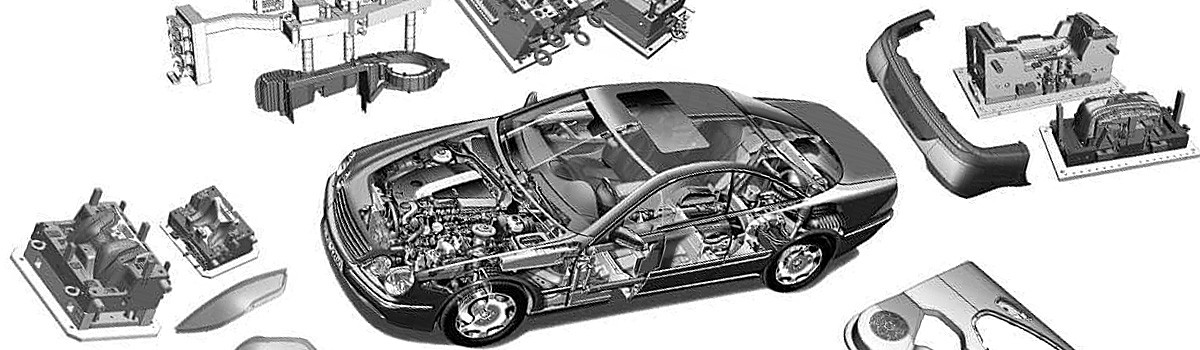

Innovative Injection Molding Solutions For the Automotive Industry

Ukubumba umjovo kungenye yazo - thola ukuthi ubuchwepheshe obusha bomjovo wepulasitiki bumayelana nani futhi usebenzise izixazululo ezisezingeni eliphezulu embonini yezimoto.

Ngabe kusebenza kanjani ukubumba komjovo wepulasitiki?

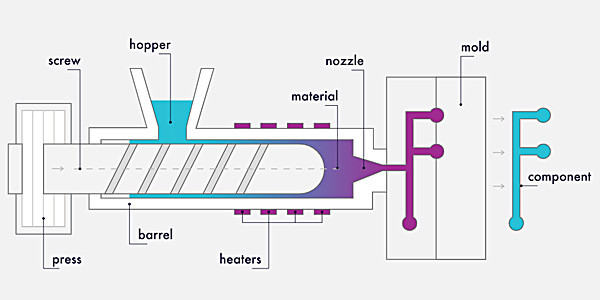

Ukubumba komjovo wePlastiki kuyinqubo yokukhiqiza ethuthukisiwe ehlanganisa ukudala izingxenye ezibunjweni ezilungiselelwe ngokukhethekile. Imishini yokubumba imijovo inika amandla ukukhiqizwa okunembayo kwezingxenye ngezinjongo ezihlukene kanye namapharamitha ahlukene. Ngaphambi kokuqala inqubo yokukhiqiza, ochwepheshe be-Knauf bagxila ekulungiseleleni ngokucophelela isikhunta esifanele ukugwema amaphutha okukhiqiza esikhathini esizayo. Ngenxa yalokho, ubungozi obuhlobene ne-prototypes yomkhiqizo okungenzeka yehluleke bungase buncishiswe. Ukufakwa kokubumba okwenziwe kahle kwenza kube nokwenzeka ukuthola umumo ofanele wengxenye ngayinye.

Lapho isikhunta esifanele semikhiqizo sesitholiwe, ingxenye yangempela yenqubo yokubumba umjovo wepulasitiki enezinyathelo eziningi iyenziwa. Okokuqala, ipulasitiki iyancibilika emiphongolweni ekhethekile; khona-ke ipulasitiki iyacindezelwa futhi ifakwe ezibunjeni ezilungiselelwe ngaphambilini. Ngale ndlela, izingxenye ezenziwe ngokunembile zingadalwa ngokushesha okukhulu. Yingakho ukubumba umjovo osheshayo sekudume kakhulu ezimbonini eziningi, okuhlanganisa nomkhakha wezimoto.

Ezimotweni, ukubumba komjovo wepulasitiki kusetshenziswa:

*I-PC *PS *ABS *PC/ABS *PP/EPDM

*PA6 GF30 *PP GF30 *PP+T

Ukubumba umjovo wepulasitiki wezimoto - izinzuzo:

*amathuba okukhiqiza izingxenye ezinamapharamitha ahlukene

*ukukhiqizwa okungabizi kakhulu kwezingxenye ochungechungeni olukhulu

*isivinini sokukhiqiza

*ukulethwa kwezingxenye ngokugcwele ngokuhambisana nemininingwane yekhasimende

Amapulasitiki abunjwe ngomjovo asetshenziselwa ukulungisa izingxenye zesimanje zemboni yezimoto ayizinto ze-thermoplastic.

Ngenxa yalesi sakhiwo, kungenzeka ukuwancibilikisa futhi uwafake ezibunjeni ezifanele. Enye yezinto ezisetshenziswa kulobu buchwepheshe irabha ye-silicone ewuketshezi, ebonakala ngokubumbeka okuphezulu. Emkhakheni wezimoto, i-polypropylene (EPP) enegwebu (EPP) ne-polystyrene (EPS) isetshenziswa kabanzi - izinzuzo zabo zihlanganisa izinga eliphezulu lokuguquguquka nokuqina okuhlangene nesisindo esincane.

Kungani kufanele ukhethe ubuchwepheshe bokubumba umjovo wepulasitiki?

Izinsizakalo zokubumba umjovo zithola ukuduma embonini yezimoto ngokuyinhloko ngenxa yekhwalithi yezingxenye zokugcina. Ukubumba komjovo wePlastiki kuvumela ukulethwa kwezingxenye ezithobelana ngokugcwele nokucaciswa kwamakhasimende. Ochwepheshe be-Knauf basekela abakhiqizi bemishini yoqobo, ngayo yonke inqubo yokukhiqiza yezingxenye ezibunjiwe zomjovo ngokwezifiso. Ukubumba ngokwezifiso kuyashesha futhi kusebenza kahle kakhulu uma kusetshenziswa ubuchwepheshe bokubumba umjovo - yingakho kubalulekile ukucatshangelwa.

DJmolding Injection Molding Services

I-DJmolding ikhiqiza izingxenye eziningi zemboni yezimoto isebenzisa ukubumba komjovo we-thermoplastic. Ochwepheshe bale nkampani banolwazi olunzulu ngale nqubo, baqiniswa nomsebenzi wabo kwezinye izimboni. Lokhu kuhumushela ekudaleni izixazululo zekhwalithi ephezulu zomkhakha wezimoto futhi. I-Knauf Industries inikeza uhla oluphelele lwezinsizakalo ezihlobene nenqubo yokubumba umjovo wepulasitiki. Kufanele futhi ukhumbule ukuthi umshini wokubumba umjovo wepulasitiki awuwona kuphela ithuluzi elisetshenziswa ngesikhathi sokukhiqiza - inqubo yezobuchwepheshe iqala kahle ngaphambi kokuba ipulasitiki ingene ekubunjweni.

Ukunikezwa kwe-DJmolding kufaka phakathi, isibonelo:

*ukulingisa inqubo egcwele (FS, DFM, Mold Flows) ngesisekelo semodeli yekhompuyutha - ochwepheshe benkampani basebenzisa isofthiwe eyisipesheli entsha kunazo zonke, esezingeni eliphezulu eyenza kube lula ukudalwa kwamamodeli. Enye yezinhlelo ezisetshenziswe lapha i-Moldflow, evumela ukulingisa ukugeleza kwezinto ezibunjweni ngesikhathi sokwenziwa kwezingxenye - ivumela ochwepheshe ukuba bathuthukise ukuklama kwesikhunta, kanye nenqubo yokukhiqiza elandelayo;

*ukushintsha ubunjiniyela,

*ukuhlola nokulungiselela imibiko,

*ukuthuthukiswa kwamathuluzi kanye nokuxhumana kokusetshenziswa kwawo,

*ukuxhumana kombhalo.

Izinsizakalo ezengeziwe ze-DJmolding Industries

Ukubumba umjovo wepulasitiki nokulungiselelwa kwalezi zinqubo kuyingxenye ebalulekile yezinsizakalo ze-Knauf, kodwa ukusekelwa kwenkampani kuhlanganisa nezinye izigaba zokukhiqiza. Imisebenzi eyengeziwe efana nokuhlanganisa izingxenye ezimunca umsindo, iziqeshana nama-clasp nazo ziyenziwa.

Phakathi kwamasu anikezwayo kukhona:

*ukuphrinta kwesikrini,

*ukuphrinta kwephedi,

*icwebezela eliphezulu,

*metallization kanye ne-PVD.

Imikhiqizo Ebunjiwe Yomjovo - DJmolding

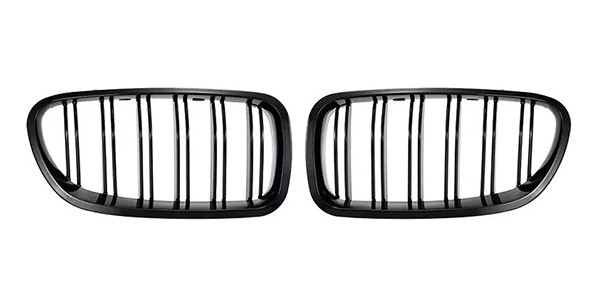

Inqubo yokubumba umjovo wepulasitiki eyenziwa yi-DJmolding inika amandla ukwakhiwa kwemikhiqizo esezingeni eliphezulu enomumo othize, osayizi kanye nemingcele. Izingxenye zepulasitiki zemboni yezimoto ziyingxenye ebalulekile yokunikezwayo - umkhakha wezimoto usebenzisa izingxenye ezibunjiwe ngomjovo ikakhulukazi ngenxa yezakhiwo zazo. Izingxenye ezikhiqizwa ngale ndlela zihlanganisa obhampa bepulasitiki, izingxenye zedeshibhodi, izinsimbi nezinye izingxenye eziningi. Izixazululo ze-Knauf zisetshenziswa abakhiqizi bezimoto abaningi emhlabeni jikelele.

Khetha i-DJmolding Industries

- khetha ukwethembeka nobungcweti

Ukubumba umjovo wepulasitiki kwenziwa ngamazinga aphezulu ekhwalithi yokukhiqiza nangokuhambisana namazinga amanje. Ubuchwepheshe besimanje buhlanganiswe nolwazi oluningi nolwazi lochwepheshe kusivumela ukuthi sikhiqize izingxenye zepulasitiki ezibunjiwe ezingcono kakhulu ezitholakala emakethe. Xhumana nathi ukuze senze izakhi zepulasitiki - sizovumelanisa ukunikeza kwethu izidingo zakho.