Ukubumba komjovo we-Silicone Rubber(LSR)

Iyini i-Liquid Silicone Rubber (LSR) yokubunjwa komjovo?

Ukubumba komjovo we-Liquid Silicone Rubber (LSR) kuyinqubo esetshenziselwa ukukhiqiza izingxenye ezithambile, eziqinile ngamavolumu aphezulu. Phakathi nenqubo, izingxenye eziningana ziyadingeka: i-injector, iyunithi yokulinganisa, idramu yokuhlinzeka, i-mixer, i-nozzle, ne-mold clamp, phakathi kwabanye.

Ukubunjwa komjovo we-Liquid Silicone Rubber (LSR) ubuchwepheshe obujwayelekile obusetshenziselwa ukukhiqizwa kwemikhiqizo ehlukene yezicelo zezokwelapha nezikagesi, phakathi kokunye. Ngaphezu kwezakhiwo ezizalwa nazo zezinto ezibonakalayo, amapharamitha wenqubo nawo abalulekile. Ukubumba umjovo we-LSR kuyinqubo yezinyathelo eziningi eyethulwa.

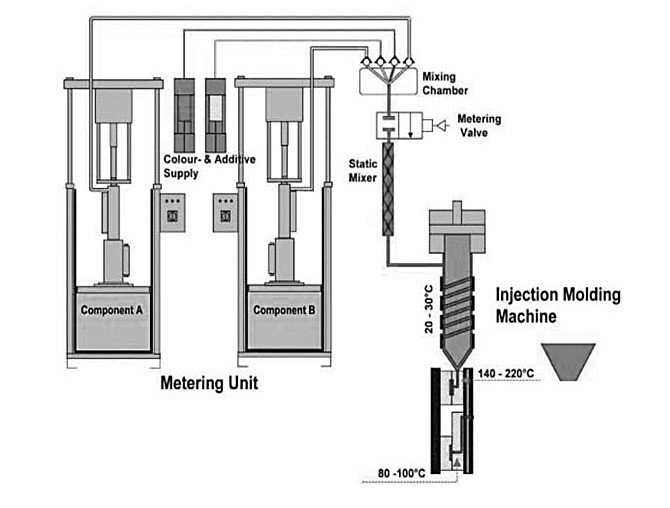

Isinyathelo sokuqala ukulungiswa kwengxube. I-LSR ivamise ukuhlanganisa izingxenye ezimbili, umbala wombala, nezithasiselo (isibonelo, okokugcwalisa), kuye ngezici ezifiselekayo zomkhiqizo wokugcina. Kulesi sinyathelo, izithako zengxube zi-homogenized futhi zingahlanganiswa nesistimu yokuqinisa izinga lokushisa ukuze kube nokulawulwa okungcono kokushisa kwe-silicone (izinga lokushisa elizungezile noma ukushisa kwe-silicone).

Namuhla, uhla olusetshenziswayo lwemikhiqizo yenjoloba ye-silicone luya luba banzi futhi luba banzi, futhi ukubumba komjovo we-LSR kuyindima ebalulekile kule mboni.

Isebenza kanjani i-Liquid Silicone Rubber Molding?

Ukubumba kwe-LSR kwehluka kancane ekubunjweni komjovo we-thermoplastic ngenxa yokuguquguquka kwayo. Njengethuluzi elivamile le-aluminium, ithuluzi lokubumba i-LSR lenziwa kusetshenziswa imishini ye-CNC ukuze kwakhiwe ithuluzi lokushisa eliphezulu elakhelwe ukumelana nenqubo yokubumba ye-LSR. Ngemuva kokugaya, ithuluzi lipholishwa ngesandla ukuze lihambisane nemininingwane yekhasimende, okuvumela izinketho eziyisithupha ezijwayelekile zokuqeda indawo.

Ukusuka lapho, ithuluzi eliqediwe lilayishwa emshinini wokunyathelisa wokubumba womjovo othize we-LSR othuthukisiwe oqondile ohloselwe ukulawula okunembile kosayizi wokudutshulwa ukuze kukhiqizwe izingxenye ze-LSR ezingaguquki. E-Mold-Making, izingxenye ze-LSR zikhishwa ngesandla esikhunjeni, njengoba izikhonkwane zomjovo zingathinta ingxenye yekhwalithi. Izinto ze-LSR zifaka ama-silicone ajwayelekile kanye namamaki athile ukuze alingane nezingxenye ezihlukene zezinhlelo zokusebenza nezimboni ezifana nezokwelapha, ezezimoto, nezibani. Njengoba i-LSR iyi-polymer ye-thermosetting, isimo sayo esibunjiwe sihlala unomphela—uma isimisiwe, ayikwazi ukuncibilika futhi njenge-thermoplastic. Lapho ukugijima sekuqediwe, izingxenye (noma isampula yokuqala esebenzayo) zifakwa emabhokisini futhi zithunyelwe ngokushesha ngemva kwalokho.

Lapha ake sikuhlole, okokuqala, kufanele sikhulume ngezinto zenjoloba ye-silicone ewuketshezi, amaphuzu asemqoka okufanele wazi ngale ndlela elandelayo:

Irabha ye-silicone ye-Liquid (LSR) ingu-insulation enhle kakhulu, ilungele amapulagi e-electronic asezingeni eliphezulu noma obuchwepheshe obuphezulu.

Izinto zenjoloba ye-silicone ewuketshezi (LSR) zilungele ukusetshenziswa endaweni yokushisa ephezulu noma ezindaweni ezinezinga lokushisa eliphansi. Izakhiwo ze-insulation, izakhiwo zemishini, kanye nezakhiwo ezibonakalayo zezinto zokwakha zihlala zingashintshile ku-200 ℃ noma ziphansi njenge -40 ℃.

Imelana ne-gasification kanye nokuguga, ngakho-ke ifanele izicelo zangaphandle.

Irabha ye-silicone ye-Liquid (LSR) imelana nowoyela, ingasetshenziswa embonini yezimayini zikawoyela. Kunamamodeli amabili: umshini wokubumba umjovo we-silicone owuketshezi we-slide omile mpo ophindwe kabili, umshini wokujova we-silicone owuketshezi ome mpo oyisilayidi, osetshenziselwa ukukhiqiza zonke izinhlobo zemikhiqizo yerabha ye-silicone edingeka kakhulu, enembayo ephezulu; umshini ophansi womjovo we-cylinder angle, ukukhiqizwa kwezivikeli ezihlanganisiwe eziyinhlanganisela, izivikeli ze-Post kanye namamodeli wendabuko weziboshwa.

Izinzuzo ze-LSR Injection Molding (LIM).

Ziningi izinzuzo ze-LSR Injection Molding (LIM). Iqhathaniswa ne-silicone compression molding.

I-liquid silicone rubber (LSR) impahla iphephe kakhudlwana, ijeli ye-silicone inebanga lokudla noma ibanga lezokwelapha. I-LSR injection molding(LIM) inokunemba okuphezulu, ingenza izingxenye zerabha ze-silicone ezinembayo kakhulu. Futhi, inomugqa omncane kakhulu wokuhlukanisa kanye ne-flash encane.

Izinzuzo zezingxenye ezibunjiwe ze-LSR

Umklamo ongenamkhawulo - Inika amandla ukukhiqizwa kwengxenye yejometri nezixazululo zobuchwepheshe kungenzeki ngenye indlela

Ngokuvumelana - Inikeza ukungaguquguquki okuphezulu kakhulu kubukhulu bomkhiqizo, ukunemba kanye nekhwalithi iyonke

Pure - I-Silicone ingenye yezinto eziphilayo ezihlolwe kakhulu ezinomlando omude wokusetshenziswa okuphephile

Unembe - Imiqondo yokuklama ithuluzi engenasici, engenalutho yezingxenye ezinesisindo esisuka ku-0.002 amagremu kuya kumakhulu ambalwa amagremu

Ithembekile - Ukusebenzisa ubuchwepheshe bamuva kwemishini, ithuluzi kanye ne-automation

Quality - Izinga lekhwalithi ye-Zero-defect ngokusebenzisa izilawuli ezingaphakathi kwenqubo

fast - Inika amandla ukukhiqizwa kwevolumu ephezulu kakhulu ngenxa yezikhathi zomjikelezo omfushane, ukusuka ezinkulungwaneni ezimbalwa kuye ezigidini

Clean - Ukusebenzisa amasu okucubungula asezingeni eliphezulu kanye nokukhiqizwa kumagumbi okuhlanza ekilasi lesi-7 nelesi-8

Kuqiza kahle - Inikeza Izindleko Eziphelele Zobunikazi eziphansi kakhulu (TCO)

Ukubunjwa komjovo we-LSR

Ubuchwepheshe obusha buhlangabezana nezidingo zamakhasimende:

I-Liquid Silicone Rubber (LSR) ingacutshungulwa ngenqubo yokubumba umjovo we-liquid (LIM). I-liquid impahla eluhlaza ixutshwe ezingxenyeni ezimbili ezihlukene ngesilinganiso esingu-1:1 futhi ijovwe ngesistimu egijimayo ebandayo ibe isikhunta esishisayo. Ukwelapha kwenzeka ngemizuzwana, kunikeza inzuzo yokuhamba ngebhayisikili okusheshayo nokukhiqizwa kwenani elikhulu.

Ngenxa yokuguquguquka ekwakhiweni nasekusetshenzisweni kwamathuluzi, ukubumba komjovo we-LSR kulungele ukukhiqiza amajiyometri ayinkimbinkimbi futhi kungahlanganisa izici ezihlukahlukene zokusebenza zibe yingxenye eyodwa. Iphinde inikeze izinzuzo ezibalulekile mayelana nokuthembeka komkhiqizo kanye nezindleko eziphelele zobunikazi.

I-LSR Liquid Silicone Rubber Molding Process

Umshini wokubumba umjovo werabha we-DJmolding liquid abicah ubukeka ufana nemishini yokubumba yomjovo we-thermoplastic. Zombili izinhlobo zokunyathelisa zisebenzisa izingxenye zomshini eziyisisekelo ezifanayo, iyunithi ye-clamp, neyunithi yomjovo.

Iyunithi yokubumba umshini wokubumba umjovo we-LSR iyafana nerabha ewuketshezi ye-silicone nemishini ye-thermoplastic. Imishini yokubumba umjovo we-silicone ngokuvamile inenqama ye-hydraulic futhi ingaba nokuguquguquka kwe-hydraulic. Eminye imishini yokunyathelisa iklanywe ngenqama kagesi ene-toggle. Ngokungafani nezingcindezi eziphakeme ezisetshenziselwa ukubumba izingxenye ze-thermoplastic, ingcindezi yomjovo we-silicone ewuketshezi isebangeni lama-800 PSI. Inhloso ye-clamp ukuqukatha amandla okunweba we-silicone, ngokugcina isikhunta sivaliwe njengoba i-silicone iphulukisa.

Iyunithi yomjovo ye-silicone ewuketshezi isebenza ngokupholisa ngomgqomo wamanzi opholile kanye nombhobho ukuvimbela i-silicone ewuketshezi ukuthi ingalapheki. Amayunithi omjovo we-Thermoplastic asebenza ngendlela ephambene, adinga umgqomo nobhobho ukuze kushiswe ku-300F noma ngaphezulu ukuze kugcinwe izinto ezihambayo. Amayunithi okubumba umjovo owuketshezi nawo asebenza ngaphansi kwengcindezi ephansi (ngaphansi kuka-1,000 PSI), kuyilapho ozakwabo bawo be-thermoplastic begijima kumashumi ezinkulungwane ze-PSI.

I-silicone ewuketshezi ivamise ukunikezwa ngepheyile elingamalitha angu-5 noma ezigubhu ezingamalitha angama-55. Kunengxenye A kanye Nengxenye B. Ama-Colourants afika ngendlela yokuhlakazeka futhi ngokuvamile angu-1-3% ngesisindo se-silicone ehlanganisiwe. Iyunithi ye-silicone dousing iphampa ingxenye eyodwa ye-silicone kanye nengxenye eyodwa ye-silicone yengxenye B ngamapayipi ahlukene ukuya kumxube omile. Ngaphezu kwalokho, umbala umpontshelwa kusihlanganisi esimile kusetshenziswa elinye ipayipi. Izingxenye ezixubile zibe sezifakwa emphinjeni wombhobho wokubumba umjovo ngendlela yevalvu yokuvala.

I-DJmolding iwuchwepheshe bokubumba umjovo we-silicone yerabha ewuketshezi (LSR) kanye nomkhiqizi wezingxenye zenjoloba eziwuketshezi ezivela e-china.

I-Liquid Silicone Rubber Injection Workshop

Imikhiqizo Yomjovo ye-LSR QC

Imikhiqizo ye-LSR

Imikhiqizo ye-LSR

Inqubo yethu yokubumba irabha ye-silicone ewuketshezi ikhiqiza ama-prototypes angokwezifiso kanye nezingxenye zokukhiqiza ezisetshenziswa ekugcineni ezinsukwini eziyi-15 noma ngaphansi. Sisebenzisa isikhunta se-aluminium esihlinzeka ngamathuluzi akongayo kanye nemijikelezo yokukhiqiza esheshayo, futhi sigcina amabanga ahlukahlukene nama-durometers wezinto ze-LSR.

Inikeza ukuvumelana okuphezulu kakhulu kobukhulu, ukunemba, ikhwalithi iyonke.

Indlela yethu ephelele yokubumba i-Liquid Silicone Rubber incike ekubambisaneni namakhasimende ukuthuthukisa izixazululo ezintsha ezisekelwe ekucacisweni okuyingqayizivele kanye nezidingo.

I-Liquid Silicone Rubber (LSR) Umjovo wokubumba inqubo yokukhiqiza ehlanganisa ukujova irabha ye-silicone ewuketshezi esikhunjini ukuze kwakhiwe imikhiqizo ehlukahlukene. I-LSR iyinto eguquguqukayo eye yanda kakhulu ngenxa yezakhiwo zayo ezihlukile, okuhlanganisa i-biocompatibility, ukuzinza kwe-thermal, nokumelana namakhemikhali. Kulesi sihloko, sizoxoxa ngezinzuzo zokubumba umjovo we-LSR futhi sihlole ukusetshenziswa okuhlukahlukene kwalobu buchwepheshe.

Isebenza Kanjani I-LSR Injection Molding?

Ukubumba komjovo we-LSR (Liquid Silicone Rubber) kuyinqubo yokukhiqiza ekhiqiza izingxenye zenjoloba ezisezingeni eliphezulu nezinembayo. Kuyinzuzo ekudaleni izimo eziyinkimbinkimbi nemiklamo enemininingwane emihle kakhulu nokuvumelana. Inqubo ibandakanya ukujova irabha ye-silicone ewuketshezi endaweni yokubunjwa, ukuyivumela ukuthi yelaphe futhi iqine ibe yisimo oyifunayo. Nasi isifinyezo esifushane sokuthi umsebenzi wokubumba umjovo we-LSR usebenza kanjani:

Ukulungiselela Isikhunta: Inqubo iqala ngokulungiselela isikhunta. Isikhunta ngokuvamile siqukethe ama-halves amabili, uhlangothi lomjovo, nohlangothi olubambayo, oluhlanganayo ukuze kwakheka imbobo ye-silicone. Ngemuva kokwelashwa, isikhunta siyahlanzwa futhi simbozwe nge-ejenti yokukhulula ukuze kube lula ukususwa kwengxenye.

Ukulungiselela I-Silicone: Irabha ye-silicone ewuketshezi iyizingxenye ezimbili ezihlanganisa i-silicone eyisisekelo kanye ne-ejenti yokwelapha. Lezi zingxenye zixutshwe ndawonye ngesilinganiso esinembile. Ingxube ikhishwa umoya ukuze kukhishwe noma yimaphi amabhamuza angathinta ikhwalithi yengxenye yokugcina.

Umjovo: Irabha eyi-silicone ewuketshezi exutshwe negassed idluliselwa kuyunithi yomjovo. Iyunithi yomjovo ishisa impahla ezingeni lokushisa elithile ukuze inciphise i-viscosity yayo futhi yenze kube lula ukugeleza. I-material ijova emgodini wesikhunta nge-nozzle noma i-sprue.

Ukwelapha: Uma irabha ye-silicone ewuketshezi isijovwe emgodini wesikhunta, iqala ukuphola. Inqubo yokwelapha ngokuvamile iqalwa ukushisa, nakuba ezinye isikhunta zingasebenzisa ezinye izindlela, njengokukhanya kwe-UV. Ukushisa kubangela ukuba i-silicone ihlangane futhi iqine, yenze isikhunta. Isikhathi sokuphulukisa siyahlukahluka kuye ngokuthi ingxenye yomklamo kanye nempahla ye-silicone.

Ukupholisa kanye Nokususwa Kwengxenye: Ngemva kwenqubo yokuphulukisa, isikhunta siyapholiswa ukuvumela i-silicone ukuthi isethwe ngokugcwele. Isikhathi sokupholisa singahluka kodwa ngokuvamile sifushane kunesikhathi sokwelapha. Uma selipholile, isikhunta siyavulwa, futhi ingxenye eqediwe iyasuswa. Indawo ingase idinge izinyathelo ezengeziwe zokucubungula ngemva kokucubungula, njengokunquma impahla eningi noma ukuhlola noma yikuphi ukukhubazeka.

Ukubumba komjovo we-LSR kunikeza izinzuzo ezimbalwa, okuhlanganisa ukukhiqiza amajiyometri ayinkimbinkimbi futhi ayinkimbinkimbi, ukungaguquguquki okuhle kakhulu kwengxenye, ukunemba okuphezulu, nokumelana nezinga lokushisa elidlulele, amakhemikhali, nokuguga. Isetshenziswa kakhulu ezimbonini ezahlukahlukene zezokwelapha, zezimoto, ze-elekthronikhi, nemikhiqizo yabathengi.

Kubalulekile ukuqaphela ukuthi lena incazelo eyenziwe lula yenqubo yokubumba umjovo we-LSR, futhi ukusebenza kwangempela kungase kuhluke kuye ngokuthi imishini ethile, izinto zokwakha, kanye nengxenye yezidingo.

Izinzuzo zokubunjwa komjovo we-LSR

Ukubumba komjovo we-LSR (irabha ye-silicone ewuketshezi) kuyinqubo yokukhiqiza eguquguqukayo enikeza izinzuzo ezimbalwa kunezindlela zokubumba zendabuko. Ukubumba umjovo we-LSR kuhilela ukujova i-silicone ewuketshezi esikhunjeni bese uyiphulukisa ibe yifomu eliqinile ukuze kwakhiwe umkhiqizo osuphelile. Nazi ezinye zezinzuzo eziyinhloko zokubumba umjovo we-LSR:

Ukunemba nokuvumelana

Ukubumba komjovo we-LSR kunikeza ukunemba okukhethekile nokuvumelana ekudaleni izingxenye eziyinkimbinkimbi, eziyinkimbinkimbi ezinemininingwane emihle. I-silicone ewuketshezi ijova esikhunjeni ngaphansi kwengcindezi ephezulu, igcwalise ngisho nezikhala ezincane namakhona ukuze kukhiqizwe izingxenye eziyinkimbinkimbi kakhulu. Ukwengeza, ukubunjwa kwe-LSR kuvumela ukungaguquguquki okukhulu nokuphindaphinda, kunciphisa ithuba lokukhubazeka nokungahambisani komkhiqizo wokugcina.

Izingxenye Ezisezingeni Eliphezulu

Ukubumba komjovo we-LSR kungakhiqiza izingxenye eziphezulu, eziqinile ezimelana nokuguga, ukushisa, nemisebe ye-UV. Izinto ze-LSR zinezakhiwo ezinhle kakhulu zomzimba, kufaka phakathi ukunwebeka okuphezulu, isethi yokucindezela okuphansi, nokumelana namazinga okushisa aphezulu. Lokhu kwenza ukubumba komjovo we-LSR kube yinketho efanelekile yokukhiqiza izingxenye ezidinga ukunemba okuphezulu nokuqina, njengamadivayisi wezokwelapha, izingxenye zezimoto, nemikhiqizo yabathengi.

Kuqiza kahle

Ukubumba umjovo we-LSR kungaba indlela yokukhiqiza engabizi kakhulu yokukhiqiza izingxenye ezinkulu. Ukunemba okuphezulu kwenqubo nokungaguquguquki kusiza ekunciphiseni udoti nezinto ezilahliwe, kuyilapho izimfuneko eziphansi zabasebenzi kanye nezikhathi zokukhiqiza eziphumelelayo zinciphisa izindleko zokukhiqiza. Ukwengeza, izinto ze-LSR zihlala isikhathi eside, zinciphisa isidingo sokushintsha njalo noma ukulungiswa kwezingxenye.

yizinhlobonhlobo

Ukubumba komjovo we-LSR kungakhiqiza izingxenye ezihlukahlukene ezinobukhulu obuhlukahlukene, ubujamo, namajiyometri. I-silicone ewuketshezi ingabunjwa ibe yizimo eziyinkimbinkimbi neziyinkimbinkimbi ngemininingwane ecolisisiwe, iyenze ifaneleke ukukhiqiza izingxenye ezidinga ukunemba okuphezulu nokunemba. Ukwengeza, ukubumba komjovo we-LSR kungaba nezici ezinamazinga ahlukene obulukhuni nokuthamba, okuvumela ukuklanywa komkhiqizo okungaphezu kokuvamile kanye nokuvumelana nezimo.

Izikhathi Ezincishisiwe Zomjikelezo

Ukubumba komjovo we-LSR kunezikhathi zomjikelezo osheshayo, okuvumela ukukhiqiza inani elikhulu lezingxenye ngesikhathi esifushane uma kuqhathaniswa. I-silicone ewuketshezi ijovwa esibunjeni bese yelapheka ibe yifomu eliqinile ngemizuzwana, okuyenza ibe inketho ekahle yokugijima kokukhiqiza kwevolumu ephezulu.

I-Low Waste Generation

Ukubumba umjovo we-LSR kukhiqiza imfucuza encane kakhulu, njengoba i-silicone ewuketshezi ijova ngqo esikhunjeni futhi yelashwe ukuze yakhe isimo esifunekayo. Lokhu kuphambene nezinye izinqubo zokukhiqiza, ezinjengomshini noma ukusakaza, okukhiqiza izinto ezilahliwe ezibalulekile. Ukwengeza, izinto ze-LSR zingagaywa kabusha futhi zisetshenziswe kabusha, kuncishiswe isidingo sezinto ezintsha futhi kuncishiswe ukuphehlwa kukadoti.

Ukuphepha Okuthuthukisiwe

Izinto ze-LSR ngokuvamile azinawo amakhemikhali ayingozi njengama-phthalates, i-BPA, ne-PVC, okuwenza aphephe kubasebenzi nakubathengi. Ukwengeza, inqubo yokushisa ephansi esetshenziswa ekubumbeni umjovo we-LSR ayidingi izinyibilikisi eziyingozi noma amanye amakhemikhali, inciphisa ingozi yokuchayeka ezintweni eziyingozi.

Isikhathi Esincishisiwe Sokuya Emakethe

Ukubumba umjovo we-LSR kunganciphisa isikhathi sokumaketha imikhiqizo emisha, njengoba kuvumela ukwenziwa kwe-prototyping ngokushesha kanye nokugijima kokukhiqiza okusheshayo. Ukunemba okuphezulu kwenqubo nokungaguquguquki kusiza ukuqinisekisa ukuthi umkhiqizo wokugcina uhlangabezana nokucaciswa okufunayo, kunciphisa isidingo semijikelezo eminingi yokufanisa nokuhlola.

Ukuzenzekelayo

Ukubumba umjovo we-LSR kungenziwa ku-othomathikhi kakhulu, kunciphise isidingo somsebenzi wezandla kanye nokwehlisa ukusetshenziswa kwamandla. Ukwengeza, i-automation ingathuthukisa ukusebenza kahle, inciphise izindleko zabasebenzi, futhi ithuthukise ukungaguquguquki kanye nekhwalithi yomkhiqizo wokugcina.

Ububi bokubunjwa komjovo we-LSR

Nakuba ukubumba komjovo we-LSR (irabha ye-silicone ewuketshezi) kunikeza izinzuzo eziningi, kuphinde kube nokubi okumbalwa okufanele kucatshangelwe lapho unquma ukuthi uzoyisebenzisa yini le nqubo yokukhiqiza. Nazi ezinye zezinkinga ezinkulu zokubumba umjovo we-LSR:

Utshalomali Olukhulu Lokuqala

Enye yezinto ezimbi kakhulu zokubumba umjovo we-LSR ukutshalwa kwezimali okuphezulu kokuqala okudingekayo ukuze kumiswe okokusebenza kanye nezibungu. Imishini yokubumba umjovo we-LSR kanye namathuluzi kungabiza, ikakhulukazi kusikhunta ngokwezifiso noma ukukhiqiza okuncane. Lokhu kungenza ukubumba umjovo we-LSR kungabizi kakhulu ezinkampanini ezinesabelomali esincane noma imikhiqizo enesidingo esilinganiselwe.

Ukukhetha Okunomkhawulo

Ngenkathi izinto ze-LSR zinikeza izakhiwo ezinhle kakhulu zomzimba, zilinganiselwe ekukhetheni impahla. Ngokungafani ne-thermoplastics yendabuko, inani elilinganiselwe lezinto ezisekelwe ku-silicone ziyatholakala ukuze zisetshenziswe ekubunjweni komjovo we-LSR. Ukuthola izinto ezisetshenziswayo ezifanele izinhlelo zokusebenza ezithile noma imikhiqizo kungakwenza kube inselele.

Izikhathi Ezinde Zokuphulukisa

Ukubumba komjovo we-LSR kudinga izikhathi zokuphulukisa ezinde kunezinqubo zokubumba ezijwayelekile zokujova. I-silicone ewuketshezi idinga isikhathi ukuze yelashwe futhi iqine, okungaholela ezikhathini ezinde zokukhiqiza kanye nokuncipha kokusebenza kahle. Ukwengeza, izikhathi zokuphulukisa ezinde zingenza ukukhiqiza izingxenye ezithile ezinamajiyometri ayinkimbinkimbi noma ayinkimbinkimbi kube inselele.

Kudingeka Ukusethwa Kwamakhono Akhethekile

Ukubumba umjovo we-LSR kudinga ulwazi olukhethekile nobungcweti, okuhlanganisa ukuqonda okujulile kwezakhiwo nokuziphatha kwe-silicone ewuketshezi. Lokhu kungenza kube inselele ezinkampanini ukuthola abasebenzi abaqeqeshiwe abazosebenzisa futhi banakekele okokusebenza, ikakhulukazi ezindaweni lapho ukubumba komjovo we-LSR kungavamile kakhulu.

Izinselele Zokubumba

Ukubumba umjovo we-LSR kungaletha izinselelo ezimbalwa okufanele zibhekwe ukuze kuqinisekiswe ukukhiqizwa kwezingxenye ezisezingeni eliphezulu. Isibonelo, i-silicone ewuketshezi ingaba lula noma i-burrs, ithinte ikhwalithi yomkhiqizo wokugcina. Ukwengeza, ama-ejenti akhulula isikhunta angase adingeke ukuthi asuse izingxenye esikhunjeni, ezingase zithinte isiphetho somkhiqizo wokugcina kanye nezakhiwo zemishini.

Ukuqedwa Kwendawo Elinganiselwe

Ukubumba umjovo we-LSR kunqunyelwe mayelana nokuqedwa kwendawo, njengoba i-silicone ewuketshezi ingahambisani nokumbozwa okuthile noma ukuqedwa. Lokhu kungenza ukuzuza izinto zobuhle ezifiselekayo noma ukusebenza kwemikhiqizo ethile noma izinhlelo zokusebenza kube inselele.

Izinketho Zombala Ezikhawulelwe

Ukubumba komjovo we-LSR nakho kunqunyelwe ezinkethweni zemibala, njengoba impahla ye-silicone ewuketshezi ngokuvamile iguquguquka noma i-opaque. Nakuba ezinye izithasiselo zombala zikhona, zingaba inselele ukuzifaka endabeni ngaphandle kokuthinta izici ezibonakalayo noma ukungaguquguquki komkhiqizo wokugcina.

Amathuba Okungcoliswa Kwengxenye

Ukubumba komjovo we-LSR kungaletha ingozi yokunukubezeka uma okokusebenza noma isikhunta singanakekelwa ngokwanele noma singahlanzwa. Ukungcola kungathinta izici ezibonakalayo zomkhiqizo wokugcina, okuholela ekulimaleni noma ekuhlulekeni ngokuhamba kwesikhathi.

Ukunemba Nokunemba Ekubumbeni Umjovo we-LSR

Ukunemba nokunemba kuyizici ezibalulekile zokubumba komjovo we-LSR (Liquid Silicone Rubber), okukhiqiza izingxenye zerubha ze-silicone zekhwalithi ephezulu ezinokubekezelelana okuqinile kanye nokucaciswa okuqinile. Nazi ezinye izinto ezibalulekile ezinomthelela ekunembeni nasekunembeni ekubumbeni komjovo we-LSR:

- I-Mold Design kanye Nokwakhiwa: Isikhunta siyingxenye ebalulekile yenqubo yokubumba umjovo we-LSR, njengoba inquma ukuma nobukhulu bokugcina bengxenye. Isikhunta kufanele siklanywe futhi sakhiwe ngokunembile ukuze kuqinisekiswe ukuthi ingxenye yokugcina ihlangabezana nemibandela oyifunayo. Isikhunta kufanele senziwe ngezinto ezisezingeni eliphezulu futhi sakhiwe ukuze singabekezelelani kahle ukuze kuncishiswe amaphutha nokuqinisekisa ukunemba.

- Ukulawulwa Kweyunithi Yomjovo: Iyunithi yomjovo ilawula ukugeleza kwerabha ye-silicone ewuketshezi esikhunjeni. Ukulawulwa okunembile kweyunithi yomjovo kubalulekile ekuzuzeni izingxenye ezinembile nezingashintshi. Iyunithi yomjovo kufanele ilinganiswe futhi ilawulwe ukuze kuqinisekiswe ukuthi impahla ijova emgodini wesikhunta ngesivinini esifanele, ukucindezela, kanye nevolumu.

- Ukulawula izinga lokushisa: Ukulawula izinga lokushisa kuyisici esibalulekile enqubweni yokubumba umjovo we-LSR, njengoba kuthinta i-viscosity yezinto kanye nesikhathi sokuphulukisa. Izinga lokushisa kufanele lilawulwe ngokucophelela ukuze kuqinisekiswe ukuthi impahla igeleza kahle esikhunjeni nokuthi inqubo yokwelapha yenzeka ngesilinganiso esifanele.

- Ikhwalithi Yezinto ezibonakalayo: Ikhwalithi yezinto ze-LSR ibalulekile ekuzuzeni ukunemba nokunemba engxenyeni yokugcina. Ukuqinisekisa ukuphulukiswa okufanele nokuvumelana, impahla kumele ingabi nakungcola futhi ihlanganiswe nesilinganiso esifanele.

- Ukucubungula Ngemva: Izinyathelo zokucubungula ngemva kokusikwa kanye nokuhlola zibalulekile ukuze kuzuzwe ukunemba nokunemba ekubumbeni umjovo we-LSR. Ingxenye kufanele inqunywe ibe yizilinganiso ezifanele futhi ihlolwe ukuze kutholakale ukukhubazeka noma ukungapheleli.

Ukubumba komjovo we-LSR kunikeza ukunemba okuhle kakhulu nokunemba, okuvumela ukwakhiwa kwezingxenye ezinokubekezelelana okuqinile kanye nokucaciswa okuqinile. Ingakwazi ukukhiqiza izingxenye ezinekhwalithi engaguquki kanye nokuhluka okuncane kusuka kucezu kuya emininingwaneni. Lokhu kukwenza kube ukukhetha okuhle ezinhlelweni zokusebenza lapho ukunemba nokunemba kubaluleke khona, njengakumishini yezokwelapha, izingxenye zezimoto, nemikhiqizo kagesi.

Izikhathi Zokukhiqiza Ezisheshayo

Ukubumba komjovo we-silicone yerabha ye-Liquid (LSR) kuyinqubo ethandwayo yokukhiqiza ekhiqiza imikhiqizo ye-silicone yekhwalithi ephezulu enezindawo ezinhle kakhulu ezifana nokumelana namakhemikhali, ukumelana nezinga lokushisa, kanye ne-biocompatibility. Kodwa-ke, izikhathi zokukhiqiza zokubumba umjovo we-LSR kwesinye isikhathi zingahamba kancane, okungabambezela inqubo yokukhiqiza futhi kwenyuse izindleko. Nazi ezinye izindlela zokuthuthukisa izikhathi zokukhiqiza zokubumba umjovo we-LSR:

- Sebenzisa umshini wokubumba umjovo osebenza kahle: Ukukhetha umshini ofanele kubalulekile ukuze kusheshiswe ukukhiqizwa. Bheka idivayisi engafaka i-LSR ngokushesha ngaphandle kokudela ikhwalithi. Cabangela ukusebenzisa umshini wejubane lomjovo ophezulu, ukunciphisa isikhathi somjikelezo futhi uthuthukise ukusebenza kahle kokukhiqiza.

- Lungiselela ukwakheka kwesikhunta: Ukwakheka kwesikhunta nakho kuyisici esibalulekile esithinta isikhathi sokukhiqiza sokubumba komjovo we-LSR. Lungiselela ukwakheka kwesikhunta ukuze uqinisekise ukuthi i-LSR ijovwe kahle nangokufana. Cabanga ukusebenzisa isikhunta esinosayizi wesango elikhulu ukuze uthuthukise ukuhamba kwe-LSR futhi unciphise isikhathi somjikelezo.

- Sebenzisa isistimu yomgijimi oshisayo: Isistimu yomgijimi oshisayo ingathuthukisa ukusebenza kahle kokubumba komjovo we-LSR ngokugcina i-LSR ezingeni lokushisa elifanele kuyo yonke inqubo yomjovo. Lokhu kunganciphisa isikhathi somjikelezo futhi kuthuthukise ikhwalithi yomkhiqizo wokugcina.

- Shisisa kuqala i-LSR: Ukushisa kuqala i-LSR ngaphambi komjovo nakho kungasiza ukunciphisa isikhathi sokukhiqiza. Ukushisa kuqala i-LSR kungathuthukisa ukugeleza kwayo futhi kunciphise isikhathi sokujova, okuholela ezikhathini zomjikelezo osheshayo kanye nokusebenza kahle okuthuthukisiwe.

- Yehlisa isikhathi sokuphulukisa: Isikhathi sokuphulukisa se-LSR singancishiswa ngokukhuphula izinga lokushisa lokuphulukisa noma ngokusebenzisa i-ejenti yokwelapha ngokushesha. Kodwa-ke, kubalulekile ukugcina ikhwalithi yomkhiqizo wokugcina ngenkathi unciphisa isikhathi sokwelapha.

Ukukhiqiza Okungabizi kakhulu

Ukubumba komjovo we-silicone yerabha ye-Liquid (LSR) kuyinqubo edumile yokukhiqiza yokukhiqiza imikhiqizo yezinga eliphezulu ye-silicone. Kodwa-ke, izindleko zokubumba umjovo we-LSR zingathinta abakhiqizi, ikakhulukazi lapho bekhiqiza amanani amakhulu. Nazi ezinye izindlela zokwenza ukubumba komjovo we-LSR kungabizi kakhulu:

- Lungiselela ukwakheka komkhiqizo: Idizayini yomkhiqizo ingaba nomthelela omkhulu ezindlekweni zokubumba umjovo we-LSR. Ngokuthuthukisa ukuklama, abakhiqizi banganciphisa inani lezinto ezisetshenzisiwe, ezingehlisa izindleko eziphelele zokukhiqiza. Ukwengeza, ukwenza lula inqubo kunganciphisa inkimbinkimbi yesikhunta, kunciphise izindleko zamathuluzi.

- Sebenzisa izinqubo ezizenzakalelayo: Ukusebenzisa izinqubo ezizenzakalelayo kungathuthukisa ukusebenza kahle kokubumba komjovo we-LSR futhi kunciphise izindleko zabasebenzi. Izinqubo ezizenzakalelayo ezifana nokubamba irobhothi kanye nokudla okuzenzakalelayo kunganciphisa isikhathi somjikelezo futhi kuthuthukise ukukhiqiza okuphelele.

- Sebenzisa isikhunta sekhwalithi ephezulu: Isikhunta sekhwalithi ephezulu singathuthukisa ukusebenza kahle komjovo we-LSR futhi sinciphise udoti. Ukusebenzisa isikhunta esiqinile nesinembayo kunganciphisa isidingo sokulungiswa njalo noma ukushintshwa, konga imali ngokuhamba kwesikhathi.

- Lungiselela inqubo yokukhiqiza: Ukuthuthukisa inqubo yokukhiqiza kunganciphisa ukungcola futhi kuthuthukise ukusebenza kahle, kunciphise izindleko. Lokhu kungafaka nokuthuthukisa imingcele yokubumba yomjovo, njengejubane lomjovo, izinga lokushisa, nokucindezela, ukunciphisa udoti wezinto ezibonakalayo nokunciphisa isikhathi somjikelezo.

- Yehlisa imfucuza yezinto ezibonakalayo: Ukunciphisa udoti wezinto ezibonakalayo kunganciphisa kakhulu izindleko zokubumba umjovo we-LSR. Lokhu kungafezwa ngokusebenzisa isistimu yokulinganisa enembayo ukuze kulawulwe izinto ezisetshenziswayo, ukuqinisekisa ukuthi isikhunta siklanywe ngokwanele futhi sithuthukisiwe ukuze kuncishiswe impahla eyeqile, kanye nokuvuselela izinto ezengeziwe ukuze zisetshenziswe esikhathini esizayo.

I-High-Quality Surface Finishs

Ukubumba komjovo we-silicone yerabha ye-Liquid (LSR) kuyinqubo ethandwayo yokukhiqiza yokukhiqiza imikhiqizo yezinga eliphezulu ye-silicone enezici ezinhle kakhulu ezifana nokumelana nezinga lokushisa, ukumelana namakhemikhali, kanye nokuvumelana kwe-biocompatibility. Ngaphezu kwalezi zakhiwo, ukufeza ukuqedwa kwekhwalithi ephezulu kubalulekile ezinhlelweni eziningi. Nazi ezinye izindlela zokufinyelela ukuqedwa kwekhwalithi ephezulu ekubunjweni komjovo we-LSR:

- Sebenzisa isikhunta sekhwalithi ephezulu: Isikhunta sekhwalithi ephezulu sibalulekile ukuze uthole ukuqedwa kwekhwalithi ephezulu. Isikhunta kufanele senziwe ngezinto ezisezingeni eliphezulu futhi sibe nesiphetho esibushelelezi. Ukwengeza, isikhunta kufanele siklanywe ngendlela efanele yokukhipha umoya ukuze kuvinjwe amabhamuza omoya ukuthi angakheki, okungaba nomthelela omubi ekugcineni.

- Sebenzisa impahla ye-LSR yekhwalithi ephezulu: Ukusebenzisa impahla ye-LSR yekhwalithi ephezulu nakho kungathuthukisa isiphetho esingaphezulu. Izinto ezisezingeni eliphezulu ze-LSR zenziwa ukuze zibe ne-viscosity ephansi, engathuthukisa ukuhamba kwezinto futhi inciphise ukubukeka kwamamaki okugeleza nokunye ukungapheleli.

- Lungiselela amapharamitha okubumba umjovo: Ukuthuthukisa amapharamitha afana nezinga lokushisa, isivinini somjovo, nokucindezela nakho kungathuthukisa ukuphela kwendawo. Isivinini somjovo kufanele sithuthukiswe ukuze kuvinjwe noma yikuphi ukunqwabelana kwempahla noma imidweshu. Izinga lokushisa nokucindezela kufanele futhi kulawulwe ngokucophelela ukuze kugwenywe ukuwohloka kwempahla noma ukungqubuzana.

- Sebenzisa izinqubo zokubumba ngemva kokubumba: Izinqubo zokubumba ngemva kokubumba ezifana nokusikwa, ukupholishwa, nokunamathiswa nakho kungathuthukisa isiphetho esingaphezulu semikhiqizo ye-LSR. Ukunquma kungasusa noma iyiphi i-flash noma impahla eyengeziwe engxenyeni. Ukupholisha kungashelela noma yikuphi ukungapheleli okungaphezulu. I-coating inganikeza isendlalelo esengeziwe sokuvikela futhi sithuthukise ukubukeka komlingiswa.

- Yenza ukugcinwa okuvamile komshini wokubumba umjovo: Ukugcinwa njalo kubalulekile ukuze kuqinisekiswe ukukhiqizwa okungaguquki kanye nekhwalithi ephezulu. Umshini kufanele uhlanzwe njalo ukuze ugweme ukungcola, futhi isikhunta kufanele sihlolwe izimpawu zokuguga noma ukulimala.

Ukubumba komjovo we-LSR kwezicelo zezokwelapha

Ukubumba umjovo we-LSR kuyinqubo yokukhiqiza ebandakanya ukujova irabha ye-silicone ewuketshezi (LSR) esikhunjini ukuze kwakhiwe umkhiqizo wokugcina. Le nqubo isetshenziswa kabanzi embonini yezokwelapha ngenxa yezakhiwo eziyingqayizivele ze-LSR, okwenza kube yimpahla efanelekile yezicelo zezokwelapha.

I-LSR iwumsebenzi we-biocompatible kanye ne-hypoallergenic engaqukethe amakhemikhali ayingozi, okwenza iphephe kumishini yezokwelapha nezimila. Iphinde imelane nokukhula kwebhaktheriya futhi kulula ukuyibulala amagciwane, okubalulekile ezindaweni zokwelapha lapho ukuhlanzeka nokulawula ukutheleleka kubaluleke kakhulu.

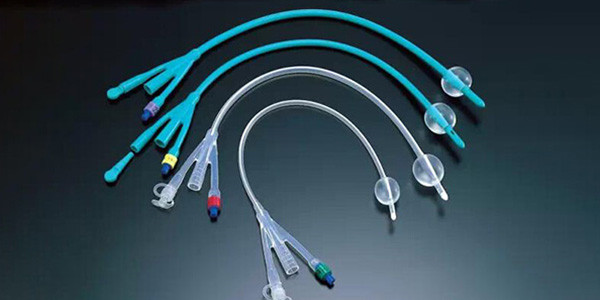

Ukubumba umjovo we-LSR kuyinqubo eqondile nephumelelayo evumela ukudalwa kwezingxenye zezokwelapha eziyinkimbinkimbi neziyinkimbinkimbi ezinokubekezelelana okuqinile. Lokhu kubalulekile ezinhlelweni zezokwelapha lapho ukunemba nokunemba kubaluleke khona, njengokwenza izinto ezifakelwayo ezifana nama-catheter, izakhi ze-pacemaker, namajoyinti okwenziwa.

Ngaphezu kokuvumelana kwayo nokunemba kwayo, i-LSR inezici ezinhle kakhulu zokusebenzisa imishini okuyenza ibe into efanelekile yezicelo zezokwelapha. I-LSR imelana nokuguga, imelana namazinga okushisa adlulele, futhi inezici ezinhle kakhulu zokuvala ugesi. Lezi zakhiwo zenza i-LSR ibe yinto ethandwayo yohlu olubanzi lwezicelo zezokwelapha, okuhlanganisa:

- Ama-Catheter namashubhu: I-LSR ivame ukusetshenziselwa ukwenza ama-catheter kanye neshubhu ngenxa yokuvumelana kwayo kwezinto eziphilayo, ukuguquguquka, kanye nokumelana ne-kink.

- Amadivayisi afakelwayo: I-LSR ivame ukusetshenziselwa ukukhiqiza izinto ezifakelwayo ezifana namalunga okwenziwa, izingxenye ze-pacemaker, namathuluzi okuhlinza ngenxa yokuqina nokuhambisana kwayo ne-biocompatibility.

- Izigxivizo zezokwelapha kanye nama-gaskets: I-LSR ivame ukusetshenziselwa ukuwenza ngenxa yokumelana nokushisa okudlulele kanye nokukwazi ukugcina izakhiwo zayo ngokuhamba kwesikhathi.

Ukubumba umjovo we-LSR kuyinqubo eguquguqukayo futhi ephumelelayo yokukhiqiza imishini yezokwelapha nezingxenye. Izakhiwo zayo eziyingqayizivele ziyenza ibe yimpahla efanelekile yohlu olubanzi lwezicelo zezokwelapha, futhi ukunemba kwayo nokunemba kuqinisekisa ukuthi imikhiqizo ihlangabezana nezindinganiso eziphakeme kakhulu zekhwalithi nokuphepha.

Ukusetshenziswa kwe-LSR embonini yezimoto

I-Liquid Silicone Rubber (LSR) iya ngokuya isetshenziswa embonini yezimoto ezinhlobonhlobo zezicelo ngenxa yezakhiwo ezihlukile eziyenza ibe yimpahla efanelekile yezingxenye zezimoto. I-LSR iyi-elastomer yokwenziwa eyakhiwe ngokubumba umjovo, okuvumela ukunemba okuphezulu nokunemba ekukhiqizeni izingxenye zezimoto eziyinkimbinkimbi neziyinkimbinkimbi.

I-LSR inezinto ezinhle kakhulu zomshini, eziyenza ifaneleke izingxenye zezimoto ezidinga ukuqina, ukumelana nezinga lokushisa eliphezulu, nempilo ende yesevisi. I-LSR imelana nokuhuzuka, ukuguga, nokuklebhuka, okuyenza ilungele izingxenye zezimoto ezihlangabezana nokungqubuzana okungapheli, njengama-seal, ama-gaskets, nama-O-rings.

Enye yezinzuzo ezibaluleke kakhulu ze-LSR embonini yezimoto amandla ayo okumelana nokuhlukahluka kwezinga lokushisa okwedlulele. I-LSR ingasebenza kahle ezindaweni ezinezinga lokushisa eliphezulu neliphansi, iyenze ibe into efanelekile yezingxenye zezimoto ezichayeke emazingeni okushisa aphezulu, njengezingxenye zenjini, amasistimu wokukhipha umoya, namapayipi e-turbocharger.

Enye inzuzo ebalulekile ye-LSR embonini yezimoto ikhono layo lokuhlinzeka ngophawu oluhle kakhulu ngokumelene noketshezi namagesi. I-LSR iwumsebenzi omelana kakhulu ohlinzeka ngophawu oluthembekile, ngisho nangaphansi kwengcindezi ephezulu, okuyenza ilungele ukusetshenziswa kuma-gaskets ezimoto kanye nezimpawu.

I-LSR futhi inezici ezinhle kakhulu zokuvala ugesi, eziyenza ifaneleke ukusetshenziswa ezingxenyeni zikagesi embonini yezimoto, njengezixhumi, izinzwa, namasistimu okubasa. I-LSR ingamelana nama-voltage aphezulu kagesi futhi inengozi ephansi ye-arcing kagesi noma amasekhethi amafushane, okuyenza ibe into enokwethenjelwa yokusetshenziswa kukagesi.

Sekukonke, i-LSR inezinzuzo eziningi eziyenza ibe into efanelekile yezingxenye zezimoto, okuhlanganisa ukuqina, ukumelana nezinga lokushisa eliphezulu, izici ezinhle kakhulu zokuvala, kanye nokufakwa kukagesi. Ukusetshenziswa kwe-LSR embonini yezimoto kulindeleke ukuthi kukhule eminyakeni ezayo njengoba abakhiqizi befuna ukuthuthukisa ukwethembeka, ukuphepha, nokusebenza kwemikhiqizo yabo kuyilapho benciphisa izindleko futhi bethuthukisa ukusebenza kahle kokukhiqiza.

Izicelo Zemboni Yezogesi ze-LSR

I-Liquid Silicone Rubber (LSR) iyinto esetshenziswa kakhulu embonini ye-elekthronikhi ngenxa yokuqina kwayo okuhle kakhulu kokushisa, ukumelana namakhemikhali, kanye nezakhiwo zokufakwa kukagesi. Isetshenziswa ezinhlelweni ezahlukahlukene ezifana ne-encapsulation, ukubekwa uphawu, kanye nokubumba izinto ze-elekthronikhi.

Enye yezinhlelo zokusebenza eziyinhloko ze-LSR embonini ye-elekthronikhi isekuhlanganisweni kwezingxenye ze-elekthronikhi, njengamasekhethi ahlanganisiwe (ama-IC), izinzwa, nezixhumi. I-encapsulation ivikela lezi zingxenye kumswakama, uthuli, nokunye ukungcola, okungabangela ukugqwala futhi kuthuntubeze ukusebenza. I-LSR iyinto efanelekile yokuhlanganisa ngenxa ye-viscosity yayo ephansi, amandla aphezulu okudabula, nokunamathela okuhle kakhulu kuma-substrates ahlukahlukene. Iphinde inikeze izakhiwo ezinhle ze-dielectric, ezibalulekile ekusebenzeni kukagesi.

I-LSR iphinde ivale izingxenye ze-elekthronikhi ukuvimbela ukungena komswakama nokunye ukungcola. Impahla ingabunjwa ibe yizimo nosayizi ngokwezifiso ukuze ilingane nezingxenye ze-elekthronikhi ezihlukahlukene. Izigxivizo ze-LSR zivame ukusetshenziswa ezindaweni ezinokhahlo, njengasemanzini nasezimotweni, lapho kufanele zimelane namazinga okushisa aphakeme kanye nokuchayeka kwamakhemikhali.

I-Potting ingesinye isicelo esibalulekile se-LSR embonini yezogesi. Ukubumba kuhlanganisa ukugcwalisa imbobo ezungeze ingxenye ethile ngezinto eziwuketshezi ukuze uyivikele ezicini zemvelo njengokushaqeka, ukudlidliza, kanye nomswakama. I-LSR iyinto efanelekile yokubhobhoza ngenxa ye-viscosity yayo ephansi, evumela ukuthi igeleze kalula ezungeze izimo eziyinkimbinkimbi, kanye nokuzinza kwayo okuphezulu kokushisa, okuqinisekisa ukuthi ingxenye ihlala ivikelekile emazingeni okushisa aphezulu.

I-LSR iphinde isetshenziselwe ukwenza izinkinobho nezinkinobho, izingxenye ezijwayelekile kumishini kagesi njengezilawuli kude, izibali, namakhibhodi. Izinto ezenziwe ngokwezifiso kakhulu zingabunjwa zibe yizimo nobukhulu obuhlukahlukene ngezindlela ezihlukahlukene kanye namazinga obunzima.

Aerospace Industry Applications of LSR

I-Liquid Silicone Rubber (LSR) iyinto esetshenziswa kakhulu embonini ye-aerospace ngenxa yezakhiwo zayo ezihlukile, njengokuzinza okuphezulu kokushisa, ukumelana namakhemikhali, kanye nezakhiwo ezinhle kakhulu zemishini. Isetshenziswa ezinhlelweni ezahlukahlukene ze-aerospace njengokuvalwa, ukubopha, nokufaka izinto ze-elekthronikhi kanye nokwenza ama-gaskets, ama-O-rings, neminye imininingwane ebalulekile.

Esinye sezicelo eziyinhloko ze-LSR embonini ye-aerospace ukuvala nokuhlanganisa izingxenye zezindiza. Impahla ingabunjwa kalula ibe yizimo eziyinkimbinkimbi nosayizi, iyenze ilungele ukupakisha nokuxhuma amathangi kaphethiloli, izingxenye zenjini, namasistimu kagesi. I-LSR inikeza ukunamathela okuhle kakhulu kuma-substrates ahlukahlukene futhi ingamelana nezimo zemvelo ezinzima, njengamazinga okushisa adlulele kanye nokuchayeka kwamakhemikhali.

I-LSR iphinde isetshenziswe ekubumbeni izingxenye ze-elekthronikhi ezinhlelweni ze-aerospace. I-viscosity ephansi yento eyivumela ukuthi igeleze kalula eduze komumo oyinkimbinkimbi, ihlinzeka ngokuvikeleka okuhle kakhulu kwezingxenye ze-elekthronikhi ezibucayi ngokumelene nokudlidliza, ukushaqeka, kanye nezici zemvelo ezifana nomswakama kanye nokushintsha kwezinga lokushisa.

Okunye ukusetshenziswa okubalulekile kwe-LSR embonini ye-aerospace ukukhiqiza ama-gaskets, ama-O-rings, nezinye izinto zokuvala. I-LSR ingenziwa ngendlela oyifisayo ukuze ihlangabezane nezidingo ezithile, ezifana nezinga lokushisa nokumelana nokucindezela, futhi ivame ukusetshenziswa ezinhlelweni zokusebenza eziphezulu lapho izinto zenjoloba zendabuko zingase zingafaneleki.

Ngaphezu kokuvala nokuhlanganisa izinhlelo zokusebenza, i-LSR iphinde isetshenziselwe ukwenza izingxenye zokukhanyisa zendiza, njengamalensi nama-diffuser. Izinto ezibonakalayo ezibonakalayo zikwenza kube ukukhetha okuhle kwalezi zinhlelo zokusebenza, ukuhlinzeka ngokudluliswa kokukhanya okuhle kakhulu, kuyilapho izakhiwo zayo zemishini ziqinisekisa ukuqina nokumelana nezinto zemvelo ezifana nemisebe ye-UV kanye nokushintshashintsha kwezinga lokushisa.

Ukudla-Ibanga Lokudla LSR Umjovo Molding

I-Food-Grade Liquid Silicone Rubber (LSR) iyimpahla ekhethekile esetshenziswa emikhiqizweni yokubumba yomjovo ehlangana nokudla, njengezitsha zasekhishini, imikhiqizo yezingane, kanye nokupakishwa kokudla. Kuyinto ehlanzekile ephezulu ehlangabezana nezindinganiso eziqinile zokulawula ukuphepha kokudla.

Enye yezinzuzo eziyinhloko ze-Food-Grade LSR ukumelana kwayo namazinga okushisa aphezulu, okuyenza ilungele ukusetshenziswa ezitsheni zasekhishini ezifana nama-spatula, izipuni, kanye nesikhunta sokubhaka. Ingakwazi ukumelana namazinga okushisa afika ku-450°F (232°C), iyenze iphephe ekuphekeni nasekubhakeni izinhlelo zokusebenza.

I-Food-Grade LSR iphinde isetshenziselwe ukwenza imikhiqizo yezingane, njengama-pacifiers kanye nezingono zamabhodlela. Le mikhiqizo kufanele ihlangabezane nezindinganiso eziqinile zokuphepha ukuze kuqinisekiswe ukuthi iphephile ezinganeni. I-LSR iyinto efanelekile yalezi zinhlelo zokusebenza ngenxa yokuvumelana kwayo okuhle kakhulu, ukuthambile, nokuqina.

Okunye ukusetshenziswa okubalulekile kwe-Food-Grade LSR kusekufakweni kokudla. Impahla ingabunjwa ibe yizimo nosayizi abahlukahlukene, iyenze ilungele ukukhiqiza iziqukathi zokugcina ukudla, amathreyi e-ice cube, neminye imikhiqizo. I-LSR imelana namakhemikhali futhi inezici ezinhle kakhulu zokuvala, iqinisekisa ukuthi okuqukethwe kwephakheji kuhlala kukusha futhi akungcoliswa.

I-Food-Grade LSR iphinde isetshenziselwe ukwenza imikhiqizo yezokwelapha njengezinto ezibonakalayo zamazinyo kanye nemishini yokufakelwa. I-biocompatibility, ukuqina, kanye nekhono lokuphindaphinda imininingwane emihle kwenza kube ukukhetha okuhle kulezi zinhlelo zokusebenza.

Sekukonke, i-Food-Grade LSR iyimpahla ekhethekile elungele ukukhiqiza imikhiqizo ehlangana nokudla, njengezitsha zasekhishini, imikhiqizo yezingane, kanye nokupakishwa kokudla. Ukumelana namazinga okushisa aphezulu, i-biocompatibility, kanye nezakhiwo ezinhle kakhulu zokuvala kuyenza ibe into efanelekile yalezi zinhlelo zokusebenza. Impahla iphinde isetshenziselwe ukwenza imikhiqizo yezokwelapha ngenxa ye-biocompatibility yayo kanye nekhono lokuphindaphinda imininingwane emihle.

Ukubumba Umjovo we-LSR Wemikhiqizo Yezingane

Ukubumba komjovo we-LSR (Liquid Silicone Rubber) kuyinqubo yokukhiqiza esetshenziselwa ukukhiqiza imikhiqizo eminingi eyenziwe ngerabha ye-silicone. Enye yezinhlelo ezidume kakhulu zokubumba umjovo we-LSR ukukhiqiza imikhiqizo yezingane, futhi lokhu kungenxa yezinzuzo eziningi ezinikezwa yi-LSR ngemikhiqizo yezingane, okuhlanganisa ukuphepha, ukuqina, kanye nokuhlanzeka kalula.

Ukubumba umjovo we-LSR kuhilela ukujova irabha ye-silicone ewuketshezi esikhunjeni, eselapheka futhi iqiniswe. Le nqubo ivumela ukudala izimo eziyinkimbinkimbi kanye nemiklamo kanye nokusetshenziswa kwemibala ehlukene kanye nokuthungwa. Umphumela uba umkhiqizo osuphelile othambile, oguquguqukayo, futhi omelana nokushisa namakhemikhali.

Enye yezinzuzo eziyinhloko zokubumba umjovo we-LSR wemikhiqizo yezingane ukuphepha. Irabha ye-Silicone ayinabo ubuthi, i-hypoallergenic, futhi ayinawo amakhemikhali ayingozi njenge-BPA, i-phthalates, ne-PVC. Lokhu kukwenza kube ukukhetha okudumile emikhiqizweni ehlangana nezingane, njengama-pacifiers, izindandatho zamazinyo, nezingono zamabhodlela. Ukubumba umjovo we-LSR nakho kuvumela ukwakhiwa kwemikhiqizo engenamachopho abukhali noma imithungo engalimaza isikhumba esithambile somntwana.

Ukuqina kungenye inzuzo yokubumba umjovo we-LSR. Irabha ye-silicone imelana nokuguga, okuyenza ifaneleke emikhiqizweni esetshenziswa njalo noma ephathwa kabi, njengama-pacifiers noma izindandatho zamazinyo. Imvelo ethambile futhi eguquguqukayo yempahla iphinda iyenze ibe mancane amathuba okuthi iphuke noma iqhekeke lapho yehliswa, inciphise ingozi yokulimala enganeni.

Ukubumba umjovo we-LSR nakho kunikeza ukuhlanzwa okulula, okubalulekile emikhiqizweni yezingane okufanele ihlanzwe njalo. Irabha ye-silicone ayinazimbobo futhi ingahlanzwa kalula ngensipho namanzi noma ifakwe kumshini wokuwasha izitsha ukuze ihlanzwe kahle.

I-LSR Injection Molding Yezimpahla Zezemidlalo

Ukubumba komjovo we-LSR (Liquid Silicone Rubber) kuyinqubo edumile yokukhiqiza imikhiqizo ehlukahlukene, okuhlanganisa nezimpahla zezemidlalo. Ukubumba umjovo we-LSR kunikeza izinzuzo ezimbalwa zokukhiqiza izimpahla zezemidlalo, okuhlanganisa ukuguquguquka, ukuqina, nokumelana nezinga lokushisa elidlulele nezimo zemvelo.

Enye yezinzuzo eziyinhloko zokubumba umjovo we-LSR wezimpahla zemidlalo ukuguquguquka. Irabha ye-Silicone iyimpahla ethambile, ethambile engabunjwa ibe yizinhlobonhlobo nemiklamo. Lokhu kuvumela ukwakhiwa kwezimpahla zemidlalo ezisebenziseka kalula futhi ezihambisana nomzimba, njengegiya lokuvikela noma izinto zokubambelela.

Ukuqina kungenye inzuzo yokubumba umjovo we-LSR wezimpahla zemidlalo. Irabha ye-silicone imelana nokuguga, okuyenza ifaneleke emikhiqizweni esetshenziswa njalo noma ephathwa kabi, njengamabhola, ama-paddles, noma ama-racket. Okubalulekile kungamelana namazinga okushisa adlulele nezimo zemvelo, njengokuchayeka elangeni noma emanzini, ngaphandle kokululaza noma ukuwohloka.

Ukubumba komjovo we-LSR nakho kuvumela ukwakhiwa kwemikhiqizo ekwazi ukumelana nomthelela kanye nokuhuzuka. Amandla aphezulu okudabula nokunwebeka kwento ngesikhathi sekhefu kuyenza ifaneleke ukukhiqiza izinto ezivikelayo ezifana namalayini okuzivikela, onogada bomlomo, nama-shin guards. Ngaphezu kwalokho, ukubumba komjovo we-LSR kuvumela ukwakhiwa kwezindawo ezingasheleli noma ukubamba okokusebenza, njengezibambo noma izibambo ze-racquet.

Enye inzuzo yokubumba umjovo we-LSR wezimpahla zemidlalo ukudala imikhiqizo okulula ukuyihlanza nokuyinakekela. Irabha ye-silicone ayinambobo futhi ingasulwa kalula ngendwangu emanzi noma iwashwe ngensipho namanzi. Lokhu kuyenza ibe into efanelekile emikhiqizweni esetshenziswa njalo, njengemishini yokuzivocavoca noma omati be-yoga.

Ukubumba Umjovo we-LSR Wempahla Yasekhaya

Ukubumba umjovo we-LSR kuyinqubo yokukhiqiza esebenzisa i-Liquid Silicone Rubber (LSR) ukwakha izingxenye ezibunjiwe. Le nqubo ilungele ukukhiqiza impahla yasendlini yekhwalithi ephezulu njengezitsha zasekhishini, imikhiqizo yezingane, nezinsiza zokugezela. Ukubumba umjovo we-LSR kunikeza izinzuzo ezimbalwa, okuhlanganisa ukunemba okuphezulu, ukungaguquguquki, nokuqina, okuyenza ibe ukukhetha okuhle kakhulu kwemikhiqizo yasendlini edinga ukubekezelelana okuqinile nokusebenza okuphakeme.

Inqubo yokubumba umjovo we-LSR ihlanganisa ukujova into ewuketshezi ye-silicone esikhunjeni. Isikhunta sibe sesishisiswa, futhi izinto eziwuketshezi ze-silicone ziyaphulukisa futhi ziqine zibe yisimo esifisayo. Le nqubo i-othomathikhi kakhulu, evumela ukukhiqizwa kwezingxenye ezingaguquki ezinokubekezelelana okuqinile kanye nokuqedwa okuhle kakhulu kwendawo. Le nqubo iphinde ivumele ukukhiqiza amajiyometri ayinkimbinkimbi okungaba nzima noma okungenzeki ukuwafeza ngezinye izinqubo zokubumba.

Izimpahla zasendlini ezivame ukukhiqizwa kusetshenziswa ukubumba komjovo we-LSR zifaka izinto zasekhishini ezifana nezikhafula nezinkezo zokupheka, imikhiqizo yezingane njengama-pacifiers nezingono zamabhodlela, kanye nezinsiza zokugezela ezifana nezihloko zokugeza nezixubho. Le mikhiqizo idinga ukubumba okunembayo ukuze ihlangabezane namazinga okuphepha nokusebenza, futhi ukubumba komjovo we-LSR kunikeza ukunemba nokuvumelana okudingekayo ukuze kukhiqizwe impahla yasendlini yekhwalithi ephezulu ehlangabezana nalawa mazinga.

Enye yezinzuzo eziyinhloko zokubumba umjovo we-LSR wempahla yasendlini ukuqina kwayo. Izinto ze-LSR zimelana nokushisa okuphezulu, imisebe ye-UV, namakhemikhali, okuzenza zilungele imikhiqizo ehlala isikhathi eside. Ukwengeza, izinto ze-LSR ziyi-hypoallergenic, zizenza ziphephe ukusetshenziswa emikhiqizweni yezingane nezinye izimpahla zasendlini ezihlangana nesikhumba.

Enye inzuzo yokubumba umjovo we-LSR yikhono layo lokukhiqiza izingxenye ezinomphetho osezingeni eliphezulu. Inqubo ivumela ukudala izici ngokuqedwa okubushelelezi, okucwebezelayo ukumelana nokuklwebheka nama-scuffs. Lokhu kwenza ukubumba komjovo we-LSR kube yinketho efanelekile yokukhiqiza impahla yasendlini edinga ukubukeka okukhangayo, njengezitsha zasekhishini nezinsiza zokugezela.

Ukuqhathanisa nezinye Izinhlobo Zokubumba Irabha

Ukubumba komjovo we-LSR (Liquid Silicone Rubber) kuyinqubo yokukhiqiza edumile yokukhiqiza imikhiqizo ehlukahlukene yenjoloba, futhi inikeza izinzuzo ezimbalwa kunezinye izinhlobo zezinqubo zokubumba iraba. Nazi ezinye iziqhathaniso phakathi kokubunjwa komjovo we-LSR nezinhlobo ezahlukene zokubunjwa kwenjoloba:

- I-Compression Molding: Ukubumba ukucindezela kuyinqubo evamile yokukhiqiza izingxenye ezinkulu noma izingxenye ezinobunjwa obuyinkimbinkimbi. Ekubunjweni kokucindezela, inani lerabha elikalwe ngaphambilini lifakwa esikhunjeni esishisayo, futhi ingcindezi isetshenziswa kuze kube yilapho irabha iphulukiswa. Uma kuqhathaniswa nokubunjwa komjovo we-LSR, ukubumba kokucindezelwa kuyinqubo ehamba kancane futhi kungabangela ukuhlukahluka kwengxenye yobukhulu ngenxa yokusabalalisa kwengcindezi engalingani. Ukubumba komjovo we-LSR, ngakolunye uhlangothi, kuvumela ukulawula okunembile kwezingxenye zobukhulu futhi kungakhiqiza izimo eziyinkimbinkimbi ezinokubekezelelana okuqinile.

- Ukudlulisa Ukubumba: Ukudlulisa ukubumba kufana nokubumba kokucindezelwa kodwa kuhilela ukusebenzisa i-plunger ukudlulisa irabha ebhodweni lomjovo iye esikhunjeni. Ukubunjwa kokudlulisa kungakhiqiza izingxenye ngokunemba okuphezulu futhi kufanelekile ukwenza izingxenye ezinosayizi ophakathi. Kodwa-ke, ingaba kancane futhi ibize kakhulu kunokubumba umjovo we-LSR.

- Ukubunjwa komjovo: Ukubumba umjovo kuyinqubo ehlanganisa ukujova irabha encibilikisiwe esikhunjeni ngomfutho omkhulu. Ukubumba umjovo kungakhiqiza izingxenye ngokushesha nangokunembile, kodwa kungase kungafaneleki ukwenza izingxenye ezinemiklamo eyinkimbinkimbi noma imininingwane. Uma kuqhathaniswa nokubunjwa komjovo, ukubumba komjovo we-LSR kuvumela ukwakhiwa kwezingxenye ezinemininingwane enembile kanye nemiklamo eyinkimbinkimbi namaphethini.

- I-Extrusion: I-Extrusion iyinqubo esetshenziselwa ukukhiqiza izingxenye ezinephrofayili ye-cross-sectional eqhubekayo, njengamapayipi, ama-seal, nama-gaskets. I-Extrusion iyinqubo esheshayo futhi engabizi, kodwa ingase ingafaneleki ukukhiqiza izimo eziyinkimbinkimbi noma izingxenye ezinokubekezelelana okuqinile. Ukubumba komjovo we-LSR, ngakolunye uhlangothi, kungaba nezingxenye ezinobumo obuyinkimbinkimbi nokubekezelelana okuqinile, okuyenza ifaneleke ukukhiqiza imikhiqizo efana nemishini yezokwelapha, izingxenye zezimoto, nezimpahla zabathengi.

Ukucatshangelwa Komklamo Wokubumba Umjovo we-LSR

Kuningi okucatshangelwayo okubalulekile okufanele kubhekwe lapho kwakhiwa izingxenye zokubumba umjovo we-LSR ukuze kuqinisekiswe inqubo yokukhiqiza eyimpumelelo. Lokhu kucatshangelwa kufaka phakathi ukukhethwa kwezinto, ukwakheka kwesikhunta, ingxenye yejometri, kanye nemisebenzi yokubumba ngemuva.

Ukukhetha izinto ezibonakalayo kuwukucatshangelwa okubalulekile lapho uklama izingxenye zokubumba umjovo we-LSR. Izinto ezisetshenziswayo zenjoloba ye-silicone ewuketshezi ziza ngama-durometer ahlukahlukene, ama-viscosity, nemibala, futhi ukukhetha impahla efanele kubalulekile ukuze kuzuzwe izici ezifiselekayo zomkhiqizo wokugcina. Ukukhethwa kwezinto kufanele kucabangele izidingo zohlelo lokusebenza, njengokumelana nezinga lokushisa, ukumelana namakhemikhali, nokuqina.

Idizayini yesikhunta ingenye indlela ebalulekile yokubumba umjovo we-LSR. Idizayini yesikhunta kufanele ithuthukiswe ukuze ikhiqize ingxenye efiselekayo yejometri futhi icabangele ukugeleza kwempahla, ukupholisa, nokukhipha. Isikhunta kufanele siklanywe ngendlela efanele yokufaka isango kanye nezinhlelo zokukhipha umoya futhi sibe nemigodi eyanele ukuze kuzuzwe izinga eliphezulu lokukhiqiza.

Ingxenye yejiyomethri nayo ibalulekile lapho uklama izingxenye zokubumba umjovo we-LSR. Ingxenye yejiyomethri kufanele ithuthukiswe ukuze kuzuzwe izici zemishini ezifiselekayo zomkhiqizo wokugcina kanye nobuhle. Lokhu kungabandakanya ukusebenzisa ama-engeli asalungiswa ukuze kube lula ukuphuma esibunjeni, ukusebenzisa izimbambo ukukhulisa ukuqina, nokubeka ama-angela namasistimu okukhipha umoya ukuze kuthuthukiswe ukugeleza kwempahla.

Ukusebenza kwangemuva kokubumba kufanele futhi kucatshangelwe lapho kwakhiwa izingxenye zokubumba umjovo we-LSR. Imisebenzi yangemva kokubumba ingase ihlanganise ukunquma, ukukhipha imali, kanye nokusebenza kokuhlanganiswa kwesibili. Le misebenzi kufanele ithuthukiswe ukuze kuncishiswe ukumosha nokunciphisa izindleko zabasebenzi.

Okunye ukucatshangelwa kwedizayini yokubumba umjovo we-LSR kungabandakanya ukusetshenziswa kwama-undercuts, ukubekwa kwezikhonkwane ze-ejector, kanye nokusetshenziswa kwemigqa yokuhlukanisa. Lezi zici kufanele zicatshangelwe ngesikhathi senqubo yokuklama ukuze kuqinisekiswe ukuthi umkhiqizo wokugcina uhlangabezana nezidingo ezidingekayo futhi ungakhiqizwa ngempumelelo.

Izinzuzo Zendawo Ezungezile Nokusimama Kokubumba Umjovo we-LSR

Ukubumba umjovo we-LSR kunikeza izinzuzo ezimbalwa zemvelo kanye nokusimama ngaphezu kwezinqubo zokukhiqiza ezivamile, okukwenza kube inketho ekhangayo ezinkampanini ezifuna ukunciphisa indawo yazo yemvelo.

Enye yezinzuzo eziyinhloko zemvelo zokubumba umjovo we-LSR ukukhiqizwa kwayo kwemfucuza okuphansi. Inqubo ikhiqiza imfucuza encane kakhulu, njengoba irabha ye-silicone ewuketshezi ijova ngqo esikhunjeni futhi yelashwe ukuze yakhe umumo oyifunayo. Lokhu kuphambene nezinye izinqubo zokukhiqiza, ezinjengomshini noma ukusakaza, okukhiqiza izinto ezilahliwe ezibalulekile.

Ukubumba umjovo we-LSR nakho kunamandla okunciphisa ukusetshenziswa kwamandla kanye nokukhishwa kwegesi ebamba ukushisa. Inqubo ingaba ngokuzenzakalela, inciphise isidingo somsebenzi wezandla futhi yehlise ukusetshenziswa kwamandla. Ukubumba komjovo we-LSR kuyinqubo yezinga lokushisa eliphansi edinga amandla amancane kunezinye izinqubo zokubumba, njengokubumba umjovo noma ukubumba i-blower. Lokhu kungaholela ekongeni amandla okuphawulekayo kanye nokunciphisa ukukhishwa kwamagesi abamba ukushisa.

Enye inzuzo yokusimama yokubumba umjovo we-LSR amandla okusebenzisa izinto ezigaywe kabusha. Izinto ze-LSR zingagaywa kabusha futhi ziphinde zisetshenziswe, kunciphisa isidingo sezinto ezintsha futhi kuncishiswe ukukhiqizwa kukadoti. Ukwengeza, impilo ende yemikhiqizo ye-LSR isho ukuthi ingasetshenziswa kabusha noma iphinde isetshenziswe, kuphinde kwehliswe imfucuza futhi kunwetshwe umjikelezo wempilo womkhiqizo.

Ukubumba umjovo we-LSR nakho kunganciphisa ukusetshenziswa kwamakhemikhali ayingozi ekukhiqizeni. Izinto ze-LSR ngokuvamile azinawo amakhemikhali anobuthi njengama-phthalates, i-BPA, ne-PVC, okuwenza aphephe kubasebenzi nakubathengi. Ukwengeza, inqubo yokushisa ephansi esetshenziswa ekubunjweni komjovo we-LSR ayidingi izinyibilikisi eziyingozi noma amanye amakhemikhali.

Ikusasa Lokubumba Umjovo we-LSR

Ikusasa lokubumba umjovo we-LSR liqhakazile, ngenqubo enikeza izinzuzo ezimbalwa kunezindlela zokukhiqiza ezivamile. Ukubumba umjovo we-LSR kuzosebenza ngempumelelo kakhulu, kungabizi kakhulu, futhi kube nobungane bemvelo njengoba ubuchwepheshe buthuthuka.

Enye yezindawo ezithembisa kakhulu ngekusasa lokubumba komjovo we-LSR ukusetshenziswa kwamasu okukhiqiza okungeziwe. Ukukhiqiza okungeziwe, okwaziwa nangokuthi ukuphrinta kwe-3D, kuvumela ukudalwa kwamajiyometri ayinkimbinkimbi nezingxenye ezenziwe ngokwezifiso okungaba nzima noma okungenzeki ukuzikhiqiza kusetshenziswa izindlela zokukhiqiza ezivamile. Njengoba ubuchwepheshe buthuthuka, ukubumba komjovo we-LSR kuzohlanganiswa kakhulu nokukhiqiza okungeziwe, okuvumela ukuthi kukhiqizwe imikhiqizo ethuthuke kakhulu futhi emisha.

Enye indawo yentuthuko yesikhathi esizayo yokubumba umjovo we-LSR ukusebenzisa izinto ezithuthukisiwe. Njengoba kwakhiwa izinto ezintsha, ukubumba komjovo we-LSR kungathatha ngokunenzuzo izici zabo eziyingqayizivele, njengokuqina okuthuthukisiwe, ukumelana nezinga lokushisa, noma ukuhambelana kwezinto eziphilayo. Lokhu kuzovumela imikhiqizo ekhethekile nakakhulu, njengezigxivizo zezokwelapha noma izingxenye zezimboni ezisebenza kahle kakhulu.

Ukuhlanganiswa okuqhubekayo kokuzenzakalela kanye namarobhothi kuzinqubo zokubumba umjovo we-LSR nakho kungase kube inkambiso ebalulekile esikhathini esizayo. Ukuzenzakalela kungathuthukisa ukusebenza kahle, kunciphise izindleko zabasebenzi, futhi kuthuthukise ukungaguquguquki kanye nekhwalithi yomkhiqizo wokugcina. Njengoba ubuchwepheshe buthuthuka, ukubumba komjovo we-LSR kuzozenzakalela nakakhulu, amarobhothi nobuhlakani bokwenziwa budlala indima ebaluleke kakhulu ekukhiqizeni.

Okokugcina, ukusimama kanye nesibopho sezemvelo cishe kuzoqhubeka nokuba yizisusa eziphawulekayo esikhathini esizayo sokubumba umjovo we-LSR. Njengoba abathengi namabhizinisi ngokuya begxila ekwehliseni imfucuza kanye nokunciphisa umthelela wabo kwezemvelo, ukubumba umjovo we-LSR kuzoba inketho ekhangayo nakakhulu yokukhiqiza imikhiqizo yekhwalithi ephezulu enendawo ephansi yemvelo. Ukuthuthukiswa kwezinto ezisimeme kakhudlwana, ukugaywa kabusha kanye nokusetshenziswa kabusha kwezinto, kanye nokusebenzisa imithombo yamandla avuselelekayo kungenzeka kudlale indima ebaluleke kakhulu esikhathini esizayo sokubumba umjovo we-LSR.

Isiphetho:

Sengiphetha, ukubumba umjovo we-LSR kuyinqubo yokukhiqiza enokwethenjelwa nephumelelayo enezinzuzo eziningi ezimbonini ezihlukahlukene. I-LSR iwumsebenzi oguquguqukayo onezici zokusebenza ezihlukile, okuyenza ilungele izinhlelo zokusebenza eziningi. Ngokuthuthuka okuqhubekayo kubuchwepheshe be-LSR kanye nesidingo esikhulayo semikhuba yokukhiqiza esimeme, ikusasa lokubumba umjovo we-LSR liqhakazile.