5 Izinsalela Zepulasitiki Ezivamile Ezisetshenziswa Ekubumbeni Umjovo

1 ekuseni umbhalo block. Chofoza hlela inkinobho ukushintsha lo mbhalo. Lorem ipsum dolor ahlale Amet, consectetur Ukuqapha Tracker. Indlela Tracker Tracker, software nec ullamcorper mattis, dapibus leo pulvinar.

Njengoba kunamakhulu ezimpahla kanye nezinsalela zobunjiniyela ezitholakala emakethe namuhla, inqubo yokukhetha impahla yemisebenzi yokubumba imijovo yepulasitiki ingase ibonakale inzima ekuqaleni.

Kwa-DJmolding, siyaqonda izinzuzo eziyingqayizivele kanye nezakhiwo zezinhlobo ezahlukene zamapulasitiki futhi sisebenzisana eduze namakhasimende ukuze sithole okuyifanele kakhulu iphrojekthi yawo.

Ayini Ama-Plastic Resins?

Siphila ezweni elizungezwe izinhlaka zepulasitiki. Ngenxa yezindawo zabo ezifiselekayo eziningana, ama-resin epulasitiki angatholakala kukho konke kusuka kumabhodlela neziqukathi kuya ezingxenyeni zezimoto nezokwelapha nokunye okuningi. Ama-resin epulasitiki ahlanganisa umndeni omkhulu wezinto zokwakha ngayinye enezindawo zayo ezihlukile ezizenza zilungele ukusetshenziswa okuhlukile. Lapho ukhetha i-resin efanele yephrojekthi yakho, kubalulekile ukuqonda ukuthi uhlobo ngalunye lunikeza ini.

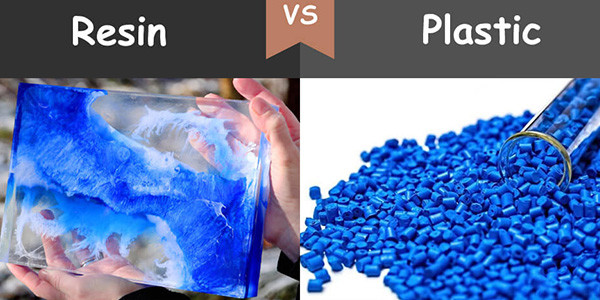

Uyini Umehluko Phakathi Kwe-resin nePlastiki?

I-resin nepulasitiki kokubili kuyinhlanganisela ebalulekile, kodwa kufaka phakathi umehluko obalulekile, okuhlanganisa:

*Umsuka: Ngenkathi ama-resin eyenzeka ngokwemvelo ezitshalweni, amapulasitiki akhiwe futhi ngokuvamile atholakala kumakhemikhali e-petrochemicals.

*Incazelo: Ipulasitiki iwuhlobo lwe-resin yokwenziwa, kuyilapho ama-resin eyinhlanganisela ye-amorphous engaba ingxenye eqinile noma eqinile.

*Ukuzinza nokungcola: Ipulasitiki izinzile kune-resin futhi ayinakho ukungcola. Ngama-resin, ukungcola akukwazi ukugwenywa.

*Ubunzima: Ipulasitiki iminyene futhi iqinile, kuyilapho inhlaka iyinto enamathelayo futhi i-viscous.

*Umthelela kwezemvelo: Njengoba i-resin ingokwemvelo, inikeza enye indlela evumelana nemvelo kunepulasitiki. Ipulasitiki incipha kancane futhi ngokuvamile inezithako ezinobuthi ezingaholela ekungcoleni kwemvelo.

Izicelo Ezivamile Zokubumba Umjovo We-Plastiki

Ukubunjwa komjovo wePlastiki kuhambisana nezinhlobonhlobo zezinto ze-resin. Lapho unquma inhlaka elungile yezidingo zakho, kubalulekile ukuqonda izidingo zohlelo lwakho lokusebenza. Izicelo ezijwayelekile zama-resin okubumba umjovo ahlukahlukene zifaka:

ABS

I-ABS ebunjwe ngomjovo isetshenziswa ezinhlotsheni eziningi zokusebenza, okuhlanganisa amapuleti odonga epulasitiki okukhipha ugesi, izigqoko ezivikelayo, okhiye bekhibhodi, izinto zikagesi, nezinto zezimoto ezifana nezitho zomzimba ezizenzakalelayo, amakhava amasondo, namadeshibhodi. Iphinde isetshenziselwe uhla lwezinto zokufakwa ezimbonini, izinto zezemidlalo, nezimpahla zabathengi.

Celson (Acetal)

Ngenxa yokungqubuzana kwayo okuphansi, i-Celson eyenziwe ngomjovo ilungele amasondo e-pulley, amabhande okuthutha, amagiya namabheringi. Lokhu okubalulekile kungaphinda kutholakale ezingxenyeni ezihlukahlukene zobunjiniyela ezisebenza kahle kakhulu, amasistimu wokukhiya, izibhamu, amafreyimu ezibuko zamehlo, nezinsimbi.

I-polypropylene

I-polypropylene yokufaka umjovo isetshenziswa ezinhlobonhlobo zezimboni, ezentengiselwano, nezicelo zabathengi. Isibonelo, ingatholakala emizimbeni yamathuluzi kagesi, izinto zikagesi, izingxenye zokupakisha, izimpahla zemidlalo, iziqukathi zokugcina, namathoyizi ezingane.

Ama-HIPS

Ngenxa yokuthi i-HIPS ifaka amandla omthelela aphezulu, ingatholakala ezintweni zikagesi, okokuphrinta, izimpawu, nezingxenye zemishini. Ezinye izinhlelo zokusebenza ezivamile zihlanganisa amathoyizi ezingane kanye nezingxenye zikagesi.

LDPE

Ngenxa yokuguquguquka kwayo kanye nokumelana nomswakama kanye namakhemikhali, i-LDPE ebunjwe ngomjovo ivamise ukusetshenziselwa izinhlelo zokusebenza ezihlanganisa izingxenye zedivayisi yezokwelapha, izivikeli zezintambo nezintambo, amabhokisi amathuluzi, namathoyizi ezingane.

Izinto Ezibalulekile Okufanele Zicatshangwe Lapho Ukhetha Impahla Yokubumba Umjovo

Izingxenye zepulasitiki zangokwezifiso ezivela ku-DJmolding ukuze uqinisekise ukuthi ukhetha inhlaka elungile yephrojekthi yakho, khumbula okuhlukile okulandelayo:

*Amandla omthelela - Ezinye izinhlelo zokusebenza zidinga amandla esisekelo amaningi kunezinye, ngakho-ke amandla omthelela we-Izod we-resin kufanele anqunywe kusukela ekuqaleni.

*Amandla okubamba - Amandla okugcina eqinile, noma amandla amakhulu, akala ukumelana kwenhlaka ekuqineni kanye nekhono layo lokumelana nomthwalo othile ngaphandle kokuhlukana.

*Flexural modulus of elasticity - Lokhu kubhekisela ezingeni impahla engagotshwa ngalo ngaphandle kokulimala futhi iphinde ibuyele esimweni sayo sasekuqaleni.

*Ukuchezuka kokushisa - Lokhu kubaluleke kakhulu ezinhlelweni ezidinga ukusebenza kwe-insulating noma ukubekezelelana kwezinhlobonhlobo zamazinga okushisa.

*Ukumuncwa kwamanzi - Lokhu kusekelwe emaphesentini oketshezi oluthathwa yimpahla ngemva kwamahora angu-24 wokucwiliswa.

Ukukhethwa Kwezinto Ngokwezifiso nge-DJmolding

I-Djmolding ingumkhiqizi wokubumba umjovo wepulasitiki, ikhiqiza izingxenye zepulasitiki ezine-acrylic (PMMA), i-acrylonitrile butadiene styrene (ABS), inayiloni (polyamide, PA), i-polycarbonate (PC), i-polyethylene (PE), i-polyoxymethylene (POM), i-polypropylene (PP), i-polystyrene (PS) nokunye

Ukukhetha impahla efanele kusukela ekuqaleni ngeke nje kukugcinele isikhathi, nemali kodwa kuzophinde kuqinisekise ukusebenza kahle nokwenziwayo. Cwaninga izinketho zakho ngokucophelela, bese uthintana nomdidiyeli womjovo wepulasitiki onolwazi ukuze usize ukunquma ukukhetha okufanele.