Isevisi Yokukhiqiza Umthamo Ophansi

Amabhizinisi amancane ngokuvamile adinga usizo lokuthola izixazululo zokukhiqiza ezithengekayo ezingakhiqiza amanani aphansi emikhiqizo ngaphandle kokufaka izindleko eziphezulu. Amabhizinisi amancane anezinsiza ezilinganiselwe ngokuvamile adinga ukunqoba umgoqo obalulekile ngenxa yemfuneko yezindleko zokudala amanani amakhulu ezindleleni zokukhiqiza zendabuko. Kodwa-ke, ngokuvela kwezinsizakalo zokukhiqiza umthamo ophansi, amabhizinisi amancane manje angakhiqiza imikhiqizo emincane ngengxenyana yezindleko zezindlela zokukhiqiza ezijwayelekile. Lesi sihloko sizohlola izinzuzo zezinsizakalo zokukhiqiza umthamo ophansi nokuthi zingasiza kanjani amabhizinisi amancane ukuthi ahlale encintisana.

Kuyini Ukukhiqiza Ivolumu Ephansi?

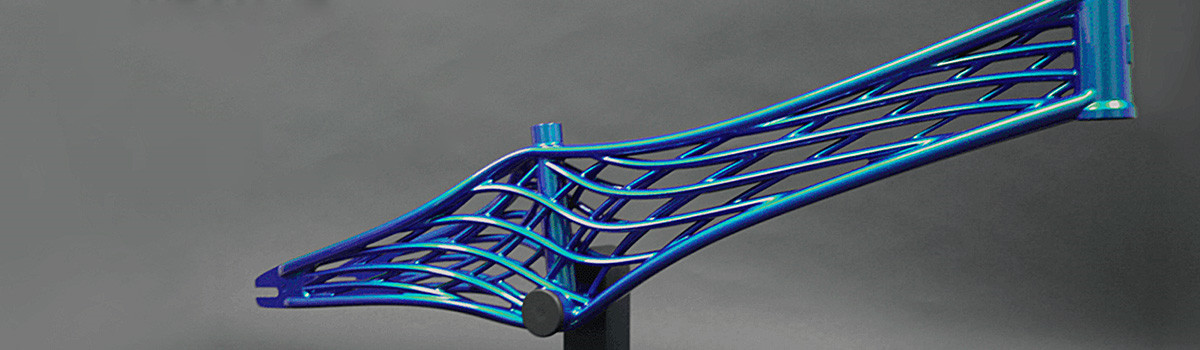

Ukukhiqizwa kwevolumu ephansi kubhekisela ekukhiqizeni inombolo encane yemikhiqizo, ngokuvamile esukela kumayunithi ambalwa kuya kumakhulu ambalwa, kusetshenziswa izinqubo namasu okukhiqiza. Abakhiqizi baklama ukukhiqiza umthamo ophansi ukuze kuhlangatshezwane nezidingo ezithile zamabhizinisi amancane noma aqalayo, ngokungafani nokukhiqizwa ngobuningi, okugxile ekukhiqizeni amanani amakhulu. Le ndlela ivumela izinkampani ukuthi zigweme izindleko eziphezulu zangaphambili kanye nezingozi zokukhiqiza amanani amakhulu. Izinsizakalo zokukhiqiza umthamo ophansi zisebenzisa ukubumba komjovo, ukwenziwa kwemishini ye-CNC, ukuphrinta kwe-3D, kanye nokwenza amashidi ensimbi ukuze kukhiqizwe kahle amaqoqo amancane emikhiqizo, okwenza kube yisixazululo esikahle kumabhizinisi afuna izinketho zokukhiqiza ezingabizi kakhulu.

Izinzuzo Zokukhiqiza Ivolumu Ephansi Yamabhizinisi Amancane

Ukukhiqiza umthamo ophansi kunikeza amabhizinisi amancane izinzuzo ezimbalwa, okuhlinzeka ngezinketho zokukhiqiza ezingabizi ezihambisana nezidingo zabo ezithile. Nazi izinzuzo ezibalulekile zokukhiqiza umthamo ophansi:

- Ukonga Izindleko:Amabhizinisi amancane angagwema izindleko eziphezulu zangaphambili ezihambisana nokukhiqizwa ngobuningi bendabuko ngokukhetha ukukhiqiza umthamo ophansi. Ibenza bakwazi ukukhiqiza amanani amancane ngaphandle kwezindleko zokusetha ezeqile noma isidingo sokutshala izimali ezibalulekile.

- Izikhathi zokushintsha ngokushesha:Izinsizakalo zokukhiqiza umthamo ophansi zibeka phambili izikhathi zokushintsha ngokushesha, okuvumela amabhizinisi amancane ukuthi alethe ngokushesha imikhiqizo yawo emakethe. Lobu buchule bubenza bakwazi ukuphendula ngokushesha ezidingweni zemakethe futhi basebenzise amathuba asafufusa.

- Ukuguquguquka Ezinqubweni Zokukhiqiza:Ngokukhiqiza umthamo ophansi, amabhizinisi angakhetha ezinqubweni ezihlukahlukene zokukhiqiza ngokusekelwe ekucacisweni kwemikhiqizo yawo, okubavumela ukuba bavumelanise indlela yokukhiqiza nezidingo zabo ezithile. Amasu amaningi, okuhlanganisa ukubumba umjovo, ukwenza imishini ye-CNC, ukuphrinta kwe-3D, nokwenziwa kwensimbi yeshidi, kuhlinzeka ngokuguquguquka okudingekayo ukuze kuhlangatshezwane nezidingo ezithile.

- Imikhiqizo Yokugcina Yekhwalithi Ephezulu:Ukukhiqizwa kwevolumu ephansi kugcina amazinga ekhwalithi aqinile naphezu kokukhiqiza amanani amancane. Abakhiqizi basebenzisa amathuluzi athuthukile nobungcweti ukuze baqinisekise ukuthi umkhiqizo ngamunye uhlangabezana nezicaciso ezidingekayo, okuholela emikhiqizweni yokugcina yekhwalithi ephezulu.

- I-Design for Manufacturing (DFM):Amasevisi okukhiqiza umthamo ophansi ngokuvamile asekela ukwenziwa ngcono kwedizayini. Abakhiqizi basebenzisana namabhizinisi phakathi nesigaba sokuklama, banikeza imininingwane ebalulekile yokuthuthukisa ukwenziwa komkhiqizo, okuholela ekukhiqizeni okuphumelelayo nokungabizi.

- Amasevisi Wokukopisha:Izinsizakalo eziningi zokukhiqiza umthamo ophansi zinikeza amandla okwenza i-prototyping, okwenza amabhizinisi amancane akwazi ukuphindaphinda emiklameni yemikhiqizo yawo ngaphambi kokukhiqiza ngokugcwele. I-Prototyping isiza ukukhomba nokubhekana namaphutha edizayini, ihlole ukusebenza, futhi iqoqe impendulo ebalulekile ukuze ithuthukiswe okwengeziwe.

- Izinketho zezinto kanye nenqubo:Izinsizakalo zokukhiqiza umthamo ophansi zinikeza inhlobonhlobo yezinto zokwakha kanye nezinqubo zokukhiqiza ukuze zivumelane nezidingo zemikhiqizo ehlukahlukene. Amabhizinisi angakhetha izinketho ezifanele ngokusekelwe emandleni, ukuqina, ubuhle, kanye nezindleko.

- Ukungafinyeleli:Ukukhiqiza umthamo ophansi kunikeza izinketho zokukala kumabhizinisi amancane. Njengoba isidingo sikhula, izinkampani zingakwazi ukulungisa kahle amanani okukhiqiza ngaphandle kokutshalwa kwezimali okubalulekile noma ukulungisa kabusha, okuqinisekisa uguquko olushelelayo lokuhlangabezana nezidingo zemakethe.

- Izingozi Ezincishisiwe Zokusungula: Ukukhiqiza umthamo ophansi kunciphisa ubungozi be-inventory kumabhizinisi amancane. Bangakwazi ukukhiqiza imikhiqizo ngokufunwa kakhulu noma balondoloze uhlu lwempahla engenamandla, behlise izindleko nezingozi ezihlobene ne-inventory eyeqile kanye nokuphelelwa yisikhathi okungaba khona.

Ukonga Izindleko Ngokukhiqiza Ivolumu Ephansi

Ukukhiqiza umthamo ophansi kunikeza izinzuzo ezimbalwa zokonga izindleko zamabhizinisi, ikakhulukazi emikhiqizweni emincane. Nazi ezinye izinzuzo ezibalulekile zokonga izindleko ngokukhiqiza umthamo ophansi:

- Izindleko Zokusetha Ezincishisiwe:Izinqubo zokukhiqiza zendabuko ngokuvamile zibandakanya izindleko zokusetha eziphezulu, ikakhulukazi zokukhiqiza ezincane. Amabhizinisi angagwema lezi zindleko zangaphambili ngokuthuthukisa inqubo yokukhiqiza amanani amancane ngokusebenzisa ukukhiqiza umthamo ophansi.

Awekho Inani Elincane Le-oda: Ngokungafani nokukhiqizwa ngobuningi okuvamile, izinsizakalo zokukhiqiza umthamo ophansi ngokuvamile azidingi inani elincane le-oda. Amabhizinisi angonga imali ku-inventory eyengeziwe kanye nokumosha ngokukhiqiza kuphela okudingekayo.

- Izindleko Zamathuluzi Eziphansi:Izinsizakalo zokukhiqiza umthamo ophansi zisebenzisa amathuluzi nezinto zokusebenza ezilungiselelwe amanani amancane, ukunciphisa izindleko zamathuluzi kanye nokunciphisa ubungozi bokuphelelwa yisikhathi.

- Izindleko Zezinto Eziphansi: Ukukhiqiza okuvamile kuvame ukudinga ukuthengwa kwenqwaba yezinto, okungaholela ekusetshenzisweni kwempahla nokumosha ngokweqile. Ngokukhiqiza umthamo ophansi, amabhizinisi angakwazi uku-oda amanani amancane, ehlise imfucuza futhi anciphise izindleko zempahla.

- Izindleko Ezehlisiwe Zabasebenzi: Ukukhiqiza umthamo ophansi ngokuvamile kudinga abasebenzi abambalwa kunokukhiqizwa ngobuningi bendabuko, okuholela ezindleko eziphansi zebhizinisi.

- Agile Manufacturing:Ukukhiqizwa kwenani eliphansi kunikeza izinqubo zokukhiqiza ezishesha, okuvumela amabhizinisi ukuthi aphike ngokushesha ngokususelwa esidingweni semakethe, kunciphisa ubungozi bokukhiqiza inani eliningi lokusungula kanye nemfucuza.

Izikhathi Zokushintsha Ngokushesha

Ukukhiqizwa kwevolumu ephansi kubhekisela ekukhiqizeni inombolo encane yemikhiqizo, ngokuvamile engaphansi kwamayunithi angu-10,000. Lolu hlobo lokukhiqiza luvame ukudingeka lapho kwakhiwa imikhiqizo emisha, kuhlolwa isidingo semakethe sento ethile, noma kukhiqizwa izindatshana ezinezici ezikhethekile ezisezingeni eliphansi.

Izikhathi zokushintsha ngokushesha zokwenziwa kwevolumu ephansi zibalulekile ukuze kuhlangatshezwane nesidingo semakethe, kuncishiswe izikhathi zokuhola, futhi kusheshiswe isikhathi sokuya emakethe kwemikhiqizo emisha. Nawa amanye amasu okuthola izikhathi zokushintsha ngokushesha zokukhiqiza umthamo ophansi:

- Lungiselela inqubo yokukhiqiza: Inqubo kufanele inciphise izikhathi zokukhiqiza futhi ikhulise ukusebenza kahle. Lokhu kuhlanganisa ukuhlonza izingqinamba, ukwenza lula izinyathelo zokukhiqiza, kanye nokuqinisekisa ukuthi inqubo yokukhiqiza ithambile futhi iyashesha.

- Sebenzisa ubuchwepheshe bokukhiqiza idijithali: Ubuchwepheshe bokukhiqiza idijithali, njengokuphrinta kwe-3D, umshini we-CNC, nokubumba umjovo, bunganciphisa kakhulu izikhathi zokukhiqiza nezindleko. Lobu buchwepheshe buvumela ukukhiqiza izingxenye nezingxenye ngokunemba okuphezulu nokunemba, okuvumela izikhathi zokushintsha ngokushesha.

- Sebenza nomkhiqizi onesipiliyoni: Umkhiqizi ochwepheshe uzoqonda ngokujulile inqubo yokukhiqiza futhi anganikeza imininingwane nezincomo zokunciphisa izikhathi zokukhiqiza. Bazoba nolwazi oludingekayo kanye nemishini yokukhiqiza imikhiqizo esezingeni eliphezulu ngokushesha nangempumelelo.

- Sebenzisa ukukhiqiza okufika ngesikhathi (i-JIT): Ukukhiqiza kwe-JIT isu lokukhiqiza elikhiqiza kuphela izinto lapho zidingeka. Leli su lisiza ukunciphisa amaleveli e-inventory, ukunciphisa izikhathi zokuhola, nokuthuthukisa ukusebenza kahle kokukhiqiza.

- Sebenzisa imikhuba yokukhiqiza eshesha: Imikhuba yokukhiqiza esheshayo isebenzisa izinqubo eziguquguqukayo nobuchwepheshe ukuze ivumelane ngokushesha nezimfuneko ezishintshayo zemakethe. Le ndlela ivumela abakhiqizi ukuthi baphendule ngokushesha ekuthuthukisweni komkhiqizo omusha namathuba emakethe.

- Yamukela i-automation: Ubuchwepheshe bokuzenzakalela, obufana namarobhothi nobuhlakani bokwenziwa, bungasiza ukwenza lula izinqubo zokukhiqiza kanye nokwenza ngcono ukusebenza kahle. Lobu buchwepheshe bungenza imisebenzi ephindaphindwayo ngokushesha nangokunembe kakhulu kunabantu, buvumela izikhathi zokushintsha ngokushesha.

- Sebenzisa abahlinzeki abathembekile: Abahlinzeki abathembekile bangahlinzeka ngezinto zokwakha nezingxenye zekhwalithi ephezulu ngesikhathi, okunciphisa ukubambezeleka kwenqubo yokukhiqiza. Kubalulekile ukusungula ubudlelwano obuqinile nabahlinzeki kanye nokuqinisekisa ukuthi banamandla adingekayo ukuze bahlangabezane nezidingo zokukhiqiza.

Izinqubo Zokukhiqiza Ezivumelanayo

Ukuzibophezela kwethu kukhwalithi nokwaneliseka kwamakhasimende kuqinisekisa ukuthi wonke umkhiqizo uhlangabezana noma udlula okulindele.

- Inkampani yethu izibophezele ekuhlinzekeni ngezinqubo zokukhiqiza eziguquguqukayo ezingavumelana nezidingo eziguqukayo zamakhasimende ethu. Siyaqonda ukuthi yonke iphrojekthi ihlukile futhi ingase idinge izindlela ezihlukene, futhi siklama izinqubo zethu zokukhiqiza ukuze zibe nezinto ezihlukahlukene futhi zivumelane nezimo.

- Onjiniyela bethu abanolwazi nochwepheshe bangakwazi ukuhlela izinqubo zethu zokukhiqiza ukuze zivumelane nezidingo zakho, kungakhathaliseki ukuthi ukukhiqizwa kwevolumu ephansi noma ephezulu, i-prototyping esheshayo, noma ukwenziwa ngokwezifiso. Singakhiqiza imikhiqizo eminingi, kusukela ezingxenyeni ezincane eziyinkimbinkimbi kuye kwezinkulu.

- Sisebenzisa ubuchwepheshe bamuva kanye nezinto zokusebenza ukuze siqinisekise ukuguquguquka okukhulu nokusebenza kahle ezinqubweni zethu zokukhiqiza. Imishini yethu inamakhono athuthukile wesoftware namandla okuzishintsha, okusenza sikwazi ukushintsha phakathi kokucaciswa kwemikhiqizo ehlukene kanye namavolumu okukhiqiza ngokushesha.

- Sinikeza izinqubo ezihlukahlukene zokukhiqiza, okuhlanganisa imishini ye-CNC, ukubumba umjovo, ukuphrinta kwe-3D, ukusika i-laser, nokuningi. Ithimba lethu lingasebenza nawe ukuze linqume indlela efaneleke kakhulu yezidingo zephrojekthi yakho ngokusekelwe ezintweni ezibonakalayo, ubunkimbinkimbi bomklamo, kanye nevolumu yokukhiqiza.

- Futhi siklama izinqubo zethu zokukhiqiza ukuze zikhule, okusenza sikwazi ukukhuphula umkhiqizo ngokushesha njengoba isidingo sikhula. Ngokuya ngezidingo zakho ezithile, singakwazi ukukhiqiza amaqoqo amancane noma inani elikhulu lemikhiqizo.

- Siyaqonda ukuthi isikhathi sokuya emakethe sibalulekile kumakhasimende ethu amaningi, futhi izinqubo zethu zokukhiqiza ezivumelana nezimo zisenza sikwazi ukuhlinzeka ngezinsizakalo zokwenziwa kwezithombe ezisheshayo nezokuthuthukisa umkhiqizo. Ngobuchwepheshe bethu obuthuthukile nobungcweti, singakwazi ukukhiqiza ama-prototypes ekhwalithi ephezulu ngokushesha nangempumelelo, okukuvumela ukuthi uhlole futhi ucwenge imiklamo yakho ngaphambi kokuthuthela ekukhiqizeni ngobuningi.

- Sibeka kuqala ukulawulwa kwekhwalithi kuzo zonke izinqubo zethu zokukhiqiza futhi sisebenzisa izinqubo zokuhlola nokuhlola eziqinile ukuze siqinisekise ukuthi wonke umkhiqizo uyahlangabezana noma udlula lokho okulindelwe yikhasimende lethu. Ithimba lethu liqapha isinyathelo ngasinye senqubo, kusukela ekukhethweni kwezinto ezibonakalayo kuya ekuhlolweni kokugcina nokuqinisekiswa.

- Ukuzibophezela kwethu ekuguquguqukeni kudlulela ngalé kwezinqubo zethu zokukhiqiza. Siyakwazisa ukuxhumana okuvulekile nokusebenzisana namakhasimende ethu, okusivumela ukuthi siqonde izidingo zawo futhi sinikeze izixazululo ezihambisanayo. Ithimba lethu eliphendulayo lokusekela amakhasimende lihlala litholakala ukuze libhekane ngokushesha nanoma yikuphi ukukhathazeka noma imibuzo.

Imikhiqizo Yokuphela Yekhwalithi Ephezulu

Inkampani yethu izibophezele ekuletheni imikhiqizo esezingeni eliphezulu ehlangabezana noma edlula lokho okulindelwe yikhasimende lethu.

- Enkampanini yethu, sibeka phambili ukuletha imikhiqizo yokugcina yekhwalithi ephezulu ukuze ihlangabezane namazinga aqondile amaklayenti ethu. Siyaqonda ukuthi ikhwalithi ibalulekile futhi silwela ukweqa okulindelekile ngokuhlinzeka ngemikhiqizo esezingeni eliphezulu eyakhelwe ukuhlala.

- Sisebenzisa izinyathelo eziqinile zokulawula ikhwalithi kukho konke ukukhiqiza ukuze siqinisekise ukuthi isinyathelo ngasinye sihlangabezana namazinga aphezulu. Kusukela ekukhethweni kwezinto ezibonakalayo kuya ekukhiqizeni nasekuhlanganiseni, ithimba lethu elinolwazi liqapha isigaba ngasinye ukuze liqinisekise ikhwalithi nobuqotho bemikhiqizo yokugcina.

- Sisebenza nenethiwekhi yabahlinzeki abathembekile abasihlinzeka ngezinto ze-premium ezihlangabezana nokucaciswa kwekhwalithi okuqinile. Kungakhathaliseki ukuthi izinsimbi, amapulasitiki, izinhlanganisela, noma ezinye izinto ezikhethekile, sithola kuphela kubathengisi abahloniphekile ukuze siqinisekise ikhwalithi ephezulu kakhulu emikhiqizweni yethu.

- Senza izinqubo zethu zokukhiqiza ngokunemba nokunaka imininingwane. Sisebenzisa ubuchwepheshe obuthuthukisiwe nezinto zokusebenza ukuze siqinisekise ukunemba, ukungaguquguquki, nokuphindaphinda kuwo wonke umkhiqizo esiwukhiqizayo. Ochwepheshe bethu abanekhono nonjiniyela baqapha ngokucophelela ukukhiqiza ukuze bakhombe futhi baxazulule izinkinga ezingaba khona noma ukuchezuka kukhwalithi oyifunayo.

- Siyaqonda ukuthi ukwaneliseka kwekhasimende akuncikile kuphela kwikhwalithi yomkhiqizo wokugcina kodwa futhi nokusebenza kwawo nokusebenza kwawo. Senza ukuhlola okuphelele kanye nezinqubo zokuqinisekisa ukuze siqinisekise ukuthi imikhiqizo yethu iyahlangabezana noma idlule yonke imininingwane edingekayo kanye nezimfuneko zokusebenza.

- Ukuthuthukiswa okuqhubekayo kuwumgomo oyinhloko wenkampani yethu. Sifuna ngenkuthalo impendulo kumakhasimende ethu futhi silwela ukufaka imininingwane yawo ezinhlelweni zethu zokukhiqiza. Ngokwamukela isiko eliqhubekayo lokufunda nokuthuthukisa, sihlala siphakamisa ikhwalithi yemikhiqizo yethu yokugcina.

- Ukuzibophezela kwethu ekuletheni imikhiqizo yokuphela kwekhwalithi ephezulu kunabela ezimbonini nasezimbonini ezihlukahlukene. Noma ngabe yizimpahla zabathengi, izingxenye zezimoto, izinto zikagesi, noma okokusebenza kwemboni, sinolwazi nezinsiza zokuhlangabezana namazinga athile ekhwalithi omkhakha ngamunye.

- Siyakuqonda ukubaluleka kokulethwa ngesikhathi ngaphandle kokubeka engcupheni ikhwalithi. Izinqubo zethu zokukhiqiza ezihlelekile kanye nokugeleza komsebenzi okuphumelelayo kusenza sikwazi ukuhlangabezana nezinsuku zokugcina zamaphrojekthi kuyilapho sigcina izinga eliphezulu lokulawula ikhwalithi.

- Ukuzinikela kwethu emikhiqizweni yokugcina yekhwalithi ephezulu kusenze sathola idumela eliqinile kanye nesisekelo samakhasimende athembekile. Siyaziqhenya ngokwaneliseka kwamakhasimende ethu, futhi ukuzibophezela kwethu ngekhwalithi kuqinisekisa ukuthi yonke imikhiqizo ephuma endaweni yethu ingeyekhwalithi nobuciko obusezingeni eliphezulu.

I-Design for Manufacturing (DFM)

I-Design for Manufacturing (DFM) iyindlela ehlanganisiwe egxile ekuthuthukiseni ukwakheka komkhiqizo ukuze kuthuthukiswe ukwenziwa kwawo. I-DFM ihlose ukunciphisa izindleko zokukhiqiza, ukunciphisa isikhathi sokuhlanganisa, nokuqinisekisa imikhiqizo yokugcina yekhwalithi ephezulu ngokucabangela izinqubo zokukhiqiza ekuqaleni kwesigaba sokuklama. Nawa amanye amachashazi abalulekile achaza ukubaluleka nezimiso ze-DFM:

- Imiklamo eyenziwe lula:I-DFM igcizelela ukwenza lula imiklamo yomkhiqizo ukuze kuqedwe ubunkimbinkimbi obungadingekile, ukunciphisa inani lezingxenye, nokwenza lula izinqubo zokuhlanganisa. Le ndlela isiza ukunciphisa izindleko zokukhiqiza ngokunciphisa udoti wezinto ezibonakalayo, amaphutha okuhlanganisa, nesikhathi sokukhiqiza.

- Ukukhetha okubalulekile: Ukukhetha okufanele kubalulekile ku-DFM ukuze kuqinisekiswe ukuhambisana nezinqubo zokukhiqiza. Abaklami kufanele bacabangele izici ezifana nokutholakala kwezinto ezibonakalayo, izindleko, amandla, kanye nokulula kokwakhiwa. Ukukhetha izinto ezihambisana nekhono lokukhiqiza kungathuthukisa kakhulu ukusebenza kahle kokukhiqiza kukonke.

- Idizayini yokuhlanganisa (DFA):I-DFA iyingxenye ebalulekile ye-DFM egxile ekwakhiweni kwemikhiqizo yamaqembu alula futhi asebenza kahle. Kubandakanya ukucatshangelwa kwezinto ezifana nokuma kwengxenye, ukumiswa kwezingxenye, kanye nemiklamo yemojuli. I-DFA yehlisa izindleko zabasebenzi, ithuthukisa ikhwalithi yomkhiqizo, futhi ifinyeze izikhathi zokuhola ngokukhiqiza izinqubo zokuhlanganisa.

- Ukubekezelela kanye nokucatshangelwa okufanele: Ku-DFM, abaklami bacabangela ngokucophelela ukubekezelelana kanye nokulingana phakathi kwezingxenye ukuze kuqinisekiswe ukuhlanganiswa nokusebenza okufanele. Ngokuchaza ukubekezelelana okufanele, abaklami banganciphisa amathuba okuba nezinkinga zokuhlanganisa, bathuthukise ukushintshashintsha kwengxenye, futhi banciphise isidingo sokusebenza kabusha noma ukulungisa phakathi nokukhiqiza.

Ukuhambisana kwenqubo yokukhiqiza: I-DFM ibheka amakhono kanye nemikhawulo yezinqubo ezikhethiwe zokukhiqiza. Ukuze kuqinisekiswe ukukhiqizwa okuphumelelayo, abaklami kufanele baqonde izithiyo zamasu ahlukahlukene okukhiqiza, njengokubumba umjovo, ukukhanda imishini, noma ukulingisa, kanye nemikhiqizo yokuklama izinqubo zokukhiqiza ezingakhiqiza ngokushesha.

- I-Design for testability (DFT):I-DFT iyingxenye ebalulekile ye-DFM egxile ekwakhiweni kwemikhiqizo enezici ezakhelwe ngaphakathi zokuhlola okuphumelelayo nokulawula ikhwalithi. Ngokuhlanganisa izici ezifana namaphoyinti okuhlola, ukufinyelela kuma-probe, noma amakhono okuzihlola, i-DFT inika amandla ukuhlola okusebenza kahle ngesikhathi sokukhiqiza, inciphisa amathuba okuba imikhiqizo enephutha ifinyelele emakethe.

Izinsizakalo Zokukopisha

Izinsizakalo ze-Prototyping zinikeza isixazululo esibalulekile ezinkampanini nakubantu abafuna ukwenza imibono yabo iphile futhi baqinisekise imiklamo yabo ngaphambi kokukhiqizwa ngobuningi. Lawa masevisi ahlanganisa uhla lwamakhono, okuvumela ukudalwa kwama-prototypes asebenzayo afana kakhulu nomkhiqizo wokugcina. Nawa amanye amachashazi angukhiye agqamisa ukubaluleka kanye nezinzuzo zezinsizakalo ze-prototyping:

- Inqubo yokuklama ephindaphindayo:Izinsizakalo ze-Prototyping zinika amandla indlela yokuklama ephindaphindwayo, evumela abaklami ukuthi bacwenge futhi bathuthukise imiqondo yabo ngokuphindaphinda okuningi. Ngokudala nokuhlola ama-prototypes ngokushesha, abaklami bangakwazi ukuhlonza amaphutha edizayini, benze izinguquko ezidingekayo, futhi bathuthukise ukusebenza komkhiqizo wokugcina nobuhle.

- Ubufakazi bomqondo: Ama-prototypes awubufakazi obuphathekayo bokwenzeka komqondo kanye nempumelelo engaba khona. Ngokwenza isibonelo esisebenzayo, abasunguli nosomabhizinisi bangakhombisa ukusebenza kwemibono yabo kubatshalizimali, ababambiqhaza, noma amakhasimende angaba khona. Lobu bufakazi bomqondo bungawandisa kakhulu amathuba okuthola uxhaso noma ukuzuza ukwesekwa ukuze kuthuthukiswe okunye.

- Ukuqinisekiswa kwedizayini nokuhlola:Izinsizakalo ze-Prototyping zinikeza ithuba lokuhlola nokuqinisekisa imiklamo yomkhiqizo ngaphambi kokukhiqiza ngokugcwele. Ama-prototypes asebenzayo avumela ukuhlolwa komhlaba wangempela, impendulo yomsebenzisi, nokuhlolwa kokusebenza. Ngokuhlonza kanye nokubhekana namaphutha edizayini kusenesikhathi, izinsiza ze-prototyping zisiza ukunciphisa ubungozi, zehlise izindleko, futhi zithuthukise ikhwalithi iyonke yomkhiqizo wokugcina.

- Ukwenza ngokwezifiso nokwenza kube ngokwakho:Izinsizakalo ze-Prototyping zinikeza ukuguquguquka kokudala ama-prototypes aklanywe ngokwezifiso ahambisana nezidingo ezithile. Noma ngabe umumo ohlukile, usayizi, noma ukusebenza, lawa masevisi avumela abaklami ukuthi bahlole amathuba ahlukahlukene futhi bathuthukise ama-prototypes amelela ngokunembile umbono wabo. Lesi sici sokwenza ngendlela oyifisayo sisiza ukusungula izinto ezintsha futhi sikhuthaze ukuthuthukiswa kwemikhiqizo eqondene nawe kakhulu.

- Ukonga isikhathi nezindleko:Ukusebenzisa izinsizakalo ze-prototyping kungaholela ekongeni isikhathi esibalulekile kanye nezindleko phakathi nokuthuthukiswa komkhiqizo. Ama-prototypes asiza ukuvimbela ukusetshenzwa kabusha okumba eqolo kanye nezibuyekezo phakathi nokukhiqizwa ngobuningi ngokuhlonza izinkinga zedizayini kusenesikhathi. Ukwengeza, amasu e-prototyping asheshayo, njengokuphrinta kwe-3D, anika amandla izikhathi zokushintsha ngokushesha, anciphisa isikhathi sokuya emakethe futhi avumele ukuphindaphinda okusheshayo.

- Ukusebenzisana nokuxhumana:Ama-prototypes angamathuluzi okuxhumana asebenzayo phakathi kwabaklami, onjiniyela, kanye nababambiqhaza. Banikeza ukumelwa okubambekayo komkhiqizo, okuvumela ukuxhumana okusobala nokubambisana okungcono. Ama-prototype asiza impendulo eyakhayo, aqondise okulindelekile, futhi aqinisekise ukuthi wonke umuntu ohilelekile unokuqonda okwabiwe ngokubukeka nokusebenza komkhiqizo wokugcina.

Izinto zokwakha kanye nezinqubo ezitholakalayo zokukhiqiza ivolumu ephansi

Inkampani yethu inikeza uhla olubanzi lwezinto zokwakha kanye nezinqubo zokukhiqiza umthamo ophansi.

- Inkampani yethu inikeza izinhlobonhlobo zezinto zokwakha kanye nezinqubo eziklanyelwe ukukhiqiza umthamo ophansi. Kungakhathaliseki ukuthi udinga ukukhiqizwa kwenqwaba encane noma i-prototyping, singahlangabezana nezidingo zakho ezihlukile ngenkathi sigcina izindinganiso zekhwalithi ephezulu.

- Ukukhethwa kwethu kwezinto zokwakha kuhlanganisa izinketho ezihlukahlukene ezifanele ukukhiqizwa kwevolumu ephansi. Kusukela ezinsimbi zomdabu ezifana ne-aluminiyamu nensimbi kuya kuzinhlanganisela ezithuthukisiwe namapulasitiki, singakwazi ukwamukela ukucaciswa komkhiqizo okuhlukahlukene kanye nezimfuneko zokusebenza.

- Ngaphezu kwezinsimbi namapulasitiki, sisebenza ngokukhethekile ezintweni ezifana nezitsha zobumba, ama-elastomers, nezindwangu, okusivumela ukuthi sibhekelele izimboni ezihlukahlukene nezinhlelo zokusebenza. Ochwepheshe bethu bezinto zokwakha bangakuqondisa ekukhetheni izinto ezifanele kakhulu izidingo zakho zephrojekthi.

- Siklama izinqubo zethu zokukhiqiza umthamo ophansi ukuze zivumelane nezimo futhi zisebenze kahle, zinikeze amandla ukukhiqiza okubiza imali eningi ngaphandle kokubeka engcupheni ikhwalithi. Sisebenzisa amasu athuthukile afana ne-CNC machining, ukuphrinta kwe-3D, ukubumba umjovo, nokusakazwa kwe-vacuum ukuze sithole imiphumela enembile nephindaphindwayo.

- Imishini ye-CNC ifaneleka kakhulu ukukhiqizwa kwevolumu ephansi njengoba ihlinzeka ngokunemba okuphezulu nokuguquguquka. Ngemishini yethu yesimanje kanye nochwepheshe bemishini abanekhono, singakwazi ukukhiqiza ngokuphumelelayo izingxenye eziyinkimbinkimbi ezinokubekezelelana okuqinile.

- Ukuphrinta kwe-3D, noma ukukhiqiza okungeziwe, kungenye inketho ethandwayo yokukhiqizwa kwevolumu ephansi. Ivumela i-prototyping esheshayo nezinguquko zedizayini eziphindaphindayo, ukunciphisa izikhathi zokuhola nezindleko. Sisebenzisa ubuchwepheshe bokuphrinta be-3D obuhlukahlukene, okuhlanganisa i-selective laser sintering (SLS) kanye ne-fused deposition modelling (FDM), ukuze sihlinzekele ngezinto ezihlukene nezimfuneko zobukhulu.

- Ukubumba umjovo kuyindlela enhle kakhulu yokukhiqiza umthamo ophansi wezingxenye zepulasitiki. Ngokusebenzisa umklamo wethu wesikhunta nobungcweti bamathuluzi, singakhiqiza izingxenye zekhwalithi ephezulu ezinobukhulu obungaguquki kanye nokuqedwa kwendawo.

- I-vacuum casting yisixazululo esingabizi kakhulu sokwenza amaqoqo amancane ama-prototypes ekhwalithi ephezulu noma izingxenye ezisetshenziswa ekugcineni. Le nqubo ivumela ukusetshenziswa kwezinto ezihlukahlukene futhi ingaphindaphinda ngokunembile imininingwane eyinkimbinkimbi kanye nokwenza.

- Sibeka phambili ukulawulwa kwekhwalithi nokuhlola okunzima kuyo yonke inqubo yokukhiqiza umthamo ophansi ukuze siqinisekise ukuthi wonke umkhiqizo uhlangabezana noma wedlula okulindele. Ithimba lethu elinolwazi liqapha isinyathelo ngasinye, kusukela ekukhethweni kwezinto ezibonakalayo kanye nokwenza ngcono inqubo ukuya ekuhlolweni kokugcina nokuqinisekiswa.

- Siyaziqonda izinselele eziyingqayizivele nezimfuneko zokukhiqiza umthamo ophansi, futhi ithimba lethu elizinikele lizibophezele ekuletheni imiphumela evelele ngesikhathi nangaphakathi kwesabelomali. Kungakhathaliseki ukuthi udinga ama-prototypes ambalwa noma ukukhiqizwa okulinganiselwe, siklama izinto zethu zokusebenza nezinqubo ukuze sihlangabezane nezidingo zakho ezithile futhi sinikeze izinga eliphezulu lokwaneliseka kwamakhasimende.

Ukujova Ukujova

Ukubumba umjovo kuyinqubo yokukhiqiza esetshenziswa kabanzi ehlanganisa ukudala izingxenye zepulasitiki ngokujova izinto ezincibilikisiwe esikhunjini. Inikeza izinzuzo ezimbalwa, okwenza kube ukukhetha okudumile kokukhiqizwa ngobuningi. Nawa amanye amachashazi angukhiye agqamisa ukubaluleka kanye nezinzuzo zokubumba umjovo:

- Ukuhlukahluka:Ukubumba komjovo kunikeza ukuguquguquka okukhethekile mayelana nomklamo wengxenye nokuba yinkimbinkimbi. Ingakhiqiza izingxenye eziyinkimbinkimbi neningiliziwe ezinomumo, ubukhulu, nezici ezihlukahlukene, okuhlanganisa izindonga ezincane, ama-undercuts, namajiyometri ayinkimbinkimbi. Lokhu kuguquguquka kuvumela ukudalwa kwemikhiqizo eyenziwe ngokwezifiso ukuze ihlangabezane nezidingo ezithile.

- Ukukhiqiza okungabizi kakhulu:Ukubumba umjovo kuphumelela kakhulu ekugijimeni kokukhiqiza okukhulu. Uma sesidale isikhunta sokuqala, ukukhiqiza kuba ngokushesha futhi kungabizi kakhulu. Ijubane eliphezulu lokukhiqiza kanye nekhono lokukhiqiza izingxenye eziningi ngesikhathi esisodwa kunciphisa kakhulu izindleko zeyunithi ngayinye, okukwenza kube ukukhetha ukonga kokukhiqiza umthamo omkhulu.

- Izinhlobonhlobo zezinto:Ukubumba komjovo kusekela inhlobonhlobo yezinto ezisetshenziswayo ze-thermoplastic kanye ne-thermosetting, okuvumela abaklami ukuthi bakhethe izinto ezifanele kakhulu abazisebenzisayo. Izinto ezinezici ezihlukahlukene, njengokuguquguquka, ukuqina, ukukhanya, noma ukumelana nokushisa namakhemikhali, zingakhiqiza izingxenye ezinokusebenza okuhlukahlukene.

- Ukuvumelana nekhwalithi:Ukubumba komjovo kuqinisekisa ukufana kwengxenye okuhle kakhulu nokunemba kobukhulu. Imvelo ezenzakalelayo yenqubo inciphisa iphutha lomuntu, okuholela ekukhiqizeni okufanayo nokuphindaphindayo. Ukwengeza, uhlelo lokubumba oluvaliwe luhlinzeka ngokulawula okunembile phezu kwezimo zokubumba, okuvumela ukukhiqizwa kwezingxenye ezisezingeni eliphezulu ezinokubekezelelana okuqinile kanye nokukhubazeka okuncane.

- Ukusebenza kahle okuphezulu kokukhiqiza:Ukubumba komjovo kunikeza imijikelezo yokukhiqiza esheshayo, okuvumela ukuphuma okuphezulu kwezingxenye esikhathini esifushane uma kuqhathaniswa. Ngokuhlanganisa izikhathi zomjikelezo osheshayo namandla okwenza inqubo ngokuzenzakalelayo, amabhizinisi angakwazi ukuzuza ukukhiqiza okwandayo kanye nokusebenza kahle okuphelele kokukhiqiza. Lokhu kusebenza kahle kwenza ukubumba umjovo kube yinketho efanelekile yokuhlangabezana nezikhathi ezidingekayo zokukhiqiza.

- Ukuhambisana kwedizayini yokukhiqiza (DFM):Ukubumba komjovo kuhambisana kahle nemigomo ye-Design for Manufacturing (DFM). Inketho enhle kakhulu yezinqubo ze-DFM, amandla ayo ahlanganisa ukudala izimo eziyinkimbinkimbi, ukwenza ngcono ukusetshenziswa kwezinto ezibonakalayo, kanye nokuhlanganisa izici ezifana nama-snap fit noma amahinge aphilayo. Abaklami bangasebenzisa lawa makhono ukuze bathuthukise ukwenziwa, banciphise izindleko, futhi bathuthukise ukusebenza kahle kokukhiqiza.

I-CNC Machining

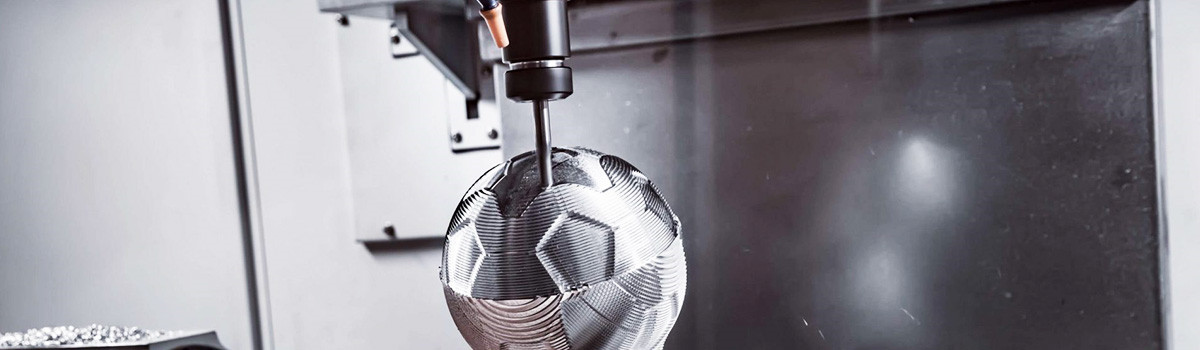

I-CNC machining, noma umshini wokulawula izinombolo wekhompuyutha, inqubo esetshenziselwa ukudala izingxenye ezinembile neziyinkimbinkimbi ezivela ezintweni ezingavuthiwe njengensimbi, ipulasitiki, noma ukhuni. Le nqubo yokukhiqiza ihlanganisa ukusebenzisa isofthiwe ye-computer-aid design (CAD) ukuze udizayine imodeli ye-3D yengxenye, eguqulwa ibe ikhodi yomshini futhi isetshenziselwe ukulawula umshini we-CNC. I-CNC machining inezinhlelo zokusebenza eziningi, kusukela ezimbonini ze-aerospace nezezimoto kuya emikhiqizweni yabathengi namadivayisi wezokwelapha.

Inqubo ye-CNC machining ibandakanya izinyathelo ezimbalwa, ezihlanganisa:

- Idizayini: Isinyathelo sokuqala ekwenzeni imishini ye-CNC ukwakha imodeli ye-3D yengxenye usebenzisa isofthiwe ye-CAD. Sibe sesiguqula le modeli ibe ikhodi yomshini, esiyisebenzisa ukulawula umshini we-CNC.

- Ukukhetha okubalulekile: Impahla eluhlaza ikhethwa ngokusekelwe ezintweni ezifunwayo zengxenye yokugcina, njengamandla, ukuqina, nokumelana nokushisa.

- Ukusethwa komshini: Sihlela umshini we-CNC ngekhodi yomshini futhi sivikele impahla eluhlaza emshinini.

- Imishini: Umshini we-CNC usebenzisa amathuluzi ahlukahlukene, njengama-drill, ama-lathes, nezigayo, ukuze ususe izinto ezibonakalayo ezintweni ezingavuthiwe ngokuya ngekhodi yomshini. Le nqubo inembile futhi ingakha izimo eziyinkimbinkimbi nezici.

- Ukucubungula okuthunyelwe: Uma umshini usuqediwe, ingxenye ingase idinge ukucutshungulwa kwangemuva, njengokugcotshwa kwesihlabathi noma ukupholishwa, ukuze kuzuzwe isiphetho nokuthungwa okufunayo.

Izinzuzo zemishini ye-CNC ziningi, kufaka phakathi:

- hle: Imishini ye-CNC inembile futhi ingakha izingxenye ezinokubekezelelana okuphansi okungamayintshi angu-0.001.

- Ukuphumelela: I-CNC machining iyinqubo yokukhiqiza esebenza kahle kakhulu engakhiqiza izingxenye ngokushesha nangokunembile.

- Ukwenza ngokwezifiso:Imishini ye-CNC ingakhiqiza izingxenye ezenziwe ngezifiso kakhulu ezihambisana nezidingo ezithile nezinto ezithandwayo.

- Ubunkimbinkimbi:Imishini ye-CNC ingakha izimo eziyinkimbinkimbi kakhulu nemiklamo engaba nzima noma engenzeki ukuyikhiqiza kusetshenziswa izindlela zokukhiqiza zendabuko.

- Ukuvumelana: Imishini ye-CNC ikhiqiza izingxenye ezinezinga eliphezulu lokungaguquguquki, iqinisekisa ukuthi ucezu ngalunye luhlangabezana nokucaciswa okuqondile.

CNC machining has anhlobonhlobo izicelo kuzo zonke izimboni ezahlukene, kuhlanganise:

- I-Aerospace:Sisebenzisa imishini ye-CNC ukukhiqiza izinjini zezindiza, amaphiko, nezingxenye zamagiya okuhlala.

- Izithuthi: Sisebenzisa imishini ye-CNC ukwenza izingxenye zezinjini, ukuthunyelwa, kanye ne-chassis.

- Ezokwelapha: Imishini ye-CNC yenza amathuluzi okuhlinza, izimila, nama-prosthetics.

- Imikhiqizo yabathengi:Sisebenzisa imishini ye-CNC ukukhiqiza yonke into kusuka kumakesi e-smartphone kuya ezintweni zikagesi zasekhishini.

- I-Architecture: Sisebenzisa imishini ye-CNC ukukhiqiza izingxenye zokwakha nezici zokuhlobisa.

Ukuphrinta kwe-3D

Ukuphrinta kwe-3D, okwaziwa nangokuthi ukukhiqiza okungeziwe, kuwubuchwepheshe obuguqukayo obusanda kuguqula imboni yokukhiqiza. Le nqubo ihilela ukufakwa kwezingqimba, ngokuvamile ipulasitiki noma insimbi, phezu kwayo kuze kube yilapho yakhe isimo esifiswayo, idala into ebonakalayo. Ukuphrinta kwe-3D kunezinhlobonhlobo zezinhlelo zokusebenza, kusukela ku-prototyping nokuthuthukiswa komkhiqizo kuya ekukhiqizeni izimila zezokwelapha kanye nemikhiqizo yabathengi eyenziwe ngokwezifiso.

Inqubo yokuphrinta ye-3D ibandakanya izinyathelo ezimbalwa, ezihlanganisa:

- Idizayini: Isinyathelo sokuqala ekuphrinteni kwe-3D ukwakha imodeli yedijithali yento efiswayo usebenzisa isofthiwe ye-computer-aid design (CAD). Bese, silayisha le modeli kuphrinta ye-3D.

- Ukuphrinta: Iphrinta ye-3D iqala inqubo yokuphrinta ngokwenza ungqimba oluncane lwempahla, ngokuvamile ipulasitiki noma insimbi, futhi iyihlanganise nesendlalelo sangaphambilini isebenzisa ukushisa noma okunamathelayo. Siphinda le nqubo isendlalelo ngesendlalelo kuze kube sakha yonke into.

- Ukucubungula okuthunyelwe: Uma ukuphrinta sekuqediwe, into ingase idinge ukucutshungulwa kwangemuva, njengokugcotshwa kwesihlabathi noma ukupholisha, ukuze kuzuzwe isiphetho nokuthungwa okufunayo.

Izinzuzo zokuphrinta kwe-3D ziningi, kufaka phakathi:

- Ukwenza ngokwezifiso:Ukuphrinta kwe-3D kusenza sikwazi ukudala imikhiqizo eyenziwe ngezifiso kakhulu efanelana nezidingo ezithile nokuthandwayo.

- Isivinini:Ukuphrinta kwe-3D kuyinqubo ye-prototyping esheshayo engakhiqiza ngokushesha into ebonakalayo kusuka kumodeli yedijithali.

- Kuqiza kahle:Ukuphrinta kwe-3D kungaba inqubo yokukhiqiza engabizi kakhulu, ikakhulukazi emikhiqizweni emincane noma imikhiqizo eyenziwe ngokwezifiso.

- Ubunkimbinkimbi: Ukuphrinta kwe-3D kungakha izimo eziyinkimbinkimbi kakhulu nemiklamo engaba nzima noma engenakwenzeka ukuyikhiqiza kusetshenziswa izindlela zokukhiqiza ezivamile.

- Ukuncishiswa kukadoti: Ukuphrinta kwe-3D kunciphisa imfucuza ngokusebenzisa izinto ezidingekayo kuphela ukudala into.

Ukuphrinta kwe-3D kunohlu olubanzi lwezinhlelo zokusebenza kuzo zonke izimboni ezahlukahlukene, kufaka phakathi:

- Ukukhiqiza: Singasebenzisa ukuphrinta kwe-3D ukwenza i-prototyping, ukuthuthukiswa komkhiqizo, kanye nokugijima okuncane kokukhiqiza.

- Ezokwelapha: Ukuphrinta kwe-3D kungakhiqiza ama-prosthetics angokwezifiso, izimila, namamodeli okuhlinza ngezinhloso zokuhlela nokuqeqesha.

- I-Architecture: Singasebenzisa ukuphrinta kwe-3D ukuze sakhe amamodeli esikali nezingxenye zokwakha.

- Imfashini: Ukuphrinta kwe-3D kungakha izingubo eziyingqayizivele, ezenziwe ngezifiso nezesekeli.

- Imfundo: Ukuphrinta kwe-3D kungasetshenziswa ezikoleni ukufundisa imiqondo yokuklama nobunjiniyela.

Ukukhiqizwa kweShidi Leshidi

Ukwenziwa kwensimbi yamashidi kuyinqubo yokukhiqiza ebandakanya ukubumba amashidi ensimbi abe izakhiwo nemikhiqizo ehlukene. Le nqubo ihlanganisa ukusika, ukugoba, ukubhoboza, namasu okushisela ukuze kuguqulwe amashidi ensimbi ayisicaba abe yizinhlobonhlobo, osayizi, kanye nemiklamo. Izimboni eziningi, kusukela kwezokwakha kuye kwezezimoto, zisebenzisa ukwakhiwa kweshidi lensimbi, futhi kubalulekile ukukhiqiza izinto eziningi zansuku zonke, okuhlanganisa izinto zasendlini nezinto zikagesi.

Inqubo yokwenza amashidi ensimbi ihilela izinyathelo ezimbalwa, ezihlanganisa:

- Idizayini:Isinyathelo sokuqala ekwakhiweni kwensimbi yeshidi siwukwenza uhlelo lomkhiqizo owufunayo. Amabhizinisi angasebenzisa isofthiwe ye-computer-aid technique (CAD) ukuze afinyelele izilinganiso ezinembile nezicaciso.

- Ukuzisika:Ngemva kokuphothula umklamo, abakhiqizi basika ishidi lensimbi libe usayizi odingekayo kanye nokuma besebenzisa amasu ahlukahlukene, njenge-laser noma i-jet yamanzi.

- Ukubopha: Isinyathelo esilandelayo ukuguqula ishidi lensimbi libe yisimo oyifunayo. Abakhiqizi basebenzisa amathuluzi akhethekile njengamabhuleki ukuze bakhe ama-engeli namajika ensimbi.

- Ukubhoboza:Amasu okubhoboza asetshenziswa ukudala izimbobo noma ezinye izimo ensimbi. Lokhu kungabandakanya ukugxiviza noma ukubhoboza, kuye ngobunkimbinkimbi bomklamo.

Welding: Ekugcineni, abakhiqizi bashisela izingcezu ezihlukahlukene zensimbi ndawonye ukuze bakhe umkhiqizo wokugcina. Ngokubeka insimbi ekushiseni okuphezulu, siyayincibilikisa futhi siyixube, senze isibopho esiqinile nesihlala isikhathi eside.

Ukwenziwa kwensimbi yeshidi kunezinzuzo eziningana kunezinye izinqubo zokukhiqiza. Lokhu kubandakanya:

- Ukuvumelana nezimo: Ishidi lensimbi lingalolongwa libe cishe noma yimuphi umumo noma usayizi, okulenze libe nezinto ezihlukahlukene emikhiqizweni eminingi.

- Amandla:Insimbi yeshidi iqinile futhi ihlala isikhathi eside, iyenza ilungele imikhiqizo edinga ukuqina nokuthembeka okuphezulu.

- Kuqiza kahle: Ishidi lensimbi lishibhile, okulenza libe inketho ethengekayo yokukhiqizwa ngobuningi bemikhiqizo.

- hle:Ukwenziwa kwensimbi yeshidi kusenza sikwazi ukuthola izilinganiso ezinembile kanye nokucaciswa, siqinisekisa ukuthi senza umkhiqizo ngamunye ube kumazinga afanele.

Izimboni ezihlukahlukene zisebenzisa i-sheet metal fabrication, kuhlanganise:

- Ukwakhiwa: Izinkampani zisebenzisa insimbi yeshidi ukwenza amapayipi e-HVAC, izinto zokufulela, nezinye izingxenye zesakhiwo ezakhiweni.

- Izithuthi:Abakhiqizi bezimoto basebenzisa insimbi yeshidi ukukhiqiza imizimba yemoto, izingxenye zenjini, nezinye izingxenye.

- I-elekhoni: Abakhiqizi basebenzisa insimbi yeshidi ukuze bakhe amakesi ekhompyutha, amagobolondo omakhalekhukhwini, nezinye izingxenye.

- I-Aerospace:Abakhiqizi bezindiza basebenzisa insimbi ukuze bakhiqize izingxenye nezingxenye zendiza.

Casting

Ukulingisa kuyinqubo ebalulekile embonini yezokuzijabulisa. Kubandakanya ukukhetha abalingisi nabanye abalingisi abazobamba iqhaza kwifilimu, ithelevishini, yaseshashalazini, nezinye izinhlobo zemidiya. Umqondisi omuhle wokulingisa angenza noma aphule ukukhiqizwa, njengoba abalingisi abalungile bengenza umbhalo uphile futhi adale okuhlangenwe nakho okukhumbulekayo kokubuka kwababukeli. Kulokhu okuthunyelwe kwebhulogi, sizohlola ukubaluleka kokulingisa kanye nezici ezibalulekile ekwenzeni izinqumo eziyimpumelelo zokusakaza.

Okokuqala futhi okubaluleke kakhulu, indima yomqondisi wokulingisa ukuthola abalingisi abahamba phambili kulo msebenzi. Inqubo yokulingisa umlingisi ayihlanganisi nje kuphela amakhono abo kodwa nohlelo lwabo, izinga lobuchwepheshe, nokufaneleka kwengxenye. Umqondisi wokulingisa omuhle uzosebenzisana eduze nomqondisi nabakhiqizi ukuze baqonde umbono wokudala wephrojekthi bese befuna abalingisi abangenza lowo mbono uphile.

Ezinye zezinto ezibalulekile abaqondisi abalingisi abazicabangelayo lapho behlola abalingisi zifaka:

- Ikhono lokulingisakuyisici esibaluleke kakhulu, njengoba ukusebenza okuhle kakhulu kungenza noma kwephule iphrojekthi. Abaqondisi bezokulingisa bazobheka abalingisi abazoletha ukusebenza okugculisayo nokuthinta imizwa.

- Ukubukeka komzimba: Ukubukeka komlingisi kwesinye isikhathi kubalulekile endimeni. Isibonelo, uma umlingisi emude futhi eblonde, umqondisi womlingisi uzobeka phambili abalingisi abafana naleyo ncazelo.

- Ukutholakala:Amashejuli wokuqopha angadingeka, ngakho abaqondisi abalingisi kufanele bacabangele ukutholakala komlingisi ngaphambi kokuthatha isinqumo. Uma umlingisi esezibophezele kwenye iphrojekthi, angadinga usizo ukuze abambe iqhaza elisha.

- Ubungcweti:Ukulingisa kuwumsebenzi, futhi abaqondisi abalingisi bazobheka abalingisi abangochwepheshe nabathembekile. Abantu ngabanye kufanele bafike ngesikhathi, bazilungiselele ngokwanele, futhi baphathe umsebenzi ngokucophelela ukuze babonise inhlonipho ngomsebenzi.

Ekugcineni, isinqumo sokusakaza esiyimpumelelo sidinga inhlanganisela yalezi zici. Umlingisi angase abe nethalente elimangalisayo, kodwa uma engatholakali noma engahambisani nezidingo zomzimba zendima, angase angabi yisinqumo esingcono kakhulu.

Ngokungeziwe ekukhetheni abalingisi bezindima ezithile, abaqondisi abalingisi nabo badlala indima ebalulekile ekulolongeni bonke abalingisi bomdlalo. Lapho wenza isinqumo, kubalulekile ukucabangela izici ezihlukahlukene, ezihlanganisa:

- I-Chemistry: Kwezinye izimo, ubudlelwano babalingiswa bunenjongo njengokudlalwa komuntu ngamunye. Abaqondisi bezokulingisa bazobheka abalingisi abanamakhemikhali emvelo esikrinini.

- Ukuhlukahluka:Ukumelwa kubaluleke kakhulu embonini yezokuzijabulisa, futhi abaqondisi abalingisi bavame ukulwela ukwakha abalingisi abahlukahlukene ababonisa umhlaba wangempela.

- Ukuqashelwa komkhiqizo: Kwezinye izimo, ukulingisa umlingisi owaziwayo kungadala umsindo wephrojekthi. Kumafilimu azimele noma imikhiqizo emincane, ukuheha ukunaka kungabaluleka. Yilapho usizo lwethu lusiza khona.

I-Extrusion

I-Extrusion iyinqubo yokukhiqiza ebandakanya ukubumba into ngokuyiphusha ngedayidi ukuze kwakhiwe umumo othile noma iphrofayili. Abakhiqizi bavame ukusebenzisa le nqubo ukwenza imikhiqizo yepulasitiki neyensimbi njengamapayipi, amashubhu, namashidi. Lapha, sizoxoxa nge-extrusion, ukuthi isebenza kanjani, kanye nezicelo zayo.

Isebenza Kanjani I-Extrusion?

I-Extrusion isebenza ngokuphusha impahla ngokusebenzisa idayi usebenzisa i-extruder. I-extruder iqukethe i-hopper, isikulufu, kanye nento yokushisisa. Umsebenzisi uphakela impahla eluhlaza ku-hopper, bese eyihambisa kusikulufu. Isikulufu siyazungeza, siphushe into esetshenziswayo endaweni yokushisisa, lapho sincibilika khona futhi sixutshwe. Umshini wenza into encibilikisiwe ngedayizi, lapho ithatha khona umumo noma iphrofayili oyifunayo. Impahla ekhishiwe ibe isipholile futhi isikwe ubude obufunayo.

Izicelo ze-Extrusion

I-Extrusion inezicelo eziningi ezimbonini ezahlukahlukene, kufaka phakathi:

- Ukwakhiwa: I-Extrusion isetshenziswa embonini yokwakha ukwakha amapayipi epulasitiki nensimbi, amashubhu, namashidi.

- Okufakiwe:I-Extrusion isetshenziswa embonini yokupakisha ukwenza ifilimu yepulasitiki kanye namashidi emikhiqizo yokugoqa.

- Izithuthi:I-Extrusion isetshenziswa embonini yezimoto ukuze kwakhiwe izinto zepulasitiki nezensimbi zezimoto, njengokunquma kanye ne-weatherstripping.

- Ukudla nesiphuzo: I-Extrusion isetshenziswa embonini yokudla neziphuzo ukwenza iziqukathi zepulasitiki nezensimbi zokugcina nokuthutha ukudla neziphuzo.

Izinzuzo Extrusion

I-Extrusion inikeza izinzuzo eziningi kunezinye izinqubo zokukhiqiza, okuhlanganisa:

- Kuqiza kahle: I-Extrusion iyindlela yokukhiqiza engabizi kakhulu, evumela ukukhiqizwa kwevolumu ephezulu ngemfucuza encane.

- Iyahluka:Abakhiqizi bangasebenzisa i-extrusion ukuze bakhe izinhlobonhlobo zomumo namaphrofayili, okwenza kube inqubo yokukhiqiza yendawo yonke.

- Ukuvumelana: I-Extrusion ikhiqiza imiphumela engaguquki, iqinisekisa ukuthi umkhiqizo ngamunye uyafana.

- Isivinini: I-Extrusion iyinqubo esheshayo, evumela ukukhiqizwa kwevolumu ephezulu ngesikhathi esifushane.

- Quality: I-Extrusion ikhiqiza imikhiqizo yekhwalithi ephezulu enendawo ebushelelezi.

Ukusika I-Laser

Ukusika i-laser kuyinqubo yokukhiqiza edumile esebenzisa ugongolo lwe-laser ukusika izinto zokwakha zibe yizimo nobukhulu obuhlukahlukene. Inikeza izinzuzo eziningi kunezindlela zokusika zendabuko, njengokunemba, isivinini, nokuguquguquka. Lokhu okuthunyelwe kwebhulogi kuzodingida ukusikwa kwe-laser, ukuthi kusebenza kanjani, nezinye zezinhlelo zokusebenza zayo.

Iyini i-Laser Cutting?

Ukusika i-laser kuyinqubo yokukhiqiza esebenzisa ugongolo lwe-laser ukusika izinto zibe yizimo nobukhulu obuhlukahlukene. Kuyindlela edumile yokusika izinto ezahlukahlukene, kufaka phakathi insimbi, ukhuni, ipulasitiki, nendwangu. Ama-opharetha angalawula i-laser beam ukuze asike umumo namaphethini anembayo ngodoti omncane.

Ngabe I-Laser Cutting isebenza kanjani?

Ukusika i-laser kusebenza ngokuqondisa ugongolo lwelaser olunamandla amakhulu ezintweni ezisikiwe. I-laser resonator ikhiqiza i-laser beam, bese igxila ezintweni ngokusebenzisa izibuko namalensi. I-laser beam egxilile iyancibilika, ishise, noma ihwamulise indwangu, idale ukusika okuhlanzekile nokunembayo.

Izicelo Laser Cutting

Ukusika i-laser kunezinhlelo eziningi ezisetshenziswa ezimbonini ezahlukahlukene, kufaka phakathi:

- Ukukhiqiza:Imboni yokukhiqiza isebenzisa kakhulu ukusika kwe-laser ukusika nokubumba izinto ezahlukahlukene. Cabangela ukubhala izwi elisebenzayo. Kuyinzuzo ekudaleni izimo eziyinkimbinkimbi namaphethini okungaba nzima noma okungenzeki ukuwafeza kusetshenziswa izindlela zokusika zendabuko.

- I-Architecture: Ukusika i-laser kusetshenziswa embonini yezokwakha ukwakha amaphaneli okuhlobisa, izikrini, nezinye izakhi zokuklama.

- Ukuhlobisa:Ukusika i-laser kusetshenziswa embonini yobucwebe ukwenza imiklamo eyinkimbinkimbi ezinsimbi eziyigugu.

- Izithuthi: Imboni yezimoto isebenzisa ukusika kwe-laser ukusika nokubumba izingxenye zensimbi.

- I-elekhoni:Imboni ye-elekthronikhi isebenzisa ukusika kwe-laser ukusika nokubumba amabhodi wesifunda nezinye izici.

Izinzuzo Laser Cutting

Ukusika i-laser kunikeza izinzuzo eziningi kunezindlela zokusika zendabuko, kufaka phakathi:

- hle:Ukusika i-laser kukhiqiza ukusikeka okunembile okunemfucuza encane, okuvumela ukusetshenziswa ngokuphumelelayo kwezinto.

- Isivinini: Ukusika i-laser kuyashesha kunezindlela zokusika zendabuko, okuvumela izikhathi ezimfishane zokukhiqiza.

- Ukuhlukahluka:Ukusika i-laser kungasika izinto eziningi ezahlukahlukene, kufaka phakathi insimbi, ukhuni, ipulasitiki nendwangu.

- Ukuvumelana: Ukusika kwe-Laser kukhiqiza imiphumela engaguquki, iqinisekisa ukuthi ukusika ngakunye kuyefana.

- Ukuzenzekelayo: Ukusika i-laser kungenziwa ngokuzenzakalelayo, okuvumela ukukhiqizwa kwevolumu ephezulu ngokungenelela okuncane komuntu.

Ukukhetha Umhlinzeki Wesevisi Yokukhiqiza Ivolumu Ephansi Ngakwesokudla

Ukukhiqiza umthamo ophansi kuyingxenye ebalulekile yokuletha umkhiqizo wakho emakethe. Ikuvumela ukuthi ukhiqize amanani amancane omkhiqizo wakho ukuze uhlole imakethe futhi wenze izinguquko ezidingekayo ngaphambi kokudlulela ekukhiqizeni okukhulu. Ukukhetha umhlinzeki wesevisi wokukhiqiza umthamo ophansi olungile kubalulekile empumelelweni yomkhiqizo wakho. Kulokhu okuthunyelwe kwebhulogi, sizoxoxa ngokubaluleka kokukhetha umhlinzeki wesevisi wokukhiqiza umthamo ophansi ofanele kanye namathiphu okwenza ukukhetha okufanele.

Kungani Kubalulekile Ukukhetha Umhlinzeki Wesevisi Yokukhiqiza Ivolumu Ephansi Ngakwesokudla?

Ukukhetha umhlinzeki wesevisi wokukhiqiza umthamo ophansi olungile kubalulekile ngenxa yezizathu ezimbalwa:

- Ikhwalithi yokulawula: Umhlinzeki wesevisi olungile uzoqinisekisa ukuthi umkhiqizo wakho uhlangabezana nezindinganiso zakho.

- Ukulethwa ngesikhathi: Ukukhetha umhlinzeki wesevisi othembekile kungasiza ukuqinisekisa ukuthi umkhiqizo wakho ufanelekile.

- Ukuphathwa kwezindleko: Umhlinzeki wesevisi ohloniphekile angakusiza ukuphatha izindleko ngokukhomba izindlela zokunciphisa izindleko.

- Innovation:Ukukhetha umhlinzeki wesevisi onolwazi embonini yakho kungakusiza ukuthi ubone amathuba amasha okuqamba izinto ezintsha nokuthuthukiswa komkhiqizo.

Amathiphu Wokukhetha Umhlinzeki Wesevisi Yokukhiqiza Ivolumu Ephansi Ngakwesokudla

- Nquma izidingo zakho: Ngaphambi kokukhetha umhlinzeki wesevisi wokukhiqiza umthamo ophansi, kubalulekile ukucacisa izidingo zakho. Ukuze uqinisekise ukwethulwa ngempumelelo komkhiqizo, kubalulekile ukuchaza ngokucacile ukucaciswa komkhiqizo wakho, imakethe eqondiwe, kanye nomugqa wesikhathi wokulethwa.

- Cwaninga abahlinzeki bezinsizakalo abangaba khonaku-inthanethi futhi uhlole ukubuyekezwa nezilinganiso zabo. Ungakwazi futhi ukufinyelela kwamanye amabhizinisi embonini yakho ukuze uthole izincomo.

- Linganisa isipiliyoni nobungcweti:Khetha umhlinzeki wesevisi onolwazi embonini yakho kanye nekhono emkhiqizweni owenzayo. Kubalulekile ukuxhumana nezidingo zakho ngokucacile ukuze umkhiqizo owutholayo uhlangabezane nalokho okulindele.

- Cabangela indawo:Ukukhetha umhlinzeki wesevisi oseduze nebhizinisi lakho kungasiza ekunciphiseni izindleko zokuthumela futhi uqinisekise ukulethwa ngesikhathi.

- Linganisa izindleko:Nakuba izindleko kungafanele kube ukuphela kwesici esinqumweni sakho, ukuhlola izindleko zokusebenza nabahlinzeki besevisi abahlukene kubalulekile. Qhathanisa izingcaphuno bese ukhetha umhlinzeki wamanani oqhudelanayo ngenkathi usahlangabezana nezidingo zakho zekhwalithi.

- Sicela ucele isampula: Ngaphambi kokukhetha umhlinzeki wesevisi, cela isampula yomsebenzi wabo. Ukuhlola ikhwalithi yomsebenzi wabo kungakusiza ekunqumeni ukuthi bangabantu abafanelekayo yini kuphrojekthi yakho.

- Xhumana nezidingo zakho:Ukuxhumana kubalulekile ekusebenzisaneni ngempumelelo nomhlinzeki wakho wesevisi. Cacisa ngalokho okulindele futhi ukhulume nganoma yiziphi izinguquko noma izinkinga phakathi nenqubo yokukhiqiza.

Ukuxhumana nokusebenzisana noMkhiqizi

Ukuxhumana nokusebenzisana nomkhiqizi kuyizici ezibalulekile zokuletha ngempumelelo umkhiqizo wakho emakethe. Ukusungula ubudlelwano obuvulekile nobukhiqizayo nomkhiqizi wakho kubalulekile ukuze uqinisekise ukuthi umkhiqizo wakho uhlangabezana nokulindelekile futhi ulethwa ngesikhathi nangaphakathi kwesabelomali. Lokhu okuthunyelwe kwebhulogi kuzoxoxa ngokubaluleka kokuxhumana nokusebenzisana nomkhiqizi kanye namathiphu athile okusungula ubambiswano oluyimpumelelo.

Kungani Kubalulekile Ukuxhumana Nokubambisana Nomkhiqizi?

Ukuxhumana nokusebenzisana nomkhiqizi kubalulekile ngenxa yezizathu ezimbalwa:

- Ikhwalithi yokulawula:Ukuxhumana okusebenzayo nokusebenzisana nomkhiqizi kungasiza ekuqinisekiseni ukuthi ikhwalithi yomkhiqizo wakho ihlangabezana nalokho okulindele.

- Ukulethwa ngesikhathi:Ukusungula imigqa ecacile yokuxhumana kungakusiza uqinisekise ukulethwa ngesikhathi komkhiqizo wakho.

- Ukuphathwa kwezindleko:Ukusebenzisana nomkhiqizi kungakusiza ukuphatha izindleko ngokuhlonza izindlela zokunciphisa izindleko.

- Innovation:Ukusebenzisana nomkhiqizi kungakusiza ukuhlonza ukusungula okusha kanye namathuba okuthuthukisa umkhiqizo.

Amathiphu Wokusungula Ubambiswano Oluphumelelayo Nomkhiqizi

- Misa okulindelwe okucacile:Kubalulekile ukusungula okulindelekile kumkhiqizo wakho kusukela ekuqaleni. Ukuhlonza ukucaciswa komkhiqizo wakho, imakethe eqondiwe, nomugqa wesikhathi wokulethwa kuyadingeka ukuze uqinisekise ukulethwa komkhiqizo ngempumelelo.

- Gcina imigudu yokuxhumana evulekile:Ukuxhumana njalo nomkhiqizi kungasiza ekuvimbeleni ukungezwani futhi kuqinisekise ukuthi iphrojekthi iqhubeka njengoba bekuhleliwe. Ukuhlela ukungena njalo nokwabelana ngezibuyekezo ngenqubekela phambili kubalulekile ukuze ugcine wonke umuntu ekhasini elifanayo.

- Gqugquzela indawo yokusebenzisana: Ukusebenzisana nomkhiqizi kubalulekile ekwakheni ubambiswano oluyimpumelelo. Kufanele samukele imiqondo emisha nezinqumo futhi sihlanganyele ukuze sithole izindlela zokuthuthukisa umkhiqizo.

- Phatha okulindelekile: Kubalulekile ukuphatha okulindelwe kuyo yonke inqubo yokukhiqiza. Sizibophezele ekubeni obala nokwethembeka mayelana nanoma yiziphi izithiyo noma izinkinga ezingase zivele futhi sizosebenza ukuthola izixazululo zokunciphisa imiphumela yazo.

- Yenza ukuhlola kokulawula ikhwalithi:Ukuhlolwa kokulawulwa kwekhwalithi okuvamile kuyo yonke inqubo yokukhiqiza kungasiza ekuhlonzeni noma yiziphi izinkinga kusenesikhathi futhi kuzigweme ekubeni izinkinga ezibaluleke kakhulu ezansi komugqa.

I-Intellectual Property Protection

I-Intellectual Property (IP) ibhekisela ekudalweni kwengqondo, njengokuqanjwa, imiklamo, nemisebenzi yobuciko, evikelwe umthetho. Ukuvikelwa kwe-IP kubalulekile kumabhizinisi nakubantu ngabanye ukuze bavikele imibono yabo futhi bavimbele abanye ukuba bayisebenzise ngaphandle kwemvume. Lokhu okuthunyelwe kwebhulogi kuzoxoxa ngokubaluleka kokuvikelwa kwempahla yengqondo kanye nezindlela ezithile zokuvikela i-IP yakho.

Kungani Kubalulekile Ukuvikela Impahla Ehlakaniphile?

Ukuvikelwa kwe-IP kubalulekile ngenxa yezizathu ezimbalwa:

- Ivikela inzuzo yokuncintisana yebhizinisi lakho: Impahla yengqondo inika izinkampani umkhawulo wokuncintisana emakethe. Isibonelo, uma unelungelo lobunikazi lomkhiqizo omusha, ungavimbela abanye ekwenzeni noma ukuthengisa lowo mkhiqizo, unikeze ibhizinisi lakho inzuzo yokuncintisana.

- Kukusiza ukuthi wenze imali engenayo:Ukuvikelwa kwe-IP kukuvumela ukuthi unikeze ilayisense impahla yakho yengqondo kwabanye futhi wenze imali ngezimali ezizuzisayo.

- Ikhuthaza ukuqamba okusha: Iukuvikelwa kwempahla yengqondo kukhuthaza ukuqamba okusha ngokukhuthaza abasunguli nabadali ukuba bakhe imibono nemikhiqizo emisha.

Izindlela Zokuvikela Impahla Yakho Yobuhlakani

- Yenza usesho olubanzi:Ngaphambi kokufaka noma yiluphi uhlobo lokuvikelwa kwe-IP, kubalulekile ukwenza usesho olunzulu ukuze uqinisekise ukuthi umbono wakho uhlukile futhi awuphuli amalungelo abanye. Ukuqinisekisa okwangempela, ukusesha noma imaphi amalungelo obunikazi adlule, izimpawu zokuthengisa, noma amalungelo okushicilela okungenzeka ukuthi asevele ekhona kuyadingeka.

- Ifayela lamalungelo obunikazi, izimpawu zokuthengisa, namalungelo okushicilela: Kuye ngokusungula kwakho noma umsebenzi wokudala, ungase udinge ukufayela amalungelo obunikazi, izimpawu zokuthengisa, noma amalungelo okushicilela. Ilungelo lobunikazi livikela umklamo, uphawu lokuhweba luvikela umkhiqizo, futhi ilungelo lobunikazi livikela imisebenzi yokuqamba. Ukufakela lezi zindlela zokuvikela kungasiza ekuvimbeleni abanye ukuthi basebenzise noma bakopishe imibono yakho.

- Sebenzisa izivumelwano zokungadaluli (ama-NDA):I-NDA yisivumelwano esisemthethweni esingasiza ukuvikela i-IP yakho lapho wabelana ngayo nabanye. Isungula ubudlelwano obuyimfihlo phakathi kwezinhlangothi futhi ivimbela umamukeli ekuvezeni umbono wakho kwabanye ngaphandle kwemvume yakho.

- Gada ukwephulwa komthetho: Ukuqapha ukwephulwa komthetho kubandakanya ukuqapha imakethe ukusetshenziswa okungagunyaziwe kwempahla yakho yengqondo. Kubalulekile ukwenza usesho olujwayelekile lwe-inthanethi ukuze uvikele impahla yakho yengqondo. Enye indlela yokuvikela okusungulile noma imisebenzi yokudala iwukusesha amakhophi angagunyaziwe nokuqapha imibukiso yohwebo yanoma yimiphi imikhiqizo ephula impahla yakho yobuhlakani.

- Gcizelela amalungelo akho:Uma uthola ukuthi othile usebenzisa impahla yakho yengqondo ngaphandle kwemvume yakho, kubalulekile ukuthatha isinyathelo. Umuntu angase acabange ukuthatha izinyathelo zomthetho noma ukuthumela incwadi yokumisa nokuyeka ukuze avimbele ukwephulwa komthetho.

Ukuphothula Inqubo Yokukhiqiza Nokwamukela Imikhiqizo Yakho

Lapho uletha umkhiqizo emakethe, ukuphothula inqubo yokukhiqiza nokwamukela umkhiqizo osuphelile kuyisinyathelo esijabulisayo nesibalulekile. Manje yisikhathi sokubona imiphumela yokusebenza kanzima kwakho nokuhlela ngokucophelela. Kodwa-ke, kunezinto ezibalulekile okufanele uzikhumbule ukuze uqinisekise ukuthi yonke into ihamba kahle futhi umkhiqizo wakho ufika njengoba bekulindelekile.

Nawa amanye amathiphu okuphothula inqubo yokukhiqiza nokwamukela imikhiqizo yakho:

- Hlola kabili yonke into ngaphambi kokuphothula ukukhiqiza:Kubalulekile ukuqinisekisa ukuthi konke kuhamba ngohlelo ngaphambi kokunikeza ukukhanya okuluhlaza ukuze kukhiqizwe ngobuningi. Kudingeka ukuthi kubuyekezwe kahle ukwakheka, izinto zokwakha, kanye nenqubo yokukhiqiza ukuze kuqinisekiswe ukunemba nokwethembeka. Noma yiziphi izinkinga ezitholakala phakathi nombukiso zingabiza ukuzilungisa, ngakho ukubhekana nanoma yiziphi izinkinga ezingaba khona kusengaphambili kubalulekile.

- Hlala uxhumene eduze nomkhiqizi wakho: Ukugcina ukuxhumana okuvulekile nomkhiqizi wakho kubalulekile ukuze uqinisekise ukuthi yonke into ihamba kahle. Ngizibophezele ukukugcina unolwazi ngokukunikeza izibuyekezo njalo, ngokuphendula imibuzo yakho, kanye nokubhekana ngokushesha nanoma yikuphi ukukhathazeka ongase ube nakho. Ukuxhumana okuhle kungasiza ukuqinisekisa ukuthi inqubo yokukhiqiza ihamba kahle.

- Zivumelanise nezimo nemigqa yesikhathi: Izikhathi zokukhiqiza ngezinye izikhathi zingashintsha, ngakho-ke kubalulekile ukuguquguquka nezinsuku zokugcina. Kungcono ukuthola umkhiqizo wekhwalithi ezinsukwini ezimbalwa kamuva kunokulindelekile kunokwamukela umkhiqizo onesici ngesikhathi. Qiniseka ukuthi unezinhlelo zezimo eziphuthumayo ezikhona zanoma yikuphi ukubambezeleka okungalindelekile.

- Hlela ukuhlolwa komkhiqizo:Ngaphambi kokuthumela imikhiqizo yakho, kuwumqondo omuhle ukuhlela ukuhlolwa komkhiqizo. Enye yezindawo esizihlanganisayo ukuhlola ukulawula ikhwalithi, ukusebenza, nokuphepha. Ukuhlola kungasiza ukuqinisekisa ukuthi umkhiqizo wakho uhlangabezana nazo zonke izindinganiso nemithetho edingekayo.

- Khetha indlela yokuthumela ethembekile:Lapho uthumela imikhiqizo yakho, ukukhetha indlela yokuthumela ethembekile nethembekile kubalulekile. Ukukhetha inkampani yenethiwekhi ethembekile, ukusebenzisa amaphakheji afanele, kanye nokuthola umshwalense owanele kubalulekile ukuze kuqinisekiswe inqubo yokuthumela ngokushelelayo.

Isiphetho

Izinsizakalo zokukhiqiza umthamo ophansi zinikeza amabhizinisi amancane isixazululo esingabizi kakhulu sokukhiqiza imikhiqizo emincane ngaphandle kokufaka izindleko eziphezulu. Lezi zinsizakalo zihlinzeka ngezikhathi ezisheshayo zokushintsha, izinqubo zokukhiqiza eziguquguqukayo, imikhiqizo yokugcina yekhwalithi ephezulu, kanye nezinto nezindlela ezahlukahlukene. Ngokukhetha umhlinzeki wesevisi wokukhiqiza umthamo ophansi ofanele futhi uxhumane naye ngempumelelo, amabhizinisi amancane angaletha ngempumelelo imikhiqizo yawo emakethe kuyilapho ehlala encintisana embonini yawo.