I-Automotive Plastic Components Umjovo Ukubumba

Izingxenye Zepulasitiki Yezimoto Namuhla

Ukusebenza kwezimoto okuphezulu kudinga izingxenye eziphatha konke. Amapulasitiki asebenza kusuka enjini kuya ku-chassis; kulo lonke ingaphakathi kuya ngaphandle. Amapulasitiki ezimoto anamuhla enza cishe u-50% wevolumu yemoto entsha kodwa engaphansi kuka-10% wesisindo sayo.

Ukuphepha

Intuthuko yezokuphepha ezintweni zanamuhla isindisa izimpilo eziningi. Izikhwama zomoya, amawindi omoya, ama-sunroof kanye nezinto ezintsha ezimunca amandla kunciphisa ukufa kwezimoto. Amamojula epulasitiki angaphambili, izihlalo eziyimojuli kanye nobhampa abamunca amandla basiza ukusindisa izimpilo unyaka nonyaka.

Izakhiwo eziyinhlanganisela yepulasitiki zingasiza izimoto ezingasindi ngenkathi zilondoloza izici zokuphepha. Lapho imoto iphahlazeka, onjiniyela bafuna isakhiwo siphuke ngendlela ebikezelwayo. Izinto zezimoto kufanele zimunce, zingadluliseli, “amandla omthelela” kubantu. Imboni ibiza lokhu “njengokuchotshozwa okulawulwayo.”

Izinhlanganisela ze-polymer eziqiniswe nge-fiber zimunca amandla aphindwe kane ensimbi. I-B-pillar iyinsika yokusekela exhuma uphahla lwemoto nomzimba wayo. Ingemuva komnyango wangaphambili futhi ihlinzeka ngomthombo omkhulu wokumelana nokungena phakathi nokushayisana.

INational Highway Traffic Safety Administration isanda kuxhasa ngezimali ucwaningo lwama-B-pillars. Ucwaningo lubheke ngokukhethekile ukwakheka kwensika ye-B-pillar eyinhlanganisela enamandla ye-carbon fibre thermoplastic. Umgomo bekuwukunquma ukonga isisindo somklamo nokuphepha kokushayisana kwezimoto uma kuqhathaniswa nesisekelo sensimbi. I-B-pillar ibonise ukonga isisindo esingamaphesenti angu-60, kanye nezimfuneko zokuphahlazeka zomthelela oseceleni owanelisiwe. Amathuluzi wokubala enze imodeli yomthelela oguqukayo kanye nezinsika ze-B zokuphendula.

Amapulastiki asiza ukusindisa izimpilo ngesikhathi semithelela yabahamba ngezinyawo. Obhampa abahlanganisa i-Polycarbonate basiza ukuvikela abagibeli ezingozini. Amapulastiki aphinde anike amandla ukuthunyelwa okusheshayo ukuze kuvikelwe abahamba ngezinyawo kakhulu ezimotweni zakwaFord. Umjovo oguquguqukayo wokuvikela abahamba ngezinyawo ogibele inzwa ohlanganiswe ngepulasitiki. Bona okwengeziwe kokuthi “Crumple Zone Blog” kanye nohambo lwethu lwe-BMW i3 Carbon Fiber Chassis Safety Components.

Amawindshields, Windows & Sunroofs

Amawindshields aseNyakatho Melika afika njengeyunithi yezendlalelo eziningi. Ngeso lengqondo ungqimba oluncane lwepulasitiki phakathi kwamashidi amabili ezacile engilazi. Inhlanganisela ingaba mncane, ibe lula futhi ibe namandla kunengilazi epholile iyodwa. Ungqimba lwepulasitiki olumelana nezinyembezi lusiza ukuvimbela ukukhishwa komuntu ongaphakathi. Eqinisweni, i-NHTSA ilinganisela ukuthi lezi zendlalelo zisiza ukuvikela ukufa kwabantu abangaphezu kuka-300 ngonyaka.

Izingxenye zepulasitiki ezingasindi zophahla zehlisa isikhungo samandla adonsela phansi anciphisa amathuba okuthi i-tip-over ngesikhathi sokuqondisa kwezingozi ezijika ekhoneni. I-polycarbonate ecacile engahlaneki manje ingamelana ne-UV futhi yehlise isisindo kakhulu. Ukuhlanganiswa kophahla lonke kungenziwa nge-polymer.

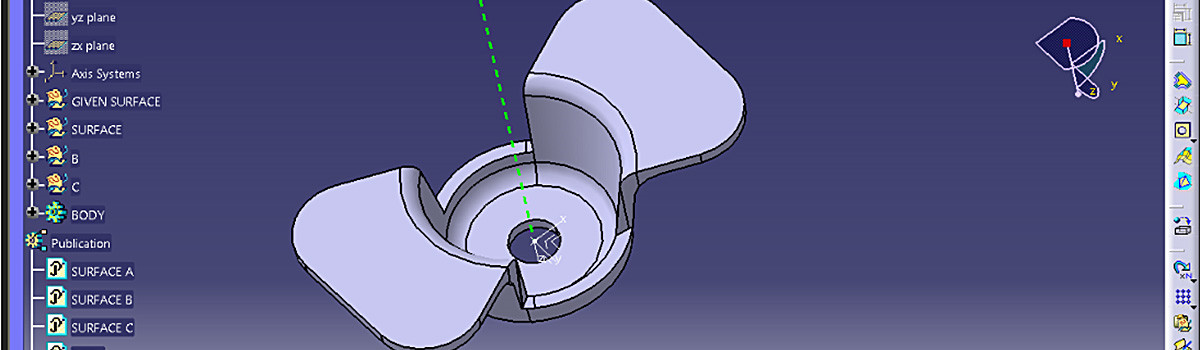

I-DJmolding's Automotive Plastic Components Umjovo wokubumba

I-Djmolding yizinkampani ezibumba umjovo wepulasitiki ezimotweni ezine-ISO/TS 16949:2009, sinikezela ngesikhunta somjovo wepulasitiki ngokwezifiso, umklami kanye nomkhiqizi wesikhunta esinembayo somjovo sisebenzisa izinsalela zebanga lobunjiniyela, ingilazi, i-tungsten, i-carbon nensimbi egcwele izinto zezimoto, i-aerospace, i-electronic, zasolwandle, zezokwelapha kanye nezicelo ze-telecom.

Amaphesenti angamashumi amabili wezinto ezisetshenziselwa ukwakhiwa kwezimoto zihlanganisa izingxenye zepulasitiki ezinezici ezihlukahlukene. Kwa-DJmolding sinikezela ngohlu lonke lwezingxenye zepulasitiki ezinkampanini zezimoto, zangaphakathi nangaphandle zezimoto, kanye nemishini yezimoto. Sisebenza ngobuchwepheshe bakamuva bomjovo wezingxenye zepulasitiki kanye nezinto zobunjiniyela bokwakhiwa kwezingxenye ezisetshenziswa amabhrendi esikhundleni sensimbi, ezimelana kakhulu, ezingasindi futhi kulula ukuzisebenzisa kabusha.

I-DJmolding njengomkhiqizi wokubumba umjovo wepulasitiki kanye nomphakeli, ugxile kubuchwepheshe bokubumba umjovo we-thermoplastic. Ukwazi kwethu futhi kuhlanganisa ubuchwepheshe bokubumba umjovo wegesi, isicwebezelisi esiphezulu kanye ne-e-moulding. Izingxenye zethu zemoto ezibunjiwe zangaphandle nezangaphakathi zemboni yezimoto zakhiwe kakhulu ngalezi zinto ezilandelayo: - polystyrene (PS), - polypropylene (PP), - ABS, - PC, - PC / ABS, - PC / PMMA.

Izingxenye zemoto ezibunjwe ngomjovo wangaphakathi

Embonini yezimoto eguquguqukayo singabalingani abathembekile ekukhiqizeni izinhlobonhlobo zezingxenye zangaphakathi ezibunjwe ngomjovo. Ezimbonini zethu ezigunyaziwe ze-ISO IATF senza amaphrojekthi wengxenye yangaphakathi kubakhiqizi abahamba phambili bezimoto. Sinesipiliyoni se-OEM, umphakeli wezimoto we-Tier 1 kanye nomkhiqizi wezingxenye zezimoto zangaphakathi nezangaphandle zokunquma. Iphothifoliyo yethu yomkhiqizo wezingxenye zokubumba umjovo wangaphakathi ihlanganisa izingxenye zepulasitiki ezizenzakalelayo ezifana nalezi: izingxenye zedeshibhodi (isb: indawo yamagilavu, izinsika zezicabha nezinsika zamafasitela), izinsimbi zokulungisa amakholomu, izibambo zeminyango, izimbobo zomoya, amakhonsoli aphakathi nendawo, amamojula ophahla, njll.

Izingxenye zemoto ezibunjwe ngomjovo wangaphandle

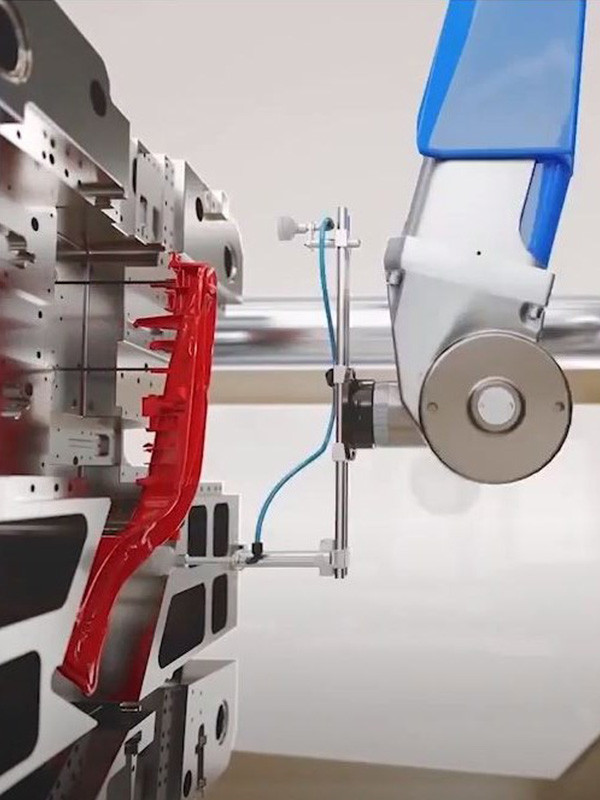

Ukubumba umjovo kuyindlela efanelekile yokwenza uhla olubanzi lwezingxenye zemoto yangaphandle. Ithimba lethu lochwepheshe bokubumba umjovo abanolwazi lisebenzisana eduze nama-OEM ezimoto kanye namakhasimende e-Tier 1 ukuze lihlole futhi lichaze zonke izidingo zobuchwepheshe futhi ngenxa yalokho lenze ngokugcwele ukukhiqizwa kwezingxenye zemoto zangaphandle ezingenasici. Singabakhi bokubumba umjovo wepulasitiki wezingxenye zangaphandle zezimoto isb: ama-mudguards (ama-fenders), amakhothamo amasondo, ama-grilles, izibambi zezinzwa, ama-floor rails, ama-trunk trim covers ngaphambili nangemuva, obhampa kanye nezicabha zemoto zangaphandle, amapaneli eminyango. Izingxenye zethu zepulasitiki zokujova zezimoto zitholakala ezinhlobonhlobo zezimoto emhlabeni jikelele.

Umgomo wethu uwukunikeza inani elikhulu kumakhasimende ethu. Ngaphandle kokukhiqiza izingxenye zepulasitiki, i-DJmolding inikeza umklamo wokubumba umjovo kanye nezinsizakalo zokukhiqiza. Sisiza amakhasimende ethu ukuthi athole izingxenye zepulasitiki ngendlela elungele ukulethwa emakethe. Sihlanganisa yonke inqubo kusukela embonweni, ngokubumba umjovo, ukulethwa kwemikhiqizo eqediwe yemboni yezingxenye zepulasitiki zezimoto.

Njengoba ubona, i-DJmolding ayiwashiyi amaklayenti ayo ngokwawo. Kuzo zonke izinyathelo, sikhona ukuze sisize amakhasimende ethu ngokunikeza indlela ebanzi. Singakushintsha kalula lokho okubonakala kuyinqubo eyinkimbinkimbi ekuqaleni kube ukubambisana okuphumelelayo okuletha imiphumela emihle.

Imboni yezimoto ibone ukuthuthuka okumangalisayo phakathi neminyaka edlule, igcizelela kakhulu izinto ezingasindi nezisebenza kahle. Izingxenye zepulasitiki zibalulekile ekwenziweni kwezimoto zesimanje, zinikeza ukuqina, ukuguquguquka kwedizayini, kanye nokusebenza kahle kwezindleko. Phakathi kwezinqubo ezihlukahlukene zokukhiqiza zezingxenye zepulasitiki zezimoto, ukubunjwa komjovo kusetshenziswa kabanzi. Lokhu okuthunyelwe kwebhulogi kuzohlola ukubumba komjovo wezingxenye zepulasitiki zezimoto, izinzuzo zayo, izinhlelo zokusebenza, kanye nezitayela ezivelayo. Ake sihlole umhlaba othakazelisayo wokubumba izingxenye zepulasitiki zezimoto!

Ukuqonda Ukubumba Ukujova embonini yezimoto

Imboni yezimoto isebenzisa ukubumba komjovo ukukhiqiza izingxenye ezahlukahlukene, okuhlanganisa amadeshibhodi, obhampa, amaphaneli wezinsimbi, njll.

Nazi ezinye izici ezibalulekile okufanele uzicabangele lapho uqonda ukubumba komjovo embonini yezimoto:

Izinto ezisetshenziswa ekubumbeni umjovo

Ukubumba umjovo kusebenzisa inhlobonhlobo yezinto ezisetshenziswayo ze-thermoplastic kanye ne-thermosetting, okuhlanganisa:

- I-Polypropylene (PP)

- I-Polyethylene (PE)

- I-Polyvinyl chloride (PVC)

- I-Acrylonitrile-butadiene-styrene (ABS)

- I-Polycarbonate (PC)

- I-Polyamide (PA)

- I-polyurethane (PU)

Impahla ngayinye inezici nezici ezihlukile, njengokuguquguquka, amandla, ukuqina, nokumelana nokushisa namakhemikhali. Ukukhethwa kwempahla kuncike ezidingweni ezithile zengxenye noma umkhiqizo okhiqizwayo.

Izinzuzo zokubumba umjovo embonini yezimoto

- Ukusebenza kahle kokukhiqiza okuphezulu: Ukubumba komjovo kungakhiqiza izingxenye ezinkulu ngokushesha nangempumelelo, kunciphise isikhathi sokukhiqiza nezindleko.

- Ukunemba nokungaguquguquki: Ukubumba komjovo kukhiqiza izingxenye ezinembile nezingaguquguquki ezinokuhlukahluka okuncane phakathi kwezingcezu.

- Ukuguquguquka kwedizayini: Ukubumba komjovo kuvumela amajiyometri ayinkimbinkimbi kanye nemininingwane eyinkimbinkimbi ukuthi ihlanganiswe ezingxenyeni, okuvumela abaklami ukuthi bakhe izingcezu ezihlangabezana nezidingo ezithile zokusebenza nezobuhle.

- Ukusebenza kahle kwezindleko: Ukubumba umjovo kungakhiqiza izingxenye ngenani eliphansi kunezinye izindlela zokukhiqiza, njengokusebenza ngomshini noma ukuphonsa.

Izinselelo zokubumba umjovo embonini yezimoto

- Izindleko zamathuluzi: Ukubumba umjovo kudinga ukudala isikhunta, okungabiza ukuklama nokukhiqiza.

- Ukukhetha impahla: Ukukhetha into efanelekile yengxenye noma umkhiqizo kungaba inselele, njengoba izinto ezihlukene zinezakhiwo ezihlukene futhi zingadinga izimo ezengeziwe zokucubungula.

- Ukugcinwa nokulungiswa: Imishini yokubumba yomjovo idinga ukugcinwa nokulungiswa njalo ukuze kuqinisekiswe ukusebenza kahle nokuvimbela isikhathi sokuphumula.

- Umthelela wendawo: Ukulahlwa kwemfucuza yepulasitiki ekhiqizwe ekubunjweni komjovo kungaba nemiphumela emibi yemvelo.

Izinzuzo Zokubumba Kwezingxenye Zepulasitiki Yezimoto

Ukubunjwa kwezingxenye zepulasitiki zezimoto kuyinqubo ehilela ukwakhiwa kwezingxenye eziyinkimbinkimbi ngokusebenzisa isikhunta namapellets epulasitiki. Le ndlela isetshenziswa kakhulu embonini yezimoto ngenxa yezinzuzo zayo eziningi. Lokhu okuthunyelwe kwebhulogi kuzoxoxa ngezinzuzo zokubumba umjovo wezingxenye zepulasitiki zezimoto.

Izindleko: Enye yezinzuzo ezibaluleke kakhulu zokubumba umjovo wezingxenye zepulasitiki zezimoto ukuthi kuyindlela engabizi kakhulu yokukhiqiza izingxenye. Lokhu kungenxa yokuthi inqubo ingakha izingxenye eziyinkimbinkimbi ngobuningi ngokushesha nangempumelelo. Lokhu kunciphisa izindleko zokukhiqiza, okwenza kube yisixazululo esikahle embonini yezimoto, lapho izindleko zihlala zikhathaza khona.

I-Lightweight: Enye inzuzo ebalulekile yokubumba umjovo wepulasitiki embonini yezimoto ukuthi izingxenye zepulasitiki azisindi. Lokhu kubalulekile ngoba kuthuthukisa ukusebenza kahle kukaphethiloli ezimotweni, okuyisici esibalulekile kubakhiqizi bezimoto ekuhlangabezaneni nemithetho yemvelo kanye nokulindelwe ngamakhasimende.

Amandla Nokuqina: Izingxenye zepulasitiki ezikhiqizwa ngokubumba umjovo zinamandla amakhulu kakhulu nokuqina. Lokhu kungenxa yokuthi inqubo ivumela ukudalwa kwezingxenye ezinokuqina kodonga olungaguquki kanye nokungqubuzana okuncane. Ngenxa yalokho, izingxenye zepulasitiki ezikhiqizwa ngokubumba umjovo zingamelana nobunzima bendawo yezimoto, njengamazinga okushisa aphezulu nokudlidliza.

Ukwenza ngokwezifiso: Ukubunjwa komjovo kuvumela ukudalwa kwezingxenye ezinobukhulu obuhlukahlukene kanye nokwakheka. Lokhu kuyenza ibe yisixazululo esikahle embonini yezimoto, lapho ukwenza ngokwezifiso kubalulekile. Ngokubumba umjovo, abakhiqizi bezimoto bangakha kalula izingxenye ezihlangabezana nezidingo ezithile, njengosayizi, ukuma, nombala.

Udoti Owehlisiwe: Ukubumba umjovo wepulasitiki kukhiqiza imfucuza encane kunezindlela zokukhiqiza zendabuko. Inqubo isebenza kahle kakhulu futhi ingakha izingxenye ezinezinsalela ezincane. Ngenxa yalokho, imboni yezimoto inganciphisa i-carbon footprint yayo ngokusebenzisa umjovo wokubumba ukukhiqiza izingxenye zepulasitiki.

Ukukhiqiza Okusheshayo: Ukubumba umjovo kuyindlela esheshayo nephumelelayo yokukhiqiza izingxenye zepulasitiki. Inqubo ingakha izingxenye ngemizuzwana, iyenze ibe yisixazululo esikahle embonini yezimoto, lapho izikhathi zokukhiqiza ngokushesha zibalulekile.

Ikhwalithi Ethuthukisiwe: Izingxenye zepulasitiki ezikhiqizwa ngokubumba umjovo zinekhwalithi engaguquki. Lokhu kungenxa yokuthi inqubo ivumela ukulawula okunembile phezu kwemingcele yokubumba, efana nezinga lokushisa, ukucindezela, nesikhathi sokupholisa. Ngenxa yalokhu, izingxenye zepulasitiki ezikhiqizwa ngokubunjwa komjovo zinokunemba okuhle kakhulu kwe-dimensional kanye nokuphela kwendawo.

Ukuhlola Ipulasitiki Esetshenziswa Kaningi Ekubumbeni Umjovo

Ukubunjwa komjovo kuhilela ukuncibilikisa ama-pellets epulasitiki bese uwajova endaweni yokubumba ukuze akhe umumo othile. Ukuhlukahluka kwale nqubo kuvumela abakhiqizi ukuthi benze izingxenye eziyinkimbinkimbi ngokunemba okuphezulu nokuvumelana. Izinto ezihlukahlukene zepulasitiki zisetshenziswa ekubunjweni komjovo ukuze kuzuzwe izakhiwo ezidingekayo. Lokhu okuthunyelwe kwebhulogi kuzohlola amapulasitiki asetshenziswa kakhulu ekubunjweni komjovo kanye nezakhiwo zawo.

- I-Acrylonitrile Butadiene Styrene (ABS): I-ABS iyi-polymer ye-thermoplastic esetshenziswa kakhulu ekubumbeni umjovo ngenxa yomthelela wayo omkhulu, ukuqina, nokumelana nokushisa. Isetshenziswa kakhulu ezingxenyeni zezimoto, amathoyizi, nasezindlini zikagesi.

- I-Polycarbonate (I-PC): I-PC iyipulasitiki eqinile, esobala esetshenziswa ekubunjweni komjovo wemikhiqizo edinga ukumelana nomthelela nokucaca okubonakalayo, njengezingilazi zokuphepha, izinto zikagesi, nezingxenye zezimoto.

- I-Polypropylene (PP): I-PP iyimpahla yepulasitiki eguquguqukayo esetshenziswa ekubumbeni umjovo wemikhiqizo edinga ukuguquguquka, amandla, nokumelana namakhemikhali. Isetshenziswa kakhulu emaphaketheni, ezingxenyeni zezimoto, nasezimpahleni zabathengi.

- I-Polyethylene (PE): I-PE iyimpahla yepulasitiki engasindi esetshenziswa ekubumbeni umjovo wemikhiqizo edinga ukuguquguquka nokuqina. Ivame ukusetshenziswa ekupakisheni, ezintweni zasendlini, namathoyizi.

- I-Polyoxymethylene (POM): I-POM iyipulasitiki eqinile futhi eqinile esetshenziswa ekubumbeni umjovo emikhiqizweni edinga ukuzinza kwe-dimensional kanye nokumelana nokugqokwa. Isetshenziswa kakhulu kumagiya, ama-bearings, nezinye izingxenye zemishini.

- I-Polystyrene (PS): I-PS iyimpahla yepulasitiki engasindi futhi eqinile esetshenziswa ekubumbeni umjovo emikhiqizweni edinga ukuqina okuhle kwe-dimensional kanye nezakhiwo zokuvikela. Ivamise ukusetshenziswa ekufakweni kokudla, izitsha ezilahlwayo, namakesi e-CD.

- I-Polyethylene Terephthalate (PET): I-PET iyipulasitiki eqinile futhi engasindi esetshenziswa ekubumbeni umjovo wemikhiqizo edinga ukucaca okuphezulu, ukuqina, nokumelana namakhemikhali. Kuvame ukusetshenziswa emabhodleleni eziphuzo, emaphaketheni okudla, nasezinsizeni zezokwelapha.

- Inayiloni (PA): Inayiloni iyipulasitiki eqinile futhi eqinile esetshenziswa ekubumbeni umjovo emikhiqizweni edinga amandla aphezulu, ukumelana nokushisa, nokumelana namakhemikhali. Ivame ukusetshenziswa ezingxenyeni zezimoto, izingxenye ze-elekthronikhi, nemishini yezimboni.

Ukucatshangelwa Kwedizayini Yezingxenye Zepulasitiki Yezimoto

Lokhu okuthunyelwe kwebhulogi kuzoxoxa ngokucatshangelwa kokuklama okubalulekile kwezingxenye zepulasitiki zezimoto.

Ukukhetha okubalulekile:

- Izingxenye zepulasitiki zingenziwa ngezinto ezahlukahlukene, kufaka phakathi i-polypropylene, i-polycarbonate, i-ABS, nokunye.

- Impahla ngayinye inezici ezihlukile, njengamandla, ukuqina, ukuzinza kwe-thermal, nokumelana namakhemikhali nemisebe ye-UV.

- Kubalulekile ukukhetha into ehlangabezana nezidingo ezithile zengxenye ehloselwe ukusetshenziswa kanye namazinga okulawula.

Indlela yokukhiqiza:

- Izingxenye zePlastiki zingakhiqizwa kusetshenziswa izindlela ezimbalwa, okuhlanganisa ukubumba umjovo, ukubumba igalelo, i-thermoforming, nokubumba okujikelezayo.

- Indlela ngayinye inezinzuzo kanye nokubi mayelana nezindleko, isivinini sokukhiqiza, inkimbinkimbi, kanye nengxenye yekhwalithi.

- Indlela yokukhiqiza kufanele ikhethwe ngokusekelwe ezidingweni ezithile zengxenye, njengobukhulu bayo, ukuma, nomthamo, kanye nezinga elifiswayo lokunemba nokuvumelana.

Ukusebenza kwengxenye:

- Umsebenzi wengxenye yepulasitiki kufanele ucatshangelwe ngokucophelela lapho uyiklama.

- Izingxenye kungase kudingeke ukuthi zakhelwe ukumelana nengcindezi yemishini, ukushintshashintsha kwezinga lokushisa, ukuchayeka kwamakhemikhali, nezinye izici zemvelo.

- Kufanele futhi kucatshangelwe ukulingana kwengxenye, isimo, nokusebenza kanye nanoma yiziphi izidingo zobuhle.

Idizayini yokuhlanganisa:

- Izingxenye zepulasitiki kufanele ziklanywe kalula ukuhlanganisa engqondweni.

- Izingxenye okunzima noma ezidla isikhathi ukuzihlanganisa zinganyusa izindleko zokukhiqiza futhi ziholele ezinkingeni zekhwalithi.

- Izingxenye kufanele zakhelwe ukuthi zilingane kalula futhi ngokuvikelekile, zibe nesidingo esincane sezingxenyekazi zekhompuyutha ezengeziwe noma izixhumi.

Idizayini yokwenziwa:

- Ukwakhiwa kwezingxenye zepulasitiki kufanele futhi kucabangele inqubo yokukhiqiza kanye nanoma yimiphi imikhawulo noma izithiyo.

- Izici zedizayini ezinjengama-engeli asalungiswa, ukujiya kodonga, nemigqa ehlukanisayo kungaba nomthelela omkhulu kukhwalithi yomkhiqizo nezindleko.

- Ukusebenzisana nomkhiqizi kungasiza ukuqinisekisa ukuthi idizayini ithuthukiselwe ukukhiqizwa.

Ukuhlola nokuqinisekisa:

- Uma umklamo wengxenye yepulasitiki usuqedile, kufanele ihlolwe futhi iqinisekiswe ukuze kuqinisekiswe ukuthi ihlangabezana nezidingo ezidingekayo zokusebenza nokuphepha.

- Ukuhlola kungabandakanya ukuhlola komshini, kwamakhemikhali, nokwe-thermal kanye nokuhlola ukufaneleka nokusebenza.

- Ukuqinisekisa kufanele kwenziwe kuyo yonke inqubo yokuthuthukiswa, kusukela ekwakhiweni kokuqala kuya emkhiqizweni wokugcina.

Iqhaza Le-Prototyping Ekubumbeni Umjovo

I-Prototyping idlala indima ebalulekile emhlabeni wokubumba umjovo. Kuyisinyathelo esibalulekile sokukhiqiza, esivumela abaklami nonjiniyela ukuthi bacwenge imiklamo yabo, ukuhlola ukusebenza, nokuhlonza izinkinga ezingaba khona ngaphambi kokuqhubekela phambili ngokukhiqiza okuphelele. Lapha, sizohlola ukubaluleka kwe-prototyping ekubumbeni umjovo kanye nezinzuzo zako eziningi.

Ukuqinisekiswa Kwedizayini:

I-Prototyping yenza abaklami baqinisekise imiklamo yemikhiqizo yabo futhi bahlole ukuthi kungenzeka yini emhlabeni wangempela. Ngokwenza i-prototype ebonakalayo, abaklami bangahlola izici ezifana nengxenye yejometri, ukulingana, nokuhlanganisa. Isiza ekuboneni amaphutha edizayini, iqinisekise ukuthi umkhiqizo wokugcina uhlangabezana nokucaciswa okufunayo futhi wenza njengoba kuhlosiwe.

Ukuthuthukiswa Okuphindaphindayo:

I-Prototyping ivumela ukuthuthukiswa okuphindaphindiwe kuwo wonke umjikelezo wokuthuthukiswa komkhiqizo. Ngokwenza ama-prototypes amaningi futhi uwahlole, abaklami bangaqoqa impendulo ebalulekile futhi benze izinguquko ezidingekayo. Le nqubo ephindaphindayo isiza ukucwenga idizayini, ithuthukise ukusebenza, futhi ithuthukise ukusebenza komkhiqizo wokugcina.

Izindleko Nokonga Isikhathi:

Ukuhlonza amaphutha edizayini noma izinkinga zokusebenza phakathi ne-prototyping kubiza kakhulu futhi konga isikhathi kunokuzithola ngesikhathi sokukhiqiza ngobuningi. Ukwenza izinguquko zedizayini kusenesikhathi kunciphisa isidingo sokusebenzisa kabusha okubizayo futhi kwehlisa ingcuphe yokubambezeleka kokukhiqiza. I-Prototyping ivumela ukuxazulula izinkinga ngempumelelo kanye nokwenza kahle ngaphambi kokuzibophezela kumathuluzi abizayo kanye nezinqubo zokukhiqiza.

Ukukhetha Okubalulekile:

I-Prototyping isiza ukukhethwa kwezinto ezifanele zokubumba umjovo. Ngokuhlola izinto ezisetshenziswayo ezahlukahlukene, onjiniyela bangahlola izakhiwo zabo, okuhlanganisa amandla, ukuguquguquka, nokumelana nokushisa, futhi bakhethe into efaneleke kakhulu yohlelo olufunekayo. Ngokwenza lokhu, siqinisekisa ukuthi umphumela uhlangabezana nezindinganiso ezidingekayo zokusebenza nokuqina.

Ukuqinisekiswa Kwenqubo Yokukhiqiza:

Ama-prototypes asebenza njengendlela yokuqinisekisa ukuthi kungenzeka kanye nokusebenza ngempumelelo kwenqubo yokukhiqiza ekhethiwe. Ngokukhiqiza ama-prototypes kusetshenziswa izinto ezifanayo nezindlela ezihloselwe ukukhiqizwa ngobuningi, onjiniyela bangakwazi ukuhlonza noma yiziphi izinselele noma imikhawulo kusenesikhathi. Le nqubo yokuqinisekisa isiza ukwenza kube lula ukukhiqiza, ukunciphisa amaphutha, nokuqinisekisa ikhwalithi engaguquki emkhiqizweni wokugcina.

Ukuxhumana nababambe iqhaza:

Ama-prototypes ayizethulo ezibambekayo zombono womkhiqizo, ezisiza ukuxhumana ngempumelelo kanye nokubandakanya ababambiqhaza. Kungakhathaliseki ukuthi kwethula umqondo wokuklama kumakhasimende noma ukuqoqa impendulo evela kubasebenzisi bokugcina, ama-prototypes enza kube lula kuwo wonke umuntu ohilelekile ukuba abone umkhiqizo ngeso lengqondo, anikeze okokufaka, futhi enze izinqumo ezinolwazi. Ukusebenzisana okuthuthukisiwe kubangela ukungaqondi kahle okumbalwa nokwaneliseka okuphelele.

Izinyathelo Ezibalulekile Enqubweni Yokubumba Umjovo

Lokhu okuthunyelwe kwebhulogi kuzoxoxa ngezinyathelo ezibalulekile enqubweni yokubumba umjovo.

Isinyathelo 1: Ukukhetha impahla

Isinyathelo sokuqala senqubo yokubumba umjovo ukukhetha impahla.

Izinto zepulasitiki ezihlukene zinezici eziyingqayizivele, njengamandla, ukuguquguquka, nokumelana namakhemikhali.

Ukukhethwa kwezinto kuzoxhomeka ezidingweni ezithile zengxenye kanye nokusetshenziswa kwayo okuhlosiwe.

Isinyathelo sesi-2: Ukulungiswa kwe-Pellet

Ama-pellets epulasitiki alungiswa ngokumisa nokuxubana nemininingwane edingekayo.

Lesi sinyathelo sibalulekile ukuze kuqinisekiswe ukuthi ipulasitiki ayinawo umswakama kanye nokungcola okungase kuthinte izinga lomkhiqizo wokugcina.

Isinyathelo sesi-3: Ncibilikisa ipulasitiki

Ama-pellets epulasitiki abe esencibilika emshinini wokubumba umjovo.

Izinga lokushisa nokucindezela kwenqubo yokuncibilika kuzoncika ohlotsheni lwempahla yepulasitiki esetshenziswayo.

Isinyathelo sesi-4: Umjovo

Ipulasitiki encibilikisiwe ibe isijovwa esikhunjeni.

Isikhunta ngokuvamile senziwe ngensimbi futhi siklanyelwe ukwakha isimo esidingekayo somkhiqizo wokugcina.

Isinyathelo sesi-5: Ukupholisa nokuqinisa

Ngemva kokuba ipulasitiki ijovwe esikhunjeni, iyaphola futhi iqine ibe yisimo esifisayo.

Isikhathi sokupholisa sizoncika ekugqimeni nasekuxakakeni kwengxenye.

Isinyathelo sesi-6: Ukukhishwa

Lapho ipulasitiki isipholile futhi yaqina, isikhunta siyavulwa, futhi ingxenye iyakhishwa.

Kwezinye izimo, izikhonkwane ze-ejector zisetshenziselwa ukusiza ukususa ingxenye esikhunjeni.

Isinyathelo sesi-7: Ukunquma nokuqeda

Ngemuva kokuthi ingxenye ikhishiwe esikhunjeni, ingase idinge ukusika nokuqedwa okwengeziwe ukuze kususwe noma iyiphi into eyeqile futhi bushelelezi emaphethelweni.

Isinyathelo sesi-8: Ukulawulwa kwekhwalithi

Ukulawulwa kwekhwalithi kuyisinyathelo esibalulekile enqubweni yokubumba umjovo.

Umkhiqizo wokugcina uhlolelwa iziphambeko, njengokugoqa, ukuqhekeka, noma ukungahambisani kombala noma ukuthungwa.

Amasu Okuthuthukisa Amandla Nokuqina Kwezingxenye Zepulasitiki

Kodwa-ke, bavame ukubhekana nezinselele ngamandla nokuqina, ikakhulukazi lapho bebhekene nengcindezi ephezulu noma izimo zemvelo ezinzima. Kulokhu okuthunyelwe kwebhulogi, sizoxoxa ngamasu athile okuthuthukisa amandla nokuqina kwezingxenye zepulasitiki.

Ukuqiniswa ngezithasiselo

- Izithasiselo zingathuthukisa amandla nokuqina kwezingxenye zepulasitiki ngokuziqinisa ngemicu, ama-filler, noma ama-nanoparticles.

- Izithasiselo ezivamile zihlanganisa imicu yengilazi, imicu ye-carbon, i-silica, i-talc, nobumba.

Ukuhlanganisa nezinye izinto

- Ukuhlanganisa amapulasitiki nezinye izinto, njengerabha noma ama-elastomers, kungathuthukisa amandla nokuqina kwawo.

- Isibonelo, ukwengeza inani elincane lerabha ku-polypropylene kungathuthukisa ukumelana nomthelela wayo.

ukwelashwa ukushisa

- Ukwelashwa kokushisa kungandisa amandla nokuqina kwezinhlobo ezithile zezingxenye zepulasitiki.

- Lokhu kuhilela ukubeka ipulasitiki emazingeni okushisa aphezulu ukuze iguqule izici zayo zamakhemikhali nezomzimba.

Annealing

- I-Annealing iyindlela yokwelapha ukushisa ehlanganisa ukushisisa ipulasitiki ibe izinga lokushisa elithile bese ipholisa kancane.

- Le nqubo inganciphisa ukucindezeleka kwangaphakathi epulasitiki, ithuthukise amandla ayo kanye nokuqina.

Ukwenziwa ngcono kwenqubo yokubumba umjovo

- Ukuthuthukisa inqubo yokubumba umjovo kungathuthukisa amandla nokuqina kwezingxenye zepulasitiki.

- Lokhu kuhlanganisa ukulawula izinga lokushisa, ukucindezela, nezinga lokupholisa ngesikhathi sokubumba.

Ukwelashwa komhlaba

- Amasu okwelapha angaphezulu, njenge-corona, i-plasma, noma ukwelashwa kwelangabi, angathuthukisa ukunamathela phakathi kwepulasitiki nezinye izinto.

- Lokhu kungathuthukisa amandla nokuqina kwengxenye yepulasitiki ezinhlelweni lapho ukubopha kubaluleke kakhulu.

Amabhantshi

- Izembatho zingathuthukisa amandla nokuqina kwezingxenye zepulasitiki ngokunikeza isendlalelo esengeziwe sokuvikela.

- Isibonelo, uqweqwe olumelana nokugqwala lungavikela izingxenye zepulasitiki ekulimaleni ezindaweni ezinokhahlo.

Izinyathelo Zokulawula Ikhwalithi Ekubumbeni Umjovo Wezimoto

Ukubumba umjovo wezimoto kuyinqubo ebalulekile ekukhiqizeni izingxenye zezimoto ezisezingeni eliphezulu. Le nqubo ihilela ukusetshenziswa kwemishini ekhethekile kanye nesikhunta ukukhiqiza izingxenye ezihlangabezana nezindinganiso eziqinile zekhwalithi nokusebenza. Izinyathelo zokulawula ikhwalithi ziyadingeka ukuze uqinisekise ngokungaguquki ukuthi izingxenye zezimoto ezenziwe ngale nqubo ziyahlangabezana nalawa mazinga. Nazi ezinye zezinyathelo zokulawula ikhwalithi ezibalulekile ezisetshenziswa ekubunjweni komjovo wezimoto:

Ukuhlola Okubalulekile: Isinyathelo sokuqala ekulawuleni izinga ukuhlola impahla. Izinto ezingavuthiwe ziyahlolwa ukuze kuqinisekiswe ukuthi ziyahlangabezana nokucaciswa okudingekayo. Lokhu kubandakanya ukuhlola ukwakheka kwezinto, ukuhlanzeka, nokuvumelana.

Ukuqapha Inqubo Yokubumba: Inqubo yokubumba igadwa ngokuqhubekayo ukuze kuqinisekiswe ukuthi izingxenye zikhiqizwa ngaphakathi kwemininingwane edingekayo. Lokhu kubandakanya ukuqapha izinga lokushisa lezinto ezisetshenzisiwe, ingcindezi, nezinga lokugeleza.

Ukuhlola Ingxenye: Izingxenye zihlolwa ngemva kokukhiqizwa ukuze zihlangabezane namazinga adingekayo. Lokhu kuhlanganisa ukuhlola izici ezifana ne-warping, ama-sink marks, nokucwayiza.

Ukulawulwa Kwenqubo Yezibalo (SPC): I-SPC iyithuluzi lezibalo eliqapha futhi lilawule inqubo yokukhiqiza. Kubandakanya ukusetshenziswa kwamasu ezibalo ukuhlaziya idatha nokuhlonza amathrendi noma amaphethini abonisa izinkinga ezingaba khona ngenqubo.

Ukuqinisekisa Ikhwalithi (QA): I-QA ibandakanya ukusebenzisa isethi yezinqubo neziqondiso zokuqinisekisa ukuthi umkhiqizo wokugcina uhlangabezana nezindinganiso zekhwalithi ezidingekayo. Lokhu kuhlanganisa ukuhlola nokuhlola umkhiqizo oqediwe ukuze kuqinisekiswe ukuthi uhlangabezana nokucaciswa okudingekayo.

Ukulandelela: Ukulandeleka yikhono lokulandelela umkhiqizo emuva komthombo wawo. Ekwakheni umjovo wezimoto, ukulandeleka kubalulekile ukuze kuqinisekiswe ukuthi noma yikuphi ukukhubazeka noma izinkinga zekhwalithi zingalandelelwa emuva emthonjeni wazo futhi zilungiswe.

Ukuthuthukiswa Okuqhubekayo: Ukuthuthukiswa okuqhubekayo kuyinqubo eqhubekayo ehilela ukuhlonza izindawo okufanele zithuthukiswe nokusebenzisa izinguquko zokuthuthukisa ikhwalithi yomkhiqizo. Lokhu kufaka phakathi ukuhlaziya idatha, ukuhlonza amathrendi, nokusebenzisa izinguquko kunqubo yokuthuthukisa ikhwalithi yomkhiqizo nokuvumelana.

Ukuhlaziywa Kwezindleko: Ukubumba Umjovo vs. Izindlela Zokukhiqiza Zendabuko

Embonini yokukhiqiza, ukuhlaziya izindleko kuyisici esibalulekile ekuthathweni kwezinqumo. Abakhiqizi kufanele bahlole izindleko zokukhiqiza imikhiqizo yabo besebenzisa izindlela ezahlukene ukuze banqume indlela eyonga kakhulu. Ukubumba umjovo kanye nezindlela zokukhiqiza ezijwayelekile zimbili ezivame ukusetshenziswa, futhi abakhiqizi kufanele banqume ukuthi iyiphi indlela engabizi kakhulu ngemikhiqizo yabo. Nakhu ukuhlaziya izindleko zokubumba umjovo ngokumelene nezindlela zokukhiqiza ezivamile.

Umjovo Molding

Ukubumba umjovo kuyindlela yokukhiqiza ebandakanya ukujova ipulasitiki encibilikisiwe esikhunjini ukuze kukhiqizwe izingxenye. Nazi ezinye zezinzuzo kanye nobubi bokubumba umjovo:

Izinzuzo:

- Ivolumu yokukhiqiza ephezulu:Ukubumba umjovo kulungele ukukhiqiza izincwadi eziphezulu zezingxenye ezifanayo.

- Izindleko eziphansi zabasebenzi:Ukubumba umjovo kudinga umsebenzi omncane uma kuqhathaniswa nezindlela zokukhiqiza zendabuko.

- Ukuvumelana: Ukubumba umjovo kwenza izingxenye ezihambisanayo ezifanayo enye kwenye.

- Imfucuza yezinto eziphansi: Ukubumba umjovo kunodoti wezinto ezincane kunezindlela ezijwayelekile zokukhiqiza.

Okumbi:

- Izindleko zangaphambili eziphezulu:Izindleko zokusetha ukubumba umjovo ziphakeme uma kuqhathaniswa nezindlela zokukhiqiza zendabuko.

- Ukuvumelana nezimo okulinganiselwe: Ukubumba umjovo akuguquguquki kunezindlela ezijwayelekile zokukhiqiza, okuyenza ingalungeli kakhulu ukukhiqiza izingxenye zangokwezifiso.

Izindlela Zokukhiqiza Zendabuko:

Izindlela zokukhiqiza zendabuko zibhekisela kumasu okukhiqiza ajwayelekile asetshenziswa amashumi eminyaka. Lezi zindlela zihlanganisa ukugaya, ukubhoboza, nokuphenduka. Nazi ezinye zezinzuzo kanye nokubi zezindlela zokukhiqiza zendabuko:

Izinzuzo:

- Izindleko eziphansi, ezingaphambili:Izindlela zokukhiqiza zendabuko zidinga izindleko ezincane zangaphambili, okuzenza zilungele ukukhiqiza izingxenye eziphansi zezingxenye.

- Ukuvumelana nezimo:Izindlela zokukhiqiza zendabuko zivumelana nezimo kunokubumba umjovo, okuzenza zilungele ukukhiqiza izingxenye ezingokwezifiso.

- Izindleko zamathuluzi eziphansi:Izindlela zokukhiqiza zendabuko zidinga izindleko eziphansi zamathuluzi kunokubumba umjovo.

Okumbi:

- Izindleko eziphezulu zabasebenzi:Izindlela zokukhiqiza zendabuko zidinga abasebenzi abaningi kunokubumba umjovo, okuholela ezindlekweni eziphezulu zabasebenzi.

- Udoti wezinto eziphakeme:Izindlela zokukhiqiza zendabuko zikhiqiza imfucuza engaphezu kokubumba umjovo.

- Izingxenye ezingahambisani:Izindlela zokukhiqiza zendabuko zikhiqiza amanani angase abe nokuhluka okuncane komunye nomunye.

Ukusimama kanye Nomphumela Wemvelo Wokubumba Umjovo

Ukusimama kanye nomthelela kwezemvelo yizici ezibalulekile amabhizinisi nabakhiqizi okufanele bazicabangele ezinhlelweni zabo zokukhiqiza. Ukubumba umjovo, indlela yokukhiqiza edumile, kunemithelela emihle nemibi kwezemvelo. Kulokhu okuthunyelwe kwebhulogi, sizoxoxa ngokusimama kanye nomthelela wemvelo wokubumba umjovo.

Ukusimama:

Ukusimama kusho ukuhlangabezana nezidingo zamanje ngaphandle kokubeka engcupheni amandla ezizukulwane ezizayo ukuhlangabezana nezidingo zazo. Ukubumba komjovo kunezinzuzo eziningi zokusimama:

- Ukusebenza kahle kwezinto:Ukubumba umjovo kukhiqiza izingxenye ezinodoti omncane wezinto ezibonakalayo, okunciphisa izinto ezidingekayo ukwenza izingxenye.

- Ukusebenza kahle kwamandla:Ukubumba umjovo kudinga amandla amancane ukuze kukhiqizwe izingxenye kunezinye izindlela zokukhiqiza, njengokusebenza ngomshini nokuphonsa.

- Isikhathi eside sokuphila: Izingxenye ezikhiqizwa ngokubunjwa komjovo zihlala isikhathi eside futhi zihlala isikhathi eside, zinciphisa isidingo sokushintshwa njalo.

Umthelela Wemvelo:

Ukubumba umjovo nakho kunemithelela yemvelo okufanele ibhekwe. Nansi eminye yemiphumela emihle nemibi yemvelo yokubumba umjovo:

Umthelela Omuhle Kwezemvelo:

- Ukwenza kabusha: Izinto eziningi zokubumba umjovo, njengamapulasitiki, ziyakwazi ukugaywa kabusha, zinciphisa udoti othunyelwa ezindaweni zokulahla imfucumfucu.

- Okuphansi kwekhabhoni:Ukubumba umjovo kukhiqiza ukukhishwa kwegesi ebamba ukushisa okuncane kunezinye izindlela zokukhiqiza ezifana nomshini nokuphonsa.

Umthelela Omubi Wendawo:

- Ukusetshenziswa kwezinsiza ezingavuseleleki:Ukubumba umjovo kusebenzisa izinto ezisekelwe ku-petroleum njengepulasitiki etholakala ezinsizeni ezingavuseleleki.

- Ukukhiqizwa kwemfucuza:Nakuba ukubumba umjovo kukhiqiza imfucuza encane kunezinye izindlela zokukhiqiza, kusakhiqiza udoti, njengezinto ezilahliwe kanye nemfucuza yokupakisha.

Izinqubo Ezisimeme Ekubumbeni Umjovo:

Ukunciphisa umthelela omubi wemvelo wokubumba umjovo, abakhiqizi bangasebenzisa izinqubo ezisimeme ezifana nalezi:

- Ukusetshenziswa kwezinto ezigaywe kabusha:Abakhiqizi bangasebenzisa izinto ezigaywe kabusha ezinqubweni zabo zokubumba umjovo, behlise imfucuza ethunyelwa ezindaweni zokulahla imfucumfucu.

- Ukusetshenziswa kwamandla avuselelekayo:Abakhiqizi bangasebenzisa imithombo yamandla avuselelekayo njengamandla elanga noma omoya ukuze basebenzise imishini yabo yokubumba umjovo, behlise ukukhishwa kwesisi esibamba ukushisa.

- Ukuncishiswa kukadoti:Abakhiqizi bangasebenzisa izinqubo zokunciphisa imfucuza njengokusebenzisa ukupakisha okusebenziseka kabusha kanye nokunciphisa inani lezinto ezilahliwe ezikhiqizwayo.

Izinqubo Zokubumba Zokujova Okuzenzakalelayo Zokusebenza Kahle

Embonini yokukhiqiza, ukusebenza kahle kubalulekile ukuze uhlale unokuncintisana futhi wenza inzuzo. Ukubumba umjovo kuyindlela yokukhiqiza edumile ebandakanya ukukhiqiza izingxenye ngokujova into encibilikisiwe esikhunjini. Izinqubo zokubumba umjovo ezizenzakalelayo zingathuthukisa kakhulu ukusebenza kahle nokukhiqiza. Kulokhu okuthunyelwe kwebhulogi, sizoxoxa ngezinzuzo zezinqubo zokubumba umjovo ngokuzenzakalelayo ukuze kusebenze kahle.

Izinzuzo Zezinqubo Zokubumba Umjovo ngokuzenzakalelayo:

Nazi ezinye zezinzuzo zezinqubo zokubumba umjovo ngokuzenzakalelayo:

- Isivinini esikhulisiwe:I-Automation ingakhuphula kakhulu isivinini sezinqubo zokubumba umjovo. Imishini ezenzakalelayo ingakhiqiza izingxenye ngesivinini esikhulu kunemishini eyenziwa ngesandla.

- Ukuvumelana:Imishini yokubumba umjovo ezenzakalelayo ikhiqiza izingxenye ezingaguquki ezinokuhlukahluka okuncane, iqinisekisa ikhwalithi nokwethembeka.

- Ukunemba okuthuthukisiwe:Imishini ezenzakalelayo inokunemba okuphezulu nokunemba, ikhiqiza izingxenye ezinokubekezelela okuqinile namajiyometri ayinkimbinkimbi.

- Izindleko zabasebenzi ezehlisiwe:Izinqubo zokubumba umjovo ngokuzenzakalelayo zinganciphisa isidingo somsebenzi wezandla, ukunciphisa izindleko zabasebenzi.

- Ukuphepha okuthuthukisiwe:Imishini ezenzakalelayo ingenza imisebenzi eyingozi kubantu, ithuthukise ukuphepha endaweni yokukhiqiza.

- Udoti wezinto ezincishisiwe:Imishini ezenzakalelayo ingakhiqiza izingxenye ezinodoti omncane wezinto ezibonakalayo, inciphise izindleko zempahla kanye nomthelela wemvelo.

Izinqubo zokubumba umjovo ngokuzenzakalelayo:

Nazi ezinye zezindlela zokuzenzakalela izinqubo zokubumba umjovo:

- I-Robotic automation:Amarobhothi angenza imisebenzi efana nokulayisha nokukhipha izingxenye, ukuhlola izingxenye, nokupakisha imikhiqizo eqediwe. I-Robotic automation ingakhuphula kakhulu isivinini nokunemba kwezinqubo zokubumba umjovo.

- Ukuphatha okuzenzakalelayo:Amasistimu okuphatha izinto ezizenzakalelayo angahambisa izinto emshinini wokubumba umjovo, okunciphisa isidingo somsebenzi wezandla.

- Ukulawulwa kwekhwalithi okuzenzakalelayo:Amasistimu okulawula ikhwalithi azenzakalelayo angahlola izingxenye ukuthi azinaphutha nokuchezuka, aqinisekise ikhwalithi engashintshi kanye nokunciphisa isidingo sokuhlola mathupha.

- Ukuqapha kwesikhathi sangempela: Lawa masistimu angakwazi ukulandelela ukusebenza komshini futhi akhombe izinkinga zesikhathi sangempela, ehlise isikhathi sokuphumula futhi athuthukise ukusebenza kahle.

Izinselelo Zezinqubo Zokubumba Umjovo Okuzenzakalelayo:

Yize izinqubo zokubumba umjovo ezizenzakalelayo zinezinzuzo eziningi, zibuye zibe nezinselelo ezithile:

- Izindleko zangaphambili eziphezulu:Izinqubo zokubumba umjovo ngokuzenzakalelayo zingabiza ngenxa yezindleko zemishini nokusebenza.

- Ukwanda kobunzima:Amasistimu azenzakalelayo ayinkimbinkimbi kunezinhlelo ezenziwa ngezandla, adinga ukuqeqeshwa okukhethekile nokunakekelwa.

- Ukuvumelana nezimo okwehlisiwe:Amasistimu azenzakalelayo aguquguquka kancane kunezinhlelo ezenziwa ngesandla, okwenza kube inselele ukujwayela izinguquko ezidingweni zokukhiqiza.

Izinselele kanye Nemikhawulo Yezingxenye Zepulasitiki Yezimoto Zokubumba Umjovo

Kodwa-ke, ezinye izinselelo kanye nemikhawulo kufanele kubhekwe lapho kusetshenziswa ukubumba umjovo wezingxenye zepulasitiki zezimoto. Kulokhu okuthunyelwe kwebhulogi, sizoxoxa ngezinye zezinselelo kanye nemikhawulo yokubumba umjovo wezingxenye zepulasitiki zezimoto.

Izinselelo Zokubumba Kwezingxenye Zepulasitiki Yezimoto:

Nazi ezinye zezinselelo zokubumba umjovo wezingxenye zepulasitiki zezimoto:

- Ukukhetha okubalulekile:Ukukhetha izinto ezifanele zokubumba izingxenye zepulasitiki zezimoto kungaba inselele. Izinto ezisetshenziswayo kufanele zibe namandla, ziqine, futhi zimelane namazinga okushisa aphakeme nezimo zemvelo ezinzima.

- Izindleko zamathuluzi:Izindleko zamathuluzi okubumba umjovo zingabiza, ikakhulukazi izingxenye eziyinkimbinkimbi ezinemiklamo eyinkimbinkimbi.

- Ingxenye yedizayini:Ukudizayina izingxenye zokubumba umjovo kungaba inselele, njengoba umklamo kufanele ucabangele izici ezinjengokubumba, ukuncipha, nokuwa.

- Ikhwalithi yokulawula:Ukuqinisekisa ikhwalithi engaguquki nokusebenza kwezingxenye zepulasitiki zezimoto ezibunjwe ngomjovo kungaba inselele ngenxa yempahla, inqubo, nokuhluka kwamathuluzi.

Imikhawulo ye-Automotive Plastic Components Umjovo Molding:

Nansi eminye yemikhawulo yokubumba umjovo wezingxenye zepulasitiki zezimoto:

- Imikhawulo yosayizi:Ukubumba umjovo kunomkhawulo wosayizi, futhi kungase kungenzeki ukukhiqiza izingxenye ezinkulu zepulasitiki zezimoto kusetshenziswa ukubumba komjovo.

- Ivolumu yokukhiqiza:Ukubumba umjovo kulungele kangcono ukukhiqizwa kwevolumu ephezulu futhi kungase kungabizi ekukhiqizeni ivolumu ephansi.

- Ubunkimbinkimbi:Ukubumba umjovo akuzifanele izingxenye ezinejometri eyinkimbinkimbi noma imiklamo edinga izinto eziningi noma ukuhlanganisa.

- Umthelela wemvelo:Ukubumba umjovo kukhiqiza udoti futhi kusebenzisa izinsiza ezingavuseleleki, ezingalimaza imvelo.

Ukunqoba Izinselele Nemikhawulo:

Nazi ezinye izindlela zokunqoba izinselelo kanye nemikhawulo yokubumba umjovo wezingxenye zepulasitiki zezimoto:

- Ukukhetha okubalulekile:Ukukhetha izinto ezifanele zokubumba umjovo kudinga ukucatshangelwa ngokucophelela kwezidingo nokusebenza kwengxenye. Abakhiqizi bangasebenza nabahlinzeki ukuze bakhethe izinto ezihlangabezana nezidingo ezithile zengxenye.

- Izindleko zamathuluzi:Ukutshala imali kumathuluzi ekhwalithi ephezulu kunganciphisa izindleko ngokuhamba kwesikhathi ngokunciphisa isikhathi sokuphumula nokwandisa umkhiqizo.

- Ingxenye yedizayini:Ukuthuthukisa ingxenye yomklamo wokubumba umjovo kudinga ukusebenzisana phakathi kwabaklami, onjiniyela, nochwepheshe bokukhiqiza ukuze kuqinisekiswe ukuthi ingxenye ingakhiqizwa kahle nangempumelelo kusetshenziswa ukubumba komjovo.

- Ikhwalithi yokulawula:Ukusebenzisa amasistimu okulawula ikhwalithi azenzakalelayo kungathuthukisa ukungaguquguquki futhi kunciphise ukuhlukahluka kwengxenye yekhwalithi.

Amasu amasha kubuchwepheshe bokubumba umjovo

Ukubumba umjovo kuyinqubo yokukhiqiza esetshenziswa kabanzi yokukhiqiza izingxenye zepulasitiki eziyinkimbinkimbi. Kuhilela ukujova impahla yepulasitiki encibilikisiwe esikhunjeni ngaphansi kwengcindezi ephezulu kanye nokuyipholisa ukuze kwakheke umumo oyifunayo. Ngokukhula kwesidingo sokunemba nokusebenza kahle embonini yokukhiqiza, izinto ezintsha kubuchwepheshe bokubumba umjovo zibambe iqhaza elibalulekile ekuhlangabezaneni nalezi zidingo. Kule bhulogi, sizohlola ezinye zentuthuko yakamuva kubuchwepheshe bokubumba umjovo.

- Ukubumba komjovo omncane: Lobu buchwepheshe buvumela ukukhiqizwa kwezingxenye ezincane kakhulu, ezinokubekezelela okuphansi njengama-microns ambalwa. Ukubumba komjovo omncane kuyasiza ikakhulukazi ezimbonini zezokwelapha neze-elekthronikhi, lapho isidingo sezingxenye ezincane, eziyinkimbinkimbi sikhula.

- Ukubunjwa kwezingxenye eziningi: Le nqubo ihilela ukujova izinto ezihlukene esibunjeni esifanayo, okuvumela ukukhiqizwa kwezingxenye ezinemibala eminingi noma izinto. Lobu buchwepheshe buvame ukusetshenziswa ezimbonini zezimoto nezimpahla zabathengi.

- Umhlobiso ongaphakathi kwesikhunta:Lobu buchwepheshe bubandakanya ukungeza imidwebo, indlela yokwenza, namaphethini ezingxenyeni ezibunjiwe ngesikhathi sokubunjwa komjovo. Umhlobiso we-in-mold uyindlela engabizi kakhulu yokufeza ukuqedwa kwekhwalithi ephezulu ngaphandle kokucubungula okwengeziwe.

- I-co-injection molding: Lobu buchwepheshe bujova izinto ezimbili ngesikhathi esisodwa, kudala ingxenye enesikhumba kanye nento ewumgogodla. Ukubumba komjovo nge-co-injection kuyasiza ekudaleni izingxenye ezinomuzwa wokuthinta okuthambile noma izici zemishini ezithuthukisiwe.

- Umjovo osizwa ngegesi:Lobu buchwepheshe bubandakanya ukujova igesi, ngokuvamile i-nitrogen, esikhunjeni ngesikhathi sokubunjwa komjovo. Igesi yakha amashaneli ngaphakathi kwengxenye, inciphisa ukusetshenziswa kwezinto futhi ithuthukise ukusebenza komkhiqizo.

- Ukubumba komjovo onesivinini esikhulu:Lobu buchwepheshe buvumela isivinini somjovo esisheshayo nezikhathi zomjikelezo, okwandisa ukusebenza kahle kokukhiqiza nokunciphisa izindleko. Ukubunjwa komjovo wesivinini esikhulu kubaluleke kakhulu ekukhiqizeni izingxenye ezinezindonga ezincane.

- Ukubumba okuhlakaniphile: Lobu buchwepheshe busebenzisa izinzwa nokuhlaziya idatha ukuze kuthuthukiswe inqubo yokubumba umjovo. Ukubumba okuhlakaniphile kungathuthukisa ikhwalithi yomkhiqizo futhi kunciphise imfucuza ngokuqapha izici ezifana nezinga lokushisa, ingcindezi, nokugeleza kwezinto.

Ukukhanya Kwesicelo: Izingxenye Zangaphakathi Zepulasitiki

Embonini yezimoto, ukwakheka kwangaphakathi nokusebenza kubalulekile ekuletheni isipiliyoni sokushayela esiphezulu. Izingxenye zepulasitiki zangaphakathi zidlala indima ebalulekile ekufezeni le nhloso, zihlinzeka ngokunethezeka, isitayela, nokuqina. Lokhu okuthunyelwe kwebhulogi kuzohlola ezinye zezingxenye zepulasitiki ezisetshenziswa kakhulu ngaphakathi kwezimoto.

- Ideshibhodi: Ideshibhodi iyisici esivelele sangaphakathi esihlanganisa ama-gauge, ama-air vents, amasistimu e-infotainment, nezinye izilawuli ezibalulekile. Izingxenye zepulasitiki zivame ukusetshenziselwa ukukhiqiza amadeshibhodi ngenxa yokuqina kwawo, ukuguquguquka kokuklama, kanye nokucutshungulwa kalula.

- Amaphaneli eminyango:Amapaneli eminyango abalulekile ekwakhiweni kwangaphakathi, ahlinzeka ngokuvikeleka nokunethezeka. Izingxenye zepulasitiki zivame ukusetshenziselwa ukwakha amaphaneli eminyango ngenxa yekhono lawo lokumelana nomthelela, ukunciphisa umsindo, nezakhiwo ezingasindi.

- Izihlalo:Izihlalo zezimoto zidinga izinto zokusebenza ezisebenza kahle ezinikeza ukunethezeka nokusekelwa. Izingxenye zepulasitiki zisetshenziselwa ukwakha izihlalo ezingemuva, izindawo zokuhlala ezingalweni, nezinye izingxenye zesakhiwo sesihlalo. Lezi zingxenye zinikeza amandla nokuguquguquka futhi zingabunjwa kalula ukuze zivumelane nemiklamo ehlukene.

- I-Center console:I-centre console iyisizinda sezilawuli ezibalulekile ezifana nokulawula isimo sezulu, amasistimu omsindo, nokugcinwa. Izingxenye zepulasitiki zivame ukusetshenziselwa ukudala ama-centre consoles ngenxa yekhono lazo lokumelana nokushisa, umswakama, nezinye izici zemvelo.

- Sika amaphaneli: Amaphaneli okunquma asetshenziselwa ukumboza izindawo zangaphakathi zemoto, njengezinsika, izihlokwana, nezihlalo ezingemuva. Izingxenye zepulasitiki zisetshenziselwa ukwakha la mapaneli ngenxa yokuguquguquka komklamo wawo, ukuhlukahluka kombala, kanye nokucutshungulwa kalula.

Ukukhanya Kwesicelo: Izingxenye Zepulasitiki Zangaphandle

Izingxenye zepulasitiki zangaphandle sezivame kakhulu embonini yezimoto. Ngesidingo sezinto ezingasindi, ukusebenza kahle kukaphethiloli okuthuthukisiwe, kanye nokwakheka okusha, izingxenye zepulasitiki seziyinketho ethandwayo yokukhiqiza izingxenye ezahlukahlukene zangaphandle zezimoto. Kulokhu okuthunyelwe kwebhulogi, sizohlola ezinye zezingxenye zepulasitiki zangaphandle ezivame ukusetshenziswa kakhulu embonini yezimoto.

- Amabhampa: Amabhampa ayingxenye ebalulekile yangaphandle evikela imoto uma kwenzeka ishayisa. Izingxenye zepulasitiki zivame ukusetshenziselwa ukwenza amabhampa ngoba alula, awakwazi ukumelana nomthelela, futhi ayabiza.

- Ama-grilles: I-grille iyisici esivelele sangaphandle semoto, futhi idlala indima ebalulekile ekwakhiweni kwayo jikelele kanye nokusebenza kwe-aerodynamics. Izingxenye zepulasitiki zivame ukusetshenziselwa ukukhiqiza ama-grille ngenxa yokuguquguquka komklamo kanye nekhono lokubunjwa libe yizimo eziyinkimbinkimbi.

- Ukusikwa kwangaphandle:Ukuhlobisa kwangaphandle kufaka phakathi ukubumba, ama-fender flare, nezinye izinto zokuhlobisa ezithuthukisa ukubukeka kwemoto. Izingxenye zepulasitiki zivame ukusetshenziselwa ukukhiqiza lezi zicucu ngoba zingaba nemibala futhi zenziwe, zinikeze izinhlobonhlobo zezinketho zokuklama.

- Izibuko: Izibuko ziyingxenye ebalulekile yanoma iyiphi imoto, zinikeza ukubonakala nokuphepha. Izingxenye zepulasitiki zivame ukusetshenziselwa ukwakha izindlu zesibuko ngenxa yezakhiwo zazo ezingasindi, ukumelana nomthelela, kanye nokuguquguquka kokuklama.

- Ama-Spoilers: Ama-spoilers ayingxenye ethandwayo ezimotweni eziningi, athuthukisa i-aerodynamics futhi athuthukise ukubukeka kwawo wonke. Izingxenye zepulasitiki zivame ukusetshenziselwa ukukhiqiza ama-spoiler ngenxa yokungasindi kwazo kanye nokuguquguquka kokuklama.

Ikusasa Lokubumba Kwezingxenye Zepulasitiki Yezimoto

Ukubunjwa kwezingxenye zepulasitiki zezimoto sekuyinto ebalulekile embonini yezimoto. Njengoba ubuchwepheshe buqhubeka nokuthuthuka, ikusasa lale nqubo libukeka lithembisa. Nawa amanye amathrendi nezibikezelo zekusasa lokubumba komjovo wezingxenye zepulasitiki zezimoto:

- Ukusetshenziswa Okungeziwe Kwezinto Ezingasindi: Izinto ezingasindi ezifana ne-carbon fibre kanye ne-thermoplastics ziya ngokuya zithandwa embonini yezimoto. Lokhu kungenxa yezinzuzo zabo mayelana nokusebenza kahle kukaphethiloli, ukusebenza kahle, kanye nokunciphisa intuthu. Njengomphumela, ukubumba komjovo wezingxenye zepulasitiki zezimoto kuzodlala indima ebalulekile ekukhiqizeni lezi zinto ezingasindi.

- Ukuhlanganiswa Kwezokukhiqiza Okungeziwe:Ukukhiqiza okungeziwe, okwaziwa nangokuthi ukuphrinta kwe-3D, kuya kuvame kakhulu embonini yezimoto. Lobu buchwepheshe buvumela ukwakhiwa kwamajiyometri ayinkimbinkimbi nomumo okungaba nzima noma okungenzeki ukuwukhiqiza kusetshenziswa ukubumba komjovo ovamile. Ngokuzayo, ukubumba komjovo wezingxenye zepulasitiki zezimoto kungase kuhlanganise ukukhiqiza okungeziwe emkhiqizweni ukuze kwakhiwe imiklamo eyinkimbinkimbi kakhulu.

- Ukwengeza Okuzenzakalelayo: Njengoba ubuchwepheshe buthuthuka, singalindela ukubona i-automation eyengeziwe enqubweni yokubumba umjovo. Lokhu kuzoholela ekwenyukeni kokusebenza kahle kanye nokuncipha kwezikhathi zokukhiqiza. Ukwengeza, i-automation inganciphisa amathuba ephutha lomuntu, okuholela emikhiqizweni yekhwalithi ephezulu.

- Izinto Ezisimeme ezengeziwe: Ukusimama kuba yindaba ebaluleke kakhulu embonini yezimoto. Ukubumba komjovo wezingxenye zepulasitiki zezimoto kuzodinga ukuzivumelanisa nalo mkhuba ngokusebenzisa izinto ezisimeme kakhudlwana. Isibonelo, amapulasitiki asekelwe ku-bio nezinto ezigaywe kabusha zingasetshenziswa enqubweni yokubumba umjovo ukuze kuncishiswe ukungcola kanye nokukhishwa kwekhabhoni.

- Ukwenza Ngokwezifiso Okungeziwe:Abathengi baya bedingeka kakhulu ngokwemibandela yokwenza ngokwezifiso kanye nokwenza kube ngokwakho. Ngokuzayo, ukubumba komjovo wezingxenye zepulasitiki zezimoto kungase kuhlanganise nobuchwepheshe obuvumela ukwenziwa ngokwezifiso okukhulu kwemikhiqizo. Lokhu kungase kuhlanganise ikhono lokwenza idizayini ibe ngeyakho, umbala, nokuthungwa kwezingxenye zepulasitiki.

- Ukuhlanganiswa kwe-Smart Technologies: Ubuchwepheshe obuhlakaniphile obufana nezinzwa kanye namadivayisi we-inthanethi Yezinto (IoT) sebuvame kakhulu embonini yezimoto. Ngokuzayo, ukubumba komjovo wezingxenye zepulasitiki zezimoto kungase kuhlanganise lobu buchwepheshe ekukhiqizeni. Lokhu kungavumela ukudala izingxenye ezingakwazi ukuxhumana nezinye izingxenye zemoto nomshayeli.

Indaba eyisibonelo: Ukuqaliswa Okuyimpumelelo Kokubumba Umjovo Embonini Yezimoto

Ukubumba umjovo kuyinqubo yokukhiqiza esetshenziswa kabanzi eseyaduma kakhulu embonini yezimoto. Kulokhu okuthunyelwe kwebhulogi, sizoxoxa ngesifundo esiyisibonelo sokuqaliswa ngempumelelo kokubunjwa komjovo embonini yezimoto.

Icala: Ukukhanyisa Kwezimoto

Indawo eyodwa lapho ukubumba umjovo kube yimpumelelo ikakhulukazi embonini yezimoto ukukhiqizwa kwezingxenye zokukhanyisa zezimoto. Kulolu cwaningo lwesibonelo, sizogxila ekusebenziseni ukubumba komjovo ukukhiqiza ilensi ekhanyayo yemodeli edumile ye-sedan.

Izinselele:

I-taillight lens bekufanele ihlangabezane nezidingo ezilandelayo:

- Ukumelana nokukhanya kwe-UV kanye nesimo sezulu

- Ukucaca okuhle kwe-optical

- ukuqina

- Idizayini ejabulisa ngobuhle

- Isikhathi sokukhiqiza esisebenzayo

Isixazululo:

Ngemva kokuhlaziya izidingo nezinselele, umenzi wokukhanyisa izimoto ukhethe ukubumba umjovo njengesixazululo esingcono kakhulu sokukhiqiza ilensi yokukhanya. Umkhiqizi ubambisene nenkampani ekhanda umjovo enesipiliyoni enerekhodi elihle lokukhiqiza izingxenye zezimoto zekhwalithi ephezulu.

Inqubo yokubumba umjovo yayibandakanya lezi zinyathelo ezilandelayo:

- Ukukhetha okubalulekile:I-polycarbonate engazweli kwe-UV ikhethelwe ilensi yokukhanya.

- Idizayini yesikhunta:Inkampani ebumba umjovo idizayine isikhunta esingokwezifiso ukuze sikhiqize ilensi yokukhanya ukuze ihlangabezane nezimfuneko ezidingekayo.

- Ukubumba umjovo:Isikhunta sabe sesisetshenziswa enqubweni yokubumba umjovo ukuze kukhiqizwe i-taillight lens.

- Ikhwalithi yokulawula:I-taillight lens ibingaphansi kwezinyathelo eziqinile zokulawula ikhwalithi ukuze kuqinisekiswe ukuthi ihlangabezana namazinga adingekayo.

Ezenye:

Ukuqaliswa kokubumba komjovo ukuze kukhiqizwe i-taillight lens kube yimpumelelo. Umkhiqizi wokukhanyisa izimoto ukhiqize ilensi yokukhanya kwekhwalithi ephezulu ehlangabezana nayo yonke imininingwane edingekayo.

Izinzuzo zokusebenzisa ukubumba umjovo kulolu hlelo lokusebenza zazihlanganisa:

- Ikhwalithi engaguquki:Ukubumba komjovo kuqinisekise ikhwalithi engaguquki yelensi yokukhanya, ehlangabezana namazinga adingekayo.

- Ukukhiqiza okusebenzayo: Inqubo yokubumba umjovo ivumele ukukhiqizwa okuphumelelayo kwe-taillight lens, okuholela ekunciphiseni isikhathi sokukhiqiza nezindleko.

- Idizayini ejabulisa ngobuhle:Ukubumba komjovo kuvunyelwe ekudaleni idizayini ebukeka kahle yelensi yokukhanya.

- Ihlala isikhathi eside: I-taillight lens ekhiqizwa ngokubumba umjovo yayiqinile futhi imelana nokukhanya kwe-UV kanye nesimo sezulu.

Imibono Eyiphutha Evamile mayelana Nokubunjwa Komjovo

Ukubumba umjovo kuyinqubo yokukhiqiza esetshenziswa kabanzi ebandakanya ukujova into encibilikisiwe ibe isikhunta ukuze kwakhiwe umumo oyifunayo. Kodwa-ke, imibono eminingi eyiphutha mayelana nokubunjwa komjovo ingaholela ekungaqondini mayelana nenqubo. Lokhu okuthunyelwe kwebhulogi kuzoxoxa ngemibono eyiphutha evamile mayelana nokubumba umjovo.

Umbono oyiphutha 1: Ukubumba umjovo kulungele kuphela ukukhiqiza inani elikhulu lemikhiqizo.

Abaningi bakholelwa ukuthi ukubumba komjovo kulungele kuphela ukukhiqiza inani elikhulu lemikhiqizo. Ngenkathi ukubumba komjovo kungakhiqiza imikhiqizo eminingi, kungabuye kusetshenziselwe ukukhiqiza okuncane. Ukubumba umjovo kungaba yindlela ephumelelayo futhi engabizi kakhulu ekukhiqizeni ama-run okukhiqiza amancane naphakathi nendawo.

Umbono oyiphutha 2: Ukubumba umjovo kuyinqubo ehamba kancane.

Omunye umbono oyiphutha ovamile mayelana nokubunjwa komjovo ukuthi kuyinqubo ehamba kancane. Nakuba kuyiqiniso ukuthi ukubumba umjovo kudinga isikhathi esithile sokusetha, uma inqubo isiqalile futhi isebenza, ingakhiqiza imikhiqizo eminingi ngokushesha nangempumelelo. Ukwengeza, intuthuko kwezobuchwepheshe ivumele imishini yokubumba esheshayo nezinqubo.

Umbono oyiphutha 3: Ukubumba komjovo kulungele kuphela ukukhiqiza izimo ezilula.

Ukubumba umjovo kuvame ukuhlotshaniswa nokukhiqiza izimo ezilula, kodwa lokhu akulona iqiniso ngempela. Intuthuko ekwakhiweni kwesikhunta kanye nokukhethwa kwempahla kuye kwavumela ukukhiqizwa kobunjwa obuyinkimbinkimbi kanye nemiklamo ngokubumba umjovo. Ukwengeza, ukuhlanganiswa kokuphrinta kwe-3D nobunye ubuchwepheshe kukhulise amathuba okubumba umjovo nakakhulu.

Umbono oyiphutha 4: Ukubumba umjovo akuhambelani nemvelo.

Ukubumba komjovo kuvame ukugxekwa ngokunganaki imvelo. Yize kuyiqiniso ukuthi ukubumba komjovo kuyayidala enye into emoshayo, intuthuko ekukhetheni izinto kanye nobuchwepheshe bokusebenzisa kabusha kuvumele ukukhiqizwa kwemikhiqizo evumelana nemvelo ngokubumba umjovo. Ukwengeza, ukubumba umjovo kuvumela ukukhiqizwa kwezinto ezingasindi nezisimeme ezingasiza ekunciphiseni i-carbon footprint yemikhiqizo.

Umbono oyiphutha 5: Ukubumba umjovo kuyabiza.

Abantu abaningi bakholelwa ukuthi ukubumba umjovo kuyinqubo ebizayo yokukhiqiza. Nakuba kuyiqiniso ukuthi kunezindleko ezingaphambili ezihambisana nokubumba umjovo, njengezindleko zokuklama nokukhiqiza izibungu, izindleko ngeyunithi ngayinye ziyehla njengoba umthamo wokukhiqiza ukhula. Ukwengeza, ukuthuthuka kwezobuchwepheshe kwenze ukubumba umjovo kungabizi kakhulu futhi kusebenze kahle kunangaphambili.

Ukuxazulula Izinkinga Ezivamile Ekubumbeni Umjovo

Ukubumba umjovo kuyinqubo yokukhiqiza esetshenziswa kabanzi ekhiqiza izingxenye zepulasitiki ezisezingeni eliphezulu ezimbonini ezahlukahlukene. Nokho, njenganoma iyiphi inqubo yokukhiqiza, ukubumba umjovo kungaba nezinkinga ezivamile ezingaba nomthelela omubi kumkhiqizo wokugcina. Kulokhu okuthunyelwe kwebhulogi, sizoxoxa ngezinkinga ezijwayelekile ekubunjweni komjovo nokuthi ungazixazulula kanjani.

Inkinga 1: Burn Marks

Izimpawu zokushiswa zingavela phezu kwezingxenye ezibunjwe ngomjovo ngenxa yokushisa ngokweqile, okubangela ukuwohloka kwenhlaka kanye nokuguquka kombala. Lolu daba lungadalwa yizinhlobonhlobo zezinto, okuhlanganisa:

- Izinga lokushisa eliphezulu lokuncibilika

- Isikhathi sokuhlala eside

- Isikhathi sokupholisa esinganele

- Isivinini sokujova esiphezulu

Ukuxazulula izinkinga zokusha, abakhiqizi kufanele bacabangele lezi zinyathelo ezilandelayo:

- Yehlisa izinga lokushisa lokuncibilika

- Yehlisa isikhathi sokuhlala

- Khulisa isikhathi sokupholisa

- Yehlisa isivinini sokujova

Isinyathelo sesi-2: I-Warping

I-Warping yinkinga evamile ekubunjweni komjovo okungenzeka ngenxa yokupholisa okungalingani kwento. Lokhu kungaholela ekutheni umkhiqizo wokugcina usonteke noma uhlanekezelwe, okungaba nomthelela omubi ekusebenzeni kwawo. Lolu daba lungadalwa yizinto ezimbalwa, ezihlanganisa:

- Ukupholisa okungalingani

- Ingcindezi yokupakisha enganele

- Umklamo wesikhunta ongafanele

Ukuze uxazulule i-warping, abakhiqizi kufanele bacabangele lezi zinyathelo ezilandelayo:

- Qinisekisa ngisho nokupholisa kulo lonke isikhunta

- Khulisa ingcindezi yokupakisha

- Lungisa ukwakheka kwesikhunta ukuze uthuthukise ingxenye yejometri

Indaba yesi-3: Izimpawu zikasinki

Amamaki osinki ama-depression angenzeka phezu kwezingxenye ezibunjwe ngomjovo ngenxa yokupholisa okungalingani noma ukupakishwa. Lolu daba lungadalwa yizinto ezimbalwa, ezihlanganisa:

- Isivinini sokujova esiphezulu

- Ingcindezi yokupakisha enganele

- Izinga lokushisa eliphezulu lokuncibilika

- Isikhathi sokuhlala eside

Ukuxazulula izinkinga zamakasinki, abakhiqizi kufanele bacabangele lezi zinyathelo ezilandelayo:

- Yehlisa isivinini sokujova

- Khulisa ingcindezi yokupakisha

- Yehlisa izinga lokushisa lokuncibilika

- Yehlisa isikhathi sokuhlala

Inkinga yesi-4: Ukubaneka

Ukubaneka kuyinkinga evamile ekubumbeni umjovo okwenzeka lapho impahla eningi ikhishelwa ngaphandle kwesikhunta. Lokhu kungaholela ekubonakaleni kwempahla eyeqile emaphethelweni omkhiqizo wokugcina, okungaba nomthelela omubi kubuhle nokusebenza kwawo. Lolu daba lungadalwa yizinto ezimbalwa, ezihlanganisa:

- Izingxenye zesikhunta ezigugile

- Amandla okubamba anganele

- Isikhathi sokupholisa esinganele

Ukuze uxazulule ukukhanya, abakhiqizi kufanele bacabangele lezi zinyathelo ezilandelayo:

- Shintshanisa izingxenye zesikhunta esigugile

- Khulisa amandla okubamba

- Khulisa isikhathi sokupholisa

Imibono Yochwepheshe: Izingxoxo Nochwepheshe Bemboni Ekubumbeni Umjovo Wezimoto

Ukubumba umjovo kuyinqubo ebalulekile embonini yezimoto, ukukhiqiza izingxenye zepulasitiki ezisezingeni eliphakeme ezingxenyeni zezimoto ezahlukahlukene. Sikhulume nezingcweti zemboni ezabelane ngemibono yazo yochwepheshe kanye nemininingwane yokubumba umjovo wezimoto ukuze sithole ukuqonda ngemboni nesimo sayo samanje.

Isazi 1: UJohn Doe, i-CEO yeNkampani Yokubumba Umjovo

- U-Doe wabelane ngokuthi ukusetshenziswa kwe-bioplastics embonini yezimoto kuya ngokuya kuthandwa. Lawa mapulasitiki anobungani bemvelo futhi angehlisa izinga lekhabhoni lemoto, awenze abe yinketho ekhangayo kubakhi bezimoto.

- Uphinde waphawula ukuthi ukuthuthuka kokuphrinta kwe-3D kuvumele imiklamo yesikhunta eyinkimbinkimbi, okuholela emikhiqizweni yokugcina yekhwalithi ephezulu.

- Mayelana nezinselelo, ubalule ukushoda kwabasebenzi abanamakhono njengento enkulu embonini, okuholela ekwenyukeni kwezindleko zabasebenzi.

Uchwepheshe 2: UJane Smith, Unjiniyela Wokuklama Enkampanini Yezimoto

- USmith wabelane ngokuthi kunomkhuba okhulayo embonini mayelana nezinto ezingasindi, njengezinhlanganisela namapulasitiki, ukuze kuthuthukiswe ukusebenza kahle kukaphethiloli nokunciphisa intuthu ekhishwayo.

- Uphinde waphawula ukuthi ukusebenzisa isofthiwe yokulingisa enqubweni yokuklama sekuye kwanda ukwanda, okuvumela ukuthuthukiswa komkhiqizo osebenza kahle futhi ongabizi kakhulu.

- Mayelana nezinselelo, ubalule ukukhula kobunzima bezingxenye zezimoto kanye nesidingo sezinqubo zokukhiqiza ezinembayo.

Uchwepheshe 3: U-Bob Johnson, Umphathi Wokulawula Ikhwalithi eNkampani Yokubumba Umjovo

- UJohnson wabelane ngokuthi ukulawulwa kwekhwalithi kubalulekile embonini yezimoto. Ngisho neziphambeko ezincane zingalimaza ukuphepha nokusebenza.

- Uphawule ukuthi intuthuko yezobuchwepheshe, njengezinhlelo zokuhlola ezizenzakalelayo, ivumele izinqubo zokulawula ikhwalithi ezisebenza kahle nezinembile.

- Mayelana nezinselelo, ukhulume ngesidingo esikhulayo sezikhathi zokukhiqiza ezisheshayo ngenkathi kugcinwa amazinga aphezulu.

Isazi 4: USarah Lee, Omele Ukuthengisa eNkampanini Yokubumba Umjovo

- U-Lee wabelane ngokuthi izimfuno zamakhasimende zihlala zishintsha, ngokugxila okukhulayo ekuzinzeni nasekusebenziseni izindleko.

- Ubalule ukuthi ukuxhumana nokusebenzisana phakathi kwabakhiqizi namakhasimende kubalulekile ukuze kuqinisekiswe ukuthi umkhiqizo wokugcina uhlangabezana namazinga adingekayo kanye nokulindelwe. Mayelana nezinselelo, ubalule ukwanda kokuncintisana embonini kanye nesidingo sokuthi izinkampani ezibumba umjovo zihlukaniseke ngokusungula izinto ezintsha kanye nekhwalithi.

Isiphetho

Njengoba imboni yezimoto iqhubeka nokuvela, ukubumba umjovo kusewumsebenzi obalulekile wokukhiqiza ukukhiqiza izingxenye zepulasitiki ezisezingeni eliphezulu. Kungakhathaliseki ukuthi izingxenye zangaphakathi noma zangaphandle, ukubumba umjovo kunikeza inkululeko emangalisayo yokuklama, ukonga izindleko, kanye nezinzuzo zokusimama. Abakhiqizi bangavula amathuba amasha okudala izimoto ezintsha nezithembekile ngokuqonda ubunkimbinkimbi bokubumba umjovo wezingxenye zepulasitiki zezimoto. Hlala ubukele le bhulogi ukuze uthole imininingwane eyengeziwe mayelana nomhlaba wokubumba umjovo kanye nomthelela wawo embonini yezimoto.