I-Thermoplastic Injection Molding

Ukubumba komjovo we-Thermoplastic kuyinqubo ethandwayo yokukhiqiza esetshenziselwa ukwakha izingxenye zepulasitiki ezihlukahlukene zezimboni eziningi. Le nqubo ihilela ukuncibilikisa ama-pellets epulasitiki bese uwajova esikhunjeni ukuze akhiqize isimo esinezinhlangothi ezintathu. Ukubumba komjovo we-Thermoplastic kusebenza kahle kakhulu futhi kubiza kakhulu ukukhiqiza amavolumu amakhulu ezingxenye zepulasitiki zekhwalithi ephezulu ezinokubekezelelana okuqinile. Lo mhlahlandlela obanzi uzohlola izici ezahlukahlukene zokubumba umjovo we-thermoplastic, okuhlanganisa izinzuzo nezinkinga zayo, izinhlobo ze-thermoplastics ezisetshenziswayo, inqubo yokubumba umjovo, ukucatshangelwa komklamo, nokunye okuningi.

Umlando we-Thermoplastic Injection Molding

Umlando wokubumba umjovo we-thermoplastic uhlanganisa ikhulu leminyaka lokuthuthuka kwezobuchwepheshe, ukuthuthukiswa kwezinto ezibonakalayo, kanye nokusetshenziswa kwezimboni. Kusukela ekuqaleni kwayo okuthobekile njengenqubo yokubumba i-celluloid kuya kubuchwepheshe banamuhla obuyinkimbinkimbi, ukubumba umjovo kuyaqhubeka nokuba yindlela ebalulekile yokukhiqiza, eqhuba ukusungulwa nokubumba izimboni ezihlukahlukene.

- Ukuthuthukiswa Kwasekuqaleni:UJohn Wesley Hyatt kanye nomfowabo u-Isaya bakha umshini wokuqala osebenzayo wokubumba umjovo, belandela umsuka wokubumba umjovo we-thermoplastic emuva ngasekupheleni kwekhulu le-19. Ngo-1872, bathola ilungelo lobunikazi umshini owasebenzisa i-plunger ukujova i-celluloid endaweni yokubunjwa, okwenza izinto eziqinile. Lokhu kuphumelela kwabeka isisekelo senqubo yesimanje yokubumba umjovo.

- Ukuthuthuka Kwezinto:Ekuqaleni kwekhulu lama-20, ukwethula ama-polymer amasha okwenziwa kwavula amathuba amasha okubumba umjovo. I-Bakelite, i-phenolic resin, ibe yinto ethandwayo yokubumba ngenxa yezakhiwo zayo ezinhle kakhulu zokuvikela ugesi. Kuwo wonke ama-1930s kanye nawo-1940s, ukuthuthuka kwekhemistri ye-polymer kwaholela ekuthuthukisweni kwamanye ama-thermoplastics, njenge-polystyrene ne-polyethylene, okuqhubekisele phambili ukwandisa ububanzi bezinto ezilungele ukubumba umjovo.

- Ukutholwa Kwezimboni: Ukwamukelwa okusabalele kokubunjwa komjovo we-thermoplastic kwaqala ngeminyaka yawo-1950 njengoba abakhiqizi babona ukusebenza kahle kwayo kwezindleko kanye nokuguquguquka kwayo. Ukwethula imishini enengcindezi ephezulu kuvunyelwe izikhathi zomjikelezo osheshayo kanye nokwanda kwamavolumu okukhiqiza. Ngenxa yalokho, kwaba khona ukukhethwa okuhlukahlukene kwemikhiqizo yokusetshenziswa komuntu siqu kanye nezimboni. Lezi zihlanganisa izingxenye zemoto, izinto zasendlini, nezinto zokudlala.

- Okusunguliwe Kwezobuchwepheshe:Phakathi namashumi eminyaka, ubuchwepheshe bokubumba umjovo buqhubekile nokuvela. Ngawo-1960, kwavela imishini elawulwa ngekhompiyutha, eyenza ukulawula okunembile kwenqubo yokubumba. Ukwethulwa kwezinhlelo zokugijima ezishisayo ngeminyaka yawo-1980 kwehlisa imfucuza futhi kwathuthukisa ukusebenza kahle ngokuqeda isidingo sabagijimi kanye nezihlahla. Eminyakeni yakamuva, i-automation, irobhothi, kanye nentuthuko yokuphrinta ye-3D iye yashintsha kakhulu imboni yokubumba umjovo, yavumela imiklamo eyinkimbinkimbi futhi yehlisa isikhathi sokukhiqiza.

- Ukusimama kanye Nokugaywa kabusha:Ngokukhula kokukhathazeka kwemvelo, imboni yokubumba umjovo yamukele izindlela zokusimama. Abakhiqizi bathuthukise ama-thermoplastic asuselwa ku-bio futhi aphinde agaywa kabusha, anciphisa ukuthembela ezintweni ezisekelwe kuphethiloli. Ukwengeza, ubuchwepheshe bokugaywa kabusha obuthuthukisiwe buvumele ukucutshungulwa kabusha kwemfucuza yangemva komthengi kanye neyangemva kwezimboni, kunciphisa umthelela wemvelo wokubumba komjovo we-thermoplastic.

- Amathemba Ekusasa:Ikusasa lomjovo we-thermoplastic libukeka lithembisa. Imboni ihlola izinto ezintsha ezinjengokubumba komjovo omncane wezingxenye ezincane, amasu ezinto eziningi kanye nokunqwabelana ngokweqile kwezingxenye eziyinkimbinkimbi, kanye nokuhlanganisa ubuchwepheshe obuhlakaniphile bokuqapha inqubo kanye nokwenza kahle. Ngaphezu kwalokho, abacwaningi balindele inqubekelaphambili ezintweni ezingaboli kahle kanye nokukhiqiza okungeziwe ukuze kuguqule insimu, kwenze ukubumba komjovo kuqhubeke futhi kusebenze izinto ezihlukahlukene.

Izinzuzo ze-Thermoplastic Injection Molding

Ukubumba komjovo we-Thermoplastic kunikeza izinzuzo eziningi kubakhiqizi. Inikeza ukuguquguquka komklamo, okuvumela imiklamo eyinkimbinkimbi neyinkimbinkimbi enezici ezihlukahlukene. Inqubo yonga imali, inciphisa udoti wempahla futhi yehlise izindleko zamayunithi. Ukubumba komjovo we-Thermoplastic kusekela izinto eziningi, kuhlinzeka ngokuguquguquka kwezinhlelo zokusebenza ezahlukahlukene.

- Ukuguquguquka Komklamo:Ukubumba komjovo we-Thermoplastic kuvumela imiklamo eyinkimbinkimbi neyinkimbinkimbi enezici ezifana nama-undercuts, izindonga ezincanyana, nogqinsi oluhlukahlukene, okuhlinzeka abaklami inkululeko enkulu.

- Ukusebenza Kwezindleko: Inqubo isebenza kahle kakhulu, inciphisa udoti wezinto ezibonakalayo futhi yehlisa izindleko zamayunithi. Ukubumba ngesikhathi esisodwa izingxenye eziningi kanye nemijikelezo yokukhiqiza esheshayo kunomthelela ekongeni izindleko.

- I-Material Versatility: Ukubumba komjovo we-Thermoplastic kusekela inhlobonhlobo yezinto ezisetshenziswayo, okwenza abakhiqizi bakwazi ukukhetha inketho efaneleke kakhulu yohlelo ngalunye, okuhlanganisa izinto eziqinile noma eziguquguqukayo, ezibonisa ngale noma ezikhanyayo, nezinto ezimelana namakhemikhali.

- Amandla Nokuqina:Ama-thermoplastics abunjwe ngomjovo angabonisa izici ezinhle kakhulu zemishini, njengamandla aphezulu, ukuqina, nokumelana nomthelela. Izinketho zokuqinisa, njengengilazi noma i-carbon fibers, zithuthukisa lezi zakhiwo.

- Ukuvumelana Nekhwalithi:Ukubumba komjovo kuqinisekisa ikhwalithi engaguquki yengxenye nengxenye kanye nokunemba kobukhulu, ukuletha ukubekezelelana okuqinile nemikhiqizo ethembekile. Le nqubo iphinde inikeze isiphetho esibushelelezi nesifanayo, esisusa isidingo semisebenzi eyengeziwe yokuqedela.

- I-Scalability kanye Nokukhiqiza Okuningi:Ukubunjwa komjovo kuyahlaziywa kusuka kumthamo ophansi kuye phezulu, okuyenza ifanelekele ukukhiqizwa ngobuningi. Uma abakhiqizi bedala isikhunta, bangakwazi ukukhiqiza inani elikhulu lezingxenye ezifanayo ngokuhlukahluka okuncane.

- Ukuhlanganisa nokuhlanganisa:Izingxenye ezibunjwe ngomjovo zingahlanganisa izingxenye eziningi zibe yisiqephu esisodwa, zinciphise isidingo sezinqubo ezengeziwe zokuhlanganisa. Lokhu kuhlanganiswa kuthuthukisa ukusebenza komkhiqizo, kunciphisa isikhathi sokuhlanganisa, futhi kwehlisa izindleko.

- Ukusimama:Imboni yokubumba umjovo ikhombisa ukugxila okukhulayo kokusimama. Ukutholakala kwezinto ezisekelwe ku-bio kanye nezinto ezigaywe kabusha kuvumela ukukhiqiza imikhiqizo evumelana nemvelo. Ukusetshenziswa kahle kwezinto ezibonakalayo kanye nokuphinda kusetshenziswe kabusha kwe-thermoplastics kunomthelela enqubweni yokukhiqiza eluhlaza.

Lezi zinzuzo zikwenze kwaba indlela yokukhiqiza eyamukelwa kabanzi kuzo zonke izimboni ezihlukahlukene, ihlinzeka ngezixazululo zekhwalithi ephezulu, ezongayo, nezinobungani nemvelo ezidingweni zemikhiqizo eyinkimbinkimbi.

Ukubi kwe-Thermoplastic Injection Molding

Ngenkathi ukubumba komjovo we-thermoplastic kunikeza izinzuzo eziningi, kubuye kube nokubi okuningana. Abakhiqizi badinga ukuhlola ngokucophelela lezi zici futhi bazikale ngokuqhathanisa nezinzuzo ukuze banqume ukufaneleka kokubunjwa komjovo we-thermoplastic kwezinhlelo zabo zokusebenza ezithile.

- Utshalomali Olukhulu Lokuqala: Ukusetha umsebenzi wokubumba umjovo we-thermoplastic kudinga ukutshalwa kwezimali okubalulekile kokuqala ekwakhiweni kwesikhunta nokwakhiwa kanye nokuthenga imishini ekhethekile. Izindleko ezihambisana nokudala isikhunta nokusebenzisa amathuluzi zingaba nkulu, ikakhulukazi emiklamo eyinkimbinkimbi neyinkimbinkimbi.

- Imikhawulo yedizayini: Ngenkathi ukubumba komjovo we-thermoplastic kunikeza ukuguquguquka kokuklama, imikhawulo ethile ikhona. Isibonelo, ukuzuza ukujiya kwezindonga ezifanayo kuyo yonke ingxenye kungaba inselele, okuholela ekuhlukeni kokusatshalaliswa kwezinto ezibonakalayo kanye nobuthakathaka obungaba khona besakhiwo. Ukwengeza, ukuba khona kwama-undercuts noma amajiyometri ayinkimbinkimbi kungase kudinge ukusetshenziswa kwezici zesikhunta ezengeziwe noma imisebenzi yesibili, izindleko ezikhulayo kanye nesikhathi sokukhiqiza.

- Izikhathi Ezinde Zokuhola:Inqubo yokuklama nokwenza isikhunta sokubumba umjovo ingadla isikhathi, okuholela ezikhathini zokuhola ezinde zokuthuthukiswa komkhiqizo. Inqubo yokuphinda idizayini, ukukhiqizwa kwesikhunta, nokuhlola kungangeza isikhathi esibalulekile kuwo wonke umugqa wesikhathi wokukhiqiza, okungenzeka ungafaneleki amaphrojekthi anezinsuku zokugcina eziqinile.

- Imikhawulo Yokukhetha Okubalulekile:Yize ukubumba komjovo we-thermoplastic kusekela inhlobonhlobo yezinto zokwakha, kunemikhawulo nezingqinamba ezithile. Ezinye izinto ezisetshenziswayo zingase zibe nezidingo ezithile zokucubungula noma ukutholakala okulinganiselwe, okunomthelela ekukhethweni kwedizayini nokukhetha okubalulekile kohlelo oluthile.

- Imikhawulo Yosayizi Wengxenye:Imishini yokubumba yomjovo inomkhawulo wosayizi, kokubili ngokobukhulu bomzimba bedivayisi kanye nobukhulu besikhunta esingazamukela. Ukukhiqiza izingxenye ezinkulu kungadinga imishini ekhethekile noma ezinye izindlela zokukhiqiza.

- Umthelela Wemvelo:Ngenkathi imboni isebenzela ukusimama, inqubo yokubumba umjovo we-thermoplastic isakhiqiza udoti, okuhlanganisa izinsalela kanye nezihlahla. Ukulahlwa ngendlela efanele kanye nokugaywa kabusha kwalezi zinto ezisetshenziswayo kuyadingeka ukuze kuncishiswe umthelela wendawo.

- Ubunkimbinkimbi bokuthuthukisa Inqubo:Ukufeza imingcele yenqubo efanelekile yokubumba umjovo we-thermoplastic kungaba yinkimbinkimbi futhi kudle isikhathi. Abakhiqizi kufanele balawule ngokucophelela futhi bandise izinga lokushisa, ukucindezela, amazinga okupholisa, nezikhathi zomjikelezo ukuze kuqinisekiswe ingxenye engashintshi yekhwalithi nokunciphisa amaphutha.

Izinhlobo ze-Thermoplastics Ezisetshenziswa Ekubumbeni Umjovo

Lezi izibonelo ezimbalwa nje ze-thermoplastics evame ukusetshenziswa ekubumbeni umjovo. Impahla ngayinye inezici ezihlukile, iyenza ifanelekele izinhlelo zokusebenza ezithile ngokusekelwe emandleni, ukuguquguquka, ukumelana namakhemikhali, ukubonakala, kanye nezindleko. Abakhiqizi kufanele bacabangele lezi zakhiwo kanye nezidingo lapho bekhetha i-thermoplastic efanele yamaphrojekthi abo okubumba umjovo.

- I-Polypropylene (PP):I-Polypropylene iyi-thermoplastic eguquguqukayo evame ukusetshenziswa ekubumbeni umjovo. Inikeza ukumelana kwamakhemikhali okuhle kakhulu, ukuminyana okuphansi, namandla omthelela omuhle. I-PP (i-polypropylene) inezinhlelo ezibanzi zokupakisha, izingxenye zezimoto, izinto zasendlini, nemishini yezokwelapha.

- I-Polyethylene (PE):I-polyethylene ingenye i-thermoplastic esetshenziswa kakhulu ekubumbeni umjovo. Itholakala ngezindlela ezihlukahlukene, njenge-high-density polyethylene (HDPE) kanye ne-low-density polyethylene (LDPE). I-PE inikeza ukumelana okuhle kwamakhemikhali, ukuqina, nokuguquguquka, okwenza ifaneleke amabhodlela, iziqukathi, namapayipi.

- I-Polystyrene (PS):I-Polystyrene iyi-thermoplastic eguquguqukayo eyaziwa ngokucaca kwayo, ukuqina, nokuthengeka kwayo. Ithola ukusetshenziswa okuvamile emaphaketheni, empahleni yabathengi, nasemikhiqizweni elahlwayo. I-PS (i-polystyrene) ivumela ukucutshungulwa okusheshayo futhi inikeza ukuzinza okuhle kwe-dimensional, kodwa ingaba brittle futhi ibe lula ekuqhekekeni kokucindezeleka kwemvelo.

- I-Acrylonitrile Butadiene Styrene (ABS): I-ABS iyi-thermoplastic edumile eyaziwa ngokumelana nomthelela omuhle kakhulu nokuqina. Ihlanganisa izakhiwo ze-acrylonitrile, i-butadiene, ne-styrene ukuze kwakhiwe impahla eguquguqukayo efanele izingxenye zezimoto, izindlu zikagesi, namathoyizi.

- I-Polyvinyl Chloride (PVC): I-PVC iyi-thermoplastic esetshenziswa kakhulu eyaziwa ngokumelana namakhemikhali okuhle kakhulu, ukuqina, kanye nezindleko eziphansi. Kungaba lukhuni noma kuguquguquke kuye ngokwakhiwa kanye nezithasiselo ezisetshenzisiwe. I-PVC (i-polyvinyl chloride) ithola ukusetshenziswa okuvamile ekwakhiweni, ekufakweni kukagesi, emikhiqizweni yokunakekelwa kwempilo, nasekupakisheni.

- I-Polycarbonate (PC): I-Polycarbonate iyi-thermoplastic ebonakalayo enomthelela ongavamile kanye nokumelana nokushisa okuphezulu. Ithola ukusetshenziswa okuvamile ezinhlelweni ezidinga ukucaca okubonakalayo, njengezingxenye zezimoto, izigqoko zokuzivikela, nezibonisi zikagesi.

- Inayiloni (Polyamide):Inayiloni iyi-thermoplastic eqinile futhi ehlala isikhathi eside eyaziwa ngezakhiwo zayo ezinhle kakhulu zemishini kanye nokumelana namakhemikhali. Ithola ukusetshenziswa okuvamile ezinhlelweni ezidinga amandla aphezulu, njengezingxenye zezimoto, izingxenye zezimboni, nezimpahla zabathengi.

- I-Polyethylene Terephthalate (PET):I-PET iyi-thermoplastic ethandwayo yokukhiqiza amabhodlela, iziqukathi, nezinto zokupakisha. Inikeza ukucaca okuhle, ukumelana namakhemikhali, kanye nezakhiwo zokuvimbela, okuyenza ifanele ukusetshenziswa kokudla neziphuzo.

Izakhiwo ze-Thermoplastics Esetshenziswa Ekubumbeni Umjovo

Lezi zakhiwo ze-thermoplastics zidlala indima ebalulekile ekunqumeni ukufaneleka kwazo kwezicelo zokubumba umjovo othize. Abakhiqizi kufanele bacabangele lezi zakhiwo ngokucophelela futhi bakhethe i-thermoplastic efanele ngokusekelwe ekusebenzeni okufunayo, izimo zemvelo, nezidingo zezindleko.

- Izici zemishini:I-Thermoplastics esetshenziswa ekubumbeni umjovo ingabonisa izici ezihlukahlukene zemishini, okuhlanganisa amandla aqinile, ukumelana nomthelela, namandla okuguquguquka. Lezi zakhiwo zinquma ikhono lempahla lokumelana namandla asetshenzisiwe kanye nokuqina kwawo kukonke ezinhlelweni ezihlukene.

- Ukumelana Namakhemikhali:Ama-thermoplastic amaningi asetshenziswa ekubumbeni umjovo anokumelana okuphawulekayo namakhemikhali, izinyibilikisi namafutha. Lesi sakhiwo sibalulekile ezinhlelweni ezibandakanya ukuchayeka endaweni enzima noma izinto ezibolayo.

- Ukuqina Kokushisa:Ukuzinza kokushisa kwe-thermoplastics kubhekisela emandleni azo okumelana nezinga lokushisa eliphakeme ngaphandle kokuwohloka okukhulu. Amanye ama-thermoplastics abonisa ukumelana nokushisa okuhle kakhulu, okubavumela ukuthi bagcine izakhiwo zabo zemishini ngisho namazinga okushisa aphezulu.

- Izakhiwo zikagesi:I-Thermoplastics esetshenziswa ekubumbeni umjovo ingaba nezinto ezithile zikagesi, okuhlanganisa ukufakwa kukagesi, ukuqhutshwa kwe-conductivity, noma amandla e-dielectric. Lezi zakhiwo zibalulekile ekusetshenzisweni kwezimboni zikagesi neze-elekthronikhi, lapho izinto ezisetshenziswayo kufanele zinikeze ukusebenza okuthembekile kukagesi.

- Ukungafihli nokucaca:Ama-thermoplastic athile, njenge-polycarbonate ne-PET, anikeza ukukhanya okuhle kakhulu nokucaca, okuwenza afanelekele izinhlelo zokusebenza ezidinga izakhiwo zokubona. Abakhiqizi bavamise ukusebenzisa lezi zinto emikhiqizweni efana namafasitela abonisa ngale, amalensi, nezibonisi.

- Ukuvumelana nezimo kanye nokuqina: Ukuvumelana nezimo kanye nokuqina kuyizici ezibalulekile ze-thermoplastics ezisetshenziswa ezinhlelweni ezidinga ukumelana nomthelela nokuqina. Amanye ama-thermoplastic, njenge-ABS nenayiloni, anikeza ukuqina okuhle kakhulu, okuwavumela ukuthi amelane nemithelela ephindaphindiwe ngaphandle kokuphuka.

- Ukuzinza kweDimensional:Ukuzinza kwe-Dimensional kusho ikhono le-thermoplastic lokugcina isimo nosayizi ngaphansi kwezimo ezihlukene, okuhlanganisa nokushintsha kwezinga lokushisa. Izinto ezisebenza ngokuzinza okuhle kwe-dimensional ziqinisekisa ubukhulu bezingxenye ezingaguquki, zinciphisa ubungozi bokungqubuzana noma ukuhlanekezela.

- Ukuhambisana Kwekhemikhali:Ukuhambisana kwamakhemikhali kwe-thermoplastics kubhekisela ekhonweni lazo lokumelana nokucekelwa phansi noma ukusebenzisana namakhemikhali ahlukahlukene, okuhlanganisa ama-asidi, izisekelo, nezinyibilikisi. Ukuqinisekisa ukusebenza kahle, ukukhetha i-thermoplastic engakwazi ukumelana nemvelo ethile yamakhemikhali ezohlangana nayo ekusetshenzisweni okuhlosiwe kubalulekile.

- Ubuningi: I-Thermoplastics inobukhulu obuhlukahlukene, obungaba nomthelela wesisindo sabo kanye nengxenye yayo yonke impahla. Izinto ezisezingeni eliphansi, njenge-polyethylene, zinikeza izixazululo ezingasindi, kuyilapho izinto eziphakeme kakhulu, njenge-polypropylene, zinikeza amandla angeziwe kanye nokuqina.

Inqubo yokubumba umjovo: Isinyathelo ngesinyathelo

Inqubo yokubumba umjovo ilandela lezi zinyathelo, okuvumela ukukhiqizwa okuphumelelayo nokunembayo kwezingxenye zekhwalithi ephezulu ze-thermoplastic. Isinyathelo ngasinye sidinga ukulawula nokuqapha ngokucophelela ukuze kuqinisekiswe ubukhulu bezingxenye ezingaguquki, izakhiwo zezinto ezibonakalayo, kanye nekhwalithi iyonke.

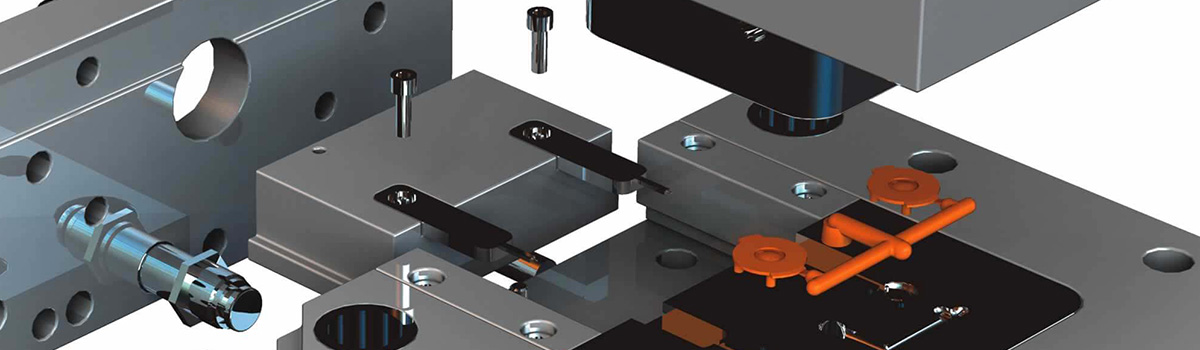

- Ukuklanywa Kwesikhunta Nokwenziwa: Isinyathelo sokuqala enqubweni yokubumba umjovo ukuklama nokwakhiwa kwesikhunta. Abakhiqizi kumele bakhe idizayini yesikhunta enembayo nenemininingwane ukuze kuzuzwe ukucaciswa kwengxenye abayifunayo. Abakhiqizi bese benza isikhunta besebenzisa amasu ahlukahlukene, njenge-CNC noma i-electrical discharge machining (EDM).

- Ukulungiselela Material: Isinyathelo esilandelayo ukulungiselela uma isikhunta sesilungile. Ama-pellets e-Thermoplastic noma ama-granules akhethwa ngokusekelwe ezintweni ezibonakalayo ezidingekayo futhi ancibilike ku-hopper. Ama-opharetha abe esephakela impahla emgqonyeni womshini wokubumba umjovo, lapho uncibilika khona futhi uhlanganiswe ne-homogenization.

- Umjovo:Phakathi nesigaba somjovo, opharetha bajova i-thermoplastic encibilikisiwe emgodini wesikhunta ngaphansi kwengcindezi ephezulu. Iyunithi yomjovo womshini iphusha into encibilikisiwe ngombhobho kanye nasesikhunjeni. Impahla igcwalisa umgodi wokubumba, ithatha isimo sengxenye oyifunayo.

- Ukupholisa kanye Nokuqinisa:Ngemva kokugcwalisa isikhunta, opharetha bavumela ipulasitiki encibilikisiwe ukuthi iphole futhi iqine. Ukupholisa kubalulekile ukuze kuzuzwe ukuzinza kwe-dimensional kanye nokwakheka kwengxenye efanele. Ama-opharetha angakwazi ukulawula inqubo yokupholisa ngokuzungeza into epholile ngamashaneli angaphakathi kwesikhunta noma ngokusebenzisa amapuleti okupholisa.

- Ukuvula Nokukhishwa Kwesikhunta:Ama-opharetha avula isikhunta futhi akhiphe ingxenye engxenyeni yesikhunta uma ipulasitiki isiqinile. Isistimu yokukhipha ngaphakathi komshini isebenzisa izikhonkwane, amapuleti ejector, noma ukuqhuma komoya ukuze isuse isifunda esikhunjeni. Isikhunta sibe sesilungele umjikelezo womjovo olandelayo.

- Ngemuva kokucubungula: Ngemuva kokukhishwa, ingxenye ingase yenze imisebenzi yangemva kokucubungula, njengokunquma, ukususa, noma ukuqedwa kwendawo. Lezi zinyathelo zisiza ukususa okubalulekile okudlulele, imiphetho eshelelayo, futhi kuthuthukise ukubukeka kokugcina kwengxenye.

- Ukuhlolwa kwekhwalithi: Isinyathelo sokugcina sibandakanya ukuhlola izingxenye ezijovwe ngekhwalithi nokuqinisekisa ukuthi ziyahlangabezana nezidingo ezishiwo. Amasu ahlukahlukene okulawula ikhwalithi, okuhlanganisa ukulinganisa kobukhulu, ukuhlola okubonakalayo, nokuhlola ukusebenza, angasetshenziswa ukuze kuqinisekiswe ikhwalithi nobuqotho bengxenye.

- Ukugaywa kabusha nokusetshenziswa kabusha kwempahla:Noma iyiphi into eyeqile noma ehlakazekile ekhiqizwe ngesikhathi sokubunjwa komjovo ingaphinda isetshenziswe futhi isetshenziswe kabusha. Ukunciphisa ukusetshenziswa kwezinto ezintsha ze-thermoplastic kusiza ukunciphisa imfucuza futhi kuthuthukise ukusimama.

Impahla Esetshenziswa Ekubumbeni Umjovo

Lezi zingxenye zemishini zenza kube lula inqubo yokubumba umjovo, ukusuka ekuncibilikeni nasekujoveni okokusebenza kwe-thermoplastic kuye ekubumbeni, ekupholiseni, nasekukhipheni ingxenye yokugcina. Ukusebenza nokugcinwa ngendlela efanele kwalezi zingxenye zemishini kubalulekile ukuze kuzuzwe ukukhiqizwa kokubumba komjovo okuseqophelweni eliphezulu.

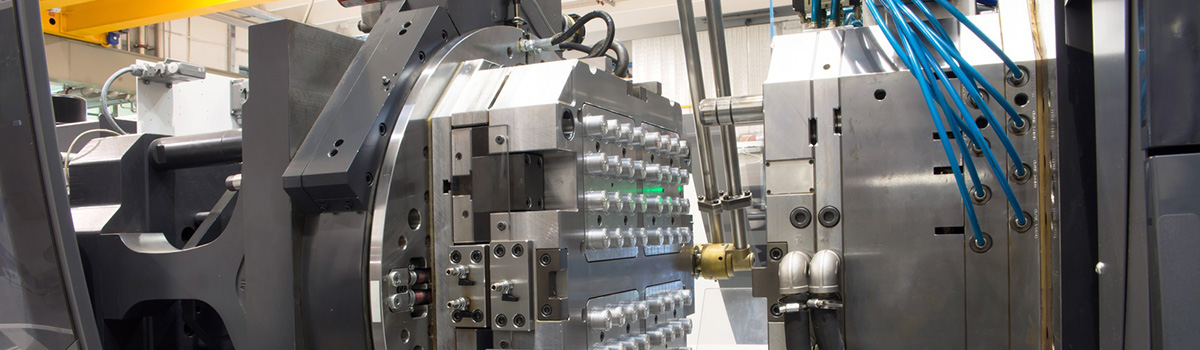

- Umshini Wokubumba Umjovo:Imishini yokuqala ekubumbeni umjovo inesibopho sokuncibilikisa i-thermoplastic impahla, ukuyijova esibunjeni, nokulawula inqubo.

- Isibungu: Isikhunta, esiklanyelwe ukwenza isimo esifiselekayo nezici zengxenye yepulasitiki, sihlanganisa izingxenye ezimbili, umgodi kanye nomgogodla. Ama-opharetha ayifaka kuyunithi yokubopha yomshini wokubumba umjovo.

- I-Hopper:Isitsha esibamba i-thermoplastic kwifomu ye-pellet noma ye-granular futhi siyifake emgqonyeni womshini wokubumba umjovo ukuze incibilike futhi ijovwe.

- Umgqomo kanye nesikulufu: Umphongolo, i-cylindrical chamber, iyancibilika futhi yenza into efanayo ne-thermoplastic njengoba isikulufu sizungeza ngaphakathi kwawo ukuze sincibilike, sixube, futhi simise okokusebenza.

- Amasistimu wokushisisa nokupholisa:Imishini yokubumba imijovo inezinto zokufudumeza, njengezifudumezi zikagesi noma izifudumezi ezisebenzisa amafutha ashisayo, ukuphakamisa izinga lokushisa lomgqomo, nezinhlelo zokupholisa, ezifana nokujikeleza kwamanzi noma uwoyela, ukupholisa isikhunta futhi kuqiniswe ingxenye yepulasitiki.

- Isistimu ye-Ejector:Isusa ingxenye ebunjiwe ku-mold cavity ngemva kokuqina, ngokuvamile isebenzisa izikhonkwane ze-ejector, amapuleti, noma ukuqhuma komoya phakathi nokuvula isikhunta.

- Uhlelo lokulawula:Iqapha futhi ilawule amapharamitha ahlukahlukene wenqubo yokubumba umjovo, ivumela opharetha ukuthi basethe futhi balungise imingcele efana nesivinini somjovo, izinga lokushisa, ukucindezela, nesikhathi sokupholisa.

Imishini Yokubumba Umjovo: Izinhlobo Nezimpawu

Uhlobo ngalunye lomshini wokubumba umjovo lunezici zalo kanye nezinzuzo zalo, okuvumela abakhiqizi ukuthi bakhethe idivayisi efanelekile kakhulu ngezidingo zabo ezithile zokukhiqiza.

- Imishini yokubumba yomjovo weHydraulic: Le mishini isebenzisa amasistimu we-hydraulic ukuze ikhiqize ingcindezi edingekayo yokujova ipulasitiki encibilikisiwe esibunjeni. Baziwa ngamandla abo okubamba aphezulu, ukulawula okunembile, kanye nokuguquguquka ekuphatheni ama-thermoplastic ahlukahlukene. Imishini ye-Hydraulic ilungele ukukhiqizwa okukhulu futhi ingakwazi ukufaka isikhunta esiyinkimbinkimbi.

- Imishini yokubumba yomjovo kagesi:Imishini kagesi isebenzisa ama-servo motors kagesi ekusebenzeni komshini, okuhlanganisa umjovo, ama-clamping, namasistimu ejector. Banikeza ukulawula okunembayo, ukusebenza kahle kwamandla, kanye nezikhathi zokuphendula ngokushesha kunemishini yama-hydraulic. Imishini kagesi ilungele izinhlelo zokusebenza zokubumba ezidinga ukuphindaphinda nokunemba okuphezulu.

- Imishini Yokubumba I-Hybrid Injection:Imishini eyi-Hybrid ihlanganisa izinzuzo zako zombili i-hydraulic kanye namadivayisi kagesi. Basebenzisa inhlanganisela yezinhlelo ze-hydraulic kanye ne-electric servo ukuze bathole ukunemba okuphezulu, ukusebenza kahle kwamandla, nokusebenza kahle kwezindleko. Imishini ye-Hybrid ifaneleka ezinhlobonhlobo zezinhlelo zokusebenza, ihlinzeka ngebhalansi phakathi kokusebenza kanye nezindleko zokusebenza.

- Imishini Yokubumba Yokujova Okubili: Imishini enamapulangwe amabili inomklamo oyingqayizivele onamacwecwe amabili ahlukene okubamba isikhunta. Lo mklamo unikeza ukuzinza okuthuthukisiwe, ukuvumelanisa kwesikhunta okuthuthukisiwe futhi uvumela osayizi abakhulu besikhunta namandla aphezulu okubamba. Imishini yamapulangwe amabili ifanele izingxenye ezinkulu neziyinkimbinkimbi ezidinga ukubunjwa okunembile.

- Imishini Yokubumba Yezingxenye Eziningi:Abakhiqizi baklama le mishini ukuze ikhiqize izingxenye ezinempahla eminingi noma imibala emjikelezweni owodwa wokubumba. Anamayunithi ahlukahlukene omjovo kanye nesikhunta, okuvumela ukujova ngasikhathi sinye kwezinto ezihlukene. Imishini enezingxenye eziningi inikeza ukuguquguquka nokusebenza kahle ekukhiqizeni izingxenye eziyinkimbinkimbi ezinezici ezihlukahlukene.

- Imishini yokubumba imijovo emincane:Idizayinelwe ngokukhethekile ukukhiqiza izingxenye ezincane nezinembayo, imishini yokubumba imijovo emincane inikezela ngokunemba okuphezulu nokunemba okumangalisayo. Bangakwazi ukukhiqiza imininingwane eyinkimbinkimbi ngokubekezelelana okuqinile kanye nokuchithwa okuncane kwezinto ezibonakalayo. Izinto zikagesi, izisetshenziswa zezokwelapha, kanye ne-micro-optics ngokuvamile zisebenzisa imishini yokubumba imijovo emincane.

Ukucatshangelwa kwe-Mold Design yokubunjwa komjovo

Ukucatshangelwa kokuklanywa kwesikhunta ngokucophelela kubalulekile ekukhiqizeni umjovo ophumelelayo wokubumba.

- Ingxenye yokuklama:Idizayini yesikhunta kufanele ihambisane nezidingo ezithile zengxenye, okuhlanganisa ukuma kwayo, ubukhulu, nezici zokusebenza. Abakhiqizi kufanele bacabangele kahle ama-engeli asalungiswa, ukujiya kodonga, ama-undercuts, nanoma yiziphi izici ezidingekayo ukuze baqinisekise ukukhululeka kokukhipha kanye nengxenye yekhwalithi.

- I-Mold Material: Ukukhethwa kwe-mold material kubalulekile ukuze kuzuzwe ukuqina, ukuzinza kwe-dimensional, nokumelana nokushisa. Izinto ezijwayelekile zokubumba zihlanganisa ama-alloys ensimbi, ama-alloys e-aluminium, nezinsimbi zamathuluzi. Ukukhethwa kwezinto kuncike ezintweni ezifana nevolumu yokukhiqiza, ingxenye eyinkimbinkimbi, nokuphila kwamathuluzi okulindelekile.

- Uhlelo Lokupholisa:Ukupholisa okuphumelelayo kubalulekile ukuze kuqiniswe ingxenye efanele kanye nokunciphisa isikhathi somjikelezo. Idizayini yesikhunta kufanele ihlanganise amashaneli okupholisa noma izinto ezifakwe kahle ukuze kuqinisekiswe ukupholisa kwesikhunta okufanayo. Ukupholisa ngendlela efanele kunciphisa ubungozi be-warpage, ukuncipha, kanye nokukhubazeka kwengxenye.

- Ukuhamba:Ukukhipha umoya okwanele kuyadingeka ukuvumela ukuphuma komoya namagesi ngesikhathi sokujova. Ukukhipha umoya okwanele kungaholela ezicupheni zegesi, izimpawu zokusha, noma ukugcwaliswa kwengxenye okungaphelele. Abakhiqizi bangakwazi ukuthola umoya ngokuhlanganisa imisele yokukhipha umoya, izikhonkwane, noma ezinye izindlela ekwakhiweni kwesikhunta.

- Isistimu Yokukhipha:Idizayini yesikhunta kufanele ifake isistimu yokukhipha ephumelelayo ukuze ikhiphe ngokuphepha nangempumelelo ingxenye ebunjiwe emgodini wesikhunta. Isistimu yokukhipha ingaqukatha izikhonkwane ze-ejector, imikhono, noma ezinye izindlela, ezibekwe ngendlela efanele ukuze zigweme ukuphazamiseka komsebenzi noma izici ezibucayi.

- Idizayini yesango:Isango yilapho ipulasitiki encibilikisiwe ingena khona emgodini wesikhunta. Idizayini yesango kufanele iqinisekise ukugcwaliswa okufanelekile kwengxenye, ukunciphisa imigqa yokugeleza, futhi kuvimbele ukuqandisa kwempahla ngaphambi kwesikhathi. Imiklamo yesango evamile ihlanganisa amasango asemaphethelweni, amasango omhubhe, nezinhlelo zomgijimi oshisayo, kuye ngezidingo zengxenye nezinto ezibonakalayo.

- Umugqa wokuhlukanisa:Umklamo wesikhunta kufanele uchaze umugqa wokuhlukanisa ofanelekayo, okuwumugqa lapho izingxenye ezimbili zesikhunta zihlangana khona. Ukubekwa kahle komugqa wokuhlukanisa kuqinisekisa ukuphazima okuncane nokungafani kolayini wokuhlukanisa futhi kusiza ukuhlanganisa isikhunta okuphumelelayo.

- Ukugcinwa Kwesikhunta Nokusebenza: Abakhiqizi kufanele bacabangele ukunethezeka kokulungiswa, ukukhanda, kanye nokusevisa isikhunta. Izingxenye zesikhunta kufanele zifinyeleleke kalula ukuze zihlanzwe, zihlolwe futhi zifakwe esikhundleni. Ukufaka izici ezifana nokufakwa okushintsha ngokushesha noma amadizayini esikhunta angathuthukisa ukusebenza kwesikhunta.

Izinto Zokubumba Ezisetshenziswa Ekubumbeni Umjovo

Ukusebenzisana nochwepheshe bezinto zokubumba nokucabangela izidingo ezithile zohlelo lokusebenza lokubumba kungasiza ekunqumeni into efanelekile kakhulu yokufeza ukusebenza kahle kwesikhunta kanye nengxenye yekhwalithi.

- Ama-alloys ensimbi: Ama-alloys ensimbi, njengezinsimbi zamathuluzi (isb, i-P20, i-H13) nezinsimbi ezingenasici, zivame ukusetshenziselwa isikhunta sokubumba umjovo ngenxa yokuqina kwazo okuhle kakhulu, ukumelana nokushisa, nokungagugi. Lezi zinto zingakwazi ukumelana namazinga okushisa aphezulu kanye nezingcindezi kunqubo yokubumba umjovo futhi zinikeze ukuzinza okuhle kwe-dimensional ukukhiqiza izingxenye zekhwalithi ephezulu.

- Aluminiyamu Alloys:Ama-alloys e-aluminium, afana ne-7075 kanye ne-6061, alula futhi ahlinzeka ngokuhambisa kahle kwe-thermal, okuwenza afanelekele isikhunta esidinga ukupholisa okuphumelelayo. Abakhiqizi bavamise ukusebenzisa isikhunta se-aluminium ukwenza i-prototyping, ukukhiqizwa kwevolumu ephansi, noma izinhlelo zokusebenza lapho ukunciphisa isisindo kubaluleke kakhulu. Kodwa-ke, isikhunta se-aluminium singase sibe nokuqina okuphansi uma kuqhathaniswa nama-alloys ensimbi.

- Ama-Copper Alloys:Ama-alloys e-Copper, njenge-beryllium yethusi, abonisa ukuqhutshwa kwe-thermal ephezulu kanye nokusebenza kahle. Zithola ukusetshenziswa ezikhunjini ezidinga ukudluliswa kokushisa okuhle kakhulu ukuze kuphole ngempumelelo. Ama-alloys ethusi angasiza ukunciphisa izikhathi zomjikelezo ngokukhipha ukushisa ngokushesha engxenyeni ebunjiwe, okuholela ekuqinisweni ngokushesha.

- Izinsimbi zamathuluzi:Izinsimbi zamathuluzi, okuhlanganisa i-H13, i-S7, ne-D2, yakhelwe izinhlelo zokusebenza zamathuluzi ezisebenza kahle kakhulu. Lezi zinsimbi zinikeza inhlanganisela yamandla aphezulu, ubulukhuni, nokumelana nokugqoka. Izinsimbi zamathuluzi zifanelana nesikhunta esinevolumu ephezulu yokukhiqiza, izinto ezi-brasive, noma izimo zokubumba ezinzima.

- I-Nickel Alloys:Ama-Nickel alloys, afana ne-Inconel ne-Hastelloy, aziwa ngokumelana nokugqwala okukhethekile, amandla okushisa aphezulu, nokuzinza kokushisa. Abakhiqizi basebenzisa lezi zingxubevange ekubunjweni okubamba izinto ezonakalisayo noma ezidinga ukumelana nezinga lokushisa elidlulele kanye nezindawo zokubumba ezinolaka.

- Izinto Ezihlanganisiwe:Izinto eziyinhlanganisela, njengamapulasitiki aqinisiwe noma izinhlanganisela ezinokufakwa kwensimbi, ngezikhathi ezithile zisetshenziselwa izinhlelo ezithile zokubumba. Lezi zinto zinikeza ibhalansi yezakhiwo, njengamandla aphezulu, ukuzinza okushisayo, nesisindo esincishisiwe. Isikhunta esiyinhlanganisela singaba ezinye izindlela ezingabizi kakhulu ezidingweni ezithile zokukhiqiza.

Izinhlobo Zesikhunta Sokujova

Ukubumba umjovo kuyinqubo yokukhiqiza eguquguqukayo futhi esetshenziswa kabanzi yezingxenye zepulasitiki.

- I-Two-Plate Mold:Isikhunta esinamapuleti amabili wuhlobo oluvame kakhulu lomjovo. Iqukethe amapuleti amabili, i-cavity plate, kanye ne-core plate, ehlukanayo ukuze ivumele ukukhishwa kwengxenye ebunjiwe. I-cavity plate iqukethe uhlangothi lwesigxobo sesikhunta, kuyilapho ipuleti eliyinhloko lihlala ohlangothini oluyinhloko. Abakhiqizi basebenzisa isikhunta esinamapuleti amabili ukukhiqiza izinhlobonhlobo zezingxenye ngenxa yokwakheka kwazo okulula.

- Isikhunta se-Three-Plate:Isikhunta se-three-plate inguqulo ethuthukisiwe yesikhunta samacwecwe amabili. Ihlanganisa ipuleti elengeziwe, i-runner, noma ipuleti le-sprue. Ipuleti lomgijimi lidala isiteshi esihlukile se-sprue, abagijimi, namasango, okuvumela ukususwa kalula kwengxenye ebunjiwe. Abakhiqizi ngokuvamile basebenzisa ezintathu-plate isikhunta ukuze uthole imininingwane nge eziyinkimbinkimbi gating izinhlelo noma lapho ugwema umsalela wesango phezu ucezu kuyinto efiselekayo.

- Isikhunta se-Hot Runner:Umgijimi kanye nesistimu yesango ishiswa ekubunjweni komgijimi oshisayo, okuqeda isidingo sokuqiniswa kanye nokuncibilika kabusha kwezinto phakathi nomjikelezo ngamunye. Isistimu yomgijimi oshisayo iqukethe ama-nifolds ashisayo namabhobho agcina isimo sokuncibilika sepulasitiki. Isikhunta se-hot runner sinikeza izinzuzo ezifana nesikhathi esincishisiwe somjikelezo, ukuchithwa kwempahla ephansi, kanye nekhwalithi yengxenye ethuthukisiwe ngokunciphisa izinsalela zesango.

- Cold Runner Mold: Isikhunta se-cold runner sinesistimu yokugijima yendabuko kanye nesango lapho ipulasitiki encibilikisiwe igeleza ngezigijimi ezibandayo eziqina ngomjikelezo ngamunye. Abasebenza ngokulandelayo basusa izigijimi eziqinile, okuholela ekumoshweni kwezinto ezibonakalayo. Abakhiqizi bavamise ukusebenzisa isikhunta se-runner esiyinkimbinkimbi ukukhiqiza ivolumu ephansi noma lapho izindleko zempahla zingabalulekile kangako ngenxa yedizayini yazo eqonde kakhudlwana.

- Faka Isikhunta:Faka isikhunta sifaka insimbi noma ipulasitiki embotsheni yesikhunta ngesikhathi sokubumba umjovo. Okufakwayo kungafakwa ngaphambili esikhunjeni noma kufakwe izinqubo ezizenzakalelayo. Lesi sikhunta sivumela ukuhlanganisa izingxenye ezengeziwe noma izakhi zokuqinisa engxenyeni ebunjiwe, ithuthukise ukusebenza kwayo noma amandla.

- I-Overmold: Ukweqa kuhlanganisa ukubumba into eyodwa phezu kwenye, ngokuvamile ukuhlanganisa i-substrate yepulasitiki eqinile nge-elastomer ethambile noma i-thermoplastic. Le nqubo ivumela ukwakhiwa kwezingxenye ezinempahla eminingi noma ukwakheka kwesikhunta esisodwa, enikeza ukubamba okuthuthukisiwe, ukugoba, noma izici zobuhle.

Izinto Ezithinta Izindleko Zokubumba Umjovo

Ukucabangela lezi zici kungasiza abakhiqizi balinganisele futhi bandise izindleko zokubumba umjovo, kuqinisekiswe ibhalansi phakathi kwekhwalithi, ukusebenza kahle, kanye nokusebenza kahle kwezindleko ezidingweni zabo ezithile zokukhiqiza.

- Ingxenye Eyinkimbinkimbi:Ubunkimbinkimbi bomklamo wengxenye budlala indima ebalulekile ekunqumeni izindleko zokubumba umjovo. Amajiyometri ayinkimbinkimbi, ama-undercuts, izindonga ezincane, noma izici eziyinkimbinkimbi zingadinga amathuluzi angeziwe, isikhunta esikhethekile, noma imijikelezo emide, okwandisa izindleko zokukhiqiza zizonke.

- Ukukhetha Okubalulekile:Ukukhethwa kwempahla ye-thermoplastic kuthinta izindleko zokubumba umjovo. Izinto ezisetshenziswayo ezihlukene zinamanani ahlukahlukene ngekhilogremu, futhi izici ezifana nokutholakala kwezinto ezibonakalayo, izakhiwo, nezimfuneko zokucubungula zingathonya izindleko zento yonke.

- I-Tooling kanye ne-Mold Design: Izindleko zokuqala zokusebenzisa kanye nokuklama isikhunta zibalulekile ezindlekweni zokubumba umjovo. Izinto ezinjengobunzima besikhunta, inani lezimbobo, ubukhulu besikhunta, nezinto zokukhunta zinomthelela ezindlekweni zamathuluzi nezokukhiqiza isikhunta. Izibunjwa eziyinkimbinkimbi kakhulu noma isikhunta esidinga izici ezithuthukisiwe zingakhuphula ukutshalwa kwezimali kwangaphambili.

- Ivolumu Yokukhiqiza: Umthamo wokukhiqiza uthinta ngqo izindleko ingxenye ngayinye ekubumbeni umjovo. Izincwadi eziphakeme zivame ukuholela ezomnotho wesilinganiso, ukunciphisa izindleko ingxenye ngayinye. Ngokuphambene, ukukhiqizwa kwevolumu ephansi kungase kubize izindleko eziphezulu ngenxa yokusetha, ukusebenzisa amathuluzi, nokumosha izinto.

- Isikhathi Somjikelezo: Isikhathi somjikelezo, esihlanganisa izigaba zokupholisa nokukhipha, sithinta umthamo wokukhiqiza kanye nezindleko zizonke. Izikhathi zomjikelezo omude ziphumela ekuncishisweni komkhiqizo kanye namanani angaba phezulu. Ukulungiselela ukwakheka kwesikhunta, isistimu yokupholisa, nemingcele yenqubo kunganciphisa izikhathi zomjikelezo futhi kuthuthukise ukusebenza kahle.

- Izimfuneko Zekhwalithi:Izidingo zekhwalithi eqinile noma izitifiketi ezithile zingathinta izindleko zokubumba umjovo. Ukuhlangabezana nokubekezelela okunembile, izimfuneko zokuqedwa kwendawo, noma ukuhlola okwengeziwe kungase kudinge ezinye izinsiza, izinqubo, noma ukuhlolwa, okwengeza kuzo zonke izindleko.

- Imisebenzi yesibili:Uma izingxenye ezibunjiwe zidinga imisebenzi yangemva kokucubungula njengokuhlanganisa, ukupenda, noma izinyathelo ezengeziwe zokuqeda, le misebenzi ingangeza kuzindleko zokubumba zizonke.

- Umhlinzeki nendawo:Ukukhethwa komhlinzeki wokubumba umjovo kanye nendawo yabo kungathinta izindleko. Izindleko zabasebenzi, izindleko eziphezulu, izinto zokuhamba, kanye nezindleko zokuhamba ziyahlukahluka ngokuya ngendawo yomphakeli, okunomthelela kuzo zonke izindleko zokukhiqiza.

Ukulawulwa Kwekhwalithi Ekubumbeni Umjovo

Ukusebenzisa izinyathelo zokulawula ikhwalithi eqinile kuyo yonke inqubo yokubumba umjovo kusiza ekuhlonzeni nasekuxazululeni izinkinga ezingaba khona, ukuchezuka, noma ukungqubuzana, ukuqinisekisa ukukhiqizwa kwezingxenye zekhwalithi ephezulu ezihlangabezana nokucaciswa nezimfuneko zekhasimende.

- Ukuqapha Inqubo: Ukuqapha okuqhubekayo kwamapharamitha enqubo ebalulekile, njengezinga lokushisa elincibilikayo, ingcindezi yomjovo, isikhathi sokupholisa, nesikhathi somjikelezo, kuqinisekisa ukuvumelana nokuphindaphinda ekukhiqizeni ingxenye. Ukuqapha kwesikhathi sangempela namasistimu azenzakalelayo angathola ukuhluka noma ukuphambuka kumapharamitha asethiwe, okuvumela ukulungiswa okufika ngesikhathi kanye nokugcina ukuqina kwenqubo.

- Ukuhlola kanye Nesilinganiso:Ukubuyekezwa okuvamile kanye nokukalwa kwezingxenye ezibunjiwe kubalulekile ukuze kuqinisekiswe ukunemba kobukhulu, ingxenye yekhwalithi, nokuhambisana nokucaciswa. Amasevisi ethu ahlanganisa izinhlobonhlobo zezindlela zokulawula ikhwalithi, ezifana nokulinganisa ubukhulu, ukuhlaziya ikhwalithi yendawo ephezulu, ukuhlola okubonakalayo, nokwenza izivivinyo zokusebenza. Amasu okuhlola ahlukahlukene, afana nemishini yokukala edidiyelwe (CMM) kanye nezinhlelo zokuhlola ezibonakalayo nezibonwayo, asetshenziswa ukuze kuhlolwe okunembile.

- Ukulawulwa Kwenqubo Yezibalo (SPC): I-SPC ibandakanya ukuqoqa nokuhlaziya idatha yenqubo yokuqapha nokulawula ikhwalithi yokubumba umjovo. Izindlela zezibalo, ezifana namashadi okulawula nokuhlaziya amandla okucubungula, zisiza ukuhlonza amathrendi, ukuthola ukuhlukahluka kwezinqubo, nokuqinisekisa ukuthi inqubo ihlala ingaphakathi kwemikhawulo yokulawula echaziwe. I-SPC inika amandla ukukhonjwa okusebenzayo kwezinkinga futhi isiza ukuthuthukiswa kwenqubo.

- Ukuhlola Okubalulekile: Ukuhlola izinto zokusetshenziswa, ezifana ne-thermoplastics, izithasiselo, nama-colorants, kuqinisekisa ikhwalithi yazo nokufaneleka kokubunjwa komjovo. Ukuhlolwa kwezinto ezibonakalayo kungase kuhlanganise ukuhlaziywa kwe-melt flow index (MFI), izakhiwo zemishini, izici ezishisayo, nokwakheka kwezinto. Ukuqinisekisa ikhwalithi yezinto kusiza ukuvimbela amaphutha nokungahambisani ezingxenyeni ezibunjiwe.

- Ukugcinwa Kwamathuluzi Nokuhlola:Ukunakekelwa okufanele kanye nokuhlolwa njalo kwesikhunta somjovo kubalulekile ukuze kuqinisekiswe izinga lokubumba umjovo. Ukuhlanza njalo, ukugcotshwa, nokuhlolwa kwezingxenye zesikhunta kusiza ukuvimbela ukuguga, ukulimala, noma ukonakala okungase kuthinte ingxenye yekhwalithi. Ukulungiswa ngesikhathi noma ukushintshwa kwezingxenye zesikhunta ezigugile noma ezilimele kubalulekile ukuze kugcinwe ukusebenza kokubumba okungaguquki.

- Amadokhumenti kanye nokulandelelwa:Ukugcina imibhalo ephelele kanye namarekhodi okulandeleka kubalulekile ekulawuleni ikhwalithi ekubumbeni umjovo. Kubalulekile ukurekhoda amapharamitha enqubo, imiphumela yokuhlolwa, ulwazi lwempahla, nanoma yiziphi izinguquko noma ukulungiswa okwenziwe ngesikhathi sokukhiqiza. Amadokhumenti afanelekile anika amandla ukulandeleka kwezingxenye, kusiza ukuhlaziya imbangela yezimpande, futhi aqinisekise ukungaguquguquki kwekhwalithi.

- Ukuqeqeshwa Nokuthuthukiswa Kwamakhono: Ukunikeza ukuqeqeshwa okwanele nezinhlelo zokuthuthukisa amakhono kubaqhubi, ochwepheshe, nabasebenzi bokulawula ikhwalithi kuthuthukisa ukuqonda kwabo izinqubo zokubumba umjovo, izidingo zekhwalithi, namasu okuhlola. Abasebenzi abaqeqeshwe kahle bangakwazi ukubona amaphutha, baxazulule izinkinga, futhi basebenzise izinyathelo zokulungisa ngempumelelo, baqinisekise ukukhiqizwa kwekhwalithi ephezulu.

Ukukhubazeka Okujwayelekile Kokubumba Umjovo kanye nokuthi Ungakugwema Kanjani

Ukuhlolwa okuvamile, ukuqapha, nokuhlaziya izinqubo zokubumba umjovo kanye nokugcinwa okufanele nokulungiswa kwemishini nezibungu kungasiza ekuhlonzeni nasekuxazululeni lezi zinkinga ezivamile.

- Sink Marks:Amamaki osinki ama-depressions noma ama-indentation ebusweni bengxenye ebunjiwe okubangelwa ukupholisa okungalingani noma ukushwabana. Umuntu kufanele acabangele indawo efanele yesango kanye nomklamo, idizayini yesistimu yokupholisa efanele, kanye nokusabalalisa ukujiya kodonga okufanayo ukuze agweme izimpawu zokucwila. Ukwandisa umfutho womjovo noma ukulungisa isikhathi sokupholisa nakho kungasiza ekunciphiseni izimpawu zokucwila.

- Ikhasi lempi:I-Warpage isho ukuwohloka noma ukugoba kwengxenye ebunjiwe ngemva kokukhishwa ngenxa yokupholisa okungalingani noma izingcindezi ezisalayo. Ukugcina ubukhulu bodonga obufanayo, ukusebenzisa imigudu efanele yokupholisa, nokuqinisekisa ukugcwaliswa okunokulinganisela nokupakishwa kwesikhunta kubalulekile ukuvimbela i-warpage. Ukuthuthukisa izinga lokushisa lokukhunta, ukusebenzisa ama-engeli asalungiswa afanelekile, nokulawula izinga lokushisa lempahla nesivinini somjovo kungasiza ukunciphisa i-warpage.

- Flash:Ukubalaza kwenzeka lapho okubalulekile okudlulele kugeleza emugqeni wokuhlukanisa wesikhunta, okuholela ekubonakaleni okuncane, okungafuneki noma into eyengeziwe engxenyeni yokugcina. Umuntu angavimbela ngokuphumelelayo ukukhanya ngokuqinisekisa ukuklanywa kwesikhunta esifanele, okuhlanganisa ukusebenzisa amandla okuqinisa anele, ukuqondanisa okunembayo, nokusebenzisa izindlela ezifanele zokungenisa umoya. Ukuthuthukisa amapharamitha wenqubo njengokucindezela komjovo, izinga lokushisa, nesikhathi somjikelezo kunciphisa ukukhanya.

- Ishothi emfushane:Ukudubula okusheshayo kwenzeka lapho into ejovwe ingagcwali isikhunta, okuholela engxenyeni engaphelele. Ukukhetha impahla efanele, ukuqinisekisa izinga lokushisa elanele lokuncibilika kanye ne-viscosity, nokugcina ingcindezi yomjovo efanele kanye nesikhathi kubalulekile ukuze ugweme izithombe ezimfushane. Ukwengeza, ukuqinisekisa idizayini yesikhunta yomgijimi owanele nosayizi wesango kanye nokukhipha umoya okulungile kungasiza ukuvimbela ukushutha okusheshayo.

- Imigqa Ye-Weld:Imigqa yokushisela yenzeka lapho izingxenye ezimbili noma ngaphezulu ezincibilikisiwe ezigeleza zihlangana futhi ziqina, okuholela emugqeni obonakalayo noma umaka endaweni ethile. Isango elihle nedizayini yomgijimi, izinga lokushisa elilungile lokuncibilika, isivinini somjovo, nokulungisa ukugeleza kwezinto ezibonakalayo kanye nengxenye yejometri kunganciphisa imigqa yokushisela. Ukuhlaziywa kokugeleza kwesikhunta kanye nokwenza kahle kokubekwa kwesango nakho kungasiza ukuvimbela noma ukunciphisa imigqa yokushisela.

- Burn Marks:Izimpawu zokushiswa wukushintshashintsha kombala noma amachashazi amnyama ebusweni bengxenye ebunjiwe ebangelwa ukushisa ngokweqile noma ukushisisa ngokweqile kwento. Ukugwema izinga lokushisa elincibilikayo ngokwedlulele, ukusebenzisa amashaneli okupholisa afanelekile, nokuthuthukisa isikhathi somjikelezo kungasiza ukuvimbela izimpawu zokusha. Ukukhipha umoya okwanele, ukuklanywa kwesango ngendlela efanele, nokulawula izinga lokushisa lesikhunta nakho kunomthelela ekunciphiseni izimpawu zokusha.

Ukusebenza Kwangemva Kokubumba: Ukuqeda kanye Nokuhlanganisa

Ngemuva kokubunjwa komjovo, izingxenye eziningi ezibunjiwe zingadinga ukuqedwa okwengeziwe nokusebenza kokuhlanganisa ukuze kuzuzwe umkhiqizo wokugcina owufunayo. Le misebenzi yangemuva kokubumba ingase ihlanganise:

- Ukunquma:Susa noma iyiphi into eyeqile noma ifleshi eduze kwengxenye ebunjiwe usebenzisa amathuluzi okunquma noma okusika.

- Surface Ukwelashwa:Ukuthuthukisa ukubukeka noma ukusebenza kwengxenye yendawo kusetshenziswa amasu ahlukahlukene afana nokudweba, ukuhlanganisa, noma ukuthumela umbhalo.

- Umhlangano:Ukuhlanganisa izingxenye ezibunjiwe eziningi noma ukwengeza izingxenye ezifana nezinamathiselo, okokufaka, noma amalebula ukuze uqedele umkhiqizo wokugcina.

- Ukuhlola:Ukuqinisekiswa kwengxenye yekhwalithi nokusebenza ngezindlela ezihlukahlukene zokuhlola njengokuhlaziywa kobukhulu, ukuhlolwa kwezakhiwo zezinto ezibonakalayo, noma ukuhlola ukusebenza.

- Ukupakisha Nokuthumela:Ukupakishwa okufanele kanye nokulebula komkhiqizo oqediwe ukuze uthunyelwe kumakhasimende noma abasebenzisi bokugcina.

Ukukhethwa kwemisebenzi yangemva kokubumba kuncike ekusetshenzisweni okukhethekile kanye nezici zomkhiqizo zokugcina ezifiswayo. Ukubambisana okuseduze phakathi kochwepheshe bokubumba umjovo, ochwepheshe bokuqedela kanye nokuhlanganisa, kanye nekhasimende kubalulekile ekuzuzeni ikhwalithi nokusebenza komkhiqizo ofunekayo. Ukuhlela kahle kanye nokuhlanganisa imisebenzi yangemva kokubumba ohlelweni lokukhiqiza kungasiza ekuqinisekiseni ukukhiqizwa okuphumelelayo kanye nokulethwa ngesikhathi kwemikhiqizo yekhwalithi ephezulu.

Ukubumba Umjovo vs. Ezinye Izinqubo Zokukhiqiza Ipulasitiki

Inqubo ngayinye yokukhiqiza ipulasitiki inezinzuzo kanye nokulinganiselwa, okubenza bafanelekele izinhlelo zokusebenza ezahlukene.

- Umjovo Molding Ukubumba umjovo kuyinqubo yokukhiqiza eguquguqukayo futhi esetshenziswa kabanzi yokukhiqiza izingxenye zepulasitiki. Inikeza izinzuzo ezifana nokusebenza kahle kokukhiqiza okuphezulu, ukuphindaphinda kwengxenye okunembayo, kanye nekhono lokudala amajiyometri ayinkimbinkimbi. Ukubumba komjovo kulungele ukugijima kokukhiqizwa kwevolumu ephezulu futhi kuvumela ukusebenzisa anhlobonhlobo ezinto zokwakha ze-thermoplastic. Inikeza ukunemba okuhle kakhulu kobukhulu nokuqedwa kwendawo, okuyenza ifaneleke ezimbonini ezahlukahlukene njengezezimoto, izimpahla zabathengi, namadivayisi wezokwelapha.

- I-Blow Molding: I-Blow molding iyinqubo esetshenziswa ngokuyinhloko ukukhiqiza izingxenye zepulasitiki ezingenalutho, njengamabhodlela, iziqukathi, nezinto zezimoto. Kuhilela ukuncibilika kwepulasitiki bese uyivuthela emgodleni wesikhunta, udale umumo oyifunayo. Ukubunjwa kwe-Blow kulungele ukukhiqizwa kwevolumu ephezulu futhi kungakhiqiza izingxenye ezinkulu, ezingasindi ezinobukhulu obufanayo bodonga. Kodwa-ke, kunqunyelwe ngokwengxenye yobunkimbinkimbi nokukhethwa kwezinto ezibonakalayo uma kuqhathaniswa nokubunjwa komjovo.

- I-Thermoforming:I-Thermoforming inqubo esetshenziselwa ukukhiqiza izingxenye zepulasitiki ngokushisisa ishidi le-thermoplastic futhi lilolonge kusetshenziswa isikhunta noma ukwenza i-vacuum. Ithola ukusetshenziswa okuvamile emaphaketheni, emikhiqizweni elahlwayo, kanye nemikhiqizo emikhulu efana namathreyi namakhava. I-Thermoforming inikeza ukukhiqizwa okungabizi kakhulu kwezingxenye ezinkulu futhi ivumela ukwenza i-prototyping ngokushesha. Kodwa-ke, inomkhawulo ngokuphathelene nobunkimbinkimbi bengxenye, ukukhethwa kwezinto ezibonakalayo, nokunemba kobukhulu obuqhathaniswa nokubunjwa komjovo.

- I-Extrusion:I-Extrusion iyinqubo eqhubekayo yokukhiqiza amaphrofayili epulasitiki, amashidi, amashubhu, namafilimu. Kubandakanya ukuncibilika kwe-resin yepulasitiki bese uyiphoqa ngedayidi ukuze udale umumo oyifunayo. I-Extrusion ifanele ukukhiqiza ubude obude, obuqhubekayo bemikhiqizo yepulasitiki ene-cross-section engaguquki. Nakuba i-extrusion inikeza amanani aphezulu okukhiqiza nokusebenza kahle kwezindleko, ikhawulelwe ngokuya ngezingxenye eziyinkimbinkimbi zejometri nokulawula okunemba kwe-dimensional uma kuqhathaniswa nokubumba umjovo.

- I-Compression Molding:Ukubumba kokucindezelwa kuhlanganisa ukubeka inani elikalwe ngaphambilini le-thermosetting endaweni yesikhunta esishisayo nokuyicindezela ngaphansi kwengcindezi ephezulu ize iphole. Ithola ukusetshenziswa okuvamile ekukhiqizeni izingxenye ezinamandla aphezulu nokuzinza kwe-dimensional, njengezingxenye zezimoto kanye nokufakwa kukagesi. Ukubumba kokucindezelwa kunikeza ukungaguquguquki okuhle kwengxenye, ukusebenza kahle kokukhiqiza okuphezulu, kanye nekhono lokusebenzisa inhlobonhlobo yezinto. Kodwa-ke, kunqunyelwe ngokwengxenye yobunkimbinkimbi nesikhathi somjikelezo uma kuqhathaniswa nokubunjwa komjovo.

Izicelo ze-Thermoplastic Injection Molding

Izimboni ezahlukahlukene zisebenzisa kakhulu ukubumba komjovo we-thermoplastic ngenxa yokuguquguquka kwayo, ukusebenza kahle, nokusebenza kahle kwezindleko. Ezinye zezicelo zokubumba umjovo we-thermoplastic zifaka:

- Imboni Yezimoto: Imboni yezimoto isebenzisa kakhulu ukubumba komjovo we-thermoplastic ukwenza izingxenye ezihlukahlukene, okuhlanganisa ukunquma kwangaphakathi nangaphandle, amadeshibhodi, amaphaneli eminyango, obhampa, nezixhumi zikagesi. Inqubo ivumela ukuphindaphinda kwengxenye enembile, amajiyometri ayinkimbinkimbi, nezinto ezingasindi, ukuthuthukisa ukusebenza kahle kukaphethiloli kanye nokuguquguquka kwedizayini.

- Izimpahla zabathengi:Ukubumba umjovo kuthola ukusetshenziswa okubanzi ekukhiqizeni izimpahla ezithengwayo ezifana nempahla yasendlini, izinto zikagesi, iziqukathi zokupakisha, namathoyizi. Inqubo ivumela ukukhiqizwa ngobuningi bemikhiqizo ehlala isikhathi eside, yekhwalithi ephezulu enobukhulu obungaguquki kanye nokuqedwa kwendawo. Iphinde ivumele izinketho zokwenza ngokwezifiso kanye nokuphindaphinda komkhiqizo okusheshayo.

- Amadivayisi Ezokwelapha:Ukubumba umjovo kudlala indima ebalulekile embonini yezokwelapha ekukhiqizeni inhlobonhlobo yamadivayisi, okuhlanganisa amasirinji, amathuluzi okuhlinza, izingxenye ezifakelwayo, nezinhlelo zokulethwa kwezidakamizwa. Inqubo iqinisekisa ukukhiqizwa kwezingxenye ezingabandakanyi, ezinembayo, nezihambisana ne-biocompatible ezihlangabezana nezidingo eziqinile zokulawula zomkhakha wezokunakekelwa kwempilo.

- Imboni Yezogesi Nezogesi:Imboni ye-elekthronikhi isebenzisa ukubumba komjovo ukwenza izixhumi zikagesi, izivalo, amaswishi, nezinye izinto. Le nqubo inikeza ukunemba kobukhulu obuphezulu, ukuqedwa kwengaphezulu okuhle kakhulu, kanye nekhono lokuhlanganisa izici ezifana nokufaka ukubumba nokunqwabelanisa, okuvumela ukukhiqizwa okuphumelelayo kwama-elekthronikhi ayinkimbinkimbi.

- Imboni yokupakisha:Izimboni ezahlukahlukene, ezihlanganisa ukudla nesiphuzo, ezemithi, nokunakekela komuntu siqu, ngokuvamile zisebenzisa ukubumba umjovo ukukhiqiza iziqukathi zokupakisha zepulasitiki, amakepisi, izinto ezivaliweyo namabhodlela. Inqubo ivumela ukudalwa kwezixazululo zokupakisha ezingasindi, ezihlala isikhathi eside, nezikhanga ngobuhle ngemijikelezo yokukhiqiza ephumelelayo.

- Imboni ye-Aerospace:Umkhakha we-aerospace usebenzisa ukubumba komjovo ukwenza izinto ezingasindi nezisebenza kakhulu njengamapayipi omoya, abakaki, amaphaneli angaphakathi, nezingxenye zesakhiwo. Inqubo ivumela ukusetshenziswa kwezinto ezithuthukisiwe kanye namajiyometri ezingxenye eziyinkimbinkimbi, okunikela ekwehliseni isisindo kanye nokwenza ngcono ukusebenza kahle kukaphethiloli.

Umthelela Wezemvelo Wokubumba Umjovo We-Thermoplastic

Ukubumba komjovo we-Thermoplastic kuyinqubo yokukhiqiza edumile ngenxa yezinzuzo zayo eziningi, kodwa futhi kubalulekile ukucabangela umthelela wayo kwezemvelo. Nanka amaphuzu okufanele uwacabangele:

- Ukusebenza Okubalulekile:Ukubumba umjovo we-Thermoplastic kuthuthukisa ukusebenza kahle kwezinto ngokunciphisa imfucuza. Inqubo isebenzisa ukulawula okunembayo phezu kwenani lempahla ejovwe esikhunjeni, inciphisa isidingo sempahla eyeqile. Abakhiqizi bangasebenzisa amasu okugaya kanye nokugaywa kabusha ukuze baphinde basebenzise izinsalela noma izingxenye ezinqatshiwe, kuqhutshekwe nokunciphisa udoti wezinto ezibonakalayo.

- Ukusetshenziswa Kwamandla:Abakhiqizi baklama imishini yokubumba umjovo ukuze isebenzise amandla, namamodeli esimanje ahlanganisa ubuchwepheshe obuthuthukisiwe njengama-servo motors namadrayivu esivinini ashintshashintshayo. Lezi zici zithuthukisa ukusetshenziswa kwamandla ngokunciphisa ukusetshenziswa kwamandla ngesikhathi sokubumba, okuholela ezidingweni eziphansi zamandla kanye nomthelela oncishisiwe wemvelo.

- Ukuphathwa Kwemfucuza:Ngenkathi benciphisa udoti wezinto ezibonakalayo, abakhiqizi kufanele basebenzise izindlela ezifanele zokuphatha udoti ukuze baphathe izinto ezisele, ama-sprues, noma izigijimi. Abakhiqizi bangasungula izinhlelo zokugaywa kabusha ukuze baqoqe futhi basebenzise kabusha imfucumfucu yepulasitiki ekhiqizwe ngesikhathi sokubumba umjovo, ngaleyo ndlela behlise imfucuza ethunyelwa ezindaweni zokulahla imfucumfucu.

- Ukunciphisa I-Emission: Ukubumba komjovo we-Thermoplastic ngokuvamile kukhiqiza umoya omncane kunezinye izinqubo zokukhiqiza. Abakhiqizi banganciphisa ukukhishwa kwezinto ezikhishwayo ngokusebenzisa izinto ezivumelana nemvelo, ukusebenzisa amathuluzi okonga amandla, futhi basebenzise amasistimu okukhipha umoya athuthukile nokuhlunga ukuze bathwebule noma yikuphi ukukhishwa okukhishiwe.

- Izinketho Zezinto Eziqhubekayo:Ukukhethwa kwezinto ze-thermoplastic kungaba nomthelela omkhulu ekuzinzeni kwemvelo kokubunjwa komjovo. Ukukhetha amapulasitiki angaboli noma asuselwe ku-bio, kanye nezinto ezigaywe kabusha noma ezigaywa kabusha, kungasiza ukwehlisa ingqikithi yendawo yonke yenqubo.

Ukucatshangelwa Komjikelezo Wokuphila: Ukucabangela umjikelezo wokuphila wonke womkhiqizo obunjiwe kubalulekile ekuhloleni umthelela wawo kwezemvelo. Phakathi nezigaba zokuklama nokukhetha impahla, abakhiqizi kufanele bacabangele izici ezifana nokuqina kwengxenye, ukugaywa kwayo kabusha, kanye namandla okulahlwa kokuphela kwempilo noma ukusetshenziswa kabusha.

Ikusasa Le-Thermoplastic Injection Molding

Ikusasa lokubumba komjovo we-thermoplastic libukeka lithembisa, ngokuthuthuka okuqhubekayo kwezobuchwepheshe kanye nesidingo esikhulayo sekhwalithi ephezulu, izingxenye ezinembayo kuzo zonke izimboni ezihlukahlukene. Ezinye zezinto ezibalulekile ezilindeleke eminyakeni ezayo zihlanganisa:

- Ukwenyuka kokusetshenziswa kwe-automation kanye namarobhothi ukuthuthukisa ukusebenza kahle nokunciphisa izindleko.

- Imizamo igxile ekuthuthukiseni izinto ezintsha nezinqubo zokuthuthukisa ingxenye yokusebenza nokunika amandla izinhlelo zokusebenza ezintsha.

- Ukwamukelwa okukhulayo kwezinqubo ezizinzile, ezifana nokusebenzisa izinto ezigaywe kabusha kanye nokwandisa ukusetshenziswa kwamandla, ukunciphisa umthelela wemvelo wokubumba umjovo.

- Ukuhlanganiswa okukhulu kobuchwepheshe bedijithali, njengokuphrinta kwe-3D nesofthiwe yokulingisa, ukuze kuthuthukiswe izinqubo zokuklama nokukhiqiza.

Imakethe yokubumba umjovo emhlabeni wonke iyakhula, ikakhulukazi emazweni asathuthuka, eqhutshwa ukwanda kwesidingo semikhiqizo yepulasitiki ezimbonini ezahlukahlukene.

Ukukhetha Uzakwethu Wokubumba Umjovo Olungile

Ukukhetha uzakwethu ofanele wokubumba umjovo kubalulekile empumelelweni yephrojekthi yakho. Zinike isikhathi sokuhlola izinketho eziningi, uvakashele isayithi, futhi uhlanganyele ezingxoxweni ezijulile ukuze uqinisekise ubudlelwano obuhambisanayo nobuhlala isikhathi eside.

- Ubungcweti nolwazi:Bheka umlingani wokubumba umjovo onolwazi olunzulu nolwazi embonini. Kufanele babe nerekhodi elifakazelwe lokuletha imikhiqizo esezingeni eliphezulu nezisombululo kumakhasimende emikhakheni eyahlukene. Cabangela ukuqonda kwabo ngezinto ezihlukahlukene, imiklamo yesikhunta, nezinqubo zokukhiqiza.

- Amakhono Okukhiqiza: Hlola amakhono okukhiqiza kazakwethu wokubumba umjovo. Qinisekisa ukuthi banendawo ehlome kahle enemishini nobuchwepheshe besimanje ukubhekana nezidingo zephrojekthi yakho. Cabangela umthamo wabo wokukhiqiza, ikhono lokuphatha izingxenye ezihlukene zosayizi nobunkimbinkimbi, kanye nekhono lokuhlangabezana nevolumu oyifunayo kanye nezikhathi zesikhathi.

- Ukuqinisekisa ikhwalithi:Ikhwalithi ibalulekile ekubumbeni umjovo. Hlola amasistimu okulawula ikhwalithi kanye nezitifiketi zozakwethu ongase abe khona. Bheka ozakwethu abalandela izindinganiso zekhwalithi eziqinile, abanezinqubo zokuhlola eziqinile, futhi benze ukuhlola okuphelele ukuze uqinisekise ingxenye yekhwalithi nokuvumelana.

- Usekelo Lokuklama Nobunjiniyela:Uzakwethu othembekile wokubumba umjovo kufanele anikeze ukwesekwa kwedizayini nobunjiniyela ukuze uthuthukise ingxenye yakho yedizayini ukuze yenzeke. Kufanele babe nonjiniyela abanekhono abanganikeza okokufaka okubalulekile ekukhetheni izinto ezibonakalayo, ukwakheka kwesikhunta, kanye nokwenza ngcono inqubo ukuze kuthuthukiswe ingxenye yekhwalithi nokusebenza kahle.

- Ukuncintisana Kwezindleko:Nakuba izindleko kungafanele kube yiyona kuphela into enqumayo, kubalulekile ukuhlola intengo nokuncintisana kwezindleko zozakwethu wokubumba umjovo. Cela izingcaphuno ezinemininingwane futhi ucabangele izindleko zamathuluzi, izindleko zezinto ezibonakalayo, izindleko zabasebenzi, nanoma yiziphi izinsizakalo ezengeziwe abazihlinzekayo.

- Ukuxhumana Nokubambisana:Ukuxhumana okuphumelelayo nokusebenzisana kubalulekile ukuze ubudlelwano obuphumelelayo. Qinisekisa ukuthi uzakwethu obumba umjovo unemigudu yokuxhumana emihle, uphendula imibuzo yakho, futhi angakunikeza izibuyekezo ezijwayelekile zephrojekthi. Indlela yokusebenzisana izosiza ukuqinisekisa ukuthi sihlangabezana nezidingo zakho futhi sibhekane ngokushesha nanoma yiziphi izinselele.

- Izinkomba Nezibuyekezo zekhasimende:Funa izinkomba zamakhasimende noma funda ukubuyekezwa/ubufakazi ukuze uthole imininingwane mayelana nezipiliyoni zamanye amaklayenti nozakwethu wokubumba umjovo. Ukuthola lolu lwazi kungasiza ukunquma ukwethembeka kwabo, ukushesha, kanye nezinga eliphelele lokwaneliseka kwamakhasimende.

Isiphetho

Ukubumba komjovo we-Thermoplastic kuyindlela eguquguqukayo futhi engabizi kakhulu yokukhiqiza izingxenye zepulasitiki ngobuningi. Ikhono layo lokukhiqiza izimo eziyinkimbinkimbi ngokunemba okuphezulu nokungaguquguquki seliphenduke inketho edumile ezimbonini ezahlukahlukene, okubandakanya ezezimoto, ezokwelashwa, eze-electronics, kanye nezimpahla zabathengi. Ngokuqonda izici ezihlukene zokubumba umjovo we-thermoplastic, okuhlanganisa izinzuzo zayo, ukonakala, nokucatshangelwa kwedizayini, ungenza izinqumo ezinolwazi mayelana nokukhetha uzakwethu ofanele wokubumba umjovo ngezidingo zebhizinisi lakho.