i-weld inokuqhafaza ngesantya esahlukileyo ukushiya umgca wobungqina ojikeleze i-weld xa ulungisa ukuthungwa.

Iimbumba kufuneka zifudunyezwe kakuhle phambi kokuba zifakwe kwi-welding. Ukuba ayishushu ngokufanelekileyo, inokubangela ukuba i-weld iphole ngokukhawuleza. Ukuba oku kuyenzeka, naxa usebenzisa imathiriyeli efanayo, iya kubangela ukuba i-weld ifakwe ngesantya esahlukileyo esiya kufuna ukufudumeza uxinzelelo ukwenza intsimbi ibe yesiqhelo ukuze ifumane i-etch ethe gqolo ngesona siphumo silungileyo sokulungisa.

Ngenkqubela phambili yoshishino lwe-laser texturing siye saqulunqa inkqubo yokulungisa i-laser kwi-DJmoldng enokusetyenziswa kuyo nayiphi na isikhunta nokuba i-laser textured okanye i-chemically efakwe ukulungisa iindawo ezonakalisiweyo. Ngale nkqubo singakwazi ukulungisa i-laser indawo kwaye sidibanise kwi-texture ekhoyo sisusa naziphi na iziphene ezibonakalayo ezibuyisela isixhobo sakho kwimeko entsha.

Ukungunda okuGuquliweyo

Silungiselela idatha ngokwethu, iCAD / CAM, kwaye sicebisa indlela efanelekileyo yokulungisa.

Ukugcinwa koMngundo

Sisebenzisa i-chemistry yethu ukucoca iindawo ezivaliweyo kwaye sibulela kwi-tonnage ye-crane yethu sinokukhonza ukubumba ukuya kwiitoni ezingama-20.

Ukulungiswa kokungunda okonakeleyo

Silinganisa iimilo ezonakalisiweyo kwaye sibuyisela imeko yokuqala.

IDatha ye-2D/3D engekhoyo

Ngaba idata yokungundo yakho ilahlekile? Sinako ukunceda. Siyakwazi ukulinganisa kunye nokwenza iindawo ezithile ukulungisa ukungunda.

Ukuchaneka okuphezulu

Senza iiodolo zakho kwiinkqubo ezisemgangathweni ngokuchaneka okuphezulu. Ubuchule bethu buyanda ngayo yonke iodolo njengomboneleli wenkonzo kule nkalo ikhethekileyo. Sisebenzisa iitekhnoloji zala maxesha, ngokuyinxenye ezizenzekela ngokupheleleyo ezifana ne-plasma welding, i-E-welding kunye ne-laser-welding. Oomatshini be-CNC abazenzekelayo ngokupheleleyo basebenza ngenkxaso yekhompyutha kunye nokuchaneka okuphezulu.

Ezinye iinkonzo

Ukongeza ekuveliseni, ekulungiseni nasekulungiseni i-injection molds kunye nokwenza oomatshini be-semi-automatic kwimizi-mveliso yeemoto, amayeza kunye nezobugcisa, sikwabonelela ngezinye iinkonzo ezinxulumene nazo.

ukudizayina

Siyila kwaye sikwakhela ifomu kwinkqubo yesoftware ye3D.

Ukukhuselwa

Silungiselela isixhobo senjongo enye kwisoftware ye3D ukuze ukwazi ukuyizama ngokusebenza phambi kokuba uqhube uthotho.

Laser Welding

Silungisa ngononophelo iimbumba zakho ezingqushiweyo. Akukho uxinzelelo lwangaphakathi kwintsimbi ngexesha le-welding.

Ubunjineli obuchanekileyo kunye noMatshini

Sisebenza ngokuchaneka kwe-0.01 mm. Amagcisa ethu anamava asebenza ngoomatshini beNC, iisinki kunye nabasiki bengcingo.

Ukuveliswa kunye noYilo loLawulo kunye neJigs yokuMeta

Ukuhlola kunye nokulinganisa iijigi kwenza kube lula ukujonga ukubumba kwakho okugqityiweyo. Sikhathalela ukuyila kunye nemveliso.

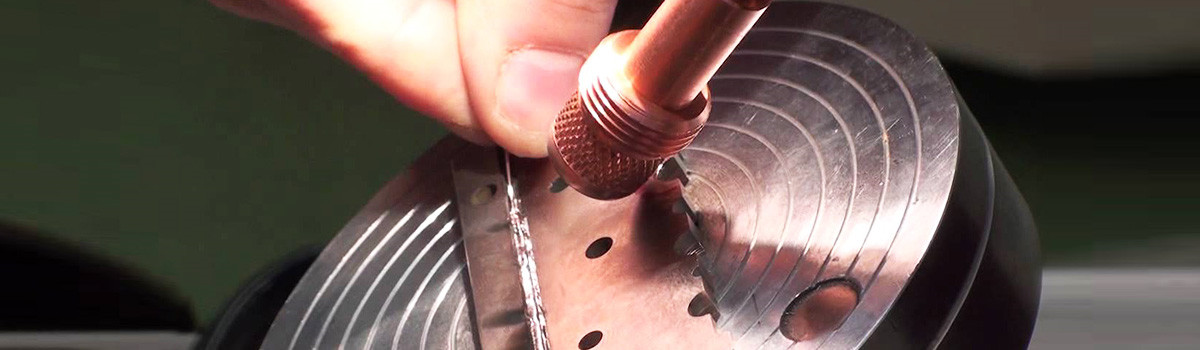

ICopper eyenziwe ngokweSiko okanye iiElectrode zeGrafite

Sivelisa ubhedu kunye nee-electrode zegraphite eziyimfuneko kwi-EDM (i-cavity sinking) machining.

Umgangatho oqinisekisayo

Nokuba ukulungiswa, utshintsho lweprofayili okanye imveliso entsha - siya kukuqinisekisa ngezisombululo ezitsha kwiimfuno zakho. Sikunika izisombululo ezenziwe ngokufanelekileyo kunye nezisekelwe kwiimfuno ezinomgangatho ophezulu kunye nesiphumo esihlala ixesha elide esiya kukuqinisekisa ekusebenziseni imihla ngemihla kwimveliso yakho.

Iodolo nganye yodwa

Abathengi bethu balindele iimveliso ezisemgangathweni, ubugcisa kunye nokuthembeka. Siseka intsebenziswano yexesha elide.