Ukukhiqiza Isikhunta sokujova

Ipulasitiki yinto evamise ukusetshenziselwa imikhiqizo ezimbonini ezahlukahlukene. Amathoyizi, izingxenye zezimoto, izinto zezokwelapha, amathuluzi, nokunye konke kwenziwa ngepulasitiki. Izinto eziningi zepulasitiki noma esihlangabezana nazo ekuphileni kwethu kwansuku zonke zikhiqizwa ngokushintsha inhlaka encibilikisiwe ibe idizayini ethile enenqubo yokukhiqiza ebizwa ngokuthi i-plastic injection molding. Le nqubo esebenza kahle kakhulu ingenza izingxenye ngosayizi nomumo abaningi futhi ingaphindaphinda ingxenye efanayo izikhathi eziningi isebenzisa isikhunta esifanayo. Enhliziyweni yale nqubo isikhunta, esaziwa nangokuthi i-tooling. Inqubo yokukhiqiza isikhunta yekhwalithi ephezulu ibalulekile ekukhiqizeni izingxenye zekhwalithi ngenkathi kugcinwa ukusebenza okungabizi kakhulu. Ingxenye yekhwalithi izokhuphuka futhi izindleko zephrojekthi zizokwehla lapho kutshalwa imali ekukhiqizeni isikhunta sekhwalithi ephezulu.

Izinyathelo Zokubumba Umjovo

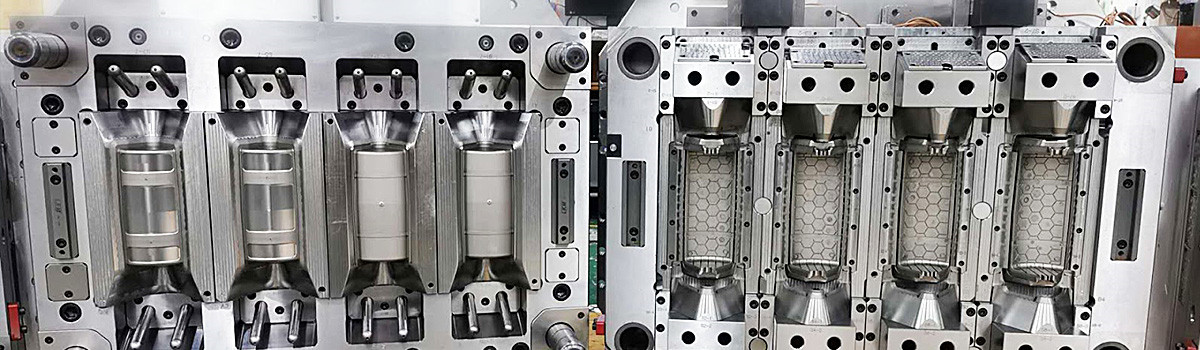

Ukubumba umjovo kungenye yezinqubo ezivame kakhulu zokukhiqiza ezisetshenziselwa ukukhiqiza izimpahla zepulasitiki. Kuyinqubo edingeka kakhulu engakhiqiza kabusha ingxenye efanayo izikhathi eziyizinkulungwane. Inqubo iqala ngefayela le-Computer Aid Design (CAD) eliqukethe ikhophi yedijithali yengxenye. Ifayela le-CAD libe selisetshenziswa njengesethi yemiyalelo yokusiza enqubweni yokukhiqiza isikhunta. Isikhunta, noma ithuluzi, ngokuvamile lenziwa ngezingcezu ezimbili zensimbi. Umgodi osesimweni sengxenye usikwa ohlangothini ngalunye lwesikhunta. Lesi sikhunta ngokuvamile senziwe nge-aluminium, insimbi, noma i-alloy.

Ngemuva kokukhiqizwa kwesikhunta, isinyathelo esilandelayo ukukhetha impahla yepulasitiki efanele. Ukukhethwa kwezinto kuzoxhomeka endleleni ingxenye yokugcina ezosetshenziswa ngayo. Izinto zepulasitiki zinezici ezihlukahlukene okufanele zicatshangelwe. Lokhu kubandakanya kukho konke ukubukeka nomuzwa, kanye nokumelana namakhemikhali, ukushisa, nokuhuzuka. Khuluma nochwepheshe bakwa-DJmolding ukuze ufunde kabanzi mayelana nezinto zepulasitiki ezitholakalayo zokubumba umjovo.

Izinto ezikhethiwe ziqala njenge-pellet yepulasitiki efakwa ku-hopper emshinini wokubumba umjovo. Ama-pellets adlula egumbini elishisayo lapho ancibilikiswa khona, acindezelwe, abese ejova emgodini wesikhunta. Uma ingxenye isipholile, izingxenye ezimbili zesikhunta ziyavuleka ukukhipha ingxenye. Umshini ube ususetha kabusha ukuze uqale inqubo futhi.

Iyiphi Impahla Esetshenziselwa Ukwenza Isikhunta?

Ukukhiqizwa kwesikhunta kwenziwa ngensimbi, i-aluminium, noma i-alloy. I-DJmolding isebenzisa insimbi yekhwalithi ephezulu ekwenzeni isikhunta. Ukukhiqizwa kwesikhunta sensimbi kubiza kancane kunokusebenzisa i-aluminium noma ingxubevange. Izindleko eziphakeme ngokuvamile zincishiswa ukuphila okude kakhulu kwezibungu zensimbi. Izibungu ze-aluminium, nakuba ishibhile ukuzikhiqiza, azihlali isikhathi eside njengensimbi futhi kufanele zishintshwe njalo. Isikhunta sensimbi ngokuvamile sizohlala imijikelezo engaphezu kwezinkulungwane eziyikhulu. Isikhunta se-aluminium sizodinga ukushintshwa kaningi. Ukukhiqizwa kwesikhunta sensimbi kungaveza imiklamo eyinkimbinkimbi kakhulu engafinyeleleki nge-aluminium. Izibunjwa zensimbi nazo zingalungiswa noma zilungiswe nge-welding. Izibunjwa ze-Aluminium zizodinga ukwenziwa ngomshini kusukela ekuqaleni uma isikhunta sonakalisiwe noma ukuze kufakwe izinguquko. Izibunjwa zensimbi ezisezingeni eliphezulu zingasetshenziswa izinkulungwane, amakhulu ezinkulungwane, futhi ngezinye izikhathi imijikelezo efinyelela esigidini.

Izingxenye Zesikhunta Somjovo

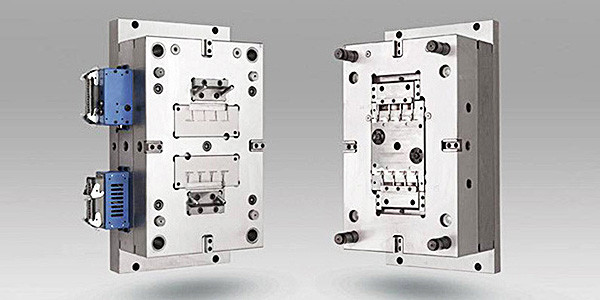

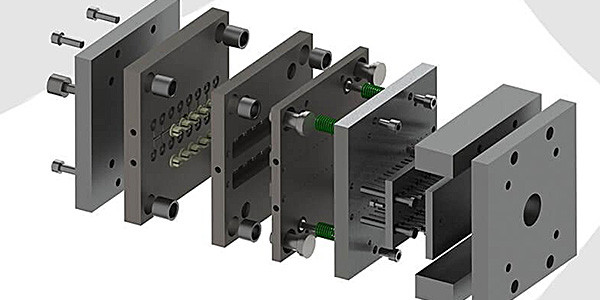

Isikhunta esiningi somjovo sakhiwe izingxenye ezimbili - uhlangothi luka-A nohlangothi luka-B, noma umgodi kanye nomgogodla. Uhlangothi lwe-cavity ngokuvamile luwuhlangothi olungcono kakhulu kuyilapho enye ingxenye, ingqikithi, izoba nokungapheleli okubonakalayo okuvela kumaphini e-ejector aphusha ingxenye eqediwe ngaphandle kwesikhunta. Isikhunta somjovo sizophinda sifake amapuleti okusekela, ibhokisi le-ejector, ibha yokukhipha, izikhonkwane ze-ejector, amapuleti e-ejector, i-sprue bushing, nendandatho yendawo.

Ukubumba umjovo kuyinqubo yokukhiqiza enezicucu eziningi ezihambayo. Ngezansi kunohlu lwamagama achaza izingcezu eziningi ezidingekayo ekukhiqizeni isikhunta nokubumba umjovo. Ithuluzi liqukethe amapuleti ensimbi amaningana ngaphakathi kohlaka. Uhlaka lwesikhunta lufakwa emshinini wokubumba umjovo futhi lubanjwe endaweni yawo ngezinsimbi. Ukusikwa kwesikhunta somjovo okubukwa ngasohlangothini kuzofana nesemishi elinesendlalelo esiningi esihlukene. Bheka i-Injection Molding Glossary yethu ukuze uthole uhlu olugcwele lwamagama.

Uhlaka Lwesikhunta noma Isisekelo Sesikhunta: Uchungechunge lwamapuleti ensimbi abamba izingxenye zesikhunta ndawonye, okuhlanganisa izimbotshana, ama-cores, isistimu yokugijima, isistimu yokupholisa, nesistimu yokukhipha.

Ipuleti: Ingxenye eyodwa yesikhunta sensimbi. Lelipuleti alinazo izingxenye ezihambayo. Ingaqukatha umgodi noma umongo.

Ipuleti le-B: Enye ingxenye yesikhunta sensimbi. Ipuleti liqukethe izingxenye ezihambayo noma isikhala sokuvumela izingxenye ezihambayo ukuthi zihlanganyele nengxenye eqediwe - ngokuvamile izikhonkwane ze-ejector.

Amapuleti okusekela: Amapuleti ensimbi ngaphakathi kohlaka lwesikhunta olunikeza ukuzinza phakathi nenqubo yokubumba.

I-Ejector Box: Iqukethe isistimu ye-ejector esetshenziselwa ukusunduza ingxenye eqediwe ngaphandle kwesikhunta.

Amapuleti e-Ejector: Ipuleti lensimbi eliqukethe ibha ye-ejector. Ipuleti le-ejector liyahamba ukuze likhiphe umkhiqizo oqediwe ngemva kokubunjwa.

Ibha ye-Ejector: Ingxenye yepuleti le-ejector. Izikhonkwane ze-ejector zixhunywe kubha ye-ejector.

Izikhonkwane ze-Ejector: Izikhonkwane zensimbi ezithinta ingxenye eqediwe bese ziyiphusha ngaphandle kwesikhunta. Omaki bephinikhodi ye-ejector bayabonakala kwezinye izinto ezibunjwe ngomjovo, ngokuvamile okubhalwe ukuthi kuyindilinga okutholakala ngemuva kwengxenye.

I-Sprue Bushing: Isiqephu sokuxhuma phakathi kwesikhunta kanye nomshini wokubumba umjovo lapho i-resin encibilikisiwe izongena emgodini.

Sprue: Indawo kuhlaka lwesikhunta lapho inhlaka encibilikisiwe ingena khona emgodini wesikhunta.

Indandatho yendawo: Iringi yensimbi eqinisekisa ukuthi umlomo wombhobho womshini wokubumba umjovo uhlangana kahle nesihlahla se-sprue.

I-Cavity noma i-Die Cavity: Ukubonakala kwe-concave ekubunjweni, ngokuvamile okwenza indawo yangaphandle yengxenye ebunjiwe. Isikhunta siqokwa njengesikhala esisodwa noma i-multi-cavity kuye ngenani lezo zifo.

Core: Ukuvela kwe-convex ekubunjweni, ngokuvamile kwakha indawo engaphakathi yengxenye ebunjiwe. Lena ingxenye ephakanyisiwe yesikhunta. Iphambana nomgodi. I-resin encibilikisiwe ihlale iphushwa emgodini, igcwalisa isikhala. I-resin encibilikisiwe izokwakha eduze komgogodla ophakanyisiwe.

Uhlelo lomgijimi noma lomgijimi: Iziteshi ezingaphakathi kwesikhunta sensimbi ezivumela inhlaka encibilikisiwe ukuthi igeleze isuka ku-sprue-to-cavity noma i-cavity-to-cavity.

Isango: Ukuphela komgijimi lapho i-resin encibilikisiwe ingena emgodini wesikhunta. Kukhona ezahlukene isango imiklamo isicelo ezahlukene. Izinhlobo zesango ezivame ukusetshenziswa zifaka iphinikhodi, i-speed, fan, i-edge, idiski, ifeni, umhubhe, ubhanana noma i-cashew, neshizolo. Ukwakhiwa kwesango nokubekwa kuyizinto ezibalulekile ngaphambi kokuqala inqubo yokukhiqiza isikhunta.

Uhlelo Lokupholisa: Uchungechunge lwamashaneli kugobolondo langaphandle lesikhunta. Lezi ziteshi zisakaza uketshezi ukusiza inqubo yokupholisa. Izingxenye ezipholile ngendlela engafanele zingase zibonise ukonakala okuhlukahlukene kwendawo noma kwesakhiwo. Inqubo yokupholisa ngokuvamile yenza iningi lomjikelezo wokubumba umjovo. Ukunciphisa izikhathi zokupholisa kungathuthukisa kakhulu ukusebenza kahle kwesikhunta kanye nezindleko eziphansi. I-Fathom inikeza i-Conformal Cooling yezinhlelo zokusebenza eziningi zokubumba ezizokwandisa ukusebenza kahle kwesikhunta kuze kufike ku-60%

I-DJmolding Mold Production for Different Molding Processes

Inqubo yokubumba umjovo wepulasitiki ingalungiswa ukuze ihlangabezane nezidingo ezihlukene neziyinkimbinkimbi. Nakuba ilungele ukukhiqiza amavolumu amakhulu ezingxenye zepulasitiki ezilula, ingasetshenziswa futhi ukwakha izingxenye eziyinkimbinkimbi ngokumangalisayo ezinamajiyometri ayinkimbinkimbi noma ama-assemblies.

I-Multi-Cavity noma Isikhunta Somndeni - Lesi sikhunta sinezimbotshana eziningi kuhlaka olulodwa lwesikhunta esikhiqiza izingxenye eziningana ezifanayo noma ezihlobene ngomjikelezo ngamunye womjovo. Lena indlela ekahle yokwandisa amavolumu wokugijima futhi wehlise inani lesiqephu ngasinye.

Okweqile - Le ndlela yokubumba umjovo isetshenziselwa ukwakha izingxenye ezenziwe ngezinhlobo ezimbili ezahlukene zepulasitiki. Isibonelo esihle salokhu kungaba umzimba wokubhoboza ophathwayo noma isilawuli segeyimu esinegobolondo langaphandle eliqinile elinezibambo ezithambile, ezenziwe ngerabha. Ingxenye ebibunjwe ngaphambilini iphinde ifakwe esikhunjeni esenziwe ngokukhethekile. Isikhunta sivaliwe futhi ungqimba lwesibili lwepulasitiki ehlukene lwengezwa phezu kwengxenye yokuqala. Lena inqubo ekahle lapho kudingeka ukuthungwa okubili okuhlukene.

Faka Ukubumba - Inqubo yokubumba umjovo evumela ukufakwa kwensimbi, i-ceramic, noma izingcezu zepulasitiki engxenyeni yokugcina. Izingxenye zensimbi noma ze-ceramic zifakwa esikhunjini bese ipulasitiki encibilikisiwe ijova esikhunjini ukuze kwakhiwe ucezu olungenamthungo olwenziwe ngezinto ezimbili ezihlukene. I-insert molding ilungele izinhlelo zokusebenza zezimoto njengoba kuyindlela entsha yokunciphisa isisindo nokunciphisa impahla ebiza kakhulu njengensimbi. Esikhundleni sokwenza ucezu lonke ngensimbi, izingcezu zokuxhuma kuphela ezidinga ukuba yinsimbi kuyilapho yonke into izokwenziwa ngepulasitiki.

I-Co-Injection Molding - Ama-polymers amabili ahlukene ajovwa ngokulandelana noma ngesikhathi esifanayo emgodini. Le nqubo ingasetshenziswa ukudala izingxenye ezinesikhumba sohlobo olulodwa lwepulasitiki olunomgogodla womunye.

I-Thin Wall Molding - Uhlobo lokubumba lomjovo olugxile ezikhathini zomjikelezo omfushane kanye nokukhiqiza okuphezulu ukukhiqiza izingxenye zepulasitiki ezincane, ezilula, nezishibhile.

Umjovo Werabha – Irabha ijovwa esikhunjeni kusetshenziswa inqubo efana nokubumba umjovo wepulasitiki. Izingxenye zenjoloba zidinga ingcindezi eyengeziwe ekubumbeni umjovo ngempumelelo.

Umjovo weCeramic - Inqubo yokubumba ngomjovo kusetshenziswa izinto zobumba. I-Ceramic yinto eqinile ngokwemvelo, engasebenzi ngamakhemikhali esetshenziswa ezimbonini ezahlukahlukene. Umjovo we-Ceramic udinga izinyathelo ezengeziwe ezengeziwe; okuhlanganisa ukucwilisa noma ukuphulukisa izingxenye ezisanda kubunjwa ukuze kuqinisekiswe ukuqina kwesici.

I-Low-Pressure Plastic Injection Molding - Izingxenye zepulasitiki ezikhiqizwa ngengcindezi ephansi. Lokhu kuwusizo ikakhulukazi emisebenzini edinga ukufakwa kwezingxenye ezithambile, ezifana ne-electronics.

Xhumana no-DJmolding ukuze uthole ulwazi olwengeziwe mayelana nokubunjwa komjovo wepulasitiki. Ithimba lethu lochwepheshe lingakusiza ngephrojekthi yakho ebunjwe ngomjovo wepulasitiki.