I-Custom Plastic Injection Molding

Ukubumba komjovo ngokwezifiso kulungele izingxenye zepulasitiki lapho impumelelo incike ekuzuzeni izici ezithile zomshini noma zobuhle. I-DJmolding plastic injection molding iqhutshwa umgomo oyinhloko wokusiza amakhasimende akhiqize izingxenye zepulasitiki ezihamba phambili. Akukho ongaziwa ngobunkimbinkimbi, izinselele zedizayini zenza ngempela isifiso sethu sokukusungulela izinto ezintsha. Ukusibandakanya kusenesikhathi kusenza sikwazi ukwengeza inani enqubweni yokuklama.

Izinzuzo Zokubumba Umjovo Wepulasitiki

Izici ezinemininingwane

Cabangela imininingwane yobuhle noma yokusebenza ukuze uthuthukise umkhiqizo wakho: umbhalo ophrintiwe, izimonyo noma izindawo ezithungwe, ukuhlobisa okungaphakathi kwesikhunta, ama-snap fit, amahinji aguqukayo, ubulukhuni obuhlukahlukene.

Ukusebenza Okuphezulu

Ukusebenza kahle komjovo wepulasitiki wokubumba akufaniswe. Senza izindleko ezingadingekile engxenyeni yakho kanye nethuluzi. Onjiniyela bethu asebenesikhathi eside beklama kanye nabadidiyeli abangochwepheshe benza kahle kakhulu kulokhu.

Ukusebenza Okuthuthukisiwe

Sisebenza kanzima ukuze siqonde umsebenzi ohlosiwe wengxenye yakho futhi sihlangabezane nezinjongo zakho ezibalulekile ngokusebenzisa isayensi yezinto ezibonakalayo, izimiso zokuklama, amathuluzi okuhlaziya, nezilawuli zenqubo.

Izinhlobonhlobo Zezinto Ezibalulekile

Khetha ezintweni ezingaphezu kuka-200, impahla kanye nezinsalela zobunjiniyela. Sizokusiza ubhalansise ukusebenza kanye nentengo futhi sikhombe okunye okulingana nokokusebenza ukuze unciphise izindleko.

Inqubo yokubumba umjovo

Ukubumba umjovo wePlastiki kungenye yezindlela ezindala kakhulu zokukhiqiza amapulasitiki kanye nesinyathelo esibalulekile ekuthuthukisweni kwezingxenye zabakhiqizi bemikhiqizo. Kuphinde kube yisixazululo esihle kubakhiqizi abafuna ukuguqula izingxenye zensimbi ezisindayo zibe ipulasitiki. Ichazwa ngendlela yayo elula, le nqubo isebenzisa ama-polymer noma ama-resin epulasitiki okuthi lapho ishiswa, incibilika futhi ijovwe ngaphansi kwengcindezi ephezulu ibe isikhunta esingokwezifiso, ikhiqize izingxenye zepulasitiki ezizosetshenziswa ekukhiqizeni umkhiqizo.

Nakuba leyo nqubo ibonakala iqondile, empeleni ingaba inkimbinkimbi futhi idinga ulwazi oluphezulu oluvela kumlingani ohlanganisa umjovo ongabhekana nezidingo zakho ezihlukile zemboni, imininingwane, ukusetshenziswa kokuphela kanye nemikhawulo yesikhathi / yesabelomali. Indawo engcono kakhulu ongaqala ngayo ukuthola ulwazi oluyisisekelo lwenqubo yokubumba ipulasitiki kanye nezinqubo ezingcono kakhulu zokuklama.

Ukubumba Kwesayensi

Indlela yokubumba yesayensi izuzisa ukukhiqizwa kwezingxenye ezibalulekile ezidinga ukusebenza okuthile nokunemba okuphezulu. Ubuchwepheshe bethu bokubumba obuphambili buqinisekisa ukuphindaphinda nokuvumelana. Lokho kusho ukuthi umkhiqizo esikwenzela wona namuhla, umkhiqizo esikwenzela wona kusasa.

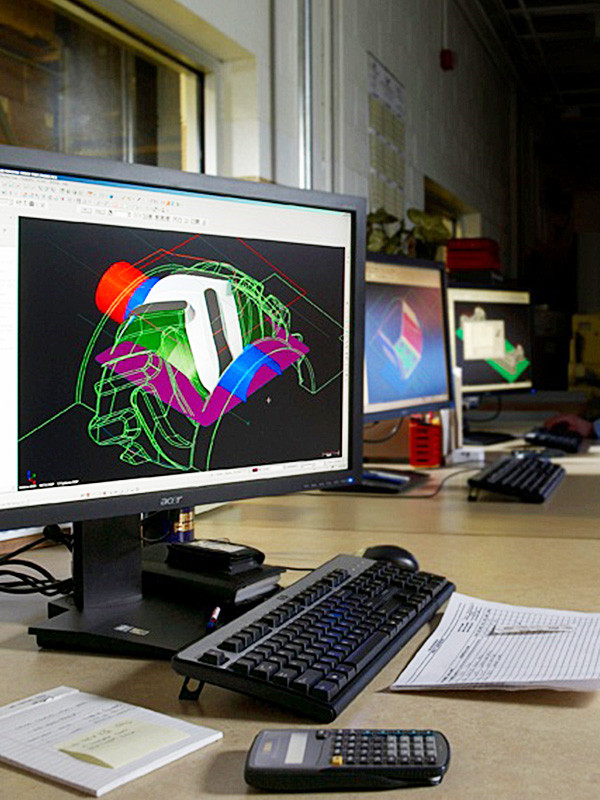

Ukubumba umjovo wesayensi kuqala ngesikhathi sokuthuthukiswa kwamathuluzi. Izinto ezinjengokucindezela, izinga lokushisa, isikhathi sokugcwalisa i-cavity zenziwa ukuze ukwakheka kwesikhunta kunciphise amathuba okuhlukahluka. Ukuhlaziywa kokugeleza kwesikhunta kukhombisa izindawo zokugcina zengxenye okufanele zigcwaliswe, ukuthi izinto zizohambisana kanjani nesikhunta, futhi kuveza amaphuzu angaba khona e-warp nengcindezi. Isinyathelo esisebenzayo esihlinzeka ngokuhlaziywa kokuqagela konjiniyela kanye nesilinganiso futhi sivumele ukunqunywa okulula kwempumelelo noma ukwehluleka kwengxenye noma iphrojekthi.

Izinqubo zokukhiqiza eziqinile ziphinde zisebenzisa indlela yesayensi ngokuqapha kanye nezilawuli zenqubo ezizenzakalelayo ezinciphisa izinsalela nesikhathi sokucubungula. Uma kwenzeka kube noshintsho noma ukungasebenzi kahle, kuhlonzwa ngokushesha futhi kubekwe yodwa ngaphambi kokuthi kwenziwe izingxenye ezingavumelani.

Okweqile

Izinto ezimbili (noma ngaphezulu) zingahlanganiswa zibe ingxenye eyodwa ene-overmolding. Le nqubo ivame ukusetshenziselwa indawo ethintekayo ehlukile, njengendawo yokubamba ethambile. Ukweqa kungaba ipulasitiki phezu kwe-substrate yepulasitiki noma irabha phezu kwe-plastic substrate, ngokuvamile eyenziwa inqubo yokubumba imijovo emibili. Ukwakhiwa kwe-resin nemibala ingahluka. Izinzuzo zobuhle be-overmolding kulula ukuzibona, kodwa futhi ziqeda imisebenzi yesibili. I-overmolding ifaneleka kakhulu kumathuluzi anokubanjwa ngesandla, izinto ezibanjwa ngesandla, amarobhothi lapho kudingeka khona ukubamba irabha, noma nje ukuthuthukisa ukubukeka kwengxenye enemibala ehlukile.

Faka Ukubumba

Ukufaka ukubumba kufana nokugoqa ngokweqile kodwa kufaka into ebekwe ngaphakathi kwesikhunta. Faka amabhondi okubumba epulasitiki kokufakwayo, ngokuvamile okuyinsimbi noma ipulasitiki. Ukufakwa okunemicu kuvamile. Lokhu kuqeda ukusebenza uma kusetshenziswa njengenye indlela yezinsimbi, izinto zokunamathisela, noma i-heat-staking. Ukufaka nakho kuqinisa ingxenye. Okufakiwe kulayishwa ngesandla noma nge-robotic automation.

Ingxenye yokuhlobisa nokulebula

Umhlobiso ongaphakathi kwesikhunta (IMD) kanye nokulebula okungaphakathi kwesikhunta (IML) kusetshenziselwa ukudala ukubukeka okuphawulekayo okunezithombe noma amalebula. Ngokuqondiswa amarobhothi kanye nokubamba kwe-electrostatic noma i-vacuum, imbondela yefilimu ephrintiwe yengezwa emgodini wesikhunta ngaphambi kokujova inhlaka yepulasitiki encibilikisiwe. Le nqubo idala isibopho esihlala njalo phakathi kwelebula nengxenye eqediwe, ngokuvamile isusa noma yisiphi isidingo semisebenzi yangemva kokucubungula. Uhlu olubanzi lokuthungwa, umbala, kanye nezinketho zokumboza ngaphezulu kushiya umnyango uvule amathuba okudala. Sikukhuthaza ukuthi ukhulume nomphathi wephrojekthi yakho mayelana nezinketho zokuthuthukisa umkhiqizo wakho.

Isevisi Yokubumba Umjovo Wepulasitiki Yangokwezifiso eChina

DJmolding Operating kusukela 2010 | I-AFAQ ISO/TS 16949, UL kanye nezitifiketi ze-ISO, ikakhulukazi ezihlinzeka nge-3D Printing Company eminingi Emhlabeni Wamanje.

Kwa-Djmolding sisebenza ngokukhethekile ekukhiqizeni izingxenye ezibunjwe ngomjovo wepulasitiki wekhwalithi ephezulu namathuluzi esikhunta. Sihlinzeka ikakhulukazi ngokukhiqiza kwethu umjovo wepulasitiki ezinkampanini eziningi zokuphrinta ze-3D emhlabeni. Sinemishini engu-55 yamarobhothi kanye nokukhiqiza umjovo wepulasitiki othomathikhi.Sinikeza zonke izinsizakalo zomshini nokuqeda ukwenza amathuluzi avela ezintweni ezihlukahlukene, futhi singakhiqiza izingxenye eziqediwe ezingu-100 kuya ku-200k + kuwo wonke amapulasitiki amakhulu. Okusehlukanisa ngempela ukuqinisekiswa kwethu okuthuthukisiwe kwempahla, ukuhlola nokuhlola ukuze siqinisekise ukuthi izingxenye zakho ziyahlangabezana futhi zidlule okulindelekile. Xhumana nochwepheshe bethu bamazwe ngamazwe bokubumba umjovo ukuze uthole isaphulelo samahhala namuhla.

I-DJmolding Plastic Injection Molding Process

Uma amathuluzi akho okubumba umjovo wepulasitiki eselungile, inqubo yokubumba iqukethe izinyathelo eziyisisekelo ezilandelayo:

Isinyathelo 1. I-resin yepulasitiki ifika ngamapellets aluhlaza. Lezi ziyomiswa zibe umswakamo ofanele, bese kuthi uma kunesidingo zingaxutshwa nama-pigments noma ama-master batch colorants.

Isinyathelo sesi-2. Ama-pellets omisiwe athululelwa ku-hopper yomshini wokubumba. Isikulufu esiphindaphindayo ngaphakathi komgqomo womshini sizothutha lawa ma-pellets siye esikhunjeni.

Isinyathelo sesi-3. Ngaphakathi komgqomo, ama-pellets axutshwe futhi ashiswe kuze kube yilapho encibilika ngokugcwele, enza i-resin liquid.

Isinyathelo sesi-4. Isikhunta esishisayo sivala ngokuzenzakalelayo futhi i-resin, ngaphansi kwengcindezi enkulu, ijova ngesango futhi ingene emgodini wesikhunta.

Isinyathelo sesi-5. Isikhunta sipholile ukuze siqinise ingxenye ngaphakathi.

Isinyathelo sesi-6. Isikhunta siyavuleka bese ingxenye iyakhishwa ukuze kuqalwe umjikelezo omusha.

Ukubekezelelana Kokubumba Umjovo wePlastiki

Zonke izinto zepulasitiki zizokhula futhi zinkontileka ngaphansi kwethonya lokushisa nomswakama. Umhlahlandlela wethu wokubekezelela uzonikeza ulwazi olujwayelekile mayelana nezici zezinhlobo ze-resin ezivame kakhulu ezicini ezijwayelekile.

Sizosebenza eduze nawe ukuze sithuthukise imiklamo yakho yokukhiqiza. Sizokhombisa noma yiziphi izindawo lapho ukuklama okungalungile kungaveza khona ukucindezelwa kwe-thermal, ukuncipha, i-warping, njll. Bheka umhlahlandlela wethu wokuklama ukuze uthole ulwazi olwengeziwe mayelana nokukhubazeka okuvamile nokuthi ungakugwema kanjani.

Ngaphandle kokuthi kucaciswe ngenye indlela, sithobela ukubekezelela okujwayelekile kwe-DIN 16742 kokubunjwa komjovo wepulasitiki. Funda mayelana nezindinganiso zekhwalithi ezibonakalayo esizisebenzisayo ezingxenyeni ezibunjwe ngomjovo.

Izinto Zokubumba Umjovo Wepulasitiki

I-Djmolding yenza amathuluzi okubumba umjovo futhi ifa nge-Aluminium 7075, P20 ne-NAK80 izinsimbi ezingaqinile kancane kanye ne-H13 eqinile ngokugcwele. Ukwengeza, sinikeza ukuqedwa okujwayelekile kwe-SPI, umbhalo we-EDM kanye nohlu lwezinhlobonhlobo ezifakiwe.

Ngayinye yalezi zinhlobo zezinto ezibonakalayo izoba nezinzuzo ezihlukile zezinhlelo zokusebenza ezithile. *Izinqumo zihlanganisa:

*Izindleko zezinto ezingavuthiwe

*Ukuqina nokumelana nokugqwala noma imihuzuko

*Ukusebenziseka

*Ikhono lokuthatha ipholishi ephezulu

*Isikhathi esidingekayo sokwelapha ukushisa

*Impilo yamathuluzi elindelwe

Xhumana nochwepheshe bethu bezobuchwepheshe ukuze ufunde kabanzi mayelana nokuthi iyiphi ekulungele.

Izingxenye Zepulasitiki Ezijovwe

Kunezinkulungwane zamapulasitiki e-thermoforming kanye ne-thermosetting ongakhetha kuwo kuphrojekthi yakho. Ngaphezu kwalokho, izici zemishini namakhemikhali zingathuthukiswa futhi ngezithasiselo ezinjengemicu yengilazi, iziqinisi ze-UV kanye nezinto zokugcoba. Ishidi lethu lezinto zokwakha lizokunikeza imininingwane enemininingwane eyengeziwe mayelana nezinhlobo ezijwayelekile kanye nokubekezelelana ongakulindela ngakunye.

Ukukhetha kwakho ama-resin kungancika kokukodwa noma ngaphezulu kokulandelayo:

*Ukumelana ne-UV, amakhemikhali, imihuzuko kanye nomthelela

*Izindleko zezinto ezingavuthiwe

*Amandla omshini

*Isisindo kanye nokuminyana

*Ukuguquguquka

*Ukungafihli

*Ukusebenziseka kabusha

Xhumana noyedwa wochwepheshe bethu bezobuchwepheshe ukuze ufunde kabanzi mayelana nezakhiwo ezibalulekile.

Isitolo sokujova i-DJmolding:

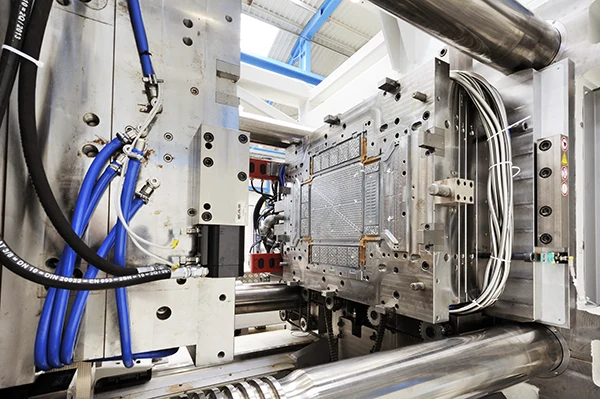

Isikhunta esiholayo somjovo wepulasitiki kanye nomkhiqizi wesevisi ye-prototyping esheshayo

I-Djmolding ingenye yezinkampani ezibumba umjovo wepulasitiki ezaziwa kakhulu e-China. Isitolo sethu sokubumba umjovo sifakwe amasethi angama-50 emishini yokubumba yomjovo enembayo ephezulu, esukela kumathani angama-30 kuye kwangama-800, angeniswa kakhulu evela eTaiwan naseJapan, isitolo sethu somjovo sisebenza amahora angama-24 ngosuku, izinsuku eziyi-7 ngesonto, futhi sihlinzeka ngokukhiqiza. amasevisi.

Sinesipiliyoni ngemikhiqizo ehlukahlukene yepulasitiki yezimboni eziningi, okubandakanya: ezezimoto, ezokwelashwa, izibani, imishini yezemidlalo, izinto zikagesi zasekhaya kanye nezolimo. I-Djmolding iphumelele i-AFAQ ISO/TS 16949, UL kanye ne-ISO 9001 Certifications kusukela ngo-2010, Siphinde sibe nabantu abangu-15 be-IPQC bahlale bebuka ukukhiqizwa kwethu futhi bahlole ingxenye yekhwalithi, Lokhu kuqinisekisa ukuthi umkhiqizo wethu ugcina izinga eliphezulu kakhulu. Kule minyaka engu-9 edlule, i-Djmolding isungule idumela eliqinile lokukhiqiza ithuluzi lekhwalithi ephezulu nengxenye ngentengo enengqondo.Sigcina ubudlelwano obuqinile bebhizinisi ne-appx. Amakhasimende angama-50, ikakhulukazi avela e-USA naseYurophu.

I-Custom Plastic Injection Molding

Ukubumba komjovo wepulasitiki okungokwezifiso kuyindlela entsha nephumelelayo yokukhiqiza izingxenye zepulasitiki ezisezingeni eliphezulu. Le nqubo yokukhiqiza isebenzisa isikhunta ukuze ilolonge izinto zepulasitiki zibe yizimo eziyinkimbinkimbi nosayizi, okwenza kube yisixazululo esifanelekile sezimboni ezihlukahlukene. Lokhu okuthunyelwe kwebhulogi kuzongena kujule ekubunjweni komjovo wepulasitiki wangokwezifiso futhi kuhlole izinzuzo zayo, izinhlelo zokusebenza, nezindlela ezihamba phambili.

Ukuqonda inqubo yokubumba umjovo ngokwezifiso

Ukubumba komjovo ngokwezifiso kuyinqubo yokukhiqiza esetshenziselwa ukukhiqiza izingxenye zepulasitiki ngamavolumu amakhulu. Kubandakanya ukuncibilikisa ama-pellets epulasitiki noma ama-granules bese uwajova esikhunjeni ngaphansi kwengcindezi ephezulu, lapho epholisa khona futhi aqine ukuze akhe umumo oyifunayo. Nansi indlela inqubo yokubumba umjovo esebenza ngayo:

- Ukubamba: Izingxenye ezimbili zesikhunta, ezibizwa ngokuthi “ithuluzi,” ziboshelwa ndawonye ngamandla anele ukumelana nokucindezela komjovo.

- Umjovo: Ama-pellets epulasitiki ayancibilika emgqonyeni oshisayo futhi ajovwe esikhunjeni ngokusebenzisa uhlelo lokugijima ngaphansi kwengcindezi ephezulu. Ipulasitiki igcwalisa umgodi wokubumba futhi ithatha isimo sesikhunta.

- Ukupholisa: Ipulasitiki ingapholisa futhi iqine ngaphakathi kwesikhunta ukuze kugcinwe umumo oyifunayo.

- I-Ejection: Isikhunta sivuleka uma ipulasitiki isipholile futhi ingxenye eqediwe ikhishiwe.

- Phinda: Inqubo-ke iyaphindwa ukuze kwakhiwe izingxenye ezifanayo eziningi.

Ukubumba umjovo kukhiqiza imikhiqizo yepulasitiki, kusukela ezingxenyeni ezincane kuya ezintweni ezinkulu njengezingxenye zezimoto nezinto zikagesi zasendlini. Inqubo isebenza kahle kakhulu futhi ingakhiqiza izingxenye ezinejometri eyinkimbinkimbi nokubekezelelana okuqinile, futhi inembile, enodoti omncane namazinga aphansi alahliwe.

Inqubo idinga okokusebenza okukhethekile, okuhlanganisa isikhunta, umshini wokubumba umjovo, kanye nesistimu yokulawula ukuze kuqinisekiswe imiphumela enembile nengaguquguquki. Isikhunta ngokuvamile senziwe ngensimbi futhi singaklanywa ukukhiqiza izingxenye eziningi kusetshenziswa ukubunjwa kwe-multi-cavity.

Ukubumba komjovo nakho kungasetshenziswa ngezinto ezahlukahlukene, kufaka phakathi ama-thermoplastics, ama-thermosets, nama-elastomers. Impahla ngayinye inezici ezihlukile futhi ingafanelana nezinhlelo zokusebenza ezithile.

Sekukonke, ukubumba umjovo kuyinqubo yokukhiqiza enemisebenzi eminingi futhi ephumelelayo esetshenziswa kabanzi ezimbonini eziningi.

Izinzuzo zokubumba umjovo wepulasitiki wangokwezifiso

Ukubumba komjovo wepulasitiki okungokwezifiso kuyinqubo yokukhiqiza esetshenziselwa ukwakha izingxenye zepulasitiki zangokwezifiso ngamavolumu amakhulu. Nazi ezinye zezinzuzo zale nqubo:

Ukusebenza okuphezulu nokukhiqiza: Ukubumba komjovo wepulasitiki okungokwezifiso kuyinqubo esebenza kahle kakhulu engakhiqiza izingxenye ezinkulu zezingxenye ezifanayo ngokushesha nangokungaguquguquki. Lokhu kwenza kube yisinqumo esihle sokukhiqiza ngobuningi bezingxenye zepulasitiki.

Ukuhlukahluka: Inqubo ingasetshenziswa ngezinhlobonhlobo zezinto zepulasitiki, kufaka phakathi ama-thermoplastics, ama-thermosets, nama-elastomers. Lokhu kuvumela inhlobonhlobo yezingxenye zemiklamo kanye nezicelo.

Ukuvumelana nokunemba: Ukubumba komjovo kunikeza imiphumela engaguquki nenembayo, ngokubekezelelana okuqinile kanye nokuhluka okuncane phakathi kwezingxenye. Lokhu kuqinisekisa ukuthi ucezu ngalunye luyafana nolunye, olubalulekile ezinhlelweni eziningi zokusebenza.

Okungabizi kakhulu: Ukubunjwa komjovo wepulasitiki ngokwezifiso kungabiza kakhulu ekugijimeni kokukhiqiza kwevolumu ephezulu. Izindleko zokuqala zamathuluzi zingaba phezulu, kodwa izindleko zengxenye ngayinye ziyehla njengoba ivolumu ikhula.

Ubunkimbinkimbi: Ukubumba komjovo kungakhiqiza izingxenye ezinobumo obuyinkimbinkimbi namajiyometri, okuhlanganisa izindonga ezincane nezici eziyinkimbinkimbi. Lokhu kuvumela ukuguquguquka okukhulu komklamo futhi kuvumela ukukhiqizwa kwezinto okungaba nzima noma okungenakwenzeka ukukhiqiza usebenzisa ezinye izindlela.

Imfucuza encane: Ukubumba komjovo kukhiqiza imfucuza encane uma kuqhathaniswa nezinye izinqubo zokukhiqiza, njengoba noma iyiphi ipulasitiki eyeqile ingagaywa kabusha futhi isetshenziswe kabusha.

Ekupheleni kwendawo: Ukubumba umjovo kungakhiqiza izingxenye ezinezinga eliphezulu lokuqedwa kwendawo ngaphandle kokusebenza okwengeziwe ngemva kokucubungula noma ukuqeda. Lokhu kwenza kube yisixazululo esingabizi kakhulu sokudala izingcezu ezinokubukeka okubushelelezi nokupholishiwe.

Ukuzenzekelayo: Ukubumba umjovo kungenziwa ngokuzenzakalelayo, ngamarobhothi alayisha futhi akhiphe izingxenye ezivela ekubunjweni kanye nezici zokuhlola nokuhlunga. Lokhu kunciphisa isidingo somsebenzi wezandla futhi kwandisa ukusebenza kahle.

Ukubumba komjovo wepulasitiki ongokwezifiso kuyinqubo yokukhiqiza enemisebenzi eminingi futhi ephumelelayo enikeza izinzuzo eziningi kunezinye izindlela. Ikhono layo lokukhiqiza ngokushesha nangokunembile inqwaba yezingxenye ezifanayo liyenza ilungele izimboni eziningi, okuhlanganisa ezezimoto, i-aerospace, ezokwelashwa, kanye nezimpahla zabathengi.

Izicelo zokubumba umjovo

Ukubumba umjovo kuyinqubo yokukhiqiza esetshenziswa kabanzi ukwakha imikhiqizo ehlukahlukene yepulasitiki yezimboni. Nazi ezinye zezicelo ezivame kakhulu zokubumba umjovo:

- Imboni yezimoto: Ukubumba komjovo kukhiqiza izingxenye zezimoto ezahlukahlukene, okuhlanganisa ukugunda kwangaphakathi nangaphandle, izingxenye zedeshibhodi, izibambo zeminyango, nezingxenye zenjini. Iyakhethwa ngoba ingaba nezici ezinamandla aphezulu nokunemba kobukhulu.

- Izimpahla zabathengi: Ukubumba komjovo kudala imikhiqizo ehlukahlukene yabathengi, okuhlanganisa amathoyizi, izinto zasendlini, nezinto zikagesi. Ivumela ukukhiqiza izimo eziyinkimbinkimbi namajiyometri kanye nokuqedwa kwekhwalithi ephezulu.

- Imishini yezokwelapha: Ukubumba komjovo kusetshenziselwa ukukhiqiza izinhlobonhlobo zemishini yezokwelapha, okuhlanganisa amasirinji, izingxenye ze-IV, nemishini yokuxilonga. Inikeza ukunemba okuphezulu, ukukhiqiza okuhlanzekile, kanye nekhono lokukhiqiza izingxenye ezinejometri eyinkimbinkimbi, ebalulekile embonini yezokwelapha.

- Imboni yokupakisha: Ukubumba komjovo kukhiqiza izinto zokupakisha, ezihlanganisa amabhodlela, izimbiza, nezivalo. Ivumela ukudala iziqukathi ezingasindi neziqinile nokwenza ngokwezifiso imibala, ukwakheka, nokuma.

- Imboni ye-Aerospace: Ukubumba komjovo kusetshenziselwa ukukhiqiza izingxenye ezihlukahlukene zezingxenye ze-aerospace, okuhlanganisa izakhi zesakhiwo nokufakwa kwangaphakathi. Ivumela ukudalwa kwezinto ezisebenza kahle kakhulu ezingamelana namazinga okushisa aphezulu nezingcindezi.

- Imboni yezokwakha: Ukubumba komjovo kukhiqiza izinto zokwakha ezahlukahlukene, kufaka phakathi amapayipi e-PVC, amasistimu we-gutter, nezinto zokufulela. Inikeza ukuqina okuphezulu, ukumelana nesimo sezulu namakhemikhali, kanye nekhono lokukhiqiza izingxenye ngamavolumu amakhulu.

- Imboni yezogesi: Ukubumba komjovo kukhiqiza izingxenye ze-elekthronikhi ezihlukahlukene, ezihlanganisa izindlu, izixhumi, namaswishi. Inikeza ukunemba okuphezulu, ukufana, kanye nekhono lokukhiqiza izingxenye ezinejometri eyinkimbinkimbi, ebalulekile embonini yezogesi.

Sekukonke, ukubumba umjovo kuyinqubo yokukhiqiza eguquguqukayo engakhiqiza izingxenye eziningi zepulasitiki ezimbonini eziningi. Ikhono layo lokukhiqiza izingxenye ezinamajiyometri ayinkimbinkimbi, ukunemba okuphezulu, kanye nekhwalithi engaguquki kwenza kube ukukhetha okudumile kubakhiqizi abaningi.

Izinhlobo zezinto ezisetshenziswa ekubumbeni umjovo

Ukubumba umjovo kuyinqubo yokukhiqiza ebandakanya ukujova ipulasitiki encibilikisiwe endaweni yokubunjwa ukuze kwakheke umumo othile. Izinto ezihlukene zingasetshenziswa ekubumbeni umjovo, kuye ngezakhiwo ezifunwayo zomkhiqizo wokugcina. Nazi ezinye zezinhlobo ezivame kakhulu zezinto ezisetshenziswa ekubumbeni umjovo:

- I-Thermoplastics: Lezi yizinto ezisetshenziswa kakhulu ekubumbeni umjovo. Ziwuhlobo lwepulasitiki oluthambile futhi olubumbekayo lapho lushiswa futhi luqina lapho lupholile. I-Thermoplastics ingabunjwa futhi iphindwe kaningi ngaphandle kokulahlekelwa izakhiwo zayo. I-thermoplastics evamile esetshenziswa ekubumbeni umjovo ihlanganisa i-polypropylene, i-polyethylene, i-polystyrene, ne-nylon.

- Ama-Thermosets: Lawa amapulasitiki angabunjwa kanye kuphela. Ziyashiselwa futhi zithuthukiswe zibe yisimo esithile, futhi uma seziqinile, azikwazi ukubunjwa kabusha. Ama-Thermoset asetshenziselwa izinhlelo zokusebenza lapho kudingeka khona amandla aphezulu nokuqina. Ama-thermosets ajwayelekile asetshenziswa ekubumbeni umjovo afaka i-epoxy, i-melamine, ne-phenolic resins.

- Ama-Elastomers: Lezi zinto zinezici zokunwebeka futhi zinganwebeka futhi zibuyele esimweni sazo sokuqala. Ama-elastomer asetshenziselwa izinhlelo zokusebenza lapho kudingeka khona ukuguquguquka nokumuncwa kokushaqeka. Ama-elastomer ajwayelekile asetshenziswa ekubumbeni umjovo afaka irabha, i-silicone, ne-polyurethane.

- Izinto ezibolayo eziphilayo: Lezi zingabhidlika ngokwemvelo endaweni ezungezile ngaphandle kokushiya izinsalela eziyingozi. Zisetshenziselwa izicelo lapho ukusimama kwemvelo kuwukukhathazeka. Izinto ezijwayelekile ezibolayo ezisetshenziswa ekubumbeni umjovo zifaka i-polylactic acid (PLA) kanye ne-polyhydroxyalkanoates (PHAs).

- Izinhlanganisela ziyizinto ezenziwe ngokuhlanganisa izinto ezimbili noma ngaphezulu ezihlukene ukuze kwakhiwe into entsha enezakhiwo ezithile. Ama-composites asetshenziselwa izinhlelo zokusebenza lapho amandla aphezulu nokuqina kuyadingeka. Izinhlanganisela ezijwayelekile ezisetshenziswa ekubumbeni umjovo zifaka amapulasitiki aqiniswe ngengilazi (GRP) kanye namapulasitiki aqiniswe nge-carbon fiber (CFRP).

- Amapulasitiki agcwele insimbi amapulasitiki afakwe izinhlayiya zensimbi ukuze enze izinto ezinogesi ophezulu kanye ne-thermal conductivity nezinye izinto ezithile. Amapulasitiki agcwele insimbi asetshenziselwa izinhlelo zokusebenza ezinomshini odingekayo kagesi noma oshisayo. Amapulasitiki ajwayelekile agcwele insimbi asetshenziswa ekubumbeni umjovo ahlanganisa amapulasitiki agcwele ithusi namapulasitiki agcwele i-nickel.

Sekukonke, ukukhethwa kwezinto zokubumba umjovo kuncike ezidingweni ezithile zomkhiqizo wokugcina, okuhlanganisa amandla, ukuguquguquka, ukuqhutshwa komsebenzi, nokuqina. Abakhiqizi bavame ukukhetha izinto ezisetshenziswayo ngokuya ngezindleko, ukutholakala, ukucutshungulwa kalula, kanye nezakhiwo ezidingekayo zomkhiqizo wokugcina.

Izinto okufanele zicatshangelwe lapho ukhetha into yokubumba umjovo

Ukukhetha impahla efanelekile kubalulekile uma kuziwa ekubumbeni umjovo, njengoba kungathinta izakhiwo nokusebenza komkhiqizo wokugcina. Nazi ezinye zezinto okufanele uzicabangele lapho ukhetha into yokubumba umjovo:

- Izici zemishini: Enye yezinto ezibaluleke kakhulu okufanele zicatshangelwe lapho kukhethwa impahla yimishini yayo. Lokhu kuhlanganisa amandla ayo, ukuqina, ukuqina, nokumelana nokuguga. Izakhiwo zemishini ezidingekayo zomkhiqizo wokugcina zizoncika ekusetshenzisweni nasekucindezelekeni umkhiqizo ozovezwa kukho.

- Izici ezishisayo: Izici ezishisayo zempahla nazo zibalulekile, ikakhulukazi uma umkhiqizo wokugcina uzochayeka emazingeni okushisa aphezulu noma ukuhamba ngebhayisikili okushisayo. Lokhu kufaka iphoyinti lokuncibilika kokokusebenza, ukuqhutshwa kwe-thermal, kanye ne-coefficient yokunwetshwa kwe-thermal.

- Ukumelana namakhemikhali: Uma umkhiqizo wokugcina uchayeka kumakhemikhali, ukukhetha into engamelana nokuwohloka kwamakhemikhali kubalulekile. Izinto ezisetshenziswayo kufanele zimelane nokuchayeka kuma-asidi, izisekelo, izinyibilikisi, namanye amakhemikhali ngaphandle kokubhidliza noma ukulahlekelwa izakhiwo zawo.

- Izici zemvelo: Izinto zemvelo, ezifana nomswakama nokuchayeka kwe-UV, zingathinta izici nokusebenza kwento. Kubalulekile ukucabangela izimo zemvelo zomkhiqizo wokugcina bese ukhetha into engakwazi ukumelana nazo.

- Izindleko: Izindleko zempahla nazo ziwukucatshangelwa okubalulekile, ikakhulukazi ekugijimeni kokukhiqizwa kwevolumu ephezulu. Izindleko zempahla kufanele zikalwe ngokusebenza kwayo kanye nezakhiwo ukuze kuqinisekiswe ukuthi ukukhetha okungabizi kakhulu komkhiqizo wokugcina.

- Izidingo zokucubungula: Izidingo zokucubungula zento ethile zingaphinda zibe nomthelela ohlelweni lokukhetha. Ezinye izinto zingase zidinge imishini ethile yokucubungula noma amasu, kanti ezinye zingase zibe nzima kakhulu ukuzicubungula. Izidingo zokucubungula kufanele zicatshangelwe ukuze kuqinisekiswe ukuthi impahla ingasetshenziswa ngempumelelo enqubweni yokubumba umjovo.

- Ukuthobela imithetho: Okokugcina, kubalulekile ukucabangela noma yiziphi izimfuneko zokulawula okufanele uhlangabezane nazo umkhiqizo wokugcina. Ezinye izimboni, njengezimboni zezokwelapha nezokudla, zinemithetho eqondile yezinto ezisetshenziswa emikhiqizweni yazo. Ukukhetha into ehlangabezana nalezi zidingo zokulawula kubalulekile ukuze uqinisekise ukuthi umkhiqizo wokugcina uphephile futhi uyathobela.

Sekukonke, ukukhetha izinto ezifanele zokubumba umjovo kudinga ukucatshangelwa ngokucophelela kwezinto ezihlukahlukene, okuhlanganisa izakhiwo zemishini nezokushisa, ukumelana namakhemikhali, izici zemvelo, izindleko, izidingo zokucubungula, nokuhambisana nomthetho. Abakhiqizi kufanele balinganise lezi zici ngokuqhathanisa ukuze bakhethe into ewufanela kangcono umkhiqizo wokugcina.

Ukubaluleka kokwakhiwa kwesikhunta ekubumbeni umjovo

Ukwakhiwa kwesikhunta kuyisici esibalulekile senqubo yokubumba umjovo. Ukwakheka kwesikhunta kungathinta ikhwalithi yomkhiqizo wokugcina, kanye nokusebenza kahle kanye nempumelelo yezindleko zenqubo yokukhiqiza. Nazi ezinye zezizathu zokuthi kungani ukubunjwa kwesikhunta kubalulekile ekubumbeni umjovo:

- Ikhwalithi yomkhiqizo: Idizayini yesikhunta ingathinta ikhwalithi yomkhiqizo wokugcina. Uma isikhunta singaklanywanga ngendlela efanele, singaphumela ekulimaleni okufana ne-warping, ama-sink marks, kanye ne-flash. Lezi ziphambeko zingenza umkhiqizo wokugcina ungasebenziseki, unciphise ukusebenza, futhi ukhuphule amanani okulahlwa kanye nezindleko zokukhiqiza.

- Ukusebenza kahle kokukhiqiza: Ukwakheka kwesikhunta nakho kungathinta ukusebenza kahle kwenqubo yokukhiqiza. Uma isikhunta singakhelwanga ukugeleza nokupholisa okufanele, singaholela ezikhathini zomjikelezo omude, ukusetshenziswa kwamandla okwandayo, kanye nokuncipha kokusebenza. Idizayini yesikhunta elungiselelwe ingathuthukisa ukusebenza kahle futhi yehlise izindleko zokukhiqiza.

- Ukusebenza kahle kwezindleko: Idizayini yesikhunta nayo ingathinta ukusebenza kahle kwezindleko zenqubo yokubumba umjovo. Isikhunta esiklanywe kahle singanciphisa udoti wezinto ezibonakalayo, sithuthukise ikhwalithi yengxenye, futhi sandise ukuphuma, sinciphise izindleko zokukhiqiza. Ukwengeza, isikhunta esiklanyelwe ukukhiqizwa kwevolumu ephezulu singanciphisa izindleko ngengxenye ngayinye futhi sikhulise imbuyiselo yokutshalwa kwezimali.

- Ukwenza ngokwezifiso: Idizayini yesikhunta nayo idlala indima ebalulekile ekwenziweni ngokwezifiso komkhiqizo wokugcina. Ngokudizayina isikhunta sobumo nezici ezithile, abakhiqizi bangakha imikhiqizo efanelana nezidingo zamakhasimende abo. Lokhu kuvumela ukuguquguquka okukhulu kanye nokwehluka emakethe, okuholela ekwandiseni ukwaneliseka kwamakhasimende kanye nokwethembeka.

- Ukukhethwa kwempahla: Idizayini yesikhunta nayo ingathonya ukukhethwa kwezinto ezisetshenziswa ekubumbeni umjovo. Indlela yokubumba ingathinta ukugeleza nokupholisa kwempahla, okungaba nomthelela emishinini nasemizimbeni eshisayo yomkhiqizo wokugcina. Ngokukhetha idizayini yesikhunta elungile, abakhiqizi bangathuthukisa ukukhetha kwezinto ezibonakalayo futhi baqinisekise ukuthi umkhiqizo wokugcina uhlangabezana nezidingo zokusebenza ezifiselekayo.

Sekukonke, ukwakheka kwesikhunta kuyisici esibalulekile enqubweni yokubumba umjovo. Isikhunta esiklanywe kahle singathuthukisa ikhwalithi yomkhiqizo, ukusebenza kahle kokukhiqiza, ukuphumelela kwezindleko, ukwenza ngokwezifiso, nokukhethwa kwezinto ezibonakalayo. Abakhiqizi kufanele batshale isikhathi kanye nezinsiza ekuklameni isikhunta esilungiselelwe izidingo zabo ezithile ukuze bathole imiphumela engcono kakhulu enqubweni yokubumba umjovo.

Izinhlobo ezahlukene zokubumba ezisetshenziswa ekubumbeni umjovo

Ukubumba umjovo kuyinqubo yokukhiqiza eguquguqukayo engakhiqiza imikhiqizo ehlukahlukene yepulasitiki. Isici esisodwa esibalulekile esinquma ikhwalithi nokusebenza kahle komjovo wokubumba uhlobo lwesikhunta esisetshenzisiwe. Nazi ezinye zezinhlobo ezahlukene zokubumba ezisetshenziswa ekubumbeni umjovo:

- Isikhunta esinamapuleti amabili: Isikhunta esinamapuleti amabili isikhunta esivame ukusetshenziswa kakhulu ekubumbeni umjovo. Aqukethe amapuleti amabili ahlukaniswe isikhunta. Izinto zepulasitiki zijova emgodini, kuhlanganiswe amapuleti amabili ukuze enze umkhiqizo wokugcina.

- Isikhunta esinamapuleti amathathu: Ukubunjwa kwamapuleti amathathu kufana nokubunjwa kwamapuleti amabili kodwa kunepuleti eyengeziwe ehlukanisa uhlelo lomgijimi nengxenye ebunjiwe. Lokhu kuvumela ukukhishwa okulula kwengxenye futhi kunganciphisa isikhathi somjikelezo.

- Isikhunta somgijimi oshisayo: Isikhunta somgijimi oshisayo sisetshenziselwa ukugijima kokukhiqizwa kwevolumu ephezulu, njengoba singanciphisa isikhathi somjikelezo kanye nokuchithwa kwezinto ezibonakalayo. Isikhunta siqukethe isimiso somgijimi esishisayo esiletha ipulasitiki encibilikisiwe ngokuqondile emgodini wesikhunta, eqeda isidingo somgijimi obandayo.

- Isikhunta somgijimi obandayo: Isikhunta somgijimi obandayo siwuhlobo oluyisisekelo kakhulu lwesikhunta futhi luhlanganisa umhluzi, abagijimi, kanye nesikhunta. Ipulasitiki encibilikisiwe ijova emthini, efaka ipulasitiki kuma-runner bese ingena emgodini wesikhunta.

- Isikhunta somndeni: Isikhunta somndeni sikhiqiza izingxenye eziningi ngomjikelezo owodwa. Isikhunta siqukethe imigodi eminingi, ngayinye enengxenye ehlukile. Isikhunta somndeni sivame ukusetshenziselwa izingxenye ezincane, ezinomthamo omkhulu.

- Isikhunta sesitaki: Isikhunta sesitaki sikhiqiza izendlalelo eziningi zepulasitiki ngomjikelezo owodwa. Isikhunta siqukethe izingqimba eziningi zemigodi, enqwabelene phezu kwenye. Ipulasitiki ijova emigodini, bese izingqimba zibe sezihlanganiswa ukuze zenze umkhiqizo owodwa, onezingqimba eziningi.

- Faka isikhunta: Faka isikhunta sisetshenziselwa ukufaka izingxenye zensimbi noma zepulasitiki engxenyeni ebunjiwe ngesikhathi sokubumba. Okushuthekayo kufakwa emgodini wesikhunta ngaphambi kokuba upulasitiki ujovwe, bese upulasitiki uzungeza okufakwayo.

Sekukonke, uhlobo lwesikhunta esisetshenziswa ekubumbeni umjovo luncike ezidingweni ezithile zomkhiqizo okhiqizwayo. Ngokukhetha uhlobo olulungile lwesikhunta, abakhiqizi bangathuthukisa ukusebenza kahle kwenqubo yokubumba umjovo, ikhwalithi, kanye nokusebenza kahle kwezindleko.

Izindlela ezihamba phambili zokubumba umjovo

Ukubumba umjovo kuyinqubo yokukhiqiza eyinkimbinkimbi edinga ukuhlela ngokucophelela nokwenza ukufeza imiphumela oyifunayo. Nazi ezinye izinqubo ezihamba phambili zokubumba umjovo ezingasiza ukuqinisekisa ikhwalithi ephezulu, ukusebenza kahle, nokusebenza kahle kwezindleko:

- Idizayini yokwenziwa komkhiqizo: Idizayini yomkhiqizo kufanele ithuthukiselwe ukubumba umjovo. Lokhu kuhlanganisa ukunciphisa inani lezingxenye, ukuqinisekisa ukujiya kodonga olufanayo, nokugwema ama-undercuts nezinye izici ezenza kube nzima ukubumba.

- Ukukhethwa kwempahla: Izinto ezisetshenziswa ekubumbeni umjovo kufanele zikhethwe ngokuya ngezidingo zomkhiqizo. Izinto ezifana nezakhiwo zemishini, izakhiwo ezishisayo, nokumelana nemvelo kufanele kubhekwe.

- Idizayini yesikhunta: Idizayini yesikhunta kufanele ilungiselelwe umkhiqizo othile. Lokhu kuhlanganisa ukuqinisekisa ukupholisa okufanele, ukungenisa umoya, nokufaka isango, kanye nokukhetha uhlobo olufanele lwesikhunta.

- Imingcele yomjovo: Imingcele yomjovo, njengokucindezela komjovo, izinga lokushisa, kanye nesivinini, kufanele ilawulwe ngokucophelela futhi iqashwe ukuze kuqinisekiswe ikhwalithi ephezulu kanye nokuvumelana.

- Ukunakekela: Umshini wokubumba umjovo ovamile kanye nokugcinwa kwesikhunta kubalulekile ukuze kuqinisekiswe ukusebenza kahle nokuvimbela isikhathi sokuphumula.

- Ukulawulwa kwekhwalithi: Ukulawulwa kwekhwalithi kufanele kusetshenziswe kuyo yonke inqubo yokubumba umjovo, kusukela ekuhlolweni kwempahla engenayo kuya ekuhlolweni kokugcina komkhiqizo. Lokhu kufaka phakathi izinkinga zokuqapha ezifana ne-warpage, ama-sink marks, ne-flash.

- Ukuthuthukiswa kwenqubo: Ukuthuthukiswa kwenqubo eqhubekayo kufanele kube ukugxila okuyinhloko kokusebenza kokubumba umjovo. Lokhu kufaka phakathi amamethrikhi okusebenza kwenqubo yokuqapha njengesikhathi somjikelezo, isilinganiso se-scrap, kanye nokusetshenziswa komshini nokwenza izinguquko njengoba kudingeka ukuze kuthuthukiswe ukusebenza kahle nekhwalithi.

Sekukonke, ukubumba umjovo kudinga ukunakwa ngokucophelela emininingwaneni kanye nokugxila ekuthuthukisweni okuqhubekayo. Ngokulandela izindlela ezingcono kakhulu zokubumba umjovo, abakhiqizi bangaqinisekisa ikhwalithi ephezulu, ukusebenza kahle, kanye nokusebenza kahle kwezindleko futhi bakhiqize imikhiqizo yepulasitiki yekhwalithi ephezulu ehlangabezana nezidingo zamakhasimende abo.

Izinyathelo zokulawula ikhwalithi zokubumba umjovo

Ukulawulwa kwekhwalithi kubalulekile ekubumbeni umjovo, njengoba kuqinisekisa ukuthi umkhiqizo wokugcina uhlangabezana nemininingwane edingekayo kanye namazinga. Nazi ezinye izindlela zokulawula ikhwalithi zokubumba umjovo:

- Ukuhlolwa kwezinto ezingenayo: Inqubo yokulawula ikhwalithi kufanele iqale ngokubuyekezwa kwempahla eluhlaza esetshenziselwa ukubumba umjovo. Lokhu kuhlanganisa nokuqinisekisa ukuthi okokusebenza kuwuhlobo olulungile, ibanga, nombala futhi kuhlangabezana nezicaciso ezidingekayo zemishini nezakhiwo ezishisayo.

- Ukuhlola okusacutshungulwa: Ngesikhathi sokubumba umjovo, izisebenzi zokulawula ikhwalithi kufanele zihlale zihlola umkhiqizo ukuze ziqinisekise ukuthi ulolongwa ngendlela efanele. Lokhu kufaka phakathi ukuqapha amaphutha afana nama-sink marks, i-warping, ne-flash kanye nokuqinisekisa ukuthi umkhiqizo uhlangabezana nokubekezelelana kobukhulu obudingekayo.

- Ukuhlolwa komkhiqizo wokugcina: Uma inqubo yokubumba umjovo isiqediwe, umkhiqizo wokugcina kufanele uhlolwe ukuze kuqinisekiswe ukuthi uhlangabezana nemibandela edingekayo kanye namazinga. Lokhu kufaka phakathi ukuqinisekisa ukuthi umkhiqizo awunazo iziphambeko, njengokuqhekeka, amabhamuza, nama-voids futhi uhlangabezana nokubekezelela kobukhulu obudingekayo.

- Ukulawulwa kwenqubo yezibalo: Ukulawulwa kwenqubo yezibalo (SPC) kuyindlela yokuqapha nokulawula inqubo ukuze kuqinisekiswe ukuthi ikhiqiza imiphumela yekhwalithi ephezulu engashintshi. I-SPC ihlanganisa ukuqoqa idatha kumapharamitha wenqubo ebalulekile, njengokucindezela komjovo nezinga lokushisa, nokusebenzisa ukuhlaziya kwezibalo ukuze kuhlonzwe amathrendi namaphethini abonisa ukuhlukahluka kwenqubo.

- Ukuthuthukiswa okuqhubekayo: Ukulawulwa kwekhwalithi kufanele kube inqubo eqhubekayo yokuthuthukisa njalo. Lokhu kufaka phakathi ukuhlaziya idatha yokusebenza kwenqubo, ukuhlonza izindawo okufanele zithuthukiswe, nokwenza izinguquko kunqubo ukuze kuthuthukiswe ikhwalithi nokusebenza kahle.

- Ukubhalwa nokulandeleka: Izisebenzi ezilawula ikhwalithi kufanele zigcine imibhalo enemininingwane yenqubo yokubumba umjovo, okuhlanganisa amapharamitha enqubo, imiphumela yokuhlolwa, nezenzo zokulungisa. Lo mbhalo uhlinzeka ngokulandeleka futhi usiza ukuqinisekisa ukuthi noma yiziphi izinkinga zekhwalithi zingabonakala futhi zilungiswe ngokushesha.

Sekukonke, ukulawulwa kwekhwalithi kuyisici esibalulekile sokubumba umjovo futhi kufanele kuhlanganiswe kuzo zonke izici zenqubo yokukhiqiza. Ngokusebenzisa lezi zinyathelo zokulawula ikhwalithi, abakhiqizi bangakhiqiza imikhiqizo yepulasitiki yekhwalithi ephezulu ehlangabezana nezidingo zamakhasimende abo.

Amaphutha ajwayelekile ekubumbeni umjovo nendlela yokuwavimba

Ukubumba umjovo kuyinqubo eyinkimbinkimbi engaholela ekulimaleni uma isetshenziswe ngendlela engafanele. Nazi ezinye iziphambeko ezivamile ekubumbeni umjovo nokuthi ungazivikela kanjani:

- Ama-sink marks ama-depression noma ama-dent ebusweni bomkhiqizo. Zibangelwa ukupholisa okungalingani noma ukucindezelwa kokupakisha okunganele. Qinisekisa ukuthi idizayini yesikhunta ihlanganisa ukujiya kodonga olufanayo kanye nama-engeli asalungiswa anele ukuvimbela izimpawu zokucwila. Ukulungisa ingcindezi yokupakisha nesikhathi sokupholisa nakho kungasiza ekuvimbeleni ama-sink marks.

- I-Warpage: I-Warpage iwukuhlanekezelwa komkhiqizo ngemva kokuba ususiwe esikhunjeni. Kubangelwa ukupholisa okungalingani noma izingcindezi zangaphakathi emkhiqizweni. Ukuze uvimbele i-warpage, qinisekisa ukuthi umklamo wesikhunta uhlanganisa ukujiya kodonga olufanayo kanye nesikhathi esanele sokupholisa. Gwema amakhona abukhali noma izinguquko ezingazelelwe ku-geometry yomkhiqizo, ezingadala amaphuzu okucindezeleka.

- I-Flash: I-Flash ipulasitiki eyeqile edlula imingcele yomkhiqizo, ivamise ukwenzeka emaphethelweni esikhunta. Kubangelwa ukucindezela komjovo omningi, amandla okubamba anganele, noma isikhunta esigugile. Ukuze uvimbele i-flash, lungisa ingcindezi yomjovo namandla okubamba futhi uhlole njalo ukubunjwa ukuze uthole izimpawu zokuguga.

- Amashothi amafushane: Amashothi amafushane ayenzeka lapho isikhunta sigcwele ingxenye yepulasitiki. Lokhu kungabangelwa ukucindezela komjovo okunganele noma izinga lokushisa noma umgudu wokugeleza ovinjiwe noma okhawulelwe. Ukuze uvimbele ukushutha okufushane, lungisa ukucindezela komjovo kanye nezinga lokushisa, futhi uqinisekise ukuthi ishaneli yokugeleza icacile futhi ayiphazamiseki.

- Izimpawu zokushiswa: Izimpawu zokushiswa wukushintshashintsha kombala okumnyama endaweni yomkhiqizo okubangelwa ukushisa ngokweqile noma ukungqubuzana okukhulu kwesikhunta. Ukuze uvimbele izimpawu zokusha, qinisekisa ukuthi isikhunta sipholile ngokwanele futhi sigcotshiwe, futhi ulungise isivinini somjovo nokucindezela njengoba kudingeka.

- Izikhala namabhamuza: Izikhala namabhamuza yizindawo zomkhiqizo ezingenazo izinto noma eziqukethe amaphakethe omoya. Zibangelwa umoya ovalelwe noma igesi esikhunjeni noma ukugeleza kwezinto ezinganele. Ukuze uvimbele ama-voids namabhamuza, qinisekisa ukuthi isikhunta siphuma umoya ngendlela efanele nokuthi isivinini somjovo nokucindezela kwanele ukuqinisekisa ukugeleza kwezinto ezifanayo.

Amathiphu okunakekela imishini yokubumba umjovo

Imishini yokubumba umjovo iwutshalomali olukhulu kubakhiqizi, futhi ukunakekelwa okufanele kubalulekile ukuze kuqinisekiswe ukusebenza kahle nokuphila isikhathi eside. Nawa amanye amathiphu okulungisa imishini yokubumba umjovo:

- Yenza ukuhlola njalo: Hlola okokusebenza njalo ukuze ubone noma yikuphi ukuguga, umonakalo, noma ezinye izinkinga. Hlola amapayipi amanzi, izigxivizo, nezinye izakhi ezibalulekile ukuze uqinisekise ukuthi zisesimweni esihle.

- Hlanza futhi ugcobe okokusebenza: Hlanza futhi ugcobe okokusebenza njalo ukuze uvimbele ukugqwala nokuguga. Sebenzisa imikhiqizo enconyiwe yokuhlanza neyokugcoba, bese ulandela imiyalelo yomkhiqizi.

- Gada futhi ulondoloze uwoyela we-hydraulic: Waqaphe njalo ukuze uqiniseke ukuthi ahlanzekile futhi aku-viscosity efanele. Shintsha amafutha njengoba kudingeka, futhi usebenzise uhlobo lwamafutha olunconywayo.

- Gcina amabhande e-heater: Wahlole njalo ukuze uqinisekise ukuthi asesimweni esihle futhi ashisisa ngendlela efanele. Shintshanisa noma yimaphi amabhande eheater awonakele noma agugile ngokushesha.

- Gada futhi ugcine isistimu yokupholisa: Ibalulekile ekubumbeni umjovo, njengoba ivimbela ukushisa ngokweqile kanye ne-warpage. Gada isistimu yokupholisa njalo ukuze uqinisekise ukuthi isebenza kahle, futhi uhlanze iziteshi zokupholisa njengoba kudingeka.

- Abaqhubi bezitimela: Qeqesha o-opharetha ngokusebenza okufanele kwemishini kanye nezinqubo zokuyilungisa ukuze kuvinjelwe umonakalo nokuqinisekisa ukusebenza kahle.

- Hlela ukunakekelwa okujwayelekile: Misa uhlelo lokulungisa futhi unamathele kulo. Hlela imisebenzi yokunakekela evamile, efana nokuthambisa kanye nezinguquko zikawoyela, futhi ubhale yonke imisebenzi yokulungisa.

- Gcina izingxenye eziyisipele zisesandleni: Nikeza izingxenye eziyisipele, njengamapayipi asebenza ngogesi, ama-seal, namabhande we-heater. Lokhu kuzoshintsha ngokushesha izingxenye ezilimele noma ezigugile futhi kunciphise isikhathi sokuphumula.

Ukugcinwa kahle kwemishini yokubumba umjovo kubalulekile ukuze kuqinisekiswe ukuthi isebenza kahle, ikhiqiza imikhiqizo esezingeni eliphezulu, futhi inokuphila isikhathi eside. Ngokulandela lezi zeluleko zokulungisa, abakhiqizi bangagcina imishini yabo isesimweni esiphezulu futhi banciphise izindleko zokuphumula kanye nokulungisa.

Indlela yokukhetha umkhiqizi wokubumba umjovo ofanele

Ukukhetha umenzi wokubumba umjovo ofanele kuyisinqumo esibalulekile esingaba nomthelela omkhulu kwikhwalithi nezindleko zemikhiqizo yakho. Nazi ezinye izici okufanele uzicabangele lapho ukhetha umenzi wokubumba umjovo:

- Isipiliyoni nobungoti: Funa umkhiqizi onolwazi olunzulu kanye nobuchule bokubumba umjovo. Buza ngezinqubo zabo zokukhiqiza, izinyathelo zokulawula ikhwalithi, nezitifiketi.

- Ubuchwepheshe nemishini: Bheka umenzi osebenzisa ubuchwepheshe besimanje kanye nemishini. Lokhu kungasiza ekuqinisekiseni ikhwalithi engaguquki, izikhathi zokuhola ezimfushane, nokusebenza kahle kwezindleko.

- Izinto kanye namakhono: Cabangela izinhlobo zezinto umenzi angasebenza ngazo kanye namakhono azo. Bheka umkhiqizi ongakwazi ukuphatha inhlobonhlobo yezinto zokwakha, okuhlanganisa izinto eziyisipesheli, futhi ongakhiqiza izinhlobonhlobo zosayizi nokwakheka komkhiqizo.

- Izinyathelo zokulawula ikhwalithi: Bheka umkhiqizi ogxile kakhulu ekulawuleni ikhwalithi. Buza mayelana nezinyathelo zabo zokulawula ikhwalithi, ezifana nezinqubo zokuhlola nokuhlola, nanoma yiziphi izitifiketi abangaba nazo.

- Isevisi yamakhasimende: Bheka umkhiqizi ohlinzeka ngesevisi yamakhasimende enhle kakhulu. Cabangela ukusabela, ukuxhumana, kanye nokuzimisela ukusebenza nawe ukuze uhlangabezane nezidingo zakho ezithile.

- Izindleko nesikhathi sokuhola: Cabangela izindleko zomkhiqizi nesikhathi sokuhola sephrojekthi yakho. Bheka umkhiqizi onikeza amanani okuncintisana kanye nezikhathi zokuhola ezingokoqobo ezihlangabezana nezidingo zakho.

- Izinkomba nezibuyekezo: Cela izinkomba futhi uhlole ukubuyekezwa okuku-inthanethi komkhiqizi. Lokhu kungakusiza uthole umuzwa ongcono wesithunzi sabo kanye nolwazi lwamanye amakhasimende.

Ungakhetha umenzi wokubumba umjovo ofanele wephrojekthi yakho ngokubheka lezi zici futhi wenze ucwaningo olunzulu. Umkhiqizi ohloniphekile onesipiliyoni esifanele, amakhono, kanye nokuzinikela kwikhwalithi angasiza ekuqinisekiseni ukuthi imikhiqizo yakho ikhiqizwa kahle, ngendlela engabizi kakhulu, kanye nangemininingwane yakho ngqo.

Izindleko zokucatshangelwa ekubunjweni komjovo wepulasitiki wangokwezifiso

Ukubumba komjovo wepulasitiki okungokwezifiso kuyinqubo yokukhiqiza eguquguqukayo kakhulu engakhiqiza izingxenye eziyinkimbinkimbi, ezisezingeni eliphezulu esikalini. Nokho, ukucatshangelwa kwezindleko kuyisici esibalulekile ekusebenziseni le nqubo yokukhiqiza. Nazi ezinye zezindleko ezibalulekile ekubunjweni komjovo wepulasitiki wangokwezifiso:

- Izindleko zezinto ezibonakalayo: Uhlobo nenani lezinto ezisetshenziswa enqubweni yokubumba umjovo kuzothinta intengo. Ezinye izinto, njengamapulasitiki wobunjiniyela asebenza kahle kakhulu, zibiza kakhulu kunezinye. Izindleko zezinto zingaphinde zithintwe ukuphazamiseka kwe-supply chain, isidingo semakethe, nokuguquguquka kwentengo.

- Izindleko zamathuluzi: Izindleko zokusebenzisa amathuluzi, noma isikhunta esisetshenziselwa ukukhiqiza izingxenye, yizindleko ezinkulu ekubunjweni komjovo wepulasitiki ngokwezifiso. Ubunkimbinkimbi bengxenye, inani lemigodi ekubunjweni, nezinto ezisetshenziselwa ukwakha isikhunta konke kuzothinta izindleko zamathuluzi. Ukusebenzisa amathuluzi kungabiza kusengaphambili kodwa kungasiza ukwehlisa izindleko zeyunithi ngokuhamba kwesikhathi ngokwandisa ukusebenza kahle kokukhiqiza.

- Ivolumu yokukhiqiza: Ivolumu yezingxenye ezikhiqizwayo izoba nomthelela ezindlekweni zokubumba umjovo. Ukukhiqizwa kwevolumu ephezulu kungasiza ekunciphiseni izindleko zeyunithi, kuyilapho ukukhiqizwa kwevolumu ephansi kungase kube nezindleko zeyunithi ephakeme ngenxa yesidingo sokusebenza okwengeziwe nesikhathi sokusetha.

- Izindleko zabasebenzi: Izindleko zabasebenzi ziyisici esibalulekile ekubumbeni umjovo, ikakhulukazi izingxenye eziyinkimbinkimbi ezidinga umsebenzi wezandla owengeziwe. Izinga lekhono labaqhubi kanye nobunkimbinkimbi bengxenye kuzothinta izindleko zokulethwa.

- Izindleko zokulawula ikhwalithi: Ukugcina ukulawulwa kwekhwalithi kubalulekile ukuze kuqinisekiswe ubuqotho bezingxenye. Intengo yokulawula ikhwalithi ingabandakanya okokusebenza kokuhlola, ukuhlola, nabasebenzi.

- Izindleko zokuthumela: Ukuthumela izingxenye ekhasimendeni noma kwezinye izindawo kungaba yizindleko ezinkulu, ikakhulukazi ngemininingwane emikhulu noma esindayo.

Abakhiqizi bangakhiqiza izingxenye zekhwalithi ephezulu ngenani eliphansi ngokucabangela lezi zici zezindleko kanye nokuthuthukisa inqubo yokubumba umjovo. Lokhu kungafezwa ngokunciphisa udoti wezinto ezibonakalayo, ukwandisa ukusebenza kahle kokukhiqiza, nokunciphisa izikhathi zokusetha nokushintsha. Ukusebenza nomkhiqizi wokubumba umjovo onolwazi futhi onolwazi kungasiza ekuthuthukiseni inqubo futhi kunciphise izindleko.

Amathrendi kanye nezinto ezintsha kubuchwepheshe bokubumba umjovo

Ubuchwepheshe bokubumba umjovo sebuneminyaka eminingi bukhona, kodwa kusenezinto eziningi eziqanjiwe kanye nezitayela ezakha ikusasa lale nqubo yokukhiqiza. Nawa amanye amathrendi aphezulu kanye nezinto ezintsha kubuchwepheshe bokubumba umjovo:

- Ukuphrinta kwe-3D nokukhiqiza okungeziwe: Ukuphrinta kwe-3D nokukhiqiza okungeziwe kuya ngokuya kuduma embonini yokubumba umjovo. Lobu buchwepheshe buvumela ukudalwa komumo oyinkimbinkimbi namajiyometri okunzima noma okungenakwenzeka ukufinyelelwa ngokubumba komjovo ovamile.

- Ukubumba komjovo wezinto eziningi: Ukubumba komjovo wezinto eziningi kuvumela ukudalwa kwezingxenye ezinezinto eziningi noma imibala ngeshothi elilodwa. Le nqubo inganciphisa isikhathi sokukhiqiza nezindleko futhi idale imisebenzi enezakhiwo eziyingqayizivele nokubukeka.

- I-Automation kanye ne-Industry 4.0: Ubuchwepheshe be-Automation kanye ne-Industrial 4.0, njengezinzwa ze-IoT namarobhothi, buyahlanganiswa emishinini yokubumba umjovo nezinqubo. Lokhu kungathuthukisa ukusebenza kahle kokukhiqiza, kunciphise izindleko zabasebenzi, futhi kuthuthukise nokulawulwa kwekhwalithi.

- Izinto ezisimeme nezinqubo: Njengoba izinkampani zifuna ukunciphisa umthelela wazo kwezemvelo, izinto ezisimeme nezindlela zibaluleka kakhulu embonini yokubumba umjovo. Lokhu kubandakanya ukusebenzisa izinto ezingaboli noma ezigaywe kabusha kanye nezinqubo ezinciphisa ukumosha nokusetshenziswa kwamandla.

- Ukukhiqiza okuhlakaniphile nokulungiswa kokuqagela: Ubuchwepheshe bokukhiqiza obuhlakaniphile, obufana nokufunda komshini nokulungiswa okuqagelayo, busetshenziselwa ukuthuthukisa izinqubo zokubumba umjovo nokunciphisa isikhathi sokuphumula. Lokhu kungathuthukisa ukusebenza kahle sekukonke futhi kunciphise izindleko zokunakekela.

- Izinto ezisebenza kahle kakhulu: Izinto ezintsha ezisebenza kahle kakhulu ziyathuthukiswa ukuze zibunjwe umjovo, okuhlanganisa izinto ezinamandla athuthukisiwe, ukuqina, nokumelana nokushisa. Lezi zinto zingasetshenziswa ezinhlelweni ezihlukahlukene, kusukela ezingxenyeni zezimoto kuya kumishini yezokwelapha.

Ngokuhlala unolwazi lwakamuva ngalezi zitayela nezinto ezintsha, abakhiqizi bokubumba umjovo bangahlala bencintisana futhi baqhubeke nokuhlinzeka ngezingxenye zekhwalithi ephezulu kumakhasimende abo. Njengoba kuthuthukiswa ubuchwepheshe obusha nezinto zokwakha, imboni yokubumba umjovo izoqhubeka nokuvela futhi ijwayele ukuhlangabezana nezidingo eziguqukayo zabathengi namabhizinisi.

Ukusimama ekubumbeni umjovo: ukunciphisa ukumosha nokusetshenziswa kwamandla

Ukusimama kuya ngokuya kubaluleke kakhulu embonini yokubumba umjovo njengoba izinkampani zifuna ukunciphisa umthelela wazo kwezemvelo futhi zihlangabezane nesidingo esikhulayo semikhiqizo eco-friendly. Nazi ezinye izindlela abakhiqizi bokubumba umjovo abanganciphisa ukumosha nokusetshenziswa kwamandla:

- Sebenzisa izinto ezisimeme: Ukukhethwa kwempahla kuyisici esibalulekile ekusimameni. Abakhiqizi bokubumba umjovo bangasebenzisa izinto ezibolayo noma ezigaywe kabusha ukuze banciphise umthelela wendawo. Amapulasitiki angaboli, isibonelo, angabhidlika ngokwemvelo ngokuhamba kwesikhathi futhi anciphise inani lemfucuza ezindaweni zokulahla. Izinto ezigaywe kabusha, ezifana namapulasitiki agaywe kabusha ngabathengi, nawo angasiza ekunciphiseni ukumosha nokusetshenziswa kwamandla.

- Nciphisa udoti wezinto ezibonakalayo: Abakhiqizi bokubumba umjovo banganciphisa futhi udoti wezinto ezibonakalayo ngokuthuthukisa ukwakheka kwengxenye kanye nesikhunta. Lokhu kubandakanya ukunciphisa inani lezinto ezisetshenziswa ngokweqile, ukunciphisa inani lemigodi esikhunjeni, nokunciphisa isisindo sonke sengxenye. Ngokunciphisa udoti wezinto ezibonakalayo, abakhiqizi bangonga ezindlekweni zezinto ezibonakalayo futhi banciphise umthelela wabo kwezemvelo.

- Thuthukisa ukusebenza kahle kokukhiqiza: Abakhiqizi bokubumba umjovo bangathuthukisa izinqubo zabo zokukhiqiza ukuze banciphise ukusetshenziswa kwamandla. Lokhu kufaka phakathi ukusebenzisa imishini yokubumba yomjovo esebenza kahle kakhulu, ukwenza ngcono imingcele yenqubo yokubumba, nokunciphisa isikhathi sokuphumula. Ngokunciphisa ukusetshenziswa kwamandla, abakhiqizi bangonga ezindlekweni zamandla futhi banciphise i-carbon footprint yabo.

- Sebenzisa izinqubo ezisimeme: Abakhiqizi bokubumba umjovo bangasebenzisa izinqubo ezisimeme ekusebenzeni kwabo, njengokugaywa kabusha kanye nezinhlelo zokunciphisa imfucuza, ukusebenzisa imithombo yamandla avuselelekayo, kanye nokukhuthaza ukusimama phakathi kwabasebenzi babo nabahlinzeki. Ngokukhuthaza izinqubo ezisimeme kulo lonke uchungechunge lokunikezela, abakhiqizi bangasiza ukudala imboni esimeme kakhudlwana iyonke.

- Sebenzisa ukupakisha okusimeme: Okokugcina, abakhiqizi bokubumba umjovo bangasebenzisa izinto zokupakisha ezisimeme kanye nemiklamo ukunciphisa udoti nomthelela wemvelo. Lokhu kuhlanganisa ukusebenzisa izinto zokupakisha ezibolayo noma ezigaywa kabusha, ukunciphisa imfucumfucu yokupakisha, kanye nokuklama ukupakisha okungasebenziseka kabusha noma okugcwalisekayo.

Ngokusebenzisa lezi zinqubo ezisimeme, abakhiqizi bokubumba umjovo banganciphisa umthelela wabo kwezemvelo futhi bakhe imboni esimeme kakhudlwana iyonke. Njengoba ukuqina kuya ngokuya kubaluleke kakhulu kubathengi nakumabhizinisi, abakhiqizi bokubumba umjovo ababeka phambili ukusimama bazoba sesimweni esihle ukuhlangabezana nesidingo esikhulayo semikhiqizo eco-friendly.

Ukuthi ukubumba komjovo wepulasitiki okungokwezifiso kuqhathaniswa kanjani nezinye izinqubo zokukhiqiza

Ukubumba komjovo wepulasitiki okungokwezifiso kuyinqubo yokukhiqiza edumile yokukhiqiza izingxenye zepulasitiki zekhwalithi ephezulu ngobuningi. Kodwa-ke, ezinye izinqubo eziningana zokukhiqiza zingasetshenziswa ukwenza izingxenye zepulasitiki, ngayinye enezinzuzo kanye nokubi. Nasi isiqhathaniso sokubumba komjovo wepulasitiki ngokwezifiso nezinye izinqubo zokukhiqiza:

- Ukuphrinta kwe-3D: Ukuphrinta kwe-3D ubuchwepheshe obukhula ngokushesha obuvumela ukudalwa kobumo obuyinkimbinkimbi namajiyometri. Nakuba ukuphrinta kwe-3D kungasetshenziselwa ukukhiqiza okuncane, ukubumba umjovo ngokuvamile akubizi kakhulu futhi kusebenza kahle kunokubumba umjovo ukukhiqiza izingxenye ezinkulu.

- I-Blow Molding: I-Blow Molding iyinqubo yokukhiqiza eyenza izingxenye zepulasitiki ezingenalutho, njengamabhodlela neziqukathi. Nakuba i-blow molding ifaneleka ukukhiqiza izici eziningi, ukubumba komjovo ngokuvamile akunembeli kangako kunokubunjwa komjovo futhi kungase kungafaneleki ekudaleni izimo eziyinkimbinkimbi kakhulu namajiyometri.

- I-CNC Machining: I-CNC machining iyinqubo yokukhiqiza ekhiphayo ehlanganisa ukusika nokubumba izingxenye kusuka kubhlokhi eqinile yempahla. Ngenkathi ukwenziwa kwemishini ye-CNC kulungele ukukhiqiza izingxenye ezinemba okuphezulu ngamanani amancane, ngokuvamile akubizi kakhulu noma kusebenza kahle njengokubumba umjovo.

- Ukubumba Okujikelezayo: Ukubumba okujikelezayo kuyinqubo yokukhiqiza ebandakanya ukuzungezisa isikhunta esizungeze izimbazo ezimbili eziqondile ngenkathi siyishisa. Nakuba ukubumba okujikelezayo kungakhiqiza izingxenye ezinkulu ezinejometri eyinkimbinkimbi, ukubumba komjovo ngokuvamile akunembeli kangako kunokubumba umjovo futhi kungase kungafaneleki ukwenza izingxenye ezincane.

- I-Thermoforming: I-Thermoforming iyinqubo yokukhiqiza ehlanganisa ukushisa ishidi lepulasitiki bese libunjwa phezu kwesikhunta. Nakuba i-thermoforming ingakhiqiza izingxenye ezinkulu ezinamajiyometri alula, ukubumba umjovo ngokuvamile akunembe kangako kunokubumba umjovo futhi kungase kungafaneleki ukudala izimo eziyinkimbinkimbi kakhulu namajiyometri.

Ukubumba komjovo wepulasitiki okungokwezifiso kuyinqubo yokukhiqiza eguquguqukayo futhi engabizi kakhulu yokukhiqiza izingxenye zepulasitiki zekhwalithi ephezulu ngobuningi. Nakuba ezinye izinqubo zokukhiqiza zingase zifaneleke kangcono izinhlelo zokusebenza ezithile noma umthamo wokukhiqiza, ukubumba umjovo ngokuvamile kuyisinqumo esikhethwa kubakhiqizi abaningi ngenxa yejubane lakho, ukunemba, kanye nokusebenza kahle kwezindleko. Ekugcineni, ukukhetha kwenqubo yokukhiqiza kuzoncika ezintweni ezahlukahlukene, okubandakanya ukwakheka kwengxenye, umthamo wokukhiqiza, kanye nesabelomali.

Ubuhle nobubi bokubumba umjovo wangaphandle

Ukubumba umjovo we-Outsourcing kuwumkhuba ojwayelekile ezinkampanini ezifuna ukukhiqiza izingxenye zepulasitiki ngaphandle kokutshala imali emishini yazo yokubumba umjovo noma ubuchwepheshe. Nakuba ukukhishwa kwemisebenzi kunganikeza izinzuzo ezimbalwa, kuphinde kube nezihibe ezingaba khona. Nazi ezinye izinzuzo nezingozi zokukhipha umjovo wokubumba:

buhle:

- Ukonga Izindleko: Ukubunjwa komjovo wangaphandle ngokuvamile kubiza kakhulu kunokusetha indawo yokukhiqiza yangaphakathi. Lokhu kuyiqiniso ikakhulukazi ezinkampanini ezincane kuya kweziphakathi ezidinga imali eyengeziwe noma umthamo ukuze zithethelele ukutshala impahla ebizayo kanye nabasebenzi.

- Ubungcweti: Izinkampani zokubumba umjovo zisebenza ngokukhethekile ekukhiqizeni futhi zinekhono lokuqinisekisa ukuthi izingxenye zikhiqizwa ngezinga eliphezulu. Ngokukhipha umjovo wokubumba, izinkampani zingazuza kulwazi lochwepheshe abanolwazi.

- Amandla: Izinkampani zokubumba umjovo zingakhiqiza izingxenye eziningi ngokushesha nangempumelelo. Lokhu kuzuzisa kakhulu ezinkampanini okufanele zenze imiqulu emikhulu yezici.

- Ukuvumelana nezimo: Ukubunjwa komjovo wangaphandle kuvumela izinkampani ukuthi zivumelane nezimo ezinhlelweni zazo zokukhiqiza. Izinkampani zingalungisa umthamo wazo wokukhiqiza noma zishintshele ezingxenyeni ezihlukene ngaphandle kokukhathazeka ngezindleko ezinkulu zokushintsha imishini nokubunjwa.

bawo:

- Ukuxhumana: Ukubumba umjovo wangaphandle kungadala izinselelo zokuxhumana phakathi kwekhasimende nenkampani. Ukungaqondi kahle noma ukubambezeleka kokuxhumana kungadala amaphutha noma ukubambezeleka kokukhiqiza.

- Ukulawulwa Kwekhwalithi: Ukukhipha umjovo wokubumba kusho ukuthembela enkampanini yangaphandle ukukhiqiza izingxenye ezisezingeni elidingekayo lekhwalithi. Ukulawula ikhwalithi kungaba inselele lapho usebenza nenkampani yangaphandle, futhi kuhlale kunengozi yokwamukela izici okufanele zihlangabezane nezicaciso ezidingekayo.

- Ukuncika: Ukubumba umjovo wangaphandle kusho kuye ngenkampani yokukhiqiza yangaphandle. Lokhu kungadala ubungozi mayelana nokuthembeka, ukuzinza, kanye nezikhathi zokulethwa komphakeli.

- I-Intellectual Property: Ukukhishwa komjovo wokusebenza kungadala ubungozi bokuvikela impahla yengqondo. Izinkampani zidinga ukuqinisekisa ukuthi imiklamo nobuchwepheshe bazo zivikelwe izinyathelo ezifanele zomthetho.

Amathemba esikhathi esizayo wokubumba umjovo wepulasitiki wangokwezifiso

Ukubumba komjovo wepulasitiki okungokwezifiso bekuyinqubo yokukhiqiza ethembekile futhi eguquguqukayo amashumi eminyaka ambalwa. Eminyakeni yamuva nje, intuthuko kwezobuchwepheshe nezinto zokwakha iqhubekile nokuthuthukisa amakhono namandla okubumba umjovo. Nawa amanye amathemba esikhathi esizayo wokubumba umjovo wepulasitiki wangokwezifiso:

- Ukwamukelwa kobuchwepheshe be-Industrial 4.0: Ukuhlanganiswa kobuchwepheshe be-Industrial 4.0, obufana nobuhlakani bokwenziwa, ukufunda ngomshini, kanye ne-Intanethi Yezinto (IoT), kulindeleke ukuthi kukhuphule okuzenzakalelayo, kuthuthukise ukulawulwa kwekhwalithi, futhi kuthuthukise izinqubo zokukhiqiza ekubumbeni umjovo.

- Ukwenyuka kokusetshenziswa kwezinto ezibolayo: Ukukhathazeka ngemvelo kuqhuba ukwamukelwa kwezinto ezibolayo ekubunjweni komjovo. Izinto ezibolayo ezibolayo zinikeza enye indlela esimeme kumapulasitiki endabuko futhi zingasiza ekunciphiseni udoti nomthelela wemvelo.

- Isidingo esikhulayo sokwenziwa kwemishini yezokwelapha: Isidingo semishini yezokwelapha siyakhula ngenxa yokuguga kwabantu kanye nentuthuko kwezobuchwepheshe bezokwelapha. Ukubumba umjovo kuyinqubo yokukhiqiza edumile yamadivayisi ezokwelapha ngenxa yokunemba kwawo, isivinini, kanye nokusebenza kahle kwezindleko.

- Ukunwetshwa kwamakhono okuphrinta e-3D: Ukuthuthukiswa kobuchwepheshe bokuphrinta be-3D kwenze ukuba kukhiqizwe izingxenye eziyinkimbinkimbi neziyinkimbinkimbi ebezingenzeki ngaphambilini ukuthi zenziwe kusetshenziswa ukubumba komjovo. Kodwa-ke, ukuphrinta kwe-3D kusahamba kancane futhi kubiza kakhulu uma kuqhathaniswa nokubumba umjovo, futhi lobu buchwepheshe obubili cishe buzoqhubeka buphelelisana kunokuba bushintshe obubodwa.

- Ukwandisa ukubumba komjovo wezinto eziningi: Ukubumba umjovo wezinto eziningi kubandakanya ukusebenzisa izinto ezimbili noma ngaphezulu ezihlukene enqubweni yokubumba yomjovo owodwa. Lobu buchwepheshe bunikeza izinzuzo ezimbalwa, okuhlanganisa ukusebenza kwengxenye okuthuthukisiwe, isisindo esincishisiwe, nokonga izindleko.

- Intuthuko kubuchwepheshe bamathuluzi: Ukuthuthukiswa kwezinto ezintsha zamathuluzi nemiklamo kulindeleke ukuthi kukhuphule isivinini, ukusebenza kahle, kanye nokunemba kokubumba komjovo. Isibonelo, iziteshi zokupholisa ezihlelekile ekusetshenzisweni kwamathuluzi zingathuthukisa izikhathi zomjikelezo futhi zinciphise ukusetshenziswa kwamandla.

Isiphetho:

Ukubumba komjovo wepulasitiki okungokwezifiso kuyinqubo yokukhiqiza enamandla eyenza ukukhiqizwa kwezingxenye zepulasitiki zekhwalithi ephezulu ngokunemba okukhulu nokusebenza kahle. Ngokuqonda inqubo yokubumba umjovo, ukukhetha izinto ezifanele kanye nemiklamo yesikhunta, nokusebenzisa izindlela ezingcono kakhulu zokulawula ikhwalithi nokugcinwa kwemishini, amabhizinisi angakwazi ukuthuthukisa imisebenzi yawo yokubumba umjovo futhi azuze impumelelo enkulu. Njengoba amathrendi amasha kanye nezinto ezintsha zivela embonini, ukuhlala usesikhathini samanje nokuhlola amathuba amasha okuthuthukisa ukusimama, ukusebenza kahle, kanye nenzuzo yokubumba umjovo wepulasitiki ngokwezifiso kubalulekile.