Izinsizakalo Zokubumba Umjovo Wepulasitiki

Ukubumba umjovo wePlastiki kuyinkqubo yokugcwalisa ithuluzi lokubumba nge-resin ewuketshezi yepulasitiki ngaphansi kwengcindezi enkulu. Ithuluzi lingase lihlanganise imbobo eyodwa noma amakhulu emigodi ukuze kwenziwe izinombolo ezingapheli zezingxenye.

Kunezinzuzo eziningi zokubumba umjovo wepulasitiki. Lokhu kufaka phakathi ikhono lokwenza izingxenye ezinkulu zezingxenye ngokushesha, ikhwalithi ephezulu yendawo, ama-resin amaningi ongakhetha kuwo, ukuguquguquka kombala, kanye namathuluzi aqinile angahlala iminyaka.

* Izinkulungwane zama-resin ongakhetha kuzo

* Umnotho wezinga

* Izinzile futhi iyaphindaphindeka

* Ikhwalithi ephezulu kakhulu

* I-Overmolding yezinketho eziningi zokuklama

* Multi-cavity kanye namathuluzi omndeni

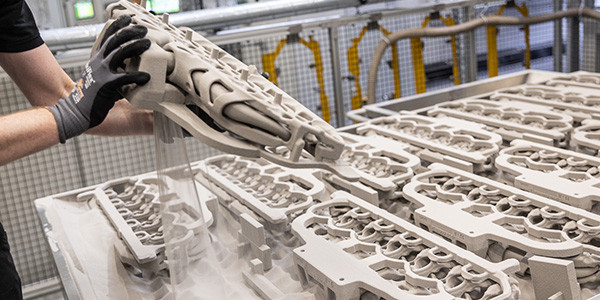

Ukubumba umjovo wepulasitiki kuyinqubo yokukhiqiza ebandakanya ukuncibilikisa ama-pellets epulasitiki bese uwajova endaweni yokubumba ukuze kwakhiwe into enezinhlangothi ezintathu. Le nqubo iqala ngemikhiqizo eminingi, kusukela ezingxenyeni ezincane ezinembayo kuya ezingxenyeni ezibalulekile zezimoto. Ukubumba umjovo wepulasitiki kunikeza izinzuzo eziningi kunezinye izinqubo zokukhiqiza, okuhlanganisa amanani aphezulu okukhiqiza, ukuguquguquka kokuklama, kanye nokusebenza kahle kwezindleko. Lo mhlahlandlela uzobheka ngokujulile ekubunjweni komjovo wepulasitiki futhi uhlole ukusetshenziswa kwawo okuhlukahlukene, izinzuzo, kanye nemikhawulo

I-Custom Plastic Injection Molding

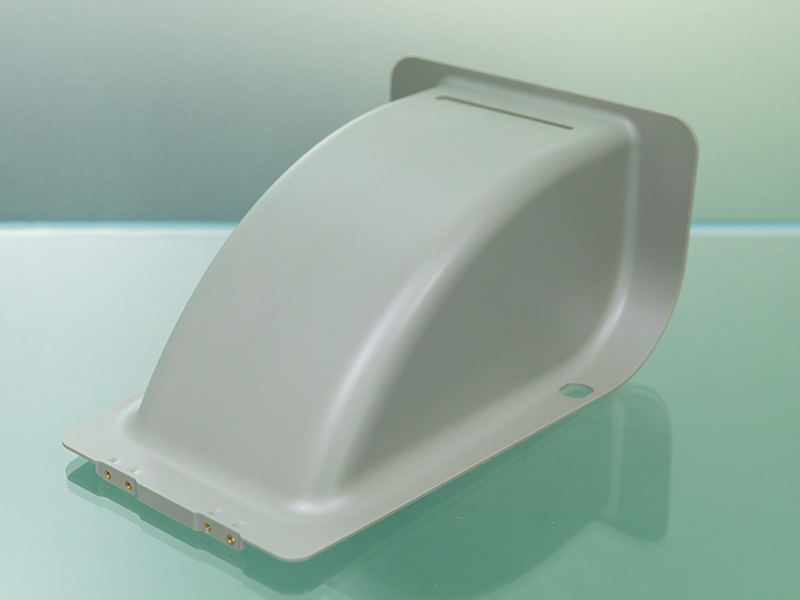

Izingxenye zepulasitiki zenziwe njengokucaciswa kwakho futhi azinikezwa noma yiliphi elinye ikhasimende. Lezi kungaba izingxenye zobunjiniyela, amakepisi, izinto zokupakisha, izingxenye zezokwelapha njll.

Ukubumba komjovo we-Silicone Rubber(LSR)

Ukubumba komjovo we-Liquid Silicone Rubber (LSR) kuyinqubo esetshenziselwa ukukhiqiza izingxenye ezithambile, eziqinile ngamavolumu aphezulu. Phakathi nenqubo, izingxenye eziningana ziyadingeka: i-injector, iyunithi yokulinganisa, idramu yokuhlinzeka, i-mixer, i-nozzle, ne-mold clamp, phakathi kwabanye.

Isevisi Yokuvikela Ngokushesha

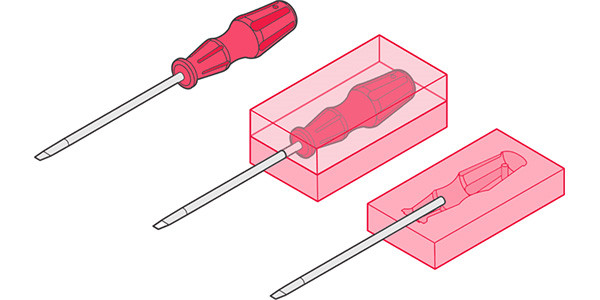

I-prototyping esheshayo yinqubo yokuthuthukisa ama-prototypes emikhiqizo ngokushesha okukhulu. I-Prototyping iyingxenye ebalulekile yokuthuthukiswa komkhiqizo. Kulapho amaqembu abaklami adala khona umkhiqizo wokuhlola ukuze asebenzise imibono yawo.

Kuyinqubo yokuthuthukisa ama-prototypes ngokushesha okukhulu ukulingisa ukwakheka komkhiqizo wokugcina. Kuwuchungechunge lwamasu asetshenziswa ukwenza imodeli yesilinganiso sengxenye ebonakalayo noma umhlangano kusetshenziswa idatha ye-CAD.

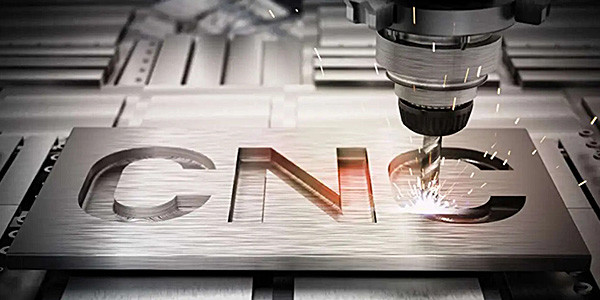

I-CNC imele ukulawulwa kwezinombolo zekhompyutha, okuwubuchwepheshe bokulawula amathuluzi okwenza ngokuzenzakalela ngokusebenzisa ikhompuyutha encane enamathiselwe ethuluzini. Imishini ye-CNCs izosebenza ngokwemiyalo ehleliwe enekhodi, njengokuhamba kwemishini, izinga lokuphakelwa kwezinto, isivinini, njalo njalo. Asikho isidingo sokuthi opharetha balawule umshini ngesandla, ngakho-ke, i-CNC isiza ukuthuthukisa ukusebenza kahle nokunemba ngezinga elikhulu.

I-Automotive Plastic Components Umjovo Ukubumba

Ukusebenza kwezimoto okuphezulu kudinga izingxenye eziphatha konke. Amapulasitiki asebenza kusuka enjini kuya ku-chassis; kulo lonke ingaphakathi kuya ngaphandle. Amapulasitiki ezimoto anamuhla enza cishe u-50% wevolumu yemoto entsha kodwa engaphansi kuka-10% wesisindo sayo.

Senze isikhunta futhi sibe nokukhiqizwa okuvamile kwe-Automotive Plastic Parts ephakela imboni yezimoto. Siye sasebenzisana nabakhiqizi bezimoto abambalwa abaziwayo.

I-Recycled Plastic Injeciton Molding

Amapulasitiki agaywe kabusha abhekisela ezintweni zepulasitiki eziphinde zenziwe kabusha. Ingavela kweminye imikhiqizo yepulasitiki noma imfucuza ewumphumela wenqubo yokubumba umjovo wepulasitiki. Lezi zinto ezigaywe kabusha zingaba yinoma yiluphi uhlobo noma umbala, futhi uma uzisebenzisa ukwenza imikhiqizo ngokubumba umjovo, akukho ukulahleka kwekhwalithi.

Ukubunjwa komjovo wevolumu ephansi

Kwa-DJmolding, umnikelo wethu wokukhiqiza ofunekayo, wevolumu ephansi ngomjovo wokubumba—osebenzisa amathuluzi e-aluminium—uyindlela esheshayo, engabizi kakhulu yokukhiqiza amakhulu ezinkulungwane zezingxenye ezibunjiwe ezisetshenziswa ekugcineni.

Isevisi Yokukhiqiza Umthamo Ophansi

Amabhizinisi amancane ngokuvamile adinga usizo lokuthola izixazululo zokukhiqiza ezithengekayo ezingakhiqiza amanani aphansi emikhiqizo ngaphandle kokufaka izindleko eziphezulu. Amabhizinisi amancane anezinsiza ezilinganiselwe ngokuvamile adinga ukunqoba umgoqo obalulekile ngenxa yemfuneko yezindleko zokudala amanani amakhulu ezindleleni zokukhiqiza zendabuko. Kodwa-ke, ngokuvela kwezinsizakalo zokukhiqiza umthamo ophansi, amabhizinisi amancane manje angakhiqiza imikhiqizo emincane ngengxenyana yezindleko zezindlela zokukhiqiza ezijwayelekile. Lesi sihloko sizohlola izinzuzo zezinsizakalo zokukhiqiza umthamo ophansi nokuthi zingasiza kanjani amabhizinisi amancane ukuthi ahlale encintisana.

I-High Volume Injection Molding

Njengoba ngaphezu kwezinkulungwane zezindawo zokubumba umjovo wepulasitiki kanye nezindawo zokukhiqiza zepulasitiki ongakhetha kuzo zonke izindawo, iziphi ezinye zezimfanelo eziphezulu ezenza inkampani yokubumba igqame? Lapho ukhetha umhlinzeki, izici eziningi okufanele zicatshangelwe; okuhlanganisa amakhono, ukuqinisekiswa kwekhwalithi, isithunzi senkampani, izindleko, nesikhathi sokulethwa. Ukuthola umshini wokubumba umjovo wepulasitiki ofanele ukuze uvumelane nezidingo zakho kungase kubonakale kudla isikhathi kodwa ukunquma izidingo zakho eziphansi neziphezulu zevolumu kuqala nokuthi zingashintsha kanjani ngokuhamba kwesikhathi, kuzokusiza ukunciphisa izinketho zakho.

I-Thermoplastic Injection Molding

Ukubumba komjovo we-Thermoplastic kuyinqubo ethandwayo yokukhiqiza esetshenziselwa ukwakha izingxenye zepulasitiki ezihlukahlukene zezimboni eziningi. Le nqubo ihilela ukuncibilikisa ama-pellets epulasitiki bese uwajova esikhunjeni ukuze akhiqize isimo esinezinhlangothi ezintathu. Ukubumba komjovo we-Thermoplastic kusebenza kahle kakhulu futhi kubiza kakhulu ukukhiqiza amavolumu amakhulu ezingxenye zepulasitiki zekhwalithi ephezulu ezinokubekezelelana okuqinile. Lo mhlahlandlela obanzi uzohlola izici ezahlukahlukene zokubumba umjovo we-thermoplastic, okuhlanganisa izinzuzo nezinkinga zayo, izinhlobo ze-thermoplastics ezisetshenziswayo, inqubo yokubumba umjovo, ukucatshangelwa komklamo, nokunye okuningi.

Faka ukubumba komjovo kuyinqubo yokukhiqiza esetshenziswa kabanzi ekukhiqizeni izingxenye zepulasitiki eziyinkimbinkimbi ezinezingxenye ezishumekiwe. Le nqubo ihlanganisa ukufaka izingxenye zensimbi noma zepulasitiki endaweni yokubumba ngaphambi kwenqubo yokubumba umjovo. Impahla encibilikisiwe ibe isigeleza izungeze into efakiwe, idale isibopho esiqinile phakathi kwezinto ezimbili. Faka ukubumba komjovo kunikeza izinzuzo ezimbalwa, okufaka ukuguquguquka kwedizayini okuthuthukisiwe, isikhathi esincishisiwe sokuhlanganisa, nokusebenza kwengxenye okuthuthukisiwe. Lo mhlahlandlela ophelele uzohlola amasu ahlukene, izinzuzo, kanye nokusetshenziswa kokubumba komjovo wokufaka.

I-overmolding iyinqubo yokukhiqiza lapho i-substrate noma ingxenye eyisisekelo ihlanganiswa nento eyodwa noma ngaphezulu ukuze kwakhiwe umkhiqizo wokugcina onokusebenza okuthuthukisiwe, ukuqina, nobuhle. Le nqubo ithole ukuduma eminyakeni yamuva nje ngenxa yekhono layo lokuthuthukisa ikhwalithi nokusebenza kwemikhiqizo ngenkathi yehlisa izindleko futhi yenza inqubo yokuhlanganisa ibe lula. I-Overmolding ithola izinhlelo zokusebenza ezimbonini ezahlukahlukene, njengezezimoto, zikagesi, izisetshenziswa zezokwelapha, nemikhiqizo yabathengi. Ukuze uqonde kabanzi le nqubo, lesi sihloko sizocubungula izici eziningi zokunqwabelana, okuhlanganisa amasu, izinto zokwakha, kanye nokusetshenziswa kwayo.

Ukubumba Imijovo Yemibala Emibili

Ukubumba umjovo onemibala emibili, noma ukubumba umjovo odubula kabili, kuyinqubo yokukhiqiza esetshenziselwa ukukhiqiza izingxenye zepulasitiki ezinemibala emibili noma izinto ezisetshenziswayo. Le nqubo ihilela ukujova ezinye izinto ezimbili zibe isikhunta esisodwa ukuze udale indima ngokuqedwa kwamathoni amabili noma izici ezihlukile zokusebenza. Ukubumba umjovo onemibala emibili kunezinhlelo zokusebenza eziningi ezimbonini ezahlukahlukene, okuhlanganisa nezimoto, ezokwelashwa, nemikhiqizo yabathengi. Le ndatshana izocubungula imininingwane yokubumba umjovo onemibala emibili, izinzuzo zayo, imikhawulo, kanye nezicelo.

Isevisi Yokukhiqiza Efunwa Ngayo

Ezweni lanamuhla elisheshayo, isidingo sokusebenza kahle nokuvumelana nezimo ekukhiqizeni siye sakhula. Faka izinsiza zokukhiqiza ezifunekayo, indlela eguquguqukayo yokubumba kabusha amapharadigmu okukhiqiza ajwayelekile. Le ndatshana ingena ijule emcabangweni, izinzuzo, izinhlelo zokusebenza, kanye namathemba ezinsizakalo zokukhiqiza ezidingeka kakhulu, enikeza ukukhanya kokuthi ziguqula kanjani izimboni emhlabeni jikelele.

Ukuze uthole okwengeziwe mayelana nemikhiqizo namasevisi epulasitiki e-DJmolding, sicela usithinte nge-imeyili: info@jasonmolding.com