Thermoplastic Injection Molding

Ukubumba inaliti ye-Thermoplastic yinkqubo yokwenziwa edumileyo esetyenziselwa ukwenza iindawo ezahlukeneyo zeplastiki kumashishini amaninzi. Le nkqubo ibandakanya ukunyibilika iipellet zeplastiki kunye nokutofa kubo kwi-mold ukuvelisa imilo emithathu-dimensional. Ukubumba inaliti ye-Thermoplastic kusebenza kakhulu kwaye kuyabiza kakhulu ekuveliseni umthamo omkhulu wamalungu eplastiki akumgangatho ophezulu anokunyamezelana okuqinileyo. Esi sikhokelo sibanzi siya kuphonononga imiba eyahlukeneyo yokubumba inaliti ye-thermoplastic, kubandakanya izinto eziluncedo kunye nezingeloncedo, iintlobo ze-thermoplastics ezisetyenzisiweyo, inkqubo yokubumba inaliti, ukuqwalaselwa koyilo, kunye nokunye okuninzi.

Imbali ye-Thermoplastic Injection Molding

Imbali yokubumba inaliti ye-thermoplastic ithatha ngaphezulu kwenkulungwane yenkqubela phambili yetekhnoloji, uphuhliso lwemathiriyeli, kunye nokusetyenziswa kwemizi-mveliso. Ukusukela kwisiqalo esithobekileyo njengenkqubo yokubumba i-celluloid ukuya kwitekhnoloji ephucukileyo yanamhlanje, ukubumba inaliti kuyaqhubeka kububuchule obubalulekileyo bokwenza, ukuqhuba ukuqamba izinto ezintsha kunye nokubumba amashishini ahlukeneyo.

- Uphuhliso lwakwangoko:UJohn Wesley Hyatt kunye nomntakwabo u-Isaya baphuhlise umatshini wokuqala wokubumba inaliti, belanda imvelaphi yokubumba inaliti ye-thermoplastic emva ngasekupheleni kwenkulungwane ye-19. Ngo-1872, benza ipatent kwisixhobo esasebenzisa iplunger ukufaka i-celluloid kumgodi wokungunda, senza izinto eziqinileyo. Le mpumelelo yabeka isiseko senkqubo yanamhlanje yokubumba inaliti.

- Ukuqhubela phambili kwiMathiriyeli:Ekuqaleni kwenkulungwane yama-20, ukwazisa iipholima ezintsha zokwenziwa kwavula amathuba amatsha okubumba inaliti. I-Bakelite, i-phenolic resin, yaba yinto eyaziwayo yokubumba ngenxa yeempawu zayo ezibalaseleyo zombane. Kuyo yonke iminyaka yoo-1930 kunye no-1940, ukuqhubela phambili kwi-polymer chemistry kukhokelele kuphuhliso lwezinye ii-thermoplastics, ezifana ne-polystyrene kunye ne-polyethylene, eyandisa ngakumbi uluhlu lwezixhobo ezifanelekileyo zokubumba inaliti.

- Ukwamkelwa koMzimveliso: Ukwamkelwa okuxhaphakileyo kokubumba inaliti ye-thermoplastic kwaqala ngeminyaka yoo-1950 njengoko abavelisi beqaphela ukusebenza kwayo ngeendleko kunye nokuguquguquka kwayo. Ukwazisa oomatshini boxinzelelo oluphezulu oluvunyelwe ixesha lokujikeleza ngokukhawuleza kunye nokwandisa umthamo wemveliso. Ngenxa yoko, kuye kwakho ukhetho olwahlukeneyo lweemveliso zomntu kunye nezoshishino. Ezi zinto zaziquka izinto zemoto, izixhobo zasekhaya, nezinto zokudlala.

- Izinto ezintsha zobuGcisa:Ukutyhubela amashumi eminyaka, itekhnoloji yokubumba inaliti iqhubekile nokuvela. Ngeminyaka yee-1960, kwavela oomatshini abalawulwa yikhompyutha, okwenza ukuba kube lula ukulawula inkqubo yokubumba. Ukuqaliswa kweenkqubo zeembaleki ezishushu kwiminyaka yoo-1980 kwanciphisa inkunkuma kunye nokuphucula ukusebenza kakuhle ngokuphelisa imfuno yeembaleki kunye ne-sprues. Kwiminyaka yakutshanje, i-automation, irobhothi, kunye nenkqubela phambili yoshicilelo ye-3D iye yaliguqula ngakumbi ishishini lokubumba inaliti, ivumela uyilo oluntsonkothileyo kunye nokunciphisa ixesha lemveliso.

- Uzinzo kunye nokuRisayikilishwa:Ngokukhula kokukhathazeka kokusingqongileyo, ishishini lokubumba inaliti liye lamkela imilinganiselo yokuzinza. Abavelisi baphuhlise i-bio-based and recycled thermoplastics, ukunciphisa ukuthembela kwizinto ezisekelwe kwi-fuel-based. Ukongeza, ubuchwephesha obuphuculweyo bokurisayikilisha buvumele ukusetyenzwa kwakhona kwenkunkuma yasemva kwabathengi nasemva kwemizi-mveliso, ukunciphisa impembelelo yokusingqongileyo yokubumba inaliti ye-thermoplastic.

- Amathemba ekamva:Ikamva lokubumba inaliti ye-thermoplastic libukeka lithembisa. Ishishini liphonononga izinto ezintsha ezifana nokubumba i-micro-injection yamacandelo amancinci, ubuchule bezinto ezininzi kunye nokugqithisa ngaphezulu kwamalungu anzima, kunye nokudibanisa iteknoloji yobukrelekrele yokubeka iliso kunye nokwenza ngcono. Ngaphaya koko, abaphandi balindele ukuqhubela phambili kwimathiriyeli eyonakaliswayo kunye nemveliso eyongezelelweyo ukwenza utshintsho kwintsimi, ukwenza ukubumba inaliti kuzinze ngakumbi kwaye kuguquguquke.

Izinto eziluncedo kwi-Thermoplastic Injection Molding

Ukubumba inaliti ye-Thermoplastic kubonelela ngeenzuzo ezininzi kubavelisi. Ibonelela ngobubhetyebhetye boyilo, ivumela uyilo oluntsonkothileyo noluntsonkothileyo oluneempawu ezahlukeneyo. Inkqubo ingabizi kakhulu, inciphisa inkunkuma yezinto kunye nokunciphisa iindleko zeyunithi. Ukubumba inaliti ye-Thermoplastic ixhasa izixhobo ezininzi, ibonelela ngeendlela ezahlukeneyo kwizicelo ezahlukeneyo.

- Ukuguquguquka koyilo:Ukubumba inaliti ye-Thermoplastic kuvumela uyilo oluntsonkothileyo noluntsokothileyo oluneempawu ezinje ngee-undercuts, iindonga ezibhityileyo, kunye nobukhulu obahlukeneyo, ukubonelela abayili ngenkululeko enkulu.

- Ukusebenza kakuhle kweendleko: Inkqubo isebenza kakuhle kakhulu, inciphisa inkunkuma yezinto kunye nokunciphisa iindleko zeyunithi. Ukubumba ngaxeshanye kwamacandelo amaninzi kunye nemijikelo yokuvelisa ngokukhawuleza igalelo ekongeni iindleko.

- Izinto eziNyeezohlukeneyo: Ukubumba inaliti ye-Thermoplastic ixhasa uluhlu olubanzi lwezixhobo, ivumela abavelisi ukuba bakhethe eyona ndlela ifanelekileyo kwisicelo ngasinye, kubandakanywa eqinile okanye eguquguqukayo, ecacileyo okanye e-opaque, kunye nezixhobo ezichasene neekhemikhali.

- Ukomelela kunye noKuhlala ixesha elide:I-thermoplastics eyenziwe nge-injection inokubonisa iipropathi ezigqwesileyo zoomatshini, njengamandla aphezulu, ukuqina, kunye nokumelana nempembelelo. Iinketho zokuqinisa, njengeglasi okanye iifayibha zekhabhoni, ziphucula ngakumbi ezi zakhiwo.

- Ukungqinelana kunye noMgangatho:Isitofu sokubumba siqinisekisa umgangatho ohambelanayo wenxalenye kunye nokuchaneka komda, ukuhambisa ukunyamezela okuqinileyo kunye neemveliso ezithembekileyo. Inkqubo iphinda ibonelele ngokugqibeleleyo kunye nomgangatho olinganayo, ukuphelisa imfuno yokugqiba imisebenzi eyongezelelweyo.

- Ukubaleka kunye neMveliso enkulu:I-injection yokubumba i-scalable ukusuka kwi-low to high volumes, iyenza ilungele imveliso yobuninzi. Nje ukuba abavelisi benze ukungunda, banokuvelisa inani elikhulu lamalungu afanayo kunye nokwahluka okuncinci.

- Ukudityaniswa kunye neNdibano:Iinxalenye ezibunjiweyo ze-injection zingabandakanya amacandelo amaninzi kwisiqwenga esinye, ukunciphisa imfuno yeenkqubo ezongezelelweyo zokuhlanganisa. Oku kudityaniswa kwandisa ukusebenza kwemveliso, kunciphisa ixesha lokuhlanganisa, kunye neendleko eziphantsi.

- Ukuzinza:Ishishini lokubumba inaliti libonisa ukugxila okukhulayo kuzinzo. Ubukho bezinto ezisekwe kwibhayoloji nakwizinto ezisetyenzisiweyo zivumela ukuvelisa iimveliso ezihambelana nokusingqongileyo. Ukusetyenziswa okusebenzayo kwezinto kunye nokuphinda kusetyenziswe i-thermoplastics kunegalelo kwinkqubo yokuvelisa eluhlaza.

Ezi zibonelelo zenze ukuba ibe yindlela yokuvelisa eyamkelwa ngokubanzi kuwo wonke amashishini ahlukeneyo, ibonelela ngezisombululo ezikumgangatho ophezulu, ezingabizi kakhulu, nezinobuhlobo nokusingqongileyo kwiimfuno zemveliso entsonkothileyo.

Ukungalungi kwi-Thermoplastic Injection Molding

Ngelixa ukubumba inaliti ye-thermoplastic kubonelela ngeenzuzo ezininzi, kukwakho nezinto ezingeloncedo ezininzi. Abavelisi kufuneka bavavanye ngononophelo le miba kwaye bayilinganise ngokuchasene nezibonelelo ukumisela ukufaneleka kokubumba inaliti ye-thermoplastic kwizicelo zabo ezithile.

- Utyalo-mali oluPhezulu oluPhezulu: Ukuseta umsebenzi wokubumba inaliti ye-thermoplastic kufuna utyalo-mali lokuqala olubalulekileyo kuyilo lokungunda kunye nokwenza kunye nokuthenga oomatshini abakhethekileyo. Iindleko ezinxulumene nokudala ukubumba kunye nezixhobo zinokuba zikhulu, ngakumbi kuyilo oluntsonkothileyo noluntsonkothileyo.

- Imida yoyilo: Ngelixa ukubumba inaliti ye-thermoplastic kunika ukuguquguquka koyilo, imida ethile ikhona. Ngokomzekelo, ukufezekisa ubuninzi bodonga obufanayo kuyo yonke indawo kunokuba ngumngeni, okukhokelela kwiiyantlukwano ekuhanjisweni kwezinto eziphathekayo kunye nobuthathaka obunokubakho bolwakhiwo. Ukongezelela, ubukho be-undercuts okanye i-geometries eyinkimbinkimbi inokufuna ukusetyenziswa kweempawu ezongezelelweyo zokubumba okanye imisebenzi yesibini, ukunyuka kweendleko kunye nexesha lokuvelisa.

- Amaxesha AmanqathaInkqubo yokuyila kunye nokuyila imibumba yokubumba inaliti inokuthatha ixesha elide, okukhokelela kwixesha elide lokukhokelela ekuphuhlisweni kwemveliso. Inkqubo yokuphindaphinda ukuyila, ukuveliswa kokubumba, kunye nokuvavanya kunokongeza ixesha elibalulekileyo kwixesha elipheleleyo lemveliso, elinokuthi lingafanelanga iiprojekthi ezinemihla yokugqibela.

- Imiqobo yoKhetho lweMathiriyeli:Nangona inaliti ye-thermoplastic ixhasa uluhlu olubanzi lwezixhobo, kukho imida kunye nemiqobo ethile. Ezinye izinto zinokuba neemfuneko ezithile zokusetyenzwa okanye ukufumaneka okulinganiselweyo, okuchaphazela ukhetho loyilo kunye nokukhethwa kwezinto eziphathekayo kwisicelo esithile.

- Imida yobungakanani benxalenye:Imishini yokubumba i-injection inomlinganiselo wobungakanani, zombini ngokwemiqathango yobukhulu bomzimba wesixhobo kunye nobukhulu bemibumbo abanokuthi bayenze. Ukuvelisa iindawo ezinkulu kunokufuna izixhobo ezikhethekileyo okanye ezinye iindlela zokuvelisa.

- Impembelelo yokusingqongileyo:Ngelixa ishishini lisebenzela ukuzinza, inkqubo yokubumba inaliti ye-thermoplastic isavelisa imathiriyeli eyinkunkuma, kubandakanywa nenkunkuma kunye ne-sprues. Ukulahlwa ngokufanelekileyo kunye nokuhlaziywa kwezi zinto ziyimfuneko ukunciphisa impembelelo yokusingqongileyo.

- Ukuntsonkotha koPhuculo lweNkqubo:Ukufezekisa iiparameters zenkqubo efanelekileyo yokubumba inaliti ye-thermoplastic kunokuba nzima kwaye kudle ixesha. Abavelisi kufuneka balawule ngononophelo kwaye bandise ubushushu, uxinzelelo, amazinga okupholisa, kunye namaxesha okujikeleza ukuqinisekisa umgangatho ongaguqukiyo wenxalenye kunye nokunciphisa iziphene.

Iintlobo ze-Thermoplastics ezisetyenziswa kwi-Injection Molding

Le yimizekelo nje embalwa ye-thermoplastics edla ngokusetyenziswa ekubumbeni inaliti. Isixhobo ngasinye sineempawu ezizodwa, okwenza ukuba zilungele izicelo ezithile ezisekelwe kumandla, ukuguquguquka, ukuxhathisa imichiza, ukungafihli kunye neendleko. Abavelisi kufuneka baqwalasele ezi zakhiwo kunye neemfuno xa bekhetha i-thermoplastic efanelekileyo kwiiprojekthi zabo zokubumba inaliti.

- Ipolypropylene (PP):I-Polypropylene yi-thermoplastic eguquguqukayo esetyenziswa rhoqo xa kubumba inaliti. Ibonelela ngokumelana neekhemikhali okugqwesileyo, ukuxinana okuphantsi, kunye namandla empembelelo entle. I-PP (i-polypropylene) inezicelo ezibanzi zokupakisha, izixhobo zemoto, izixhobo zendlu, kunye nezixhobo zonyango.

- Polyethylene (PE):Polyethylene yenye esetyenziswa kakhulu thermoplastic ekubumbeni inaliti. Ifumaneka kwiifom ezahlukeneyo, ezifana ne-high-density polyethylene (HDPE) kunye ne-polyethylene ephantsi (LDPE). I-PE inika ukuxhathisa okulungileyo kweekhemikhali, ukuqina, kunye nokuguquguquka, okwenza ukuba ilungele iibhotile, izikhongozeli kunye nemibhobho.

- Ipolystyrene (PS):I-Polystyrene yi-thermoplastic eguquguqukayo eyaziwayo ngokucaca kwayo, ukuqina, kunye nokufikeleleka kwayo. Ifumana ukusetyenziswa okuqhelekileyo kwipakethe, iimpahla zabathengi, kunye neemveliso ezilahlayo. I-PS (i-polystyrene) ivumela ukucutshungulwa ngokukhawuleza kwaye ibonelela ngokuzinza okuhle kwe-dimensional, kodwa inokuba yi-brittle kwaye ichaphazeleke ekuqhekekeni koxinzelelo lwendalo.

- I-Acrylonitrile Butadiene Styrene (ABS): I-ABS yi-thermoplastic edumileyo eyaziwa ngokugqwesa kwayo ukumelana nefuthe kunye nokuqina. Idibanisa iipropati ze-acrylonitrile, i-butadiene, kunye ne-styrene ukwenza izinto eziguquguqukayo ezifanelekileyo kwiindawo zemoto, izindlu ze-elektroniki kunye namathoyizi.

- I-Polyvinyl Chloride (PVC): I-PVC yi-thermoplastic esetyenziswa ngokubanzi eyaziwa ngokugqwesa kwayo ukumelana neekhemikhali, ukuqina, kunye neendleko eziphantsi. Inokuthi ibe lukhuni okanye iguquguquke ngokuxhomekeke ekuqulunqweni kunye nezongezo ezisetyenzisiweyo. I-PVC (i-polyvinyl chloride) ifumana ukusetyenziswa okuqhelekileyo kulwakhiwo, ukugquma kombane, iimveliso zempilo, kunye nokupakishwa.

- Ipolycarbonate (PC): I-Polycarbonate yi-thermoplastic ebonakalayo enempembelelo engaqhelekanga kunye nokumelana nobushushu obuphezulu. Ifumana ukusetyenziswa okuqhelekileyo kwizicelo ezifuna ukucaca kwe-optical, ezifana nezixhobo zemoto, izigcina-ntloko zokhuseleko, kunye neziboniso zombane.

- Inayiloni (Polyamide):Inayiloni yi-thermoplastic eyomeleleyo kwaye ehlala ixesha elide eyaziwa ngeempawu zayo ezibalaseleyo zoomatshini kunye nokumelana neekhemikhali. Ifumana ukusetyenziswa okuqhelekileyo kwizicelo ezifuna amandla aphezulu, anje ngeendawo zeemoto, izinto zoshishino, kunye nempahla yabathengi.

- I-Polyethylene Terephthalate (PET):I-PET yi-thermoplastic eyaziwayo yokuvelisa iibhotile, izikhongozeli, kunye nezinto zokupakisha. Inika ukucaca okulungileyo, ukuchasana kweekhemikhali, kunye neempawu zomqobo, okwenza ukuba zilungele izicelo zokutya kunye neziselo.

Iipropati ze-Thermoplastics ezisetyenziswa kwi-Injection Molding

Ezi mpawu ze-thermoplastics zidlala indima ebalulekileyo ekumiseleni ukufaneleka kwazo kwizicelo ezithile zokubumba inaliti. Abavelisi kufuneka baqwalasele ngononophelo ezi zakhiwo kwaye bakhethe i-thermoplastic efanelekileyo ngokusekwe ekusebenzeni okufunwayo, iimeko zokusingqongileyo kunye neemfuno zeendleko.

- Iinkcazelo ngoomatshini:I-Thermoplastics esetyenziswa ekubumbeni inaliti inokubonisa iipropathi ezahlukeneyo zoomatshini, kubandakanya ukomelela, ukuxhathisa, kunye namandla okuguquguquka. Ezi zakhiwo zimisela amandla ezinto eziphathekayo okumelana namandla asetyenzisiweyo kunye nokuqina kwayo ngokubanzi kwizicelo ezahlukeneyo.

- Ukumelana neMichiza:Uninzi lwe-thermoplastics olusetyenziswa ekubumbeni inaliti lunokuxhathisa okumangalisayo kwiikhemikhali, izinyibilikisi kunye neoyile. Le propati ibalulekile kwizicelo ezibandakanya ukuvezwa kwimo engqongileyo erhabaxa okanye izinto ezidlekayo.

- Uzinzo lweThermal:Uzinzo olushushu lwe-thermoplastics lubhekiselele ekukwazini kwabo ukumelana namaqondo obushushu aphakamileyo ngaphandle kokuthotywa okubalulekileyo. Ezinye ii-thermoplastics zibonisa ukumelana nobushushu, okubavumela ukuba bagcine iimpawu zabo zoomatshini nokuba kubushushu obuphezulu.

- Iinkcazelo ngeempawu zoMbane:I-Thermoplastics esetyenziswa ekubumbeni inaliti inokuba neempawu ezithile zombane, kubandakanya ukugqunywa kombane, ukuqhubeleka, okanye amandla e-dielectric. Ezi zakhiwo ziyimfuneko kwizicelo kumashishini ombane kunye ne-elektroniki, apho izinto kufuneka zinikeze ukusebenza kombane okuthembekileyo.

- Ukungafihli kunye nokucaca:Ii-thermoplastics ezithile, ezifana ne-polycarbonate kunye ne-PET, zibonelela ngokucacileyo ngokucacileyo kunye nokucaca, zizenza zilungele izicelo ezifuna iimpawu zokukhanya. Abavelisi bahlala besebenzisa ezi mathiriyeli kwiimveliso ezinje ngeefestile ezikhanyayo, iilensi, kunye neziboniso.

- Ukuguquguquka kunye nokuqina: Ukuguquguquka kunye nokuqina zizinto ezibalulekileyo ze-thermoplastics ezisetyenziselwa izicelo ezifuna ukuxhathisa impembelelo kunye nokuqina. Ezinye ze-thermoplastics, ezifana ne-ABS kunye ne-nylon, zibonelela ngokuqina okubalaseleyo, okubavumela ukuba bamelane neempembelelo eziphindaphindiweyo ngaphandle kokwaphuka.

- Uzinzo lweDimensional:Uzinzo lweDimensional lubhekisa kwisakhono se-thermoplastic ukugcina imilo kunye nobukhulu bayo phantsi kweemeko ezahlukeneyo, kubandakanywa utshintsho lobushushu. Izinto eziphathekayo ezinozinzo olufanelekileyo lwe-dimensional ziqinisekisa imilinganiselo yenxalenye engaguqukiyo, ukunciphisa umngcipheko wokulwa okanye ukuphazamiseka.

- Ukuhambelana kweMichiza:Ukuhambelana kwemichiza ye-thermoplastics kubhekiselele ekukwazini kwabo ukumelana nokuthotywa okanye ukusebenzisana neekhemikhali ezahlukeneyo, kubandakanya iiasidi, iziseko, kunye nezinyibilikisi. Ukuqinisekisa ukusebenza kakuhle, ukukhetha i-thermoplastic enokumelana nemekobume ethile yeekhemikhali eya kudibana nayo kwisicelo esicetywayo kubalulekile.

- Ubungakanani: I-Thermoplastics inobunzima obahlukeneyo, obunokuthi buchaphazele ubunzima babo kunye neempawu zenxalenye epheleleyo. Izinto eziphantsi, ezifana ne-polyethylene, zinika izisombululo ezilula, ngelixa izinto eziphezulu, ezifana ne-polypropylene, zinika amandla kunye nokuqina.

Inkqubo yokubumba isitofu: Inyathelo ngenyathelo

Inkqubo yokubumba inaliti ilandela la manyathelo, ivumela ukuveliswa okusebenzayo kunye nokuchanekileyo kweendawo eziphezulu ze-thermoplastic. Inyathelo ngalinye lifuna ulawulo olucokisekileyo kunye nokubeka iliso ukuqinisekisa ukuba imilinganiselo yenxalenye engaguqukiyo, iipropathi zezinto eziphathekayo, kunye nomgangatho jikelele.

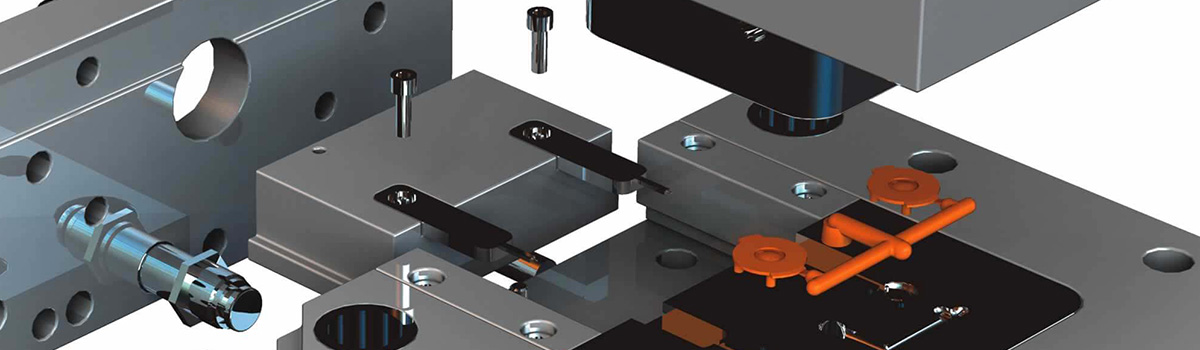

- Uyilo lokungunda kunye noKwakha: Isinyathelo sokuqala kwinkqubo yokubumba isitofu kuyilo kunye nokwenziwa kwesikhunta. Abavelisi kufuneka benze uyilo lokungunda oluchanekileyo noluneenkcukacha ukufezekisa iinkcukacha ezifunekayo zenxalenye. Abavelisi emva koko benza i-mold besebenzisa iindlela ezahlukeneyo, ezifana ne-CNC okanye i-electrical discharge machining (EDM).

- Ukulungiswa kwezinto: Isinyathelo esilandelayo kukulungiselela xa isikhunta silungile. Iipilisi ze-Thermoplastic okanye i-granules zikhethwa ngokusekelwe kwizinto ezifunwayo kwaye zinyibilike kwi-hopper. AbaSebenzi ke ngoko bondla izinto kwi-barrel yomatshini wokubumba inaliti, apho idlula ukunyibilika kunye ne-homogenization.

- Inaliti:Ngethuba lesigaba sokutofa, abaqhubi bafaka i-thermoplastic etyhidiweyo kwi-mold cavity phantsi koxinzelelo oluphezulu. Iyunithi yokutofa yomatshini ityhala imathiriyeli enyibilikisiweyo ngombhobho ukuya kumngundo. Izinto eziphathekayo zigcwalisa i-mold cavity, ithatha ubume benxalenye efunwayo.

- Ukupholisa kunye nokuqinisa:Emva kokuzalisa isikhunta, abaqhubi bavumela iplastiki etyhidiweyo ukuba ipholile kwaye iqine. Ukupholisa kubalulekile ekufezekiseni uzinzo lwe-dimensional kunye nokwakheka kwenxalenye efanelekileyo. Abanini-zithuthi banokuyilawula inkqubo yokupholisa ngokujikelezisa isisipholisi ngemijelo engaphakathi komngundo okanye ngokusebenzisa iipleyiti zokupholisa.

- Ukuvulwa kokungunda kunye nokuKhutshwa:Abasebenzisi bavula ukungunda kwaye bakhuphe indawo kumngxuma wokungunda xa iplastiki iqinile. Inkqubo yokukhupha ngaphakathi kumatshini isebenzisa izikhonkwane, iipleyiti ze-ejector, okanye ukuqhuma umoya ukususa ummandla kwi-mold. Umngundo ke ulungele umjikelo olandelayo wokutofa.

- Emva kokwenziwa komsebenzi: Emva kokukhutshwa, inxalenye inokuthi iqhube imisebenzi emva kokulungiswa, njengokulungisa, ukuchithwa, okanye ukugqitywa kwendawo. La manyathelo anceda ukususa imathiriyeli engaphezulu, imiphetho erhabaxa egudileyo, kunye nokuphucula inkangeleko yokugqibela yenxalenye.

- Ukuhlolwa koMgangatho: Inyathelo lokugqibela libandakanya ukuhlola iindawo ezitofelweyo zomgangatho kunye nokuqinisekisa ukuba ziyahlangabezana neemfuno ezichaziweyo. Iindlela ezahlukeneyo zolawulo lomgangatho, kubandakanywa umlinganiselo we-dimensional, uhlolo olubonakalayo, kunye novavanyo olusebenzayo, zinokuqeshwa ukuqinisekisa umgangatho kunye nokuthembeka kwenxalenye.

- Ukurisayikilisha kunye nokuSetyenziswa kwakhona kweMathiriyeli:Naziphi na izinto ezigqithisileyo okanye ezilahliweyo ezenziwe ngexesha lokubumba inaliti zinokuphinda zisetyenziswe kwaye zisetyenziswe kwakhona. Ukunciphisa ukusetyenziswa kwezinto ezintsha ze-thermoplastic kunceda ukunciphisa inkunkuma kunye nokuphucula ukuzinza.

Izixhobo ezisetyenziswa kwi-Injection Molding

Ezi zixhobo zezixhobo ziququzelela inkqubo yokubumba isitofu, ukusuka ekunyibilikeni nasekufakeni izinto ze-thermoplastic ukuya ekubunjweni, ukupholisa, kunye nokukhupha inxalenye yokugqibela. Ukusebenza ngokufanelekileyo kunye nokugcinwa kwezi zixhobo zezixhobo zibalulekile ekufezekiseni ukuveliswa kokubumba ngokufanelekileyo, okukumgangatho ophezulu.

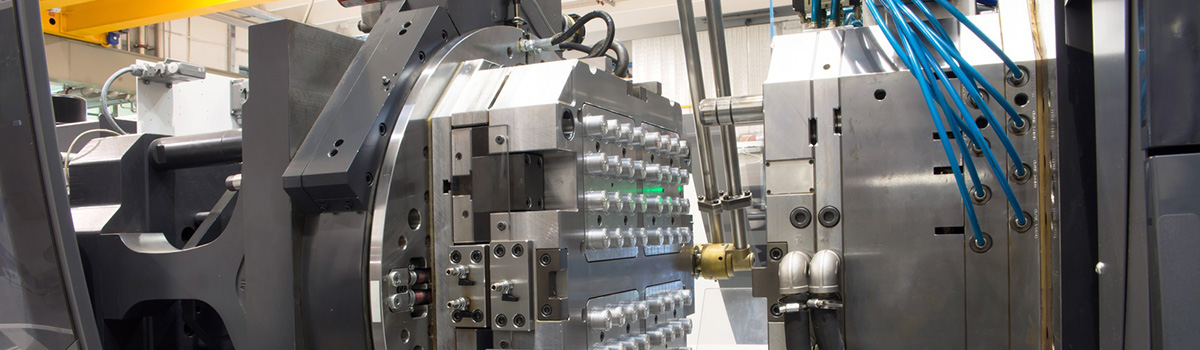

- Umatshini wokubumba wokutofa:Isixhobo esiphambili ekubunjweni kwenaliti sinoxanduva lokunyibilikisa izinto ze-thermoplastic, ukugalela kwi-mold, kunye nokulawula inkqubo.

- Umngundo: I-mold, eyenzelwe ukwenza umzobo ofunwayo kunye neempawu zenxalenye yeplastiki, iqulethe i-halves ezimbini, i-cavity kunye ne-core. Abasebenzisi bawuxhoma kwiyunithi yokubambelela kumatshini wokubumba inaliti.

- I-Hopper:Isikhongozeli esibambe imathiriyeli ye-thermoplastic kwi-pellet okanye kwifomu yegranular kwaye siyifake kumbhobho womatshini wokubumba wokubumba ukuze unyibilike kunye nokutofa.

- Umphanda kunye neScrew: I-barrel, i-cylindrical chamber, iyancibilika kwaye i-homogenizes impahla ye-thermoplastic njengoko i-screw ijikeleza ngaphakathi kwayo ukuze inyibilike, idibanise, kwaye ilinganise izinto eziphathekayo.

- Iinkqubo zokufudumeza kunye nokupholisa:Imishini yokubumba i-injection inezinto zokufudumeza, ezifana nezifudumezi zombane okanye izifudumezi ezisebenzisa ioli eshushu, ukuphakamisa ubushushu bombhobho, kunye neenkqubo zokupholisa, ezifana nokujikeleza kwamanzi okanye ioli, ukupholisa ukubumba kunye nokuqinisa inxalenye yeplastiki.

- Inkqubo ye-Ejector:Isusa indawo ebunjiweyo kumgodi wokungunda emva kokuqina, ngokuqhelekileyo kusetyenziswa izikhonkwane ze-ejector, iipleyiti, okanye uqhushumbo lomoya ngexesha lokuvulwa kokungunda.

- Inkqubo yoLawulo:Ukubeka iliso kunye nokulawula iiparamitha ezahlukeneyo zenkqubo yokubumba inaliti, evumela abaqhubi ukuba basete kwaye bahlengahlengise iiparamitha ezinjengesantya sokutofa, ubushushu, uxinzelelo kunye nexesha lokupholisa.

I-Injection Molding Machines: Iintlobo kunye neempawu

Uhlobo ngalunye lomatshini wokubumba inaliti luneempawu kunye neenzuzo zalo, ezivumela abavelisi ukuba bakhethe esona sixhobo sifanelekileyo kwiimfuno zabo zokuvelisa.

- Oomatshini bokuBumba beSitofu seHydraulic: Aba matshini basebenzisa iisistim ze-hydraulic ukuvelisa uxinzelelo oluyimfuneko lokutofa iplastiki etyhidiweyo kwi-mold. Baziwa ngamandla abo okubamba aphezulu, ulawulo oluchanekileyo, kunye nokuguquguquka ekuphatheni ii-thermoplastics ezahlukeneyo. Oomatshini be-Hydraulic bafanelekile kwimveliso enkulu kwaye banokufaka i-molds eyinkimbinkimbi.

- Oomatshini bokuBumba boMbane bokuTofa:Oomatshini bombane basebenzisa ii-motor ze-servo zombane ekusebenzeni komatshini, kubandakanya inaliti, i-clamping, kunye ne-ejector systems. Banikezela ngolawulo oluchanekileyo, ukusebenza kakuhle kwamandla, kunye namaxesha okuphendula ngokukhawuleza kunoomatshini behydraulic. Oomatshini bombane bafanelekile kwizicelo zokubumba ezichanekileyo ezifuna ukuphindaphinda okuphezulu kunye nokuchaneka.

- Oomatshini bokuBumba be-Hybrid Isitofu:Oomatshini be-Hybrid badibanisa izibonelelo zezixhobo zombini ze-hydraulic kunye nombane. Basebenzisa indibaniselwano yenkqubo ye-hydraulic kunye ne-servo yombane ukufezekisa ukuchaneka okuphezulu, ukusebenza kakuhle kwamandla, kunye nokusebenza kakuhle kweendleko. Oomatshini be-Hybrid bafanelekile kuluhlu olubanzi lwezicelo, ukubonelela ngokulinganisela phakathi kweendleko zokusebenza kunye nokusebenza.

- Oomatshini bokuBumba abaneepleyiti ezimbini: Oomatshini abaneepleyiti ezimbini banoyilo olulodwa kunye neepleyiti ezimbini ezihlukeneyo zokubethelela ukubumba. Olu luyilo lubonelela ngozinzo olongeziweyo, ulungelelwaniso lokungunda oluphuculweyo kwaye luvumela ubungakanani obukhulu bokubumba kunye namandla aphezulu okubamba. Oomatshini beeplate ezimbini bafanelekile kwiindawo ezinkulu kunye neziyinkimbinkimbi ezifuna ukubumba okuchanekileyo.

- Oomatshini bokuBumba baMacandelo amaninzi:Abavelisi bayila aba matshini ukuvelisa iinxalenye ezinezixhobo ezininzi okanye imibala kumjikelo omnye wokubumba. Zineeyunithi ezahlukeneyo zokutofa kunye nokungunda, okwenza inaliti ngaxeshanye yezinto ezahlukeneyo. Oomatshini bamacandelo amaninzi banikezela ukuguquguquka kunye nokusebenza kakuhle ekuveliseni iindawo ezinzima ezineempawu ezahlukeneyo.

- Oomatshini bokuBumba beMicro-Injection:Ilungiselelwe ngokukodwa ukuvelisa iindawo ezincinci kunye nezichanekileyo, oomatshini bokubumba i-micro-injection banikezela ngokuchaneka okuphezulu kunye nokuchaneka. Banokuvelisa iinkcukacha eziyinkimbinkimbi kunye nokunyamezela okuqinileyo kunye nenkunkuma encinci yezinto eziphathekayo. I-Electronics, izixhobo zonyango, kunye ne-micro-optics zivame ukusebenzisa oomatshini bokubumba be-micro-injection.

Iingqwalasela zoYilo lomngundo wokuBunjwa kwesitofu

Iingqwalasela zoyilo lokungunda ngononophelo zibalulekile kwimveliso yokubumba isitofu esiyimpumelelo.

- Uyilo lwenxalenye:Uyilo lokungunda kufuneka luhambelane neemfuno ezithile zenxalenye, kubandakanywa ukumila kwayo, imilinganiselo, kunye neempawu zokusebenza. Abavelisi kufuneka baqwalasele ngokufanelekileyo ii-engile zokuyila, ubukhulu bodonga, ii-undercuts, kunye naziphi na izinto eziyimfuneko ukuze kuqinisekiswe ukukhululeka kokukhutshwa kunye nomgangatho wenxalenye.

- Izinto zokungunda: Ukukhethwa kwezinto zokubumba kubalulekile ekufezekiseni ukuqina, ukuzinza kwe-dimensional, kunye nokumelana nobushushu. Izinto eziqhelekileyo zokubumba ziquka i-alloys yensimbi, i-aluminium alloys, kunye neentsimbi zesixhobo. Ukhetho lwemathiriyeli luxhomekeke kwizinto ezifana nomthamo wemveliso, ukuntsonkotha kwenxalenye, kunye nobomi besixhobo obulindelekileyo.

- Inkqubo Yokupholisa:Ukupholisa okusebenzayo kubalulekile kwinxalenye efanelekileyo yokuqinisa kunye nokunciphisa ixesha lomjikelo. Uyilo lokungunda kufuneka lubandakanye imijelo yokupholisa okanye izifakelo ezibekwe ngendlela yobuchule ukuqinisekisa ukupholisa komngundo okufanayo. Ukupholisa okufanelekileyo kunciphisa umngcipheko we-warpage, i-shrinkage, kunye neziphene.

- Ukubonisa:Ukukhupha umoya okwaneleyo kuyimfuneko ukuvumela ukuphunyuka komoya kunye neegesi ngexesha lenkqubo yokutofa. Ukungangeni komoya okwaneleyo kunokukhokelela kwimigibe yerhasi, kuphawu lokutshisa, okanye ukuzaliswa kwenxalenye engaphelelanga. Abavelisi banokufikelela ekuphuhliseni umoya ngokubandakanya iigrooves, izikhonkwane, okanye ezinye iindlela kuyilo lokungunda.

- Inkqubo yokukhupha:Uyilo lokubumba kufuneka lubandakanye inkqubo yokukhupha esebenzayo ukuze ikhuphe ngokukhuselekileyo nangokufanelekileyo inxalenye ebunjiweyo kwi-mold cavity. Inkqubo yokukhupha inokuba nezikhonkwane ze-ejector, imikhono, okanye ezinye iindlela, ezibekwe ngokucwangcisekileyo ukuphepha ukuphazamiseka komsebenzi okanye iimpawu ezibalulekileyo.

- Uyilo lweSango:Isango kulapho iplastiki etyhidiweyo ingena khona kumngxuma wokungunda. Uyilo lwesango kufuneka luqinisekise ukuzaliswa kwenxalenye efanelekileyo, ukunciphisa imigca yokuhamba, kunye nokuthintela ukukhenkceza kwezinto ezingaphambi kwexesha. Uyilo lwesango oluqhelekileyo lubandakanya amasango e-edge, amasango etonela, kunye neenkqubo zembaleki ezishushu, kuxhomekeke kwiimfuno zenxalenye kunye neempawu eziphathekayo.

- Umgca wokwahlulahlula:Uyilo lokubumba kufuneka luchaze umgca wokwahlula ofanelekileyo, ongumgca apho iziqingatha ezibini zobumba zidibana khona. Ukubekwa ngokufanelekileyo komgca wokwahlulahlula kuqinisekisa ukukhanya okuncinci kunye nokungahambelani komgca wokwahlula kwaye kuququzelele ukudityaniswa kokungunda okusebenzayo.

- ULondolozo lomngundo kunye nokuSebenza: Abavelisi kufuneka baqwalasele lula ukulungiswa, ukulungiswa, kunye nenkonzo yokungunda. Amalungu okungunda kufuneka afikeleleke ngokulula ekucoceni, ekuhlolweni, nasekutshintshweni kwawo. Ukudibanisa iimpawu ezifana nokufakwa kotshintsho olukhawulezayo okanye uyilo lwemodyuli kunokuphucula ukusebenza komngundo.

Izinto zokungunda ezisetyenziswa kwi-Injection Molding

Ukusebenzisana kunye neengcali zezinto zokubumba kunye nokuqwalasela iimfuno ezithile zesicelo sokubumba kunokuncedisa ukufumanisa eyona nto ifanelekileyo yokufezekisa ukusebenza kakuhle kokubumba kunye nomgangatho wenxalenye.

- Ingxubevange yentsimbi: Ingxubevange yentsimbi, njengentsimbi yesixhobo (umzekelo, i-P20, i-H13) kunye neentsimbi ezingenasici, ziqhele ukusetyenziselwa ukubumba isitofu sokubumba ngenxa yokuqina kwazo okugqwesileyo, ukumelana nobushushu, kunye nokunganyangeki. Ezi zixhobo zinokumelana namaqondo obushushu aphezulu kunye noxinzelelo kwinkqubo yokubumba inaliti kwaye zinikeze uzinzo oluhle lomgangatho wokuvelisa iindawo ezikumgangatho ophezulu.

- Iingxube zeAluminiyam:I-alloys ye-aluminium, efana ne-7075 kunye ne-6061, ilula kwaye inika i-conductivity efanelekileyo ye-thermal, ibenza bafaneleke ukubumba okudinga ukupholisa okusebenzayo. Abavelisi bahlala besebenzisa iimolds ze-aluminium kwiprototyping, ukuveliswa kwevolumu ephantsi, okanye izicelo apho ukunciphisa ubunzima kubalulekile. Nangona kunjalo, ukubumba kwe-aluminium kunokuba nokuqina okuphantsi xa kuthelekiswa ne-alloys yensimbi.

- Iialloyi zobhedu:I-alloys ye-Copper, efana ne-beryllium yethusi, ibonisa ukuqhutyelwa kwe-thermal ephezulu kunye nokusebenza kakuhle. Bafumana ukusetyenziswa kwizingundo ezifuna ukugqithiselwa kobushushu obubalaseleyo ukupholisa okusebenzayo. I-alloys yobhedu inokunceda ukunciphisa amaxesha okujikeleza ngokukhupha ngokukhawuleza ubushushu ukusuka kwindawo ebunjiweyo, okubangela ukuqina ngokukhawuleza.

- Izixhobo zentsimbi:Iintsimbi zesixhobo, kuquka i-H13, i-S7, kunye ne-D2, yenzelwe ukusetyenziswa kwezixhobo zokusebenza eziphezulu. Ezi zintsimbi zinika indibaniselwano yamandla aphezulu, ukuqina, kunye nokumelana nokunxiba. Iintsimbi zesixhobo zilungele ukubumba ezinomthamo ophezulu wemveliso, izinto ezinqabileyo, okanye iimeko zokubumba ezifunayo.

- I-Nickel Alloys:I-nickel alloys, njenge-Inconel kunye ne-Hastelloy, ziyaziwa ngokuxhathisa kwazo okungaqhelekanga, amandla obushushu obuphezulu kunye nokuzinza kwe-thermal. Abavelisi basebenzisa ezi ngxubevange kwimibumbo ephatha izinto ezonakalisayo okanye ezifuna ukuxhathisa kumaqondo obushushu agqithisileyo kunye nemo engqongileyo yokubumba.

- Izinto ezidityanisiweyo:Izinto ezixubileyo, ezifana neeplastiki ezomeleziweyo okanye iimbumba ezinokufakwa kwesinyithi, zisetyenziselwa ukubumba izinto ezithile. Ezi zixhobo zibonelela ngokulinganisela kweempawu, njengamandla aphezulu, ukuzinza kwe-thermal, kunye nokunciphisa ubunzima. Imibumbo ehlanganisiweyo inokuba ziindlela ezingabizi kakhulu kwiimfuno ezithile zemveliso.

Iindidi zokutofa kokungunda

Isitofu sokubumba yinkqubo yokwenza izinto ezininzi kwaye isetyenziswa ngokubanzi kwiindawo zeplastiki.

- Iipleyiti ezimbini zokungunda:Umngundo oneepleyiti ezimbini lolona hlobo luxhaphakileyo lwenaliti yokungunda. Iqukethe amacwecwe amabini, i-cavity plate, kunye ne-core plate, eyahlula ukuvumela ukukhutshwa kwenxalenye ebunjiweyo. Ipleyiti yombhobho iqulathe icala lomngxunya lokungunda, ngelixa ipleyiti engundoqo igcina icala elingundoqo. Abavelisi basebenzisa iimbumba zeepleyiti ezimbini ukuvelisa uluhlu olubanzi lwamalungu ngenxa yoyilo lwazo olulula.

- Iipleyiti ezintathu zokungunda:I-mold-plate mold yinguqu ephambili ye-mold-plate mold. Iquka ipleyiti eyongezelelweyo, imbaleki, okanye ipleyiti ye-sprue. Ipleyiti yembaleki yenza umjelo owahlukileyo we-sprue, iimbaleki, kunye namasango, ukuvumela ukususwa lula kwenxalenye ebunjiweyo. Abavelisi ngokuqhelekileyo basebenzisa ii-molds ze-plate ezintathu kwiinkcukacha kunye neenkqubo zokugaya eziyinkimbinkimbi okanye xa ugwema i-vestige yesango kwisiqwenga esinqwenelekayo.

- Umngundo weMbaleki eshushu:Umgijimi kunye nenkqubo yesango ishushu kwi-mold runer molds, isusa isidingo sokuqiniswa kunye nokunyibilika kwakhona kwezinto ngexesha lomjikelo ngamnye. Inkqubo yembaleki eshushu iquka izinto ezininzi ezifudumalayo kunye nemilomo egcina imo enyibilikayo yeplastiki. Iimolds zembaleki ezishushu zibonelela ngezinto eziluncedo ezifana nexesha elincitshisiweyo lomjikelo, inkcitho ephantsi yemathiriyeli, kunye nokuphuculwa komgangatho wenxalenye ngokunciphisa iingcango zesango.

- Umngundo oMbaleki obandayo: Iimbumba zembaleki ezibandayo zinembaleki yemveli kunye nenkqubo yesango apho iplastiki etyhidiweyo ihamba ngeembaleki ezibandayo eziqinisa kunye nomjikelo ngamnye. Abasebenzisi ke ngoko basusa iimbaleki eziqinileyo, okukhokelela kwinkunkuma yezinto. Abavelisi ngokuqhelekileyo basebenzisa iimbumba ezimbaleki ezintsonkothileyo zokuvelisa umthamo ophantsi okanye xa iindleko zemathiriyeli zingabalulekanga kangako ngenxa yoyilo lwazo oluthe ngqo.

- Faka uMngundo:Faka iimolds ziquka isinyithi okanye iplastiki efakwe kwi-mold cavity ngexesha lokubumba. Ukufakwa kunokufakwa kwangaphambili kwi-mold okanye kufakwe ngeenkqubo ezizenzekelayo. Esi sibumba sivumela ukudibanisa amacandelo ongezelelweyo okanye ukuqinisa izinto kwinxalenye ebunjiweyo, ukuphucula ukusebenza kwayo okanye amandla.

- Overmold: Ukugqithisa kakhulu kubandakanya ukubumba imathiriyeli enye phezu kwenye, ngokwesiqhelo ukubopha isiseko seplastiki esomeleleyo kunye ne-elastomer ethambileyo okanye i-thermoplastic. Le nkqubo ivumela ukudalwa kweengxenye kunye nezixhobo ezininzi okanye ukuthungwa kwi-mold enye, ukubonelela ngokuphucuka ukubamba, ukunyusa, okanye iimpawu zobuhle.

Izinto Ezichaphazela Iindleko Zokubumba Isitofu

Ukuthathela ingqalelo ezi zinto kunokunceda abavelisi baqikelele kwaye baphucule iindleko zokubumba inaliti, ukuqinisekisa ulungelelwaniso phakathi komgangatho, ukusebenza kakuhle, kunye nokuphumelela kweendleko kwiimfuno zabo ezithile zemveliso.

- Ukuntsonkotha kwenxalenye:Ubunzima boyilo lwenxalenye ludlala indima ebalulekileyo ekumiseleni iindleko zokubumba inaliti. Iijometri ezintsonkothileyo, ii-undercuts, iindonga ezibhityileyo, okanye iimpawu ezintsonkothileyo zinokufuna izixhobo ezongezelelweyo, iimolds ezikhethekileyo, okanye imijikelo emide, ukonyusa ixabiso lokwenziwa kwemveliso.

- Ukhetho lwezixhobo:Ukukhethwa kwezinto ze-thermoplastic kuchaphazela iindleko zokubumba inaliti. Izixhobo ezahlukeneyo zinamaxabiso ahlukeneyo ngekhilogram nganye, kwaye izinto ezinjengokufumaneka kwezinto, iipropati, kunye neemfuno zokusetyenzwa zingaphembelela ixabiso lemathiriyeli iyonke.

- Izixhobo kunye noyilo lokungunda: Isixhobo sokuqala kunye neendleko zoyilo lokungunda zibalulekile kwiindleko zokubumba inaliti. Izinto ezinjengobunzima bokungunda, inani lemingxuma, ubungakanani bokungunda, kunye nemathiriyeli yokungunda inegalelo kwiindleko zokwenziwa kwezixhobo kunye nokwenziwa komngundo. Imingundo entsonkothileyo ngakumbi okanye umngundo odinga iimpawu eziphambili unokunyusa utyalo-mali lwangaphambili.

- Umthamo weMveliso: Umthamo wemveliso uchaphazela ngokuthe ngqo iindleko ngenxalenye yokubumba inaliti. Iincwadi eziphezulu zihlala zikhokelela kuqoqosho lwesikali, ukunciphisa iindleko ngenxalenye. Ngakolunye uhlangothi, ukuveliswa kwevolumu ephantsi kunokubangela iintlawulo eziphezulu ngenxa yokuseta, izixhobo, kunye nenkcitho yezinto eziphathekayo.

- Ixesha lomjikelo: Ixesha lokujikeleza, elibandakanya izigaba zokupholisa kunye ne-ejection, lichaphazela amandla okuvelisa kunye neendleko ezipheleleyo. Amaxesha omjikelo omde akhokelela ekuncitshisweni kwemveliso kunye namaxabiso anokuba phezulu. Ukuphucula uyilo lokubumba, inkqubo yokupholisa, kunye neeparamitha zenkqubo kunokunciphisa amaxesha okujikeleza kunye nokuphucula ukusebenza kakuhle.

- Iimfuno zoMgangatho:Iimfuno ezingqongqo zomgangatho okanye iziqinisekiso ezithile zinokuchaphazela iindleko zokubumba inaliti. Ukuhlangabezana nokunyamezelwa okuchanekileyo, iimfuno zokugqiba umphezulu, okanye uvavanyo olongezelelweyo lunokufuna ezinye izixhobo, iinkqubo, okanye ukuhlolwa, ukongeza kwindleko iyonke.

- Imisebenzi yesibini:Ukuba iindawo ezibunjiweyo zifuna imisebenzi emva kokulungiswa okufana nokuhlanganisa, ukupeyinta, okanye amanyathelo okugqiba okongezelelweyo, le misebenzi inokongeza kwindleko yokubumba i-injection jikelele.

- Umthengisi kunye nendawo:Ukukhethwa komthengisi wokubumba inaliti kunye nendawo yabo kunokuchaphazela iindleko. Iindleko zabasebenzi, ii-overheads, izinto zokusebenza, kunye neendleko zothutho ziyahluka ngokwendawo yomthengisi, okuchaphazela iindleko zokwenziwa kwazo zonke.

Ulawulo loMgangatho kwi-Injection Molding

Ukuphumeza amanyathelo okulawula umgangatho owomeleleyo kuyo yonke inkqubo yokubumba inaliti inceda ukuchonga nokujongana neziphene ezinokubakho, ukutenxa, okanye ukungangqinelani, ukuqinisekisa ukuveliswa kwamacandelo akumgangatho ophezulu ahlangabezana neenkcukacha zabathengi kunye neemfuno.

- Ukubeka iliso kwinkqubo: Ukubeka iliso okuqhubekayo kwiiparamitha zenkqubo engundoqo, ezifana nobushushu obunyibilikayo, uxinzelelo lwenaliti, ixesha lokupholisa, kunye nexesha lokujikeleza, liqinisekisa ukuhambelana kunye nokuphindaphinda kwimveliso yenxalenye. Ixesha langempela lokubeka iliso kunye neenkqubo ezizenzekelayo ziyakwazi ukubona ukuhluka okanye ukuphambuka kwiiparitha ezimiselweyo, ukuvumela ukulungiswa kwexesha kunye nokugcina ukuzinza kwenkqubo.

- Uhlolo kunye noMlinganiselo:Ukuphononongwa rhoqo kunye nokulinganisa iindawo ezibunjiweyo zibalulekile ukuze kuqinisekiswe ukuchaneka kobukhulu, umgangatho wenxalenye, kunye nokubambelela kwiinkcukacha. Iinkonzo zethu zibandakanya uluhlu lweendlela zolawulo lomgangatho, ezinjengokulinganisa imilinganiselo, ukuhlalutya umgangatho womphezulu, ukwenza uhlolo olubonakalayo, kunye nokwenza iimvavanyo zokusebenza. Iindlela ezahlukeneyo zokuhlola, ezinje ngoomatshini bokulinganisa abalungelelanisiweyo (CMM) kunye neenkqubo zokuhlola zamehlo nezibonwayo, zisetyenziselwa uvavanyo oluchanekileyo.

- Ulawulo lweNkqubo yoBalo (SPC): I-SPC ibandakanya ukuqokelela kunye nokuhlalutya idatha yenkqubo ukubeka iliso kunye nokulawula umgangatho wokubumba inaliti. Iindlela zezibalo, ezifana neetshathi zokulawula kunye nohlalutyo lwezakhono zenkqubo, zinceda ukuchonga iintsingiselo, ukufumanisa ukuhluka kwenkqubo, kunye nokuqinisekisa ukuba inkqubo ihlala ngaphakathi kwimida yolawulo echaziweyo. I-SPC yenza ukuba kuchongwe imiba esebenzayo kwaye iququzelele ukufaneleka kwenkqubo.

- Uvavanyo Lwezinto: Ukuvavanya imathiriyeli ekrwada, enje nge-thermoplastics, izongezo, kunye nemibala, iqinisekisa umgangatho wazo kunye nokufaneleka kokubumba inaliti. Uvavanyo lwezinto eziphathekayo lunokubandakanya uhlalutyo lwe-melt flow index (MFI), iimpawu zomatshini, iimpawu ze-thermal, kunye nokwakhiwa kwezinto. Ukuqinisekisa umgangatho wezinto eziphathekayo kunceda ukukhusela iziphene kunye nokungahambelani kwiindawo ezibunjiweyo.

- ULondolozo lweZixhobo kunye noHlolo:Ukugcinwa ngendlela eyiyo kunye nokuhlolwa rhoqo kweenaliti zokungunda kubalulekile ukuze kuqinisekiswe umgangatho wokubumba inaliti. Ukucoca rhoqo, ukuthambisa, kunye novavanyo lwamalungu okungunda kunceda ukuthintela ukuguga, ukonakala, okanye ukuthotywa okunokuthi kuchaphazele umgangatho wenxalenye. Ukulungiswa kwangexesha okanye ukutshintshwa kwezinto ezigugileyo okanye ezonakalisiweyo zokungunda zibalulekile ukuze kugcinwe ukusebenza kokubumba okungaguqukiyo.

- Amaxwebhu kunye nokulandelelwa:Ukugcina amaxwebhu abanzi kunye neerekhodi zokulandeleka kubalulekile kulawulo lomgangatho wokubumba inaliti. Kubalulekile ukurekhoda iiparamitha zenkqubo, iziphumo zokuhlola, ulwazi lwempahla, kunye naluphi na utshintsho okanye uhlengahlengiso olwenziwe ngexesha lemveliso. Amaxwebhu afanelekileyo enza ukuba kulandeleke iinxalenye, kuququzelele uhlalutyo lwesizathu, kwaye kuqinisekise ukuhambelana kumgangatho.

- Uqeqesho noPhuhliso lweZakhono: Ukubonelela ngoqeqesho olwaneleyo kunye neenkqubo zophuhliso lwezakhono kubaqhubi, amagcisa, kunye nabasebenzi bolawulo lomgangatho kuphucula ukuqonda kwabo iinkqubo zokubumba inaliti, iimfuno zomgangatho, kunye nobuchule bokuhlola. Abasebenzi abaqeqeshwe kakuhle banokubona iziphene, baxazulule iingxaki, kwaye basebenzise amanyathelo okulungisa ngokufanelekileyo, ukuqinisekisa imveliso ekumgangatho ophezulu.

Isitofu esiqhelekileyo sokubumba iziphene kunye nendlela yokuziphepha

Ukuhlolwa rhoqo, ukubeka iliso, kunye nohlalutyo lweenkqubo zokubumba inaliti kunye nokugcinwa okufanelekileyo kunye nokulungelelaniswa kwezixhobo kunye nokubumba kunokunceda ukuchonga nokujongana nezi ziphene eziqhelekileyo.

- Amanqaku eSinki:Amanqaku e-sink kukudandatheka okanye ukungena kumphezulu wenxalenye ebunjiweyo ebangelwa ukupholisa okungalinganiyo okanye ukushwabana. Omnye kufuneka athathele ingqalelo indawo eyiyo yesango kunye noyilo, uyilo olululo lwenkqubo yokupholisa, kunye nokusabalalisa ubukhulu bodonga olufanayo ukuphepha amanqaku e-sink. Ukonyusa uxinzelelo lwenaliti okanye ukulungelelanisa ixesha lokupholisa nako kunokunceda ukunciphisa amanqaku e-sink.

- Iphepha lemfazwe:I-Warpage ibhekiselele kutshintsho okanye ukugoba kwenxalenye ebunjiweyo emva kokukhutshwa ngenxa yokupholisa okungalinganiyo okanye uxinzelelo olushiyekileyo. Ukugcina ubukhulu bodonga obufanayo, ukusebenzisa iindlela zokupholisa ezifanelekileyo, kunye nokuqinisekisa ukuzaliswa okulinganayo kunye nokupakishwa kwesikhunta kubalulekile ukukhusela i-warpage. Ukuphucula ubushushu bomngundo, ukusebenzisa ii-engile eziyidrafti ezifanelekileyo, kunye nokulawula ubushushu bemathiriyeli kunye nesantya sokutofa kunokunceda ukunciphisa i-warpage.

- Flash:Ukudanyaza kwenzeka xa imathiriyeli engaphezulu impompoza kumgca wokwahlula kubumba, okukhokelela kuqikelelo olucekethekileyo, olungafunwayo okanye imathiriyeli eyongezelelweyo kwindawo yokugqibela. Ubani unokuthintela ngokufanelekileyo ukukhanya ngokuqinisekisa uyilo olufanelekileyo lokungunda, kuquka ukusebenzisa amandla afanelekileyo okubamba, ulungelelwaniso oluchanekileyo, nokusebenzisa iindlela ezifanelekileyo zokukhupha umoya. Ukuphucula iiparamitha zenkqubo ezifana noxinzelelo lwenaliti, ubushushu, kunye nexesha lomjikelo kunciphisa ukukhanya.

- Umfanekiso omfutshane:Ukudubula okukhawulezayo kwenzeka xa into etofweyo ingagcwalisi i-mold cavity, ibangele inxalenye engaphelelanga. Ukukhethwa kwezinto ezifanelekileyo, ukuqinisekisa ubushushu obufanelekileyo bokunyibilika kunye ne-viscosity, kunye nokugcina uxinzelelo olufanelekileyo lwenaliti kunye nexesha kubalulekile ukuphepha iifoto ezimfutshane. Ukongeza, ukuqinisekiswa koyilo lokungunda kwimbaleki eyaneleyo kunye nobukhulu besango kunye nokungena ngokufanelekileyo kunokunceda ukuthintela ukudubula ngokukhawuleza.

- Imigca yeWeld:Imigca ye-weld yenzeke xa izinto ezimbini okanye ngaphezulu ezityhidiweyo ezihamba phambili zidibana kwaye ziqina, okukhokelela kumgca obonakalayo okanye uphawu kwinxalenye yomhlaba. Isango elilungileyo kunye noyilo lwembaleki, ubushushu obufanelekileyo bokunyibilika, isantya sokutofa, kunye nokulungelelanisa ukuhamba kwezinto kunye nenxalenye yejometri inokunciphisa imigca yeweld. Uhlalutyo lokuhamba komngundo kunye nokubekwa kakuhle kwesango nako kunokunceda ukuthintela okanye ukunciphisa imigca ye-weld.

- Amanqaku okutshisa:Amanqaku atshisayo yi-discolorations okanye amachaphaza amnyama kumphezulu wenxalenye ebunjiweyo ebangelwa bubushushu obugqithisileyo okanye ukutshisa kwezinto. Ukuphepha ubushushu obugqithisileyo bokunyibilika, ukusebenzisa amajelo okupholisa afanelekileyo, kunye nokwandisa ixesha lomjikelo kunokuncedisa ukuthintela ukutshiswa kwamanqaku. Ukungenisa umoya okwaneleyo, ukuyilwa kwesango ngokufanelekileyo, kunye nokulawula ubushushu bomngundo nako kunegalelo ekunciphiseni amabala okutsha.

Imisebenzi ye-Post-Molding: Ukugqitywa kunye neNdibano

Emva kokubunjwa kwenaliti, iindawo ezininzi ezibunjiweyo zinokufuna ukugqiba okongeziweyo kunye nokusebenza kwendibano ukufezekisa imveliso yokugqibela efunekayo. Le misebenzi yasemva kokubumba inokubandakanya:

- Ukucheba:Susa nayiphi na imathiriyeli engaphezulu okanye umbane ojikeleze indawo ebunjiweyo usebenzisa izixhobo zokucheba okanye zokusika.

- Treatment Surface:Ukuphucula inkangeleko okanye ukusebenza kwenxalenye yomhlaba kusetyenziswa iindlela ezahlukeneyo zokupeyinta, ukugquma, okanye ukuthumela imiyalezo.

- Ndibano:Ukudibanisa iindawo ezininzi ezibunjiweyo okanye ukongeza amacandelo afana neziqhoboshi, izifakelo, okanye iilebhile ukugqibezela imveliso yokugqibela.

- Uvavanyo:Ukuqinisekiswa komgangatho wenxalenye kunye nokusebenza ngeendlela ezahlukeneyo zovavanyo ezinje ngohlahlelo lobukhulu, uvavanyo lweepropathi zezinto, okanye uvavanyo lokusebenza.

- Ukupakisha nokuthumela:Ukupakishwa okufanelekileyo kunye neelebhile zemveliso egqityiweyo yokuthunyelwa kubathengi okanye abasebenzisi bokugqibela.

Ukukhethwa kwemisebenzi emva kokubumba kuxhomekeke kwisicelo esithile kunye neempawu ezifunwayo zokugqibela zemveliso. Intsebenziswano esondeleyo phakathi kweengcali zokubumba inaliti, ukugqiba kunye neengcali zokuhlanganisa, kwaye umthengi ubalulekile ekufezekiseni umgangatho ofunekayo wemveliso kunye nokusebenza. Ukucwangciswa okufanelekileyo kunye nokudibanisa imisebenzi emva kokubumba kwinkqubo yokuvelisa inokunceda ukuqinisekisa ukuveliswa ngokufanelekileyo kunye nokuhanjiswa kwexesha leemveliso eziphezulu.

Isitofu sokubumba vs. Ezinye Iinkqubo zokwenziwa kwePlastiki

Inkqubo nganye yokuvelisa iplastiki ineenzuzo kunye nokunciphisa, okwenza ukuba zilungele izicelo ezahlukeneyo.

- Ukubunjwa kwesitofu: Isitofu sokubumba yinkqubo yokwenza izinto ezininzi ezininzi kwaye isetyenziswa ngokubanzi ukuvelisa iinxalenye zeplastiki. Inika iingenelo ezifana nokusebenza okuphezulu kwemveliso, ukuphindaphinda kwenxalenye echanekileyo, kunye nokukwazi ukwenza iijiyometri ezinzima. Ukubunjwa kwe-injection kukulungele ukuveliswa komthamo ophezulu kwaye kuvumela ukusebenzisa uluhlu olubanzi lwezinto ze-thermoplastic. Ibonelela ngokuchaneka okugqibeleleyo komgangatho kunye nokugqitywa komphezulu, kuyenza ilunge kumashishini ahlukeneyo afana neemoto, iimpahla zabathengi, kunye nezixhobo zonyango.

- Ukubumba ukuvuthela: Ukubumba ukuvuthela yinkqubo esetyenziswa ikakhulu ukuvelisa iindawo zeplastiki ezingenanto, ezifana neebhotile, izikhongozeli, kunye nezinto zemoto. Kubandakanya ukunyibilika kweplastiki kunye nokuyifaka kwi-mold cavity, ukudala imilo oyifunayo. Ukubumba ukuvuthela kufanelekile kwimveliso ephezulu kwaye kunokuvelisa iindawo ezinkulu, ezikhaphukhaphu ezinobunzima obufanayo bodonga. Nangona kunjalo, inqunyelwe ngokwenxalenye yobunzima kunye nokukhethwa kwezinto eziphathekayo xa kuthelekiswa nokubumba inaliti.

- Thermoforming:I-Thermoforming yinkqubo esetyenziselwa ukuvelisa iinxalenye zeplastiki ngokufudumeza ishidi le-thermoplastic kunye nokubumba usebenzisa i-molds okanye i-vacuum forming. Ifumana ukusetyenziswa okuqhelekileyo kwipakethe, iimveliso ezilahlwayo, kunye neemveliso ezinkulu ezifana neetreyi kunye namagquma. I-Thermoforming inikezela ngemveliso enexabiso eliphantsi kumacandelo amakhulu kwaye ivumela ukuba kwenziwe ngokukhawuleza. Nangona kunjalo, inemida malunga nobunzima benxalenye, ukukhetha izinto eziphathekayo, kunye nokuchaneka komda xa kuthelekiswa nokubumba inaliti.

- I-Extrusion:I-Extrusion yinkqubo eqhubekayo yokuvelisa iiprofayili zeplastiki, amaphepha, iityhubhu, kunye neefilimu. Kubandakanya ukunyibilika kweplastiki yentlaka kwaye uyinyanzele ngokufa ukuze wenze imilo efunekayo. I-Extrusion ifanelekile ukuvelisa ubude obude, obuqhubekayo beemveliso zeplastiki kunye ne-cross-section ehambelanayo. Ngelixa i-extrusion ibonelela ngamazinga aphezulu emveliso kunye nokusebenza kakuhle, ilinganiselwe ngokwecandelo elintsonkothileyo lejometri kunye nolawulo oluchanekileyo lwe-dimensional xa kuthelekiswa nokubumba inaliti.

- Ukubunjwa koxinzelelo:Ukubunjwa koxinzelelo kubandakanya ukubeka inani elilinganiswe kwangaphambili le-thermosetting kwi-cavity yokungunda eshushu kwaye uyicinezele phantsi koxinzelelo oluphezulu de uphilise. Ifumana ukusetyenziswa okuqhelekileyo ekuveliseni iindawo ezinamandla aphezulu kunye nokuzinza kwe-dimensional, ezifana nezixhobo zemoto kunye nokugquma kombane. Ukubumba ukunyanzeliswa kubonelela ngokuhambelana kakuhle kwenxalenye, ukusebenza kakuhle kwemveliso, kunye nokukwazi ukusebenzisa uluhlu olubanzi lwezixhobo. Nangona kunjalo, inqunyelwe ngokwenxalenye yobunzima kunye nexesha lomjikelo xa kuthelekiswa nokubumba inaliti.

Usetyenziso lwe-Thermoplastic Injection Molding

Amashishini ahlukeneyo asebenzisa ukubumba inaliti ye-thermoplastic ngenxa yokuguquguquka kwayo, ukusebenza kakuhle, kunye nokusebenza kakuhle kweendleko. Ezinye zezicelo zokubumba inaliti ye-thermoplastic ziquka:

- Umzi mveliso weemoto: Ishishini leemoto lisebenzisa kakhulu ukubumba inaliti ye-thermoplastic ukwenza izinto ezahlukeneyo, kubandakanya i-trim yangaphakathi nangaphandle, iideshibhodi, iipaneli zocango, ii-bumpers, kunye nezihlanganisi zombane. Inkqubo ivumela ukuphindaphinda kwenxalenye echanekileyo, iijiyometri ezinzima, kunye nezixhobo ezikhaphukhaphu, ukuphucula ukusebenza kakuhle kwamafutha kunye nokuguquguquka koyilo.

- Impahla zomthengi:Isitofu sokubumba sifumana usetyenziso olubanzi ekuveliseni iimpahla zabathengi ezifana nezixhobo zasekhaya, izixhobo zombane, izikhongozeli zokupakisha, kunye nezinto zokudlala. Inkqubo ivumela ukuveliswa kobuninzi beemveliso ezihlala ixesha elide, ezikumgangatho ophezulu ezinemilinganiselo engaguqukiyo kunye nokugqitywa komphezulu. Ikwavumela iinketho zokwenza ngokwezifiso kunye nokuphindaphindwa kwemveliso ngokukhawuleza.

- Izixhobo zonyango:Ukubumba isitofu kudlala indima ebalulekileyo kwishishini lezonyango ekuveliseni uluhlu olubanzi lwezixhobo, kubandakanywa iisirinji, izixhobo zotyando, amacandelo afakelwayo, kunye neenkqubo zokuhanjiswa kweziyobisi. Inkqubo iqinisekisa ukuveliswa kwamalungu angenazintsholongwane, achanekileyo, kunye ne-biocompatible ahlangabezana neemfuno ezingqongqo zolawulo lwecandelo lezempilo.

- Ishishini loMbane kunye noMbane:Umzi mveliso wombane usebenzisa isitofu sokubumba ukwenza iziqhagamshelo zombane, izivalo, izitshixo, kunye nezinye izinto. Inkqubo inikezela ngokuchaneka komgangatho ophezulu, ukugqiba umgangatho obalaseleyo, kunye nokukwazi ukubandakanya iimpawu ezifana nokufaka ukubumba kunye nokugqithisa, okuvumela ukuveliswa ngokufanelekileyo kweendibano ze-elektroniki ezinzima.

- Ishishini lokuPakisha:Amashishini ahlukeneyo, kuquka ukutya kunye nesiselo, amayeza, kunye nokunyamekela komntu, ngokuqhelekileyo asebenzisa isitofu sokubumba ukuvelisa izitya zokupakisha zeplastiki, iikepusi, ukuvalwa, kunye neebhotile. Inkqubo yenza ukuba kuyilwe izisombululo zokupakishwa ezikhaphukhaphu, ezihlala ixesha elide, nezinomtsalane ngobuchule obunemijikelo yokwenziwa kwemveliso.

- Ishishini le-Aerospace:Icandelo le-aerospace liqeshe isitofu sokubumba ukwenza izinto ezinobunzima obulula kunye nokusebenza okuphezulu njengemibhobho yomoya, izibiyeli, iiphaneli zangaphakathi, kunye nezakhiwo. Inkqubo ivumela ukusetyenziswa kwezinto eziphambili kunye neejometri zenxalenye entsonkothileyo, igalelo ekunciphiseni ubunzima kunye nokuphucula ukusebenza kakuhle kwamafutha.

Impembelelo yokusiNgqongileyo ye-Thermoplastic Injection Molding

Ukubumba inaliti ye-Thermoplastic yinkqubo yokwenziwa kwemveliso edumileyo ngenxa yeenzuzo zayo ezininzi, kodwa kukwabalulekile ukuthathela ingqalelo ifuthe layo lokusingqongileyo. Nazi ezinye iingongoma ekufuneka uziqwalasele:

- Ubuchule bokuSebenza:Ukubumba inaliti ye-Thermoplastic kukhuthaza ukusebenza kakuhle kwezinto ngokunciphisa inkunkuma. Inkqubo isebenzisa ulawulo oluchanekileyo kumthamo wezinto ezifakwe kwi-mold, ukunciphisa imfuno yezinto ezingaphezulu. Abavelisi banokuphinda basebenzise ubuchule bokuphinda basebenzise izinto ezilahliweyo okanye ezilahliweyo, nto leyo enciphisa ngakumbi inkunkuma yezinto.

- Ukusetyenziswa Kwamandla:Abavelisi bayila oomatshini bokubumba inaliti ukuze basebenzise amandla, kunye neemodeli zangoku ezibandakanya itekhnoloji ephezulu efana neemotor ze-servo kunye nesantya esiguqukayo sokuqhuba. Ezi mpawu zikwandisa ukusetyenziswa kwamandla ngokunciphisa ukusetyenziswa kwamandla ngexesha lokubumba, okukhokelela kwiimfuno ezisezantsi zamandla kunye nokunciphisa impembelelo yokusingqongileyo.

- Ulawulo lweNkunkuma:Ngelixa becutha inkunkuma yezinto eziphathekayo, abavelisi kufuneka baphumeze iindlela ezifanelekileyo zokulawula inkunkuma ukuze baphathe izinto ezishiyekileyo, i-sprues, okanye iimbaleki. Abavelisi banokuseka iinkqubo zokurisayikilisha ukuqokelela nokusebenzisa kwakhona inkunkuma yeplastiki eveliswe ngexesha lokutofa, ngokwenjenjalo kuncitshiswa inkunkuma ethunyelwa kwiindawo zokulahla inkunkuma.

- Unciphiso lweMishini: Ukubumba inaliti ye-Thermoplastic ngokuqhelekileyo kuvelisa izinto ezikhutshwayo ezisezantsi kunezinye iinkqubo zokuvelisa. Abavelisi banokunciphisa ukukhutshwa kwezinto ezikhutshwayo ngokusebenzisa izinto ezihambelana ne-eco-friendly, ukuphumeza izixhobo ezonga amandla, kunye nokusebenzisa iinkqubo eziphucukileyo zokukhupha kunye nokucoca ukubamba nakuphi na ukukhutshwa okukhutshiweyo.

- Izinto eziKhethekileyo eziZinzileyo:Ukukhethwa kwezixhobo ze-thermoplastic kunokuchaphazela kakhulu ukuzinza kokusingqongileyo kwenaliti yokubumba. Ukukhetha i-biodegradable okanye iiplastiki ezisekwe kwibhayoloji, kunye nezinto eziphinda zisetyenziswe okanye ezinokurisayikilishwa, kunokunceda ukunciphisa unyawo olupheleleyo lwenkqubo.

Iingqwalasela zoMjikelo woBomi: Ukuqwalasela umjikelo wobomi bonke bemveliso ebunjiweyo ibalulekile ekuvavanyeni impembelelo yayo yokusingqongileyo. Ngexesha loyilo kunye nenqanaba lokukhetha imathiriyeli, abavelisi kufuneka bathathele ingqalelo imiba efana nokuqina kwenxalenye, ukusebenziseka kwayo ngokutsha, kunye nokubanakho ukulahlwa kokuphela kobomi okanye ukuphinda kusetyenziswe.

Ikamva le-Thermoplastic Injection Molding

Ikamva lokubumba inaliti ye-thermoplastic lijongeka lithembisa, ngokuqhubela phambili okuqhubekayo kwitekhnoloji kunye nokwanda kwemfuno yomgangatho ophezulu, iindawo ezichanekileyo kuwo wonke amashishini ahlukeneyo. Olunye lophuhliso oluphambili olulindelekileyo kwiminyaka ezayo lubandakanya:

- Ukunyuka kokusetyenziswa kwe-automation kunye nerobhothi ukuphucula ukusebenza kakuhle kunye nokunciphisa iindleko.

- Iinzame zijolise ekuphuhliseni izinto ezintsha kunye neenkqubo zokuphucula ukusebenza kwenxalenye kunye nokwenza izicelo ezintsha.

- Lulwamkelo olukhulayo lwezenzo ezizinzileyo, ezinjengokusebenzisa imathiriyeli esetyenzisiweyo kunye nokwandisa ukusetyenziswa kwamandla, ukunciphisa impembelelo yokusingqongileyo yokubumba inaliti.

- Ukudityaniswa okukhulu kobuchwepheshe bedijithali, njengokuprinta kwe-3D kunye nesoftware yokulinganisa, ukuphucula uyilo kunye neenkqubo zokuvelisa.

Imarike yokubumba inaliti yehlabathi iyakhula, ngakumbi kuqoqosho olusakhulayo, oluqhutywa kukwanda kwemfuno yeemveliso zeplastiki kumashishini ahlukeneyo.

Ukukhetha iqabane lokuBumba leSitofu esiLungileyo

Ukukhetha iqabane lokubumba inaliti elungileyo kubalulekile kwimpumelelo yeprojekthi yakho. Thatha ixesha lokuvavanya iinketho ezininzi, undwendwele indawo, kwaye uzibandakanye kwiingxoxo ezicokisekileyo ukuze uqinisekise intsebenziswano ehambelanayo nehlala ixesha elide.

- Ubungcali kunye namava:Khangela iqabane lokubumba inaliti ngolwazi olubanzi kunye namava kushishino. Kufuneka babe nerekhodi eqinisekisiweyo yokuhambisa iimveliso ezikumgangatho ophezulu kunye nezisombululo kubathengi kumacandelo ahlukeneyo. Qwalasela ukuqonda kwabo izinto ezahlukeneyo, uyilo lokungunda, kunye neenkqubo zokuvelisa.

- Ubunakho bokuVelisa: Vavanya amandla okwenza iqabane lokubumba inaliti. Qinisekisa ukuba baneziko elixhotyiswe kakuhle elinoomatshini bale mihla kunye nobuchwepheshe bokusingatha iimfuno zeprojekthi yakho. Qwalasela umthamo wabo wemveliso, ukukwazi ukuphatha ubungakanani bamacandelo ahlukeneyo kunye nobunzima, kunye nokukwazi ukuhlangabezana nomthamo wakho wemveliso owunqwenelayo kunye namaxesha.

- Ukuqinisekisa umgangatho:Umgangatho ubaluleke kakhulu ekubunjweni kwesitofu. Vavanya iinkqubo zokulawula umgangatho kunye neziqinisekiso zeqabane elinokubakho. Khangela amaqabane alandela imigangatho yomgangatho ongqongqo, aneenkqubo zokuhlola ezomeleleyo, kwaye enze uvavanyo olubanzi ukuqinisekisa umgangatho wenxalenye kunye nokungaguquguquki.

- Uyilo kunye neNkxaso yobuNjineli:Iqabane elithembekileyo lokubumba inaliti kufuneka libonelele ngenkxaso yoyilo kunye nobunjineli ukuze uphucule uyilo lwenxalenye yakho ukwenzela ukwenziwa. Kuya kufuneka babe neenjineli ezinobuchule ezinokubonelela ngegalelo elixabisekileyo ekukhetheni izinto eziphathekayo, uyilo lokubumba, kunye nokuphucula inkqubo yokuphucula umgangatho kunye nokusebenza kakuhle.

- Ukhuphiswano kwiindleko:Ngelixa iindleko zingafanele ukuba yiyo kuphela into emiselayo, kubalulekile ukuvavanya amaxabiso kunye nokhuphiswano lweendleko zeqabane lokubumba inaliti. Cela iikowuti ezineenkcukacha kwaye uqwalasele iindleko zezixhobo, iindleko zemathiriyeli, iindleko zabasebenzi, kunye nazo naziphi na iinkonzo ezongezelelweyo abazinikezelayo.

- Unxibelelwano kunye neNtsebenziswano:Unxibelelwano olusebenzayo kunye nentsebenziswano zibalulekile kwintsebenziswano eyimpumelelo. Qinisekisa ukuba iqabane lokubumba inaliti lineendlela zonxibelelwano ezilungileyo, liyayiphendula imibuzo yakho, kwaye linokubonelela ngohlaziyo lweprojekthi rhoqo. Indlela yokusebenzisana iya kunceda ukuqinisekisa ukuba siyahlangabezana neemfuno zakho kwaye silungise ngokukhawuleza nayiphi na imingeni.

- IiReferensi zabaThengi kunye noPhononongo:Khangela iireferensi zabathengi okanye ufunde uphononongo / ubungqina ukuze ufumane ulwazi kumava abanye abathengi kunye neqabane lokubumba inaliti. Ukufumana olu lwazi kunokunceda ukumisela ukuxhomekeka kwabo, ukukhawuleza, kunye nenqanaba elipheleleyo lokwaneliseka kwabathengi.

isiphelo

Ukubumba inaliti ye-Thermoplastic yindlela eguquguqukayo nengabizi kakhulu yokwenza iinxalenye zeplastiki ngobuninzi. Isakhono sayo sokuvelisa iimilo ezintsonkothileyo ngokuchaneka okuphezulu kunye nokungaguquguquki kuye kwaba lukhetho oludumileyo kumashishini ahlukeneyo, kubandakanya iimoto, ezonyango, i-elektroniki kunye nempahla yabathengi. Ngokuqonda imiba eyahlukeneyo yokubumba inaliti ye-thermoplastic, kubandakanya iingenelo zayo, izinto ezingeloncedo, kunye noqwalaselo loyilo, unokwenza izigqibo ezinolwazi malunga nokukhetha iqabane elifanelekileyo lokubumba inaliti kwiimfuno zeshishini lakho.