Icala eKorea

I-Plastic Injection Parts' Wall Thickness Design Design yezinkampani zaseKorea Auto

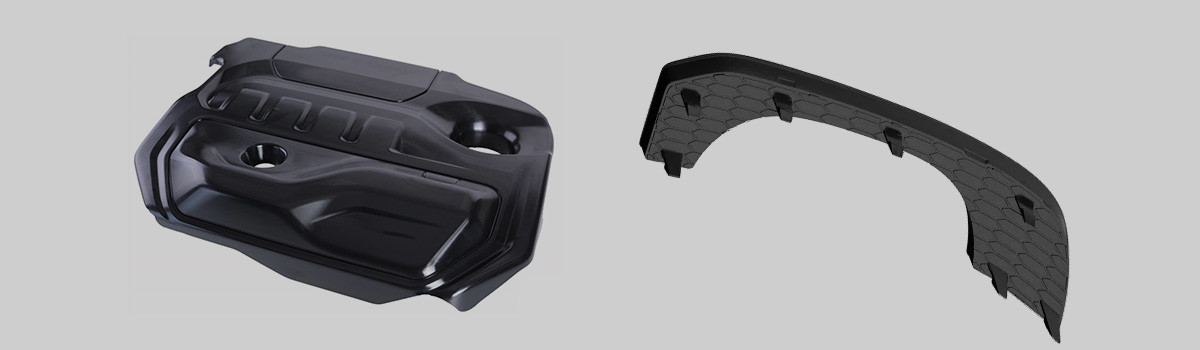

Izingxenye zepulasitiki zithengwa kakhulu ngemoto, futhi ukuqina kwayo kwesakhiwo kuzoba nomthelela empilweni yakho yonke futhi ishayele iphephile, ngakho-ke abakhiqizi be-Korean Auto bathenga izingxenye zepulasitiki eziqinile kakhulu. Imboni Yezimoto izosebenzisa izingxenye eziningi zepulasitiki emotweni, izinkampani zasendaweni zase-Korea zokujova azikwazi ukuhlinzeka ngempahla enkulu, futhi laba bakhi be-Auto bazothenga izingxenye zepulasitiki phesheya kwezilwandle, njengo-DJmolding wase-China.

Izingxenye zepulasitiki zibaluleke kakhulu emotweni, ngakho-ke ungadizayina kanjani ukuqina kodonga lwezingxenye zepulasitiki zezinkampani ze-Korean Auto? Manje, i-DJmolding izokukhombisa idizayini yokujiya kwezingxenye zomjovo wepulasitiki.

Incazelo yobukhulu bodonga

Ukuqina kwezindonga kuyisici esiyisisekelo sezingxenye zepulasitiki. Uma ingaphandle lezingxenye zepulasitiki libizwa ngokuthi udonga lwangaphandle, indawo yangaphakathi ibizwa ngokuthi udonga lwangaphakathi, khona-ke kukhona inani lokujiya phakathi kwezindonga zangaphandle nezingaphakathi. Inani libizwa ngokuthi ukujiya kodonga. Inani elifakiwe lapho igobolondo likhishwa ku-software ngesikhathi sokuklanywa kwesakhiwo kungashiwo ukuthi ukujiya kodonga.

Umsebenzi wokujiya kodonga

Ngodonga lwangaphandle lwemikhiqizo

Udonga lwangaphandle lwezingxenye lufana nesikhumba sangaphandle sezingxenye. Udonga lwangaphakathi luwuhlaka lwamathambo ezingxenye. Imiphumela ehlukene yokubukeka ingafinyelelwa ngokwelashwa okungaphezulu kodonga lwangaphandle lwezingxenye. Udonga lwangaphakathi luvele luxhumanise izakhiwo (izimbambo, ama-screw bar, ibhande njll.) ndawonye futhi lunike amandla amandla athile ezingxenyeni. Okwamanje, ezinye izakhiwo zingagcwaliswa ngesikhathi sokubumba ukutheleleka. Azikho izidingo ezithile zezindonga zangaphakathi nangaphandle (ukupholisa, umhlangano). Imvamisa, yenziwa ibe iphelele ukuze izingxenye zibe namandla anele okuvikela izingxenye zangaphakathi ekulimazeni noma ekuphazamiseni imvelo.

Okwezingxenye zangaphakathi zomkhiqizo

Njengobakaki othwalayo noma oxhumayo, azikho izidingo eziqinile zezindonga zangaphakathi nezingaphandle, ezingasungula ezinye izakhiwo (izimbambo, izikulufo, amabhande njll) odongeni olungaphandle ngokwemibandela yangempela. Kodwa-ke, ngenxa yokukhiqiza okulula (ikakhulukazi kubhekisela lapho isikhunta sangaphambili nangemuva sihlukaniswa, ukuze kugcinwe izingxenye zepulasitiki ekubunjweni kwangemuva, ubuso bangaphambili besikhunta, okumele udonga lwangaphandle luklanywe ngendlela elula ngangokunokwenzeka. Uma kungenjalo, ukulungisa i-engeli yokuklama yesikhunta sangaphambili nesemuva, ngisho ube ne-thimble esikhunjini sangaphambili noma i-undercut encane ekubunjweni kwangemuva), futhi ngokuvamile uklame ezinye izakhiwo odongeni lwangaphakathi.

Kungakhathaliseki ukuthi izingxenye zegobolondo noma izingxenye zangaphakathi, ukujiya kodonga kubalulekile njengendawo yokwamukela yephinikhodi yesikhunta, okuvumela izingxenye ukuthi zikhishwe kahle.

Izimiso zokuklama ukujiya kodonga:

Ekwakhiweni kwezingxenye zepulasitiki, ukushuba kodonga kuyinto ehamba phambili, ebalulekile njengesisekelo sesakhiwo. Ezinye izinhlaka kumele zakhelwe phezu kwayo. Phakathi naleso sikhathi, kuphinde kuthinte izakhiwo zemishini, ukwakheka, ukubukeka, izindleko zezingxenye zepulasitiki. Ngakho, ukushuba odongeni kufanele kusekelwe ezicini ezingenhla ukuklama.

Ishilo ukuthi ukujiya kodonga kudinga inani elithile. Uma kunevelu, isho ukujiya kodonga olulinganayo. Uma kunamanani amaningi, kubhekisela ebukhulu obungalingani bodonga. Umehluko phakathi kokulingana noma ukungalingani uzokwethulwa ngemuva. Manje, sizokhuluma ngesimiso sokuklama ukushuba kodonga kufanele silandelwe.

1. Ngokusekelwe kumgomo wezakhiwo zemishini:

Ishilo ukuthi kungakhathaliseki ukuthi izingxenye zegobolondo noma izingxenye zangaphakathi, zombili zidinga izinga elithile lamandla. Ngaphandle kwezinye izici, amandla okukhululwa kokumelana ayadingeka lapho kucutshungulwa ukwakheka kwezingxenye. Kulula ukukhubazeka uma ingxenye incane kakhulu. Ngokuvamile, ukushuba kodonga kuyanda, amandla ezingxenye ayanda (ukuqina kodonga kukhuphuka ngo-10%, amandla azokhula cishe ngo-33%). Uma ubukhulu bodonga budlula ububanzi obuthile, ukungeza ukuqina kodonga kuzokwehlisa amandla ezingxenye ngenxa yokuncipha kanye ne-porosity. Ukwanda kokuqina kodonga kuzokwehlisa amandla ezingxenye futhi kwandise isisindo, kunwebe umbuthano wokubumba umjovo, izindleko, njll. ngokusobala, ukwandisa amandla ezingxenye ngokumane ukwandise ukushuba kodonga akulona uhlelo olulungile. Kungcono ukusebenzisa izici zejiyomethri ukwandisa ukuqina, njengezimbambo, amajika, izindawo eziboshiwe, iziqinisekiso, njll.

Akunqunyelwe ukuthi ngenxa yokulinganiselwa kwesikhala nezinye izici, amandla ezingxenye ezithile abonakala ngokuyinhloko ngobuningi bodonga. Ngakho-ke, kunconywa ukunquma ukujiya kodonga olufanele ngokulingisa ukulingisa komshini uma amandla eyisici esibalulekile. Ngempela, inani lokujiya kodonga kufanele futhi lihambisane nemigomo esemthethweni elandelayo.

2. Ngokusekelwe kumgomo wokwakheka:

Ubukhulu bodonga lwangempela ubukhulu besikhunta phakathi kwesikhunta sangaphambili nangemuva. Lapho i-resin encibilikisiwe igcwalisa umgodi wokubumba futhi ipholile, ukushuba kodonga kuyatholakala.

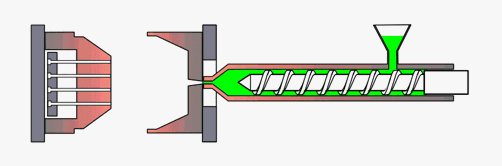

1) I-resin encibilikisiwe igeleza kanjani ngesikhathi sokujova kanye nenqubo yokugcwalisa?

Ukugeleza kwepulasitiki ngaphakathi komgodi kungathathwa njengokugeleza kwe-laminar. Ngokombono we-fluid mechanics, uketshezi lwe-laminar lungathathwa njengezendlalelo zoketshezi eduze kwesinye ezishelelayo ngaphansi kwesenzo sokugunda amandla.

Ngesikhathi sokubumba umjovo, i-resin encibilikisiwe ihlangana nodonga lwabagijimi (udonga lwesigxobo sesikhunta), okwenza izingqimba zomfudlana zinamathele odongeni lwabagijimi (noma udonga lwesigxobo sesikhunta) olupholiswe kuqala. Isivinini singuziro, futhi kukhona ukumelana nokungqubuzana okukhiqizwa ngongqimba lwaso loketshezi oluseduze. Dlula kanje, isivinini sesendlalelo esiphakathi nendawo siphezulu kakhulu. Ifomu lokugeleza lapho isivinini se-laminar sincipha eduze kodonga lomgijimi (noma udonga lwesigxobo sesikhunta) nhlangothi zombili.

Ungqimba oluphakathi luwuketshezi oluwuketshezi, kanti ungqimba lwesikhumba luwungqimba oluqinile. Njengoba isikhathi sokupholisa sidlula, ungqimba lwesiqalekiso luzokhula. Indawo yengxenye ephambanayo yongqimba lwamanzi izoba yincane kancane kancane. Ukuqina kokugcwalisa, amandla omjovo ayanda. Ngempela, kunzima kakhulu ukusunduza incibilikisiwe emgodini wesikhunta ukugcwalisa umjovo.

Ngakho-ke, ubukhulu bodonga lwamadonga bunomthelela omkhulu ekugelezeni nasekugcwaliseni izingxenye ezibunjiwe zomjovo ngesikhathi senqubo yokubumba umjovo, futhi inani layo alikwazi ukuba lincane kakhulu.

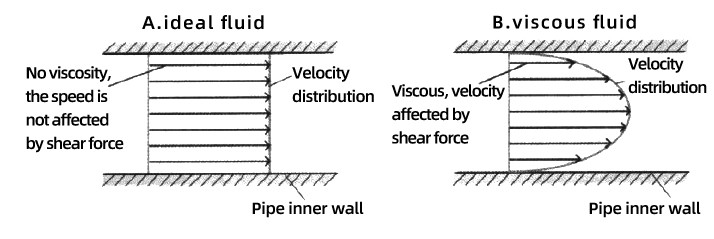

2) I-viscosity yokuncibilika kwepulasitiki nayo inethonya elikhulu ku-fluidity

Uma ukuncibilika kungaphansi kwesenzo sangaphandle, futhi kukhona ukunyakaza okuhlobene phakathi kwezendlalelo, kuzoba namandla okungqubuzana kwangaphakathi okukhiqizwa ukuphazamisa ukunyakaza okuhlobene phakathi kwezingqimba zoketshezi. Amandla okungqubuzana angaphakathi akhiqizwa uketshezi abizwa ngokuthi i-viscosity. Ukulinganisa amandla e-viscosity nge-viscosity eguqukayo (noma i-viscosity coefficient). Ngokwezinombolo isilinganiso sokucindezeleka kwe-shear nezinga lokugunda lokuncibilika.

I-viscosity yokuncibilika ikhombisa izici zokukhululeka lapho ukuncibilika kwepulasitiki kugeleza. Kuyisilinganiso sokumelana nokuncibilika kokugeleza. Ukuphakama kwe-viscosity, kukhudlwana ukumelana noketshezi, kuba nzima nakakhulu ukugeleza. Izici ezinethonya ze-viscosity encibilikayo azithinti nje kuphela ezihlotshaniswa nesakhiwo samangqamuzana, kodwa futhi zihlobene nezinga lokushisa, ingcindezi, izinga lokugunda, izithasiselo, njll. (ngemuva kokunquma izinhlobo zezinto zepulasitiki, izinga lokushisa, ingcindezi, izinga lokugunda, izithasiselo. kanye nezinye izici phakathi nenqubo yokubumba umjovo zingashintshwa ukuze kushintshwe uketshezi lwepulasitiki enqubweni yokubumba umjovo. Ngokuzayo, sizobhala i-athikili ngesihloko se-liquidity kuye ngesimo.)

Ngenkathi, ekusetshenzisweni kwangempela, i-Melt Index ikhombisa ukugcwala kwezinto zepulasitiki ekucutshungulweni. Lapho inani liphakeme, kuba ngcono ukugcwala kwempahla. Ngokuphambene nalokho, i-fluidity yezinto izoba yimbi kakhulu.

Ngakho-ke, ipulasitiki ene-fluidity enhle kulula ukugcwalisa i-mold cavity, ikakhulukazi izingxenye zokubumba umjovo ezinezakhiwo eziyinkimbinkimbi.

I-fluidity yamapulasitiki asetshenziswa ngokuvamile ingahlukaniswa izigaba ezintathu ngokuya ngezidingo zokuklama isikhunta:

①I-fluidity enhle: i-PA, i-PE, i-PS, i-PP, i-CA, i-poly(4) i-methyl pentylene;

②I-fluidity emaphakathi: ama-resin ochungechunge lwe-polystyrene (njenge-ABS, AS), i-PMMA, i-POM, i-PPO;

③Ukungamanzi kahle: I-PC, i-PVC eqinile, i-PPO, i-PSF, i-PASF, i-fluoroplastics.

Njengoba singabona ku-Fig. ngenhla, impahla ene-fluidity empofu kakhulu, izidingo zobukhulu obuncane bodonga zizoba phezulu. Lokhu kwethulwe kumbono wokugeleza kwe-laminar.

Inani elinconyiwe lokujiya kodonga ngenhla liyinombolo nje elondolozayo. Kuhlelo lokusebenza lwangempela, osayizi bezingxenye bahlanganisa ezincane, eziphakathi nendawo ezinkulu, isithombe esingenhla asicacisi uhla lwereferensi.

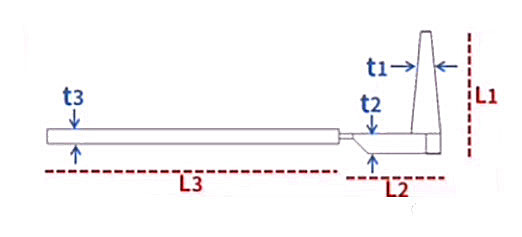

3) Singabala ngesilinganiso sobude bokugeleza

Isilinganiso sobude bokugeleza kwepulasitiki sibhekisela esilinganisweni sobude (L) nobukhulu bodonga (T) bokugeleza kwepulasitiki okuncibilika. Lokho kusho ukujiya kodonga olunikeziwe, ukuphakama kwesilinganiso sobude bokugeleza, kulapho ukuncibilika kwepulasitiki kugeleza khona. Noma uma ubude bokugeleza kokuncibilika kwepulasitiki buqinisekile, isilinganiso sobude bokugeleza sikhulu, ubukhulu bodonga bungaba buncane. Ngakho-ke, isilinganiso sobude bokugeleza kwepulasitiki sithinta ngokuqondile inani lokudla nokusabalalisa imikhiqizo yepulasitiki. Futhi, kuthinta ukushuba kodonga lwepulasitiki.

Ukuze kunembe kakhudlwana, ububanzi benani obuthile bogqinsi bodonga lungatholwa ngokubalwa kwesilinganiso sobude bokugeleza. Ngempela, leli nani lihlobene nezinga lokushisa lezinto ezibonakalayo, izinga lokushisa lesikhunta, idigri yokupholisha, njll. liyinani elilinganiselwe lebanga kuphela, izimo ezihlukene zihlukile, kunzima ukunemba, kodwa lingasetshenziswa njengenani lokubhekisela.

Ukubalwa kwesilinganiso sobude bokugeleza:

L/T (inani) = L1/T1 (isiteshi esikhulu) + L2/T2 (ishaneli ehlukanisiwe) + L3/T3 (umkhiqizo) Isilinganiso sobude bokugeleza obaliwe kufanele sibe ngaphansi kwenani elinikezwe kuthebula lempahla ebonakalayo, ngaphandle kwalokho kungase kube Isenzo sokungagcwalisi kahle.

Ngokwesibonelo

Igobolondo lerabha, impahla ye-PC, ukujiya kodonga yi-2, ibanga lokugcwalisa lingama-200, umgijimi buyi-100, ububanzi babagijimi bu-5.

Calculation: L/T(total)=100/5+200/2=120

Inani lereferensi lesilinganiso sobude bokugeleza kwe-PC ngu-90, okusobala ukuthi liphakeme kunevelu yesithenjwa. Isivinini somjovo kanye nokucindezela kudinga ukunyuswa njengoba kunzima ukujova, noma kudinga ngisho nemishini ethile yokubumba esebenza kahle kakhulu. Uma ithatha amaphuzu amabili okuphakelayo noma ishintsha indawo yokuphakela, ibanga lokugcwalisa lemikhiqizo lingancishiswa libe yi-100, okuyi-L/T(ingqikithi)=100/5+100/2=70. Isilinganiso sobude manje singaphansi kwenani eliyireferensi futhi kulula ekubumbeni umjovo. L/T(ingqikithi)=100/5+200/3=87 lapho ukujiya kodonga kuguqulwa kube ngu-3, okuvumela ukubumba komjovo okuvamile.

3. Ngokusekelwe kumgomo wokubukeka:

Ukusebenza okuqondile kokuqina kodonga okuthinta ukubukeka kwezingxenye kungokulandelayo:

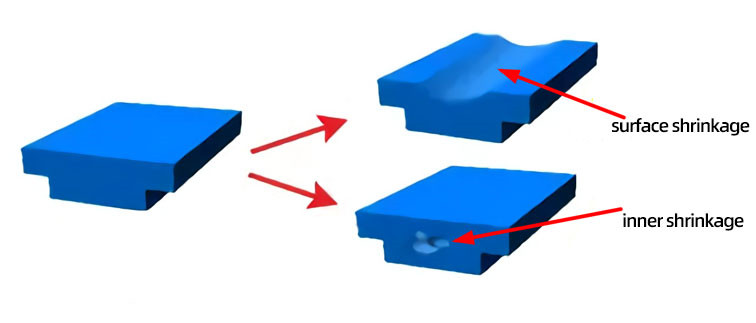

I-1) Ubukhulu bodonga obungalingani: ukushwabana kwendawo (okuhlanganisa nokukhubazeka kokubukeka njengokushwabana, imigodi, ukuphrinta okuminyene nokuncane), ukuwohloka kwe-warping, njll.

I-2) Ukuqina kodonga okwedlulele: amaphutha afana nokushwabana kwendawo kanye nezimbobo zangaphakathi zokushwabana.

3) Ukuqina kodonga kuncane kakhulu: amaphutha njengokuntuleka kweglue, ukuphrinta kwethimble, i-warpage kanye nokuguqulwa.

ukuncipha noma i-porosity

Ukuncipha noma ukuqina kwe-porosity ngokuvamile kwenzeka ezindaweni eziwugqinsi odongeni. Indlela yokusebenza: ngokomgomo wokuqiniswa kwezinto, i-porosity yangaphakathi kanye nokuncipha komhlaba ngesikhathi senqubo yokubumba umjovo kungenxa yokufinyela okuqhubekayo phakathi nenqubo yokupholisa. Uma ukushwabana kugxilwe endaweni eyiqhwa ngemuva, kodwa kungeke kwakhiwe ngokushesha, ukuncipha kanye ne-porosity kungenzeka kakhulu ngaphakathi.

Izimiso zokuklama zokuqina kodonga ngenhla zethulwa ezicini ezine, okuyizakhiwo zemishini, ukwakheka, ukubukeka, izindleko. Uma usebenzisa umusho owodwa ukuchaza ukuklanywa kokuqina kodonga, lelo inani lokuqina kodonga lwezingxenye ezibunjiwe zomjovo kufanele libe lincane ngangokunokwenzeka futhi lifane ngangokunokwenzeka ngaphansi kwesimo sokwanelisa izakhiwo zemishini nokusebenza kokucubungula. Uma kungenjalo, kufanele ishintshwe ngokufanayo.

I-DJmolding inikeza imiklamo yezingxenye zepulasitiki nezinsizakalo zokukhiqiza ze-markte yomhlaba, uma ufuna ukuqala iphrojekthi yakho, sicela usithinte njengamanje.