Insiza Yezemishini ye-CNC

Iyini i-CNC Machining

I-CNC imele ukulawulwa kwezinombolo zekhompyutha, okuwubuchwepheshe bokulawula amathuluzi okwenza ngokuzenzakalela ngokusebenzisa ikhompuyutha encane enamathiselwe ethuluzini. Imishini ye-CNCs izosebenza ngokwemiyalo ehleliwe enekhodi, njengokuhamba kwemishini, izinga lokuphakelwa kwezinto, isivinini, njalo njalo. Asikho isidingo sokuthi opharetha balawule umshini ngesandla, ngakho-ke, i-CNC isiza ukuthuthukisa ukusebenza kahle nokunemba ngezinga elikhulu.

DJmolding CNC amakhono machining

Imishini ye-CNC efunwa kakhulu ye-prototyping esheshayo nezingxenye zokukhiqiza, izitolo zemishini ye-DJmolding CNC ezinolwazi futhi ezihlolwe kahle.

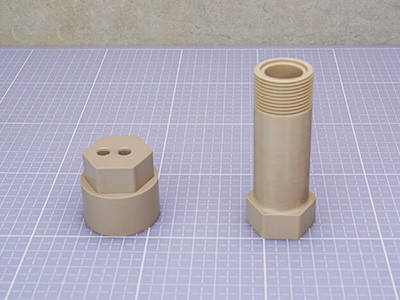

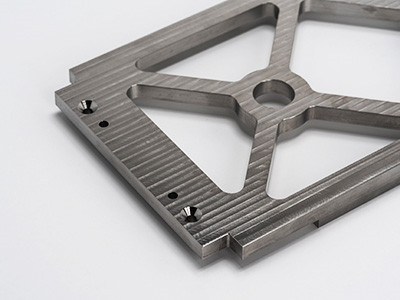

Sisebenzisa cishe lonke uhlobo lwesigayo se-CNC kanye nesikhungo sokujika, futhi siyaziqhenya ngokukwazi ukwenza umshini noma yini oyidingayo, kusukela ekubambeni okulula, 'okwenziwa ngomshini' kuya kumajiyometri anzima, aphilayo anokubekezelelana okuqinile. Ngesicelo, singakwazi futhi ukukhiqiza izingxenye nge-EDM nama-grinders. Yakha izimvilophu, osayizi besici obuncane kanye nemihlahlandlela yedizayini iyahlukahluka ekugayweni nasekujikeni.

CNC Milling Izikhungo

Ngokwamafayela e-CAD ekhasimende, thola ikhotheshini yokugaya ye-CNC emahoreni angama-24.

Isevisi Yokuguqula i-CNC

Ngokwamafayela e-CAD ekhasimende, thola isilinganiso esisheshayo se-CNC emahoreni angama-24.

Amakhono esevisi yokugaya i-DJmolding CNC

Kusukela ku-prototyping ukuya ekukhiqizeni okugcwele kuyagijima. I-axis yethu engu-3, i-axis engu-3+2 kanye nezikhungo zokugaya ezigcwele ze-5-eksisi zizokuvumela ukuthi ukhiqize izingxenye ezinembe kakhulu nezisezingeni eliphezulu ukuze uhlangabezane nezidingo zakho eziqine kakhulu.

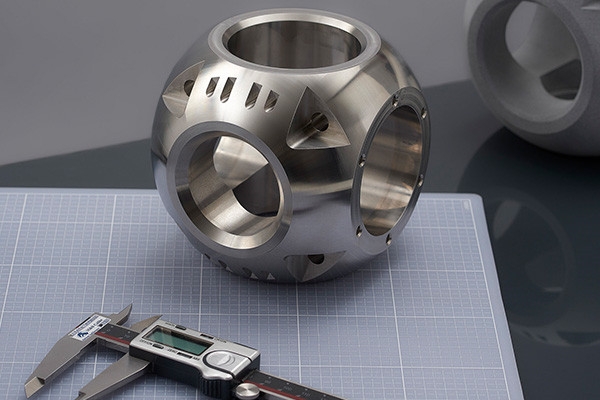

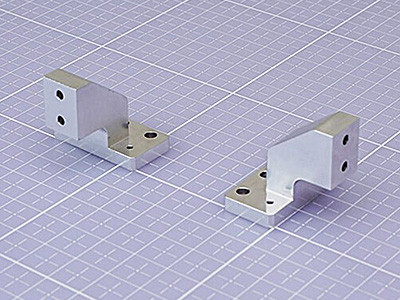

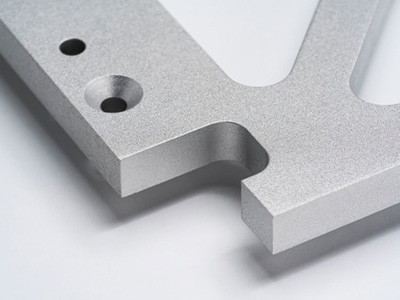

Igalari yezingxenye zomshini ze-CNC

Sisebenza ngomshini ama-prototypes asheshayo kanye nama-oda wokukhiqiza wevolumu ephansi kumakhasimende ezimbonini eziningi: i-aerospace, izimoto, ezokuvikela, ze-elekthronikhi, ukuqalisa kwehadiwe, okuzenzakalelayo kwezimboni, imishini, ukukhiqiza, imishini yezokwelapha, uwoyela negesi namarobhothi.

I-Aluminium 7075-T6

I-Aluminium 6061-T6

I-Aluminium 6082

I-Aluminium 6063

I-PeEK

Omashini abanekhono basebenzisa umshini we-CNC ngokuhlela izindlela zamathuluzi ngokusekelwe kujometri yezingxenye zokugcina ezenziwe ngomshini. Ulwazi lwengxenye yejiyomethri lunikezwa imodeli ye-CAD (umklamo osizwa ngekhompyutha). Imishini ye-CNC ingasika cishe noma iyiphi ingxubevange yensimbi nepulasitiki eqinile ngokunemba okuphezulu nokuphindaphindeka, yenze izingxenye ezenziwe ngomshini ngokwezifiso zifanele cishe yonke imboni, okuhlanganisa i-aerospace, yezokwelapha, amarobhothi, izinto zikagesi, nezimboni. I-DJmolding ihlinzeka ngezinsizakalo ze-CNC futhi inikeza izingcaphuno zangokwezifiso ze-CNC ezintweni ezingaphezu kuka-40 kusukela ku-aluminium yempahla kanye ne-acetal kuya ku-titanium ethuthukisiwe namapulasitiki anjiniyela afana ne-PEEK ne-Teflon.

Indawo etholakalayo yokuqedwa komshini we-CNC

Ama-surface finishes asetshenziswa ngemuva komshini futhi angashintsha ukubukeka, ubulukhuni bobuso, ubulukhuni kanye nokumelana namakhemikhali ezingxenyeni ezikhiqiziwe.

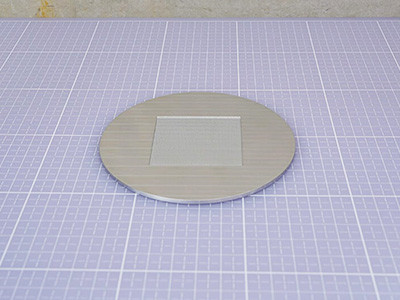

Njengomshini (Ra 3.2μm / Ra 126μin)

Lokhu ukuphela kwethu okujwayelekile. Izingxenye zenziwe ngomshini futhi zikhishwe, imiphetho ebukhali i-chamfered.

Ukwenza imishini ebushelelezi (Ra 1.6μm / Ra 63μin)

Ukwenza imishini ebushelelezi kufana nokuqeda 'Njengomshini' kodwa okunamamaki omshini angabonakala kancane. Izingxenye zenziwa ngomshini kokuphakelayo okuphansi, akukho ukupholisha ngesandla okufakwayo.

I-Bead Blasted

Izingxenye ziwuhlalu oluqhunyiswe ngobuhlalu bengilazi okuholela ekuthungeni okusanhlamvu.

Ibhulashi + I-Electropolished (Ra 0.8μm / Ra 32μin)

Izingxenye zixutshwe futhi zi-electropolished. Kuhle ukunciphisa ubuncane bengxenye.

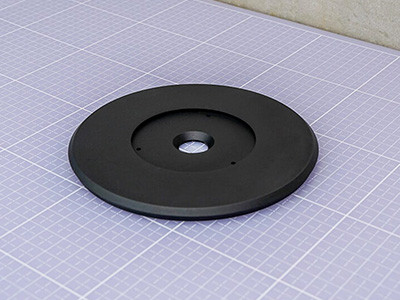

I-oxide emnyama

Isebenza kuma-steels, i-black oxide inamathela ekuguquleni okusetshenziselwa ukuthuthukisa ukumelana nokugqwala nokunciphisa ukubonakaliswa kokukhanya.

Ibhulashi + uhlobo lwe-Anodized II (Glossy)

Izingxenye zixutshwe bese zifakwa ngohlobo II. Ilungele ukukhulisa ukumelana nokugqwala kwengxenye. Ngokuvamile kubangela umbala ocwebezelayo.

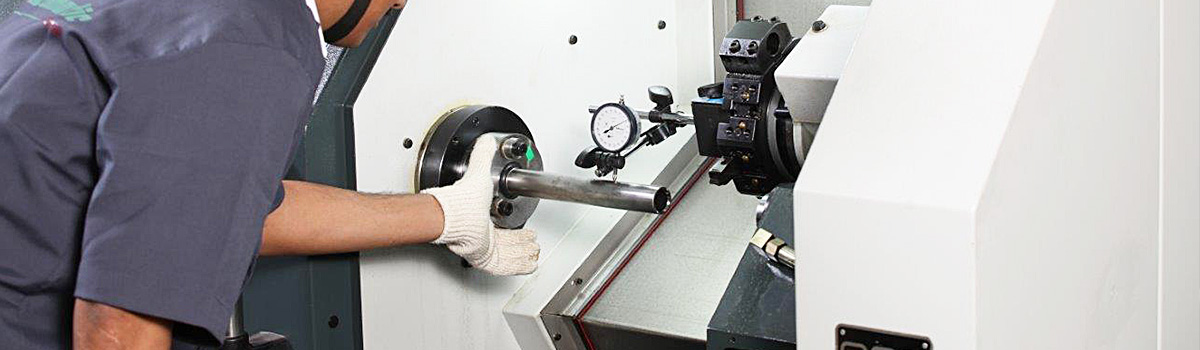

Imishini ye-CNC (Computer Numerical Control) iwumgogodla wokukhiqiza wesimanje. Baguqule inqubo yokukhiqiza ngokunikeza ukunemba, isivinini, nokuguquguquka ukuze kukhiqizwe izingxenye eziyinkimbinkimbi nezingxenye. Kodwa-ke, ukuze kuqinisekiswe ukuthi imishini ye-CNC isebenza ezingeni elifanele, idinga ukunakekelwa okujwayelekile, ukulungiswa, nokuseviswa. Abahlinzeki besevisi yomshini we-CNC bahlinzeka ngezinsizakalo eziningi ukuze kuqinisekiswe ukuthi le mishini isebenza kahle nangempumelelo. Kulokhu okuthunyelwe kwebhulogi, sizoxoxa ngezici ezihlukahlukene zesevisi yomshini we-CNC nokuthi iwazuzisa kanjani amabhizinisi okukhiqiza.

Iyini Isevisi Yomshini we-CNC?

I-CNC imele iComputer Numerical Control, okusho umshini olawulwa uhlelo lwekhompyutha. Imishini ye-CNC isetshenziselwa imisebenzi ehlukahlukene, okuhlanganisa ukusika, ukubhola, ukugaya, nokujika.

Izinsizakalo zomshini we-CNC zibandakanya ukusebenzisa le mishini ukwenza imisebenzi enembe kakhulu nephindaphindekayo. Lezi zinsizakalo zivame ukusetshenziswa ekukhiqizeni, ezidinga izingxenye eziqondile nezingaguquguquki.

Ukusebenzisa umshini we-CNC, uhlelo luqala ngokudalwa kusetshenziswa isofthiwe ye-computer-aid design (CAD). Uhlelo lube selulayishwa emshinini, osebenzisa iziqondiso ukwenza umsebenzi owufunayo ocezwini lwento.

Imishini ye-CNC ingasetshenziswa ngezinto ezihlukahlukene, okuhlanganisa insimbi, ipulasitiki, izinkuni, nezinhlanganisela. Banikeza izinzuzo eziningi, okuhlanganisa izikhathi zokukhiqiza ezisheshayo, ukunemba okuphezulu, kanye nekhono lokudala izimo eziyinkimbinkimbi nezici.

Kungani Isevisi Yomshini We-CNC Ibalulekile?

Imishini ye-CNC (Computer Numerical Control) isibalulekile ezimbonini zokukhiqiza, ikakhulukazi ekukhiqizeni izimoto, i-aerospace, kanye nemishini yezokwelapha. Le mishini iyazisebenzela, ngakho ingakwazi ukusebenza isikhathi eside ngaphandle kokungenelela komuntu. Imishini ye-CNC ingakhiqiza izingxenye eziyinkimbinkimbi ngokunemba okuphezulu nokunemba, okuzenza zibaluleke kakhulu ekukhiqizeni.

Isevisi yomshini we-CNC ibalulekile ngezizathu ezimbalwa. Okokuqala futhi okubaluleke kakhulu, iqinisekisa ukuthi imishini isebenza ezingeni elifanele. Imishini ye-CNC inezingxenye eziningi ezihambayo ezidinga ukulungiswa njalo ukuze kuvinjelwe ukuguga, okungaholela ekulimaleni kwemishini kanye nesikhathi sokukhiqiza. Ukunakekelwa okujwayelekile kanye nesevisi kusiza ekutholeni nasekuxazululeni izinkinga ezingase zibe khona ngaphambi kokuba zibe izinkinga ezinkulu.

Okwesibili, insizakalo yomshini we-CNC isiza ukuthuthukisa impilo yomshini. Ukusevisa okuvamile kuqinisekisa ukuthi izisetshenziswa zisebenza ngaphakathi kwemingcele eklanywe yona, kunciphisa ingcuphe yokuguga ngaphambi kwesikhathi. Lokhu kwandisa isikhathi sokuphila komshini, konga imali yomkhiqizi yokuwushintsha nokuwulungisa.

Okwesithathu, isevisi yomshini we-CNC isiza ukugcina ikhwalithi engaguquki ekukhiqizeni. Imishini ye-CNC ihlelelwe ukukhiqiza izingxenye ezinemba nokunemba okuphezulu, okubalulekile emkhathini nasekukhiqizweni kwemishini yezokwelapha. Ukusevisa okuvamile kuqinisekisa ukuthi imishini isebenza ngendlela efanele, kwakha izingcezu ezihlangabezana nokucaciswa okudingekayo nokugcina ikhwalithi yokuphuma engaguquki.

Okwesine, isevisi yomshini we-CNC isiza ukuthuthukisa ukuphepha emsebenzini. Imishini ye-CNC ingamathuluzi anamandla adinga ukuphathwa ngokucophelela ukuze kuvinjelwe izingozi. Ukusevisa okuvamile kusiza ukuhlonza izingozi zokuphepha ezingaba khona, ezingaxazululwa ngaphambi kokuba zidale ukulimala kubaqhubi noma ukulimala kwemishini.

Izinhlobo zemishini ye-CNC

Imishini ye-CNC (Computer Numerical Control) isetshenziswa kakhulu ezimbonini ezahlukahlukene zokukhiqiza ngokunemba. Le mishini isebenzisa amasistimu okulawula amakhompiyutha ukuze izenzele futhi yenze imisebenzi yemishini eyinkimbinkimbi ngokunemba okuphezulu nokusebenza kahle. Kunezinhlobo ezimbalwa zemishini ye-CNC etholakalayo, ngayinye yakhelwe izinhlelo zokusebenza ezithile. Nazi ezinye zezinhlobo ezivame kakhulu:

Imishini Yokugaya ye-CNC

- Izikhungo Zomshini Eziqondile (VMC):Le mishini inento yokuphotha eqonde mpo futhi ifanele ukusika nokubumba izinto eziqinile.

- Izikhungo Zomashini Ezivundlile (HMC):Ama-HMC ane-spindle evundlile futhi alungele ukukhanda izingcezu zokusebenza ezinkulu nezisindayo.

- Imishini ye-5-Axis:Le mishini inikeza ukunyakaza kanyekanye ezimbazoni ezinhlanu, ivumela ukusebenza kwemishini eyinkimbinkimbi futhi eyinkimbinkimbi.

CNC Lathe Machines

Izikhungo zokuvula:Le mishini isetshenziselwa imisebenzi yokuguqula ngokunemba, lapho ucezu lokusebenza luzungeza ngenkathi amathuluzi okusika ebumba into.

- Izindwangu zohlobo lwase-Swiss:Amalebula ohlobo lwase-Swiss aklanyelwe ukunemba okuphezulu kanye nezinto zokusebenza ezinobubanzi obuncane. Zifaka isihlokwana esishelelayo kanye nesihlahla somhlahlandlela ukuze kube nokunemba okuthuthukisiwe.

I-CNC Plasma Cutters

- Imishini yokusika i-Plasma isebenzisa ijethi yegesi enesivinini esikhulu ukusika izinto ezisebenza ngogesi njengensimbi, i-aluminium, nethusi. Zivame ukusetshenziselwa ukwenziwa kwensimbi kanye nezicelo zezimboni.

CNC Laser Cutting Machines

- Imishini yokusika i-laser isebenzisa i-laser beam egxilile ukuze incibilike, ishise, noma ihwamulise izinto, okuholela ekusikekeni okunembile nokuhlanzekile. Ziyakwazi ukwenza izinto ezihlukahlukene futhi zingakwazi ukuphatha izinto ezihlukahlukene njengensimbi, ukhuni, i-acrylic, namapulasitiki.

Imishini ye-CNC Router

- Amarutha e-CNC asetshenziswa ngokuyinhloko ukusika, ukubumba, nokuqopha izinto ezifana nokhuni, ipulasitiki, negwebu. Zisetshenziswa kakhulu ekwenzeni izinkuni, ukukhiqizwa kwezimpawu, kanye ne-prototyping.

Imishini ye-CNC EDM

- Imishini ye-Electrical Discharge Machining (EDM) isebenzisa ukukhishwa kukagesi ukuze isuse izinto ezisetshenziswayo. Zivame ukusetshenziselwa izimo eziyinkimbinkimbi nezinto eziqinile njengensimbi eqinile ne-titanium.

Imishini Yokugaya ye-CNC

- Imishini yokugaya isetshenziselwa ukufeza ukunemba okuphezulu kokuqedwa kwendawo kanye nobukhulu obunembile. Basebenzisa amasondo abrasive ukuze basuse impahla ku-workpiece.

CNC Cindezela amabhuleki

- Amabhuleki okucindezela asetshenziselwa ukugoba nokubumba insimbi yeshidi. Amabhuleki okucindezela alawulwa yi-CNC anikeza ukulawula okunembile phezu kwenqubo yokugoba, okuholela emiphumeleni enembile nephindaphindekayo.

Izinkinga Zomshini We-CNC Ezivamile

Nakuba imishini ye-CNC isebenza kahle kakhulu futhi ithembekile, isengathola izinkinga ezithile ezingathinta ukusebenza kwayo nokukhiqiza. Ukuqonda nokubhekana nalezi zinkinga ezivamile kubalulekile ukuze kuqinisekiswe ukusebenza kahle. Nazi ezinye zezinkinga ezijwayelekile zomshini we-CNC:

Amaphutha Okwenza

- Imiyalo yezinhlelo engalungile noma engaphelele ingaholela kumaphutha ekusebenzeni komshini.

- Izindlela zamathuluzi ezingalungile noma ukukhethwa kwamathuluzi okungalungile kungaholela ekuqedeni kahle kwendawo, ukungalungi kwe-dimensional, noma ukuphuka kwamathuluzi.

Izinkinga Zomshini

Izingxenye ezigugile noma ezilimele njengamabheringi, amabhande, noma izikulufu zebhola zingabangela ukudlala ngokweqile, okuholela ekusikeni okungalungile kanye nokunemba okuncishisiwe.

- Ukugcotshwa okungalungile noma ukunganaki kahle kungaholela ekwenyukeni kokungqubuzana, ukushisa ngokweqile, nokuguga ngaphambi kwesikhathi kwezingxenye zomshini.

Izinkinga zikagesi neze-elekthronikhi

Ukushintshashintsha kwamandla noma ukuphazamiseka kukagesi kungabangela ukuziphatha komshini okunephutha, njengokuma kungazelelwe, ukusetha kabusha, noma ukuma okungalungile.

- Izinzwa ezinephutha noma ukushintsha komkhawulo kungase kuholele ekunyakazeni komshini okungalungile noma ekufundweni kwamaphutha okungamanga.

Izinkinga Zokusebenza

- Amathuluzi okusika abuthuntu noma afakwe ngendlela engafanele angabangela ukuqedwa kahle kwendawo, ukuxoxa, noma ukuguga kwamathuluzi okweqile.

- Ukususwa kwamathuluzi okungalungile noma izilinganiso zobude bethuluzi zingase zibangele ukungalungi kobukhulu.

Izinkinga zokupholisa kanye nokususwa kwe-chip

- Ukugeleza kokupholisa okunganele noma ukukhishwa kwe-chip okungafanele kungaholela ekwakhiweni kokushisa, ukushisisa ngokweqile kwamathuluzi, kanye nempilo yamathuluzi encishisiwe.

- Ukukhishwa okunganele kwe-chip kungabangela ukuvinjelwa kwe-chip, okuthinta ukuphela kwendawo futhi kungalimaza ucezu lokusebenza noma umshini.

Amaphutha e-Software kanye Nesistimu Yokulawula

- Izingqinamba zesofthiwe noma izinkinga zokusebenzisana zingaphazamisa ukusebenza komshini futhi kubangele amaphutha noma ukuphahlazeka okungalindelekile.

- Ukulinganisa okungalungile noma izilungiselelo zepharamitha ezingalungile ngaphakathi kwesistimu yokulawula zingaholela emaphutheni okumisa noma amazinga okuphakelayo angalungile.

Izingosi zemvelo

- Ukwehluka kwezinga lokushisa, umswakama, noma uthuli kungathinta ukusebenza nokunemba kwemishini ye-CNC.

- Ukufakwa okungalungile noma ukuma komshini ngokuphathelene nezici zemvelo kungaba nomthelela ekuzinzeni nasekuthembekeni kwawo.

Ukugcinwa Kokuvikela Kwemishini Ye-CNC

Ukusebenzisa uhlelo lokulungisa lokuvikela olusebenzayo kubalulekile ukuze kukhuliswe ukusebenza, ukwethembeka, nempilo yemishini ye-CNC (Computer Numerical Control). Ukunakekelwa okuvamile kusiza ukuhlonza izinkinga ezingase zibe khona ngaphambi kokuba zibe izinkinga ezinkulu, kunciphisa isikhathi sokuphumula, futhi kuqinisekise ukusebenza kahle komshini. Nazi ezinye izindawo ezibalulekile okufanele ugxile kuzo lapho wenza ukulungiswa kokuvikela kwemishini ye-CNC:

Ukuthambisa

- Gcoba njalo izingxenye zomshini njengamabheringi, izikulufu zebhola, amaslayidi, namagiya ngokuya ngemihlahlandlela yomkhiqizi.

- Sebenzisa izinto zokugcoba ezifanele futhi uqinisekise izikhawu ezifanele zokugcoba ukuze unciphise ukungqubuzana, unciphise ukuguga, futhi ugcine ukusebenza kahle.

Cleaning

- Gcina umshini nendawo ezungezile ihlanzekile kusukela kuma-chips, izinsalela zokupholisa, nemfucumfucu.

- Hlanza njalo izihlungi, amathangi okupholisa, namathreyi e-chip ukuze ulondoloze ukusebenza kahle kokupholisa futhi uvimbele ukucinana.

Ukuhlola kanye Ukulinganisa

Yenza ukuhlola okuvamile kwezingxenye ezibalulekile ezifana nokuphotha, izibambi zamathuluzi, nezinto ezilungiswayo ukuze ubone izimpawu zokuguga noma zokonakala.

- Linganisa futhi uhlole ukunemba kwezimbazo zomshini, ama-offset amathuluzi, nezinhlelo zokubeka ukuze uqinisekise ukwenziwa kwemishini okunembayo.

Izingxenye zikagesi neze-elekthronikhi

- Hlola ukuxhunywa kukagesi, izintambo, nezintambo ukuze uthole noma yiziphi izimpawu zomonakalo noma ukuxega kokuxhuma.

- Hlola futhi uhlole izinzwa, amaswishi anomkhawulo, nezikhiya zokuphepha ukuze uqinisekise ukusebenza okufanele.

Amasistimu Okupholisa

- Gcina futhi uhlanze amasistimu okupholisa njalo ukuze uvimbele ukungcola futhi uqinisekise ukupholisa okufanele.

- Gada amazinga okupholisa, ibhalansi ye-pH, nokugxilisa ingqondo, futhi ugcwalise noma ufake esikhundleni sokupholisa njengoba kudingeka.

Isoftware kanye nohlelo lokulawula

- Njalo buyekeza futhi ulondoloze isofthiwe yomshini we-CNC kanye nesistimu yokulawula ngezinguqulo zakamuva namapeshi.

- Qinisekisa futhi ulinganise amapharamitha esistimu yokulawula, njengamazinga okuphakelayo nokusheshisa, ukuze uqinisekise ukwenziwa kwemishini okunembile.

Amathuluzi kanye Spindle

- Hlola futhi uhlanze izibambi zamathuluzi, amakholethi, nama-spindle taper njalo ukuze uqinisekise ukugoqa amathuluzi okufanele futhi unciphise ukuphuma.

- Hlola bese ushintsha amathuluzi okusika agugile noma alimele ukuze ugcine ukusebenza kahle kokusika nokuqedwa kwendawo.

Ukuqeqeshwa Kwabasebenzi kanye Nemibhalo

- Nikeza ukuqeqeshwa okuphelele kubaqhubi bemishini ngokusebenza okufanele, izinqubo zokuyilungisa, kanye nezinqubo zokuphepha.

- Gcina amarekhodi anemininingwane yemisebenzi yokulungisa, ukuhlolwa, nokulungiswa ukuze kusetshenziswe ireferensi nokuhlaziya.

Ukuhlolwa Okujwayelekile Kwemishini Ye-CNC

Ukuhlolwa njalo nokunakekelwa kwemishini ye-CNC (Computer Numerical Control) kubalulekile ukuze kuqinisekiswe ukusebenza kwayo okuphelele nokuphila isikhathi eside. Ngokwenza ukuhlola okuvamile, izinkinga ezingaba khona zingabonakala kusenesikhathi futhi izinyathelo zokuvimbela zingathathwa ukuze kugwenywe ukuwohloka okubizayo nokubambezeleka kokukhiqiza. Nawa amaphuzu abalulekile okufanele uwacabangele ngesikhathi sokuhlolwa kwemishini ye-CNC:

Ukuhlola Okubonakalayo

- Qala ngokuhlola umshini ngokubona noma yiziphi izimpawu zokuguga, ukonakala, noma izinto ezixegayo.

- Hlola ukuvuza, okufana nowoyela noma okokupholisa, okungase kubonise inkinga ngamasistimu oketshezi omshini.

- Bheka noma yimuphi umsindo ongavamile noma ukudlidliza phakathi nokusebenza komshini.

Ukuthambisa

- Qinisekisa ukuthi wonke amaphuzu okugcoba agcotshwe ngokwanele ukuze uqinisekise ukunyakaza okushelelayo kwezingxenye zomshini.

- Hlola amazinga okothambisa futhi uwagcwalise uma kunesidingo.

- Qinisekisa ukugcotshwa okufanele kwezikulufu zebhola, ama-rails angumhlahlandlela, nezinye izinto ezibalulekile.

Ukulinganiswa kwe-eksisi

Qinisekisa ukunemba kwezimbazo zomshini ngokwenza izivivinyo zokulinganisa.

- Hlola noma yikuphi ukuchezuka ekuvumelaneni okucacisiwe futhi ulungise uma kudingeka.

- Linganisa isistimu yokuhlola yomshini, uma ikhona, ukuze uqinisekise ukulinganisa okunembile.

Ukuhlola Spindle

- Hlola i-spindle ukuze uthole noma yiziphi izimpawu zokuguga, ukulimala, noma ukungahambi kahle.

- Hlola ama-spindle bearings bese uwashintsha uma kunesidingo.

- Qinisekisa ukuphuma kwe-spindle ukuze uqinisekise ukugxila ngesikhathi sokusebenza komshini.

Amathuluzi kanye nokuguqula ithuluzi

- Hlola isistimu yamathuluzi, okuhlanganisa izibambi, amakholethi, namathuluzi okusika, ukuze uthole noma yiziphi izimpawu zokuguga noma zokulimala.

- Hlola indlela yokushintsha ithuluzi ukuze isebenze kahle futhi ihambisana kahle.

- Hlanza futhi ugcobe izingxenye zokushintsha amathuluzi njengokusho kwemihlahlandlela yomkhiqizi.

Control System

- Hlola iyunithi yokulawula ye-CNC futhi uqaphele noma yimiphi imilayezo yamaphutha noma ukungasebenzi kahle.

- Qinisekisa ukuthi zonke izintambo nezixhumi ziphephile futhi zisesimweni esihle.

- Buyekeza isofthiwe yomshini, uma ikhona, ibe yinguqulo yakamuva enikezwe umenzi.

Izici Zokuphepha

- Qinisekisa ukusebenza kwezici zokuphepha, njengezinkinobho zokumisa izimo eziphuthumayo nezikhiya.

- Hlola isimo sekhava yokuvikela kanye nezithiyo ukuze uqinisekise ukuphepha komqhubi.

- Hlola isistimu ye-alamu yomshini ukuze uqinisekise ukusebenza kahle.

Amadokhumenti:

Gcina irekhodi elinemininingwane yezinsuku zokuhlolwa, okutholiwe, nanoma yikuphi ukulungiswa noma ukulungiswa okwenziwe.

- Landela ishejuli yokulungisa enconyiwe yomkhiqizi nemihlahlandlela.

- Gcina irekhodi lanoma yiziphi izingxenye eziyisipele ezisetshenzisiwe kanye nezinombolo zazo ezihambisanayo.

Ukulungiswa Kwemishini ye-CNC

Uma umshini we-CNC (Computer Numerical Control) uhlangabezana nezinkinga noma ungasebenzi kahle, ukulungisa ngokushesha kubalulekile ukuze kuncishiswe isikhathi sokuphumula nokugcina ukukhiqiza. Ukulungisa imishini ye-CNC kudinga ubungcweti nokunakwa kwemininingwane ukuze kuqinisekiswe ukuthi imishini ibuyiselwa esimweni sayo esikahle sokusebenza. Nawa amanye amaphuzu abalulekile okufanele uwacabangele lapho ulungisa imishini ye-CNC:

Diagnostics

- Qala ngokuyixilonga kahle inkinga ukuze uthole umsuka wokungasebenzi kahle.

- Hlola izingxenye zomshini, njengezinjini, amadrayivu, izinzwa, nesistimu yokulawula, ukuze ukhombe ingxenye enephutha.

- Sebenzisa amathuluzi okuxilonga kanye nesofthiwe ukusiza ekuboneni inkinga ngokunembile.

Ukushintshwa Kwezingxenye Ezinephutha

- Uma inkinga isitholakele, buyisela izingxenye ezinephutha ufake ezintsha noma ezisebenza kahle.

- Thola izingxenye zangempela ezivela kubahlinzeki abahloniphekile ukuze uqinisekise ukuhambisana nokuthembeka.

- Landela izinkombandlela zomkhiqizi wokushintsha izingxenye ezithile futhi uzilinganise uma kudingeka.

Ukulungisa Ugesi kanye Nemishini

- Yenza ukulungisa kukagesi, okuhlanganisa ukulungisa izintambo ezinephutha, izixhumi, noma amabhodi esekethe alimele.

- Lungisa noma shintsha izingxenye zemishini ezilimele, njengamabhande, amagiya, ama-pulley, nama-bearings.

- Qinisekisa ukuqondanisa okufanele kwezingxenye zemishini ukuze kugcinwe ukunemba nokunemba.

I-Software Updates and Configuration

- Buyekeza isofthiwe yomshini ibe yinguqulo yakamuva enikezwe umkhiqizi.

- Lungiselela amapharamitha wesistimu yokulawula ye-CNC kanye nezilungiselelo ngokuya ngokucaciswa komshini.

- Hlola futhi uqinisekise ukusebenza komshini ngemva kokubuyekezwa kwesofthiwe noma izinguquko zokumisa.

Ukulinganisa Nokuqondanisa

Linganisa izimbazo zomshini futhi uqinisekise ukuthi ziqondaniswe kahle ukuze uzuze ukukhanda okunembile.

- Qinisekisa ukuphuma kwe-spindle nokuqondanisa ukuze uqinisekise ukugxila ngesikhathi sokusebenza.

- Hlola futhi ulungise ukususwa kwamathuluzi omshini kanye nesinxephezelo sobude bethuluzi ngokusikwa okunembile.

Ukuhlola Nokuqinisekisa

Yenza ukuhlolwa okuphelele komshini olungisiwe ukuze uqinisekise ukuthi usebenza ngendlela efanele.

- Qinisekisa ukunemba komshini nokuphindaphinda ngokwenza ukuhlola noma ukusebenzisa ama-artifact okulinganisa.

- Gada ukusebenza komshini ngesikhathi sokusebenza kwemishini ehlukahlukene ukuze uqinisekise ukuzinza nokuthembeka.

Ukulungisa Ukuzivikela

Ncoma futhi wenze imisebenzi evamile yokuvimbela ukuze unciphise ukuphuka okuzayo.

- Hlanza futhi ugcobe izingxenye zomshini njalo ukuze uvimbele ukuguga nokuthuthukisa impilo ende.

- Gcina irekhodi lemisebenzi yokulungisa, okuhlanganisa nezinsuku, imisebenzi eyenziwe, nanoma yiziphi izingxenye ezishintshiwe.

Ukuqeqeshwa Nokwesekwa

Nikeza ukuqeqeshwa kubaqhubi bemishini ngokusetshenziswa nokugcinwa okufanele ukuze kugwenywe izinkinga ezivamile.

- Nikeza usekelo oluqhubekayo lobuchwepheshe kanye nesiqondiso sokuxazulula izinkinga ezincane ezingase ziphakame.

- Gqugquzela isiko lokunakekela umshini futhi ukhuthaze abaqhubi ukuthi babike noma yikuphi ukungahambi kahle ngokushesha.

Ukuthuthukiswa Komshini we-CNC

Imishini ye-CNC (Computer Numerical Control) yakhelwe ukuthi ihlale isikhathi eside futhi ihlale isikhathi eside, kodwa ngokuthuthuka kwezobuchwepheshe, ukuyithuthukisa kungathuthukisa ukusebenza kwayo namandla. Ukuthuthukisa imishini ye-CNC kungathuthukisa ukusebenza kahle kwayo, isivinini, nokunemba, kunikeze amabhizinisi umphetho wokuncintisana. Nawa amanye amaphuzu abalulekile okufanele uwacabangele lapho uthuthukisa imishini ye-CNC:

Ukuhlola Isimo Samanje

Qala ngokuhlola isimo samanje somshini, okuhlanganisa ihadiwe yawo nesofthiwe.

- Linganisa ubudala bomshini, isimo, nokuhambisana nokuthuthukiswa kwakamuva.

- Nquma imiphumela oyifunayo yokuthuthukisa, njengesivinini esithuthukisiwe, ukunemba, noma ukusebenza okwengeziwe.

Ikhomba Izinketho Zokuthuthukisa

- Cwaninga ubuchwepheshe bamuva kanye nentuthuko ukuze uthole ukuthuthukiswa okufanele komshini.

- Xhumana nomkhiqizi womshini noma abathengisi bezinkampani zangaphandle ukuze uthole ukuthuthukiswa okungcono kakhulu kwemodeli ethile yomshini.

- Cabangela izinketho ezifana nezilawuli ezithuthukisiwe, amasistimu wokuphotha, izishintshi zamathuluzi, nezinzwa.

Ukuthuthukisa Izingxenye Zekhompuyutha

- Thuthukisa izingxenye zezingxenyekazi zekhompuyutha ezifana nezinjini, amadrayivu, namasistimu okulawula ukuze uthuthukise isivinini nokunemba.

- Faka izinzwa ezintsha nama-probe ukuze uthuthukise ukunemba kokulinganisa futhi wenze imisebenzi ethile ngokuzenzakalelayo.

- Shintsha izingxenye ezigugile noma eziphelelwe yisikhathi ufake ezintsha ukuze uthuthukise ukuqina komshini nokuphila isikhathi eside.

Ukuthuthukisa Isofthiwe

- Thuthukisa isofthiwe yomshini ibe yinguqulo yakamuva ukuze uthuthukise ukusebenza nokusebenza.

- Faka amamojula esofthiwe amasha ukuze unike amandla imisebenzi eyengeziwe noma uthuthukise akhona kakade.

- Lungiselela isofthiwe ukuze ifane nezidingo zomshini othize.

Ukuhlola Nokuqinisekisa

- Hlola umshini othuthukisiwe ukuze uqinisekise ukuthi usebenza ngendlela efanele futhi uhlangabezana nemiphumela oyifunayo.

- Qinisekisa ukunemba komshini nokuphindaphinda ngokwenza ukuhlola noma ukusebenzisa ama-artifact okulinganisa.

- Gada ukusebenza komshini ngesikhathi sokusebenza kwemishini ehlukahlukene ukuze uqinisekise ukuzinza nokuthembeka.

Ukuqeqeshwa Nokwesekwa

- Nikeza ukuqeqeshwa kubaqhubi bemishini ngezici ezintsha nokusebenza komshini othuthukisiwe.

- Nikeza usekelo oluqhubekayo lobuchwepheshe kanye nesiqondiso sokuxazulula izinkinga ezingase ziphakame.

- Gqugquzela isiko lokunakekela umshini futhi ukhuthaze abaqhubi ukuthi babike noma yikuphi ukungahambi kahle ngokushesha.

Ukulinganisa Umshini we-CNC

Ukulinganisa kuyinqubo ebalulekile ekugcineni ukunemba nokunemba kwemishini ye-CNC (Computer Numerical Control). Ukulinganisa okuvamile kuqinisekisa ukuthi izimbazo zomshini, ama-spindle, namasistimu wamathuluzi aqondaniswe ngendlela efanele, okuholela ekusebenzeni komshini okunembile. Nawa amanye amaphuzu abalulekile okufanele uwacabangele lapho wenza ukulinganisa komshini we-CNC:

Ukulinganiswa kwe-eksisi

- Linganisa i-eksisi ngayinye yomshini ukuze uqinisekise ukuma nokunyakaza okunembile.

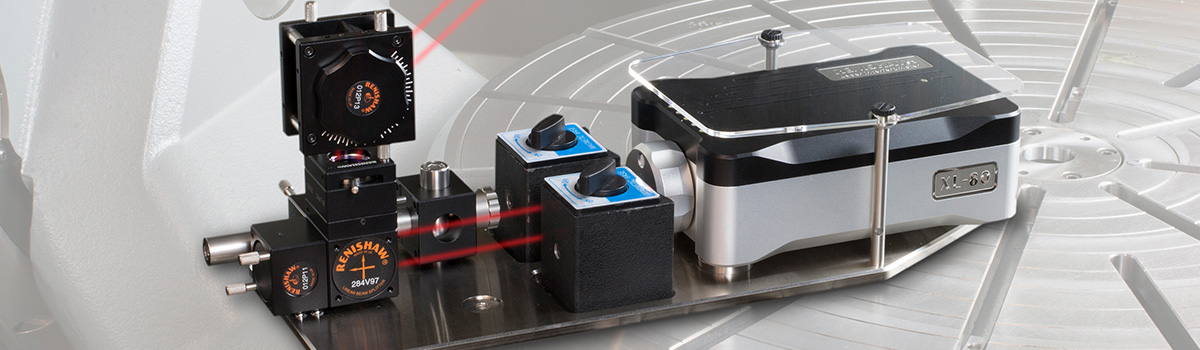

- Sebenzisa amathuluzi okulinganisa anembayo, njengama-laser interferometer noma amasistimu ebha yebhola, ukuze ulinganise ukuchezuka nokwenza izinguquko.

- Qinisekisa ukuthi ukunyakaza komugqa ne-angular kuhambisana nokubekezelelana okucacisiwe.

Isilinganiso se-Spindle Runout:

- Linganisa ukuphuma kwe-spindle ukuze uqinisekise ukugxila ngesikhathi sokusebenza komshini.

- Sebenzisa inkomba yokudayela noma ithuluzi elisuselwe kwi-laser ukuze ulinganise noma yikuphi ukugqama noma ukugegetheka ku-spindle.

- Lungisa izingxenye zokuphotha noma shintsha izingxenye ezigugile ukuze unciphise ukuphuma futhi wandise ukunemba.

Ubude Bethuluzi kanye Nokulinganisa Ithuluzi Lokunqamula

- Linganisa isistimu yokulinganisa ubude bethuluzi ukuze uqinisekise ukuma kwethuluzi okunembile.

- Sebenzisa ama-artifact okulinganisa noma izikali zobude ukuze ulinganise ubude bethuluzi bangempela futhi ubuqhathanise nezilinganiso zomshini.

- Lungisa amavelu e-offset ubude bethuluzi kusistimu yokulawula yomshini ukuze unxephezele noma yikuphi ukungafani.

Isinxephezelo Sobubanzi Bethuluzi

- Yenza ukulinganisa kwesinxephezelo sobubanzi bethuluzi ukuze uphendule ngokuhlukahluka kobubanzi bamathuluzi.

- Linganisa ububanzi bethuluzi langempela usebenzisa i-micrometer noma i-caliper bese uyiqhathanisa namanani ahleliwe omshini.

- Lungisa i-offset yamathuluzi noma amanani esinxephezelo samathuluzi ukuze unxephezele noma yimuphi umehluko futhi uzuze ukusikeka okunembile.

Ukuhlola Ukulinganisa Kwesistimu

- Uma umshini unesistimu yokuhlola, yilinganise ukuze uqinisekise ukulinganisa okunembile kwengxenye nokuqondanisa.

- Yenza izinqubo zokulinganisa ukuze uqinisekise ukunemba kwesistimu yokuhlola futhi ulungise uma kunesidingo.

- Qinisekisa ukuthi isistimu yokuhlola ithola ngokunembile izindawo nobukhulu bomsebenzi.

Spindle Speed Calibration

- Linganisa isivinini sokuphotha ukuze uqinisekise ukuthi sifana ne-RPM ecacisiwe (Ukuzungeza Ngomzuzu).

- Sebenzisa i-tachometer noma inzwa yesivinini sokuphotha ukuze ulinganise isivinini sangempela sokuphotha ngesikhathi sokusebenza.

- Lungisa amapharamitha okulawula isivinini kusistimu yokulawula yomshini ukuze uzuze i-RPM oyifunayo.

Amadokhumenti namarekhodi

- Gcina irekhodi elinemininingwane yemisebenzi yokulinganisa, okuhlanganisa izinsuku, imisebenzi eyenziwe, nanoma yikuphi ukulungiswa okwenziwe.

- Landela ishejuli yokulinganisa enconyiwe yomkhiqizi nemihlahlandlela.

- Gcina ilogu yanoma imaphi ama-artifact okulinganisa asetshenzisiwe kanye nezitifiketi zawo ezihambisanayo.

Ukuqondanisa Komshini we-CNC

Ukuqondanisa okufanele kubalulekile ukuze imishini ye-CNC (Computer Numerical Control) isebenze ngokunemba nangokunemba. Ukungaqondani kahle kwezingxenye zomshini, njenge-spindle, amasistimu wamathuluzi, nezimbazo, kungabangela amaphutha nokungahambisani nenqubo yokwenza imishini. Nawa amanye amaphuzu abalulekile okufanele uwacabangele lapho uqondanisa imishini ye-CNC:

Ihlola Isimo Somshini

Ngaphambi kokuqondisa umshini, hlola isimo sawo, kuhlanganise nesimo sezingxenye zawo.

- Hlola izindlela zomshini, izisebenzi eziholayo, nezinye izakhi zomshini ukuze ziguge futhi zilimale.

- Qinisekisa isimo sezinhlelo zokuphotha kanye namathuluzi.

Ukuqondanisa kwe-Spindle

- I-spindle iyisici esibalulekile okufanele siqondaniswe ngokunembile.

- Sebenzisa amathuluzi okulinganisa anembayo, njengenkomba yokudayela noma ithuluzi elisekelwe nge-laser, ukuze ulinganise ukuqondanisa kwe-spindle.

- Lungisa ukuma kwe-spindle kanye nezingxenye, njengama-bearings, ukuze uzuze ukuqondana okufanele.

Ebheka Izimbazo

- Hlola ukuqondanisa kwe-eksisi ngayinye yomshini ukuze uqinisekise ukunyakaza okunembile nokuma.

- Sebenzisa amathuluzi okulinganisa anembayo ukuze ulinganise ukuchezuka ku-eksisi ngayinye futhi wenze izinguquko.

- Qinisekisa ukuthi izimbazo zihamba emgqeni oqondile futhi zihambisana nokubekezelelana okucacisiwe.

Ukuqondanisa ama-Tooling Systems

- Izinhlelo zamathuluzi, okuhlanganisa abanikazi bamathuluzi nabaguquli bamathuluzi, kufanele zihambisane kahle ukuze kuqinisekiswe ukuma kwamathuluzi okunembile.

- Sebenzisa amathuluzi okulinganisa anembayo ukuze ulinganise ukuqondanisa kwezinhlelo zamathuluzi futhi wenze izinguquko uma kudingeka.

- Qinisekisa ukuthi amasistimu amathuluzi ahambisana nezimbazo zomshini nokuphotha.

Ukuhlola Nokuqinisekisa

- Ngemva kokuqondanisa umshini, yenza ukuhlola ukuze uqinisekise ukunemba nokunemba kwawo.

- Sebenzisa ama-artifact okulinganisa noma amanye amathuluzi okulinganisa ukuze uqinisekise ukuqondanisa nokunemba komshini.

- Gada ukusebenza komshini ngesikhathi sokusebenza kwemishini ehlukahlukene ukuze uqinisekise ukuzinza nokuthembeka kwawo.

Ukunakekelwa nokunakekelwa

- Njalo hlola futhi unakekele izingxenye zomshini ukuze uvimbele ukungahambi kahle nokuguga.

- Qeqesha abaqhubi bemishini ukuthi babike noma yikuphi ukungahambi kahle ngokushesha futhi benze imisebenzi yokulungisa evamile.

- Landela ishejuli yokulungisa enconyiwe yomkhiqizi nemihlahlandlela.

Ukuqondanisa kahle kwemishini ye-CNC kubalulekile ukuze kuzuzwe imisebenzi yemishini enembile nenembayo. Ngokunamathela ezinqubweni ezifanele zokuqondanisa nokwenza ukunakekelwa okuvamile, opharetha bangaqinisekisa ukuthi imishini yabo ikhiqiza izingxenye ezisezingeni eliphezulu ezinamaphutha amancane nokusebenza kabusha.

Ukugcotshwa kweMishini ye-CNC

Ukugcoba ngendlela efanele kubalulekile ekusebenzeni kahle nangempumelelo kwemishini ye-CNC (Computer Numerical Control). Izinto zokugcoba zinciphisa ukungqubuzana, zinciphisa ukuguga, ziqede ukushisa, futhi zivikele izingxenye zomshini ekulimaleni. Ukulungiswa okuvamile kokugcoba kusiza ukwandisa isikhathi sokuphila komshini futhi kuqinisekisa ukusebenza kahle. Nawa amanye amaphuzu abalulekile okufanele uwacabangele lapho ugcoba imishini ye-CNC:

Ukukhethwa Kwezinto Zokuthambisa

- Khetha izinto zokugcoba ezinconywe umkhiqizi womshini wezingxenye ezithile namasistimu.

- Cabangela izici ezifana nezinga lokushisa, isivinini, umthwalo, nendawo lapho ukhetha izinto zokugcoba.

- Sebenzisa okothambisa afanelekile ezingxenyeni ezihlukene zomshini, njengamabheringi okuphotha, amarayili omhlahlandlela, nezikulufu zamabhola.

Lubrication Isheduli

- Landela ishejuli yokugcoba enconyiwe yomkhiqizi engxenyeni ngayinye yomshini.

- Misa isimiso sokuthambisa esivamile esisekelwe ekusetshenzisweni komshini nezimo zokusebenza.

- Cabangela izici ezifana namahora okusebenza, ukushuba kokusetshenziswa, nezimo zemvelo.

Amaphuzu Okugcoba

- Khomba futhi umake wonke amaphoyinti okugcoba emshinini, okuhlanganisa izimbobo zikawoyela, okokufakwa kukagrisi, namachibi.

- Qinisekisa ukuthi zonke izindawo zokugcoba zifinyeleleka kalula futhi ziyabonakala ukuze kugcotshwe ngendlela efanele.

Izindlela Zokugcobisa

- Sebenzisa izindlela zokugcoba ezifanele zengxenye ngayinye, njengamabhavu kawoyela, amasistimu enkungu kawoyela, noma ukufaka ugrisi okwenziwa ngesandla.

- Landela amasu afanele okugcoba, njengokusebenzisa inani elifanele le-lubricant kanye nokuqinisekisa ukusatshalaliswa okulinganayo.

- Sebenzisa amasistimu okugcoba azenzakalelayo, uma ekhona, ukuze agcobise ngokungaguquki futhi anembe.

Isicelo sokuthambisa

- Hlanza izindawo zokuthambisa ngaphambi kokufaka okokugcoba ukuze ususe ukungcola, udoti, nezinsalela zokugcoba ezindala.

- Sebenzisa izinto zokugcoba ezinconyiwe, njengamabhulashi, izibhamu zamafutha, noma amathini kawoyela, ukuze usebenzise okokugcoba ngokunembile.

- Qinisekisa ukuthi okokugcoba kufinyelela kuzo zonke izindawo ezidingekayo, njengamabheringi, amagiya, nezindawo ezishelelayo.

Lubricant Ubuningi

- Faka inani elifanele lokuthambisa njengoba lishiwo umenzi womshini.

- Gwema ukugcotshwa ngokweqile, njengoba okokugcoba okweqile kungabangela ukungcola futhi kuvale izingxenye ezibalulekile.

- Gada amazinga okuthambisa njalo futhi ugcwalise njengoba kudingeka ukuze ulondoloze ukuthambisa okudingekile.

Ikhwalithi Yokuthambisa

- Sebenzisa amafutha ekhwalithi ephezulu ahlangabezana nezindinganiso zomkhakha kanye nokucaciswa kwawo.

- Gada isimo samafutha, afana ne-viscosity, ukuhlanzeka, nezinga le-oxidation, futhi uwashintshe lapho kudingeka.

- Gcina izinto zokugcoba ngendlela efanele ukuze ugcine ikhwalithi yazo nokusebenza ngempumelelo.

Qopha Ukugcina

- Gcina irekhodi elinemininingwane lemisebenzi yokugcobisa, okuhlanganisa izinsuku, izinto zokuthambisa ezisetshenzisiwe, kanye nezindawo zokugcobisa okukhulunywe ngazo.

- Gcina umkhondo wokusetshenziswa kwamafutha, okuhlanganisa nenani elisetshenzisiwe kanye nesitoko kabusha.

- Sebenzisa irekhodi njengereferensi yokulungiswa kokugcotshwa kwesikhathi esizayo nokuxazulula izinkinga.

Ukushintshwa Kwezingxenye Zomshini we-CNC

Ngokuhamba kwesikhathi, imishini ye-CNC (Computer Numerical Control) ingase idinge ukushintshwa kwezingxenye ezithile ngenxa yokuguga, ukulimala, noma isidingo sokuthuthukiswa. Ukushintshwa ngokushesha nangokunembile kwezingxenye zomshini we-CNC kubalulekile ukuze kugcinwe ukusebenza komshini futhi kuncishiswe isikhathi sokuphumula. Nawa amanye amaphuzu abalulekile okufanele uwacabangele lapho ushintsha izingxenye zomshini we-CNC:

Thola Inkinga

- Hlola kahle umshini ukuze ubone ingxenye enephutha noma eyonakele.

- Hlaziya izimpawu, imilayezo yamaphutha, noma ukuziphatha okungavamile komshini ukuze ukhombe inkinga.

- Sebenzisa amathuluzi okuxilonga futhi ubheke imibhalo yomshini noma imihlahlandlela yomkhiqizi yokuxazulula inkinga.

Umthombo Izingxenye Zangempela

- Thenga izingxenye ezishintshayo kubahlinzeki abahloniphekile noma ngokuqondile kumkhiqizi womshini.

- Qinisekisa ukuthi izingxenye ziyiqiniso futhi zihambisana nokucaciswa kwezingxenye zangempela.

- Cabangela izici ezifana nekhwalithi, ukuhambisana, newaranti lapho ukhetha izingxenye ezishintshayo.

Ukuqaqa nokufaka

- Landela izinqubo neziqondiso ezifanele zokuqaqa umshini nokukhipha ingxenye enephutha.

- Thatha izinyathelo zokuphepha ezidingekayo ukuze uvikele izingxenye ezibucayi futhi uqinisekise ukuphepha komuntu siqu ngesikhathi sokuqaqa.

- Faka ngokucophelela ingxenye eshintshayo, ulandela imiyalelo yomkhiqizi kanye nezicaciso zetorque ezinconyiwe.

Ukulinganisa nokuhlola

- Ngemva kokushintsha ingxenye, linganisa umshini ukuze uqinisekise ukusebenza kahle nokuqondanisa.

- Yenza izinguquko ezidingekayo noma ukuqondanisa ukuze uqinisekise ukunemba nokunemba.

- Yenza ukuhlola okuphelele ukuze uqinisekise ukuthi ingxenye yokumiselela iyixazululile inkinga futhi umshini usebenza ngendlela efanele.

Amadokhumenti kanye nokugcinwa kwamarekhodi

- Gcina amarekhodi anemininingwane ezingxenye ezishintshiwe, okuhlanganisa usuku, ingxenye yenombolo, nolwazi lomhlinzeki.

- Gcina ilogu yomlando wokulungiswa komshini, okuhlanganisa konke ukumiselela, ukulungiswa, nokuthuthukiswa.

- Sebenzisa amadokhumenti njengesithenjwa sokulungiswa okuzayo nokuxazulula izinkinga.

Ukulungisa Ukuzivikela

- Hlola futhi unakekele umshini njalo ukuze ubone izinkinga ezingaba khona ngaphambi kokuthi ziholele ekuhlulekeni kwengxenye.

- Landela ishejuli enconyiwe yokuvikela yokuvikela yomshini kanye nezingxenye zawo.

- Shintshanisa izingxenye ngokuqhubekayo ngokusekelwe ekusetshenzisweni, ubude bempilo obulindelwe, noma ubungozi obaziwayo.

Ukuqeqeshwa Nokwesekwa

- Ukuhlinzeka ngoqeqesho kubaqhubi bemishini nabasebenzi abalungisayo ngezinqubo ezifanele zokushintshwa kwengxenye.

- Nikeza usekelo oluqhubekayo lobuchwepheshe kanye nesiqondiso sokuxazulula noma yiziphi izinkinga ezingase ziphakame phakathi noma ngemva kokushintshwa kwengxenye.

- Gqugquzela isiko lokunakekela ngokushesha futhi ukhuthaze abaqhubi ukuthi babike noma yikuphi ukungahambi kahle ngokushesha.

Ngokulandela la maphuzu abalulekile kanye nokusebenza nabahlinzeki abahloniphekile kanye nochwepheshe abanolwazi, ukushintshwa kwezingxenye zomshini we-CNC kungenziwa ngempumelelo. Ukushintshwa kwengxenye okufika ngesikhathi nokunembile kusiza ukuqinisekisa ukusebenza kahle komshini, kunwebe ubude bayo bempilo, futhi kunciphise ukuphazamiseka kumashejuli okukhiqiza.

Ukuseviswa kwe-CNC Machine Spindles

Imishini yokuphotha ye-CNC (Computer Numerical Control) idlala indima ebalulekile ekunembeni nasekusebenzeni kokusebenza komshini. Ukuqinisekisa ukusebenza okuhle nokuphila isikhathi eside, ukuseviswa njalo kwama-spindles omshini we-CNC kubalulekile. Nawa amanye amaphuzu abalulekile okufanele uwacabangele uma kuziwa ekusezweni kwama-spindles omshini we-CNC:

Ukulungisa Ukuzivikela

- Ukunakekelwa okuhleliwe kubalulekile ukuze kugwenywe isikhathi sokuphumula esingalindelekile kanye nokulungiswa okumba eqolo.

- Dala ishejuli yesondlo ehlanganisa ukuhlolwa okuvamile kanye nemisebenzi yokusevisa.

- Landela izincomo zomkhiqizi ngezikhawu zokunakekela kanye nezinqubo.

Ukuhlanza Nokugcoba

- Hlanza i-spindle njalo ukuze ususe udoti, uthuli, nezinsalela zokupholisa ezingase zibe nomthelela ekusebenzeni.

- Sebenzisa ama-ejenti okuhlanza afanelekile nezindlela ezinconywe umenzi.

- Gcoba izingxenye zokuphotha ngokweziqondiso ezishiwo ukuze uqinisekise ukusebenza kahle futhi uvimbele ukuguga.

Ukuhlola Ibhande kanye Bearing

- Hlola isimo samabhande ukuze uthole izimpawu zokuguga, ukuqhekeka, noma ukulimala. Zishintshe uma kunesidingo.

- Hlola amabheringi ukuze uthole umsindo owedlulele, ukudlidliza, noma ukwakheka kokushisa, okungase kubonise isidingo sokushintshwa noma ukulungiswa.

- Qondanisa kahle namabhande e-tension ukuze kugcinwe ukudluliswa kwamandla aphezulu.

Ukugcinwa Kwesistimu Yokupholisa

- Hlanza njalo futhi ugcine isistimu yokupholisa ukuze uvimbele ukungcola nokuvala.

- Hlola amaleveli okupholisa, izihlungi, namaphampu ukuze asebenze kahle.

- Gada ikhwalithi yokupholisa bese uyishintsha lapho kudingekile ukuze ugcine izimo zokusika ezifanele futhi uvimbele ukulimala kokupholisa.

I-Spindle Runout kanye nebhalansi

- Linganisa ukuphuma kwe-spindle usebenzisa amathuluzi anembayo ukuze uqinisekise ukugxila nokunemba.

- Linganisa i-spindle uma kubonakala ukudlidliza ngokweqile noma ukusika okungalingani.

- Bhekana nanoma yiziphi izinkinga ngokushesha ukuze ugweme ukulimala okungaba khona ku-spindle noma ucezu lomsebenzi.

Ukuhlolwa Kwesistimu Kagesi

- Hlola uxhumo lukagesi, izintambo, nezinzwa ukuze uthole izimpawu zokulimala noma ukungasebenzi kahle.

- Hlola i-spindle motor nokusebenza kokushayela ukuze uqinisekise ukusebenza kahle.

- Linganisa amasistimu okulawula isivinini ukuze ugcine i-RPM yokuphotha enembile.

Usizo Lochwepheshe

- Bandakanya ochwepheshe abaqeqeshiwe noma abamele abakhiqizi ukuze uthole isevisi eyinkimbinkimbi noma ukulungisa.

- Ukuqeqesha njalo abaqhubi kanye nabasebenzi abalungisayo mayelana nezinqubo ezifanele zokuphatha kanye nokulungisa.

- Funa iseluleko sochwepheshe mayelana nezinkinga zokuxazulula izinkinga ngaphandle kokulungiswa okujwayelekile.

Ukuhlolwa Kwesistimu Kagesi Yomshini we-CNC

Uhlelo lukagesi lomshini we-CNC luyingxenye ebalulekile ethinta ngokuqondile ukusebenza nokuthembeka kwawo. Ukuhlolwa njalo kwesistimu kagesi kuyadingeka ukuze kuqinisekiswe ukusebenza okuphephile nokusebenza kahle. Nawa amanye amaphuzu abalulekile okufanele uwacabangele lapho uhlola isistimu kagesi yemishini ye-CNC:

Ukuhlola Okubonakalayo

- Qala ngokuhlola ngokubona izakhi zikagesi ukuze uthole izimpawu zomonakalo, njengezintambo ezixegayo, izintambo eziphukile, noma izixhumi ezishile.

- Hlola noma yikuphi ukuxhuma okuxekethile noma amatheminali angase athinte ukuqhutshwa kukagesi.

- Bheka ubufakazi bokushisa ngokweqile, njengokushintsha umbala noma ukuncibilika kwezingxenye.

Ukunikezwa kwamandla kagesi

- Qinisekisa ukuthi umshini uthola i-voltage efanele nokuthi ugesi uzinzile futhi usekelwe kahle.

- Hlola izintambo zikagesi ezinkulu noxhumo ukuze uthole noma yiziphi izimpawu zokuguga noma zokonakala.

- Hlola ukusebenza kwama-circuit breaker nama-fuse ukuze uqinisekise ukuthi ahlinzeka ngokuvikeleka okwanele.

Lawula iKhabhinethi

- Vula iKhabhinethi yokulawula bese uhlola izingxenye zangaphakathi, njengamabhodi wesekethe, ama-relay, nezixhumi.

- Bheka izimpawu zokushisa ngokweqile, njengezimpawu zokushile noma iphunga elinamandla lokushiswa.

- Hlola ukuthi zonke izintambo nezixhumi ziboshwe ngokuvikelekile futhi zilebulwe ngendlela efanele.

Amasistimu weMoto kanye neDrayivu

- Hlola izinjini namadrayivu ukuze uthole noma yiziphi izimpawu zokulimala, njengezintambo ezixegayo noma amabhulashi agugile.

- Hlola ukusebenza kwamadrayivu ezimoto futhi uqinisekise ukuthi ahlinzeka ngesilawuli sokunyakaza esibushelelezi nesinembayo.

- Linganisa i-motor current ukuze uqinisekise ukuthi ingaphakathi kwebanga elishiwo ukuze isebenze kahle.

Uhlelo Lwezimo Eziphuthumayo

- Hlola izinkinobho zokumisa izimo eziphuthumayo ukuze uqinisekise ukuthi zisebenza kahle futhi ungamisa umshini ngokushesha esimweni esiphuthumayo.

- Hlola izintambo kanye noxhumo lwesistimu yokumisa izimo eziphuthumayo ukuze uthole amaphutha noma ukuxhumeka okuxekethile.

Izindlela Zokuxhumana

- Hlola izixhumanisi zokuxhumana, njenge-Ethernet noma izimbobo ze-serial, ukuze uqinisekise ukuthi zisebenza ngendlela efanele.

- Hlola izixhumanisi zokuxhumana ngamadivayisi angaphandle, njengamakhompuyutha noma izilawuli ze-logicable logic (PLCs), ukuze uqinisekise ukudluliswa kwedatha okufanele.

Grounding System

- Qinisekisa ukuthi isistimu ephansi yomshini ifakwe kahle futhi ixhunyiwe.

- Hlola ubuqotho bezintambo eziphansi kanye nezixhumi ukuze uvimbele izingozi zikagesi futhi uqinisekise ukuncishiswa komsindo kagesi.

Ukulungiswa Okujwayelekile

- Misa isimiso esivamile sokulungisa isistimu kagesi, okuhlanganisa ukuhlanza, ukuqiniswa kwezixhumo, nokuhlola izintambo.

- Landela iziqondiso zomkhiqizi ngezinqubo ezinconyiwe zokulungisa nezikhawu.

- Qeqesha abaqhubi nabasebenzi abalungisa ukuphepha kukagesi kanye nokuphatha kahle umshini we-CNC.

Ukugcinwa Kwesistimu Yokupholisa Yemishini Ye-CNC

Isistimu yokupholisa yemishini ye-CNC (Computer Numerical Control) idlala indima ebalulekile ekugcineni izinga lokushisa elilungile lokusebenza, ukwandisa impilo yamathuluzi, nokuqinisekisa ukunemba komshini. Ukunakekelwa okufanele kwesistimu yokupholisa kubalulekile ukuvimbela ukushisa ngokweqile, ukugcina ikhwalithi yokupholisa, nokugwema ukulimala okungenzeka emshinini. Nawa amanye amaphuzu abalulekile okufanele uwacabangele uma kuziwa ekulungisweni kwesistimu yokupholisa yemishini ye-CNC:

Ukuhlanza Okuvamile

- Hlanza ithange lokupholisa, izihlungi, namashaneli okupholisa njalo ukuze ususe udoti, ama-chips, nodaka.

- Sebenzisa ama-ejenti okuhlanza afanelekile nezindlela ezinconywe umenzi womshini.

- Hlanza isistimu ngezikhathi ezithile ukuze uqinisekise ukuthi ukugeleza kwesipholisa akuvimbeki.

Ukugxila Okupholile

- Gada futhi ulondoloze ukugxiliswa okufanele kwesipholile ohlelweni ngokuya ngemibandela yomkhiqizi.

- Hlola okokupholisa njalo usebenzisa ama-refractometer noma amakhithi okuhlola ukuze uqinisekise ukuthi kuhlangabezana namazinga anconyiwe.

- Lungisa ukugxila ngokwengeza isipholile esisha noma amanzi njengoba kudingeka.

Isistimu yokuHlunga

- Hlola futhi uhlanze izihlungi zokupholisa njalo ukuze ususe ukungcola futhi uvimbele ukuvaleka.

- Shintsha izihlungi ngokuya ngezikhawu ezinconyiwe noma lapho zingcole kakhulu noma zilimele.

- Cabangela ukusebenzisa izihlungi zekhwalithi ephezulu noma izihlukanisi kazibuthe ukuze uthuthukise ukusebenza kahle kokuhlunga.

Ikhwalithi Epholile

- Gada izinga le-pH yesipholile, i-viscosity, kanye nokwakheka kwamakhemikhali ukuze uqinisekise ukuthi ihlala ngaphakathi kwebanga elamukelekayo.

- Hlola ukukhula kwebhaktheriya noma ukungcola okungaholela ephunga elibi noma ukonakala kokusebenza kokupholisa.

- Shintsha isipholile uma sibonisa izimpawu zokuwohloka noma sihluleka ukuhlangabezana namazinga okusebenza adingekayo.

Iphampu kanye nesilinganiso sokugeleza

- Hlola iphampu epholile ukuze usebenze kahle, ubheke noma yikuphi ukuvuza, umsindo ongajwayelekile, noma izinga lokugeleza elinciphile.

- Hlanza noma shintsha i-impeller yepompo uma igugile noma ilimele.

- Qinisekisa ukuthi izinga lokugeleza kokupholisa lingaphakathi kwebanga elinconyiwe ukuze uqinisekise ukupholisa okusebenzayo.

Ukulawula Ukushisa Okupholile

- Hlola isistimu yokulawula izinga lokushisa, njenge-chiller noma isishintshi sokushisa, ukuze ugcine izinga lokushisa elipholile ngaphakathi kwebanga elishiwo.

- Hlola izinzwa, amavalvu, nezindlela zokulawula ukuze uqinisekise ukulawulwa okunembile kwezinga lokushisa.

- Hlanza noma shintsha amaphiko okushintsha ukushisa uma evaleka ukungcola noma imfucumfucu.

Ukuqeqeshwa Kwabasebenzi

- Nikeza ukuqeqeshwa kubaqhubi bemishini ekuphatheni okupholisayo okufanele, okuhlanganisa ukugcwalisa kabusha, ukulungisa ukugxilisa ingqondo, nokubika izinkinga ezihlobene nokupholisa.

- Yalela opharetha ukuthi babone izimpawu zokuwohloka kwepholile noma ukungasebenzi kahle kwesistimu nokuthi bangaphendula kanjani ngendlela efanele.

- Thuthukisa isiko lokuhlanzeka kanye nokulungiswa kwesistimu yokupholisa okusebenzayo phakathi kwabaqhubi.

Iseviswa Izilawuli Zomshini we-CNC neSoftware

Ukusezwa njalo kwezilawuli zomshini we-CNC nesofthiwe kubalulekile ukuze kuqinisekiswe ukusebenza kahle nokugwema izinkinga ezingase zibe khona. Nawa amanye amaphuzu abalulekile okufanele uwacabangele uma kuziwa ekuseviseni izilawuli zomshini we-CNC nesofthiwe:

Izibuyekezo ze-Software

- Njalo buyekeza isofthiwe yomshini we-CNC ukuze uzuze kuzici zakamuva, ukulungiswa kweziphazamisi, nokuthuthukiswa kokusebenza.

- Landela imihlahlandlela yomkhiqizi nezincomo zokubuyekeza isofthiwe.

- Dala izipele zenguqulo yesofthiwe yomshini ngaphambi kokwenza izibuyekezo.

Ukulinganisa Nokuqondanisa

- Ngezikhathi ezithile linganisa futhi uqondanise izilawuli zomshini we-CNC ukuze ugcine ukunemba nokunemba.

- Hlola futhi ulungise ukuqondanisa kwama-eksisi, ama-Tool offset, kanye nezindawo zokusebenza eziziro.

- Qinisekisa ukunemba kwezinhlelo zophenyo, uma zikhona, bese ulinganisa kabusha uma kunesidingo.

Ubuyisele

- Njalo yenza ikhophi yasenqolobaneni yamapharamitha emishini ebalulekile, izilungiselelo, nezinhlelo zokuvimbela ukulahleka kwedatha.

- Gcina amakhophi amaningi ezipele kumadivayisi angaphandle noma isitoreji samafu ukuze uthole ukuphepha okungeziwe.

- Hlola inqubo yokubuyisela ngezikhathi ezithile ukuze uqinisekise ukuthi izipele zithembekile futhi ziyafinyeleleka.

Ukuhlola Iphaneli Yokulawula

- Hlola ngokubonakalayo iphaneli yokulawula ukuze uthole noma yiziphi izimpawu zomonakalo, njengezinkinobho eziphukile, izixhumi ezixegayo, noma izinkomba ezingasebenzi kahle.

- Hlanza iphaneli yokulawula nezinkinobho njalo ukuze ususe uthuli noma imfucumfucu engase iphazamise ukusebenza.

- Hlola ukusebenza kwephaneli yokulawula ngokuqinisekisa inkinobho ngayinye, ukushintsha, nesibonisi.

Ukuxhumeka kagesi

- Hlola ukuxhunywa kukagesi ngaphakathi kwekhabhinethi yokulawula ukuze uthole noma yiziphi izintambo ezixegayo noma ezigqwalile.

- Qinisa noma yikuphi ukuxhuma okuxekethile futhi esikhundleni sezintambo ezilimele noma izixhumi.

- Yenza ukuhlola okuphelele kwesistimu kagesi ukuze uqiniseke ukuthi isisekelo siqinile futhi unciphise ingozi yamaphutha kagesi.

Ukugcinwa kwamadivayisi okokufaka

- Hlola ukusebenza kwamadivayisi okokufaka, njengamakhibhodi, amagundane, noma izikrini zokuthinta.

- Hlanza izinto zokufaka ukuze ususe ukungcola noma izinsalela ezingase ziphazamise ukusebenza kwazo.

- Shintshanisa amathuluzi okokufaka agugile noma angasebenzi kahle ukuze ugcine ukulawula okubushelelezi nokunembile.

Ukuqeqeshwa Kwabasebenzi

- Nikeza opharetha ngokuqeqeshwa okuphelele ngezilawuli zemishini ye-CNC nesofthiwe.

- Jwayela opharetha ngemisebenzi ehlukahlukene, amamenyu, nemingcele yesixhumi esibonakalayo sokulawula.

- Yazisa opharetha ngokusetshenziswa okufanele kwezici zesofthiwe nezindlela zokuxazulula izinkinga.

Ukuhlola Okujwayelekile Kwesistimu

- Yenza ukuhlola kwesistimu ngezikhathi ezithile ukuze uhlonze isofthiwe engaba khona noma izinkinga zokulawula.

- Gada amalogi wamaphutha, ama-alamu, nemilayezo yokuxilonga yanoma yikuphi okudidayo.

- Yenza izivivinyo zokuxilonga isistimu futhi ulandele imihlahlandlela yomkhiqizi yokuxazulula izinkinga nokuxazulula izinkinga.

Ukuhlola Ukuphepha Komshini we-CNC

Ukuqinisekisa ukuphepha kwabaqhubi kanye nendawo yokusebenza kubaluleke kakhulu uma usebenza nemishini ye-CNC (Computer Numerical Control). Nawa amanye amaphuzu abalulekile okufanele uwacabangele lapho uhlola ukuphepha komshini we-CNC:

Indawo Evalekile Yomshini

- Hlola indawo ebiyelwe umshini ukuze uqinisekise ukuthi ayiguquki, ivikeleke ngendlela efanele, futhi ayinamifantu noma umonakalo.

- Qinisekisa ukuthi yonke iminyango yokufinyelela, amaphaneli, nezikhiye zokuphepha zisebenza ngendlela efanele.

- Hlola ukubonakala okufanele kwezimpawu eziyisixwayiso, amalebula, nezinkinobho zokumisa izimo eziphuthumayo.

Uhlelo Lwezimo Eziphuthumayo

- Hlola izinkinobho zokumisa izimo eziphuthumayo ukuze uqinisekise ukuthi zimisa ngokushesha ukusebenza komshini lapho ucindezelwa.

- Qinisekisa ukuthi isistimu yokumisa izimo eziphuthumayo isesimweni esifanelekile sokusebenza futhi ifinyeleleka kalula kubasebenzisi.

- Qeqesha ama-opharetha ekusebenziseni ngendlela efanele izinkinobho zokumisa izimo eziphuthumayo nezindawo zazo.

Ukuphepha Kagesi

- Hlola izakhi zikagesi ukuze uthole noma yiziphi izintambo eziveziwe, ukuxega okuxekethile, noma ukufakwa okulimele.

- Qinisekisa ukuthi uhlelo lukagesi lumiswe ngendlela efanele ukuze kuncishiswe ingozi yokushaqeka kukagesi.

- Hlola njalo ukuthi ama-circuit breaker nama-fuse asebenza kahle yini.

Ukuphepha kwamathuluzi kanye ne-Workpiece

- Hlola amathuluzi, njengamathuluzi okusika noma izinsimbi, ukuze ubone umonakalo, ukuguga, noma ukufakwa okungalungile.

- Hlola ama-workpieces ukuze uthole ukuma okuvikelekile kanye nokubopha okufanele ukuze ugweme ukugudluzwa phakathi nomshini.

- Gada ukuguga kwamathuluzi bese ushintsha amathuluzi njengoba kudingeka ukuze ugcine ukusika okuphephile nokusebenza kahle.

Ukukhanyisa okuphuthumayo

- Qinisekisa ukuthi indawo yokusebenza inezibani ezanele eziphuthumayo uma kwenzeka kunqamuka ugesi noma ezinye izimo eziphuthumayo.

- Hlola ukukhanya kwezimo eziphuthumayo njalo ukuze uqinisekise ukuthi kusebenza kahle futhi kukhanyisa indawo ngempumelelo.

Ukuphepha Komlilo

- Qinisekisa ukutholakala nokusebenza kwezicishamlilo eduze komshini we-CNC.

- Qeqesha abaqhubi ngokusetshenziswa okufanele kwezicishamlilo kanye nezinqubo zokuphuma uma kwenzeka kuba nomlilo.

- Sula indawo ezungeze umshini we-CNC wanoma yiziphi izinto ezivuthayo noma imfucumfucu.

Ukuqeqeshwa Nokuqwashisa Opharetha

- Nikeza ukuqeqeshwa okuphelele kubaqhubi mayelana nezinqubo zokusebenza eziphephile kanye nezingozi ezingaba khona eziqondene ngqo nomshini we-CNC.

- Gqugquzela isiko lokuqwashisa ngokuphepha futhi ukhuthaze abaqhubi ukuthi babike noma yikuphi ukukhathazeka ngokuphepha ngokushesha.

- Yenza imihlangano yokuphepha evamile noma izingxoxo zebhokisi lamathuluzi ukuze ukhulume ngezihloko zokuphepha futhi uqinise izinqubo eziphephile.

Ukuhambisana Namazinga Okuphepha

- Qinisekisa ukuthi umshini we-CNC uhlangabezana nezindinganiso zokuphepha ezifanele kanye nemithetho endaweni yokusebenza.

- Hlala unolwazi lwanoma yiziphi izinguquko noma izibuyekezo ezilinganisweni zokuphepha futhi uzihlanganise nokuhlolwa kokuphepha.

- Xhumana nochwepheshe bezokuphepha noma abeluleki, uma kunesidingo, ukuze uqinisekise ukuthobela kanye nezinqubo ezingcono kakhulu.

CNC Machine Cleaning

Ukuhlanza nokugcinwa njalo kwemishini ye-CNC kubalulekile ekusebenzeni kahle kwayo, ukunemba, kanye nempilo yonke. Ngokulandela lezi zinqubo zokuhlanza, opharetha bangaqinisekisa ukuthi imishini yabo ye-CNC ihlala isesimweni esifanele, inciphisa isikhathi sokuphumula futhi ikhulise ukukhiqiza.

- Ukugcina umshini ohlanzekile nonakekelwa kahle we-CNC (Computer Numerical Control) kubalulekile ekusebenzeni kwawo okuphelele nokuphila isikhathi eside. Ukuhlanzwa njalo komshini kusiza ukuvimbela ukunqwabelana kwemfucumfucu, uthuli, nama-chips okungaholela ezinkingeni zemishini nokungalungi komshini.

- Qala ngokuvala umshini bese uwunqamula emthonjeni wamandla ukuze uqinisekise ukuphepha phakathi nenqubo yokuhlanza.

- Qala ngokukhipha noma yimaphi ama-chips axegayo, imfucumfucu, noma ukusika uketshezi endaweni yokusebenza usebenzisa i-vacuum noma ibhulashi. Naka izindawo okunzima ukufinyelela kuzo, njengemifantu namakhona, lapho imfucumfucu ijwayele ukunqwabelana khona.

- Sula indawo yomshini ngendwangu ehlanzekile, engenalutha kanye nekhambi lokuhlanza elithambile. Gwema ukusebenzisa izihlanzi ezilumayo ezingalimaza isiphetho somshini. Hlanza ngokucophelela zonke izindawo eziveziwe, okuhlanganisa itafula, izintambo zokuphotha, izibambi zamathuluzi, nendawo ebiyelwe.

- Hlanza ithange lokupholisa bese ubuyisela uketshezi lokusika njalo. Uketshezi lokusika olungcolile noma olungcolile lungaphazamisa ukusebenza komshini kanye nekhwalithi yemikhiqizo eqediwe.

- Hlola izihlungi nezikrini kusistimu yokupholisa, isistimu yokuhlunga komoya, nesistimu yokuthambisa. Hlanza noma ubuyisele lezi zingxenye njengoba kudingeka ukuze uqinisekise ukuhlunga okufanele nokugeleza koketshezi.

- Naka ngokukhethekile izindlela zokuphotha zomshini nezishintsha amathuluzi. Susa noma yiziphi izinsalela noma ukunqwabelana okungase kuphazamise ukusebenza kwazo okushelelayo. Gcoba lezi zingxenye ngokweziqondiso zomkhiqizi ukuze ugcine ukusebenza kahle.

- Hlola ikhava kanye nezivunguvungu ukuze uthole noma yiziphi izimpawu zokulimala noma ukuguga. Zishintshe uma kunesidingo ukuze uvikele izinto zangaphakathi zomshini ekungcoleni.

- Ekugcineni, hlola ukuxhunywa kukagesi, izintambo, nezintambo. Qinisekisa ukuthi zivikelekile futhi azinawo umonakalo. Hlanza iphaneli yokulawula nezinkinobho ngesihlanzi esithambile ukuze ususe noma yikuphi ukungcola noma insila.

- Gcina ishejuli yokuhlanza evamile kanye nemisebenzi yokulungisa amadokhumenti. Lokhu kusiza ekulandeleleni imvamisa yokuhlanza nokuhlonza noma yiziphi izinkinga ezingaba khona kusenesikhathi.

Ukuqeqeshwa Nokusekelwa Komshini we-CNC

Ngokuhlinzeka ngokuqeqeshwa okuphelele nokusekelwa okuqhubekayo, abaqhubi bangathuthukisa amakhono adingekayo kanye nokuzethemba ukuze basebenzise imishini ye-CNC ngempumelelo. Abasebenzi abaqeqeshwe kahle baneqhaza ekukhiqizeni okuthuthukisiwe, ukunciphisa isikhathi sokuphumula, kanye nemiphumela yekhwalithi ephezulu.

- Ukuqeqeshwa okufanele nokusekelwa okuqhubekayo kubalulekile ukuze opharetha basebenzise ngempumelelo imishini ye-CNC (Computer Numerical Control) futhi bakhulise amandla abo. Izinhlelo zokuqeqesha zinikeza opharetha ulwazi namakhono adingekayo ukuze basebenze, bahlele, futhi baxazulule imishini ye-CNC.

- Qala ngokunikeza ukuqeqeshwa okuphelele ezintweni eziyisisekelo zobuchwepheshe be-CNC, okuhlanganisa ukuqonda izingxenye zomshini, amathuluzi, kanye nezisekelo zezinhlelo. Lesi sisekelo sisiza abaqhubi ukuthi babambe imiqondo ewumongo namagama ahlotshaniswa nemishini ye-CNC.

- Yethula ama-opharetha kusofthiwe ye-CAD/CAM esetshenziselwa ukudala izingxenye zemiklamo kanye nokukhiqiza izinhlelo zemishini. Ukuqeqeshwa kulawa mathuluzi e-software kwenza opharetha bakwazi ukuhlela kahle imishini ye-CNC futhi bathuthukise izinqubo zokwenza imishini.

- Nikeza ngezikhathi zokuqeqesha lapho opharetha bengazijwayeza ukusetha umshini, amathuluzi okulayisha, nokusebenzisa imisebenzi yomshini. Lokhu okwenziwayo kusiza ukwakha ukuzethemba nokujwayelana nokusebenza komshini.

- Gcizelela amaphrothokholi okuphepha kanye nezinqubo ezihamba phambili phakathi nokuqeqeshwa. Ama-opharetha kufanele aqeqeshwe ngezinqubo ezifanele zokuqalisa nokuvala umshini, ukuphatha amathuluzi okusika, kanye nokusetshenziswa kwezinto zokuzivikela (i-PPE) ukuze kuqinisekiswe indawo yokusebenza ephephile.

- Nikeza ukuqeqeshwa ngokulungiswa komshini nokunakekelwa kokuvikela. Ama-opharetha kufanele afunde ukuhlola nokugcina izingxenye ezibalulekile, njengama-spindle, amakhava endlela, namasistimu okugcoba, ukuze agcine umshini usebenza kahle.

- Nikeza ukusekelwa okuqhubekayo ngokusebenzisa imanyuwali, imibhalo, nezinsiza ze-inthanethi. Imanuwali ebanzi yomsebenzisi ehlanganisa ukusebenza komshini, izibonelo zezinhlelo, imihlahlandlela yokuxazulula inkinga, nezinqubo zokulungisa zingasebenza njengereferensi ebalulekile yabasebenzisi.

- Sungula uhlelo losekelo lapho opharetha bengafuna usizo nesiqondiso lapho behlangabezana nezinselele noma izinkinga. Lokhu kungaba ngendlela yethimba labasekeli elizinikele, inombolo yosizo lobuchwepheshe, noma izinkundla ze-inthanethi lapho opharetha bengaxhuma khona nabasebenzisi abanolwazi lwe-CNC.

- Yenza izikhathi zokuqeqesha zokuvuselela ukuze uqinise ulwazi namakhono. Ubuchwepheshe be-CNC buyashintsha ngokuhamba kwesikhathi, ngakho-ke ukugcina abaqhubi benolwazi lwakamuva ngentuthuko yakamuva namasu kuqinisekisa ukuthi bangawasebenzisa ngokugcwele amakhono omshini.

- Khuthaza abaqhubi ukuthi babambe iqhaza emicimbini yemboni, imibukiso yezohwebo, kanye nemihlangano yokufundisa ukuze bandise ulwazi lwabo kanye nokuxhumana nabanye ochwepheshe kulo mkhakha. Le micimbi ihlinzeka ngamathuba okufunda mayelana nobuchwepheshe obusha, ukwabelana ngolwazi, kanye nokuthola imininingwane yezinqubo ezihamba phambili.

Izindleko ze-CNC Machine Service

Ukuqonda izici zezindleko ezihlotshaniswa nesevisi yomshini we-CNC kubalulekile kubhajethi nokuhlela.

- Izindleko zesevisi yomshini we-CNC (Computer Numerical Control) zingahluka kuye ngezinto ezimbalwa, okuhlanganisa uhlobo lwesevisi oludingekayo, inkimbinkimbi yomshini, namazinga omhlinzeki wesevisi. Ukuqonda lezi zici kubalulekile ekwakhiweni kwesabelomali nokuqinisekisa uhlelo lokulungisa olungabizi kakhulu.

- Ukunakekelwa okujwayelekile kokuvimbela kuyisevisi evamile yemishini ye-CNC. Ngokuvamile kufaka phakathi imisebenzi efana nokuhlola, ukuhlanza, ukuthambisa, nokulinganisa. Izindleko zokunakekelwa kokuvimbela zingasukela emakhulwini ambalwa kuya ezinkulungwaneni zamaRandi ngonyaka, kuye ngobukhulu bomshini nokuba yinkimbinkimbi.

- Ukulungiswa okuphuthumayo noma okungahleliwe kungenye ingxenye yesevisi yomshini we-CNC engathinta izindleko. Lokhu kulungisa kuvame ukungalindelekile futhi kudinga ukunakwa ngokushesha ukuze kuncishiswe isikhathi sokuphumula. Izindleko zizoncika ebunzimeni benkinga, ukutholakala kwezingxenye ezishintshayo, kanye nobuchwepheshe obudingekayo ukuze kuxazululwe inkinga. Ukulungisa izimo eziphuthumayo kungasukela emakhulwini ambalwa kuya ezinkulungwaneni ezimbalwa zamadola.

- Abanye abahlinzeki besevisi banikeza izinkontileka zesevisi noma izinhlelo zokulungisa ezihlanganisa kokubili ukugcinwa kokuvimbela okujwayelekile kanye nokulungiswa kwezimo eziphuthumayo. Lezi zinkontileka zinganikeza ukonga izindleko nokuthula kwengqondo ngokuqinisekisa isevisi esheshayo nokunciphisa ingcuphe yezindleko ezingalindelekile. Izindleko zezinkontileka zesevisi ziyahlukahluka ngokusekelwe kuzinto ezifana neminyaka yomshini, ubunzima, kanye nezinga lokuhlinzekwa okunikezwayo.

- Izingxenye eziyisipele nezinto ezisetshenziswayo yizindleko ezengeziwe okufanele zicatshangelwe lapho kulungiswa imishini ye-CNC. Izingxenye ezinjengamamotho, izinzwa, amabhande, nama-bearings angase adinge ukushintshwa ngokuhamba kwesikhathi. Izindleko zalezi zingxenye zizoncika kuhlobo lomshini, imodeli, nokutholakala. Kunconywa ukugcina i-inventory yezingxenye ezisele ezisetshenziswa ngokuvamile ukuze kuncishiswe isikhathi sokuphumula nokunciphisa izindleko zokuthumela.

- Ukuvakasha kwesevisi endaweni kungase kuhilele izindleko ezengeziwe, njengezindleko zokuhamba, indawo yokuhlala, kanye nezinkokhelo zochwepheshe. Lezi zindleko zingahluka kuye ngendawo yomshini kanye nezinqubomgomo zomhlinzeki wesevisi. Izinketho zokuxilonga nokuxazulula izinkinga zingatholakala, ezingasiza ekunciphiseni isidingo sokuvakasha endaweni kanye nezindleko ezihlobene.

- Kuyatuseka ukuthola izingcaphuno kubahlinzeki besevisi abaningi ukuze uqhathanise izindleko namasevisi anikezwayo. Cabangela isithunzi, ulwazi, kanye nobuchule bomhlinzeki wesevisi, kanye nesikhathi sabo sokuphendula nokutholakala kwezimo eziphuthumayo.

- Ukutshala imali ekunakekeleni okuvamile kanye nokulungiswa okufika ngesikhathi kungasiza ekunciphiseni izindleko zesikhathi eside. Ukunganaki ukunakekelwa kungaholela ekulimaleni okuvama kakhudlwana, ukuncipha kwesikhathi sokuphila komshini, kanye nezindleko zokulungisa ezanda.

Isiphetho

Isevisi yomshini we-CNC ibalulekile ukuze kuqinisekiswe ukuthi le mishini isebenza kahle nangempumelelo. Abahlinzeki bensizakalo yomshini we-CNC bahlinzeka ngezinsizakalo eziningi zokunakekela, ukulungisa, nokuthuthukisa le mishini ukuze kuqinisekiswe ukuthi ihlangabezana nezidingo zamabhizinisi okukhiqiza. Ukunakekelwa okuvamile, ukuhlolwa, nokulungiswa kubalulekile ukuze kuvinjwe isikhathi sokuphumula kanye nokunciphisa ingozi yokulungiswa okubizayo. Ngokutshala imali kusevisi yomshini we-CNC, amabhizinisi angaqinisekisa ukuthi akhulisa amandla emishini yawo ye-CNC futhi athuthukise ukukhiqiza kwawo kukonke.