I-Plastic Injection Molding Molding Key

Noma iyiphi iphrojekthi yokubumba ephumelelayo yomjovo kufanele icabangele izici eziningi ngesikhathi esisodwa.

Ukukhetha Izinto

Izinto ezisetshenziswayo zidlala indima enkulu ekubumbeni umjovo. Umhlinzeki wokubumba umjovo onekhono angakusiza ukhethe i-thermoplastic efanela ibhajethi yakho kanye nezidingo zokusebenza. Ngenxa yokuthi ababumbi bavame ukuthola izaphulelo kumanani amakhulu amamaki e-thermoplastic abawathengayo, bangadlulisela lokho kongiwe kuwe.

Izinguquko Zokubekezelelana

Wonke umkhiqizo owenziwe ngokubumba umjovo kufanele ube nokubekezelela okuthile ukuze uvumelane nohlelo oluhlosiwe. Izinto ezithile kungase kube nzima ukuzibumba noma ukubambelela ekubekezeleni okudingekayo, futhi ukwakheka kwezinto zokusebenza kungase kuthinte ukubekezelelana kwengxenye yokugcina. Hlala uxoxisana nesibumbi sakho somjovo ngebanga lokubekezelela ukwamukelwa kwemikhiqizo ethile.

Izinga lokushisa lomgqomo kanye neNozzle

Ama-Molders kufanele agcine izinga lokushisa elithile lombhobho kanye ne-nozzle ekubunjweni komjovo ngoba athinta ikhono le-resin ukugeleza kulo lonke isikhunta. Amazinga okushisa omgqomo kanye ne-nozzle kufanele amiswe ngokunembile phakathi kokubola kwe-thermo namazinga okushisa ancibilikayo. Uma kungenjalo, kungase kubangele ukuchichima, iflash, ukugeleza kancane, noma izingxenye ezingagcwalisiwe.

Amazinga Okugeleza Kwe-Thermoplastic

Ama-molders kufanele agcine izinga lokugeleza elilungile ukuze aqinisekise ukuthi ipulasitiki evuthayo ijovwa ngokushesha ngangokunokwenzeka emgodini wesikhunta ize igcwale ngo-95% kuya ku-99%. Ukuba nesilinganiso sokugeleza esifanele kuqinisekisa ukuthi ipulasitiki igcina izinga le-viscosity elifanele ukuze ligeleze emgodini.

Ezinye izici okufanele zicatshangelwe kunoma yikuphi ukusebenza kokubumba umjovo yilezi:

*Indawo yesango

*Izimpawu zokucwila

*Vala ama-engeli

*Ukuthumela umbhalo

*Ukuma kwe-engeli okusalungiswa nokusalungiswa

*Izindawo eziphephile zensimbi

Izinyathelo Eziyisithupha Ezibalulekile Enqubweni Yokubumba Umjovo

Inqubo yokubumba umjovo ibandakanya izinyathelo eziyisithupha ezibalulekile, futhi izinkinga zingavela kunoma yisiphi salezi zigaba uma zingenziwanga kahle.

1.Ukubamba

Kule nqubo, ama-halves amabili esikhunta avikelwe ngokuqinile kusetshenziswa i-clamping unit, esebenzisa amandla we-hydraulic ukuze asebenzise amandla anele ukuvala isikhunta. Ngaphandle kwamandla okubamba anele, inqubo ingaholela ezigabeni ezingalingani zodonga, izisindo ezingaguquki, nosayizi abahlukahlukene. Amandla okuphoqa ngokweqile angabangela ukushutha okufushane, ukusha, kanye noshintsho lwezinga lokucwebezela.

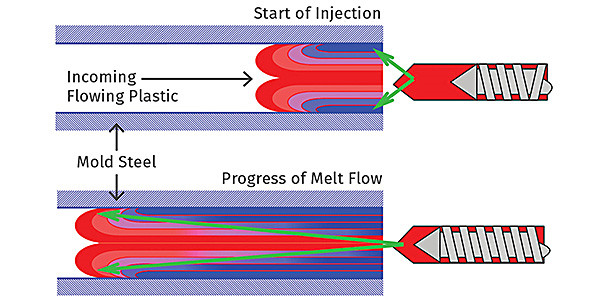

2.Umjovo

Izibunzi zijova into encibilikisiwe ye-thermoplastic esibunjeni ngedivayisi ye-ramming noma isikulufu ngaphansi kwengcindezi ephezulu. Khona-ke, ingxenye kufanele ivunyelwe ukupholisa ngezinga elifanayo. Uma kungenjalo, ingxenye yokugcina ingaba nemigqa yokugeleza noma amaphethini angafuneki athinta ubuhle bayo.

3.Ingcindezi Yokuhlala

Uma impahla ye-thermoplastic isijovwe esibunjeni, izibunzi zenza ingcindezi eyengeziwe ukuze zigcwalise imigodi ngokugcwele. Ngokuvamile babamba izinto ezincibilikisiwe ze-thermoplastic kuze kube yilapho isango lesikhunta liqina. Isikhathi sokuhlala kufanele sisebenzise ukucindezela okufanele-okuphansi kakhulu futhi kungashiya ama-sink marks kumkhiqizo ophelile. Ukucindezela okweqile kungabangela ama-burrs, ubukhulu obunwetshiwe, noma inkinga yokukhipha ingxenye ekubunjeni.

4.Kupholisa

Ngemuva kokuhlala, isikhunta siyagcwaliswa, kodwa cishe sisashisa kakhulu ukuthi singasuswa esikhunjeni. Ngakho-ke, ababumba banikeza isikhathi esithile ukuze isikhunta sibambe ukushisa epulasitiki. Izibunzi kufanele zigcine ukupholisa okwanele, okufanayo kwempahla ye-thermoplastic noma zizobeka engcupheni yokusonteka komkhiqizo wokugcina.

5.Ukuvuleka Kwesikhunta

Amapuleti anyakazayo omshini wokujova isikhunta ayavuleka. Ezinye isikhunta zinokulawula ukuqhuma komoya noma ukudonsa okuphakathi, futhi umshini wokubumba ulawula izinga lamandla asetshenziselwa ukuvula isikhunta ngenkathi uvikela ingxenye.

6.Ukususwa kwengxenye

Umkhiqizo wokugcina ukhishwa kusikhunta somjovo nge-pulse evela kusistimu yokukhipha, izinduku, noma amarobhothi. I-Nano release coatings endaweni yesikhunta isiza ukuvimbela ukudabuka noma izinyembezi ngesikhathi sokukhishwa.

Ukukhubazeka Okujwayelekile Kokubumba Okubangelwa Izinkinga Zenqubo

Kunokukhubazeka okuningana kokubumba okuhambisana nokubunjwa komjovo, okufana nalokhu:

I-Warping: I-Warping iwukuwohloka okwenzeka lapho ingxenye ithola ukushwabana okungalingani. Iveza njengomumo ongahlosiwe ogobile noma osontekile.

I-Jetting: Uma i-thermoplastic ijovwa kancane kakhulu futhi iqala ukusetha ngaphambi kokuba i-cavity igcwale, ingabangela ukujeziswa komkhiqizo wokugcina. I-Jetting ibukeka njenge-wavy jet stream phezu kwengxenye.

Amamaki osinki: Lokhu ukucindezelwa kwendawo okwenzeka ngokupholisa okungalingani noma lapho izibunzi zingakuvumeli isikhathi esanele sokuthi ingxenye iphole, okubangela ukuthi izinto ezisetshenziswayo zishwabane ngaphakathi.

Imigqa yokushisela: Lena imigqa emincane evame ukuzungeza izingxenye ezinezimbobo. Njengoba ipulasitiki encibilikisiwe igeleza izungeze imbobo, ukugeleza okubili kuyahlangana, kodwa uma izinga lokushisa lingalungile, ukugeleza ngeke kuhlangane kahle. Umphumela uba umugqa we-weld, onciphisa ukuqina namandla engxenye yokugcina.

Khipha amamaki: Uma ingxenye ikhishwe ngaphambi kwesikhathi kakhulu noma ngamandla amakhulu, izinti ze-ejector zingashiya amamaki kumkhiqizo wokugcina.

Vacuum voids: Ama-vacuum voids ayenzeka lapho amaphakethe omoya evaleleke ngaphansi kwengxenye. Zibangelwa ukuqina okungalingani phakathi kwezingxenye zangaphakathi nezingaphandle zengxenye.

Izinsizakalo Zokubumba Zokujova Kusuka ku-DJmolding

I-DJmolding, ivolumu ephezulu, uchwepheshe wokubumba umjovo ngokwezifiso, uneminyaka engu-13 yesipiliyoni sokubumba umjovo. Kusukela kwasungulwa i-DJmolding, sizinikele ekunikezeni amakhasimende ethu izingxenye ezibunjwe ngomjovo ezisezingeni eliphezulu ezitholakalayo. Namuhla, izinga lethu lokukhubazeka lingaphansi kwengxenye engu-1 esigidini ngasinye.