Uhlelo Lokulawula Ikhwalithi

Ukulawulwa kwekhwalithi akulona nje igama elishiwo ekubunjweni komjovo wepulasitiki. Iyingxenye ebalulekile yenqubo yokukhiqiza, futhi inakwa ngokuningiliziwe.

Ukuqinisekisa ukuthi inqubo yokubumba yokuhlola ipulasitiki iqhutshwa ngendlela efanele ukuze kwakhiwe umkhiqizo wezinga eliphezulu, imingcele ethile ebalulekile iyacatshangelwa. Ungathola okwengeziwe ngezansi.

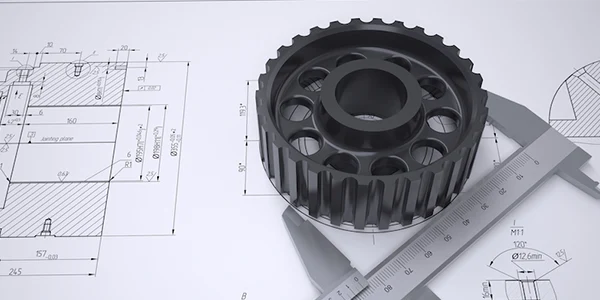

Amapharamitha okulawula ikhwalithi ku-Plastic Injection Molding

Imingcele yenqubo yizici ezibalulekile ezibekwa futhi zilandelwe ukuze kuqinisekiswe ukukhiqizwa komkhiqizo wekhwalithi ephezulu. Uhlu oluyisisekelo lwamapharamitha luhlanganisa:

*Izinga lokubekezelela

*Izindawo zokushisisa izinto

*Ingcindezi yomgodi

*Isikhathi sokujova, isivinini, kanye nezinga

*Isikhathi sokukhiqiza sisonke

*Isikhathi sokupholisa umkhiqizo

Naphezu kwamapharamitha akhethiwe, kuhlale kunethuba lokudala izingxenye ezinesici. Ukuqinisekisa ukuncishiswa kwezingxenye ezinqatshiwe, amapharamitha akhethiwe asekelwa ezinye izinqubo zokulawula ikhwalithi ezishiwo ngezansi.

*Ingqikithi Yokuphathwa Kwekhwalithi (TQM)

*Ikhwalithi Yosizo Lwekhompyutha (CAQ)

*Ukuhlela Kwekhwalithi Ethuthukisiwe (AQP)

*Ukulawulwa Kwenqubo Yezibalo (SPC)

*Ukulawulwa Kwenqubo Eqhubekayo (CPC)

*I-Automation Edidiyelwe Ngokuphelele (TIA)

Kungakhathaliseki ukuthi iyiphi inqubo yokukhiqiza, kuhlale kunokulawulwa kwekhwalithi okuhleliwe ukuze kuqinisekiswe ukuthi umkhiqizo osezingeni eliphansi awudedelwa ekusatshalalisweni okuvamile, futhi imikhiqizo engaphansi ayibuyiselwa kumthengi. Uma kuziwa ekubumbeni umjovo, kukhona ukuhlola okuningana okuhlukene kanye nezindawo zokulawula ezibekwe kuyo yonke inqubo yokukhiqiza ukuze kuqinisekiswe ukuthi umkhiqizo wokuqeda ufika ezingeni eliphezulu kakhulu lamazinga.

Ukuhlola Okubonwayo Kwezimpawu Zokucwila

Ukubumba komjovo wepulasitiki kunezinkinga zokubonisa ezisobala ezingasuswa ngokuhlolwa okubonakalayo. Izinkinga ezihlukene zingenzeka kuyo yonke inqubo yokukhiqiza, ngokusekelwe ekushiseni, okokusebenza okusetshenzisiwe, isikhathi sokusetha nokunye okuguquguqukayo okuningana. Izimpawu zokucwila yizona ezivame kakhulu. Lokhu empeleni kuyi-dimple esikhumbeni sangaphandle sepulasitiki esenzeka ngenkathi upulasitiki usathambile futhi uncibilikile. Lapho ipholisa izinto ezihlangene futhi ibangele i-dimple.

Izimpawu Zegesi Nezishiso

Izimpawu zegesi noma ukusha kungenzeka uma ipulasitiki ishiywe endaweni yokubumba isikhathi eside futhi ihangukile. Kungase futhi kwenzeke uma umoya oshisayo ocindezelwe ngaphakathi kwesikhunta ungakwazi ukubalekela isikhunta, okubangela ukuthi wakheke ngaphakathi kwesikhunta futhi ushise ipulasitiki.

I-Liquid Plastic Flashing

Ukubaneka kwenzeka lapho izingxenye ezimbili ezihlukene zesikhunta zincibilika ndawonye. Uma izingcezu ezimbili zepulasitiki ezincibilikisiwe zihlangana ngokushesha, izingcezu zingahlangana ndawonye futhi zingasuki. Izikhathi eziningi enqubweni yokukhiqiza umjovo, imikhiqizo emibili ibekwa ndawonye njengoba ngayinye iphola, kwakha isibopho sesikhashana esingahlukaniswa kalula futhi siphuke. Lokhu kuklanyelwe izizathu eziningi ezahlukene zokupakisha. Kodwa-ke, uma izinto zibekwe ndawonye futhi ipulasitiki ewuketshezi isaqina, lezi ezimbili ziyahlanganiswa futhi ukuhlukaniswa kudinga ummese noma kungenzeka kungenzeki nhlobo.

Amashothi Amafushane Nemigqa Elukiweyo

Ukudubula okufushane kwenzeka uma ipulasitiki inganele esikhunjeni. Lokhu kubangela amakhona athambile, ama-chips noma izindawo zesikhunta zivele zingaveli. Imigqa ehlanganisiwe ikhombisa lapho izindawo ezimbili ezihlukene zesikhunta sepulasitiki zahlangana khona ekuqaleni.

Ngesikhunta, impahla kufanele igcine ukubukeka okuhlangene kusuka esiqeshini esisodwa kuya kwesinye. Nokho, ngezinye izikhathi izinkinga zingavela yingakho into ngayinye idinga ukuhlolwa ngaphambi kokuba iphume ukuze ithunyelwe. Lezi yizindaba ezivame kakhulu ezikhonjwa ngokwenziwa kokulawulwa kwekhwalithi kokuhlolwa okubonakalayo.

Amapharamitha okulawula ikhwalithi ekucindezelweni kwe-Plastic Mold

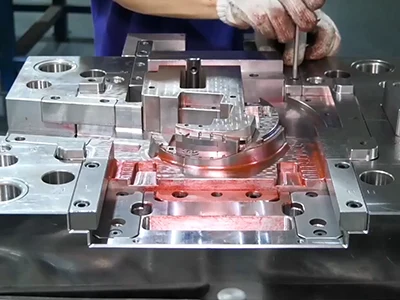

E-DJmolding, ukuqinisekiswa kwekhwalithi, izinqubo zokulawula kanye nokuqapha njengefilosofi yakhelwe engxenyeni ngayinye yomsebenzi wethu, ehlanganisa zonke izinyathelo zenqubo yethu yokwenza isikhunta sepulasitiki(ukucindezela isikhunta);

*Ukulawula ikhwalithi engenayo: zonke izinto zensimbi zamathuluzi kanye nezingxenye zangokwezifiso zokukhishwa kwempahla kufanele zihlolwe ukuze kuqinisekiswe ukuthi zonke kufanele zenelise izidingo zethuluzi lokubumba lepulasitiki langokwezifiso ngokuqinile;

*Ukulawula Kwikhwalithi yenqubo: inqubo yokwenza imishini nokuhlanganisa konke kungaphansi kokulawulwa okuqinile, ithimba le-QC lakhiwe ukuze liqondise futhi lihlole ukubekezelelana kwamathuluzi kanye nendawo ecutshunguliwe ukuze kwanelise izimfuno;

*Ukulawula ikhwalithi yokugcina: uma sekuqediwe ithuluzi lesikhunta sepulasitiki, kwacutshungulwa usayizi oyinhloko wesampula yepulasitiki yesilingo ukuze kuqinisekiswe ukuthi ayikho inqubo eyeqiwe kanye nekhwalithi yesikhunta sepulasitiki ilungile.

Sigcina izinqubo zokwamukela amasu ezibalo ukuze sihlole futhi silawule izinqubo ukuze siqinisekise ukuthi sikhiqiza ithuluzi lokubumba lepulasitiki lekhwalithi ephezulu elingashintshi, eliza ne-APQP, FMEA, PPAP, imibhalo yokulawula ikhwalithi esezingeni. Futhi siphakamisa amandla okusekela amakhasimende afunwa ukulungiselelwa kwemibhalo nokulawula ikhwalithi.

Isonto ngalinye, ithimba lethu le-QC linomhlangano wokudingida udaba ngalunye, futhi lifuna izindlela ezimayelana nokutholwa nezisombululo zokuvimbela. izingxenye zesampula zomjovo ezinokukhubazeka zilethwa ekunakekeleni kwabo bonke abasebenzi emihlanganweni yethu yekhwalithi, lapho umbono womuntu ngamunye kanye nesiphakamiso kucatshangelwa kahle futhi kwaziswa kakhulu. Futhi njalo ngenyanga ukusebenza ngesikhathi kuyakhonjiswa futhi kuboniswe ebhodini lezaziso ukuze abasebenzi bakubone futhi bafunde.

I-DJmolding isebenzisa ubuchwepheshe bokuhlola nokulinganisa obusezingeni eliphezulu obutholakalayo. Ama-micro-scopes anembayo aphezulu, i-CMM, ama-lapra-scopes, nezisetshenziswa zokulinganisa zendabuko zisetshenziswa onjiniyela bethu bekhwalithi ye-Q/C abaqeqeshwe kakhulu.

Kwa-DJmolding, sicabanga ukuthi izitifiketi zethu zekhwalithi ezifana ne-ISO 9001:2008, ukuzibophezela kwethu ekunikezeni izingxenye ezingcono kakhulu ngangokunokwenzeka ngamanani ancintisana kakhulu. Nokho, ukuzibophezela kwethu kudlula izitifiketi. Sinabasebenzi abangochwepheshe bekhwalithi abagxile kakhulu ekuqinisekiseni ukuthi sikhiqiza izingxenye zepulasitiki eziphelele ngangokunokwenzeka.

Kusukela kubasebenzi bethu bokuphatha, abasingatha yonke imibuzo ngobunyoninco kuya konjiniyela bethu abaqhubeka befuna izindlela zokuthuthukisa ingxenye yokwakheka nokukhiqiza, inkampani yethu yonke inokuqonda kwangempela ukuthi yini edingekayo ukuze kubhekwe njengababumba abahamba phambili bepulasitiki e-China. . Idumela esiziqhenya ngalo futhi esigqugquzelwa ukulithuthukisa nsuku zonke.