UbuGcisa beBatch encinci yokuBumba iPlastiki yesitofu: Ukulungelelanisa iMveliso ngokuchaneka

UbuGcisa beBatch encinci yokuBumba iPlastiki yesitofu: Ukulungelelanisa iMveliso ngokuchaneka

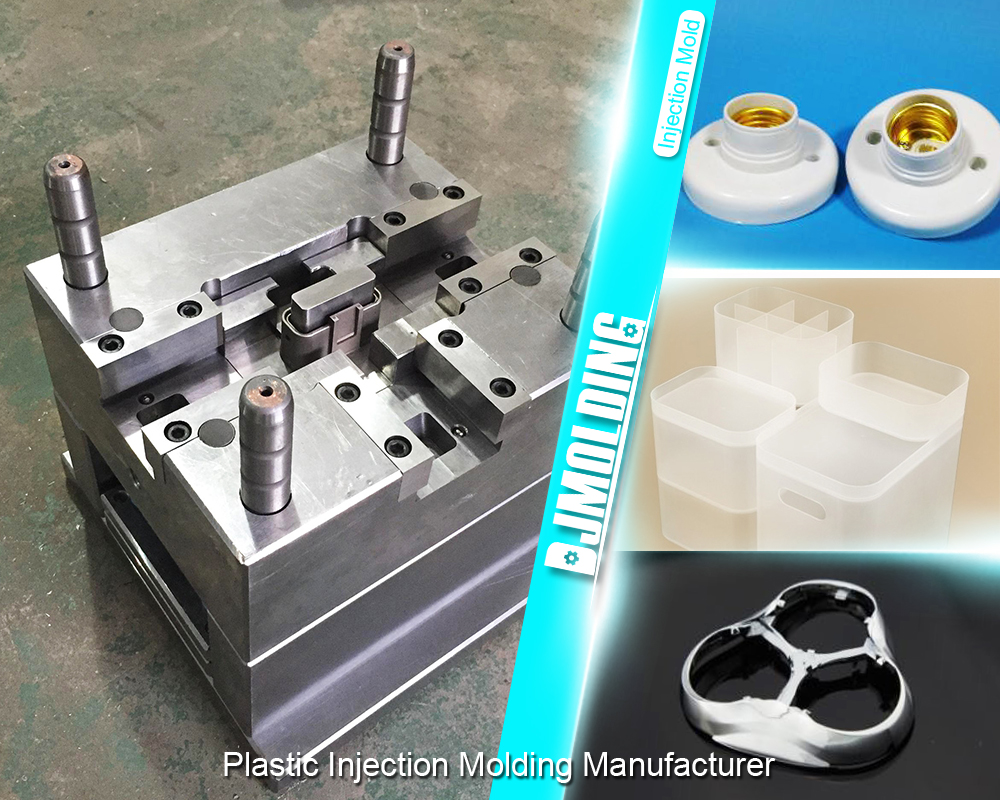

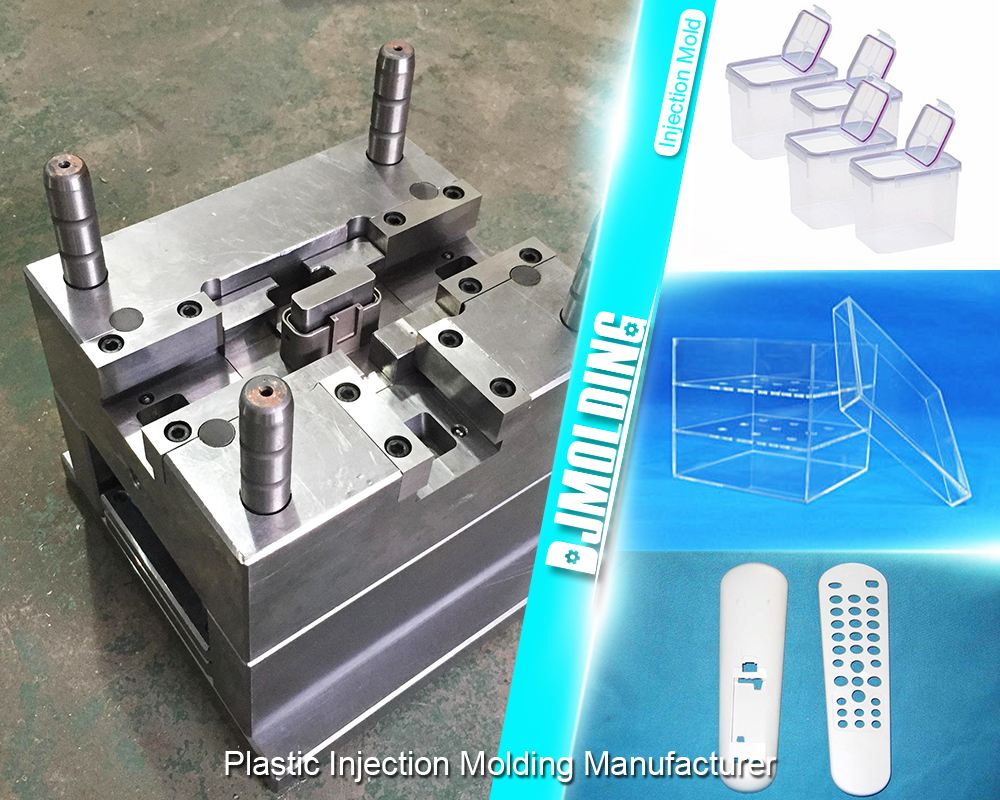

Ukubumba inaliti yeplastiki iye yavela njengendlela yokutshintsha umdlalo kwimbonakalo yanamhlanje ekhawulezayo yokuvelisa. Ukuqinisa ukuchaneka nokusebenza kakuhle kwenza ukuveliswa kobuninzi bezinto ezintsonkothileyo zeplastiki. Eli nqaku lijonga ubucukubhede bokubumba inaliti yeplastiki, iqaqambisa ukubaluleka kwayo, iingenelo, kunye nokusetyenziswa kwayo kumashishini awohlukeneyo.

Ukuqonda iBatch encinci yokuBumba isitofu sePlastiki

Inkcazo kunye neNkqubo yokuHlola

Ukubumba inaliti yeplastiki yinkqubo yokuvelisa ebandakanya ukutofa iplastiki etyhidiweyo kwindawo yokungunda ukwenza iimilo ezintsonkothileyo nezichanekileyo. Eli candelo lichaza amanyathelo enkqubo engundoqo, ukusuka ekukhethweni kwezinto ukuya ekusebenziseni amacandelo abalulekileyo afana nokubumba, iiyunithi zokutofa, kunye neenkqubo zokubamba.

Iindidi zePlastiki ezisetyenzisiweyo

Impumelelo yokubumba inaliti yeplastiki ixhomekeke ekusebenziseni iintlobo ezahlukeneyo zeeplastiki ezilungiselelwe usetyenziso oluthile. Apha, siphonononga iiplastiki ezisetyenziswa ngokuqhelekileyo, kuquka i-thermoplastics kunye ne-thermosetting polymers. Ngokuqonda iimpawu zabo ezizodwa kunye neempawu, abavelisi banokwandisa inkqubo yokubumba iziphumo eziphezulu.

Izinto eziluncedo eziphambili kwiPlastiki yeSitofu yokuBumba

Ukubumba inaliti yeplastiki kunika iingenelo ezininzi kunezinye iindlela zokwenza. Eli candelo lihlalutya kwiindleko zalo, ukuguquguquka koyilo, ukusebenza kakuhle kwemveliso, kunye nokulawulwa komgangatho ongaguqukiyo. Imizekelo yokwenyani yehlabathi kunye namabali empumelelo abonisa ngakumbi impembelelo yenguqu yokubumba inaliti yeplastiki kumashishini ahlukeneyo.

Inkqubo yokuBumba isitofu sePlastiki

Uyilo lokungunda kunye nokuLungisa

Uyilo lokungunda luyinkalo ebalulekileyo yokufakelwa kwiplastiki. Sixoxa ngokubaluleka koyilo lokubumba ukuze lusebenze ngokufanelekileyo, ukuqina, kunye nemveliso esebenzayo. Ukongezelela, sichaphazela izinto ezahlukeneyo zokubumba kunye neempawu zabo ukuqinisekisa ukukhethwa kweyona ndlela ifanelekileyo kwiprojekthi nganye.

Isigaba sokutofa

Inqanaba lokutofa libandakanya ukunyibilika kwezinto zeplastiki, ukuyicinezela, kunye nokuyitofa kumgodi wokungunda. Apha, sinika inkcazo ecacileyo yesi sigaba, sigxininisa ukubaluleka kokuchaneka kunye nokulawula. Abavelisi baphonononga ubushushu, uxinzelelo, kunye nexesha lokupholisa ukuze bafezekise umgangatho wemveliso.

Ukupholisa kunye nokuqinisa

Isigaba sokupholisa sidlala indima ebalulekileyo kwinkqubo yokubumba inaliti yeplastiki. Siphonononga iindlela zokupholisa ukuqinisekisa ukuqina okufanelekileyo kweplastiki, ukwandisa imfezeko yesakhiwo kunye nokunciphisa iziphene. Iingcali zixoxa ngobuchule obufana nolawulo lobushushu lokungunda, ukupholisa ngokusesikweni, kunye neendlela zokupholisa ngokukhawuleza.

Ukukhutshwa kunye nokugqiba

Isikhunta siyayikhupha imveliso emva kokuqina. Eli candelo lichaza inkqubo yokukhupha kwaye liqaqambise imisebenzi yesibini efana nokucheba, ukupolisha, kunye nokugqitywa komphezulu. Ngokujongana nokugqiba, abavelisi banokuphucula ubuhle bemveliso, ukusebenza, kunye nokuthengiswa.

Usetyenziso lwePlastiki yokuTofa isitofu

- Iimveliso zabathengi: Abavelisi basebenzisa kakhulu ukubumba inaliti yeplastiki ukuvelisa iimpahla zabathengi. Abavelisi basebenzisa obu buchule ukwenza izixhobo zasekhitshini, izixhobo zasekhaya, iithoyi, kunye nombane. Ukuguquguquka kokubumba inaliti yeplastiki kuvumela ukuyilwa koyilo oluntsonkothileyo, imibala eqaqambileyo, kunye neemveliso ezihlala ixesha elide eziphucula ubomi bethu bemihla ngemihla.

- Umzi mveliso weemoto: Umzi-mveliso weemoto uxhomekeke kakhulu ekubunjweni kwenaliti yeplastiki ukuvelisa izinto ezahlukeneyo. Ukusuka kwi-trim zangaphakathi kunye neepaneli zedeshibhodi ukuya kwiindawo zangaphandle ezifana ne-bumpers kunye ne-grilles, ukubumba inaliti yeplastiki kunika ukuguquguquka koyilo, ukunciphisa ubunzima, kunye nokusebenza kakuhle kweendleko. Yenza ukuba ishishini leemoto likwazi ukufezekisa umtsalane wobuhle, ukudityaniswa okusebenzayo, kunye nokuphucula ukusebenza kakuhle kwamafutha.

- Unyango kunye nokhathalelo lwempilo: Ukubumba inaliti yeplastiki kubaluleke kakhulu kumacandelo ezonyango kunye nezempilo. Abavelisi bayisebenzisela ukwenza izixhobo zonyango, izixhobo, kunye nezinto ezisetyenziswayo ezinemigangatho engqongqo yobulunga kunye nokuthotyelwa kwemithetho. Abavelisi bavelisa izinto ezinjengeesirinji, izixhumi ze-IV, izixhobo zotyando, kunye nokufakelwa kusetyenziswa izinto ezihambelana ne-biocompatible ukuqinisekisa ukhuseleko lwesigulane kunye nokusebenza okuchanekileyo.

- Ishishini lokuPakisha: Isitofu seplastiki sokubumba sisixhobo kwishishini lokupakisha. Ivumela ukuveliswa kwezikhongozeli zeplastiki, iibhotile, iikepusi, kunye nokuvalwa okusetyenziswa kumacandelo ahlukeneyo afana nokutya kunye neziselo, ukhathalelo lomntu, kunye namayeza. Ukukwazi ukwenza iimilo ezilungiselelweyo, ubungakanani, kunye neempawu zenza ukubumba inaliti yeplastiki ibe lukhetho olukhethiweyo lwezisombululo zokupakisha.

- Izixhobo zoMbane kunye nezoMbane: Ukubumba inaliti yeplastiki kuluncedo kakhulu kwishishini le-elektroniki. Iququzelela ukuveliswa kwee-casings, izihlanganisi, iiswitshi, kunye nezinye iindawo ezinzima ezifunekayo kwizixhobo zombane kunye neenkqubo zombane. Ukubumba inaliti yeplastiki iqinisekisa ukuchaneka, uzinzo lwe-dimensional, kunye nokhuseleko kwizinto ezisingqongileyo kwiimveliso zombane.

- I-Aerospace kunye noKhuseleko: Ukubumba inaliti yeplastiki ifumana izicelo kwi-aerospace kunye necandelo lokukhusela. Abavelisi basebenzisa ukubunjwa kwenaliti yeplastiki ukuvelisa izinto ezikhaphukhaphu, ezomelele kakhulu ezihlangabezana nokusebenza okungqongqo kunye neemfuno zokhuseleko. Imizekelo ibandakanya ukufakwa kwangaphakathi, iipaneli zesixhobo, izibiyeli, kunye neenkqubo zokuhambisa i-aerospace.

- Izinto zokwakha kunye nezixhobo zokwakha: Ukubumba inaliti yeplastiki inegalelo kushishino lokwakha ngokuvelisa izinto ezifana nemibhobho, izinto ezifakelwayo, ukugquma, kunye namalungu okuphahla. Ukomelela, ukunganyangeki komhlwa, kunye neendleko-zokusebenza zeemveliso ezibunjiweyo zesitofu seplastiki zizenza zilungele usetyenziso lolwakhiwo.

- Imidlalo noLonwabo: Ukubumba inaliti yeplastiki kuvelisa izixhobo zemidlalo, iimveliso zokuzonwabisa, kunye nezixhobo zangaphandle. Abavelisi banezinto ezifana nezigcina-ntloko, izixhobo zokukhusela, izixhobo zebhola, kunye nezibambo zezixhobo zisebenzisa le nkqubo. Ukubumba inaliti yeplastiki ivumela ukuyilwa kweemveliso ezikhaphukhaphu, ezichasene nempembelelo ezonyusa ukusebenza kunye nokhuseleko.

Ukuqhubela phambili kunye neeNdlela zexesha elizayo

Izinto ezintsha zobuGcisa

- Ukuzenzekelayo: I-Automation iguqule ukubumba inaliti yeplastiki, iphucula iinkqubo zemveliso kunye nokuphucula ukusebenza kakuhle. Iinkqubo ezizenzekelayo ziyakwazi ukuphatha izinto eziphathekayo, utshintsho lwesikhunta, kunye nokulawula umgangatho, ukunciphisa impazamo yabantu kunye nokwandisa imveliso.

- Ushicilelo lwe-3D: Ukudibanisa itekhnoloji yoshicilelo ye-3D kunye nokubumba inaliti yeplastiki kuvule amathuba amatsha okwenziwa kweprototyping ngokukhawuleza kunye nokwenza ngokwezifiso. Iimolds eziprintiweyo ze-3D kunye nokufakwa zingasetyenziswa ecaleni kokungunda kwendabuko, ukuvumela ukuphindaphinda ngokukhawuleza kunye nokuveliswa kwe-batch encinci ngeendleko.

- Ubukrelekrele bobugcisa (AI): I-AI idlala indima ebalulekileyo ekubumbeni inaliti yeplastiki. Isoftware ene-AI inokuhlalutya idatha yenkqubo ngexesha lokwenyani, ilungiselela iiparamitha ezinje ngobushushu, uxinzelelo, kunye nexesha lokupholisa lokuphucula umgangatho wenxalenye. Iisistim zokulondolozwa kwe-AI-powered predictive nazo zinokunceda ukukhusela ixesha lokuphumla elingalindelekanga kunye nokunciphisa iindleko zokulondoloza.

- Ukubunjwa kwezinto ezininzi: Ukukwazi ukusebenzisa izixhobo ezininzi kwinkqubo yokubumba enye yokutofa kukufumana i-traction. Abavelisi banokusebenzisa ukubumba inaliti yeplastiki ukwenza iindawo ezintsonkothileyo ezineempawu zezinto ezahlukeneyo, ezinjengokudibanisa iiplastiki eziqinileyo neziguquguqukayo. Obu buchule bokuvelisa buvumela ulawulo oluchanekileyo lwenkqubo yokubumba, yenze ukuba kuphunyezwe uluhlu olubanzi loyilo lwenxalenye kunye neejiyometri. Ukubumba izinto ezininzi kwandisa amathuba oyilo kunye nokwandisa ukusebenza kwemveliso.

- Ukubunjwa kwesitofu esincinci: I-Miniaturization yindlela ekhulayo kuwo wonke amashishini, kunye nokubumba i-micro-injection ihlangabezana nale mfuno. Obu buchule buvelisa iindawo ezincinci ezichanekileyo, ezintsonkothileyo, ezivula amathuba kumacandelo afana ne-elektroniki, izixhobo zonyango, kunye ne-microfluidics.

- Izinto eziZinzo: Njengoko uzinzo luba yeyona nto iphambili, ishishini lijonga ezinye izixhobo zokubumba inaliti yeplastiki. Iiplastiki eziguquguqukayo kunye ne-bio-based ezivela kwimithombo evuselelekayo zifumana ukuthandwa. Ukongeza, ukusebenzisa iiplastiki ezisetyenzisiweyo kunciphisa inkunkuma kwaye kuxhasa uqoqosho lwesetyhula.

- Ukwenziwa kobuchule: Ukudibanisa itekhnoloji ye-Intanethi yeZinto (IoT) ekubumbeni inaliti yeplastiki ivumela ukubeka iliso ngobukrelekrele kunye nokulawulwa kweenkqubo zemveliso. Ii-Sensors kunye noqhagamshelo luvumela ukuqokelela idatha yexesha langempela, uhlalutyo, kunye nokubeka iliso kude. Ukusebenzisa ubuchule obuzenzekelayo ekubumbeni inaliti yeplastiki kuphucula ulawulo lomgangatho, kunciphisa ixesha lokuphumla, kunye nokuphucula ukusebenza kakuhle ngokubanzi. Ezi nkqubo zinokubandakanya ukuphatha izinto ezizenzekelayo, ukususwa kwenxalenye yerobhothi, kunye neenkqubo zokuhlola umgca.

- iNyaniso eyiNqobo kunye neNyuvesi: Ekubumbeni inaliti yeplastiki, abaqulunqi kunye neenjineli basebenzisa itekhnoloji yenyani kunye neyongeziweyo yokwenyani ukuqinisekisa uyilo kunye nokuphucula iinkqubo. Abavelisi banokuchonga imiba enokubakho, balungise uyilo, kwaye banciphise ixesha lokuya kwintengiso ngokwenza iiprototypes ezibonakalayo kunye nokulinganisa inkqubo yokubumba.

Ezi nkqubela phambili kunye neendlela ezizayo zokubumba inaliti yeplastiki zibumba imeko yeshishini, zenza imveliso ikhawuleze, isebenze ngakumbi, kwaye ikhuseleke kokusingqongileyo. Ngokwamkela i-automation, ukusebenzisa ushicilelo lwe-3D kunye ne-AI, ukuhlola izixhobo ezitsha, kunye nokwamkela iindlela zokuvelisa ezikrelekrele, abavelisi banokuhlala bekhuphisana kwaye bahlangabezane neemfuno eziguqukayo zentengiso. Ukusukela ngokuqhubekayo ukwenza izinto ezintsha kuqinisekisa ukuba ukubumba inaliti yeplastiki kuhlala kuphambili kwimveliso yanamhlanje.

isiphelo

Ukubumba inaliti yeplastiki lilitye lembombo kwimveliso yanamhlanje, eyenza ukuveliswa okusebenzayo kwezinto ezintsonkothileyo zeplastiki. Ukubumba inaliti yeplastiki kuguqule iimveliso ngokuguqula amanyathelo enkqubo engundoqo, ukubonelela ngeenzuzo ezahlukeneyo, kunye nokufumana izicelo kuwo wonke amashishini amaninzi. Abavelisi banokuhlangabezana neemfuno zabathengi ezihlala zikhula ngokuchaneka, ukuguquguquka koyilo, kunye nokusebenza kakuhle kweendleko. Ishishini lokubumba inaliti yeplastiki lilungele ikamva elizele yinguqulelo kunye noxanduva lokusingqongileyo njengoko inkqubela phambili yobuchwepheshe kunye neenzame zozinzo ziqhubeleka ukuyibumba. Simema abafundi ukuba baphonononge ngakumbi kwaye bafumanise amathuba angenamda abonelelwa ngokubumba inaliti yeplastiki.

Okunye malunga ibhetshi encinci yokubumba inaliti yeplastiki,ungandwendwela Djmolding e https://www.djmolding.com/injection-mould-manufacturing/ ngolwazi olungakumbi.