I-High Volume Injection Molding

Ukubumba komjovo wevolumu ephezulu(Ukukhiqizwa Kwevolumu Ephezulu): Ukubumba komjovo wePlastiki

Njengoba ngaphezu kwezinkulungwane zezindawo zokubumba umjovo wepulasitiki kanye nezindawo zokukhiqiza zepulasitiki ongakhetha kuzo zonke izindawo, iziphi ezinye zezimfanelo eziphezulu ezenza inkampani yokubumba igqame? Lapho ukhetha umhlinzeki, izici eziningi okufanele zicatshangelwe; okuhlanganisa amakhono, ukuqinisekiswa kwekhwalithi, isithunzi senkampani, izindleko, nesikhathi sokulethwa. Ukuthola umshini wokubumba umjovo wepulasitiki ofanele ukuze uvumelane nezidingo zakho kungase kubonakale kudla isikhathi kodwa ukunquma izidingo zakho eziphansi neziphezulu zevolumu kuqala nokuthi zingashintsha kanjani ngokuhamba kwesikhathi, kuzokusiza ukunciphisa izinketho zakho.

Isevisi Ka-DJmolding Yokubumba Umjovo Wevolumu Ephezulu

Kwa-DJmolding, indawo yethu yokukhiqiza isezingeni eliphezulu, isebenza kahle ngemishini eminingana nabasebenza abanamakhono. Ngenxa yemishini yethu ehlukahlukene, singakwazi ukuphatha imisebenzi ehlukahlukene ehlukahluka kakhulu ezimbonini zazo, ikhwalithi yepulasitiki, kanye nenani lezicucu ezikhiqizwayo. Amavolumu aphansi futhi aphezulu, kusukela ekwakhiweni kuye kokukhiqiza, angaqedelwa ngaphakathi endlini okunikeza amakhasimende ethu izinzuzo zokuncintisana ngezindleko, ikhwalithi, kanye nezikhathi zokuhola.

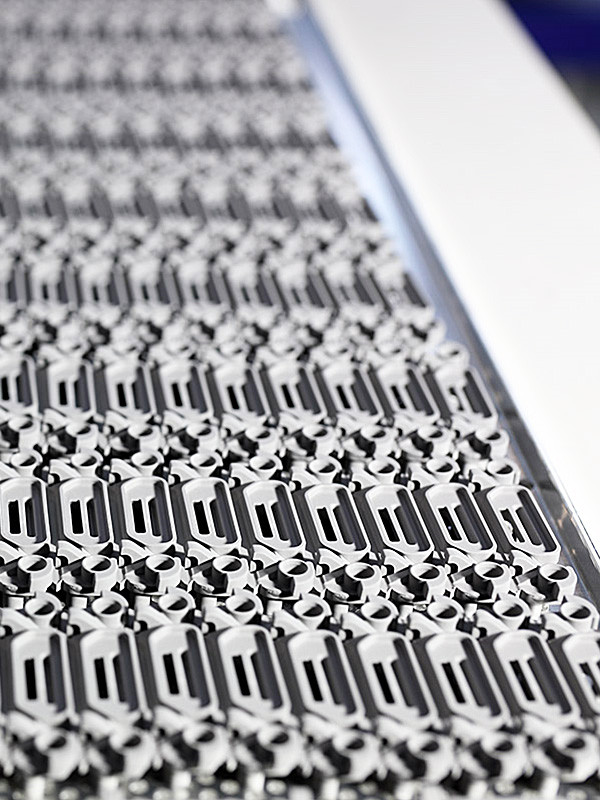

Ukubumba komjovo ka-DJmolding kuyindlela efakazelwe yokukhiqiza ivolumu ephezulu. Lena isevisi ekhethekile enikeza izingxenye ezigcwele zekhwalithi yokukhiqiza ngamavolumu afika ezigidini zezingcezu ngenyanga. Ukubunjwa komjovo wepulasitiki wevolumu ephezulu kuvumela ukunemba kokubekezelela okuphezulu, ukulahleka kwe-scrap okuphansi, nokonga izindleko.

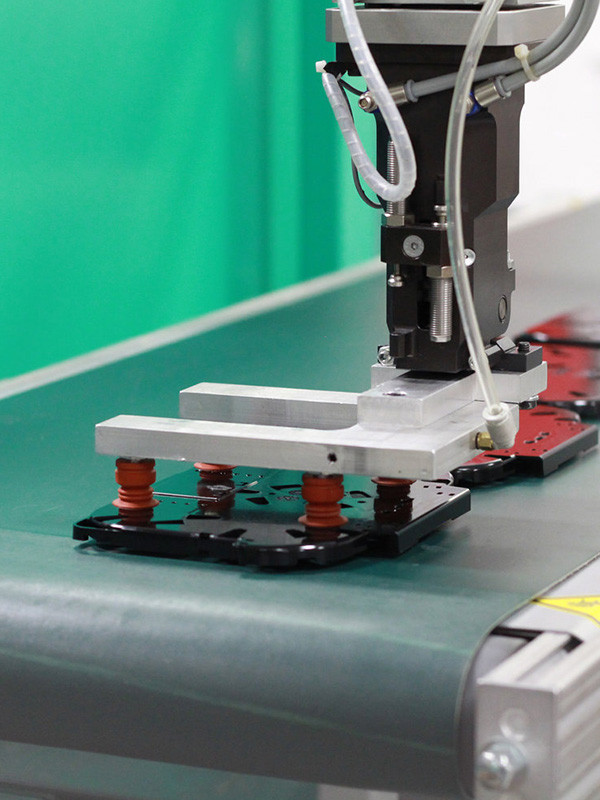

Imishini yethu eminingi yokubumba enevolumu ephezulu yenziwe ikhompuyutha futhi isebenzisa amasistimu emishini ukukhulisa ukusebenza kahle kanye nokuvikela ikhwalithi. Qiniseka ukuthi ubuka “Isistimu Yokulawula Ikhwalithi” yethu ukuze ubone ukuthi siqinisekisa kanjani ukuthi ukulawulwa kwekhwalithi kufakwa kukho konke ukukhiqizwa kwevolumu ephezulu. Lolu hlobo lokukhiqiza lulungele amabhizinisi aphakathi nendawo namakhulu noma ukukhiqizwa ngobuningi.

Izinzuzo Zokubumba Umjovo Wevolumu Ephezulu ka-DJmolding

*Ikhiqiza izingxenye eziningi ngesivinini esisheshayo

*Yehlisa izindleko zeyunithi nesikhathi somjikelezo womkhiqizi

*Ukukhiqizwa kwezingxenye okunembe nokungaguquguquki, okusezingeni eliphezulu

*Ukukhiqiza kuvame ukuzenzela ngemishini eqinile, ethembekile, ngisho nangamahora okungewona awomsebenzi

*Umsebenzi omncane wangemuva kokukhiqiza

Ukubumba Kwevolumu Ephakeme Ngokwezifiso (Imikhiqizo Yomjovo Wepulasitiki)

Ukubumba ngokwezifiso kuka-DJmolding kanye nokubumba kwevolumu ephezulu kufaka phakathi yonke into kusuka kuma-prototypes kuya enanini eligcwele lokukhiqiza. Izibungu zethu zevolumu ephezulu, kungakhathaliseki ukuthi zisebenza isikhathi esifushane, ivolumu ephezulu, noma i-multiple-cavity, ziyagadwa futhi zilawulwa ukuze uqiniseke ngazo zonke izici zokuklama nokwakhiwa kwesikhunta. Lokhu kunaka kwemininingwane yokukhiqiza kuqinisekisa izinjongo, izinjongo, kanye nemiphumela yephrojekthi esethiwe kuseshejulini kuso sonke isigaba senqubo. Konke ukubumba kwevolumu ephezulu, kusukela ekuklanyweni kuye kokukhiqiza, kuqedwa endlini futhi kunikeze amakhasimende ethu izinzuzo zokuncintisana ngezindleko, ikhwalithi, kanye nezikhathi zokuhola.

I-DJmolding isebenza neklayenti ukuklama kanye nemikhiqizo yobunjiniyela, ithuthukisa isikhunta sevolumu ephezulu esisebenza kahle kakhulu ukuze sisebenze kahle. Sihlinzeka ngokubumba kwevolumu ephezulu yekhwalithi ephezulu kakhulu embonini yokubumba umjovo wepulasitiki, enikeza inhlobonhlobo yezinsizakalo. Kusukela ekubumbeni ivolumu ephansi, ukufaka ukubumba, nokuphrinta iphedi, i-PTI, Inc. iwuphawu ongalethemba ngezinsizakalo zakho zokubumba umjovo wepulasitiki.

Izingxenye ze-DJmolding prototype zamakhasimende emikhakheni ehlukile njengezimboni zezokwelapha, zikagesi, zezandla, ezokuxhumana, nezimboni zezimoto. Kubandakanya ukucindezela komjovo nokucindezelwa okusukela ku-85-500 Ton, izinto eziningi zokubumba zevolumu ephezulu ze-DJmolding zenziwe ngekhompuyutha futhi zisebenzisa amasistimu emishini ukukhulisa ukusebenza kahle kanye nokuvikela ikhwalithi. Kwa-DJmolding sithatha isimo sengqondo sobambiswano kuwo wonke amabhizinisi, iletha iminyaka yolwazi lokubumba umjovo wepulasitiki nobungcweti bomsebenzi endaweni eklanyelwe ukuhlinzeka ngolwazi olunzulu lokubumba umjovo wepulasitiki.

Ukwakhiwa kwesikhunta esinevolumu ephezulu sidinga inhlanganisela yobuchwepheshe, izinto zokusebenza nabakhi besikhunta abaqeqeshiwe ukuze bakhe isikhunta sokujova ngokushesha ngejiyomethri ecishe ingenamkhawulo yezingxenye zepulasitiki.

Kusukela ekwakhiweni kuya ekulethweni, i-DJmolding ingaxhumanisa lonke uhlelo lwakho lokwakha amathuluzi kusukela ekuqaleni kuya ekugcineni. Isizwa uhlelo lwayo lokuqinisekisa ikhwalithi, umgomo we-PTI ukuhlinzeka ngemikhiqizo ebunjiwe ehlangabezana ngokugcwele noma eyeqa izimfuneko nokulindelwe amakhasimende ayo. Abaphathi benkampani bazibophezele ekuthuthukisweni kwekhwalithi okuqhubekayo. Ukuze uthole ikhwalithi ephezulu kanye nezinsiza ezisebenzayo zokubumba ivolumu ephezulu, xhumana ne-DJmolding. namuhla.

Izinkampani eziningi azinawo amandla okunikeza isiqalo esiphelele sokuqeda isipiliyoni sokwenza isikhunta. Noma ngabe ufuna ama-prototypes ambalwa asheshayo, izinkulungwane zamapulasitiki omthengi alungele imakethe, noma izingxenye zokukhiqiza eziyisigidi, i-DJmolding ingakunikeza okudingayo. Ivolumu ephansi futhi ephezulu, sigcizelela ngokuziqhenya ukuthi i-oda ngalinye lisezingeni elifanayo lezinga. Xhumana nochwepheshe bethu namuhla.

Kusukela ekwakhiweni kuya ekulethweni, i-DJmolding ingaxhumanisa lonke uhlelo lwakho lokwakha amathuluzi kusukela ekuqaleni kuya ekugcineni. Ukuze uthole ikhwalithi ephezulu kanye nezinsizakalo ezisebenza kahle, Cela Ikhotheshini ngokuthumela ulwazi lwakho ku info@jasonmolding.com

Inqubo yokukhiqiza yokubunjwa komjovo wevolumu ephezulu ikhiqiza izingxenye eziningi zepulasitiki ezifanayo. Le nqubo idumile ngoba iyonga, iyasebenza, futhi iletha izingcezu ezingaguquki, zekhwalithi ephezulu. Lokhu okuthunyelwe kwebhulogi kuzohlola konke okudingayo mayelana nokubumba komjovo wevolumu ephezulu, okuhlanganisa izinzuzo zako, ububi, izinhlelo zokusebenza, nokuningi.

Iyini i-High Volume Injection Molding?

Ukubumba komjovo wevolumu ephezulu kuyinqubo yokukhiqiza ekhiqiza izingxenye eziningi zepulasitiki ezifanayo. Inqubo ihilela ukujova izinto zepulasitiki ezincibilikisiwe endaweni yesikhunta ngokucindezela okukhulu namazinga okushisa, okuyivumela ukuthi iphole futhi iqine ibe yisimo oyifunayo. Le nqubo ezenzakalelayo ingakhiqiza izinkulungwane noma izigidi zezingxenye ezifanayo ngesikhathi sokukhiqiza esisodwa.

Inqubo yokukhiqiza esebenza kahle kakhulu iwukhiye wokuphumelela ekubumbeni umjovo wevolumu ephezulu. Le nqubo ihlanganisa ukusebenzisa imishini yokubumba umjovo wesivinini esikhulu kanye nezinhlelo ezizenzakalelayo ezivumela ukukhiqizwa okusheshayo nokunembayo kwezingxenye. Ukwengeza, abakhiqizi bangaqinisekisa ukuthi benza i-elementi ngayinye ngokucaciswayo ngokusebenzisa isikhunta sekhwalithi ephezulu nokusebenzisa imingcele ethile yomjovo.

Enye yezinzuzo ezibaluleke kakhulu zokubumba umjovo wevolumu ephezulu yikhono layo lokukhiqiza inani elikhulu lezingxenye ezifanayo ngokushesha futhi ngendlela engabizi kakhulu. Inqubo yokukhiqiza ilungele izimboni zezimoto, ezithengwayo, zemishini yezokwelapha nezikagesi.

Enye inzuzo yokubunjwa komjovo wevolumu ephezulu yikhono lokukhiqiza izingxenye eziyinkimbinkimbi ezinokubekezelelana okuqinile. Inqubo yokubumba umjovo inembile futhi ayiguquki, okuholela emininingwaneni eyinkimbinkimbi enomehluko omncane phakathi kwezingcezu.

Naphezu kwezinzuzo zayo eziningi, ukubumba komjovo wevolumu ephezulu kunemikhawulo ethile. Isibonelo, kungase kube nezinketho ezingcono zokukhiqiza izingxenye ezinkulu kakhulu noma ezincane, njengoba izindleko nobunkimbinkimbi bokubunjwa obudingekayo bungase buvimbele. Ukwengeza, umthamo omkhulu wepulasitiki ungaba nomthelela emvelweni, okwenza kube semqoka kubakhiqizi ukuthi bacabangele ukusimama kanye nemizamo yokuvuselela kabusha.

Ukubumba komjovo wevolumu ephezulu kuyinqubo yokukhiqiza esebenza kahle kakhulu futhi ephumelelayo engakhiqiza inani elikhulu lezingxenye ezifanayo zepulasitiki ngokushesha futhi ngendlela engabizi. Kuyisinqumo esifanelekile sezinhlobonhlobo zezimboni, futhi ukunemba kwayo nokuvumelana kwayo kuyenza ibe yisinqumo esidumile sokukhiqiza izingxenye eziyinkimbinkimbi ezinokubekezelelana okuqinile. Nakuba inokulinganiselwa okuthile, izinzuzo zokubumba umjovo wevolumu ephezulu zikwenza kube ithuluzi elibalulekile kubakhiqizi abafuna ukukhiqiza izingxenye ezinkulu zepulasitiki zekhwalithi ephezulu.

Isebenza Kanjani I-High Volume Injection Molding?

Inqubo ibandakanya izinyathelo ezimbalwa ezibalulekile, ngasinye esibalulekile ekukhiqizeni izingxenye zekhwalithi ephezulu. Lokhu okuthunyelwe kwebhulogi kuzochaza ukuthi ukubumba komjovo wevolumu ephezulu kusebenza kanjani, okuhlanganisa nezinyathelo zakho ezibalulekile nokucatshangelwa.

Isikhunta Design and Ukulungiselela

Isinyathelo sokuqala ekubumbeni umjovo wevolumu ephezulu ukuklama nokulungisa isikhunta abakhiqizi abazosisebenzisa ukukhiqiza izingxenye. Ukusebenzisana nomenzi wesikhunta kuyadingeka ukuze udale umklamo onembile ohlangabezana nayo yonke imininingwane ebalulekile yokwenza izingxenye ezidingekayo. Ngokuvamile, abakhiqizi benza isikhunta ngensimbi noma i-aluminium futhi bayiklame ukuze imelane nokucindezela okukhulu nokushisa kwenqubo yokubumba umjovo.

Ukulungiselela Izinto

Isinyathelo esilandelayo esokuba abakhiqizi balungise izinto zepulasitiki abazozisebenzisa ukukhiqiza izingxenye. Ukukhetha inhlaka yepulasitiki efanelekile kubalulekile ukuze udale izici ozifunayo, njengoba uhlobo lwe-resin esetshenziswayo luncike ezidingweni ezithile. I-resin ibe isifakwa emshinini wokubumba umjovo, ifudunyezwe, bese inyibilika ibe uketshezi.

Inqubo yokubumba umjovo

Inqubo yokubumba umjovo iqala lapho izinto zepulasitiki ezincibilikisiwe zijova emgodini wesikhunta ngokucindezela okukhulu kanye nezinga lokushisa. Isikhunta sivalwa ngaphansi kwengcindezi kuze kube yilapho ipulasitiki ipholile futhi iqina; kuleli phuzu, isikhunta siyavulwa, futhi ingxenye iyakhishwa.

Ikhwalithi yokulawula

Uma izingxenye sezikhiqiziwe, ziba nenqubo eqinile yokulawula ikhwalithi ukuze kuqinisekiswe ukuthi ziyahlangabezana nezidingo ezidingekayo. Lokhu kungase kuhlanganise ukuhlola okubonakalayo, ukukalwa, nokuhlola ukuze kuqinisekiswe ukuthi ingxenye ngayinye iyahambisana ngosayizi, umumo, kanye nekhwalithi.

Okucatshangelwayo kokubunjwa komjovo wevolumu ephezulu

Kunokucatshangelwa okuningana abakhiqizi okufanele bakukhumbule lapho besebenzisa ukubumba komjovo wevolumu ephezulu, okuhlanganisa:

- Ukukhethwa komshini: Imishini yokubumba umjovo wesivinini esiphezulu ijwayele ukusetshenziselwa ukugijima kokukhiqizwa kwevolumu ephezulu, njengoba ikwazi ukukhiqiza izingxenye ngokushesha nangokunembile.

- I-Mold Design: Idizayini yokubumba ibalulekile empumelelweni yenqubo yokubumba umjovo, njengoba kufanele ibe nenembile futhi ikwazi ukumelana nokucindezela okukhulu nokushisa kwenqubo.

- Ukukhetha Okubalulekile: Ukukhethwa kwe-resin yepulasitiki kungaba nomthelela kwikhwalithi nokusebenza kwezingxenye ezikhiqizwayo, okwenza kube semqoka ukukhetha okufanelekile komsebenzi.

- Izindleko: Nakuba ukubunjwa komjovo wevolumu ephezulu kuyinqubo yokukhiqiza engabizi kakhulu, kusenezindleko ezihlobene nokwakhiwa kwesikhunta, ukukhethwa kwempahla, nokukhiqizwa okufanele kucatshangelwe.

Izinzuzo zokubunjwa komjovo wevolumu ephezulu

Ukubunjwa komjovo wevolumu ephezulu kuye kwaguqula imboni yokukhiqiza ngokuvumela ukukhiqizwa kwezingxenye zepulasitiki ezifanayo ngamanani amakhulu ngesivinini esingenakuqhathaniswa nokusebenza kahle. Le nqubo isizuze ukuduma emikhakheni eyahlukene ngenxa yezinzuzo zayo eziningi, okuyenza ibe indlela yokukhiqiza yezinkampani ezifuna ukunciphisa izindleko, ukunciphisa ukumosha, nokwandisa umkhiqizo wokukhiqiza.

- Ukukhiqiza Okungabizi kakhulu: Ukubumba komjovo wevolumu ephezulu kusebenza kahle kakhulu futhi kuyazenzakalela, okwenza kungabizi kakhulu uma kuqhathaniswa nezinye izinqubo zokukhiqiza. Uma isikhunta sesiklanywe futhi sesilungisiwe, inqubo yokukhiqiza ingaqhubeka ngokuqhubekayo, ikhiqize izinkulungwane noma izigidi zezingxenye ezifanayo ezinezindleko ezincane zomsebenzi noma zezinto ezibonakalayo.

- Ukukhiqiza Okuphezulu: Ngemishini yokubumba umjovo wesivinini esikhulu, abakhiqizi bangakhiqiza izingxenye eziningi eziqondile ngesikhathi esifushane. Lokhu kusho ukuthi umkhiqizo wokukhiqiza ungakhula ngokushesha noma wehle ukuze uhlangabezane nesidingo esiguqukayo.

- Ikhwalithi Engaguquki: Ukunemba nokuvumelana kokubumba komjovo wevolumu ephezulu kuyenza ifaneleke ukukhiqiza izingxenye ezinokubekezelela okuqinile kanye nemininingwane eyinkimbinkimbi. Inqubo ivumela izinga eliphezulu lokunemba, iqinisekisa ukuthi ingxenye ngayinye ekhiqizwayo iyafana nezinye.

- Ukuhlukahluka Kumklamo Oyingxenye: Ukubumba komjovo wevolumu ephezulu kungakhiqiza izingxenye ezinohlu olubanzi lwemiklamo kanye nokwakheka, kufaka phakathi lezo ezinamajiyometri ayinkimbinkimbi. Lokhu kusho ukuthi abakhiqizi bangaba nezici ezihlangabezana nezidingo ezithile zekhasimende futhi bangalungisa kalula ukuklama noma izinguquko zokucaciswa komkhiqizo.

- Udoti Owehlisiwe: Ukusetshenziswa kwezibunjwa zekhwalithi ephezulu kanye nemingcele yomjovo enembile ekubunjweni komjovo wevolumu ephezulu kunciphisa inani le-scrap noma imfucuza ekhiqizwa ngesikhathi sokukhiqiza. Lokhu kusho ukuthi abakhiqizi bangenza izingxenye ezinodoti omncane wezinto ezibonakalayo, behlise izindleko kanye nomthelela wemvelo.

- Ukwenyuka Kwempumelelo Yokukhiqiza: Ukubumba komjovo wevolumu ephezulu kuzenzakalela kakhulu, okusho ukuthi kudinga umsebenzi omncane futhi kungasebenza ngokuqhubekayo ngokungenelela okuncane. Lokhu kuholela ekusebenzeni kahle kokukhiqiza, njengoba abakhiqizi bengakwazi ukukhiqiza izingxenye ngokushesha nangempumelelo ngaphandle kwesidingo somsebenzi wezandla noma ukugadwa.

Okubi kokubunjwa komjovo wevolumu ephezulu

Ukubumba komjovo wevolumu ephezulu kuyinqubo yokukhiqiza esetshenziswa kabanzi yokukhiqiza inqwaba yezingxenye ezifanayo zepulasitiki ngokushesha futhi ngendlela engabizi kakhulu. Nakuba inezinzuzo eziningi, njengokungabizi kahle kanye nekhwalithi engaguquki, kukhona futhi nokubi. Lokhu okuthunyelwe kwebhulogi kuzohlola ezinye zezinkinga zokubumba umjovo wevolumu ephezulu.

- Utshalomali Olukhulu Lokuqala: Enye yezinto ezimbi eziyinhloko zokubumba umjovo wevolumu ephezulu ukwanda kokutshalwa kwezimali kokuqala okudingekayo ukuze udizayine futhi wenze isikhunta. Lezi zindleko zingabaluleka, ikakhulukazi kumabhizinisi amancane noma lawo adinga isikhunta esingokwezifiso sezingxenye ezithile.

- Izikhathi Ezinde Zokuhola:Inqubo yokuklama nokukhiqiza isikhunta sokubumba umjovo wevolumu ephezulu ingathatha amasonto ambalwa noma ngisho izinyanga, okuholela ezikhathini zokuhola ezinde. Lokhu kungaba yingozi ezinkampanini ezidinga ukukhiqiza izingxenye ngokushesha noma ukuphendula izinguquko ezidingekayo.

- Izinketho zezinto ezilinganiselwe: Nakuba izinhlobo eziningi zama-resin epulasitiki zitholakala ekubunjweni komjovo wevolumu ephezulu, ukukhetha kungase kube nomkhawulo kuye ngohlelo oluthile. Amanye ama-resin epulasitiki angase angafaneleki ukukhiqizwa kwevolumu ephezulu ngenxa yezakhiwo zawo, ezingakhawulela ukukhetha kwezinto ezibonakalayo.

- Ukuvumelana Nokwakheka Okukhawulelwe: Ukubumba komjovo wevolumu ephezulu kuyinqubo enembayo edinga isikhunta ukuba siklanywe ngokucaciswa okuthile. Lokhu kusho ukuthi kungase kube nemikhawulo ekwakhiweni kwezingxenye ezikhiqizwa ngale nqubo, ikakhulukazi uma indawo inejometri eyinkimbinkimbi noma ezinye izidingo ezihlukile zedizayini.

- Izindleko Eziphezulu Zokulungisa Nokulungisa: Izibunjwa ezisetshenziswa ekubumbeni komjovo wevolumu ephezulu kufanele zigcinwe futhi zilungiswe njalo ukuze kuqinisekiswe ukusebenza kahle. Izindleko zokunakekelwa nokulungiswa zingaba nkulu, ikakhulukazi uma isikhunta sisetshenziswa njalo noma isikhathi eside.

Naphezu kwalezi zimbi, ukubumba komjovo wevolumu ephezulu kusalokhu kuyinqubo ethandwayo nephumelelayo yokukhiqiza ukukhiqiza inani elikhulu lezingxenye zepulasitiki ezifanayo. Ngokucubungula ngokucophelela izinzuzo nezinkinga zale nqubo, abakhiqizi bangenza izinqumo ezinolwazi mayelana nokuthi iwukukhetha okufanele yini ngezidingo zabo ezithile zokukhiqiza.

Izinto Ezisetshenziswa Ekubumbeni Umjovo Wevolumu Ephezulu

Ukukhetha izinto ezifanele zokubumba umjovo wevolumu ephezulu kubalulekile ukuze uqinisekise ikhwalithi nokusebenza komkhiqizo wokugcina. Lesi sihloko sicubungula izinto ezisetshenziswa ekubumbeni umjovo wevolumu ephezulu, izakhiwo zazo, kanye nezicelo zazo.

I-Polypropylene (PP)

I-Polypropylene iyi-polymer ye-thermoplastic evame ukusetshenziswa ekubunjweni komjovo wevolumu ephezulu ngenxa yezindleko zayo eziphansi, isilinganiso samandla kuya kwesisindo, nokuqina. I-PP isebenziseka ngezindlela eziningi ekukhiqizeni izimoto, ukupakisha, kanye nokukhiqizwa kwezimpahla zabathengi. Izinzuzo zokusebenzisa i-PP ekubumbeni umjovo zifaka imvelo yayo engasindi, ukumelana namakhemikhali, nokuzinza kwe-dimensional, okuyenza ilungele izingxenye ezinembayo.

I-Acrylonitrile Butadiene Styrene (ABS)

I-ABS iyipolymer ye-thermoplastic eyaziwa ngokuqina kwayo, ukumelana nomthelela, nokuqedwa kokucwebezela okuphezulu. Le nto isetshenziswa kakhulu kumathoyizi, izingxenye zezimoto, nasezindlini zikagesi. Ukumelana nomthelela we-ABS kuyenza ifaneleke imininingwane engaphansi komthelela noma ukushaqeka. Kulula futhi ukucutshungulwa futhi inomphetho omuhle kakhulu ongaphezulu, okuyenza ilungele ukugijima kokukhiqiza kwevolumu ephezulu.

I-Polycarbonate (PC)

I-Polycarbonate iyi-polymer ye-thermoplastic ekwazi ukumelana nomthelela, icacile ngokubonakalayo, futhi imelana nokushisa. Kuyinto edumile yezimboni zezimoto, i-aerospace, kanye ne-electronics. Izinzuzo ze-PC zifaka ukumelana okuhle kakhulu komthelela, ukucaca kokubonakalayo, nokumelana nokushisa, okuyenza ilungele izinhlelo zokusebenza ezishisa kakhulu, amalensi, nezikrini.

I-Polyethylene (PE)

I-Polyethylene iyi-polymer ye-thermoplastic eguquguqukayo, eqinile, futhi imelana namakhemikhali. Ivame ukusetshenziselwa ukukhiqiza izinto zokupakisha, izikhwama zepulasitiki, namafilimu ezolimo. Ukumelana namakhemikhali e-PE, ukuguquguquka, kanye nemvelo engasindi iyenza ilungele okokusebenza kwamakhemikhali, ukupakishwa kwamakhemikhali, kanye nezinhlelo zokusebenza ezidinga izingxenye ukuthi zigotshwe noma zigobe.

I-Polyethylene Terephthalate (PET)

I-PET iyi-polymer ye-thermoplastic enesilinganiso esiphakeme samandla-to-weight, ukucaca, kanye nezakhiwo zokuvimbela. Ikhiqiza amabhodlela eziphuzo, izitsha zokudla, nezinto zokupakisha. Izinzuzo ze-PET zifaka phakathi ibhalansi yayo yamandla-kuya-isisindo, ukucaca, kanye nezakhiwo zokuvimbela eziyenza ifanelekele izinhlelo zokusebenza lapho amandla edingeka khona, njengamabhodlela eziphuzo kanye nokupakishwa lapho okuqukethwe kufanele kuvikelwe kumswakama nomoya.

I-Polystyrene (PS)

I-Polystyrene iyi-polymer ye-thermoplastic engasindi, eyongayo futhi enezici ezinhle zokuvikela. I-PS ivamise ukusetshenziselwa ukukhiqiza izinkomishi ezilahlwayo, izinto zokupakisha, kanye nokufakwa kwensimbi, futhi izinzuzo zayo zihlanganisa izindleko eziphansi, imvelo engasindi, kanye nezakhiwo ezinhle zokugqumisa.

Izinhlobo Zemishini Yokubumba Yokujova Esetshenziselwa Ukukhiqizwa Kwevolumu Ephezulu

Le nqubo ihilela ukujova izinto zepulasitiki ezincibilikisiwe endaweni yesikhunta, lapho iqina futhi ithathe isimo sesikhunta. Imishini yokubumba yomjovo iza ngezinhlobo ezahlukene, futhi ngayinye ifanele uhlobo oluthile lokukhiqiza. Nazi izinhlobo eziphambili zemishini yokubumba umjovo esetshenziselwa ukukhiqizwa kwevolumu ephezulu:

- Imishini yokubumba yomjovo weHydraulic: Le mishini isebenzisa i-hydraulic pressure ukuze isuse isikhunta futhi ijove ipulasitiki encibilikisiwe emgodini. Zaziwa ngokukhiqiza kwazo okuphezulu kodwa futhi zinesikhathi somjikelezo ohamba kancane, ezikhawulela ukusetshenziswa kwazo ngokunemba okuphezulu nezinhlelo zokusebenza ezinesivinini esikhulu.

- Imishini yokubumba yomjovo kagesi: Le mishini isebenzisa ama-servo motors kagesi ukushayela iyunithi yomjovo kanye nesikhunta. Banikeza ukunemba okuphezulu nesivinini, okubenza balungele izimboni zobuchwepheshe obuphezulu ezifana nemishini yezokwelapha kanye ne-electronics.

- Imishini Yokubumba I-Hybrid Injection: Le mishini ihlanganisa okuhle kakhulu kwemihlaba yomibili. Basebenzisa i-hydraulic kanye nezinhlelo zikagesi ukushayela iyunithi yomjovo kanye nesikhunta. Izinjini ezihlanganisiwe zisebenza kahle futhi ziyashesha, zinomkhiqizo ophezulu ophumayo, okuzenza zilungele ukukhiqizwa kwevolumu ephezulu.

- Imishini Yokubumba Yokujova Okubili: Le mishini ikhiqiza izingxenye eziyinkimbinkimbi ezidinga izinto ezimbili ezihlukene noma imibala. Idivayisi inamayunithi amabili omjovo asebenza ndawonye ukuze enze ucezu lokugcina. Imishini yokubumba imijovo emibili ilungele ukukhiqiza imikhiqizo yekhwalithi ephezulu enezingxenye eziningi.

- Imishini Yokubumba Yokujova Okuningi:Le mishini ikhiqiza izingxenye ezenziwe ngezinto ezahlukene. Anamayunithi omjovo amaningi azivumela ukuthi zisebenzise ezinye izinto ngesikhathi esisodwa. Imishini yokubumba umjovo wezinto eziningi ilungele ukudala izingcezu ezidinga izakhiwo ezihlukile, njengamandla, ukuqina, nokuguquguquka.

- Imishini Yokubumba Yokujova Uketshezi: Le mishini isetshenziselwa ukukhiqiza izingxenye ezenziwe nge-liquid silicone rubber (LSR). Umshini ujova i-LSR emgodini wesikhunta, lapho uqina futhi uthatha isimo sesikhunta. Imishini yokubumba umjovo owuketshezi ilungele ukukhiqiza izingxenye ezidinga ukunemba okuphezulu nokuqina, njengamadivayisi ezokwelapha nezingxenye zezimoto.

Izinyathelo Zokubumba Umjovo Zokukhiqiza Ivolumu Ephezulu

Le nqubo ihilela ukujova izinto zepulasitiki ezincibilikisiwe endaweni yesikhunta, lapho iqina futhi ithathe isimo sesikhunta. Nazi izinyathelo ezibandakanyekayo kwinqubo yokubumba umjovo wokukhiqiza umthamo omkhulu:

- Ukukhetha Okubalulekile: Isinyathelo sokuqala senqubo yokubumba umjovo ukukhetha impahla efanelekile yokukhiqiza ingxenye. Impahla ekhethiwe kufanele ibe nezinto ezidingekayo, njengamandla, ukuqina, nokuguquguquka, futhi ihambisane nomshini wokubumba umjovo.

- I-Mold Design: Isinyathelo esilandelayo ukuklama isikhunta uma impahla isikhethiwe. Isikhunta kufanele silungiselelwe ngendlela eqondile yengxenye ekhiqizwayo, kuhlanganise nokuma kwayo, ubukhulu nezici zayo. Isikhunta kufanele futhi sicabangele uhlobo lomshini wokubumba umjovo osetshenziswayo kanye nezidingo ezithile zenqubo yokukhiqiza.

- Ukusethwa komshini: Ngemuva kokuthi isikhunta senziwe, umshini wokubumba umjovo uyamiswa. Lokhu kuhlanganisa ukunamathisela isikhunta kudivayisi, ukusetha izinga lokushisa elifanele nezilungiselelo zokucindezela, kanye nokuqinisekisa ukuthi yonke into isebenza ngendlela efanele.

- Umjovo: Inqubo yomjovo iqala lapho impahla yepulasitiki encibilikisiwe ijova emgodini wesikhunta. Lokhu kwenziwa kusetshenziswa iyunithi yomjovo womfutho ophezulu ophoqelela izinto ezibunjweni ngezinga elithile kanye nokucindezela.

- Ukupholisa:Ngemva kokuba impahla yepulasitiki encibilikisiwe ifakwe emgodini wesikhunta, kufanele ivunyelwe ukuba iphole futhi iqine. Lokhu kwenziwa ngokujikelezisa umoya opholile noma amanzi ngembobo yesikhunta ukunciphisa izinga lokushisa lempahla.

- Ukukhipha: Lapho izinto zepulasitiki sezipholile futhi zaqina, isikhunta siyavulwa, futhi ingxenye iyakhishwa. Inqubo ye-ejection ihilela ukusebenzisa i-mechanical noma i-hydraulic system ukusunduza ingxenye iphume emgodini wesikhunta.

- Ikhwalithi yokulawula: Ngemuva kokuthi ingxenye isikhishiwe, ingena ekuhlolweni kokulawulwa kwekhwalithi ukuze kuqinisekiswe ukuthi ihlangabezana nokucaciswa okudingekayo. Lokhu kungase kuhlanganise ukuhlolwa okubonakalayo, ukukalwa, nokuhlola ukuze kuqinisekiswe ukuthi ingxenye iyikhwalithi ephezulu futhi ayinazo izinkinga.

Ukucatshangelwa Kwedizayini Ye-High-Volume Injection Molding

Ukuklama ingxenye yepulasitiki yokubunjwa komjovo wevolumu ephezulu kudinga ukucatshangelwa ngokucophelela kwezici eziningana ukuze kuqinisekiswe ukuthi ucezu lungenziwa kahle futhi lungabizi. Nazi ezinye zokucatshangelwa kwedizayini yokubumba umjovo wevolumu ephezulu:

- Ukhuni Okubondayo: Ukuqina kodonga lwengxenye yepulasitiki kuwukucatshangelwa okubalulekile ekubumbeni umjovo. Ubukhulu bezindonga kufanele bufane ukuvimbela ukupholisa okungalingani kanye nokuguquguquka kwesiqeshana. Izindonga ezizacile zilungele ukukhiqizwa kwevolumu ephezulu njengoba zinciphisa ukusetshenziswa kwezinto kanye nesikhathi sokujikeleza, kuyilapho izindonga eziwugqinsi zifanele izingxenye ezidinga amandla engeziwe.

- Usayizi Wengxenye Nomumo: Usayizi nokuma kwengxenye kuzothinta inqubo yokubumba umjovo. Izinto ezinkulu kakhulu noma eziyinkimbinkimbi zingadinga izikhathi zomjikelezo omude noma okokusebenza okukhethekile, okwandisa izindleko zokukhiqiza. Izimo ezilula, zejiyomethri zingcono kakhulu ekukhiqizweni kwevolumu ephezulu.

- Ama-engeli asalungiswa: I-engeli yokusalungiswa i-engeli yodonga lwesigxobo sesikhunta esivumela ukukhishwa kalula kwengxenye. KuhlanganisaKuhlanganisa nama-engeli angakapheli ekwakhiweni kwengxenye kubalulekile ukuze uqinisekise ukuthi ucezu lungakhishwa ngokushesha esikhunjeni. Amanani angenawo ama-engeli asalungiswa angaholela ezinkingeni zokukhiqiza ezibizayo njengokuqhekeka noma ukuwohloka.

- Indawo yesango nosayizi:Indawo kanye nobukhulu besango, lapho impahla yepulasitiki encibilikisiwe ingena emgodini wesikhunta, kuwukucatshangelwa okubalulekile komklamo wokubumba umjovo. Indawo yesango kufanele ibekwe endaweni engeke ithinte ubuqotho besakhiwo sengxenye. Usayizi wesango kufanele ube mkhulu ngokwanele ukuvumela impahla ukuthi igeleze ngendlela efanele kodwa ingabi nkulu kangangokuthi idala amaphutha endaweni.

- Ukukhetha Okubalulekile: Ukukhethwa kwempahla kubalulekile ukuze kuqinisekiswe ukuthi ingxenye ingakhiwa ngendlela ephumelelayo futhi engabizi kakhulu. Ukukhethwa kwezinto ezibonakalayo kufanele kusekelwe ezidingweni ezithile zocezu, okuhlanganisa amandla, ukuqina, nokuvumelana nezimo.

- Isiphetho se-Surface: Ingaphezulu lengxenye liwukucatshangelwa okubalulekile ekubumbeni umjovo. Ingaphezulu lenani kufanele libe bushelelezi futhi lingabi namaphutha, njengama-wapping marks noma ama-sink marks. Ukubekwa kwesango ngendlela efanele, idizayini yesikhunta, nokukhethwa kwezinto ezibonakalayo kungafinyelela ukuqedwa okubushelelezi kwendawo.

- ukubekezelelana: Ukubekezelela izinga lokuhlukahluka elivunyelwe kubukhulu bengxenye. Ukubekezelelana kufanele kucatshangelwe phakathi nesigaba sokuklama ingxenye ukuze kuqinisekiswe ukuthi ucezu lungenziwa ngokunembile nangokunembile.

Izinyathelo Zokulawula Ikhwalithi Ekubumbeni Umjovo Wevolumu Ephezulu

Ukulawulwa kwekhwalithi kubalulekile ekubumbeni umjovo wevolumu ephezulu, njengoba kuqinisekisa ukuthi izingxenye ezikhiqizwayo ziyahlangabezana nezidingo ezidingekayo futhi azinasici. Nazi ezinye izindlela zokulawula ikhwalithi ezisetshenziswa ekubumbeni umjovo wevolumu ephezulu:

- Ukuhlolwa ngesikhathi Senqubo Yokukhiqiza: Ukubuyekeza okuvamile phakathi nenqubo yokukhiqiza kungasiza ekuboneni amaphutha kusenesikhathi futhi kuwavimbele ekubeni yizinkinga ezibaluleke kakhulu. Lokhu kungase kuhlanganise ukuhlolwa okubonakalayo, ukukalwa, nokuhlola ukuze kuqinisekiswe ukuthi ingxenye yakhiwe ngendlela efanele.

- Ukulawulwa Kwenqubo Yezibalo (SPC): I-SPC iyindlela yezibalo esetshenziselwa ukuqapha nokulawula inqubo yokukhiqiza. Kubandakanya ukuqoqwa kwedatha yenqubo yokukhiqiza nokuyihlaziya ukuze kuhlonzwe amathrendi namaphethini angase abonise izinkinga ngenqubo. I-SPC ingasiza ekutholeni nasekulungiseni izinkinga ngaphambi kokuthi ziphumele ezingxenyeni ezinokukhubazeka.

- Ukusetshenziswa Kwezisetshenziswa Ezizenzakalelayo: Okokusebenza okuzenzakalelayo, okufana namarobhothi nezinzwa, kungasiza ukuthuthukisa ukungaguquguquki nokunemba kwenqubo yokukhiqiza. Izisetshenziswa zikagesi nazo zinganciphisa ingozi yamaphutha omuntu, okuholela ekulimaleni okumbalwa.

- Ukunakekelwa Kwesikhunta:Ukugcinwa kwesikhunta ngendlela efanele kubalulekile ukuze kuqinisekiswe ukuthi izingxenye ezikhiqizwayo zisezingeni eliphezulu. Lokhu kuhilela ukuhlanza isikhunta njalo nokwenza noma yikuphi ukulungiswa okudingekayo noma ukushintshwa ukuze kuqinisekiswe ukuthi isikhunta sisebenza ngendlela efanele.

- Ukuhlolwa Kwangemuva Kokukhiqiza: Ngemva kokuba izingxenye sezikhiqiziwe, zihlolwa okokugcina ukuze kuqinisekiswe ukuthi ziyahlangabezana nemibandela edingekayo. Lokhu kungase kuhlanganise ukuhlolwa okubonakalayo, ukukalwa, nokuhlola ukuze kuqinisekiswe ukuthi izingxenye azinawo yini amaphutha.

- Ukuqeqeshwa Nemfundo: Ukuqeqeshwa nokufundiswa okufanele kwabasebenzi kungathuthukisa ikhwalithi yenqubo yokukhiqiza. Abasebenzi kufanele baqeqeshwe ngamasu afanele okukhiqiza kanye nezinyathelo zokulawula ikhwalithi ukuze kuqinisekiswe ukuthi bayakwazi ukuhlonza nokulungisa izinkinga njengoba ziphakama.

- Ukuthuthukiswa Okuqhubekayo: Ukuthuthukiswa okuqhubekayo kubalulekile ekulawuleni ikhwalithi ekubunjweni komjovo wevolumu ephezulu. Ngokubuyekeza njalo inqubo yokukhiqiza kanye nokuhlonza izindawo okufanele zithuthukiswe, abakhiqizi banganciphisa amaphutha futhi bathuthukise ikhwalithi yezingxenye ezikhiqizwayo.

Ukuhlaziywa Kwezindleko Zokubumba Umjovo Wevolumu Ephezulu

Ukubumba komjovo wevolumu ephezulu kuyinqubo yokukhiqiza engabizi kakhulu yokukhiqiza isamba esikhulu sezingxenye zepulasitiki. Kodwa-ke, izindleko zokukhiqiza izingxenye ngokubumba umjovo zingahluka ngokusekelwe ezicini eziningana. Nazi ezinye izinto ezicatshangelwayo zokuhlaziya izindleko zokubumba umjovo wevolumu ephezulu:

- Izindleko Zento: Izindleko zezinto ezingavuthiwe zingenye yezinto ezibaluleke kakhulu ezithinta intengo yokubumba umjovo. Uhlobo nekhwalithi yezinto ezisetshenzisiwe zizoba nomthelela entengo, kanti ezinye izinto zizobiza kakhulu kunezinye. Abakhiqizi kufanele bakhethe izinto ezifanele ngokuya ngezidingo ezithile zengxenye.

- Izindleko Zokusebenza: Izindleko zokusetshenziswa kwamathuluzi, okuhlanganisa isikhunta nezinye izinto ezidingekayo ekubumbeni umjovo, kungenye into ebalulekile ethinta izindleko zokukhiqiza. Izindleko zamathuluzi zingahluka kuye ngobunkimbinkimbi bengxenye, ubukhulu besikhunta, kanye nenani lemigodi ekubunjweni.

- Izindleko Zabasebenzi: Izindleko zabasebenzi ziyisici esibalulekile ekubunjweni komjovo, njengoba inqubo idinga abasebenzi abanamakhono ukuze basebenzise imishini futhi baqondise inqubo yokukhiqiza. Izindleko zomsebenzi zingahluka kuye ngendawo nolwazi lwabasebenzi.

- Izindleko ezingaphezulu: Izindleko ezingaphezulu, ezifaka izinsiza, indawo yokuhlala, nezinye izindleko, zingaba nomthelela ezindlekweni zokubumba umjovo. Lezi zindleko zingahluka kuye ngokuthi indawo yokukhiqiza ikuphi kanye nosayizi wokusebenza.

- Ivolumu Yokukhiqiza: Umthamo wokukhiqiza uyisici esibalulekile esithinta izindleko zokubumba umjovo. Umthamo wokukhiqiza ophezulu ungabangela izindleko eziphansi ngengxenye ngayinye ngenxa yesilinganiso somnotho.

- Ingxenye yokuklama: Umklamo ungaphinda ube nomthelela ezindlekweni zokubumba umjovo. Izinto eziyinkimbinkimbi noma ezidinga imishini ekhethekile zinganyusa izindleko zokukhiqiza.

- Ikhwalithi yokulawula: Izindleko zezinyathelo zokulawula ikhwalithi, okuhlanganisa ukuhlola nokuhlola, zingaba nomthelela ezindlekweni zokukhiqiza. Lezi zinyathelo ziyadingeka ukuze kuqinisekiswe ukuthi izingxenye ezikhiqizwayo ziyahlangabezana nezidingo ezidingekayo futhi azinasici.

Izimboni Ezisebenzisa I-High Volume Injection Molding

Ukubumba komjovo wevolumu ephezulu kuyindlela yokukhiqiza esetshenziswa kabanzi ekwazi ukukhiqiza inqwaba yezingxenye zepulasitiki ngokushesha nangempumelelo. Nazi ezinye izimboni ezithembele kakhulu ekubunjweni komjovo wevolumu ephezulu:

- Imboni Yezimoto: Imboni yezimoto ingomunye wabasebenzisi ababaluleke kakhulu bokubumba umjovo wevolumu ephezulu. Inqubo ikhiqiza izingxenye zepulasitiki ezahlukahlukene njengezingxenye zedeshibhodi, izibambo zezicabha, nezingcezu zokunquma zangaphakathi.

- Imboni Yezimpahla Zabathengi: Ukubumba komjovo wevolumu ephezulu kukhiqiza izimpahla ezahlukahlukene zabathengi, kufaka phakathi izinto zasendlini, amathoyizi, nezinto zikagesi. Inqubo iyakhethwa ngoba ivumela abakhiqizi ukuthi benze izingxenye ezinkulu ezishibhile.

- Imboni yezokwelapha: Imboni yezokwelapha idinga izingxenye zepulasitiki ezisezingeni eliphezulu nezinembayo zemishini yezokwelapha ehlukahlukene, njengemishini yokuxilonga, amathuluzi okuhlinza, nezinto zokwelapha ezilahlwayo. Ukubunjwa komjovo wevolumu ephezulu kuyathandwa ngoba kungakhiqiza lezi zingxenye ngokunembile nangokungaguquguquki.

- Indzawo:Imboni yokupakisha incike kakhulu ekubunjweni komjovo wevolumu ephezulu ukukhiqiza iziqukathi zepulasitiki ezahlukahlukene, izivalo, nokuvalwa. Le nqubo ibiza izindleko futhi ivumela abakhiqizi ukuthi bakhe izimo nosayizi abahlukahlukene ngokushesha.

- Imboni ye-Aerospace: Imboni ye-aerospace idinga izingxenye zepulasitiki ezisebenza kahle ezingamelana nezimo ezimbi kakhulu, njengezinga lokushisa eliphezulu nokucindezela. Ukubumba komjovo wevolumu ephezulu kukhiqiza lezi zingxenye, okuhlanganisa izingxenye zendiza zangaphakathi nezangaphandle, ama-avionics, nezinto zikagesi.

- Imboni yezokwakha: Imboni yezokwakha isebenzisa ukubumba komjovo wevolumu ephezulu ukukhiqiza izingxenye zepulasitiki ezahlukahlukene, kufaka phakathi amafreyimu amafasitela, amapayipi, kanye nokufakwa kwezinto. Le nqubo ikhethwa ngoba ivumela ukukhiqizwa kwezingxenye eziningi ezihlala isikhathi eside futhi zimelana nezimo zemvelo.

- Imboni Yezemidlalo Nezokungcebeleka: Ukubumba komjovo wevolumu ephezulu kukhiqiza izingxenye zepulasitiki ezahlukahlukene zemboni yezemidlalo nezokungcebeleka, okuhlanganisa nezigqoko zokuzivikela, amagiya okuvikela, namathoyizi. Inqubo iyakhethwa ngoba ivumela ukwenza izingxenye ezingasindi, eziqinile, nezibukeka kahle.

Izinzuzo Zokubumba Umjovo Wevolumu Ephezulu Yemboni Yezokwelapha

Imboni yezokwelapha ingenye yezimboni ezinkulu nezikhula ngokushesha emhlabeni. Ngokuthuthuka kwezobuchwepheshe kanye nesidingo esikhulayo semishini yezokwelapha nemishini, kunesidingo sezinqubo zokukhiqiza ezisebenza kahle ezingakhiqiza izingxenye ezisezingeni eliphezulu. Ukubunjwa komjovo wevolumu ephezulu kungenye yezinqubo ezinikeza izinzuzo ezimbalwa embonini yezokwelapha. Ake sihlole ezinye izinzuzo zokubumba umjovo wevolumu ephezulu embonini yezokwelapha.

- Kuqiza kahle: Ukubumba komjovo wevolumu ephezulu kuyinqubo yokukhiqiza engabizi kakhulu ekhiqiza izinto eziningi zepulasitiki ngenani eliphansi ngeyunithi ngayinye.

- Ukuvumelana: Ukubunjwa komjovo wevolumu ephezulu kuvumela ukukhiqiza izingxenye ezine-viscosity ephezulu nokunemba, okuqinisekisa ukuthi ucezu ngalunye luhlangabezana nokucaciswa okudingekayo.

- Ukwenza ngokwezifiso: Inqubo ivumela ukwenziwa ngokwezifiso kwezici ukuze zilingane nezidingo ezithile, okuhlanganisa umbala, ukuthungwa, nokokusebenza.

- Isivinini: Ukubunjwa komjovo wevolumu ephezulu kuvumela ukukhiqizwa okusheshayo kwezikhundla, ukunciphisa isikhathi sokuhola nokwandisa ukusebenza kahle.

- Quality: Inqubo yokubumba umjovo wevolumu ephezulu ikhiqiza izingxenye zekhwalithi ephezulu ezihlangabezana nezindinganiso eziqinile ezidingekayo kumishini yezokwelapha.

- Ukuzala: Inqubo yenziwa endaweni engenalutho, iqinisekisa ukuthi izingxenye ezikhiqizwayo azingcoli futhi ziphephile ukusetshenziswa kwezokwelapha.

- ukuqina: Izingxenye ezikhiqizwa kusetshenziswa ukubumba komjovo wevolumu ephezulu zihlala isikhathi eside futhi zingamelana nezindawo ezinokhahlo, ziqinisekise ukuthi zihlala isikhathi eside futhi zinciphisa isidingo sokushintshwa. Ukuqina kubalulekile embonini yezokwelapha, lapho amathuluzi nemishini kufanele imelane nokusetshenziswa njalo kanye nokuchayeka okungaba khona kumakhemikhali nezinye izinto ezinokhahlo.

- Ubunkimbinkimbi: Inqubo yokubumba umjovo wevolumu ephezulu ivumela ukukhiqizwa kwezingxenye eziyinkimbinkimbi ezinemiklamo eyinkimbinkimbi, ukuqinisekisa ukuthi imishini yezokwelapha ingenziwa ukuze ihlangabezane nezidingo eziqondile zemithi yesimanje. Inqubo ilungele ukukhiqiza izingxenye eziyinkimbinkimbi ezinezici eziyingqayizivele kanye nemiklamo ebalulekile kumishini yezokwelapha kanye nemishini.

- Ukuhlukahluka: Ukubunjwa komjovo wevolumu ephezulu kungakhiqiza izingxenye ezahlukahlukene ezinobumo nosayizi abahlukahlukene, okuyenza ilungele ukudala izingxenye zezinhlelo zokusebenza zezokwelapha ezahlukahlukene.

I-High Volume Injection Molding Yemboni Yezimoto

Ukubumba umjovo kuyinqubo yokukhiqiza ebandakanya ukujova ipulasitiki encibilikisiwe endaweni yokubumba ukuze kwakhiwe izingxenye zepulasitiki ezihlukahlukene. Le nqubo isetshenziswa kakhulu embonini yezimoto ukwenza izingxenye eziningi ezifana namaphaneli eminyango, amadeshibhodi, amaphaneli wezinsimbi, izinsimbi zangaphakathi, nezitho zomzimba zangaphandle. Ukubumba komjovo wevolumu ephezulu kuyindlela ekhethekile eyenza abakhiqizi bakwazi ukukhiqiza ngokushesha inani elikhulu lezingxenye ezifanayo.

Ukubumba komjovo wevolumu ephezulu kuyindlela yokukhiqiza esebenza kahle kakhulu enikeza izinzuzo ezimbalwa embonini yezimoto. Ezinye zalezi zinzuzo zihlanganisa:

- Ukwehliswa kwezindleko zokukhiqiza - Le nqubo i-automated kakhulu, enciphisa izindleko zabasebenzi, futhi isikhunta sivumela abakhiqizi ukuthi bakhiqize izingxenye ezifanayo ngentengo ephansi.

- Ukuvumelana kwengxenye okuthuthukisiwe - Ukubunjwa komjovo wevolumu ephezulu kuvumela ukukhiqizwa kwezingxenye ezifanayo, ukunciphisa ukuhlukahluka nokuthuthukisa ukuthungwa kwenqubo yokukhiqiza.

- Izikhathi zokukhiqiza ezisheshayo - Le nqubo i-automatic kakhulu, eyenza abakhiqizi bakwazi ukukhiqiza izingxenye eziningi ngokushesha, ukunciphisa izikhathi zokuhola.

- Izingxenye zekhwalithi ephezulu - Ukusetshenziswa kwesikhunta kuqinisekisa ukuthi izingxenye ezikhiqizwayo zisezingeni eliphezulu, ezinokukhubazeka okuncane nokungahambisani.

- Ukuvumelana nezimo -Ukubumba komjovo kuvumela ukukhiqiza izimo eziyinkimbinkimbi nemiklamo esheshayo, okunikeza abaklami ukuguquguquka okukhulu ezinhlelweni zabo.

Ukubumba umjovo kuyindlela efanelekile yokukhiqiza embonini yezimoto, njengoba inikeza izinzuzo eziningi ezithuthukisa ukusebenza kahle, ukunciphisa izindleko, kanye nokuthuthukisa ingxenye yekhwalithi. Ukubumba komjovo wevolumu ephezulu, ikakhulukazi, kuyindlela ekhethekile eyenza abakhiqizi bakwazi ukukhiqiza inani elikhulu lezingxenye ezifanayo ngokushesha nangempumelelo.

Imboni yezimoto incike kakhulu ekubunjweni komjovo ukwenza izinto ezahlukahlukene zezimoto nezimoto. Kusukela ezingxenyeni zomzimba zangaphandle kuya ekulungiseni kwangaphakathi namadeshibhodi, ukubumba umjovo sekuyinqubo ebalulekile yokukhiqiza embonini yezimoto. Ngokubumba komjovo wevolumu ephezulu, abakhiqizi bangakhiqiza inani elikhulu lezingxenye ezifanayo ngezindleko eziphansi, ngokuvumelana okuthuthukisiwe kanye nekhwalithi.

I-High Volume Injection Molding ye-Consumer Goods Industry

Ukubumba komjovo wevolumu ephezulu kuyinqubo yokukhiqiza eyamukelwa kabanzi yimboni yezimpahla zabathengi ngenxa yekhono layo lokukhiqiza izingxenye ezinkulu zekhwalithi ephezulu ngokunemba okuhle kakhulu nokuvumelana. Le nqubo ivame ukusetshenziswa ekukhiqizeni izimpahla zabathengi njengamathoyizi, i-kitchenware, nezinto zokupakisha, phakathi kokunye. Lokhu okuthunyelwe kwebhulogi kuzohlola izinzuzo zokubumba umjovo wevolumu ephezulu embonini yezimpahla zabathengi.

Izinzuzo zokubunjwa komjovo wevolumu ephezulu:

- Kuqiza kahle: Enye yezinzuzo eziyinhloko zokubumba umjovo wevolumu ephezulu ukuthi kuyindlela engabizi kakhulu yokwenza izingxenye ezinkulu zezingxenye. Le nqubo i-automated kakhulu, enciphisa izindleko zabasebenzi, futhi isikhunta singasetshenziswa kabusha, okunciphisa izindleko zempahla.

- Ukuvumelana nokunemba:Ukubumba komjovo kunikeza ukunemba okuhle kakhulu nokuvumelana ekukhiqizeni izingxenye. Lokhu kungenxa yokuthi isikhunta siklanyelwe ukucaciswa okunembile kwezakhi, ukuqinisekisa ukuthi ucezu ngalunye lulingana nekhwalithi nosayizi ofanayo.

- Ukukhiqizwa okusheshayo:Ukubumba komjovo wevolumu ephezulu kuyinqubo esheshayo, futhi izingxenye ezinkulu zezingxenye zingakhiqizwa ngokushesha uma kuqhathaniswa. Lokhu kuyenza ilungele ukukhiqiza izimpahla zabathengi ezidinga izikhathi ezisheshayo zokushintsha.

- Ukwenza ngokwezifiso: Ukubunjwa komjovo kuvumela ukwenziwa ngokwezifiso kwezingxenye kusetshenziswa izinto ezahlukahlukene, imibala, nokuqedwa kwendawo. Lokhu kuvumelana nezimo kwenza kube nokwenzeka ukukhiqiza izingxenye ezihlangabezana nezidingo eziqondile zabathengi kanye nezidingo.

Izicelo Zokubumba Umjovo Wevolumu Ephezulu Embonini Yempahla Yabathengi:

- Izinto zokupakisha:Ukubumba umjovo kusetshenziswa kabanzi ukukhiqiza izinto zokupakisha ezifana namabhodlela epulasitiki, izimbiza, nezitsha.

- Amathoyizi: Ukubumba umjovo kuyindlela edumile yokwenza amathoyizi njengoba kuvumela ukukhiqiza ngokushesha izingxenye ezinkulu zezingxenye.

- Izimpahla zasekhishini: Ukubumba umjovo kwenza izinto ezihlukahlukene zasekhishini njengezinkomishi, amapuleti, nezitsha.

- I-elekhoni: Ukubumba komjovo kusetshenziswa ukwenza izingxenye ze-elekthronikhi ezihlukahlukene njengezindlu, izinkinobho, namaswishi.

I-High Volume Injection Molding yomkhakha we-Aerospace

Imboni yezomkhathi idinga izingxenye ezisezingeni eliphezulu nezinembayo ukuze kuqinisekiswe ukuphepha nokusebenza kahle kwezindiza. Ukubumba komjovo wevolumu ephezulu sekuyinqubo ebalulekile embonini ye-aerospace njengoba inikeza isixazululo esingabizi kakhulu sokukhiqiza izinto eziningi zekhwalithi ephezulu ezinekhwalithi engaguquki. Lokhu okuthunyelwe kwebhulogi kuzoxoxa ngokubumba komjovo wevolumu ephezulu embonini ye-aerospace.

Izinzuzo ze-High Volume Injection Molding yomkhakha we-Aerospace:

Imboni ye-aerospace idinga izinto ezingasindi, eziqinile ezimelana namazinga okushisa aphakeme nezingcindezi. Ukubumba komjovo wevolumu ephezulu kunikeza izinzuzo eziningi zokukhiqiza izakhi ezinjalo, okuhlanganisa:

- Ukukhiqiza Okungabizi kakhulu: Ukubumba komjovo wevolumu ephezulu kungakhiqiza izingxenye ezinkulu ngokushesha, okuholela ekunciphiseni izindleko zokukhiqiza.

- Ikhwalithi Engaguquki: Inqubo ezenzakalelayo iqinisekisa ukuthi ingxenye ngayinye ekhiqizwayo isezingeni eliphezulu elifanayo, elibalulekile ekuphepheni nasekuthembekeni kwezingxenye zendiza.

- Amajiyometri ayinkimbinkimbi: Inqubo yokubumba umjovo ikhiqiza ubujamo obuyinkimbinkimbi namajiyometri, okungaba nzima ukuzuza ngezindlela zokukhiqiza zendabuko.

- Ukukhetha Okubalulekile: Ukubumba komjovo wevolumu ephezulu kungacubungula izinhlobonhlobo zezinto ezisetshenziswayo, kufaka phakathi izinhlanganisela, ezilungele ukusetshenziswa kwe-aerospace.

- Udoti Owehlisiwe: Izinga eliphezulu lokuzenzakalela kanye nokunemba enqubweni yokubumba umjovo liphumela ekumoshweni kwezinto ezibonakalayo ezincane kanye nezilahlwa, ezingaholela ekongeni kwezindleko ezibalulekile kanye nezinzuzo zemvelo.

Izicelo Ze-High Volume Injection Molding embonini ye-Aerospace:

Ukubunjwa komjovo wevolumu ephezulu kusetshenziswa kakhulu embonini ye-aerospace ukukhiqizwa kwezingxenye ezahlukahlukene, kufaka phakathi:

- Amapayipi omoya kanye nezinhlelo zokungenisa umoya

- Izingxenye zendiza zangaphakathi nangaphandle

- Izakhi zesakhiwo njengabakaki, iziqeshana, nezindlu

- Izingxenye zikagesi kanye nezintambo

- Ama-seal nama-gaskets

Ukukhubazeka Okujwayelekile Ekubumbeni Umjovo Wevolumu Ephezulu

Kodwa-ke, njenganoma iyiphi inqubo yokukhiqiza, ukubumba umjovo kwesinye isikhathi kungaholela ekulimaleni okungathinta ikhwalithi yomkhiqizo wokugcina. Lokhu okuthunyelwe kwebhulogi kuzoxoxa ngamaphutha ajwayelekile ekubumbeni umjovo wevolumu ephezulu nokuthi angavinjelwa kanjani.

- Sink Marks: Ama-sink marks ama-depressions noma ama-indent angenzeka phezu kwengxenye ebunjiwe. Zibangelwa ukushwabana kwempahla yepulasitiki njengoba iphola, okuholela ekusabalaliseni okungalingani kwezinto. Ukuze uvimbele izimpawu zokucwila, ukuguqula ukwakheka kwengxenye nokuqinisekisa ukushuba kodonga kuyo yonke ingxenye kuyadingeka.

- I-Warping:I-Warping ukuguqulwa kwengxenye ebunjiwe ngenxa yokupholisa okungalingani kwezinto zepulasitiki. Kuholela engxenyeni esontekile noma egobile engahlangabezani nezicaciso ezidingekayo. I-Warping ingavinjelwa ngokuqinisekisa ukuthi izinga lokushisa lesikhunta liyavumelana futhi ngokuhlanganisa izici zokuklama ezinciphisa ingcindezi engxenyeni ngesikhathi sokupholisa.

- Flash: I-Flash iwumsebenzi oweqile ophuma esilinganisweni sesikhunta futhi kungenzeka uma isikhunta singaqondani kahle noma siboshiwe. I-Flash ingavinjelwa ngokuqinisekisa ukuthi isikhunta siqondaniswe kahle nokuthi amandla okubamba anele ukubamba isikhunta sivaliwe ngesikhathi sokujova.

- Amashothi Amafushane: Ukudubula okufushane kwenzeka lapho izinto zepulasitiki zingagcwalisi yonke isikhunta, okuholela engxenyeni engaphelele. Lokhu kungabangelwa ukucindezela komjovo onganele, izinga lokushisa eliphansi lokuncibilika, noma isango elivinjiwe. Ukudubula okufushane kungavinjelwa ngokuthuthukisa imingcele yomjovo kanye nokuqinisekisa ukuthi isango liklanywe kahle futhi libekwe kahle.

- Imigqa Ye-Weld: Imigqa yokushisela iyenzeka lapho ama-flow fronts amabili noma ngaphezulu ehlangana futhi aqina, okuholela emugqeni obonakalayo noma umthungo engxenyeni ebunjiwe. Imigqa yokushisela ingavinjelwa ngokuthuthukisa ukwakheka kwesikhunta kanye nemingcele yomjovo ukuze kuqinisekiswe ukuthi izinto zepulasitiki zigeleza ngokulinganayo nangokushelela emgodini.

Amathiphu Wokuxazulula Inkinga Wokubumba Umjovo Wevolumu Ephezulu

Ukubumba komjovo wevolumu ephezulu kuyinqubo eyinkimbinkimbi edinga ukunakwa kwemininingwane nokuqapha ngokucophelela ukuze kuqinisekiswe ukuthi umkhiqizo wokugcina ungowekhwalithi ephezulu kakhulu. Izinkinga eziningi ezivamile zingavela ngesikhathi sokubumba umjovo, okungaholela ekushiyekeni komkhiqizo wokugcina. Lokhu okuthunyelwe kuzohlola amanye amathiphu ajwayelekile okuxazulula izinkinga zokubumba umjovo wevolumu ephezulu.

- Hlola Izilungiselelo Zomshini Wokubumba Umjovo: Enye yezinto zokuqala okufanele uzihlole lapho uxazulula inkinga yokubumba umjovo wevolumu ephezulu izilungiselelo emshinini wokubumba umjovo. Qinisekisa ukuthi izinga lokushisa, ingcindezi, nesikhathi somjikelezo konke kusethwe ngendlela efanele ezintweni ezithile ezisetshenzisiwe.

- Hlola Izinkinga Zokugeleza Kwezinto: Izinkinga zokugeleza kwezinto zingenye inkinga evamile ngokubumba komjovo wevolumu ephezulu. Izinto ezimbalwa, okuhlanganisa izilungiselelo ezingalungile emshinini noma ukuvaleka emshinini wokubumba umjovo, kungabangela lokhu. Qinisekisa ukuthi okokusebenza kugeleza kahle ocingweni nokuthi akukho okuvalekile emshinini wokubumba umjovo.

- Hlola i-Warping and Shrinkage: I-Warping kanye nokuncipha yizindaba ezijwayelekile ngesikhathi sokubunjwa komjovo wevolumu ephezulu. Lezi zinkinga zivame ukubangelwa ukupholisa okungalingani kwento, okungaholela ekushintshaneni noma ukushwabana komkhiqizo wokugcina. Qinisekisa ukuthi isikhathi sokupholisa sisethwe kahle ezintweni ezithile ezisetshenziswayo futhi nesistimu isebenza kahle.

- Hlola i-Air Traps: Izicupho zomoya zingenye inkinga evamile ngesikhathi sokubunjwa komjovo wevolumu ephezulu. Lokhu kwenzeka lapho umoya uvaleleka emgodini wesikhunta, okungabangela izikhala noma amabhamuza emkhiqizweni wokugcina. Qinisekisa ukuthi isikhunta sivuleke ngokwanele ukuze kuvinjwe izingibe zomoya ukuthi zingenzeki.

- Gada Inqubo: Okokugcina, ukuqapha ngokucophelela inqubo yokubumba umjovo kubalulekile ukuze kuqinisekiswe ukuthi noma yiziphi izinkinga ziyabanjwa futhi zixazululwe ngokushesha. Lokhu kungenziwa ngokuqapha izilungiselelo zomshini, ukugeleza kwempahla, kanye nenqubo yokupholisa. Ngokuqapha ngokucophelela inqubo, noma yiziphi izinkinga zingahlonzwa futhi zixazululwe ngaphambi kokuba ziholele ekulimaleni komkhiqizo wokugcina.

Izidingo Zokugcinwa Kwemishini Yokubumba Umjovo

Imishini yokubumba imijovo iyingcezu yemishini ebalulekile embonini yokukhiqiza. Zisetshenziselwa ukukhiqiza imikhiqizo ehlukahlukene, kusukela ezingxenyeni zepulasitiki kuya ezingxenyeni zensimbi. Kodwa-ke, njenganoma yimuphi omunye umshini, imishini yokubumba umjovo idinga ukunakekelwa okujwayelekile ukuze kuqinisekiswe ukusebenza kahle nokuvikela ukuwohloka okumba eqolo. Lokhu okuthunyelwe kuzohlola ezinye zezidingo zokunakekelwa kwemishini yokubumba umjovo.

- Ukumanzisa: Ukugcotshwa okufanele kungenye yezinto ezibaluleke kakhulu zokulungiswa komshini wokubumba umjovo. Izingxenye ezihambayo zomshini, njengomjovo kanye namayunithi okubamba, kufanele zigcotshwe njalo ukuze kuvinjelwe ukungqubuzana nokuguga. Ukusebenzisa uhlobo olufanele lokuthambisa nokulandela izincomo zomkhiqizi ngezikhawu zokugcoba kubalulekile.

- Ukuhlanza: Esinye isici esibalulekile sokulungiswa komshini wokubumba umjovo ukuhlanza njalo. Umshini kufanele uhlanzwe njalo ukuze kukhishwe uthuli, udoti, noma izinsalela zepulasitiki ezinganqwabelana ezingxenyeni zawo. Lokhu kuzosiza ukuvimbela ukuvaleka kwemibhobho nezihlungi zomshini, okungadala izinkinga zokusebenza noma kulimaze injini.

- Ukuhlolwa: Ukuhlolwa okuvamile nakho kuyadingeka ukuze kuqinisekiswe ukuthi umshini usesimweni esihle. Ukuhlola kufanele kuhlanganise ukuhlola noma yiziphi izimpawu zokuguga, njengokuqhekeka noma izingxenye eziphukile. Izingxenye zikagesi, njengezinzwa namaswishi, kufanele nazo zihlolwe njalo ukuze kuqinisekiswe ukuthi zisebenza ngendlela efanele.

- Ukulinganisa: Imishini yokubumba yomjovo nayo idinga ukulinganisa ukuze kuqinisekiswe ukuthi isebenza ngaphakathi kwemingcele efanele. Lokhu kuhlanganisa ukuhlola izinga lokushisa lomshini, ingcindezi, nezilungiselelo zesivinini ukuze uqinisekise ukuthi zingaphakathi kwezicaciso zomkhiqizi. Ukulinganisa kufanele kwenziwe njalo ukuze kuqinisekiswe ukuthi idivayisi isebenza ezingeni eliphezulu kakhulu.

- Ukushintshwa Kwezingxenye Ezigugile: Okokugcina, ukubuyisela noma yiziphi izingxenye ezigugile noma ezilimele ngokushesha ngangokunokwenzeka kubalulekile. Lokhu kungasiza ekuvimbeleni umonakalo owengeziwe emshinini futhi kunciphise nengozi yokuwohloka okumba eqolo. Izingxenye ezishintshwayo kufanele zibe zekhwalithi efanayo nezingxenye zangempela futhi zifakwe ochwepheshe abaqeqeshiwe.

Ukusimama kanye Nokubunjwa komjovo wevolumu ephezulu

Ukuzinza sekuyinto ebaluleke kakhulu embonini yokukhiqiza eminyakeni yamuva nje. Njengoba umhlaba uqaphela kakhudlwana umthelela wezinqubo zezimboni kwezemvelo, izinkampani zifuna izindlela zokunciphisa indawo yazo ezungezile kuyilapho zigcina ukukhiqiza kanye nenzuzo. Ukubumba komjovo wevolumu ephezulu yindawo eyodwa lapho ukusimama kungenza umthelela omkhulu.

Kunezindlela ezimbalwa lapho ukusimama kungafakwa khona ekubunjweni komjovo wevolumu ephezulu:

- Ukukhetha okubalulekile:Ukukhetha izinto ezifanele kubalulekile ukuze kuzuzwe ukusimama ekubumbeni umjovo. Izinketho eziningi zifaka ama-bioplastics, amapulasitiki agaywe kabusha, nezinto ezisekelwe ku-bio. Ngokukhetha izinto ezihambisana nemvelo futhi ezinekhabhoni ephansi, abakhiqizi banganciphisa kakhulu umthelela wabo emvelweni.

- Ukusebenza kahle kwamandla: Ukubumba komjovo wevolumu ephezulu kudinga amandla abalulekile ukuze kusebenze. Abakhiqizi banganciphisa ukusetshenziswa kwamandla futhi banciphise ukukhishwa kwekhabhoni ngokusebenzisa izinqubo nemishini yokonga amandla. Lokhu kungafezwa ngokusebenzisa imishini eyonga amandla, ukuthuthukisa izinqubo zokukhiqiza, kanye nokutshala imali emithonjeni yamandla avuselelekayo.

- Ukuncishiswa kukadoti: Ukubumba umjovo kungadala udoti omkhulu, ikakhulukazi ipulasitiki eyeqile. Ngokusebenzisa amasu okunciphisa imfucuza, abakhiqizi banganciphisa inani lemfucuza ekhiqizwayo futhi bathuthukise ukusimama kwabo. Lokhu kungafezwa ngokugaywa kabusha, ukusebenzisa kabusha izinto, kanye nokuthuthukisa inqubo yokukhiqiza ukuze kuncishiswe imfucuza.

- Ukuhlaziywa komjikelezo wempilo: Ukwenza ukuhlaziya umjikelezo wempilo kungasiza abakhiqizi baqonde umthelela wemvelo wemikhiqizo yabo kuwo wonke umjikelezo wabo wokuphila. Lokhu kuhlaziya kungasiza ekuhlonzeni izindawo lapho ukusimama kungathuthukiswa khona futhi kuqondise ekuthathweni kwezinqumo ukuze kwakhiwe imikhiqizo evumelana nemvelo.

Amaphuzu Ayinhloko:

- Ukukhethwa kwezinto kudlala indima ebalulekile ekuzuzeni ukusimama ekubumbeni umjovo.

- Izinqubo nemishini ewonga amandla kunganciphisa ukusetshenziswa kwamandla kanye nokukhishwa kwekhabhoni ephansi.

- Amasu okunciphisa imfucuza, njengokugaywa kabusha kanye nokusetshenziswa kabusha kwezinto, anganciphisa inani lemfucuza ekhiqizwayo.

- Ukuhlaziywa komjikelezo wokuphila kungasiza ukukhomba izindawo lapho ukusimama kungathuthukiswa khona.

- Ukuhlanganisa ukusimama ekubumbeni umjovo wevolumu ephezulu kungazuzisa abakhiqizi ngokunciphisa izindleko futhi kukhange kubathengi abaqaphela imvelo.

- Ikusasa Lokubumba Umjovo Wevolumu Ephezulu

Ukubumba umjovo wevolumu ephezulu bekuyinqubo ebalulekile yokukhiqiza ezimbonini eziningi amashumi eminyaka, futhi kuyaqhubeka nokubamba iqhaza elibalulekile ekukhiqizeni imikhiqizo eminingi yepulasitiki. Njengoba ubuchwepheshe buthuthuka kanye nesidingo sabathengi sishintshela emikhiqizweni esimeme kakhudlwana futhi engenziwa ngendlela oyifisayo, ikusasa lokubunjwa komjovo wevolumu ephezulu libukeka liqhakazile. Nazi ezinye zezitayela nezinto ezintsha ezakha ukuphela kwalo mkhakha.

- Ukusimama: Ngokukhula kwesidingo sabathengi semikhiqizo ehambisana nemvelo, ukusimama sekubalulekile ekubunjweni komjovo wevolumu ephezulu. Abakhiqizi bahlola izinto ezintsha, ezifana ne-bioplastic kanye nezinto ezisekelwe ku-bio, futhi basebenzisa amasu okunciphisa imfucuza ukuze banciphise umthelela wemvelo wemikhiqizo yabo.

- Ukwenza ngokwezifiso: Abathengi bafuna imikhiqizo ehlangabezana nezidingo zabo eziyingqayizivele kanye nezintandokazi zabo, futhi ukubunjwa komjovo wevolumu ephezulu kufaneleka kahle ukuhlangabezana nalesi sidingo. Intuthuko kwezobuchwepheshe, njengokuphrinta kwe-3D, yenza kube lula futhi kungabizi kakhulu ukukhiqiza izingxenye ezenziwe ngokwezifiso nemikhiqizo ngamavolumu amakhulu.

- Ukuzenzekelayo: I-automation iya ngokuya idlanga embonini yokukhiqiza, futhi ukubumba komjovo wevolumu ephezulu nakho. Izinqubo ezizenzakalelayo, ezifana nezingalo zerobhothi nomklamo osizwa ngekhompuyutha, zingathuthukisa ukusebenza kahle kokukhiqiza futhi zehlise izindleko.

- Imboni 4.0: Uguquko lwesine lwezimboni, i-Industrial 4.0, luguqula imboni yezokukhiqiza ngokuhlanganisa ubuchwepheshe obuthuthukisiwe obunjengobuhlakani bokwenziwa, i-Intanethi Yezinto (IoT), kanye nokuhlaziya idatha enkulu. Lobu buchwepheshe benza kube lula kubakhiqizi ukuthi bathuthukise izinqubo zokukhiqiza futhi bathuthukise ikhwalithi yomkhiqizo.

- Imboni yezokwelapha:Ukubumba komjovo wevolumu ephezulu kulungele kahle ukukhiqiza imishini yezokwelapha kanye nemishini ngenxa yokunemba kwayo nokuvumelana. Isidingo semikhiqizo yezokwelapha kulindeleke ukuthi sikhule, okwenza lokhu kube indawo ebalulekile embonini yokubumba umjovo.

- Izimoto zikagesi:Ukushintshela ezimotweni ezisebenza ngogesi kudala amathuba amasha embonini yokubumba umjovo wevolumu ephezulu. Izingxenye zepulasitiki, njengezindlu zamabhethri nezixhumi zikagesi, zibalulekile ezimotweni zikagesi, futhi isidingo salezi zingxenye kulindeleke ukuthi sikhule njengoba izimoto zikagesi zanda kakhulu.

Isiphetho:

Ukubumba komjovo wevolumu ephezulu kubalulekile ekukhiqizeni izingxenye ezinkulu zepulasitiki. Ngokuqonda izinzuzo, ububi, izinto zokwakha, imishini, izindlela, ukucatshangelwa kwemiklamo, izinyathelo zokulawula ikhwalithi, kanye nokusetshenziswa kokubumba komjovo wevolumu ephezulu, amabhizinisi angakwazi ukuthuthukisa izinqubo zawo zokukhiqiza, anciphise izindleko, futhi athuthukise ikhwalithi yemikhiqizo yawo. Noma ngabe ukumkhakha wezokwelapha, wezimoto, wezimpahla zabathengi, noma we-aerospace, ukubumba umjovo wevolumu ephezulu kungazuzisa ibhizinisi lakho ngokunikeza izingxenye ezingashintshi, zekhwalithi ephezulu ngentengo ebiza kancane.