Basics Of Plastic Injection Molding

Hlola inqubo yokubumba umjovo nokuthi isebenza kanjani.

Ukubumba komjovo wePlastiki kuyindlela edumile yokukhiqiza lapho ama-thermoplastic pellets aguqulwa abe amavolumu aphezulu ezingxenye eziyinkimbinkimbi. Inqubo yokubumba umjovo ifaneleka ezintweni ezihlukahlukene zepulasitiki futhi iyisici esibalulekile ekuphileni kwanamuhla—amakesi ezingcingo, izindlu zikagesi, amathoyizi, ngisho nezingxenye zezimoto bekungeke kwenzeke ngaphandle kwazo. Lesi sihloko sizohlukanisa izinto eziyisisekelo zokubumba umjovo, sichaze ukuthi ukubumba umjovo kusebenza kanjani, futhi kubonise ukuthi kuhluke kanjani ekuphrinteni kwe-3D.

Yiziphi Izisekelo Zokubumba Umjovo Wepulasitiki?

Izisekelo zenqubo yokubumba umjovo wepulasitiki zihlanganisa ukudala umklamo womkhiqizo, ukwenza ithuluzi libe isikhunta esilingana nomklamo womkhiqizo, ukuncibilikisa ama-pellets e-resin epulasitiki, kanye nokusebenzisa ingcindezi yokujova ama-pellets ancibilikisiwe esibunjeni.

Bona ukuhlukaniswa kwesinyathelo ngasinye ngezansi:

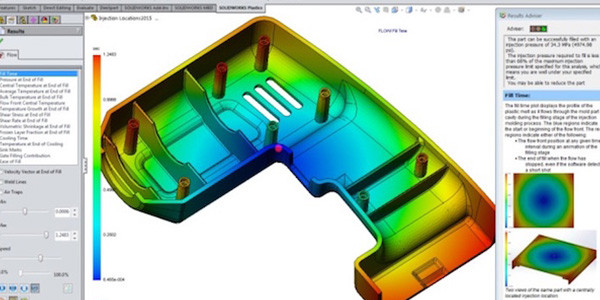

1. Ukudala Idizayini Yomkhiqizo

Abaklami (onjiniyela, amabhizinisi abenzi besikhunta, njll.) bakha ingxenye (ngefomethi yefayela le-CAD noma enye ifomethi edlulisekayo), belandela imihlahlandlela yokuklama ebalulekile eqondene nenqubo yokubumba umjovo. Abaklami kufanele bazame ukufaka izici ezilandelayo emiklamo yabo ukusiza ukukhulisa impumelelo yesikhunta sokujova epulasitiki:

*Abaphathi bokufaka/izibambiso ezinentambo

*Ukuqina kwezindonga ezihlala njalo noma eziseduze

*Izinguquko ezishelelayo phakathi kogqinsi oluguquguqukayo lwezindonga

*Izimbotshana ezingenalutho ezigabeni eziwugqinsi

*Imiphetho eyindilinga

*Ama-engeli asalungiswa ezindongeni eziqondile

*Izimbambo zosekelo

*Ukulingana kwefriction, amalunga e-snap-fit, nezinye izici zokujoyina ezingaqinisi

*Amahinji aphilayo

Ukwengeza, abaklami kufanele banciphise izici ezilandelayo ukuze banciphise amaphutha emiklamo yabo:

*Ukuqina kwezindonga ezingalingani noma ikakhulukazi izindonga ezincane/eziwugqinsi

*Izindonga eziqondile ezingenawo ama-engeli asalungiswa

*Izinguquko ezisheshayo zejiyomethri (amakhona, izimbobo, njll.)

*Izimbambo eziklanywe kabi

*Ama-undercuts/ama-overhangs

2. Ukwenza Isikhunta Sethuluzi Ukuze Silingane Umklamo Womkhiqizo

Omashini abanekhono eliphezulu nabenzi bamathuluzi, besebenzisa ukwakheka komkhiqizo, benza isikhunta samathuluzi somshini wokubumba umjovo. Isikhunta sokusebenza (esaziwa nangokuthi ithuluzi nje) yinhliziyo nomphefumulo womshini wokubumba umjovo. Aklanywe ngokucophelela ukuthi aqukathe umgodi ongemuhle womklamo womkhiqizo kanye nezici ezengeziwe ezifana nama-sprues, ama-runner, amasango, ama-vents, ama-ejector systems, iziteshi zokupholisa, nezinto ezihambayo. Izibunjwa zethuluzi zenziwe ngamabanga athile ensimbi ne-aluminium engakwazi ukumelana namashumi ezinkulungwane (futhi ngezinye izikhathi amakhulu ezinkulungwane) emijikelezo yokushisisa nokupholisa, efana ne-6063 aluminium, insimbi ye-P20, insimbi ye-H13, nensimbi engagqwali engu-420. Inqubo yokwenziwa kwesikhunta ithatha amaviki angaphezu kwangu-20 ukuqeda, okuhlanganisa kokubili ukwenziwa kanye nokugunyazwa, okwenza lesi sinyathelo sibe isici esinwetshiwe kakhulu sokubumba umjovo. Kuphinde kube ingxenye ebiza kakhulu yokubumba umjovo, futhi uma isikhunta samathuluzi senziwe, asikwazi ukuguqulwa kakhulu ngaphandle kokufaka izindleko ezengeziwe.

3. Ukuncibilikisa Amapellets e-Plastiki Resin

Ngemuva kokuthi opharetha bathole isikhunta esiphelile, sifakwa emshinini wokubumba umjovo, futhi isikhunta sivale, siqale umjikelezo wokubumba umjovo.

Ama-granules epulasitiki afakwa ku-hopper nasemgqonyeni. Isikulufu esiphindaphindayo sidonselwa emuva, okuvumela okokusebenza ukuthi kushelele esikhaleni phakathi kwesikulufu nomgqomo. Isikulufu sibe sesigxumela phambili, siphoqa okokusebenza emgqonyeni futhi sisondele kumabhande weheater lapho sincibilika khona sibe ipulasitiki encibilikisiwe. Izinga lokushisa elincibilikayo ligcinwa lingaguquki njengokucaciswa kwezinto ezibonakalayo ukuze kungabikho ukuwohloka okwenzeka emgqonyeni noma esikhunjeni ngokwaso.

4. Ukusebenzisa Ukucindezela Ukujova Ama-Pellet Ancibilikisiwe Esikhunjeni

Isikulufu esiphindaphindayo siphoqa le pulasitiki encibilikisiwe ngombhobho, ehlezi ngaphakathi kokudangala ekubunjweni okwaziwa ngokuthi i-mold sprue bushing. Ingcindezi ye-platen ehambayo ilingana nesikhunta kanye nombhobho ndawonye ngokuqinile, iqinisekisa ukuthi akukho pulasitiki ongaphuma. Ipulasitiki encibilikisiwe icindezelwa yile nqubo, ibangele ukuthi ingene kuzo zonke izingxenye zesikhunta futhi ikhiphe umoya we-cavity ngaphandle kwezikhala zesikhunta.

Izingxenye Zomshini Wokubumba Umjovo

Izingxenye zomshini wokubumba umjovo zifaka i-hopper, umgqomo, isikulufu esiphindaphindayo, i-heater(ama-heater), ipuleti elisuswayo, umlomo wombhobho, isikhunta, kanye nembobo yokukhunta.

Ulwazi olwengeziwe mayelana nengxenye ngayinye yokubumba umjovo ohlwini olungezansi:

*I-Hopper: imbobo lapho kufakwa khona ama-granules epulasitiki emshinini.

*Umphongolo: indlu yangaphandle yomshini wokubumba umjovo, oqukethe isikulufu esiphindaphindayo kanye nama-granules epulasitiki. Umgqomo usongwe ngamabhande amaningi we-heater futhi uboshwe ngombhobho oshisayo.

*Isikulufu esibuyiselanayo: ingxenye ye-corkscrew ehambisa futhi icindezele izinto zepulasitiki njengoba zincibilika emgqonyeni.

*Amahitha: eyaziwa nangokuthi amabhande okushisa, lezi zingxenye zinikeza amandla okushisa kuma-granules epulasitiki, ukuwaguqula asuke esimweni esiqinile abe uketshezi. ifomu.

*I-Plate Enyakazayo: Ingxenye enyakazayo exhunywe kumongo wesikhunta esebenza ingcindezi yokugcina womabili amahafu esikhunta angangeni moya futhi iphinde ikhiphe umongo wesikhunta lapho wembula ingxenye eqediwe.

*Nozzle: ingxenye eshisayo ehlinzeka ngokuphuma okujwayelekile kwepulasitiki encibilikisiwe emgodini wesikhunta, okugcina kokubili izinga lokushisa nokucindezela kuzinzile ngangokunokwenzeka.

*Isikhunta: ingxenye noma izingxenye eziqukethe isikhunta kanye nezici ezengeziwe ezisekelayo njengezikhonkwane zokuphuma, iziteshi zokugijima, iziteshi zokupholisa, izimbobo, njll. Okungenani, isikhunta sihlukaniswa sibe izingxenye ezimbili: uhlangothi olumile (eduze nomgqomo) kanye nesikhunta. umgogodla (epuletini elihambayo).

*Isikhunta Cavity: isikhala esingalungile lapho, lapho sigcwaliswa ngepulasitiki encibilikisiwe, sizosibumba sibe ingxenye yokugcina efiselekayo kanye nezisekelo, amasango, abagijimi, ama-sprues, njll.

Isebenza Kanjani Ukubumba Umjovo?

Uma ipulasitiki isigcwalise isikhunta okuhlanganisa ama-sprues ayo, abagijimi, amasango, njll., isikhunta sigcinwa ekushiseni okumisiwe ukuze kuvunyelwe ukuqina okufanayo kwezinto zibe yingxenye yomumo. Ukucindezela kokubamba kuyagcinwa ngenkathi kupholisa kokubili ukumisa ukugeleza okubuyela emuva emgqonyeni futhi kunciphise imiphumela enciphayo. Kuleli qophelo, ama-granules epulasitiki amaningi anezelwa ku-hopper ngokulindeleke umjikelezo olandelayo (noma ukudubula). Uma ipholile, i-platen iyavuleka futhi ivumele ingxenye eqediwe ukuthi ikhishwe, futhi isikulufu sidonselwa emuva futhi, okuvumela okubalulekile ukuthi kungene emgqonyeni futhi kuqale inqubo futhi.

Umjikelezo wokubumba umjovo usebenza ngale nqubo eqhubekayo-ukuvala isikhunta, ukondla / ukushisa ama-granules epulasitiki, ukuwacindezela ekubunjeni, ukupholisa kube ingxenye eqinile, ukukhipha ingxenye, nokuvala isikhunta futhi. Lolu hlelo luvumela ukukhiqizwa ngokushesha kwezingxenye zepulasitiki, futhi izingxenye zepulasitiki ezingaphezu kweziyi-10,000 zingenziwa ngosuku lokusebenza kuye ngomklamo, usayizi, kanye nempahla.

I-Djmolding iyizinkampani zokubumba umjovo wevolumu ephansi e-china.Inqubo yethu yokubumba umjovo wepulasitiki ikhiqiza ama-prototypes angokwezifiso kanye nezingxenye zokukhiqiza ezisetshenziswa ekugcineni ezinezikhathi zokuhola ngokushesha njengosuku olungu-1, umphakeli wengxenye ye-plastic injection yokubumba ingxenye ephansi kuze kufike ezingxenyeni eziyi-10000 ngonyaka.