Ulwelo lweRubha yeSilicone (LSR) yokuBumba iSitofu

Yintoni ukuBunjwa kweLiquid Silicone Rubber (LSR) yokuTofa?

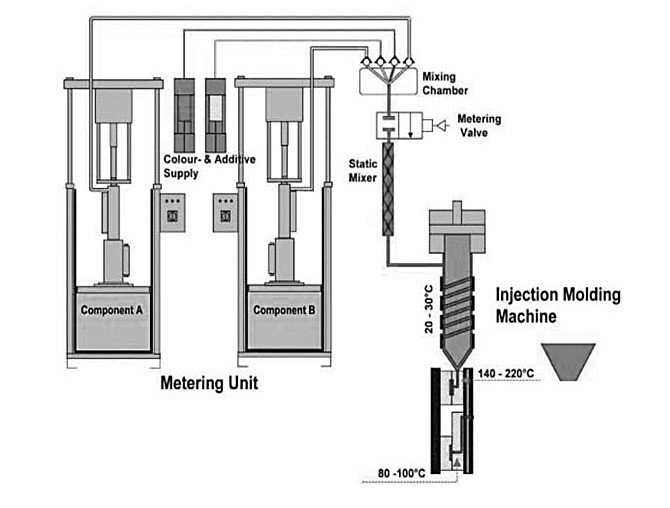

I-injection molding ye-Liquid Silicone Rubber (LSR) yinkqubo esetyenziselwa ukuvelisa iindawo ezithambileyo, ezomeleleyo kwimiqulu ephezulu. Ngexesha lenkqubo, amacandelo amaninzi ayimfuneko: i-injector, i-metering unit, i-drum yokubonelela, i-mixer, i-nozzle, kunye ne-mold clamp, phakathi kwabanye.

Ukubunjwa kwe-injection ye-Liquid Silicone Rubber (LSR) bubuchwepheshe obuqhelekileyo obusetyenziselwa ukuveliswa kweemveliso ezahlukeneyo kwizicelo zonyango kunye nombane, phakathi kwabanye. Ukongeza kwiipropathi zangaphakathi zemathiriyeli, iiparamitha zenkqubo zibaluleke kakhulu. Ukubumba inaliti ye-LSR yinkqubo yamanyathelo amaninzi evezwayo.

Isinyathelo sokuqala kukulungiswa komxube. I-LSR idla ngokuba namacandelo amabini, i-pigment, kunye ne-additives (izigcwalisi umzekelo), ngokuxhomekeke kwiipropati ezifunwayo zemveliso yokugqibela. Kule nyathelo, izithako zomxube zi-homogenized kwaye zinokudibaniswa nenkqubo yokuzinzisa ubushushu bokulawula okungcono ubushushu be-silicone (ubushushu obuphantsi okanye i-silicone preheating).

Kule mihla, uluhlu lwezicelo zeemveliso zerabha ye-silicone luya luba banzi kwaye lubanzi, kwaye ukubumba inaliti ye-LSR kuyindima ebalulekileyo kweli shishini.

Isebenza njani i-Liquid Silicone Rubber Molding?

Ukubumba i-LSR kwahluka kancinane kwisitofu se-thermoplastic ngenxa yokuguquguquka kwayo. Njengesixhobo esiqhelekileyo se-aluminium, isixhobo sokubumba i-LSR senziwe kusetyenziswa i-CNC machining ukwenza isixhobo sobushushu obuphezulu esakhiwe ukumelana nenkqubo yokubumba i-LSR. Emva kokugaya, isixhobo sigudiswa ngesandla kwiinkcukacha zomthengi, ezivumela iinketho ezintandathu zokugqiba umgangatho.

Ukusuka apho, isixhobo esigqityiweyo silayishwa kwi-LSR-specific injection molding press echanekileyo elungiselelwe ukulawula ngokuchanekileyo ubungakanani bokudubula ukuvelisa iindawo ze-LSR ezihambelanayo. Kwi-Mold-Making, iinxalenye ze-LSR zisuswa ngesandla kwi-mold, njengoko izikhonkwane ze-injector zinokuchaphazela umgangatho wenxalenye. Izinto ze-LSR zibandakanya ii-silicone eziqhelekileyo kunye namabakala athile ukuze alingane kwizicelo ezahlukeneyo kunye namashishini afana nezonyango, iimoto kunye nokukhanya. Ekubeni i-LSR i-polymer ye-thermosetting, isimo sayo esibunjiweyo sisisigxina-xa sele simisiwe, ayikwazi ukunyibilika kwakhona njenge-thermoplastic. Xa ukubaleka kugqityiwe, iinxalenye (okanye isampuli yokuqala yokuqhuba) zifakwa ebhokisini kwaye zithunyelwa ngokukhawuleza emva koko.

Apha masiyiphonononge, okokuqala, kufuneka sithethe malunga nemathiriyeli yerabha ye-silicone, iingongoma eziphambili omele uzazi ngolu hlobo lulandelayo:

Irabha yesilicone elulwelo (LSR) yeyona igqwesileyo yokugquma, ilungele umgangatho ophezulu okanye iplagi ye-elektroniki yobuchwepheshe obuphezulu.

Izinto zerubha ye-silicone yolwelo (LSR) zilungele ukusetyenziswa kwindawo yobushushu obuphezulu okanye kwindawo yobushushu obuphantsi. Iimpawu zokugquma, iipropathi zoomatshini, kunye neempawu ezibonakalayo zezixhobo zihlala zingatshintshi kwi-200 ℃ okanye ephantsi njenge -40 ℃.

Inganyangeki kwi-gasification kunye nokuguga, ngoko ifanelekile kwizicelo zangaphandle.

Irabha ye-silicone yolwelo (LSR) ayinyangeki ngeoyile, ingasetyenziswa kwishishini lemigodi yeoli. Kukho iimodeli ezimbini: umatshini wokubumba we-abicah owenziwe ngokuthe nkqo we-slide, umatshini wokubumba we-silicone othe nkqo wesilayidi, osetyenziselwa ukuvelisa zonke iintlobo zeemveliso zerabha ezichanekileyo ezichanekileyo; umatshini wokutofa nge-cylinder angle esezantsi, kukuveliswa kwee-insulators zokuxhoma ezihlanganisiweyo, i-Post insulators kunye neemodeli zemveli zokubamba.

Izinto eziluncedo kwi-LSR ye-Injection Molding (LIM).

Zininzi izinto eziluncedo kwi-LSR Injection Molding (LIM). Ithelekiswa ne-silicone yoxinzelelo lokubumba.

Irubha ye-silicone elulwelo (LSR) ikhuselekile, ijeli ye-silicone inebakala lokutya okanye ibakala lezonyango. Isitofu sokubumba i-LSR (LIM) sinokuchaneka okuphezulu, sinokwenza iindawo zerabha ezichaneke kakhulu ze-silicone. Kwakhona, inomgca wokuqhawula obhityileyo kakhulu kunye nesibane esincinci.

Izinto ezilungileyo zamalungu abunjiweyo e-LSR

Uyilo olungenamda – Yenza ukuveliswa kwenxalenye yejometri kunye nezisombululo zobugcisa akunakwenzeka ngenye indlela

Zihambelana -Ibonelela ngokuhambelana okuphezulu kakhulu kwimveliso, ukuchaneka kunye nomgangatho jikelele

ecocekileyo -I-Silicone yenye yezona zinto zivavanyiweyo kakhulu kunye nembali ende yokusetyenziswa ngokukhuselekileyo

Ngqo -Isixhobo esingenazibane, iikhonsepthi zoyilo lwesixhobo esingenamsebenzi zamalungu anobunzima obususela kwi-0.002 grams ukuya kumakhulu aliqela eegram

Thembeka -Ukusebenzisa itekhnoloji yamva nje koomatshini, izixhobo kunye ne-automation

uphawu -Zero-isiphene umgangatho womgangatho ngokusebenzisa inkqubo yolawulo

ngokukhawuleza -Inika amandla imveliso yevolumu ephezulu ngenxa yamaxesha omjikelezo omfutshane, ukusuka kumawaka aliqela ukuya kwizigidi

acocekileyo -Ukusebenzisa iindlela zokucwangcisa ezisemgangathweni kunye nemveliso kwiKlasi yesi-7 kunye ne-8 yamagumbi acocekileyo

Isebenza kakuhle emalini -Inikezela ngexabiso eliphantsi lilonke lobunini (TCO)

Ukubunjwa kwesitofu se-LSR

Itekhnoloji entsha ihlangabezana neemfuno zabathengi:

Irabha ye-Silicone ye-Liquid (LSR) inokucutshungulwa kwi-liquid injection molding (LIM) inkqubo. I-liquid ekrwada ixutywe kumacandelo amabini ahlukeneyo kumlinganiselo we-1: 1 kwaye itofwe nge-cold-runner-system ibe ngundo oshushu. Unyango lwenzeka kwimizuzwana, kunika inzuzo yokukhwela ibhayisekile ngokukhawuleza kunye nokuveliswa kwezinto ezininzi.

Ngenxa yokuguquguquka kuyilo kunye nokusetyenziswa kwezixhobo, ukubumba inaliti ye-LSR ilungile ekuveliseni iijiyometri ezintsonkothileyo kwaye inokudibanisa imisebenzi eyahlukeneyo ibe yinxalenye enye. Ikwabonelela ngeenzuzo ezibalulekileyo malunga nokuthembeka kwemveliso kunye neendleko ezipheleleyo zobunini.

I-LSR ye-Silicone ye-Silicone ye-Silicone ye-Rubber yokuBumba iNkqubo yokuBumba

Umatshini wokubumba we-DJmolding we-silicone yerabha yolwelo lwerabha ubonakala ngathi ufana noomatshini bokubumba inaliti ye-thermoplastic. Zombini ezi ntlobo zoomatshini zisebenzisa iindawo ezifanayo zoomatshini, iyunithi yokubambelela, kunye neyunithi yokutofa.

Iyunithi yokubumba umatshini wokubumba umatshini wokubumba we-LSR iyafana nerabha ye-silicone engamanzi kunye noomatshini be-thermoplastic. Oomatshini bokubumba inaliti ye-silicone bahlala benenqama ye-hydraulic kwaye banokuba ne-hydraulic toggle. Abanye oomatshini bokushicilela bayilwe ngenkunzi yombane ene-toggle. Ngokungafaniyo noxinzelelo oluphezulu olusetyenziselwa ukubumba iindawo ze-thermoplastic, uxinzelelo lwenaliti ye-silicone yolwelo luluhlu lwe-800 PSI. Injongo ye-clamp kukuqulatha amandla okwandiswa kwezinto ze-silicone, ngokugcina i-mold ivaliwe njengoko i-silicone iphilisa.

Iyunithi yokutofa ye-silicone yolwelo ibaleka ipholile ngomphanda wamanzi opholileyo kunye nombhobho ukuthintela i-silicone engamanzi ukuba inganyangeki. Iiyunithi zokutofa kwe-Thermoplastic ziqhuba ngendlela echaseneyo, zidinga umgqomo kunye nomlomo wokufudumala ukuya kwi-300F okanye ngaphezulu ukugcina izinto ezihambayo. Iiyunithi zokubumba inaliti yolwelo nazo ziqhuba kuxinzelelo olusezantsi (phantsi kwe-1,000 PSI), ngelixa abalingane babo be-thermoplastic babaleka kumashumi amawaka e-PSI.

I-silicone yolwelo idla ngokubonelelwa nge-5 gallon pail okanye i-55 gallon drums. Kukho inxalenye ye-A kunye neCandelo B. I-Colourants iza ngendlela ye-dispersions kwaye ngokuqhelekileyo i-1-3% ngobunzima be-silicone edibeneyo. I-silicone ye-dousing unit ipompo inxalenye ye-silicone kunye ne-silicone inxalenye ye-B ngokusebenzisa i-hoses eyahlukileyo ukuya kumxube omileyo. Ukongeza, umbala umpontshelwa kumxubi omileyo kusetyenziswa elinye ithumbu. Amacandelo axubileyo afakwe emqaleni wesitofu sokubumba umbhobho ngendlela yevalve yokuvala.

I-DJmolding yirabha elulwelo lwe-silicone yolwelo (LSR) yokubumba inaliti kunye nomenzi wamalungu erabha elulwelo oluvela eTshayina.

I-Liquid Silicone Rubber ye-Rubber Workshop

I-LSR i-Injection Prodcuts QC

Iimveliso zeLSR

Iimveliso zeLSR

Inkqubo yethu yokubumba irabha ye-silicone yolwelo ivelisa iiprototypes zesiko kunye neendawo zokusetyenziswa kokugqibela ngeentsuku ezili-15 okanye ngaphantsi. Sisebenzisa iimolds ze-aluminiyam ezinikezela ngezixhobo ezifanelekileyo kunye nemijikelo ekhawulezileyo yokuvelisa, kunye nesitokhwe samabanga ahlukeneyo kunye needurometers zemathiriyeli ye-LSR.

Ukubonelela ngokuhambelana okuphezulu kwimilinganiselo, ukuchaneka, umgangatho jikelele.

Indlela yethu epheleleyo yokubumba iRubha yeSilicone yeSilicone ixhomekeke ekusebenzisaneni nabathengi ukuphuhlisa izisombululo ezintsha ezisekelwe kwiinkcukacha ezizodwa kunye neemfuno.

I-Liquid Silicone Rubber (LSR) I-Injection Molding yinkqubo yokuvelisa ebandakanya ukutofa irabha ye-silicone engamanzi kwi-mold ukwenza iimveliso ezahlukeneyo. I-LSR yimathiriyeli eguquguqukayo eye yanda kakhulu ngenxa yeempawu zayo ezizodwa, kubandakanya i-biocompatibility, ukuzinza kwe-thermal, kunye nokumelana neekhemikhali. Kweli nqaku, siza kuxoxa ngeenzuzo zokubumba inaliti ye-LSR kwaye siphonononge usetyenziso olwahlukeneyo lobu buchwepheshe.

Isebenza Njani I-LSR I-Injection Molding?

I-LSR (i-Liquid Silicone Rubber) yokubumba inaliti yinkqubo yokuvelisa evelisa umgangatho ophezulu, iindawo ezichanekileyo zerabha ye-silicone. Kuluncedo ekudaleni iimilo ezintsonkothileyo kunye noyilo oluneenkcukacha ezigqwesileyo kunye nokungaguquguquki. Inkqubo ibandakanya ukutofa irabha ye-silicone elulwelo kwindawo yokungunda, ukuyivumela ukuba inyange kwaye iqine kwimilo efunekayo. Nantsi inkcazo emfutshane malunga nendlela isitofu se-LSR esisebenza ngayo:

Ukulungiselela ukungunda: Inkqubo iqala ngokulungiselela ukungunda. Umngundo udla ngokuba neziqingatha ezibini, icala lenaliti, kunye necala elibambekayo, elidibanayo ukwenza umngxuma wesilicone. Emva kokunyanga, isikhunta siyacocwa kwaye sigqutywe nge-arhente yokukhulula ukuququzelela ukususwa kwenxalenye elula.

Ukulungiswa kwe-Silicone: I-rubber ye-silicone ye-Liquid yinto enezinto ezimbini eziqulethwe kwisiseko se-silicone kunye ne-agent ephilisayo. La macandelo axutywe kunye ngomlinganiselo ochanekileyo. Umxube uhlanjululwe ukuze ususe nawaphina amaqamza omoya angachaphazela umgangatho wenxalenye yokugqibela.

Isitofu: Irabha ye-silicone exutywe kunye ne-degassed liquid idluliselwa kwiyunithi yokutofa. Iyunithi yokutofa itshisa izinto kwiqondo lokushisa elithile ukunciphisa i-viscosity yayo kwaye yenza kube lula ukuhamba. Izinto eziphathekayo zifakwe kwi-mold cavity nge-nozzle okanye i-sprue.

Ukunyanga: Nje ukuba irabha ye-silicone yolwelo itofwe kumgodi wokungunda, iqala ukuphilisa. Inkqubo yokunyanga idla ngokuqalwa bubushushu, nangona ezinye iimbumba zinokusebenzisa ezinye iindlela, ezinje ngokukhanya kwe-UV. Ubushushu bubangela ukuba i-silicone inqumle kwaye iqiniswe, yenze i-mold cavity. Ixesha lokunyanga liyahluka ngokuxhomekeke kuyilo lwenxalenye kunye nempahla ye-silicone.

Ukupholisa kunye nokususwa kwenxalenye: Emva kwenkqubo yokunyanga, isikhunta sipholile ukuvumela ukuba i-silicone ibekwe ngokupheleleyo. Ixesha lokupholisa linokwahluka kodwa lifutshane kunexesha lokunyanga. Xa sele ipholile, isikhunta siyavulwa, kwaye inxalenye egqityiweyo iyasuswa. Isikhundla sinokufuna amanyathelo ongezelelweyo emva kokulungiswa, njengokucheba izinto ezingaphezulu okanye ukuhlola naziphi na iziphene.

Ukubumba inaliti ye-LSR kunika iingenelo ezininzi, kubandakanya ukuvelisa iijiyometri ezintsonkothileyo nezintsonkothileyo, ukuhambelana okugqwesileyo kwenxalenye, ukuchaneka okuphezulu, kunye nokumelana nobushushu obugqithisileyo, iikhemikhali, kunye nokwaluphala. Isetyenziswa ngokuqhelekileyo kumashishini ahlukeneyo ezonyango, ezemoto, eze-elektroniki, kunye neemveliso zabathengi.

Kubalulekile ukuqaphela ukuba le yingcaciso eyenziwe lula yenkqubo yokubumba inaliti ye-LSR, kwaye umsebenzi wokwenene unokwahluka ngokuxhomekeke kwisixhobo esithile, iimathiriyeli, kunye nenxalenye yeemfuno.

Izinto eziluncedo kwi-LSR yokuBumba isitofu

I-LSR (irabha ye-silicone elulwelo) yokubumba inaliti yinkqubo yokwenziwa kwezinto ezininzi ebonelela ngeenzuzo ezininzi kwiindlela zokubumba zemveli. Isitofu sokubumba i-LSR ibandakanya ukutofa abicah elulwelo kwisingundo kwaye siyinyange ibe yimo eqinileyo ukwenza imveliso egqityiweyo. Nazi ezinye zeenzuzo eziphambili zokubumba inaliti ye-LSR:

Ukuchaneka kunye nokungqinelana

Ukubumba inaliti ye-LSR kunika ukuchaneka okukhethekileyo kunye nokungaguquguquki ekudaleni iindawo ezinzima, ezintsonkothileyo ezineenkcukacha ezintle. I-silicone ye-liquid ifakwe kwi-mold phantsi koxinzelelo oluphezulu, izalise i-crevices ezincinci kunye neekona ukuvelisa iindawo ezinzima kakhulu. Ukongezelela, ukubunjwa kwe-LSR kuvumela ukuhambelana okukhulu kunye nokuphindaphinda, ukunciphisa ithuba leziphene kunye nokungahambelani kwimveliso yokugqibela.

Amacandelo aphezulu

Ukubumba inaliti ye-LSR kunokuvelisa umgangatho ophezulu, iindawo ezomeleleyo ezikwaziyo ukuguga nokukrazuka, ubushushu, kunye nemitha ye-UV. Izinto ze-LSR zineempawu ezibalaseleyo zomzimba, kubandakanya ukuqina okuphezulu, isethi yoxinzelelo oluphantsi, kunye nokuchasana nobushushu obugqithisileyo. Oku kwenza ukubumba inaliti ye-LSR ibe lolona khetho lufanelekileyo lokuvelisa iindawo ezifuna ukuchaneka okuphezulu kunye nokuqina, njengezixhobo zonyango, izinto zemoto, kunye neemveliso zabathengi.

Isebenza kakuhle emalini

Ukubumba inaliti ye-LSR inokuba yindlela yokuvelisa enexabiso eliphantsi yokuvelisa iindawo ezinkulu. Ukuchaneka okuphezulu kwenkqubo kunye nokungaguquguquki kunceda ukunciphisa inkunkuma kunye nezinto ezilahliweyo, ngelixa iimfuno eziphantsi zabasebenzi kunye namaxesha asebenzayo okuvelisa anciphisa iindleko zokuvelisa. Ukongezelela, izinto ze-LSR ziphila ixesha elide, zinciphisa isidingo sokutshintshwa rhoqo okanye ukulungiswa kwamalungu.

Ukungafani

Ukubumba inaliti ye-LSR kunokuvelisa iindawo ezahlukeneyo ezinobukhulu obahlukeneyo, iimilo, kunye neejometri. I-silicone yolwelo inokubunjwa ibe yimilo eyinkimbinkimbi kunye neyinkimbinkimbi eneenkcukacha ezicokisekileyo, okwenza kube yinto efanelekileyo yokuvelisa iindawo ezifuna ukuchaneka okuphezulu kunye nokuchaneka. Ukongeza, ukubumba inaliti ye-LSR kunokuba neempawu ezinobunzima obahlukeneyo kunye nokuthamba, okuvumela ukuyilwa kwemveliso okungaqhelekanga kunye nokuguquguquka komsebenzi.

Amaxesha okuNcitshiswa komjikelo

Ukubumba inaliti ye-LSR inamaxesha omjikelezo okhawulezayo, okuvumela ukuvelisa inani elikhulu lamalungu ngexesha elifutshane. I-silicone ye-liquid ifakwe kwi-mold kwaye iphiliswe ibe yifom eqinile ngemizuzwana, iyenza ibe yinto efanelekileyo yokuvelisa imveliso ephezulu.

IsiZukulwana seNkunkuma ePhantsi

Isitofu sokubumba se-LSR sivelisa inkunkuma encinci kakhulu, njengoko i-silicone yolwelo itofwa ngokuthe ngqo kumngundo kwaye inyangekile ukwenza imilo efunekayo. Oku kuchasene nezinye iinkqubo zokuvelisa, ezinje ngomatshini okanye ukuphosa, okuvelisa izinto ezilahliweyo ezibalulekileyo. Ukongeza, izinto ze-LSR zinokuphinda zisetyenziswe kwaye zisetyenziswe kwakhona, ukunciphisa imfuno yezinto ezintsha kunye nokunciphisa ukuveliswa kwenkunkuma.

Ukhuseleko oluphuculweyo

Izinto ze-LSR azinamachiza ayingozi njenge-phthalates, i-BPA, kunye ne-PVC, nto leyo ezenza zikhuseleke ngakumbi kubasebenzi nakubathengi. Ukongeza, inkqubo yobushushu obuphantsi obusetyenziswa kwi-LSR yokubumba inaliti ayifuni izinyibilikisi ezinobungozi okanye ezinye iikhemikhali, ukunciphisa umngcipheko wokuvezwa kwezinto ezinobungozi.

Ixesha elincitshisiweyo lokuya kwiMarike

Ukubumba inaliti ye-LSR kunokunciphisa ixesha lokuthengisa iimveliso ezintsha, njengoko ivumela umboniso okhawulezayo kunye nokuqhutywa kwemveliso okukhawulezayo. Ukuchaneka okuphezulu kwenkqubo kunye nokuhambelana kunceda ukuqinisekisa ukuba imveliso yokugqibela ihlangabezana neenkcukacha ezinqwenelekayo, ukunciphisa imfuno yemijikelo emininzi yeprototyping kunye novavanyo.

into yokuZenzekelayo

Ukubumba inaliti ye-LSR kunokwenziwa ngokuzenzekelayo, ukunciphisa imfuno yomsebenzi wezandla kunye nokunciphisa ukusetyenziswa kwamandla. Ukongeza, i-automation inokuphucula ukusebenza kakuhle, ukunciphisa iindleko zabasebenzi, kunye nokuphucula ukuhambelana kunye nomgangatho wemveliso yokugqibela.

Izinto ezingeloncedo zokuBunjwa kwesitofu se-LSR

Ngelixa i-LSR (irabha yesilicone elulwelo) yokubumba inaliti ibonelela ngeenzuzo ezininzi, kukwakho nezinto ezingeloncedo ezimbalwa ekufuneka uziqwalasele xa uthatha isigqibo sokusebenzisa le nkqubo yokuvelisa. Nazi ezinye zezinto ezingalunganga zokubumba inaliti ye-LSR:

Utyalo-mali oluPhezulu oluPhezulu

Enye yezinto ezingalunganga eziphambili zokubumba inaliti ye-LSR lutyalo-mali oluphezulu olufunekayo ukuseta izixhobo kunye nokubumba. Oomatshini bokubumba inaliti ye-LSR kunye nezixhobo zinokubiza, ngakumbi kwiziko lokubumba okanye imveliso encinci. Oku kunokwenza ukubumba inaliti ye-LSR ingabizi kakhulu kwiinkampani ezinohlahlo lwabiwo-mali oluncinci okanye iimveliso ezinemfuno elinganiselweyo.

UKhetho Lwezinto eziNcinane

Ngelixa izinto ze-LSR zibonelela ngeempawu ezibalaseleyo zomzimba, zilinganiselwe ekukhetheni izinto. Ngokungafaniyo ne-thermoplastics yesiko, inani eliqingqiweyo lezinto ezisekelwe kwi-silicone ziyafumaneka ukuze zisetyenziswe kwi-LSR yokubumba inaliti. Ukufumana imathiriyeli efanelekileyo kwizicelo ezithile okanye iimveliso kunokukwenza kube nzima.

Amaxesha Amakhulu Okuphumla

Ukubumba inaliti ye-LSR kufuna amaxesha amade okunyanga kuneenkqubo zokubumba zesitofu. I-silicone ye-liquid idinga ixesha lokunyanga kunye nokuqinisa, oku kunokubangela ixesha elide lokuvelisa kunye nokunciphisa ukusebenza kakuhle. Ukongeza, amaxesha okuphilisa amade anokwenza ukuvelisa iindawo ezithile ezinobunzima bejometri okanye ezintsonkothileyo zibe ngumngeni.

Kufuneka iseti yezakhono ezikhethekileyo

Ukubumba inaliti ye-LSR kufuna ulwazi olukhethekileyo kunye nobuchule, kubandakanya ukuqonda okunzulu kweempawu kunye nokuziphatha kwe-silicone engamanzi. Oku kunokwenza kube nzima kwiinkampani ukufumana abasebenzi abafanelekileyo ukuze basebenze kwaye balondoloze izixhobo, ngakumbi kwiindawo apho ukubumba inaliti ye-LSR kunqabile.

Ukubumba imingeni

Ukubumba inaliti ye-LSR kunokuzisa imingeni embalwa ekufuneka iqwalaselwe ukuqinisekisa ukuveliswa kwamalungu akumgangatho ophezulu. Umzekelo, i-silicone engamanzi inokuthambekela ukudanyaza okanye i-burrs, echaphazela umgangatho wemveliso yokugqibela. Ukongeza, ii-agent zokukhulula i-mold zingafunwa ukuba zisuse iinxalenye kwi-mold, ezinokuchaphazela ukugqiba kwemveliso yokugqibela kunye neempawu zomatshini.

Ukugqitywa komphezulu oMda

Ukubumba inaliti ye-LSR kulinganiselwe malunga nokugqitywa komphezulu, njengoko i-silicone yolwelo ingahambelani nokwaleka okuthile okanye ukugqiba. Oku kunokwenza ukufezekiswa kobuhle obunqwenelekayo okanye iipropathi ezisebenzayo kwiimveliso ezithile okanye izicelo zibe ngumngeni.

Iinketho zoMbala oMda

Ukubumba inaliti ye-LSR kukwanqunyelwe kukhetho lombala, njengoko imathiriyeli ye-silicone elulwelo ihlala iguquguquka okanye i-opaque. Nangona ezinye izongezo zombala zikhona, zinokuba ngumngeni ukubandakanya kwizinto eziphathekayo ngaphandle kokuchaphazela iipropati ezibonakalayo okanye ukuhambelana kwemveliso yokugqibela.

Ukubakho koNgcoliseko lweNdawo

Ukubumba inaliti ye-LSR kunokubonisa umngcipheko wongcoliseko ukuba isixhobo okanye umngundo awugcinwanga ngokwaneleyo okanye awucocwanga ngokwaneleyo. Ungcoliseko lunokuchaphazela iipropati zomzimba zemveliso yokugqibela, ezikhokelela kwiziphene okanye ukusilela ekuhambeni kwexesha.

Ukuchaneka nokuchaneka kwi-LSR yokuBumba i-Injection

Ukuchaneka kunye nokuchaneka zizinto ezibalulekileyo ze-LSR (i-Liquid Silicone Rubber) yokubumba i-injection, evelisa iindawo eziphezulu ze-rubber ye-silicone kunye nokunyamezela okuqinileyo kunye neenkcukacha ezichanekileyo. Nazi ezinye izinto eziphambili ezinegalelo ekuchanekeni kunye nokuchaneka ekubumbeni inaliti ye-LSR:

- I-Mold Design kunye noKwakha: I-mold iyinxalenye ebalulekileyo yenkqubo yokubumba i-LSR ye-injection, njengoko imisela imilo yokugqibela kunye nemilinganiselo yecandelo. Ukubumba kufuneka kuyilwe kwaye kwakhiwe ngokuchanekileyo ukuqinisekisa ukuba inxalenye yokugqibela ihlangabezana neenkcukacha ezifunwayo. Isikhunta kufuneka senziwe ngezinto ezikumgangatho ophezulu kwaye zakhiwe ukunyamezelana okuqinileyo ukunciphisa iimpazamo kunye nokuqinisekisa ukuchaneka.

- Iyunithi yokulawula iyunithi: Iyunithi yokutofa ilawula ukuhamba kwerubha ye-silicone engamanzi kwi-mold. Ulawulo oluchanekileyo lweyunithi yokutofa lubalulekile ekufezekiseni iindawo ezichanekileyo nezihambelanayo. Iyunithi yokutofa kufuneka ilinganiswe kwaye ilawulwe ukuqinisekisa ukuba izinto eziphathekayo zifakwe kwi-mold cavity kunye nesantya esichanekileyo, uxinzelelo kunye nomthamo.

- Ulawulo lobushushu: Ulawulo lobushushu luyinto ebalulekileyo kwinkqubo yokubumba inaliti ye-LSR, njengoko ichaphazela i-viscosity yezinto kunye nexesha lokunyanga. Iqondo lokushisa kufuneka lilawulwe ngononophelo ukuqinisekisa ukuba izinto zihamba kakuhle kwi-mold kwaye inkqubo yokunyanga yenzeke ngesantya esichanekileyo.

- Umgangatho wezinto eziphathekayo: Umgangatho wezinto ze-LSR zibalulekile ekufezekiseni ukuchaneka nokuchaneka kwinxalenye yokugqibela. Ukuqinisekisa ukunyanga okufanelekileyo kunye nokuhambelana, izinto eziphathekayo kufuneka zingabikho ukungcola kwaye zixutywe kumlinganiselo ochanekileyo.

- I-Post-Processing: Amanyathelo okusebenza emva kokucutshungulwa kunye nokuhlolwa kubalulekile ekufezekiseni ukuchaneka kunye nokuchaneka kwi-LSR yokubumba inaliti. Inxalenye kufuneka ilungiswe kwimilinganiselo echanekileyo kwaye ihlolwe iziphene okanye ukungafezeki.

Ukubumba inaliti ye-LSR kunika ukuchaneka okugqwesileyo kunye nokuchaneka, okuvumela ukuyilwa kwamalungu anokunyamezelana okuqinileyo kunye neenkcukacha ezichanekileyo. Inokuvelisa iinxalenye ezinomgangatho ohambelanayo kunye neenguqu ezincinci ukusuka kwisiqwenga ukuya kwiinkcukacha. Oku kuyenza ibe lolona khetho lufanelekileyo kwizicelo apho ukuchaneka kunye nokuchaneka kubaluleke kakhulu, njengezixhobo zonyango, izixhobo zemoto, kunye neemveliso zombane.

Amaxesha oMveliso aKhawulezayo

Ukubumba inaliti ye-silicone yerabha (i-LSR) yinkqubo edumileyo yokuvelisa evelisa iimveliso ze-silicone ezikumgangatho ophezulu ezineempawu ezigqwesileyo ezinjengokumelana neekhemikhali, ukumelana nobushushu, kunye nokuhambelana kwezinto eziphilayo. Nangona kunjalo, amaxesha emveliso yokubumba inaliti ye-LSR ngamanye amaxesha angacotha, nto leyo inokulibazisa inkqubo yokuvelisa kunye nokunyusa iindleko. Nazi ezinye iindlela zokuphucula amaxesha emveliso yokubumba inaliti ye-LSR:

- Sebenzisa umatshini wokubumba osebenzayo: Ukukhetha umatshini ofanelekileyo kubalulekile ukukhawulezisa imveliso. Khangela isixhobo esinokufaka i-LSR ngokukhawuleza ngaphandle kokuncama umgangatho. Cinga ukusebenzisa umatshini wesantya esiphezulu sokutofa, ukunciphisa ixesha lomjikelo kunye nokuphucula ukusebenza kakuhle kwemveliso.

- Lungiselela uyilo lokungunda: Uyilo lokungunda lukwayinto ebalulekileyo echaphazela ixesha lemveliso yokubumba inaliti ye-LSR. Lungiselela uyilo lokungunda ukuqinisekisa ukuba i-LSR itofwe ngokufanelekileyo nangokulinganayo. Cinga ukusebenzisa isikhunta esinobukhulu besango elikhulu ukuphucula ukuhamba kwe-LSR kunye nokunciphisa ixesha lokujikeleza.

- Sebenzisa inkqubo yembaleki eshushu: Inkqubo yembaleki eshushu inokuphucula ukusebenza kakuhle kwe-LSR yokubumba inaliti ngokugcina i-LSR kwiqondo lokushisa elifanelekileyo kuyo yonke inkqubo yokutofa. Oku kunokunciphisa ixesha lokujikeleza kunye nokuphucula umgangatho wemveliso yokugqibela.

- Ukufudumala i-LSR: Ukufudumala i-LSR ngaphambi kokuba inaliti inokunceda ukunciphisa ixesha lokuvelisa. Ukutshisa i-LSR kunokuphucula ukuhamba kwayo kunye nokunciphisa ixesha lokujova, okukhokelela kumaxesha okujikeleza ngokukhawuleza kunye nokuphucula ukusebenza kakuhle.

- Ukunciphisa ixesha lokunyanga: Ixesha lokunyanga le-LSR lingancitshiswa ngokunyusa izinga lokushisa lokunyanga okanye ukusebenzisa i-arhente yokunyanga ngokukhawuleza. Nangona kunjalo, kubalulekile ukugcina umgangatho wemveliso yokugqibela ngelixa unciphisa ixesha lokunyanga.

Uveliso oluSebenzayo ngeendleko

Ukubumba inaliti ye-silicone yerabha (i-LSR) yinkqubo edumileyo yokuvelisa ukuvelisa iimveliso ze-silicone ezikumgangatho ophezulu. Nangona kunjalo, iindleko zokubumba inaliti ye-LSR zinokuchaphazela abavelisi, ngakumbi xa bevelisa izixa ezikhulu. Nazi ezinye iindlela zokwenza isitofu se-LSR sisebenze kakhulu:

- Lungiselela uyilo lwemveliso: Uyilo lwemveliso lunokuba nefuthe elibonakalayo kwiindleko zokubumba inaliti ye-LSR. Ngokulungisa uyilo, abavelisi banokunciphisa inani lezinto ezisetyenzisiweyo, ezinokuthoba ixabiso elipheleleyo lemveliso. Ukongeza, ukwenza lula inkqubo kunokunciphisa ubunzima bokubumba, ukunciphisa iindleko zesixhobo.

- Sebenzisa iinkqubo ezizenzekelayo: Ukusebenzisa iinkqubo ezizenzekelayo kunokuphucula ukusebenza kakuhle kwe-LSR yokubumba inaliti kunye nokunciphisa iindleko zabasebenzi. Iinkqubo ezizenzekelayo ezifana nokuphathwa kwerobhothi kunye nokutya okuzenzekelayo kunokunciphisa ixesha lokujikeleza kunye nokuphucula imveliso yonke.

- Sebenzisa i-mold ephezulu: I-mold high quality mold inokuphucula ukusebenza kakuhle kwe-LSR yokubumba inaliti kunye nokunciphisa inkunkuma. Ukusebenzisa i-mold ehlala kwaye echanekileyo ephezulu kunokunciphisa imfuno yokulungiswa rhoqo okanye ukutshintshwa, ukugcina imali kwixesha elide.

- Lungiselela inkqubo yokuvelisa: Ukuphucula inkqubo yokuvelisa kunokunciphisa inkunkuma kunye nokuphucula ukusebenza kakuhle, ukunciphisa iindleko. Oku kunokubandakanya ukwenziwa ngcono kweeparamitha zokubumba inaliti, njengesantya sokutofa, ubushushu, kunye noxinzelelo, ukunciphisa inkunkuma yezinto kunye nokunciphisa ixesha lomjikelo.

- Ukunciphisa inkunkuma yezinto eziphathekayo: Ukunciphisa inkunkuma yezinto eziphathekayo kunokunciphisa kakhulu ixabiso lokubumba inaliti ye-LSR. Oku kunokufezekiswa ngokusebenzisa inkqubo yokulinganisa echanekileyo yokulawula izinto ezisetyenzisiweyo, ukuqinisekisa ukuba isikhunta siyilwe ngokufanelekileyo kwaye siphuculwe ukunciphisa izinto ezingaphezulu, kunye nokuphinda kusetyenziswe izinto ezongezelelweyo zokusetyenziswa kwixesha elizayo.

Ukugqitywa komphezulu oPhezulu

Ukubumba inaliti ye-silicone yerabha (i-LSR) yinkqubo edumileyo yokuvelisa ukuvelisa iimveliso ze-silicone ezikumgangatho ophezulu ezineempawu ezibalaseleyo ezifana nokuxhathisa ubushushu, ukumelana neekhemikhali, kunye ne-biocompatibility. Ukongeza kwezi zakhiwo, ukuphumeza umgangatho ophezulu wokugqiba umgangatho kubalulekile kwizicelo ezininzi. Nazi ezinye iindlela zokufikelela kumgangatho ophezulu wokugqitywa komphezulu wokubumba inaliti ye-LSR:

- Sebenzisa ukungunda okukumgangatho ophezulu: Ukungunda okukumgangatho ophezulu kubalulekile ekufezekiseni umgangatho ophezulu womphezulu. Isikhunta kufuneka senziwe kwizinto ezikumgangatho ophezulu kwaye zibe nokugqiba okugudileyo. Ukongeza, isikhunta kufuneka siyilwe ngokungena ngokufanelekileyo ukuze kuthintelwe amaqamza omoya ukuba angabikho, anokuthi abe nefuthe elibi kumphezulu womhlaba.

- Sebenzisa izinto ezikumgangatho ophezulu we-LSR: Ukusebenzisa izinto eziphezulu ze-LSR kunokuphucula ukugqitywa komphezulu. Izinto eziphezulu ze-LSR zenzelwe ukuba zibe ne-viscosity ephantsi, enokuphucula ukuhamba kwezinto kunye nokunciphisa ukubonakala kwamanqaku okuhamba kunye nokunye ukungafezeki.

- Yandisa iiparamitha zokubumba inaliti: Ukuphucula iiparamitha ezinje ngeqondo lobushushu, isantya sokutofa, kunye noxinzelelo kunokuphucula ukugqitywa komphezulu. Isantya sokutofa kufuneka siphuculwe ukuze kuthintelwe naziphi na izinto zokwakha okanye ukuhluma. Ubushushu kunye noxinzelelo kufuneka zilawulwe ngononophelo ukuphepha ukuthotywa kwezinto okanye ukujija.

- Sebenzisa iinkqubo ze-post-molding: Iinkqubo ze-post-molding ezifana nokucheba, ukupholisa, kunye nokugquma kunokuphucula ukugqitywa komphezulu weemveliso ze-LSR. I-Trim inokususa nayiphi na i-flash okanye imathiriyeli engaphezulu kwinxalenye. Ukumenyeza kunokugudisa nakuphi na ukungafezeki okuphezu komhlaba. Ukugquma kunokubonelela ngoluhlu olongezelelweyo lokukhusela kunye nokuphucula ukubonakala komlingiswa.

- Ukuqhuba ukugcinwa rhoqo komatshini wokubumba umjovo: Ukugcinwa rhoqo kubalulekile ukuqinisekisa ukuveliswa okufanayo kunye nomgangatho ophezulu. Isixhobo kufuneka sicocwe rhoqo ukuze kuthintelwe ukungcoliseka, kwaye iimbumba kufuneka zihlolwe iimpawu zokugqoka okanye umonakalo.

Ukubunjwa kwesitofu se-LSR kwizicelo zoNyango

Isitofu sokubumba i-LSR yinkqubo yokuvelisa ebandakanya ukutofa irabha elulwelo abicah (LSR) kumngundo ukwenza imveliso yokugqibela. Le nkqubo isetyenziswa ngokubanzi kwishishini lezonyango ngenxa yeempawu ezizodwa ze-LSR, ezenza kube yinto efanelekileyo kwizicelo zonyango.

I-LSR yinto ehambelana ne-biocompatible kunye ne-hypoallergenic equkethe iikhemikhali ezinobungozi, eyenza ikhuselekile kwizixhobo zonyango kunye nokufakelwa. Ikwamelana nokukhula kwebhaktheriya kwaye kulula ukuyivala, oko kubalulekile kwiindawo zonyango apho ucoceko kunye nolawulo losulelo lubaluleke kakhulu.

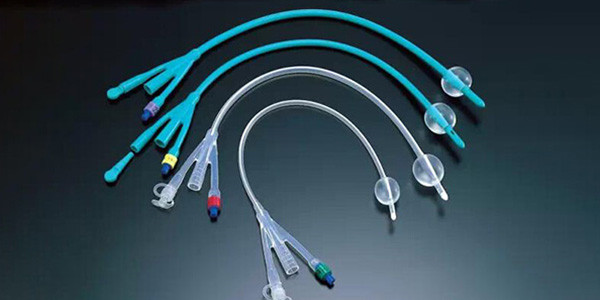

Isitofu sokubumba i-LSR yinkqubo echanekileyo nesebenzayo evumela ukuyilwa kwamalungu zonyango antsonkothileyo kunye nokunyamezelana okuqinileyo. Oku kubalulekile kwizicelo zonyango apho ukuchaneka kunye nokuchaneka kubaluleke kakhulu, njengokwenza izixhobo ezifakelwayo ezifana ne-catheters, i-pacemaker components, kunye namalungu okwenziwa.

Ukongeza kwi-biocompatibility kunye nokuchaneka kwayo, i-LSR ineempawu ezibalaseleyo zemishini eyenza ibe yinto efanelekileyo kwizicelo zonyango. I-LSR iyaxhathisa ukuguga nokukrazuka, imelana namaqondo obushushu agqithisileyo, kwaye ineempawu ezibalaseleyo zokugquma umbane. Ezi zakhiwo zenza i-LSR ibe yimathiriyeli eyaziwayo kuluhlu olubanzi lwezicelo zonyango, kubandakanya:

- I-Catheters kunye ne-tubing: I-LSR isoloko isetyenziselwa ukuvelisa i-catheters kunye ne-tubing ngenxa ye-biocompatibility yayo, ukuguquguquka, kunye nokuchasana kwe-kink.

- Izixhobo ezifakelwayo: I-LSR isetyenziswa ngokuqhelekileyo ukuvelisa izixhobo ezifakelwayo ezifana nezihlanganisi ezenziweyo, amacandelo e-pacemaker, kunye nezixhobo zotyando ngenxa yokuqina kwayo kunye ne-biocompatibility.

- Iimpawu zonyango kunye neegaskets: I-LSR isoloko isetyenziselwa ukuvelisa ngenxa yokuchasana nokushisa okugqithisileyo kunye nokukwazi ukugcina iimpawu zayo ngokuhamba kwexesha.

Ukubumba inaliti ye-LSR yinkqubo eguquguqukayo nesebenzayo yokwenza izixhobo zonyango kunye namalungu. Iimpawu zayo ezikhethekileyo zenza ukuba ibe yinto efanelekileyo kwizicelo ezininzi zonyango, kwaye ukuchaneka kwayo kunye nokuchaneka kwayo kuqinisekisa ukuba iimveliso zihlangabezana nemigangatho ephezulu yomgangatho kunye nokhuseleko.

Ukusetyenziswa kwe-LSR kuShishino lweziThuthi

I-Rubber ye-Silicone ye-Liquid (LSR) isetyenziswa ngokunyukayo kwishishini leemoto kuluhlu olubanzi lwezicelo ngenxa yeempawu ezizodwa ezenza ukuba ibe yinto efanelekileyo yezixhobo zemoto. I-LSR yilastomer eyenziweyo eyenziwe ngokubumba inaliti, ivumela ukuchaneka okuphezulu kunye nokuchaneka kwimveliso entsonkothileyo kunye neendawo ezintsonkothileyo zemoto.

I-LSR ineempawu ezibalaseleyo zoomatshini, iyenza ilungele iindawo zemoto ezifuna ukuqina, ukumelana nobushushu obuphezulu, kunye nobomi benkonzo ende. I-LSR iyaxhathisa kwi-abrasion, ukuguga, kunye nokukrazuka, nto leyo eyenza ukuba ilungele iindawo zemoto ezifumana ukukhuhlana okungaguqukiyo, okufana ne-seals, i-gaskets, kunye ne-O-rings.

Enye yezona nzuzo zibalulekileyo ze-LSR kushishino lweemoto kukukwazi ukumelana nokwahluka kobushushu obugqithisileyo. I-LSR inokusebenza ngokufanelekileyo kwiindawo ezinobushushu obuphezulu kunye nobushushu obuphantsi, iyenza ibe yeyona nto ifanelekileyo yezixhobo zemoto ezivezwe kumaqondo obushushu aphezulu, anje ngezixhobo ze-injini, iinkqubo zokukhupha umoya, kunye nemibhobho ye-turbocharger.

Olunye uncedo olubalulekileyo lwe-LSR kushishino lweemoto kukukwazi ukubonelela ngetywina eligqwesileyo ngokuchasene nolwelo kunye neegesi. I-LSR yinto exhathisayo kakhulu enika itywina elithembekileyo, naphantsi koxinzelelo oluphezulu, okwenza kube yinto efanelekileyo yokusetyenziswa kwi-gaskets yemoto kunye netywina.

I-LSR ikwanazo iimpawu ezibalaseleyo zokugquma umbane, ezenza ukuba zilungele ukusetyenziswa kumacandelo ombane kushishino lweemoto, ezifana nezihlanganisi, izinzwa, kunye neenkqubo zokulayita. I-LSR inokumelana nombane ophezulu wombane kwaye inomngcipheko ophantsi we-arcing yombane okanye iisekethe ezimfutshane, okwenza kube yinto ethembekileyo yokusetyenziswa kombane.

Lilonke, i-LSR ineenzuzo ezininzi ezenza ibe sisixhobo esifanelekileyo kumalungu emoto, kubandakanya ukuqina, ukumelana nobushushu obuphezulu, iipropathi ezibalaseleyo zokutywina, kunye nokugqunywa kombane. Ukusetyenziswa kwe-LSR kushishino lweemoto kulindeleke ukuba kukhule kwiminyaka ezayo njengoko abavelisi befuna ukuphucula ukuthembeka, ukhuseleko, kunye nokusebenza kweemveliso zabo ngelixa benciphisa iindleko kunye nokuphucula ukusebenza kakuhle kwemveliso.

Usetyenziso lweShishini loMbane lwe-LSR

I-Liquid Silicone Rubber (LSR) sisixhobo esisetyenziswa kakhulu kwishishini le-elektroniki ngenxa yozinzo olugqwesileyo lwe-thermal, ukumelana neekhemikhali, kunye neempawu zokugquma umbane. Isetyenziswa kwizicelo ezahlukeneyo ezifana ne-encapsulation, ukutywinwa, kunye nokubumba izinto ze-elektroniki.

Esinye sezicelo eziphambili ze-LSR kwishishini le-elektroniki kuku-encapsulation yamacandelo e-elektroniki, afana neesekethe ezidibeneyo (ICs), izinzwa kunye nezihlanganisi. I-encapsulation ikhusela la macandelo kumswakama, uthuli, kunye nezinye izinto ezingcolileyo, ezinokubangela ukubola kunye nokunciphisa ukusebenza. I-LSR yinto efanelekileyo yokugquma ngenxa ye-viscosity ephantsi, amandla aphezulu okukrazula, kunye nokunamathela okugqwesileyo kwii-substrates ezahlukeneyo. Ikwabonelela ngeempawu ezintle ze-dielectric, eziyimfuneko kwizicelo zombane.

I-LSR ikwatywina amacandelo e-elektroniki ukuthintela ukungena kokufuma kunye nezinye izinto ezingcolisayo. Izinto eziphathekayo zinokubunjwa zibe yimilo kunye nobukhulu obuqhelekileyo ukuze bulingane izinto ezahlukeneyo ze-elektroniki. Izitywina ze-LSR zihlala zisetyenziswa kwiindawo ezingqongileyo ezirhabaxa, ezinje ngolwandle nakwizicelo zeemoto, apho kufuneka zimelane namaqondo obushushu agqithisileyo kunye nokuvezwa kweekhemikhali.

Ukubumba sesinye isicelo esibalulekileyo se-LSR kwishishini le-elektroniki. Ukugada kubandakanya ukuzalisa umngxuma ojikeleze icandelo ngento engamanzi ukuyikhusela kwizinto zokusingqongileyo ezifana nokothuka, ukungcangcazela, kunye nokufuma. I-LSR yinto efanelekileyo yokubumba ngenxa ye-viscosity ephantsi, evumela ukuba ihambe ngokulula malunga neemilo eziyinkimbinkimbi, kunye nokuzinza kwayo okuphezulu kwe-thermal, okuqinisekisa ukuba icandelo lihlala likhuselekile kumaqondo aphezulu okushisa.

I-LSR ikwasetyenziselwa ukwenza iiphedi zamaqhosha kunye namaqhosha, amacandelo asemgangathweni kwizixhobo zombane ezifana nolawulo olukude, izixhobo zokubala, kunye nezitshixo. Izinto ezinokwenziwa ngokwezifiso kakhulu zinokubunjwa kwiimilo ezahlukeneyo kunye nobukhulu obunobume obahlukeneyo kunye namanqanaba obunzima.

Izicelo zoShishino lwe-Aerospace ye-LSR

I-Liquid Silicone Rubber (LSR) yinto esetyenziswa ngokubanzi kwishishini le-aerospace ngenxa yeempawu zayo ezizodwa, ezifana nokuzinza okuphezulu kwe-thermal, ukuchasana kweekhemikhali, kunye neempawu ezibalaseleyo zoomatshini. Isetyenziswa kwizicelo ezahlukeneyo ze-aerospace ezifana nokutywinwa, ukudibanisa, kunye nokubeka izinto ze-elektroniki kunye nokwenza iigaskets, ii-O-rings, kunye nezinye iinkcukacha ezibalulekileyo.

Esinye sezicelo eziphambili ze-LSR kwishishini le-aerospace kukutywina kunye nokudibanisa amacandelo eenqwelomoya. Izinto eziphathekayo zinokubunjwa ngokulula zibe ziimilo ezintsonkothileyo kunye nobukhulu, nto leyo eyenza ukuba ilungele ukupakisha kunye nokudibanisa iitanki zamafutha, izixhobo ze-injini kunye neenkqubo zombane. I-LSR ibonelela ngokunamathela ngokugqwesileyo kwii-substrates ezahlukeneyo kwaye inokumelana neemeko ezirhabaxa zokusingqongileyo, ezinje ngobushushu obugqithisileyo kunye nokuvezwa kweekhemikhali.

I-LSR ikwasetyenziswa ekubumbeni izinto ze-elektroniki kwizicelo ze-aerospace. I-viscosity ephantsi yemathiriyeli ivumela ukuba ihambe ngokulula ijikeleze iimilo ezintsonkothileyo, ibonelela ngokhuseleko olugqwesileyo lwamalungu anovakalelo e-elektroniki ngokuchasene nokungcangcazela, ukothuka, kunye nezinto zokusingqongileyo ezifana nokufuma kunye notshintsho lobushushu.

Olunye usetyenziso olubalulekileyo lwe-LSR kwishishini le-aerospace kukwenza ii-gaskets, ii-O-rings, kunye nezinye izinto zokutywina. I-LSR inokwenziwa ngokwezifiso ukuhlangabezana neemfuno ezithile, ezifana nokuchasana nobushushu kunye noxinzelelo, kwaye isoloko isetyenziswa kwizicelo eziphezulu zokusebenza apho izinto zerabha zendabuko zingenakufaneleka.

Ukongeza ekutywinweni nasekudibaneni kwezicelo, iLSR ikwasetyenziselwa ukwenza izinto zokukhanyisa kwinqwelomoya, ezinje ngeelensi kunye nezixhobo zokusasaza. Izinto ezibonakalayo ezibonakalayo zenza kube yinto efanelekileyo yokukhetha ezi zicelo, ukubonelela ngokugqithisela ukukhanya okugqwesileyo, ngelixa iimpawu zayo zomatshini ziqinisekisa ukuqina kunye nokuchasana nezinto zokusingqongileyo ezifana nemitha ye-UV kunye nokutshintsha kobushushu.

Ukutya-IBanga le-LSR Isitofu sokubumba

Irabha yeLiquid Silicone yeBanga lokuTya (LSR) sisixhobo esikhethekileyo esisetyenziswa kwiimveliso zokubumba zokutofa ezidibana nokutya, okufana nempahla yasekhitshini, iimveliso zabantwana, kunye nokupakishwa kokutya. Yimathiriyeli ecocekileyo ehlangabezana nemigangatho engqongqo yolawulo lokhuseleko lokutya.

Enye yeenzuzo eziphambili zoKutya-iBanga le-LSR kukuchasana nokushisa okuphezulu, okwenza kube yinto efanelekileyo yokusetyenziswa kwizinto zasekhitshini ezifana ne-spatulas, iipuni kunye nokubhaka. Iyakwazi ukumelana namaqondo obushushu ukuya kwi-450 ° F (232 ° C), iyenza ikhuseleke ekuphekeni nasekufakeni izicelo zokubhaka.

I-Food-Grade LSR ikwasetyenziselwa ukuvelisa iimveliso zabantwana, ezifana ne-pacifiers kunye neengono zebhotile. Ezi mveliso kufuneka zihlangabezane nemigangatho engqongqo yokhuseleko ukuqinisekisa ukuba zikhuselekile kwiintsana. I-LSR yimathiriyeli efanelekileyo kwezi zicelo ngenxa ye-biocompatibility egqwesileyo, ukuthamba, kunye nokuqina.

Olunye usetyenziso olubalulekileyo lwe-Food-Grade LSR kukupakisha ukutya. Izinto eziphathekayo zinokubunjwa zibe ziimilo ezahlukeneyo kunye nobukhulu, ziyenze ilungele ukwenza izitya zokugcina ukutya, iitreyi zomkhenkce kunye nezinye iimveliso. I-LSR iyaxhathisa kwiikhemikhali kwaye ineempawu ezibalaseleyo zokutywina, iqinisekisa ukuba umxholo wepakethi uhlala umtsha kwaye ukhululekile ekungcoleni.

I-Food-Grade LSR ikwasetyenziselwa ukuvelisa iimveliso zonyango ezifana nemathiriyeli yamazinyo kunye nezixhobo zokufakelwa. I-biocompatibility yemathiriyeli, ukuqina, kunye nokukwazi ukuphinda-phinda iinkcukacha ezintle kuyenza ibe lolona khetho lufanelekileyo kwezi zicelo.

Lilonke, uKutya-iBanga le-LSR sisixhobo esikhethekileyo sokwenza iimveliso ezidibana nokutya, njengempahla yasekhitshini, iimveliso zabantwana, kunye nokupakishwa kokutya. Ukuxhathisa kwayo kumaqondo obushushu aphezulu, i-biocompatibility, kunye neempawu ezibalaseleyo zokutywina ziyenza ibe yinto efanelekileyo kwezi zicelo. Isixhobo sikwasetyenziselwa ukwenza iimveliso zonyango ngenxa ye-biocompatibility kunye nokukwazi ukuphindaphinda iinkcukacha ezintle.

Isitofu se-LSR sokuBunjwa kweeMveliso zaBantwana

I-LSR (i-Liquid Silicone Rubber) yokubumba inaliti yinkqubo yokuvelisa esetyenziselwa ukuvelisa uluhlu olubanzi lweemveliso ezenziwe ngerabha ye-silicone. Esinye sezicelo ezidumileyo zokubumba inaliti ye-LSR kukuvelisa iimveliso zomntwana, kwaye oku kungenxa yeenzuzo ezininzi ezinikezelwa yi-LSR kwiimveliso zabantwana, kubandakanya ukhuseleko, ukuqina, kunye nokulula kokucoca.

Isitofu sokubumba i-LSR ibandakanya ukutofa irabha elulwelo abicah kumngundo, othi ke unyange kwaye uqina. Le nkqubo ivumela ukudala imilo enzima kunye nokuyila kunye nokusetyenziswa kwemibala eyahlukeneyo kunye nemibala. Umphumo ngumkhiqizo ogqityiweyo othambileyo, oguquguqukayo, kunye nokumelana nokushisa kunye neekhemikhali.

Enye yeenzuzo eziphambili zokubumba inaliti ye-LSR kwiimveliso zabantwana kukhuseleko. Irabha ye-Silicone ayinayo ityhefu, i-hypoallergenic, kwaye ayinazo iikhemikhali ezinobungozi ezifana ne-BPA, i-phthalates, kunye ne-PVC. Oku kuyenza ibe lukhetho oludumileyo kwiimveliso ezidibana neentsana, ezinje ngeepacifiers, iiringi zamazinyo, kunye neengono zebhotile. Ukubumba inaliti yeLSR kukwavumela ukwenziwa kweemveliso ezingenamacala abukhali okanye imithungo enokwenzakalisa ulusu oluethe-ethe lomntwana.

Ukuqina kolunye uncedo lokubumba inaliti ye-LSR. Irabha yeSilicone iyamelana nokunxiba kunye nokukrazuka, iyenza ilungele iimveliso ezisetyenziswa rhoqo okanye eziphantsi kolawulo olurhabaxa, olunje ngeepacifiers okanye iiringi zamazinyo. Ubume obuthambileyo kunye nokuguquguquka kwezinto eziphathekayo buye kwenza ukuba kungabi lula ukuphuka okanye ukuqhekeka xa behla, ukunciphisa umngcipheko wokulimala kumntwana.

Ukubumba inaliti ye-LSR ikwabonelela ngokucoca okulula, okuyimfuneko kwiimveliso zabantwana ekufuneka zicocwe rhoqo. Irabha ye-Silicone ayina-porous kwaye inokucocwa ngokulula ngesepha kunye namanzi okanye ifakwe kwi-dishwasher ukuze icoceke ngokucokisekileyo.

Ukubunjwa kwesitofu se-LSR kwiiMpahla zeMidlalo

I-LSR (i-Liquid Silicone Rubber) yokubumba inaliti yinkqubo edumileyo yokwenziwa kweemveliso ezahlukeneyo, kuquka iimpahla zemidlalo. Ukubumba inaliti ye-LSR ibonelela ngeengenelo ezininzi zokuvelisa iimpahla zemidlalo, kubandakanya ukuguquguquka, ukuqina, kunye nokumelana nobushushu obugqithisileyo kunye neemeko zokusingqongileyo.

Enye yeenzuzo eziphambili zokubumba inaliti ye-LSR kwimpahla yezemidlalo kukuguquguquka. Irabha ye-Silicone yinto ethambileyo, ethambileyo enokubunjwa kwiimilo ezahlukeneyo kunye noyilo. Oku kuvumela ukudala iimpahla zemidlalo ezikhululekile ukuzisebenzisa kwaye zihambelane nomzimba, njengezixhobo zokukhusela okanye ukubamba izixhobo.

Ukuqina lolunye uncedo lokubumba inaliti ye-LSR kwimpahla yezemidlalo. Irabha yeSilicone iyamelana nokunxiba kunye nokukrazula, iyenza ilungele iimveliso ezisetyenziswa rhoqo okanye eziphantsi kolawulo olurhabaxa, njengeebhola, iipaddles, okanye iirakethi. Isixhobo sinokumelana namaqondo obushushu agqithisileyo kunye neemeko zokusingqongileyo, ezinjengokukhanya kwelanga okanye amanzi, ngaphandle kokuthotywa okanye ukuwohloka.

Ukubumba inaliti ye-LSR ikwavumela ukuyilwa kweemveliso ezixhathisayo kwimpembelelo kunye nokuqhawuka. Amandla aphezulu wesixhobo sokukrazula kunye nobude ngexesha lekhefu kuyenza ilungele ukuvelisa izixhobo ezikhuselayo ezinje ngee-helmet liners, imilomo kunye nonogada be-shin. Ukongeza, ukubunjwa kwenaliti ye-LSR kuvumela ukudalwa kweendawo ezingatyibilikiyo okanye ukubamba izixhobo, njengezibambo okanye i-racquet grips.

Olunye uncedo lokubumba inaliti ye-LSR kwimpahla yezemidlalo kukwenza iimveliso ekulula ukuzicoca nokuzigcina. Irabha yeSilicone ayinaporous kwaye inokosulwa lula ngelaphu elimanzi okanye ihlanjwe ngesepha namanzi. Oku kuyenza ibe yimathiriyeli efanelekileyo kwiimveliso ezisetyenziswa rhoqo, njengezixhobo zokuzilolonga okanye iimethi zeyoga.

Ukubunjwa kokuTofwa kwe-LSR kwiiMpahla zaseKhaya

Ukubumba inaliti ye-LSR yinkqubo yokuvelisa esebenzisa i-Liquid Silicone Rubber (LSR) ukwenza iindawo ezibunjiweyo. Le nkqubo ilungele ukuvelisa iimpahla zekhaya ezikumgangatho ophezulu ezifana nempahla yasekhitshini, iimveliso zabantwana, kunye nezixhobo zokuhlambela. Ukubumba inaliti ye-LSR ibonelela ngeenzuzo ezininzi, kubandakanya ukuchaneka okuphezulu, ukungaguquguquki, kunye nokuqina, oko kuyenza ibe lolona khetho lubalaseleyo kwiimveliso zasekhaya ezifuna ukunyamezelana okuqinileyo kunye nokusebenza okuphezulu.

Inkqubo yokubumba inaliti ye-LSR ibandakanya ukutofa izinto ze-silicone elulwelo kumngundo. Umngundo ke shushu, kwaye ulwelo abicah imathiriyeli iyaphilisa kwaye iqina kwimilo oyifunayo. Inkqubo i-automated kakhulu, ivumela ukuveliswa kwamalungu angaguqukiyo kunye nokunyamezela okuqinileyo kunye nokugqiba okuphezulu. Le nkqubo ikwavumela ukuvelisa iijiyometri ezintsonkothileyo eziya kuba nzima okanye zingenzeki ukufikelela nezinye iinkqubo zokubumba.

Izinto zasekhaya ezidla ngokuveliswa kusetyenziswa ukubumba inaliti ye-LSR ziquka izixhobo zasekhitshini ezifana nespatula kunye namacephe okupheka, iimveliso zabantwana ezifana nezithinteli kunye neengono zebhotile, kunye nezixhobo zokuhlambela ezifana neentloko zeshawa kunye neebrashi zamazinyo. Ezi mveliso zifuna ukubunjwa okuchanekileyo ukuhlangabezana nemigangatho yokhuseleko kunye nokusebenza, kwaye ukubumba inaliti ye-LSR kunika ukuchaneka kunye nokungaguquguquki okufunekayo ukuvelisa iimpahla zekhaya ezikumgangatho ophezulu ezihlangabezana nale migangatho.

Olunye lolona ncedo luphambili lokubumba inaliti ye-LSR kwimpahla yasekhaya kukuhlala kwayo. Izinto ze-LSR ziyaxhathisa kubushushu obuphezulu, imitha ye-UV, kunye neekhemikhali, zizenza zilungele imveliso yokuqina kwexesha elide. Ukongeza, izinto ze-LSR ziyi-hypoallergenic, zibenza zikhuseleke ukusetyenziswa kwiimveliso zabantwana kunye nezinye iimpahla zendlu ezidibana nolusu.

Olunye uncedo lokubumba inaliti ye-LSR kukukwazi ukuvelisa iindawo ezinomphezulu ogqwesileyo. Inkqubo ivumela ukudala iimpawu kunye nokugqiba okugudileyo, okucwebezelayo ukumelana nemikrwelo kunye ne-scuffs. Oku kwenza ukubumba inaliti ye-LSR ibe lolona khetho lufanelekileyo lokuvelisa iimpahla zasekhaya ezifuna inkangeleko enomtsalane, njengempahla yasekhitshini kunye nezixhobo zokuhlambela.

Ukuthelekisa kunye nezinye iintlobo zeRubber Molding

I-LSR (i-Liquid Silicone Rubber) yokubumba inaliti yinkqubo yokwenziwa kwemveliso edumileyo yokuvelisa iimveliso zerabha ezahlukeneyo, kwaye ibonelela ngeenzuzo ezininzi kunezinye iintlobo zeenkqubo zokubumba irabha. Nalu olunye uthelekiso phakathi kokubumba inaliti ye-LSR kunye neentlobo ezahlukeneyo zokubumba irabha:

- Ukubunjwa koxinzelelo: Ukubumba ukunyanzeliswa yinkqubo eqhelekileyo yokuvelisa iindawo ezinkulu okanye iinxalenye ezinemilo enzima. Kwi-compression molding, inani elilinganiswe kwangaphambili lerabha lifakwe kwi-mold evuthayo, kwaye uxinzelelo lufakwe kude kube yilapho irabha iphiliswa. Xa kuthelekiswa nokubunjwa kwenaliti ye-LSR, ukunyanzeliswa kokubumba yinkqubo ecothayo kwaye kunokubangela ukuhlukahluka kwimilinganiselo ngenxa yokusabalalisa uxinzelelo olungalinganiyo. Ukubumba inaliti ye-LSR, kwelinye icala, ivumela ulawulo oluchanekileyo lwenxalenye yemilinganiselo kwaye inokuvelisa iimilo ezintsonkothileyo ezinokunyamezelana okuqinileyo.

- Ukubunjwa kwe-Transfer: Ukubunjwa kokutshintshela kufana nokubunjwa koxinzelelo kodwa kubandakanya ukusebenzisa i-plunger ukuhambisa irabha kwimbiza yokutofa ukuya kwi-mold. Ukudlulisa ukubunjwa kunokuvelisa iindawo ngokuchaneka okuphezulu kwaye zifanelekile ukwenza iindawo ezinobungakanani obuphakathi. Nangona kunjalo, inokucotha kwaye ibize kakhulu kunokubumba inaliti ye-LSR.

- I-Injection Molding: I-injection molding yinkqubo ebandakanya ukutofa irabha etyhidiweyo kwi-mold kuxinzelelo oluphezulu. Ukubumba isitofu kunokuvelisa iinxalenye ngokukhawuleza nangokuchanekileyo, kodwa kusenokungafaneleki ukwenza iinxalenye ezinoyilo oluntsonkothileyo okanye iinkcukacha. Xa kuthelekiswa nokubunjwa kwenaliti, ukubumba inaliti ye-LSR kuvumela ukuyilwa kwamacandelo aneenkcukacha ezichanekileyo kunye noyilo oluntsonkothileyo kunye neepateni.

- I-Extrusion: I-Extrusion yinkqubo esetyenziselwa ukuvelisa iinxalenye ezineprofayili eqhubekayo ye-cross-sectional, efana ne-hoses, i-seals, kunye ne-gaskets. I-Extrusion yinkqubo ekhawulezayo neyindleko, kodwa isenokungafaneleki ukuvelisa iimilo ezintsonkothileyo okanye iinxalenye ezinokunyamezelana okuqinileyo. Ukubumba inaliti ye-LSR, kwelinye icala, inokuba neenxalenye ezineemilo ezintsonkothileyo kunye nokunyamezelana okuqinileyo, kuyenza ilungele ukuvelisa iimveliso ezinje ngezixhobo zonyango, izixhobo zemoto, kunye nempahla yabathengi.

Iingqwalaselo zoyilo lwe-LSR yokuBumba isitofu

Iingqwalasela ezininzi ezibalulekileyo kufuneka ziqwalaselwe xa kuyilwa iinxalenye zokubumba inaliti ye-LSR ukuqinisekisa inkqubo yokuvelisa enempumelelo. Ezi ngqwalasela zibandakanya ukukhetha izinto, uyilo lokubumba, inxalenye yejometri, kunye nokusebenza emva kokubumba.

Ukukhethwa kwezinto eziphathekayo kukuqwalasela okubalulekileyo xa kuyilwa iinxalenye zokubumba inaliti ye-LSR. Izixhobo zerabha ye-silicone yolwelo ziza kwii-durometers ezahlukeneyo, ii-viscosities, kunye nemibala, kwaye ukukhetha imathiriyeli efanelekileyo kubalulekile ekufezekiseni iipropathi ezifunwayo zemveliso yokugqibela. Ukukhethwa kwezinto eziphathekayo kufuneka kuthathelwe ingqalelo iimfuno zesicelo, ezifana nokumelana nokushisa, ukuchasana kweekhemikhali, kunye nokuqina.

Uyilo lokungunda lolunye uqwalaselo olubalulekileyo lokubumba inaliti ye-LSR. Uyilo lokungunda kufuneka luphuculwe ukuvelisa indawo efunwayo yejometri kwaye iqwalasele ukuhamba kwezinto, ukupholisa, kunye nokukhupha. Umngundo kufuneka uyilwe ngendlela efanelekileyo yokungena kunye neenkqubo zokukhupha umoya kwaye ube nemingxuma eyaneleyo ukufikelela kwizinga eliphezulu lemveliso.

Icandelo lejometri likwabalulekile xa kuyilwa iinxalenye zokubumba inaliti ye-LSR. Inxalenye yejiyometri kufuneka iphuculwe ukuze kuphunyezwe iimpawu zomatshini ezinqwenelekayo zemveliso kunye nobuhle. Oku kunokubandakanya ukusebenzisa ii-engile eziyidrafti ukuququzelela ukukhutshwa kwi-mold, ukusebenzisa iimbambo ukwandisa ukuqina, kunye nokubeka i-gating kunye neenkqubo zokukhupha umoya ukwandisa ukuhamba kwezinto.

Imisebenzi ye-post-molding nayo kufuneka ithathelwe ingqalelo xa kuyilwa iindawo zokubumba inaliti ye-LSR. Imisebenzi ye-post-molding inokubandakanya ukucheba, ukuchithwa, kunye nokusebenza kwendibano yesibini. Le misebenzi kufuneka iphuculwe ukunciphisa inkcitho kunye nokunciphisa iindleko zabasebenzi.

Olunye uqwalaselo loyilo lokubumba inaliti ye-LSR lungabandakanya ukusetyenziswa kwee-undercuts, ukubekwa kwezikhonkwane ze-ejector, kunye nokusetyenziswa kwemigca yokwahlula. Ezi zinto kufuneka ziqwalaselwe ngexesha lenkqubo yoyilo ukuqinisekisa ukuba imveliso yokugqibela ihlangabezana neenkcukacha ezifunekayo kwaye inokuveliswa ngokufanelekileyo.

IiNzuzo zokuSingqongileyo kunye noZinzo lwe-LSR yokuBunjwa kwesitofu

Ukubumba inaliti ye-LSR kubonelela ngeenzuzo ezininzi zokusingqongileyo kunye nozinzo kwiinkqubo zokwenziwa kwemveli, oko kuyenza ibe lukhetho olunomtsalane kwiinkampani ezijonge ukunciphisa indawo yazo yendalo.

Enye yeenzuzo eziphambili zokusingqongileyo zokubumba inaliti ye-LSR kukuvelisa inkunkuma ephantsi. Inkqubo ivelisa inkunkuma encinci kakhulu, njengoko irabha ye-silicone yolwelo itofwa ngokuthe ngqo kwi-mold kwaye iphiliswe ukwenza imo efunekayo. Oku kuchasene nezinye iinkqubo zokuvelisa, ezinje ngomatshini okanye ukuphosa, okuvelisa izinto ezilahliweyo ezibalulekileyo.

Ukubumba inaliti ye-LSR kukwanakho ukunciphisa ukusetyenziswa kwamandla kunye nokukhutshwa kwegesi ye-greenhouse. Inkqubo ingaba ngokuzenzekelayo, ukunciphisa imfuno yomsebenzi wezandla kunye nokunciphisa ukusetyenziswa kwamandla. Ukubumba inaliti ye-LSR yinkqubo yobushushu obuphantsi obufuna amandla amancinci kunezinye iinkqubo zokubumba, ezifana nokubumba inaliti okanye ukuvuthela. Oku kunokubangela ukongiwa kwamandla okubalulekileyo kunye nokunciphisa ukukhutshwa kwegesi ye-greenhouse.

Olunye uncedo oluzinzileyo lokubumba inaliti ye-LSR kukukwazi ukusebenzisa imathiriyeli esetyenzisiweyo. Izinto ze-LSR zinokuphinda zisetyenziswe kwaye ziphinde zisetyenziswe, ukunciphisa imfuno yezinto ezintsha kunye nokunciphisa ukuveliswa kwenkunkuma. Ukongeza, ubomi obude beemveliso ze-LSR buthetha ukuba zingaphinda zisetyenziswe okanye ziphinde zisetyenziswe, kuncitshiswe ngakumbi inkunkuma kunye nokwandisa umjikelo wobomi bemveliso.

Ukubumba inaliti ye-LSR kunokunciphisa ukusetyenziswa kweekhemikhali eziyingozi kwimveliso. Imathiriyeli ye-LSR ayinazo iikhemikhali eziyityhefu njenge-phthalates, i-BPA, kunye ne-PVC, nto leyo ezenza zikhuseleke ngakumbi kubasebenzi nakubathengi. Ukongeza, inkqubo yobushushu obuphantsi obusetyenziswa kwi-LSR yokubumba inaliti ayifuni izinyibilikisi ezinobungozi okanye ezinye iikhemikhali.

Ikamva lokuBunjwa kwesitofu se-LSR

Ikamva lokubumba inaliti ye-LSR liqaqambile, kunye nenkqubo ebonelela ngeenzuzo ezininzi kwiindlela zokwenziwa kwemveli. Ukubumba inaliti ye-LSR kuya kusebenza nangakumbi, kungabizi mali, kwaye kube nobuhlobo nokusingqongileyo njengoko iteknoloji ihambela phambili.

Enye yezona ndawo zithembisayo kwikamva lokubumba inaliti ye-LSR kukusetyenziswa kobuchule bokwenza okongeziweyo. Imveliso eyongeziweyo, ekwabizwa ngokuba yi-3D yoshicilelo, ivumela ukuyilwa kweejometri ezintsonkothileyo kunye namalungu alungelelanisiweyo anokuba nzima okanye angenzekiyo ukuvelisa kusetyenziswa iindlela zemveli zokuvelisa. Njengoko itekhnoloji iphucuka, ukubumba inaliti ye-LSR kuya kudityaniswa ngakumbi nemveliso eyongezayo, evumela ukuba kuveliswe iimveliso ezihambele phambili kunye nezintsha.

Enye indawo yophuhliso lwexesha elizayo lokubumba inaliti ye-LSR kukusebenzisa imathiriyeli ephezulu. Njengoko kuphuhliswa izixhobo ezitsha, ukubumba inaliti ye-LSR kunokuthatha ithuba leempawu zabo ezizodwa, ezinjengokuqina okuphuculweyo, ukumelana nobushushu, okanye ukuhambelana kwezinto eziphilayo. Oku kuya kuvumela iimveliso ezikhethekileyo ngakumbi, ezifana nokufakelwa kwezonyango okanye amacandelo asebenza kakhulu kwimizi-mveliso.

Ukudityaniswa okuqhubekayo kwe-automation kunye nerobhothi kwiinkqubo zokubumba inaliti ye-LSR nayo inokuba yinto ebalulekileyo kwixesha elizayo. Ukuzenzekelayo kunokuphucula ukusebenza kakuhle, ukunciphisa iindleko zabasebenzi, kunye nokuphucula ukuhambelana kunye nomgangatho wemveliso yokugqibela. Njengoko itekhnoloji iphucuka, ukubumba inaliti yeLSR kuya kuzenzekela ngakumbi, iirobhothi kunye nobukrelekrele bokwenziwa budlala indima ebaluleke ngakumbi kwimveliso.

Okokugqibela, uzinzo kunye noxanduva lokusingqongileyo luya kuqhubeka ukuba luqhube phambili kwikamva lokubumba inaliti ye-LSR. Njengoko abathengi kunye namashishini besiya begxila ekunciphiseni inkunkuma kunye nokunciphisa impembelelo yabo kwindalo, ukubumba inaliti ye-LSR kuya kuba lolona khetho lunomtsalane ngakumbi ekuveliseni iimveliso ezikumgangatho ophezulu ezinendawo ephantsi yokusingqongileyo. Uphuhliso lwemathiriyeli ezinzileyo, ukurisayikilisha kunye nokuphinda kusetyenziswe izixhobo, kunye nokusetyenziswa kwemithombo yamandla ahlaziyekayo kunokwenzeka ukuba kudlale indima ebalulekileyo kwikamva lokubumba inaliti ye-LSR.

Isiphelo:

Ukuqukumbela, ukubumba inaliti ye-LSR yinkqubo yokwenziwa ethembekileyo nesebenzayo enezibonelelo ezininzi kumashishini ahlukeneyo. I-LSR yimathiriyeli eguquguqukayo eneempawu zokusebenza ezahlukileyo, iyenza ilungele usetyenziso oluninzi. Ngenkqubela phambili eqhubekayo kwitekhnoloji ye-LSR kunye nemfuno eyongeziweyo yeendlela ezizinzileyo zokwenziwa kwemveliso, ikamva lokubumba inaliti ye-LSR liqaqambile.