Basics Of Plastic Isitofu Molding

Phonononga inkqubo yokubumba inaliti kunye nendlela esebenza ngayo.

Ukubumba inaliti yeplastiki yindlela ethandwayo yokuvelisa apho iipellets ze-thermoplastic ziguqulwa zibe yimiqulu ephezulu yamalungu anzima. Inkqubo yokubumba inaliti ifanelekile kwizinto ezahlukeneyo zeplastiki kwaye iyinxalenye ebalulekileyo yobomi banamhlanje-iimeko zefowuni, izindlu ze-elektroniki, iithoyi, kunye neendawo zemoto azinakwenzeka ngaphandle kwayo. Eli nqaku liza kucalula iziseko zesitofu sokubumba, lichaze indlela isitofu sokubumba esisebenza ngayo, kwaye sibonise ukuba yahluke njani kushicilelo lwe-3D.

Ziziphi izinto eziSiseko zokuMbumba ngesitofu sePlastiki?

Iziseko zenkqubo yokubumba inaliti yeplastiki ibandakanya ukuyilwa koyilo lwemveliso, ukwenza isixhobo sokubumba ukuze silingane uyilo lwemveliso, ukunyibilikisa iipeliti zeplastiki zentlaka, kunye nokusebenzisa uxinzelelo lokutofa iipellets ezinyibilikisiweyo.

Bona ucazululo lwenyathelo ngalinye ngezantsi:

1. Ukudala uYilo lweMveliso

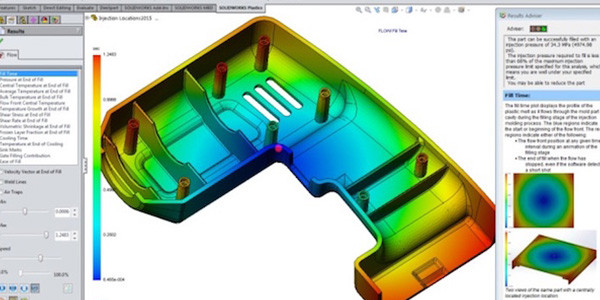

Abaqulunqi (iinjineli, amashishini abenzi bokubumba, njl. njl.) benza inxalenye (ngendlela yefayile yeCAD okanye enye ifomathi enokutshintshelwa), ngokulandela izikhokelo zoyilo ezisisiseko ezithe ngqo kwinkqubo yokubumba inaliti. Abaqulunqi kufuneka bazame ukubandakanya ezi mpawu zilandelayo kuyilo lwabo ukunceda ukwandisa impumelelo yesitofu seplastiki yokubumba:

*Abaphathi bokufaka/iziqhoboshi ezinemisonto

*Ubukhulu beendonga ezithe rhoqo okanye ezisondele rhoqo

*Utshintsho olugudileyo phakathi kobunzima bodonga oluguquguqukayo

*Imingxuma enemingxuma emacaleni ashinyeneyo

*Iindawo ezingqukuva

*Yila iiengile kwiindonga ezithe nkqo

*Iimbambo zokuxhasa

*Iifriction ziyalingana, i-snap-fit joints, kunye nezinye izinto ezingeyo-fastener zokujoyina

*Iihenjisi zokuhlala

Ukongeza, abaqulunqi kufuneka banciphise ezi mpawu zilandelayo ukunciphisa iziphene kuyilo lwabo:

*Ubungqingqwa bodonga olungafanelanga okanye ingakumbi iindonga ezibhityileyo/ezityebileyo

*Iindonga ezithe nkqo ezingena-engile zokuyila

*Utshintsho lwejiyometri ngesiquphe (iikona, imingxunya, njl.njl.)

*Iimbambo eziyilwe kakubi

*Undercuts/overhangs

2. Ukwenza i-Tooling Mold ukuze ilingane noYilo lweMveliso

Oomatshini abanezakhono eziphezulu kunye nabenzi bezixhobo, besebenzisa uyilo lwemveliso, benza i-tooling mold yomatshini wokubumba inaliti. Isixhobo sokubumba (esaziwa ngokuba sisixhobo nje) yintliziyo kunye nomphefumlo womatshini wokubumba inaliti. Ziyilwe ngononophelo ukuba ziqulathe i-cavity engalunganga yoyilo lwemveliso kunye neempawu ezongezelelweyo ezifana ne-sprues, abagijimi, amasango, i-vents, i-ejector systems, iziteshi zokupholisa, kunye nezinto ezihambayo. Iimbumba zezixhobo zenziwe ngamabakala athile entsimbi kunye ne-aluminium enokumelana namashumi amawaka (kwaye ngamanye amaxesha amakhulu amawaka) omjikelezo wokufudumeza kunye nokupholisa, njenge-6063 aluminium, i-P20 yensimbi, i-H13 yensimbi, kunye ne-420 yensimbi engenasici. Inkqubo yokwenziwa komngundo ithatha ngaphezulu kweeveki ezingama-20 ukugqiba, kubandakanywa ukwenziwa kunye nokuvunywa, nto leyo eyenza eli nyathelo libe lelona cala landisiweyo lokubumba inaliti. Ikwayeyona nxalenye ibiza kakhulu yokubumba inaliti, kwaye emva kokuba i-tooling mold yenziwe, ayinakuguqulwa kakhulu ngaphandle kokwenza iindleko ezongezelelweyo.

3. Ukunyibilikisa iiPellets zePlastiki yeResin

Emva kokuba abaqhubi befumene i-mold egqityiweyo, ifakwe kumatshini wokubumba inaliti, kwaye i-mold ivala, iqala umjikelo wokubumba inaliti.

Iigranule zeplastiki zondliwa kwi-hopper nakwi-barrel. Isikrufu esibuyiselayo sitsalwa ngasemva, sivumela izinto ukuba zityibilike kwisithuba esiphakathi kwesikrufu kunye nombhobho. Isikrufu ke siziphosela phambili, sinyanzelela imathiriyeli kumbhobho kwaye sisondele kwiibhanti zesifudumezi apho sinyibilika khona kwiplastiki etyhidiweyo. Iqondo lobushushu lokunyibilika ligcinwa lingaguquguquki ngokweenkcukacha zemathiriyeli ukuze kungabikho ukuthotywa okwenzeka kumbhobho okanye kumngundo ngokwawo.

4. Ukusebenzisa uxinzelelo lokutofa iiPellets ezinyibilikisiweyo kwiMold

Isikrufu esibuyiselanayo sinyanzelela le plastiki inyibilikayo ngombhobho, ehleli phantsi koxinzelelo kumngundo okwaziwa ngokuba yi-mold sprue bushing. Uxinzelelo lweplaten eshukumayo luhambelana nokungunda kunye nombhobho ndawonye ngokuqinileyo, ukuqinisekisa ukuba akukho plastiki inokuphuma. Iplastiki enyibilikisiweyo icinezelwa yile nkqubo, ibangela ukuba ingene kuzo zonke iindawo zomgobo wokungunda kwaye ikhuphe umoya womngxunya ngaphandle kweendawo zokubumba.

Izixhobo zoomatshini bokuBumba ngesitofu

Amalungu omatshini wokubumba inaliti abandakanya ihopper, ibhere, isikrufu esibuyiselanayo, isifudumezi (izifudumezi), iplaten eshukumayo, umlomo, umngundo, kunye nomgodi wokungunda.

Ulwazi oluthe kratya malunga nelungu ngalinye lenaliti yokubumba kuluhlu olungezantsi:

*Hopper: indawo yokuvula apho iigranuli zeplastiki zifakwa kumatshini.

*Umgqomo: indlu yangaphandle yomatshini wokubumba inaliti, equlethe i-screw ephindaphindayo kunye neegranules zeplastiki. Umgqomo usongelwe kwiibhanti ezininzi ze-heater kwaye ufakwe kwi-nozzle eshushu.

* Isikrufu esibuyiselanayo: icandelo le-corkscrew elihambisa kwaye licinezele izinto zeplastiki njengoko zinyibilika kumbhobho.

*Izifudumezi: ekwabizwa ngokuba ziibhanti zokufudumeza, la malungu abonelela ngamandla ashushu kwigranules zeplastiki, azijike asuke kwimo eqinileyo abe lulwelo. ifomu.

*Icwecwe elishenxisekayo: Icandelo elishukumayo elidityaniswe kumbindi wokungunda osebenza ngoxinzelelo lokugcina zombini iihafu zokungunda zingena moya kwaye kwakhona ukhupha undoqo wokungunda xa utyhila inxalenye egqityiweyo.

*Umbhobho: icandelo elifudunyeziweyo elibonelela ngokuphuma okusemgangathweni kweplastiki etyhidiweyo kwindawo yokungunda, igcina zombini ubushushu kunye noxinzelelo njengoko uzinzile.

*Ukungunda: icandelo okanye amacandelo aqulathe umgodi wokungunda kunye neempawu ezongezelelweyo ezixhasayo ezifana nezikhonkwane zokukhupha, itshaneli zembaleki, iziteshi zokupholisa, iivent, njl. undoqo (kwiplaten ehambayo).

*Umngxunya womngundo: indawo engalunganga ethi, xa izaliswe ngeplastiki etyhidiweyo, iya kuyibumba ibe yinxenye yokugqibela enqwenelekayo kunye nezixhaso, amasango, iimbaleki, i-sprues, njl.

Isebenza Njani Ukubumba Isitofu?

Emva kokuba iplastiki igcwalise i-mold kubandakanywa i-sprues yayo, abagijimi, amasango, njl., i-mold igcinwa kwiqondo lokushisa elimiselweyo ukuvumela ukuqiniswa okufanayo kwezinto kwi-shape shape. Uxinzelelo lokubamba lugcinwa ngelixa ukupholisa kokubini ukuyeka ukubuyisela umva kwi-barrel kunye nokunciphisa imiphumo eyanciphayo. Ngeli xesha, iigranule zeplastiki ezingaphezulu zongezwa kwi-hopper ngokulindela umjikelezo olandelayo (okanye ukudubula). Xa ipholile, i-platen ivula kwaye ivumela inxalenye egqityiweyo ukuba ikhutshwe, kwaye isikrufu sitsalwe kwakhona, sivumela izinto ukuba zingene emgqomeni kwaye ziqale inkqubo kwakhona.

Umjikelezo wokubumba i-injection usebenza ngale nkqubo eqhubekayo-ukuvala isikhunta, ukondla / ukufudumeza iigranules zeplastiki, ukuxinzelela kwi-mold, ukupholisa kwindawo eqinile, ukukhupha inxalenye, nokuvala isikhunta kwakhona. Le nkqubo ivumela ukuveliswa ngokukhawuleza kwamalungu eplastiki, kwaye ngaphezulu kwe-10,000 iinxalenye zeplastiki zingenziwa ngosuku lomsebenzi ngokuxhomekeke kuyilo, ubungakanani kunye nempahla.

I-Djmolding yinkampani yokubumba isitofu esisezantsi somthamo kwi-china.Inkqubo yethu yokubumba inaliti yeplastiki ivelisa iprototypes yesiko kunye neendawo zokusetyenziswa kokugqibela kunye namaxesha okukhokela ngokukhawuleza njengosuku olu-1, umthamo ophantsi weplastiki yokubumba inxalenye yomthengisi ukuya kuthi ga kwi-10000 ngonyaka.