Okweqile

I-overmolding iyinqubo yokukhiqiza lapho i-substrate noma ingxenye eyisisekelo ihlanganiswa nento eyodwa noma ngaphezulu ukuze kwakhiwe umkhiqizo wokugcina onokusebenza okuthuthukisiwe, ukuqina, nobuhle. Le nqubo ithole ukuduma eminyakeni yamuva nje ngenxa yekhono layo lokuthuthukisa ikhwalithi nokusebenza kwemikhiqizo ngenkathi yehlisa izindleko futhi yenza inqubo yokuhlanganisa ibe lula. I-Overmolding ithola izinhlelo zokusebenza ezimbonini ezahlukahlukene, njengezezimoto, zikagesi, izisetshenziswa zezokwelapha, nemikhiqizo yabathengi. Ukuze uqonde kabanzi le nqubo, lesi sihloko sizocubungula izici eziningi zokunqwabelana, okuhlanganisa amasu, izinto zokwakha, kanye nokusetshenziswa kwayo.

Incazelo kanye Nezimiso Zokweqa

I-overmolding ibumba into eyodwa phezu kwenye, ngokuvamile kusetshenziswa ama-thermoplastic elastomers (TPE) noma irabha ye-thermoset. Le nqubo idala ingxenye eyodwa enezinto ezimbili noma ngaphezulu, ngayinye enezakhiwo ezihlukile ezifeza injongo ethile.

Izimiso Zokugqilaza

Kunezimiso ezintathu eziyinhloko zokweqisa okufanele abakhiqizi bazicabangele:

- Ukuhambisana Kwezinto:Izinto ezisetshenziselwa ukunqwabelana ngokweqile kufanele zihambisane, futhi izinto kufanele zikwazi ukubopha ukuze zenze ingxenye eqinile futhi ehlangene. Ukunamathela phakathi kwezinto ezisetshenziswayo kubalulekile ukuze kuqinisekiswe ukuthi isici sinempahla oyifunayo.

- Idizayini ye-Overmolding:Ngaphambi kwe-overmolding, umuntu kufanele acabange ngokucophelela indlela yengxenye. Umklamo kufanele usize ukubumba into yesibili ngaphezu kweyokuqala ngaphandle kokuphazamiseka. Idizayini yomugqa wokuhlukanisa, lapho kuhlangana khona izinto ezimbili, kufanele iqinisekise ngokucophelela ukuthi akukho zikhala noma izikhala phakathi kwezinto ezimbili.

- Inqubo Yokukhiqiza:I-overmolding idinga inqubo yokukhiqiza ekhethekile ebandakanya ukubumba into eyodwa phezu kwenye. Le ndlela isebenzisa isikhunta ezimbili noma ngaphezulu, lapho isikhunta sokuqala senza izinto zokuqala, futhi isikhunta sesibili sikhiqiza impahla yesibili ngaphezu kweyokuqala. Ngemva kwalokho, sihlanganisa isikhunta ezimbili ndawonye ukuze sakhe ingxenye eyodwa.

Izinzuzo Zokunqwabelanisa

I-Overmolding inikeza izinzuzo ezimbalwa ezenza kube ukukhetha okudumile kubakhiqizi abaningi, okuhlanganisa:

- Ukuqina Okuthuthukisiwe:I-overmolding ingathuthukisa ukuqina kwengxenye ngokwengeza isendlalelo esivikelayo esingamelana nokuguga.

- I-Aesthetics ethuthukisiwe: Ukweqa kungathuthukisa ubuhle bengxenye ngokwengeza umbala noma ukuthungwa phezulu.

- Ukusebenza Okuthuthukisiwe:Ukweqa kungathuthukisa ukusebenza kwengxenye ngokungeza izici ezifana nokubamba, izinkinobho, noma amaswishi.

Izicelo ze-Overmolding

Abakhiqizi bavamise ukusebenzisa i-overmolding ukukhiqiza imikhiqizo ye-elekthronikhi efana nomakhalekhukhwini, izilawuli kude, nama-peripheral ekhompyutha. Iphinde ibe nemishini yezokwelapha, izingxenye zezimoto, nemikhiqizo yabathengi.

Ukubunjwa komjovo vs. I-Overmolding: Uyini Umehluko?

Ukubunjwa komjovo kanye ne-overmolding kuyizinqubo zokukhiqiza ezivame ukusetshenziswa ezingxenyeni zepulasitiki. Ngenkathi zombili izindlela zifaka ipulasitiki yokubumba, inomehluko ohlukile. Lokhu okuthunyelwe kwebhulogi kuzoxoxa ngomehluko phakathi kokubunjwa komjovo nokunqwabelana ngokweqile.

Ukujova Ukujova

Ukubumba umjovo kuyinqubo yokukhiqiza ebandakanya ukuncibilikisa ama-pellets epulasitiki kanye nokujova ipulasitiki encibilikisiwe endaweni yokubumba. Ipulasitiki ibe isipholile futhi ikhishwe esikhunjeni, okuholela engxenyeni yepulasitiki eqinile. Abakhiqizi basebenzisa ukubumba komjovo njengenqubo eqondile nephumelelayo yokukhiqiza imiqulu ephezulu yezingxenye zepulasitiki. Ezinye izici ezibalulekile zokubumba umjovo zifaka:

Ikhiqiza ingxenye yempahla eyodwa

- Omunye ujova into esikhunjeni ngesinyathelo esisodwa.

- Inqubo ithola ukusetshenziswa ekukhiqizeni imiqulu ephezulu yezingxenye.

- Izindleko zengxenye ngayinye ziyehla njengoba umthamo wokukhiqiza ukhula.

Okweqile

I-Overmolding iyinqubo yokukhiqiza ebandakanya ukubumba into eyodwa phezu kwesinye. Inqubo ngokuvamile yengeza into ethambile, efana nerabha phezu kwengxenye yepulasitiki eqinile ukuze ithuthukise ukuqina kwayo nobuhle bayo. Ezinye izici eziyinhloko ze-overmolding zihlanganisa:

Ikhiqiza isakhi esinezinto ezimbili

- Okokuqala, sibumba impahla yokuqala, bese sibumba eyesibili phezu kweyokuqala.

- Inqubo ithuthukisa ukuqina kanye nobuhle besici.

- Izindleko ngengxenye ngayinye ziphakeme kunokubumba umjovo ngenxa yesu elengeziwe lokubumba eyesibili ngaphezu kweyokuqala.

- Umehluko phakathi kwe-Injection Molding kanye ne-Overmolding

Umehluko oyinhloko phakathi kokubunjwa komjovo kanye ne-overmolding yilezi:

- Inani Lezinto:Ukubumba komjovo kukhiqiza ingxenye eyodwa yezinto ezibonakalayo, kuyilapho ukugoqa ngokweqile kukhiqiza ingxenye yezinto ezimbili.

- Inqubo:Ukubumba umjovo kujova ipulasitiki encibilikisiwe endaweni yokubumba ngesinyathelo esisodwa, kuyilapho ukugoqa kuhilela ukubumba into yokuqala kuqala bese ukubumba into yesibili phezu kwempahla yokuqala.

- Injongo: Abakhiqizi basebenzisa ukubumba komjovo ukukhiqiza izingxenye eziningi zepulasitiki, kuyilapho basebenzisa ukugoqa ukuze bathuthukise ukuqina nobuhle bengcezu yepulasitiki.

- Izindleko: Ukubumba umjovo kuvame ukubiza kancane ngengxenye ngayinye kunokugoqa ngokweqile, ngenxa yenqubo eyengeziwe yokubumba into yesibili ngaphezu kweyokuqala.

Izicelo Zokubumba Umjovo kanye Ne-Overmolding

Abakhiqizi bavamise ukusebenzisa ukubumba komjovo ukuze bakhiqize izimpahla zabathengi, izingxenye zezimoto, namadivayisi ezokwelapha. Futhi ngokuvamile basebenzisa i-overmolding ukuthuthukisa ukuqina nobuhle emikhiqizweni ye-elekthronikhi efana nomakhalekhukhwini nezilawuli kude.

I-Over-Shot Overmolding: I-Technique Edumile

I-overmolding ye-shot-shot, eyaziwa nangokuthi ukubumba okudutshulwa kabili noma ukubumba okudutshulwa okuningi, kuyindlela ethandwayo esetshenziselwa ukukhiqiza izingxenye zepulasitiki. Le nqubo ihlanganisa ukubumba izinto ezimbili komunye nomunye ukuze kwakhiwe umkhiqizo ophelile. Lokhu okuthunyelwe kwebhulogi kuzoxoxa ngezisekelo ze-overmolding ye-shot-shot kanye nezinzuzo zako.

Izinzuzo Zokunqwabelanisa Ngesibhamu Okubili

I-overmolding ene-shot-shot inikezela ngezinzuzo ezimbalwa kumasu wendabuko wokunqwabelanisa, okuhlanganisa:

- I-Aesthetics Ethuthukisiwe: I-overmolding yamashothi amabili ivumela ukwakhiwa kwezingxenye eziyinkimbinkimbi ezinemibala eminingi noma ukwakheka. Ukusebenzisa izinto ezihlukahlukene kungaholela emkhiqizweni wokugcina okhanga kakhulu kunowodwa owenziwe ngento eyodwa.

- Ukusebenza Okuthuthukisiwe: Ukweqa amashothi amabili kungathuthukisa ukusebenza komkhiqizo. Isibonelo, ukubamba okuthambile phezu kwesisekelo sepulasitiki esiqinile kungathuthukisa i-ergonomic yomkhiqizo nolwazi lomsebenzisi.

- Izindleko Ezincishisiwe:I-overmolding ephindwe kabili ingasiza ukunciphisa izindleko ngokuqeda isidingo semisebenzi yesibili efana nokudweba noma ukumboza. Ukwenza lokhu kungaholela enqubweni yokukhiqiza esheshayo futhi kwehlise nezindleko.

- Ukuqina Okukhulisiwe: I-overmolding ephindwe kabili ingathuthukisa ukuqina komkhiqizo. Ngokusebenzisa isisekelo sepulasitiki esiqinile esine-soft-touch grip, isibonelo, umkhiqizo mancane amathuba okuba uqhekeke noma uphuke lapho wehlisiwe.

Izicelo Zokunqwabelanisa Kwezinhlamvu Ezimbili

Izimboni ezahlukahlukene zivamise ukusebenzisa ukunqwabelana okuphindwe kabili, okuhlanganisa:

- Izithuthi: I-overmolding enamashothi amabili ikhiqiza izingxenye zezimoto, njengezingxenye zedeshibhodi nezicucu zangaphakathi zokunquma.

- Izimpahla zabathengi:I-overmolding enezinhlamvu ezimbili ikhiqiza izixubho, izinsingo, nezinto zikagesi.

- Amadivayisi Ezokwelapha:I-overmolding ephindwe kabili ikhiqiza izisetshenziswa zezokwelapha ezifana nezinsimbi zokuhlinza kanye namadivayisi okulethwa kwezidakamizwa.

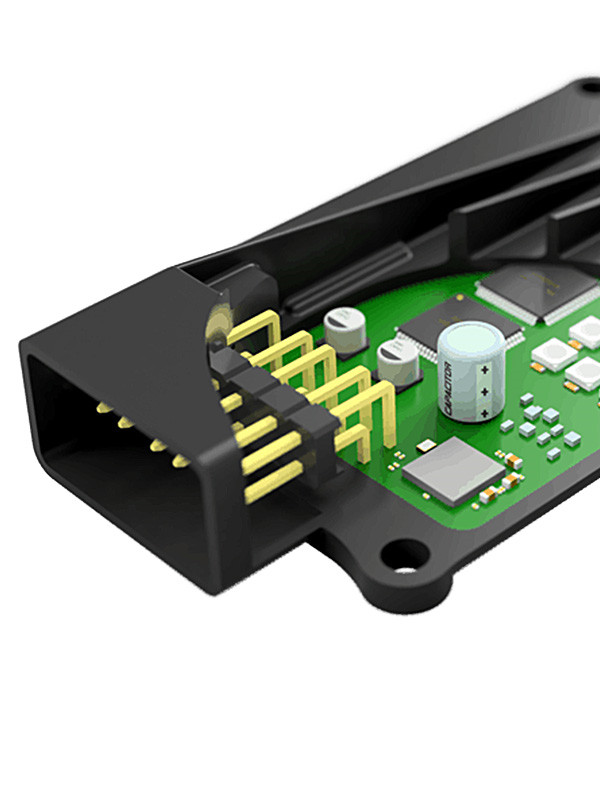

Faka Ukubumba: Ukuhlanganisa Izingxenye Ezimbili Ezihlukene

Ukufaka ukubumba kuyinqubo yokukhiqiza ebandakanya ukubumba ingxenye yepulasitiki endaweni efakwe ekhona ngaphambili noma i-substrate. Okufakiwe ngokuvamile kwenziwa ngensimbi noma ngepulasitiki futhi kungaba into efakwayo enentambo, intambo, noma ibhodi lesekethe eliphrintiwe. Lokhu okuthunyelwe kwebhulogi kuzoxoxa ngezisekelo zokufaka ukubumba kanye nezinzuzo zako.

I-Isert Molding isebenza kanjani?

Faka ukubumba kuyizinyathelo ezimbili ezibandakanya lokhu okulandelayo:

- Sibeka i-insert ibe isikhunta.

- Ipulasitiki ijovwa ngokuzungezile okufakiwe, okwenza ingxenye yepulasitiki ebunjiwe enamathele ngokuqinile kulokho okufakayo.

- Ukufakwa kwengeza amandla nokuzinza engxenyeni eqediwe, okwenza ifaneleke izinhlelo zokusebenza ezihlukahlukene.

Izinzuzo Zokufaka Ukubumba

Faka ukubumba kunikeza izinzuzo ezimbalwa kumasu okubumba endabuko, okuhlanganisa:

- Amandla Athuthukisiwe: Faka ukubumba kudala umkhiqizo oqediwe onamandla futhi ozinzile, njengoba ukufakwa kunamathele ngokuqinile engxenyeni yepulasitiki. Ukuthuthukisa ukuqina nempilo yomkhiqizo kungenzeka ngalokhu.

- Isikhathi Somhlangano Esincishisiwe: Faka ukubumba kusiza ukunciphisa isikhathi sokuhlanganisa nezindleko zabasebenzi ngokuhlanganisa izingxenye eziningi zibe ingxenye eyodwa ebunjiwe.

- Ukuguquguquka Kwedizayini Okukhulisiwe:Ukufaka ukubumba kuvumela ukudalwa kwezingxenye eziyinkimbinkimbi ngezinto eziningi, ukwakheka, nemibala, okuholela kumphumela wokugcina obukeka kangcono.

- Ukusebenza Okuthuthukisiwe: Ngokusebenzisa ukubumba okufakiwe, abakhiqizi bangathuthukisa ukusebenza komkhiqizo ngokuhlanganisa izici ezifana nokufaka imicu noma othintana nabo ngogesi.

Izicelo Zokufaka Ukubumba

Faka ukubumba kuvame ukusetshenziswa ezimbonini ezahlukahlukene, kufaka phakathi:

- Izithuthi: Faka ukubumba kukhiqiza izingxenye zezimoto njengezixhumi, izinzwa, namaswishi.

- I-elekhoni: Faka ukubumba kukhiqiza izingxenye ze-elekthronikhi njengezixhumi, izindlu, namaswishi.

- Amadivayisi Ezokwelapha:Faka ukubumba kukhiqiza ama-catheter, izixhumi, nezinzwa.

I-Soft Overmolding: Ukuthuthukisa Ukubamba Nokunethezeka

I-Soft overmolding inqubo esetshenziswa ekukhiqizeni ukwengeza into ethambile, eguqukayo kusisekelo esiqinile. Isu livumela ukungeza ungqimba lokunethezeka nokubamba emkhiqizweni, ngaleyo ndlela kuthuthukiswe ukusebenza kwawo kanye nobuhle. Lokhu okuthunyelwe kwebhulogi kuzoxoxa ngezisekelo ze-overmolding ethambile kanye nezinzuzo zako.

Isebenza Kanjani I-Soft Overmolding?

I-Soft overmolding iyizinyathelo ezimbili ezibandakanya lokhu okulandelayo:

- Sibumba isisekelo esiqinile.

- Into ethambile, eguquguqukayo ijovwa eduze kwesisekelo esibunjiwe, senze indawo enethezekile futhi ethintekayo.

- Ngokuvamile, abakhiqizi benza izinto ezithambile ezivela ku-thermoplastic elastomers (TPE) noma i-silicone. Umkhiqizo ovelayo unendawo ebushelelezi, ekhululekile ehlinzeka ngokubamba okungcono futhi uthuthukise ukuphatha.

Izinzuzo ze-Soft Overmolding

I-Soft overmolding inikeza izinzuzo ezimbalwa phezu kwamasu okubumba endabuko, okuhlanganisa:

- Ukunethezeka Okuthuthukisiwe: Ukunqwabelana okuthambile kunikeza indawo enethezekile ethuthukisa ulwazi lomsebenzisi. Impahla ethambile ihambisana nokuma kwesandla somsebenzisi, inciphisa amaphuzu okucindezela futhi ithuthukise ukubamba.

- Ukubamba Okuthuthukisiwe: Izinto ezithambile ezisetshenziselwa ukunqwabelana okuthambile kunikeza ukubamba okungcono, okunciphisa amathuba okuwisa noma ukulahlekelwa umkhiqizo. Ukuthuthukisa izindlela zokuphepha kunganciphisa ingozi yokulimala komkhiqizo.

- Kuyajabulisa ngobuhle: Ukunqwabelana okuthambile kungathuthukisa ukubukeka komkhiqizo, kuwenze uthandeke kakhulu ngobuhle. Izinto ezithambile zingenziwa ngokwezifiso ukuze zihambisane nombala nokuthungwa komkhiqizo, okwenza ukubukeka okuhlangene.

- Ihlala isikhathi eside: I-soft overmolding idala umkhiqizo oqinile ongamelana nokusetshenziswa okuvamile nokuguga. Izinto ezithambile zinikeza isivikelo esengeziwe ngokumelene nemithelela kanye nokuklwebheka, kunciphisa amathuba okulimala komkhiqizo.

Izicelo ze-Soft Overmolding

Izimboni ezahlukahlukene zivame ukusebenzisa i-soft overmolding, okuhlanganisa:

- I-Consumer Electronics: I-Soft overmolding ikhiqiza izinto zikagesi ezifana nezilawuli kude, ama-headphone, nezilawuli zemidlalo.

- Izimpahla Zezemidlalo: Abakhiqizi basebenzisa i-overmolding ethambile ukukhiqiza izimpahla zezemidlalo ezifana nokubamba amakilabhu egalofu, amarakhethi ethenisi, nezibambo zamabhayisikili.

- Amadivayisi Ezokwelapha: I-Soft overmolding ikhiqiza amathuluzi ezokwelapha njengamathuluzi okuhlinza kanye nezinsiza-kuzwa.

I-Hard Overmolding: Ukwengeza Ukuvikelwa Nokuqina

Ukugqwala okuqinile kwengeza isendlalelo sepulasitiki esiqinile phezu kwezinto ezikhona, njengerabha noma i-silicone, ukuze kwakhe indawo ehlala isikhathi eside futhi evikelayo. Umphumela uba umkhiqizo ongamelana nezindawo ezinokhahlo, umelane nokuhuzuka, futhi ubekezelele ukusetshenziswa ngokuphindaphindiwe.

Nazi ezinye zezinzuzo zokusebenzisa i-overmolding eqinile ekwakhiweni komkhiqizo:

- Ukuqina okwengeziwe: I-hard overmolding inikeza isendlalelo esengeziwe sokuvikela esingakhuphula isikhathi sokuphila somkhiqizo. Ukuvikela izinto eziyisisekelo ekugugeni nasekudabukeni kwenza imithelela ibe mancane amathuba okuthi iphuke noma yehluleke.

- Ukubamba okuthuthukisiwe:Ngokungeza isendlalelo sepulasitiki esikhohlisayo kwinto ethambile, njengerabha noma i-silicone, abakhiqizi bangakha ukubamba okungcono kwabasebenzisi. Kubalulekile ukucabangela lesi sici, ikakhulukazi emikhiqizweni esetshenziswa endaweni emanzi noma eshelelayo.

- Ukumelana nezinto zemvelo:Ukuminyanisa okuqinile kungavikela imikhiqizo ekuchayekeni elangeni, amakhemikhali, nezinye izici zemvelo ezingadala umonakalo ngokuhamba kwesikhathi. Lesi sithuthukisi sithuthukisa ikhono lomkhiqizo lokuzivumelanisa nokumelana nezimo ezihlukahlukene.

- Isikhalazo sobuhle: Ukweqa ngokweqile kungathuthukisa ukubukeka komkhiqizo. Ngokwengeza isendlalelo sepulasitiki esikhohlisayo, abakhiqizi bangakha ukubukeka okucacile, okupholishiwe okungenakwenzeka ngento eyodwa.

- Ukwenza ngokwezifiso: Ngokusebenzisa i-overmolding eqinile, izinkampani zingenza imikhiqizo yazo ngokwezifiso ngokungeza ama-logo, imibala, nezinye izici zedizayini phezulu. Lelisu lebhrendi lisiza ukwandisa ukubonakala endaweni yemakethe.

Abakhiqizi basebenzisa i-overmolding eqinile emikhiqizweni eyahlukene, kusukela kumishini yezimboni kuya ku-electronics abathengi. Nazi izibonelo ezimbalwa:

- Amadivayisi aphathwayo: Imishini eminingi ephathwa ngesandla, efana nomakhalekhukhwini namathebulethi, isebenzisa ukumboza kanzima ukuze yenze isendlalelo esivikelayo esizungeze idivayisi. Lesi sici sisiza ukuvikela idivayisi emonakalweni obangelwa ukuwa kanye nemithelela.

- Amathuluzi Amandla:Amathuluzi kagesi ngokuvamile ahlangabezana nezindawo ezinokhahlo, njengothuli nemfucumfucu. Ukusebenzisa i-overmolding eqinile kungavikela lawa mathuluzi emonakalweni futhi kunwebe ukuphila kwawo.

- Imishini yezokwelapha: Imishini yezokwelapha idinga ukuqina okuphezulu nokumelana nezinto zemvelo. I-hard overmolding ingavikela lawa madivayisi futhi aqinisekise ukuthi asebenza ngendlela efanele.

Ama-Thermoplastic Elastomers (TPEs): Izinto Ezikhethwayo Zokweqa

Uma kukhulunywa ngokugcwala ngokweqile, ziningi izinto ongakhetha kuzo, kodwa azikho ezidume kakhulu kune-Thermoplastic Elastomers (TPEs). Ama-TPE ayizinto eziguquguqukayo ezinikeza izinzuzo eziningi uma kukhulunywa ngokunqwabelana ngokweqile. Nazi ezinye zezizathu zokuthi kungani ama-TPE kuyizinto ezikhethwayo zokunqwabelana ngokweqile:

- Ukuhlukahluka:Abakhiqizi bangasebenzisa ama-TPE ukuze bahlanganise ngokweqile izinto ezihlukahlukene, okuhlanganisa izinsimbi, amapulasitiki, namarabha. Abakhiqizi bangawasebenzisa emikhiqizweni ehlukahlukene eyenziwe ngezinto ezahlukahlukene, okubenza babe inketho evumelana nezimo.

- Ukuthamba nokuvumelana nezimo: Ama-TPE anokwakheka okuthambile futhi okuvumelana nezimo, okuwenza alungele imikhiqizo egcwala ngokweqile edinga ukubamba okunethezekile. Bangakwazi futhi ukudala imikhiqizo edinga ukugoba noma ukugoba ngaphandle kokuphuka.

- Ukumelana namakhemikhali nemisebe ye-UV:Ama-TPE amelana kakhulu namakhemikhali nemisebe ye-UV, okuwenza alungele imikhiqizo evezwe ezindaweni ezinokhahlo.

- ukuqina: Ama-TPE ahlala isikhathi eside kakhulu futhi amelana nokuguga, okuwenza alungele imikhiqizo esetshenziswa njalo noma esetshenziswa kakhulu.

- Kuqiza kahle: Ama-TPE ayabiza kakhulu uma kuqhathaniswa nezinye izinto ezisetshenziselwa ukunqwabelana ngokweqile, okuwenza abe inketho ethengekayo kubakhiqizi.

- Kulula ukucubungula:Ama-TPE angacutshungulwa ngokushesha kusetshenziswa ukubumba komjovo, okuwenza abe yinketho edumile kubakhiqizi abadinga ukudala imikhiqizo eminingi ngokushesha nangempumelelo.

Ezinye izibonelo zemikhiqizo esebenzisa ama-TPE ukunqwabelanisa zihlanganisa:

- Izibambo zamathuluzi esandla: Abakhiqizi bavamise ukusebenzisa ama-TPE ukuze bagubungele izibambo zamathuluzi ezandla, njengepliers nama-screwdriver. Ukuthungwa okuthambile nokuguquguqukayo kwama-TPE kuwenza alungele ukudala ukubamba okunethezekile okungeke kushelele.

- Imishini yezemidlalo: Abakhiqizi bavamise ukusebenzisa ama-TPE ukuze bagxumeke kakhulu izisetshenziswa zezemidlalo, njengezibambo zekilabhu yegalofu nezibambo zerakhethi yethenisi. Ukuthungwa okuthambile nokuguquguqukayo kwama-TPE kuwenza alungele ukudala ukubamba okunethezekile okungeke kushelele.

- Imishini kagesi: Ama-TPE avame ukugcwala ngokweqile amagajethi e-elekthronikhi njengezilawuli kude namaselula. Ukuthungwa okuthambile nokuguquguqukayo kwama-TPE kuwenza alungele ukudala isendlalelo esivikelayo eduze kwedivayisi engeke iklwebhe noma ilimaze indawo.

I-Silicone Overmolding: Ilungele Amadivayisi Ezokwelapha Nemikhiqizo Yabathengi

I-Silicone overmolding yinqubo ebandakanya ukujova into ewuketshezi ye-silicone phezu kwe-substrate material. Le nqubo ingakha imikhiqizo ehlukahlukene yezimboni ezihlukahlukene kodwa iwusizo kakhulu kumadivayisi ezokwelapha kanye nemikhiqizo yabathengi. Lokhu okuthunyelwe kwebhulogi kuzohlola izinzuzo ze-silicone overmolding yalezi zimboni.

Izinzuzo ze-Silicone Overmolding for Medical Devices

- I-Biocompatibility:Imishini yezokwelapha ehlangana nezicubu zomuntu idinga izinto eziphephile zomzimba. I-Silicone yinto ehambisana ne-biocompatible engenabo ubuthi noma eyingozi ezicutshini eziphilayo. Ukusebenzisa lolu lwazi kumishini yezokwelapha kunenzuzo enkulu.

- Ukuhlanzeka: Imishini yezokwelapha kufanele ivalwe amagciwane ngaphambi kokusetshenziswa ukuze kuqinisekiswe ukuthi ayinamagciwane nokunye ukungcola okuyingozi. Ochwepheshe bezempilo bangasebenzisa izindlela ezahlukahlukene ukulungisa i-silicone, okuhlanganisa umusi, imisebe, nokuvalwa kwamakhemikhali. Imishini yezokwelapha ingazuza ekusebenzisaneni okuhlukahlukene kwalokhu kwaziswa.

- Ukuvumelana nezimo: Ukuguquguquka okuphezulu kwe-silicone kuvumela ukuyibumba ibe yizimo nosayizi abahlukahlukene. Ikhono lezinto ezibonakalayo ukuze livumelane nokuma komzimba liyenza ifaneleke kakhulu kumishini yezokwelapha.

- ukuqina: I-Silicone iyinto ehlala isikhathi eside engamelana nokusetshenziswa okuphindaphindiwe kanye nokuchayeka kumakhemikhali anonya. Ukuqina kwayo kanye nekhono lokumelana nokusetshenziswa okuphindaphindiwe nokuhlanza kuyenza ibe impahla efanelekile yemishini yezokwelapha.

Izinzuzo ze-Silicone Overmolding for Consumer Products

- Comfort: I-Silicone iyimpahla ethambile futhi eguquguqukayo ekhululekile ukugqokwa ngokumelene nesikhumba. Imikhiqizo yabathengi ethintana nomzimba, njengama-earbud, amawashi, nezilandeleli zokufaneleka, zilungele izinto ezifana nalezi.

- Ukuphikiswa kwamanzi: I-Silicone iyinto ekwazi ukumelana namanzi engakwazi ukumelana nokuchayeka kumswakama ngaphandle kokuwohloka noma ukulahlekelwa ukuma. Imikhiqizo yabathengi esetshenziswa ezindaweni ezimanzi, njengezibuko zokubhukuda nezipikha ezingangeni manzi, zenziwe ngokufanelekile kusukela kulokhu okubalulekile.

- Ukuguquguquka Komklamo: I-Silicone ingabunjwa ibe yizimo nobukhulu obuhlukahlukene, okuvumela abaklami ukuthi bakhe imikhiqizo eyingqayizivele futhi emisha. Lesi sakhiwo senza i-silicone ifaneleke emikhiqizweni yabathengi edinga izimo eziyinkimbinkimbi nemiklamo.

- ukuqina:I-Silicone iyinto ehlala isikhathi eside engamelana nokuchayeka emisebeni ye-UV, amazinga okushisa aphakeme, namakhemikhali anokhahlo. Lesi sici siyenza ilungele imikhiqizo yabathengi edinga ukuqina futhi ingamelana nezimo zezulu ezahlukahlukene.

I-Polyurethane Overmolding: Iguquguqukayo futhi Iqinile

I-polyurethane overmolding iyinqubo yokukhiqiza esanda kuthola ukuthandwa ngenxa yokuguquguquka kwayo nokuqina. Le nqubo ihilela ukusebenzisa ungqimba lwento ye-polyurethane phezu kwe-substrate ekhona, ukudala ukunamathela okungenamthungo, okuvikelayo okuthuthukisa amandla, ukuqina, nokusebenza kwengxenye yokuqala.

I-overmolding nge-polyurethane inikeza izinzuzo eziningi, okwenza kube inketho ekhangayo kubakhiqizi kuzo zonke izimboni ezihlukahlukene. Nazi ezinye zezinzuzo ezibalulekile:

yizinhlobonhlobo

Abakhiqizi bangasebenzisa inqubo eguquguqukayo kakhulu ye-polyurethane overmolding enama-substrates amaningi, okuhlanganisa amapulasitiki, izinsimbi, nezinhlanganisela.

Lokhu kuguquguquka kwenza i-polyurethane overmolding ibe yisixazululo esifanelekile sezinhlelo zokusebenza ezidinga ukuhlanganisa izinto ezahlukahlukene zibe ingxenye eyodwa.

ukuqina

I-polyurethane iyinto ehlala isikhathi eside engamelana nezimo ezihlukahlukene zemvelo, okuhlanganisa izinga lokushisa elidlulele, amakhemikhali anokhahlo, nokuguga okukhulu nokudabuka. Izinhlelo zokusebenza ezidinga ukusebenza okuzinzile nokuvikelwa zingazuza ekukhetheni lokhu njengenketho yazo ekahle.

Ukwenza ngokwezifiso

Abakhiqizi bangafinyelela izinga eliphezulu lokwenza ngokwezifiso nge-polyurethane overmolding, okubavumela ukuthi bakhe izimo eziyinkimbinkimbi nemiklamo. Lesi sici sikwenza kube ukukhetha okuphelele kwezinto ezidinga ukubukeka okuhlukile noma isakhiwo esisebenzayo.

Kuqiza kahle

I-polyurethane overmolding ingaba yisixazululo esingabizi kakhulu uma kuqhathaniswa nezinye izindlela zokukhiqiza, njengokubumba umjovo noma ukwenza imishini. Kungase futhi kunciphise inani lezingxenye ezidingekayo kuhlelo olunikeziwe, kunciphise isikhathi sokuhlanganisa nezindleko.

Ukubamba Okuthuthukisiwe Nenduduzo

I-polyurethane overmolding ingathuthukisa ukubamba nokunethezeka kwemikhiqizo, njengamathuluzi nezibambo, ngokunikeza indawo engasheleli okulula ukuyibamba futhi ekhululekile ukuyibamba.

I-polyurethane overmolding ingasetshenziswa ezinhlobonhlobo zezicelo, kufaka phakathi:

- Izithuthi:izingxenye zangaphakathi nezangaphandle, njengezibambo zeminyango, izingxenye zedeshibhodi, nezingcezu zokunquma.

- I-elekhoni:ukuvikela izingxenye ze-elekthronikhi ezibucayi ekulimaleni kwemvelo.

- Ezokwelapha: ukudala okokusebenza kwezokwelapha okuhlala isikhathi eside nokuhlanzekile, njengezibambo zamathuluzi okuhlinza.

- Izimpahla zabathengi: ngokudala imikhiqizo yangokwezifiso enemiklamo ehlukile kanye nokusebenza okuthuthukisiwe, njengempahla yezemidlalo nempahla yasendlini.

Ukweqisa Kwezicelo Zezimoto: Ukuthuthukisa Ubuhle Nokusebenza

Embonini yezimoto, i-overmolding iye yanda kakhulu ekuthuthukiseni ubuhle nokusebenza kwezingxenye zemoto. Le nqubo yokukhiqiza idala izingxenye zezimoto ezahlukahlukene, njengezibambo, izibambo, namafindo. Lapha, sizoxoxa ngokuthi i-overmolding isetshenziswa kanjani ezinhlelweni zezimoto ukuthuthukisa ubuhle nokusebenza.

Ukuthuthukisa I-Aesthetics

Enye yezinzuzo eziyinhloko zokugcwala ngokweqile embonini yezimoto yikhono layo lokuthuthukisa ubuhle. I-Overmolding ivumela abaklami ukuthi bakhe izimo eziyinkimbinkimbi nemiklamo okungaba nzima ukuyifinyelela ngezinqubo zokukhiqiza ezivamile. Nazi ezinye izindlela zokunqwabelana ezithuthukisa ukukhanga kobuhle bezingxenye zezimoto:

- Ukwenza ngokwezifiso: I-Overmolding ivumela ukwenza ngendlela oyifisayo, okwenza kube lula ukwakha izingxenye ezinemiklamo eyingqayizivele nenhlanganisela yemibala emesha ingaphakathi lemoto noma ngaphandle.

- Ukuthambisa: Ukweqa kungakha izindawo ezihlukene, kusukela ekuthinteni okuthambile kuye ekubambeni okuphezulu, okuthuthukisa ukuzwakala kwengxenye iyonke.

- Umkhiqizo:Abakhiqizi bangasebenzisa i-overmolding ukuze bafake izici zebhrendi, njengamalogo noma amagama emikhiqizo, ekwakhiweni.

- Quality: I-Overmolding ikhiqiza izingxenye zekhwalithi ephezulu ezinokuphela okungaguquki, okuthuthukisa ukubukeka nokuzwakala kukonke.

Ukuthuthukisa Ukusebenza

Ngokungeziwe ekuthuthukiseni ubuhle, ukugcwala ngokweqile kungathuthukisa ukusebenza kwezingxenye zezimoto. Nazi ezinye izindlela abakhiqizi abasebenzisa ngazo i-overmolding ukuze bathuthukise ukusebenza:

- Ukubamba: I-overmolding ingakha indawo engasheleli ethuthukisa ukubamba, okwenza izingxenye zibe lula ukuzisebenzisa futhi ziphephe kubashayeli nabagibeli.

- ukuqina: Ukweqa ngokweqile kungakhuphula ukuqina kwezingxenye ngokuzivikela ekugugeni nasekuchayekeni ezimweni ezinzima zemvelo.

- Ukunciphisa umsindo: I-overmolding inganciphisa umsindo ngokudala umphumela odambisayo onciphisa ukudlidliza futhi umunce umsindo.

- Ukuvikelwa:I-overmolding ingavikela izingxenye emonakalweni obangelwa imithelela noma imihuzuko, okusiza ukunweba ubude bazo bempilo.

Izicelo Zokunqwabelanisa Embonini Yezimoto

Abakhiqizi basebenzisa i-overmolding ezinhlobonhlobo zezinhlelo zokusebenza zezimoto, okuhlanganisa:

- Izingxenye zangaphakathi:I-overmolding idala amafindo, amaswishi, nezibambo zezici zangaphakathi ezifana namadeshibhodi, amaphaneli eminyango, nezindawo zokubeka izingalo.

- Izingxenye zangaphandle: I-overmolding idala izici zangaphandle ezifana nokufakwa kwe-grill, amalambu azungezile, namakhava esibuko.

- Ngaphansi kwe-hood: I-overmolding idala izingxenye ezifana nokukhwezwa kwenjini, izinzwa, nabakaki okumele bamelane nezinga lokushisa eliphezulu nezimo ezinzima.

I-Overmolding for Electronics: Ukuthuthukisa Ukusebenza Nokuthembeka

Embonini ye-electronics, i-overmolding iye yanda kakhulu ngenxa yekhono layo lokuthuthukisa ukusebenza nokuthembeka kwezingxenye ze-elekthronikhi. Lapha, sizoxoxa ngokuthi i-overmolding isetshenziswa kanjani kuma-electronics ukuthuthukisa ukusebenza nokuthembeka.

Ukuthuthukisa Ukusebenza

Enye yezinzuzo eziyinhloko zokugcwala ngokweqile embonini ye-electronics yikhono layo lokuthuthukisa ukusebenza. I-Overmolding ingathuthukisa ukusebenza kwezingxenye ze-elekthronikhi ngezindlela eziningana:

- Ukuvimbela amanzi:I-Overmolding ivumela ukuvinjelwa kwamanzi kwezingxenye ze-elekthronikhi, okwenza kube semqoka ezinhlelweni lapho ingxenye ingase ihlangane nomswakama noma ezinye izinto eziwuketshezi.

- Ukumelana Nokudlidliza: I-overmolding ingakha umgoqo osiza izingxenye ze-elekthronikhi ukuthi zimelane nokudlidliza, okubalulekile ezinhlelweni zokusebenza lapho ingxenye ingase ibhekane nokushaqeka noma ukudlidliza.

- Ukuphatha Okushisayo: I-overmolding isiza ukususa ukushisa kude nezingxenye ze-elekthronikhi, ngaleyo ndlela ithuthukise ukusebenza kwazo futhi andise ubude bazo bempilo.

- I-Insulation kagesi:I-Overmolding ingakha isendlalelo se-insulating esivikela izingxenye ze-elekthronikhi ekuphazamisekeni kukagesi, okungasiza ukuthuthukisa ukusebenza kwazo.

Ukuthuthukisa Ukwethembeka

Ngaphezu kokuthuthukisa ukusebenza, ukunqwabelana ngokweqile kungathuthukisa nokuthembeka kwezingxenye ze-elekthronikhi. Nazi ezinye izindlela lapho i-overmolding ithuthukisa ukwethembeka:

- Ukuvikelwa Ekulimaleni: I-overmolding ingavikela izingxenye ze-elekthronikhi ekulimaleni ngokomzimba, okufana nomthelela noma imihuzuko, okungasiza ukunweba ubude bazo bempilo.

- Ukumelana Namakhemikhali:I-overmolding ingavikela izingxenye ze-elekthronikhi kumakhemikhali angabangela ukugqwala noma omunye umonakalo, angasiza ukuthuthukisa ukuthembeka kwazo.

- Ingozi Encishisiwe Yokwehluleka: Ukweqa kungasiza ukunciphisa ingozi yokwehluleka ngokuvikela izingxenye ze-elekthronikhi ezicini zemvelo ezinjengomswakama, ukudlidliza, nokweqisa kwezinga lokushisa.

Izicelo Zokunqwabelanisa Embonini Yezogesi

Izinhlobonhlobo zezinhlelo zokusebenza ze-elekthronikhi zisebenzisa i-overmolding, okuhlanganisa:

- Izixhumanisi:I-overmolding idala izixhumi ezingangeni manzi nezimelana nokudlidliza ezithola izinhlelo zokusebenza kumishini ehlukahlukene kagesi.

- Amabhodi Wesifunda:I-overmolding ingavikela amabhodi esekethe kumswakama, ukudlidliza, nezinye izici zemvelo ezingadala umonakalo noma ukwehluleka.

- Izinzwa: I-overmolding ingavikela izinzwa emonakalweni obangelwa ukuchayeka kumakhemikhali anonya noma ezinye izici zemvelo.

- Amadivayisi Aphathwayo:I-overmolding idala amakesi ahlala isikhathi eside futhi angangeni manzi kumadivayisi aphathwayo, njengamaselula, amakhamera, namadivayisi e-GPS.

I-Overmolding for Medical Devices: Ukuqinisekisa Ukuphepha Nokunethezeka

I-Overmolding iye yanda kakhulu embonini yezokwelapha ukuze kuthuthukiswe ukuphepha nokunethezeka kwemishini yezokwelapha. Lapha, sizoxoxa ngokuthi i-overmolding isetshenziswa kanjani kumishini yezokwelapha ukuze kuqinisekiswe ukuphepha nokunethezeka.

Ukuqinisekisa Ukuphepha

Enye yezinzuzo eziyinhloko zokugcwala ngokweqile embonini yezokwelapha yikhono layo lokuqinisekisa ukuphepha. I-overmolding ingathuthukisa ukuphepha kwemishini yezokwelapha ngezindlela eziningana:

- I-Biocompatibility: I-overmolding ivumela ukuthi kudalwe amadivaysi ezokwelapha ahambisana ne-biocompatible, aqinisekise ukuphepha kwawo ukuze asetshenziswe emzimbeni womuntu ngaphandle kokubangela ukusabela okubi.

- Ukuhlanzeka: Ukugcwala ngokweqile kungadala imishini yezokwelapha elula ukuthi ibulawe amagciwane, okubalulekile ekuvimbeleni ukusabalala kwezifo ezindaweni zokunakekelwa kwempilo.

- I-Ergonomics: I-overmolding inika amandla ukudalwa kwemishini yezokwelapha eklanywe nge-ergonomically, engasiza ekunciphiseni ingozi yokulimala okuphindaphindiwe kwengcindezi kanye nokunye ukuphazamiseka kwemisipha phakathi kwabasebenzi bezempilo.

- ukuqina: Ukweqa ngokweqile kungadala imishini yezokwelapha ehlala isikhathi eside, engasiza ukunciphisa ingozi yokwehluleka noma ukungasebenzi kahle ngesikhathi sokusetshenziswa.

Ukuqinisekisa induduzo

Ngaphezu kokuqinisekisa ukuphepha, ukugcwala ngokweqile kungathuthukisa futhi ukunethezeka kwemishini yezokwelapha. Nazi ezinye izindlela i-overmolding ehlinzeka ngazo induduzo:

- Ukuthambisa: I-overmolding ingakha amadivaysi ezokwelapha anendawo yokuthungwa ehlinzeka ngokubamba okungcono futhi ethuthukisa ukunethezeka.

- Ukuvumelana nezimo: Ukweqa ngokweqile kungakha amadivaysi ezokwelapha aguquguqukayo, angasiza ekuthuthukiseni induduzo nokunciphisa ingozi yokulimala noma ukungakhululeki ngesikhathi sokusetshenziswa.

- Ukwenza ngokwezifiso: I-overmolding ivumela ukwenziwa ngendlela oyifisayo ukuma nokuklama kwemishini yezokwelapha ukuze ivumelane nezidingo eziyingqayizivele zesiguli ngasinye kangcono, kuthuthukise ukunethezeka nokunciphisa ubungozi bezinkinga.

Izicelo Zokunqwabelanisa Embonini Yezokwelapha

Izinhlobonhlobo zezinhlelo zokusebenza zezokwelapha zisebenzisa i-overmolding, kufaka phakathi:

- Izinsimbi Zokuhlinza: I-overmolding ingadala amathuluzi okuhlinza anokubambelela ngokunethezeka, i-ergonomics engcono, nokuqina okuthuthukisiwe.

- Izimila:Ukweqa ngokweqile kungakha izimila ezihambisana ne-biocompatible ezikhululeke kakhudlwana ezigulini futhi mancane amathuba okuba kubangele izinkinga.

- Amadivayisi okuxilonga: Ukweqa ngokweqile kungadala amadivaysi okuxilonga okulula ukuwaphatha, ahlala isikhathi eside, futhi akhululeke kakhudlwana ezigulini.

- Okugqokwayo: I-overmolding inika amandla ukudalwa kwemishini yezokwelapha egqokekayo enikeza ukunethezeka okuthuthukisiwe nokuvumelana nezimo, okuyenza kube lula ukuthi iziguli zizigqoke futhi zizisebenzise.

Ukweqa Imikhiqizo Yabathengi: Ukwengeza Inani kanye Nesikhalazo

Lapha, sizoxoxa ngokuthi i-overmolding isetshenziswa kanjani emikhiqizweni yabathengi ukwengeza inani nesikhalo.

Ukuthuthukisa I-Aesthetics

Enye yezinzuzo eziyinhloko zokugcwala ngokweqile embonini yomkhiqizo wabathengi ikhono layo lokuthuthukisa ubuhle. Ukweqa ngokweqile kungathuthukisa ukubukeka nomuzwa wemikhiqizo yabathengi ngezindlela eziningi:

- Ukuguquguquka Komklamo:I-overmolding ivumela ukuguquguquka okukhulu kwedizayini, okwenza ukudala imikhiqizo enomumo oyingqayizivele kanye nokuthungwa kube lula.

- Ukwenza Umbala Ngokwezifiso: I-Overmolding inika amandla imibala eminingi emkhiqizweni owodwa, idale imiklamo edonsa amehlo egqama eshalofini.

- Umuzwa Wokuthinta Okuthambile:I-overmolding ingakha imikhiqizo enokuthinta okuthambile, kuthuthukise ulwazi olunzulu lomsebenzisi kanye nokukhanga.

Ukwengeza Ukusebenza

Ngokungeziwe ekuthuthukiseni ubuhle, ukugcwala ngokweqile kungangeza ukusebenza emikhiqizweni yabathengi. Nazi ezinye izindlela i-overmolding enezela ngayo inani:

- Ukubamba Okuthuthukisiwe: I-overmolding ivumela ukudalwa kwemikhiqizo ngokubambelela okungcono, okuthuthukisa ukusetshenziswa kalula nokunethezeka lapho uyibamba.

- Ukuqina Okuthuthukisiwe:I-overmolding ingadala imikhiqizo ehlala isikhathi eside, ithuthukise ubude bayo bempilo kanye nenani lilonke.

- Ukuvimbela amanzi: I-overmolding yenza kube lula ukwakhiwa kwemikhiqizo engangeni manzi, ikhulise ukuguquguquka kwayo futhi ihehe abathengi.

Izicelo Zokweqisa Embonini Yemikhiqizo Yabathengi

Izinhlobonhlobo zezicelo zomkhiqizo wabathengi zisebenzisa i-overmolding, kufaka phakathi:

I-elekhoni: I-overmolding ingadala amakesi asesitayeleni futhi aqinile emishini kagesi efana namafoni namathebulethi.

Izinsiza Zezemidlalo: I-overmolding ingakha izinto zokusebenza ezinokubambelela okuthuthukisiwe nokuqina, njengezibambo zebhayisikili nezibambo zerakhethi yethenisi.

Izimpahla zasekhishini: I-overmolding ingakha i-kitchenware enokuzwakala ukuthinta okuthambile nokubamba okuthuthukisiwe, njengezitsha zokupheka nezibambo zamabhodwe namapani.

Imikhiqizo Yokunakekela Umuntu: Ukweqa ngokweqile kungakha imikhiqizo yokunakekelwa komuntu siqu ngokubukeka nomuzwa ohlukile, njengezixubho nezinsingo.

Ukucatshangelwa kwe-Overmolding Design: Ukusuka ku-Prototyping kuya ekukhiqizeni

I-overmolding ihlanganisa ukujova into yesibili phezu kwengxenye eyakhiwe ngaphambili, ukudala umkhiqizo obumbene. Ukweqa kunganikeza izinzuzo ezibalulekile, njengobuhle obuthuthukisiwe, ukusebenza okwengeziwe, nokuqina okuthuthukisiwe. Kodwa-ke, ukuklama nokukhiqiza izingxenye ezibunjiwe ngokweqile kudinga ukucatshangelwa ngokucophelela ukuze kuqinisekiswe impumelelo.

Nazi ezinye izinto ezibalulekile zokucatshangelwa kwesakhiwo sezingxenye ezibunjwe ngokweqile:

Ukuhambisana kwezinto: Izinto ezisetshenziswa ekuhlanganiseni ngokweqile kufanele zihambisane ukuze kuqinisekiswe isibopho esiqinile. Ukunamathela phakathi kwezinto ezimbili kubalulekile ekusebenzeni kwengxenye. Izinto ezinezici ezifanayo kanye nezinga lokushisa elincibilikayo zilungele ukugcwala ngokweqile.

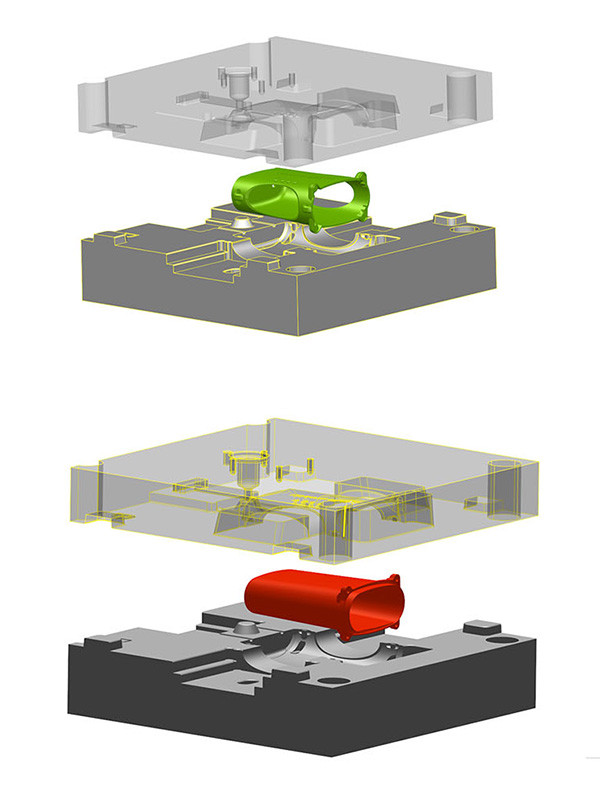

Ingxenye yedizayini: Idizayini yengxenye eyakhiwe ngaphambilini kufanele icabangele ubukhulu, ukuma, nendawo yendawo ebunjiwe. Ingxenye eklanywe kahle izoba nobukhulu obufanayo bodonga futhi ayikho ngaphansi ukuze kuqinisekiswe ukuguqulwa okubushelelezi phakathi kwezinto.

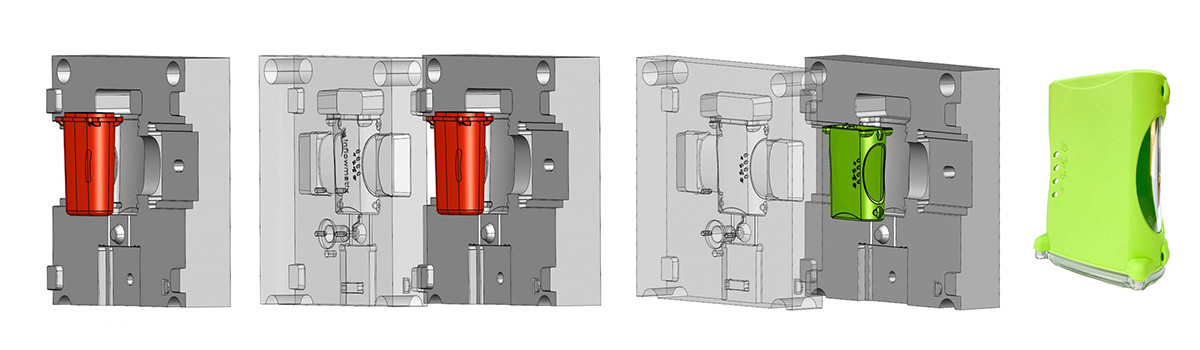

Idizayini yamathuluzi: I-tooling ye-overmolding iyinkimbinkimbi kakhulu kunokubumba okujwayelekile komjovo. Idizayini yamathuluzi kufanele ibambe ingxenye eyakhiwe ngaphambilini endaweni ngesikhathi senqubo yokugoqa, okuvumela okokusebenza kwesibili ukuthi kugeleze futhi kudlule ingxenye.

Umklami kufanele futhi adizayine okokusebenza ukuze kuncishiswe ukukhanya futhi aqinisekise isibopho esingaguquki phakathi kwezinto zokwakha.

Ukuthuthukisa inqubo: Inqubo yokweqa ihlanganisa izigaba eziningi, okuhlanganisa ukubumba ingxenye eyakhiwe ngaphambili, ukupholisa, bese ujova into yesibili. Unjiniyela kufanele athuthukise inqubo ukuze aqinisekise isibopho esingcono kakhulu phakathi kwezinto ezimbili ezisetshenziswayo futhi anciphise amaphutha afana namamaki e-warping noma ama-sink.

Lapho usuka ku-prototyping uye ekukhiqizeni, kunokucatshangelwa okwengeziwe okufanele kukhunjulwe:

Ivolumu nezindleko: I-overmolding ingabiza kakhulu kunokubunjwa komjovo wendabuko ngenxa yobunkimbinkimbi benqubo kanye nezindleko zokusebenzisa amathuluzi. Njengoba umthamo ukhuphuka, izindleko zengxenye ngayinye zingancipha, okwenza ukunqwabelana ngokweqile kwehlise izindleko zokukhiqiza okukhulu.

Ikhwalithi yokulawula: I-overmolding idinga izinyathelo eziqinile zokuqinisekisa ikhwalithi yengxenye engaguquki futhi ivimbele amaphutha. Ithimba lokulawula ikhwalithi kufanele lenze ukuhlola nokuhlola kuzo zonke izigaba zenqubo yokukhiqiza ukuze liqinisekise ukuthi ingxenye ihlangabezana nokucaciswa.

Ukukhetha komhlinzeki: Ukukhetha umphakeli ofanele wokugcwalisa i-overmolding kubalulekile empumelelweni yephrojekthi. Bheka umphakeli onolwazi lokuhlanganisa ngokweqile kanye nomlando wokukhiqiza izingxenye zekhwalithi ephezulu. Umphakeli kufanele futhi akwazi ukuhlinzeka ngosizo lwedizayini, ukuthuthukiswa kwenqubo, kanye nezinyathelo zokulawula ikhwalithi.

Ukukhiqiza Okungabizi Ngokugcwele

I-Overmolding iyinqubo yokukhiqiza ebandakanya ukujova into yesibili phezu kwengxenye eyakhiwe kusengaphambili ukuze udale umkhiqizo owodwa ohlanganisiwe. Le nqubo inganikeza izinzuzo ezibalulekile, njengobuhle obuthuthukisiwe, ukusebenza okwengeziwe, nokuqina okuthuthukisiwe. Ukweqa ngokweqile kungaba yisixazululo esingabizi kakhulu semikhiqizo ethile.

Nazi ezinye izindlela zokuthi ukugcwala ngokweqile kungasiza ekunciphiseni izindleko zokukhiqiza:

Isikhathi sokuhlanganisa esincishisiwe: Ukweqa ngokweqile kungaqeda isidingo sezingxenye ezihlukene kanye nenqubo edla isikhathi sokuzihlanganisa. Ukweqa ngokweqile kunganciphisa isikhathi sokuhlanganisa nezindleko zabasebenzi ngokudala umkhiqizo ohlangene.

Udoti wezinto ezincishisiwe: Ukubumba komjovo wendabuko kuvame ukukhiqiza udoti wezinto ezibalulekile ngenxa yama-sprues kanye nezigijimi ezidingekayo ukuze kugcwaliswe isikhunta. Ukumboza ngokweqile kunganciphisa imfucuza ngokusebenzisa ingxenye eyakhiwe ngaphambili njengomongo futhi ijove into yesibili lapho kudingeka khona.

Ukusebenza kwengxenye okuthuthukisiwe: I-overmolding ingathuthukisa ukusebenza kwengxenye nokuqina, kunciphise isidingo sokushintsha njalo noma ukulungiswa. Ukunciphisa isikhathi sokuphumula kanye nezindleko zokunakekela kungaholela ekongeni okubalulekile kwesikhathi eside.

Izindleko zamathuluzi ezehlisiwe: I-overmolding ingabiza kakhulu kunokubunjwa komjovo wendabuko ngenxa yobunkimbinkimbi benqubo kanye nezindleko zokusebenzisa amathuluzi. Kodwa-ke, kwezinye izimo, ukugcwala ngokweqile kunganciphisa izindleko zamathuluzi ngokuqeda isidingo sokubumba okuhlukene kwengxenye ngayinye. Ukweqa ngokweqile kungenza inqubo yokukhiqiza ibe lula, ikakhulukazi ezingxenyeni ezincane neziyinkimbinkimbi.

Izindleko zokuthutha ezehlisiwe: Ukweqa ngokweqile kwehlisa izindleko zokuhamba ngokususa isidingo sokuthutha nokuhlanganisa izingxenye ezihlukene kamuva. Ngokusebenzisa lokhu, kuzoba nokunciphisa ingozi yokulimala ngesikhathi sokuthutha, okuholela ekunciphiseni izingxenye ezinqatshiwe kanye nemfucuza.

Uma ucubungula ukunqwabelana kwenani eliningi ukuze kwenziwe ngendlela eyongayo, kubalulekile ukukhumbula lezi zinto ezilandelayo:

Ukukhetha okubalulekile: Izinto ezisetshenziswa ekuhlanganiseni ngokweqile kufanele zihambisane ukuze kuqinisekiswe isibopho esiqinile. Izinto ezinezici ezifanayo kanye nezinga lokushisa elincibilikayo zilungele ukugcwala ngokweqile. Ukukhetha izinto ezifanele kungase futhi kube nomthelela ekongeni izindleko zesikhathi eside ngokuthuthukisa ingxenye yokusebenza nokunciphisa izindleko zokulungisa.

Ukuthuthukisa inqubo: Inqubo yokweqa ihlanganisa izigaba eziningi, okuhlanganisa ukubumba ingxenye eyakhiwe ngaphambili, ukupholisa, bese ujova into yesibili. Ithimba lokuthuthukisa inqubo kumele lenze ngokugcwele inqubo ukuze liqinisekise isibopho esingcono kakhulu phakathi kwezinto ezimbili ezisetshenziswayo futhi linciphise amaphutha afana namamaki e-warping noma ama-sink. Ukwenza kahle inqubo nakho kungaholela ezikhathini zomjikelezo osheshayo kanye nokusebenza kahle okwandisiwe, kwehlise izindleko zokukhiqiza.

Ukukhetha komhlinzeki: Ukukhetha umphakeli ofanele wokugcwalisa i-overmolding kubalulekile empumelelweni yephrojekthi. Bheka umphakeli onolwazi lokuhlanganisa ngokweqile kanye nomlando wokukhiqiza izingxenye zekhwalithi ephezulu. Umphakeli kufanele futhi akwazi ukuhlinzeka ngosizo lwedizayini, ukuthuthukiswa kwenqubo, kanye nezinyathelo zokulawula ikhwalithi.

Ukusimama Kwemvelo kanye Nokweqisa

I-Overmolding iyinqubo yokukhiqiza ethandwayo ehlanganisa ukubumba into eyodwa phezu kwenye ukuze kwakhiwe umkhiqizo owodwa. Le nqubo ihlinzeka ngezinzuzo eziningi, okuhlanganisa ubuhle obuthuthukisiwe, ukusebenza okwengeziwe, nokuqina okukhuphukile. Kodwa kuthiwani ngomthelela wayo endaweni ezungezile? Ingabe ukukhiqiza ngokweqile kuyinqubo yokukhiqiza egcina imvelo?

Nazi ezinye izindlela zokuthi i-overmolding ibe inqubo yokukhiqiza egcina imvelo:

Udoti wezinto ezincishisiwe: Ukumboza ngokweqile kunganciphisa imfucuza ngokusebenzisa ingxenye eyakhiwe ngaphambili njengomongo futhi ijove into yesibili lapho kudingeka khona. Ukusebenzisa izinto ezincane ekukhiqizeni kunciphisa inani lemfucuza ekhiqizwayo jikelele.

Ukusetshenziswa kwamandla okwehlisiwe: I-overmolding ingawonga kakhulu kunezinqubo zokukhiqiza ezivamile ngoba ukubumba umkhiqizo owodwa kudinga amandla amancane kunokukhiqiza izingxenye ezihlukene bese uzihlanganisa kamuva.

Ukusetshenziswa kwezinto ezigaywe kabusha: Izinto eziningi zokunqwabelana zingasetshenziswa kabusha, kuncishiswe imfucuza ezindaweni zokulahla imfucuza. Ukusebenzisa izinto ezigaywe kabusha kunganciphisa nesidingo sezinto ezisetshenziswayo, ukonga imithombo yemvelo kanye nokunciphisa ukusetshenziswa kwamandla.

Isikhathi eside sokuphila komkhiqizo: I-overmolding ingathuthukisa ukusebenza kwengxenye nokuqina, okuholela emikhiqizweni ehlala isikhathi eside futhi edinga ukushintshwa okumbalwa. Ukunciphisa imfucuza ekhiqizwa ngesikhathi sokuphila komkhiqizo kunganciphisa kakhulu umthelela wawo kwezemvelo.

Ezokuthutha ezehlisiwe: Ngokuqeda isidingo sezinto zokuhamba ezihlukene kanye nokuhlanganisa kamuva izingxenye, ukugcwala ngokweqile kunganciphisa izindleko zokuhamba. Ukunciphisa inani likaphethiloli elisetshenziswa emotweni kunganciphisa umthelela wendawo futhi kunciphise ukukhishwa okuhlobene nalokho.

Kodwa-ke, kubalulekile ukuqaphela ukuthi ukugcwala ngokweqile akuyona njalo inqubo yokukhiqiza egcina imvelo. Nazi ezinye izinto okufanele uzikhumbule:

Ukukhetha okubalulekile: Izinto ezisetshenziswa ekushiseni ngokweqile kufanele zikhethwe ngokucophelela ukuze kuqinisekiswe ukuthi azihambisani nemvelo. Isibonelo, ezinye izinto zokusebenza zingase zibe inselele ukuzisebenzisa kabusha noma zingadinga ukusetshenziswa kwamandla okukhulu ukuze zikhiqize.

Ukuthuthukisa inqubo: I-overmolding kufanele ithuthukiswe ukuze kuncishiswe ukusetshenziswa kwamandla nokumosha. Enye indlela yokunciphisa udoti wezinto ezibonakalayo ukwenza ngcono imishini noma ukucwenga inqubo yokubumba ukuze isebenze kahle kakhulu.

Okucatshangwayo kokuphela kwempilo: Lapho kucutshungulwa ukuphela kokuphila komkhiqizo, abantu noma izinhlangano kufanele zicabange ukuthi zizowulahla kanjani. Imikhiqizo edakwe ngokweqile ingase ibe inselele kakhulu ukuyigaya kabusha noma ingase idinge amandla engeziwe ukulahla kunemikhiqizo evamile.

I-Overmolding kanye Nezimboni 4.0: Izinto Ezintsha Namathuba

I-overmolding iyinqubo yokukhiqiza ebandakanya ukubumba into kwenye impahla noma i-substrate. Izimboni zezimoto, zezokwelapha, neze-elekthronikhi ziyisebenzisa kakhulu. Ngokufika kwe-Industrial 4.0, ukunqwabelana ngokweqile sekube yinto entsha futhi esebenza kahle kakhulu. Lapha, sizohlola izinto ezintsha namathuba okukhula ngokweqile enkathini ye-Industry 4.0.

Amasu amasha ku-Overmolding

Ukuhlanganisa ubuchwepheshe be-Industrial 4.0 obufana ne-automation, intelligence yokwenziwa, kanye ne-Intanethi Yezinto (IoT), kuguqule inqubo yokugcwala ngokweqile. Nazi ezinye zezinto ezintsha ezivelile:

- Ama-Smart Molds: Lezi zibunjwa zifakwe izinzwa futhi zingakwazi ukuxhumana nemishini ukulungisa inqubo yokubumba. Bangakwazi futhi ukubona amaphutha futhi bazise opharetha ukuthi bathathe izinyathelo zokulungisa.

- Amarobhothi:Ukusebenzisa amarobhothi ekuhlanganiseni ngokweqile kuye kwenyusa ukusebenza kahle futhi kwehlise nezindleko zabasebenzi. Amarobhothi angakwazi ukusingatha imisebenzi ephindaphindayo njengokulayisha nokukhipha izinto zokwakha, ukunciphisa ingozi yamaphutha abantu.

- Ukuphrinta kwe-3D:Ukuphrinta kwe-3D kudale isikhunta esiyinkimbinkimbi ebesingakwazi ukukhiqiza ngaphambilini. Ukwenyuka kokuguquguquka komklamo kuye kwaholela ekwehliseni izikhathi zokuhola.

- Ukunakekela Okubikezelwayo:Ukulungiswa kokuqagela kuyindlela esebenzisa ukuhlaziya idatha ukuze ibikezele ukuthi imishini izodinga nini ukulungiswa. Le nqubo ingasiza ekuvimbeleni isikhathi sokuphumula futhi yehlise izindleko zokunakekela.

Amathuba ku-Overmolding

I-Overmolding inamathuba amaningi ku-Industry 4.0, okuhlanganisa:

- I-Lightweighting:I-overmolding ingakha izingxenye ezingasindi ngokubumba ungqimba oluncane lwempahla ku-substrate ekhanyayo. Ukunciphisa isisindo somkhiqizo wokugcina kuthuthukisa ukusebenza kahle kukaphethiloli futhi kunciphisa ukungcola.

- Ukwenza ngokwezifiso: I-Overmolding ivumela ukwenziwa ngokwezifiso kwezingxenye ngokusebenzisa izinto ezihlukene nemibala. Embonini yezokwelapha nezama-electronics abathengi, kubonakala kunendaba kakhulu, futhi kubalulekile ukucabangela lesi sici.

- Ukusimama:Ukweqa ngokweqile kungasiza ukunciphisa imfucuza ngokusebenzisa izinto ezigaywe kabusha njengama-substrates. Ngokunciphisa umthelela wemvelo wokukhiqiza, izinkampani azikwazi nje ukuthuthukisa igama lemikhiqizo yazo futhi zifake isandla ekusaseni elisimeme.

- Ukonga Izindleko: Ukuzenzakalela, amarobhothi, nokunakekelwa okuqagelayo kunganciphisa izindleko zabasebenzi futhi kukhuphule ukusebenza kahle, okuholela ekongeni kwezindleko zomkhiqizi.

Izinselele Ezeqisayo Nezixazululo

Kodwa-ke, ukunqwabelana ngokweqile kubangela izinselele ezithile abakhiqizi okufanele bazinqobe ukuze bakhiqize izingxenye ezibunjiwe zekhwalithi ephezulu. Kulesi sihloko, sihlola ezinye zezinkinga nezisombululo ezidlulele.

Izinselele

- Ukunamathela: Ukweqa ngokweqile kudinga ukuthi izinto ezimbili ezisetshenzisiwe zinamathelane, futhi ukunamathela okungekuhle kuholela ekuqhekekeni, ekuqhekekeni, noma ekuqoqweni kwezinto ezibunjwe ngokweqile.

- I-Warping:Ngesikhathi senqubo yokweqa, i-substrate ingakhubaza ngenxa yokushisa okuphezulu nokucindezela okufakiwe. I-Warping ithinta kabi ikhwalithi iyonke yengxenye.

- Ukuhambisana kwezinto:Izinto ezisetshenziswa ku-overmolding kumele zihambisane ukuze kuqinisekiswe ukunamathela okuhle nokuvimbela ukulwa. Izinto ezingafani zingaholela ekuhlanganeni okubi kanye nokwehluleka kwempahla.

- Umugqa wokuhlukanisa: Umugqa wokuhlukanisa yilapho izinto ezimbili zihlangana khona. Ukuklama okungalungile komugqa wokuhlukanisa kungaholela emaphuzwini abuthakathaka kumkhiqizo oqediwe nokunciphisa ukuqina.

- Ukugeleza kwezinto: Inqubo yokugcwala ngokweqile idinga ukuthi into yesibili igeleze izungeze i-substrate, igcwalise yonke imifantu. Ukugeleza kwempahla okungekuhle kungaholela embozweni engaphelele, i-voids, noma amaphuzu abuthakathaka.

Solutions

- Ukulungiswa kwendawo: Ukulungisa ingaphezulu le-substrate kubalulekile ekuzuzeni ukunamathela okuhle. Indawo engaphezulu kufanele ihlanzeke, yome, futhi ingabi nakungcola okufana namafutha nemfucumfucu. Ukwelapha kusengaphambili i-substrate ngabagqugquzeli bokunamathela nakho kungathuthukisa ukubopha.

- Idizayini efanele yamathuluzi: Idizayini kufanele icabangele izinto ezisetshenziswayo kanye nengxenye yejometri ukuvimbela ukungqubuzana nokuqinisekisa ukugeleza okuhle kwempahla. Ukusebenzisa amathuluzi akhethekile, njengokubumba okufakiwe, kungathuthukisa ukuqina namandla kwengxenye.

- Ukukhetha okubalulekile: Izinto ezisetshenziswa ekuhlanganiseni ngokweqile kufanele zihambisane nokuzuza ukuhlangana okuhle nokuvimbela ukulwa. Ukusebenzisa izinto ezinama-coefficients afanayo wokwandisa okushisayo kunganciphisa ukucindezelwa kwengxenye ngesikhathi sokubumba.

- Idizayini yomugqa wokuhlukanisa: Lapho uklama umkhiqizo, kubalulekile ukucabangela umugqa wokuhlukanisa ukuze uqinisekise amandla awo ngokucophelela. Ukusebenzisa imigqa yokuhlukanisa eyindilinga kunconywa kakhulu ukuvimbela ukugxila kwengcindezi.

- Ukulungiselela inqubo yokubumba umjovo: Ukulungiselela inqubo kungathuthukisa ukugeleza kwezinto futhi kuvimbele ama-voids noma amaphuzu abuthakathaka. Ukulawula izinga lokushisa, ukucindezela, nesivinini sokujova kubalulekile ukuze uthole imiphumela emihle.

Izikhombisi-ndlela Ezizayo Zokweqisa: Amathrendi Asafufusa Nobuchwepheshe

I-Overmolding, inqubo ebandakanya ukubumba enye into ibe kwenye, bekuyindlela edumile embonini yokukhiqiza amashumi eminyaka. Kodwa-ke, ngokuthuthuka kwezobuchwepheshe kanye nokugxila okukhulu ekuzinzeni, ukugcwala ngokweqile manje kubhekene nokwanda kokuthandwa. Lapha, sizoxoxa ngezikhombisi-ndlela zesikhathi esizayo ze-overmolding, okuhlanganisa amathrendi avelayo kanye nobuchwepheshe.

Okuthrendayo ku-Overmolding:

Ukusimama: Ukusimama kuyinto ehamba phambili ezinkampanini eziningi, futhi ukugcwala ngokweqile kungasiza ekunciphiseni udoti futhi kuthuthukise ukusebenza kahle ezinqubweni zokukhiqiza. Ukusebenzisa izinto ezigaywe kabusha kanye nama-polymers abolayo ekushiseni ngokweqile kuya kwanda, kunciphisa umthelela wendawo.

I-Miniaturization: Njengoba ubuchwepheshe buthuthuka, isidingo semikhiqizo emincane, elula, futhi eyinkimbinkimbi kakhulu siyakhula. I-overmolding ivumela ukwakhiwa kwezingxenye ezincane, eziyinkimbinkimbi kakhulu ezihlala isikhathi eside futhi ezisebenza kahle, okuyenza ibe yinketho efanelekile kuthrendi ye-miniaturization.

Ukwenza ngokwezifiso: Abathengi bafuna imikhiqizo eqondene nawe kakhulu, futhi ukugcwala ngokweqile kunikeza ikhono lokwenza imikhiqizo ibe ngokwezifiso ngemibala ehlukene, ukwakheka, nezinto zokwakha. Njengoba ukwenza ngokwezifiso kufinyeleleka kakhudlwana futhi kufinyeleleka kalula, silindele ukuthi lo mkhuba ukhule.

Ubuchwepheshe be-Overmolding:

I-In-Mold Decoration (IMD): I-In-Mold Decoration ubuchwepheshe obudala indawo ehlotshisiwe ngesikhathi sokugcwala ngokweqile. Lobu buchwepheshe buvumela ukudalwa kwemikhiqizo enemiklamo eyinkimbinkimbi namaphethini, okuyenza ibe ilungele ithrendi yokwenza ngokwezifiso.

Faka Ukubumba: Faka ukubumba kubandakanya ukugoqa ingxenye noma ingxenye evele ikhona. Lobu buchwepheshe bulungele ukwenza i-miniaturization ngoba bukhiqiza izici ezincane, eziyinkimbinkimbi.

I-Multi-Shot Overmolding: I-Multi-shot overmolding ihilela ukusebenzisa izinto eziningi zokwakha ingxenye eyodwa noma umkhiqizo. Lobu buchwepheshe buvumela imikhiqizo yokudala enokwakheka okuhlukile, imibala, nezinto zokwakha, okuyenza ilungele ithrendi yokwenza ngokwezifiso.

Ukubumba Komjovo Okuhlangene: Ukubumba komjovo ngokuhlanganyela kubandakanya ukujova izinto ezimbili noma ngaphezulu esikhunjeni esisodwa. Lobu buchwepheshe buvumela ukudalwa kwemikhiqizo enenhlanganisela yezakhiwo, njengamandla nokuguquguquka.

Izinzuzo ze-Overmolding:

Udoti Owehlisiwe: I-overmolding iqeda isidingo sezingxenye ezihlukene kanye nezingxenye, okuholela kunqubo yokukhiqiza esebenza kahle futhi esimeme.

Ukuqina Okuthuthukisiwe: I-Overmolding inikeza ukuqina namandla okwenyuka emikhiqizweni, okuyenza imelane kakhulu nokuguga.

Kuqiza kahle: I-overmolding ingaba enye indlela engabizi kakhulu ezindleleni zokukhiqiza zendabuko, ikakhulukazi lapho kukhiqizwa izingxenye ezincane, eziyinkimbinkimbi kakhulu.

Izinsizakalo Zokweqisa Nabahlinzeki: Ukukhetha Uzakwethu Olungile

Kodwa-ke, ukuthola umhlinzeki wesevisi oweqisayo kungaba inselele, ikakhulukazi uma kubhekwa inhlobonhlobo yabahlinzeki nezinsizakalo ezitholakalayo. Lapha, sizoxoxa ngezinto ezibalulekile okufanele zicatshangelwe lapho ukhetha umhlinzeki wesevisi we-overmolding.

Izinto Okufanele Zicatshangelwe:

Experience: Bheka umhlinzeki wesevisi onomlando ofakazelwe we-overmolding. Hlola iphothifoliyo yomhlinzeki ukuze ubone ukuthi banolwazi yini lokusebenza kumaphrojekthi afana neyakho.

Amakhono: Qinisekisa ukuthi umhlinzeki angakwazi ukuhlangabezana nezidingo zakho ezithile, okuhlanganisa ukukhetha okubalulekile, izinketho zokwenza ngokwezifiso, nevolumu yokukhiqiza.

Quality: Ikhwalithi ibalulekile ekuhlanganiseni ngokweqile, njengoba ngisho nokukhubazeka okuncane kungaholela ekuhlulekeni komkhiqizo. Bheka umhlinzeki onesistimu yokulawula ikhwalithi eqinile egunyazwe izinhlangano ezilawulayo ezifanele.

Izindleko: Ukweqa ngokweqile kungabiza, ngakho ukukhetha umhlinzeki wamanani oqhudelanayo ngaphandle kokubeka engcupheni ikhwalithi kubalulekile.

Ukuxhumana: Bheka umhlinzeki owazisa ukuxhumana okucacile nokusobala. Umhlinzeki kufanele aphendule imibuzo yakho futhi akugcine unolwazi kuyo yonke inqubo yokukhiqiza.

Isikhathi esiholayo: Cabangela isikhathi sokuhola somhlinzeki, njengoba ukubambezeleka kungaba nomthelela ohlelweni lwakho lokukhiqiza. Qinisekisa ukuthi umhlinzeki angakwazi ukuhlangabezana nezinsuku zakho zokugcina ezidingekayo.

Indawo: Ukukhetha umhlinzeki oseduze nendawo yebhizinisi lakho kunganciphisa izindleko zokuhamba kanye nezikhathi zokuhola.

Insizakalo yekhasimende: Khetha umhlinzeki owazisa isevisi yamakhasimende futhi ozosebenzisana nawe ukuxazulula noma yiziphi izinkinga.

Abahlinzeki Bensiza:

Izinkampani Zokubumba Umjovo: Izinkampani eziningi zokubumba umjovo zinikeza izinsizakalo zokugaxa ngokweqile njengomnikelo owengeziwe. Lezi zinkampani zinenzuzo yesipiliyoni ekubumbeni umjovo futhi zinganikeza uhla oluphelele lwezinsizakalo, okuhlanganisa ukukhetha kwezinto ezibonakalayo kanye nezinketho zokwenza ngokwezifiso.

Izinkampani Zokukhiqiza Izinkontileka: Izinkampani ezikhiqiza izinkontileka zihlinzeka ngezinsizakalo zokukhiqiza ezimbonini ezahlukahlukene. Lezi zinkampani zivame ukuba nolwazi olubanzi ekusetshenzisweni ngokweqile futhi zinganikeza izixazululo ezingabizi kakhulu zokukhiqiza umthamo omkhulu.

Abahlinzeki Bezipesheli: Abahlinzeki abakhethekile bagxila ezicini ezithile zokunqwabelana ngokweqile, njengokusebenza kwamathuluzi noma ukukhethwa kwezinto. Laba bahlinzeki banganikeza ulwazi olukhethekile olungase lube lusizo kumaphrojekthi ayinkimbinkimbi noma ahlukile.

Isiphetho

I-overmolding iyinqubo eguquguqukayo nesebenzayo engathuthukisa ukusebenza komkhiqizo, ukuqina, nobuhle kuzo zonke izimboni ezihlukene. Ngohlu lwezinto, amasu, kanye nokusetshenziswa, ukunqwabelana ngokweqile kunikeza amathuba amaningi kubakhiqizi ukuthi bakhe imikhiqizo yekhwalithi ephezulu ehlangabezana nezidingo nokuthandwa ngabathengi. Abakhiqizi bangenza izinqumo ezinolwazi futhi bahlale bencintisana emakethe yanamuhla ngokucabangela ukuklama, izindleko, ukusimama, kanye nezici ezintsha zokukhuphuka ngokweqile. Noma ngabe ungumklami womkhiqizo, unjiniyela, noma umnikazi webhizinisi, ukuqonda umqondo wokweqisa kungakusiza ukuthi uthathe imikhiqizo yakho uyiyise kwelinye izinga.