Plastain Injection Molding

Ukubumba umjovo wepulasitiki kuyinqubo yokukhiqiza ebandakanya ukuncibilikisa ama-pellets epulasitiki bese uwajova endaweni yokubumba ukuze kwakheke into enezinhlangothi ezintathu. Le nqubo iqala ngemikhiqizo eminingi, kusukela ezingxenyeni ezincane ezinembayo kuya ezingxenyeni ezibalulekile zezimoto. Ukubumba umjovo wepulasitiki kunikeza izinzuzo eziningi kunezinye izinqubo zokukhiqiza, okuhlanganisa amanani aphezulu okukhiqiza, ukuguquguquka kokuklama, kanye nokusebenza kahle kwezindleko. Lo mhlahlandlela uzobheka ngokujulile ekubunjweni komjovo wepulasitiki futhi uhlole ukusetshenziswa kwawo okuhlukahlukene, izinzuzo, kanye nemikhawulo.

Umlando Wokubumba Umjovo Wepulasitiki

Ukubumba umjovo wePlastiki kuyinqubo yokukhiqiza ebandakanya ukujova ipulasitiki encibilikisiwe endaweni yesikhunta ukuze kwakheke umumo othile. Umlando wokubumba umjovo wepulasitiki ungalandelelwa emuva ngasekupheleni kwawo-1800 lapho i-celluloid, uhlobo lwepulasitiki, yasungulwa okokuqala. Kodwa-ke, kwakungawo-1940 lapho ukubumba komjovo wepulasitiki kwasetshenziswa kabanzi njengendlela yokukhiqiza.

Phakathi neMpi Yezwe II, isidingo semikhiqizo yepulasitiki ekhiqizwa ngobuningi sakhula, futhi abakhiqizi baqala ukufuna izindlela ezintsha neziphumelela kakhudlwana zokuyikhiqiza. Ngo-1946, uJames Watson Hendry, umsunguli waseMelika, wenza umshini wokuqala wokubumba umjovo wesikulufa, owaguqula imboni yokubumba umjovo wepulasitiki. Lo mshini uvumele ukulawula inqubo yokujova okunembe kakhudlwana nokungaguquguquki, okwenza ukukhiqiza izingxenye ezinkulu zepulasitiki kufinyeleleke futhi kusebenze kahle.

Kuwo wonke ama-1950 kanye nawo-1960, intuthuko kubuchwepheshe bepulasitiki yaqhubeka nokwenza ngcono inqubo yokubumba umjovo wepulasitiki. Ukwethulwa kwezinto ezintsha, njenge-polystyrene ne-polyethylene, kwakha izingxenye zepulasitiki eziyinkimbinkimbi futhi eziqinile. Ukwengeza, ukuthuthukiswa kobuchwepheshe bomshini wokubumba, okuhlanganisa ukusebenzisa amasistimu we-hydraulic, kwenze inqubo yokubumba umjovo yasebenza ngempumelelo futhi yangabizi kakhulu.

Namuhla, ukubumba komjovo wepulasitiki kuyinqubo ezenzakalelayo esetshenziselwa ukukhiqiza imikhiqizo eminingi yepulasitiki, kusukela kumathoyizi nezimpahla zabathengi kuya ezingxenyeni zezimoto namadivayisi wezokwelapha. Ngokuthuthukiswa kwezinto ezintsha kanye nobuchwepheshe, inqubo yokubumba umjovo wepulasitiki iyaqhubeka nokuvela futhi ithuthuke, iqinisekisa ukuthi izohlala iyindlela ebalulekile yokukhiqiza iminyaka eminingi.

Izisekelo Zokubumba Umjovo Wepulasitiki

Ukubumba umjovo wepulasitiki kuyinqubo yokukhiqiza yokwakha izingxenye nemikhiqizo eyenziwe ngezinto zepulasitiki. Le nqubo ihilela ukujova ipulasitiki encibilikisiwe esikhunjeni, esipholisa futhi siqine ukuze sakhe isimo esidingekayo.

Izinyathelo eziyisisekelo ezihilelekile kunqubo yokubumba umjovo wepulasitiki zimi kanje:

- I-Mold design: Isinyathelo sokuqala kule nqubo ukuklama isikhunta esizosetshenziselwa ukwakha ingxenye oyifunayo. Isikhunta ngokuvamile senziwe ngensimbi futhi kufanele silungiselelwe ukulandisa ngokuncipha njengoba ipulasitiki iphola futhi iqina.

- Ukulungiswa kwezinto: Izinto zepulasitiki ezisetshenziswa enqubweni yokubumba umjovo ziza ngendlela yamapellets noma ama-granules, okumele ancibilikiswe phansi futhi alungiselelwe ukujova esikhunjeni. Lokhu ngokuvamile kwenziwa ku-hopper, lapho ipulasitiki ishiselwa ezingeni lokushisa elithile futhi inyibilikiswe ibe yisimo esiwuketshezi.

- Umjovo: Uma ipulasitiki isincibilikisiwe, ijovwa esikhunjeni kusetshenziswa umshini wokubumba umjovo okhethekile. Umshini ucindezela ipulasitiki encibilikisiwe, uyiphoqe emgodini wesikhunta, lapho ithatha khona ukuma kwesikhunta.

- Ukupholisa nokuqinisa: Ngemva kokuba ipulasitiki ijovwe esikhunjeni, ingapholisa futhi iqine. Lokhu kungathatha noma yikuphi ukusuka kumasekhondi ambalwa ukuya emaminithini ambalwa, kuye ngosayizi nobunkimbinkimbi bengxenye.

- Ukukhipha: Uma ipulasitiki isipholile futhi yaqina, isikhunta siyavulwa, futhi ingxenye iyakhishwa. Indawo ingase idinge umsebenzi wokuqedela owengeziwe, njengokunquma noma ukusenta isihlabathi, ukuze kususwe ipulasitiki eyeqile noma imiphetho emangelengele.

Ukubumba komjovo wepulasitiki kuyinqubo eqondile nephindaphindwayo, okuyenza ilungele izingxenye ezikhiqiza ngobuningi nemikhiqizo enekhwalithi engashintshi. Futhi iguquguquka kakhulu, njengoba ingakha izingcezu nemikhiqizo ngobukhulu obuhlukahlukene, ubujamo, nobunkimbinkimbi. Ezinye zezicelo ezivame kakhulu zokubumba umjovo wepulasitiki zifaka ukukhiqizwa kwamathoyizi, izimpahla zabathengi, izingxenye zezimoto, kanye nemishini yezokwelapha.

Inqubo yokubumba ngomjovo wePlastiki: Isinyathelo ngesinyathelo

Ukubumba umjovo wePlastiki kuyinqubo eyinkimbinkimbi ehlanganisa izinyathelo ezimbalwa. Nansi inkomba yesinyathelo ngesinyathelo yenqubo yokubumba umjovo wepulasitiki:

- Ukuklama Isikhunta: Isinyathelo sokuqala ukuklama isikhunta esisetshenziselwa ukwakha ingxenye. Isikhunta ngokuvamile senziwe ngensimbi noma nge-aluminiyamu futhi kufanele silungiselelwe ukuthwala ukuncipha kwento yepulasitiki njengoba iphola.

- Ukudala Isikhunta: Uma umklamo wokubumba usuqediwe, ukhiqizwa kusetshenziswa isofthiwe ye-computer-aid design (CAD) kanye nemishini yokukhiqiza ikhompyutha (CAM). Isikhunta kufanele senziwe ngomshini ngokucophelela futhi sipholishwe ukuze kuqinisekiswe ukunemba nokuphela komkhiqizo wokugcina.

- Ukukhethwa Kwezinto Ezibalulekile: Impahla yepulasitiki ye-resin esetshenziselwa inqubo yokubumba umjovo kumele ikhethwe ngokuya ngezidingo zengxenye, njengamandla ayo, ukuguquguquka, umbala, nokuthungwa kwayo.

- Ukulungiselela Okubalulekile: Impahla yepulasitiki ekhethiwe ibe isishisiswe ezingeni elithile lokushisa bese inyibilika ibe uketshezi. Izinto ezisetshenziswayo zibe sezijovwa ehophini yomshini wokubumba.

- I-Injection Molding: Izinto zepulasitiki ezincibilikisiwe zijova emgodini wesikhunta kusetshenziswa umshini wokubumba umjovo okhethekile. Umshini usebenzisa ingcindezi ezintweni zepulasitiki, uziphoqa ukuba ungene emgodini wesikhunta, lapho uthatha khona ukuma kwesikhunta.

- Ukupholisa: Uma isikhunta sesigcwele ipulasitiki, singapholisa futhi siqine. Isikhathi sokupholisa sinqunywa izici zezinto zepulasitiki, ubukhulu nokuqina kwengxenye, kanye nezinga lokushisa lesikhunta.

- Ukukhipha: Ngemva kokuba ipulasitiki iqinile, isikhunta siyavulwa, futhi ingxenye ikhishwa esikhunjeni kusetshenziswa izikhonkwane ze-ejector.

- Ukuqeda: Ingxenye ekhishiwe ingase idinge umsebenzi wokuqedela owengeziwe, njengokunquma, ukusenta isihlabathi, noma ukupenda, ukuze kususwe noma iyiphi ipulasitiki eyeqile noma imiphetho emangelengele.

- Ukulawulwa Kwekhwalithi: Ingxenye eqediwe ihlolwa ngokucophelela ukuze ihlangabezane nezicaciso ezidingekayo namazinga ekhwalithi.

Ukubumba umjovo wePlastiki kungakhiqiza izingxenye nemikhiqizo ehlukahlukene ngobukhulu obuhlukahlukene, ubujamo, nobunkimbinkimbi. Le nqubo isetshenziswa kakhulu ezimbonini eziningana, okuhlanganisa ezezimoto, ezokwelashwa, ezithengwayo, nezogesi.

Izinhlobo Zepulasitiki Ezisetshenziswa Ekubumbeni Umjovo

Izinhlobo eziningi zepulasitiki zingasetshenziswa ekubumbeni umjovo. Ukukhethwa kwezinto zepulasitiki kuzoncika ezidingweni ezithile zomkhiqizo noma ingxenye ekhiqizwayo, njengamandla, ukuguquguquka, ukuqina, nokubukeka. Nazi ezinye zezinhlobo ezivame kakhulu zepulasitiki ezisetshenziswa ekubumbeni umjovo:

- I-Polyethylene (PE): I-PE yinto esetshenziswa kabanzi yepulasitiki eyaziwa ngamandla ayo nokuguquguquka. Isetshenziselwa ukukhiqiza imikhiqizo ehlukahlukene, okuhlanganisa izinto zokupakisha, amathoyizi, kanye nemishini yezokwelapha.

- I-Polypropylene (PP): I-PP yinto yepulasitiki engasindi futhi eqinile evame ukusetshenziswa embonini yezimoto ezingxenyeni zangaphakathi, njengamadeshibhodi namaphaneli eminyango. Iphinde ikhiqize izinto zokupakisha, njengeziqukathi namabhodlela.

- I-Polycarbonate (PC): I-PC iyipulasitiki eqinile futhi esobala evame ukusetshenziselwa ukukhiqiza izingxenye ze-elekthronikhi, njengamakesi ekhompuyutha nawefoni. Iphinde isetshenziselwe amalensi amalambu kanye nezingxenye zedeshibhodi embonini yezimoto.

- I-Acrylonitrile Butadiene Styrene (ABS): I-ABS iyimpahla yepulasitiki enemisebenzi eminingi eyaziwa ngamandla ayo, ukuqina, nokumelana nokushisa. Ivamise ukusetshenziselwa ukukhiqiza izingxenye zezimoto, njengamadeshibhodi, ama-fender flare, amathoyizi, nezimpahla zabathengi.

- I-Polyamide (PA): I-PA, eyaziwa nangokuthi inayiloni, iyinsimbi eqinile futhi engasindi yepulasitiki evame ukusetshenziswa ekukhiqizeni izingxenye zezimoto, njengamakhava enjini kanye nezinhlelo zokungenisa umoya. Iphinde ikhiqize imishini yezemidlalo, njengamabhuzu e-ski nama-racket ethenisi.

- I-Polystyrene (PS): I-PS iyipulasitiki engasindi futhi eqinile evame ukusetshenziswa ekukhiqizeni izinto zokupakisha, njengezinkomishi, amathreyi, nezitsha zokudla. Iphinde ikhiqize izimpahla zabathengi, njengamathoyizi nezingxenye ze-elekthronikhi.

- I-Polyethylene Terephthalate (PET): I-PET iyiplastiki eqinile futhi esobala evame ukusetshenziselwa ukukhiqiza izinto zokupakisha, njengamabhodlela neziqukathi. Ibuye isetshenziswe embonini yendwangu ukukhiqiza imicu nezindwangu.

Lezi ezinye zezinhlobo ezimbalwa ezivame kakhulu zepulasitiki ezisetshenziswa ekubumbeni umjovo. Ezinye izinhlobo eziningi zezinto zepulasitiki ziyatholakala, ngayinye inezindawo nezici ezihlukile. Ukukhethwa kwempahla yepulasitiki kuzoncika ezidingweni ezithile zengxenye noma umkhiqizo okhiqizwayo.

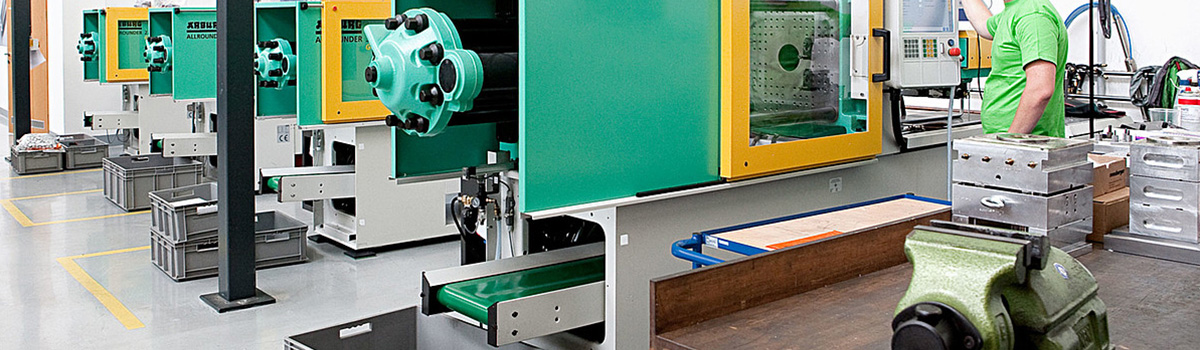

Izinhlobo Zemishini Yokubumba Yokujova

Imishini yokubumba yomjovo iza ngezinhlobo nosayizi abahlukahlukene, ngayinye yakhelwe ukuhlangabezana nezidingo ezithile zokukhiqiza. Nazi ezinye zezinhlobo ezivame kakhulu zemishini yokubumba umjovo:

- Umshini Wokubumba Umjovo We-Hydraulic: Lo mshini usebenzisa amandla we-hydraulic ukukhiqiza ingcindezi yokujova ipulasitiki esibunjeni. Imishini yeHydraulic ivamise ukusetshenziselwa izingxenye ezibalulekile ezidinga amandla amakhulu okubamba.

- Umshini Wokubumba Umjovo Kagesi: Imishini kagesi isebenzisa amamotho kagesi ukunika amandla iyunithi yomjovo kanye nendlela yokubopha. Baziwa ngokunemba okuphezulu nokusebenza kahle kwamandla, okubenza badume ngokukhiqiza izingxenye ezincane, eziyinkimbinkimbi.

- Umshini Wokubumba Umjovo We-Hybrid: Imishini yeHybrid ihlanganisa izinzuzo zamadivayisi we-hydraulic kanye nogesi, isebenzisa kokubili amandla we-hydraulic namandla kagesi ukukhiqiza ingcindezi edingekayo namandla. Imishini ye-Hybrid inikeza ibhalansi enhle yejubane, ukunemba, nokusebenza kahle kwamandla.

- Umshini Wokubumba Umjovo Oqondile: Imishini emile ikhiqiza izingxenye ezidinga ukubunjwa okufakiwe noma ukubunjwa ngokweqile. Zineyunithi yokugoqa eqondile evumela ukufinyelela okulula kusikhunta, okuzenza zilungele ukudala izingxenye ezincane noma eziyinkimbinkimbi.

- Umshini Wokubumba Wokujova Okubili: Imishini edubula kabili ikhiqiza izingxenye ezinezinto ezihlukile noma imibala. Idivayisi inamayunithi amabili omjovo, ngalinye likwazi ukujova izinto zangaphandle esikhunjeni. Lolu hlobo lomshini luvame ukusetshenziselwa ukukhiqiza izingxenye zezimoto, njengezibambo namafindo.

- I-Multi-Shot Molding Molding Machine: Imishini eminingi edubulayo ikhiqiza izingxenye ezinezinto ezingaphezu kwezimbili noma imibala. Idivayisi inamayunithi omjovo amaningi, ngalinye likwazi ukujova into ehlukile esikhunjeni. Lolu hlobo lomshini luvame ukusetshenziselwa ukukhiqiza izimpahla ezithengwayo, njengezixubho nezinsingo.

- Umshini Wokubumba Wokujova Kagesi Wonke: Imishini kagesi yonke isebenzisa amamotho kagesi ukunika amandla iyunithi yomjovo, umshini wokubopha, kanye nesikhunta. Zaziwa ngokunemba kwazo okuphezulu, isivinini, kanye namandla azo, okuzenza zidume ngokukhiqiza izingxenye ezincane, ezinemba kakhulu.

Lezi ezinye zezinhlobo ezimbalwa ezivame kakhulu zemishini yokubumba umjovo. Umshini ngamunye unezici nezinzuzo ezihlukile, okwenza kube semqoka ukukhetha umshini ofanele izidingo ezithile zokukhiqiza.

Izingxenye Zomshini Wokubumba Umjovo

Imishini yokubumba umjovo inezingxenye eziningana ezakha izingxenye zepulasitiki ezivela ezintweni ezingavuthiwe. Nazi izingxenye ezibalulekile zomshini wokubumba umjovo:

I-Hopper: I-reservoir ibamba impahla yepulasitiki eluhlaza ngaphambi kokuthi ifakwe emshinini wokubumba umjovo. Impahla ngokuvamile isesimweni samapellets noma impushana.

Umgqomo: Umphongolo yingxenye ende, eyisilinda yomshini wokubumba umjovo ogcina isikulufu, esincibilikisa futhi sixube izinto zepulasitiki.

Isikulufu: Isikulufu siyidivayisi ezungezisayo ngaphakathi kombhobho ephusha izinto zepulasitiki ziye phambili futhi ziwuncibilikise ngokungqubuzana nokushisa.

Iyunithi yomjovo: Iyunithi yomjovo ihlanganisa i-hopper, umphongolo, nesikulufu futhi inesibopho sokuncibilikisa nokujova ipulasitiki esikhunjeni.

Iyunithi yokugoqa: Iyunithi yokubopha inesibopho sokubamba ngokuvikelekile isikhunta futhi ifake ingcindezi edingekayo phakathi nenqubo yokubumba umjovo.

Isikhunta: Isikhunta siyithuluzi elenza umumo nosayizi wengxenye yepulasitiki. Isikhunta ngokuvamile senziwe ngensimbi futhi siqukethe amahhafu amabili ahlanganayo.

Umbhobho: Umbhobho ingxenye yeyunithi yomjovo exhuma umshini wokubumba umjovo nesikhunta. Impahla yepulasitiki encibilikisiwe ijovwa ngombhobho kanye nasesikhunjini.

Isistimu yokupholisa: Isistimu yokupholisa inesibopho sokupholisa ingxenye yepulasitiki uma isijovwe esikhunjeni. Lokhu kuqinisekisa ukuthi ucezu luqinile futhi lungasuswa esikhunjeni ngaphandle kokulimala.

Iphaneli yokulawula: Iphaneli yokulawula iyisixhumi esibonakalayo esivumela opharetha ukuthi aqaphe futhi alungise izilungiselelo zomshini wokubumba umjovo, njengezinga lokushisa, ukucindezela, nesikhathi somjikelezo.

Ngayinye yalezi zingxenye idlala indima ebalulekile enqubweni yokubumba umjovo, futhi kubalulekile ukugcina nokwandisa ucezu ngalunye ukuze kuqinisekiswe ukuthi izingxenye ezisezingeni eliphezulu zikhiqizwa kahle.

Ithuluzi Lokubumba Lomjovo: Idizayini kanye Nokukhiqiza

Ukubumba umjovo wamathuluzi kubhekisela ekuklameni nasekukhiqizeni isikhunta esisetshenziswa emishinini yokubumba umjovo ukukhiqiza izingxenye zepulasitiki. Izinga nokusebenza kahle kwezibunjwa kuthinta ngqo ikhwalithi kanye nokukhiqiza kwenqubo yokubumba umjovo. Nazi izinyathelo ezibalulekile ekwakhiweni nasekukhiqizeni amathuluzi okubumba umjovo:

Ukwakhiwa komkhiqizo: Isinyathelo sokuqala sokubumba umjovo wamathuluzi ukuklama umkhiqizo ozokhiqizwa. Idizayini yomkhiqizo ihlanganisa ukunquma usayizi wengxenye, ukwakheka, nokokusebenza, kanye nanoma yiziphi izici ezithile noma izidingo.

Ukwakhiwa kwesikhunta: Inqubo yokuklama isikhunta iqala lapho umklamo womkhiqizo usuphothuliwe. Umklami wesikhunta uzonquma uhlobo olungcono kakhulu lwesikhunta, inani lemigodi edingekayo, nosayizi nokuma kwesikhunta.

Ukwakhiwa kwesikhunta: Isikhunta sakhiwe ngokusekelwe ekwakhiweni kwesikhunta, kusetshenziswa izinto ezisezingeni eliphezulu njengensimbi noma i-aluminium. Isikhunta ngokuvamile senziwa ngama-halves amabili, ngalinye liqukethe imbobo eyodwa noma ngaphezulu.

Ukuhlanganiswa kwesikhunta: Uma isikhunta sesakhiwe, siyahlanganiswa futhi sihlolwe ukunemba nokusebenza. Isikhunta kufanele simelane nokucindezela nokushisa kwenqubo yokubumba umjovo.

Ukuhlolwa kwesikhunta nokuqinisekiswa: Ngemva kokuba isikhunta sesihlanganisiwe, siyahlolwa futhi siqinisekiswe ukuze kuqinisekiswe ukuthi sikhiqiza izingxenye zekhwalithi ephezulu ezihlangabezana nezimfuneko zomkhiqizo. Isikhunta singadinga ukulungiswa noma ukuguqulwa ukuze sithuthukise ukusebenza kwaso.

Ukugcinwa kwesikhunta: Ukugcinwa njalo nokulungiswa kwesikhunta kubalulekile ukuze kuqinisekiswe ukuthi isikhathi eside nokusebenza kwayo. Lokhu kuhlanganisa ukuhlanza, ukugcoba, nokufaka esikhundleni sanoma yiziphi izingxenye ezigugile noma ezilimele.

Amathuluzi okubumba umjovo adinga ukunemba nobungcweti ukuze akhiqize izingxenye zekhwalithi ephezulu ngokungaguquki nangempumelelo. Ngokulandela umklamo ophelele kanye nenqubo yokukhiqiza, abakhiqizi bangenza isikhunta esihlangabezana nezidingo eziyingqayizivele zemikhiqizo yabo futhi bathuthukise izinqubo zabo zokubumba umjovo.

Izinhlobo Zokusebenzisa I-Injection Molding Tooling

Ukubumba umjovo kuyinqubo yokukhiqiza esetshenziswa kabanzi yokukhiqiza izingxenye ngobuningi. Kubandakanya ukujova ipulasitiki encibilikisiwe endaweni yesikhunta bese uyivumela ukuthi iphole futhi iqine ibe yisimo oyifunayo. I-injection molding tooling iyinqubo yokudala isikhunta esisetshenziswa ekubumbeni umjovo. Kunezinhlobo eziningana zamathuluzi okubumba umjovo, ngayinye inezinzuzo zayo kanye nokubi.

- Isikhunta se-Two-Plate Izibunzi ezinamapuleti amabili ziwuhlobo olulula kakhulu lwethuluzi lokubumba lomjovo. Aqukethe amapuleti amabili ahlanganiswe ndawonye ukuze enze isikhunta. Ipulasitiki encibilikisiwe ijova embobeni ngesango futhi ivunyelwe ukuba iphole futhi iqine. Uma ingxenye isidaliwe, amapuleti amabili ahlukaniswa, futhi inani liyakhishwa. Ukubunjwa kwamapuleti amabili kuvame ukusetshenziselwa izingxenye ezincane kuya ezimaphakathi ezinamajiyometri alula.

- Isikhunta se-Three-Plate Isikhunta esinamapuleti amathathu sifana nesikhunta esinamapuleti amabili, kodwa sinepuleti eyengeziwe, eyaziwa ngokuthi i-stripper plate, ehlukanisa ingxenye ebunjiwe ohlelweni lomgijimi. Isistimu yomgijimi iyinethiwekhi yesiteshi eletha ipulasitiki encibilikisiwe emgodini wesikhunta. Isikhunta esinamapuleti amathathu sisetshenziselwa izingxenye ezibalulekile kanye namajiyometri ayinkimbinkimbi.

- Isikhunta se-Hot Runner Ezikhunjini zomgijimi oshisayo, ipulasitiki encibilikisiwe ijova ngqo emgodini wesikhunta ngochungechunge lwamashaneli ashisayo kunokuba ingene esangweni. Lokhu kunciphisa impahla emoshwayo ohlelweni lomgijimi, okuholela kunqubo esebenza kahle kakhulu. Isikhunta somgijimi oshisayo sisetshenziselwa ukukhiqizwa kwevolumu ephezulu yezingxenye eziyinkimbinkimbi.

- Isikhunta Somndeni Isikhunta somndeni sikhiqiza izingxenye eziningi esikhunjeni esisodwa. Zinemigodi ehlukahlukene ehlelwe ngendlela evumela ukukhiqizwa kwezizinda eziningi ngesikhathi esisodwa. Isikhunta somndeni sivame ukusetshenziselwa izingxenye ezinevolumu emincane ukuya kosayizi ophakathi.

- Faka Isikhunta Faka isikhunta sikhiqiza izingxenye ezidinga ukufakwa kwensimbi noma ipulasitiki. Izinto ezifakwayo zifakwa emgodini wesikhunta ngaphambi kokujova ipulasitiki encibilikisiwe. Uma ipulasitiki isipholile futhi iqina, ingxenye kanye nokufakwayo kuboshwe unomphela. Faka isikhunta sisetshenziselwa izikhundla ezidinga amandla, ukuqina, noma ukukhanga kobuhle.

- I-Overmolding Overmolding iyinqubo lapho ingxenye ibunjwa phezu kwenye. Ivamise ukusetshenziselwa izikhundla ezidinga ukuthinta okuthambile noma ukubamba okuthuthukisiwe. Ukweqa kuhlanganisa ukusetha ingxenye engaphansi noma ingxenye eyisisekelo kuqala bese ubumba into yesibili phezu kwayo. Impahla yesibili ingaba uhlobo oluhlukile lwepulasitiki, into efana nerabha, noma i-thermoplastic elastomer.

Sengiphetha, ukukhetha kwamathuluzi okubumba umjovo kuncike ohlotsheni lwengxenye ekhiqizwayo, umthamo wokukhiqiza odingekayo, kanye nezinga lobunkimbinkimbi elihilelekile ekwakhiweni kwengxenye. Ukukhetha amathuluzi afanele kubalulekile ukuqinisekisa ukuthi inqubo isebenza kahle futhi iyonga imali.

Imihlahlandlela yokubumba yokubumba umjovo

Ukubumba umjovo kuyinqubo yokukhiqiza esetshenziswa kabanzi yokukhiqiza izingxenye zepulasitiki. Ukuklama izingxenye zokubumba umjovo kudinga ukuqonda kahle inqubo, izinto zokwakha, kanye nemihlahlandlela yokuklama okufanele ilandelwe ukuze kuqinisekiswe ukuthi imininingwane ingakhiqizwa ngempumelelo. Nansi eminye imihlahlandlela yokubumba umjovo okufanele uyikhumbule:

Ukuqina Kodonga, Ukuqina kodonga lwengxenye kufanele kufane futhi kube mncane ngangokunokwenzeka ngenkathi kugcinwa amandla adingekayo nokusebenza. Lokhu kusiza ukunciphisa isikhathi sokupholisa kanye nomjikelezo futhi kunciphisa ubungozi bokungqubuzana nezimpawu zokucwila.

Izimbambo kanye Nezinduna Izimbambo kanye nabaphathi kungasetshenziswa ukukhulisa amandla nokuqina kwengxenye. Izimbambo akufanele zibe ngaphezu kuka-60% wogqinsi oluvamile lodonga, futhi abaphathi kufanele baphindwe izikhathi ezingu-1.5 ukushuba odongeni okungelona lona.

I-engeli Esalungiswa, I-engeli yokusalungiswa okungenani engu-1-2 degrees kufanele isetshenziswe kuzo zonke izindawo eziqondile ukuze kube lula ukukhishwa kwengxenye nokuvimbela ukulimala kwesikhunta.

Ama-Fillets nama-Radii Sharp amakhona nemiphetho kufanele kugwenywe ukuze kuvinjelwe ukugxiliswa kwengcindezi, okungaholela ekuqhekekeni nasekuhlulekeni. Esikhundleni salokho, ama-fillets nama-radii kufanele asabalalise ukucindezeleka futhi athuthukise amandla engxenye.

Amasango Nabagijimi Indawo nokuklanywa kwamasango nabagijimi kubalulekile ukuze kuzuzwe ingxenye enhle yezinga. Iminyango kufanele ibe mincane ngangokunokwenzeka engxenyeni ewugqinsi kakhulu yengxenye. Abagijimi kufanele bakhelwe ukunciphisa ukwehla kwengcindezi nokwandisa ukugeleza.

I-Surface Finish Indawo engaphezulu yengxenye kufanele icaciswe ngokusekelwe ezidingweni zohlelo lokusebenza. Ukuqedwa okuphezulu kungase kudingeke ezicucu ezibonakalayo, kuyilapho ukuqedwa kwendawo ephansi kungase kwamukeleke ezingxenyeni ezifihliwe.

Ukukhethwa Kwempahla Impahla ekhethelwe ingxenye kufanele ifanele ukubumba umjovo futhi ihlangabezane nemishini edingekayo, eshisayo, kanye nezakhiwo zamakhemikhali.

Imisebenzi Yesibili Ekubumbeni Umjovo

Ukubumba umjovo kuyinqubo yokukhiqiza eguquguqukayo esetshenziselwa ukukhiqiza izingxenye zepulasitiki ezahlukahlukene. Ngokungeziwe enqubweni yokuqala yokubumba, izikhundla eziningi zidinga imisebenzi yesibili ukuze kuzuzwe umumo oyifunayo, ukuqeda, noma ukusebenza. Nansi eminye imisebenzi yansuku zonke yesibili ekubumbeni umjovo:

- Ukunquma ukususa impahla eningi engxenyeni ebunjiwe ngemva kokuthi ikhishiwe esikhunjeni. Lokhu ngokuvamile kwenziwa kusetshenziswa umshini wokunquma noma umshini we-CNC. Ukunquma ngokuvamile kuyadingeka ukuze kuzuzwe ukuma kokugcina nosayizi wengxenye.

- Ukushisela kuhlanganisa izingxenye zepulasitiki ezimbili noma ngaphezulu zisebenzisa ukushisa, ingcindezi, noma inhlanganisela yakho kokubili. Lokhu kuvame ukusetshenziselwa ukudala izici ezinkulu noma eziyinkimbinkimbi ezingakwazi ukukhiqizwa ngesikhunta esisodwa.

- Ukuhlobisa kuyinqubo yokwengeza izici ezibonakalayo noma ezisebenzayo ebusweni bengxenye ebunjiwe. Lokhu kungafaka ukudweba, ukuphrinta, ukulebula, noma ukusebenzisa ukuthungwa noma iphethini.

- Ukuhlanganisa kuyinqubo yokuhlanganisa izingxenye eziningi ukuze udale umkhiqizo ophelele. Lokhu kungenziwa ngokusebenzisa izinsimbi, izinamathiselo, noma ezinye izindlela zokuhlanganisa.

- I-Insert Molding Insert molding ihlanganisa ipulasitiki eduze kwensimbi eyakhiwe ngaphambili noma ipulasitiki. Lokhu kuvame ukusetshenziselwa ukudala izingxenye ezinezinga eliphezulu lamandla noma ukuqina.

- I-Overmolding Overmolding iyinqubo yokubumba into yesibili phezu kwengxenye eyakhiwe ngaphambili. Lokhu kungangeza indawo yokuthinta okuthambile, kuthuthukise ukubamba, noma kudale ucezu olunamathoni amabili noma lezinto eziningi.

- I-coating isebenzisa ungqimba oluncane lwempahla endaweni yengxenye ukuze kuthuthukiswe ukubukeka kwayo, ukuqina, noma ezinye izici. Lokhu kungafaka izinto zokumboza ezifana ne-chrome, i-nickel, noma i-powder coatings.

Izinzuzo Plastic Injection Molding

Ukubumba umjovo wePlastiki kuyinqubo yokukhiqiza esetshenziswa kabanzi yokukhiqiza izingxenye zepulasitiki ngokunemba okuphezulu, ukungaguquguquki, kanye nekhwalithi. Kuhilela ukujova ipulasitiki encibilikisiwe endaweni yesikhunta futhi uyivumele iphole futhi iqine. Nazi ezinye izinzuzo zokubumba umjovo wepulasitiki:

- Ukusebenza Okuphezulu Nokukhiqiza Ukubumba komjovo wePlastiki kuyinqubo esebenza kahle kakhulu futhi ezenzakalelayo engakhiqiza izingxenye ezinkulu zezingxenye ezinokuvumelana okuphezulu nekhwalithi. Ngobuchwepheshe obuthuthukisiwe be-automation, isikhathi somjikelezo wokukhiqiza singancishiswa sibe imizuzwana, okuvumela ukukhiqizwa kwevolumu ephezulu yezingxenye eziyinkimbinkimbi neziyinkimbinkimbi.

- Ukunemba Okuphezulu Nokunemba komjovo ukubumba kukhulisa ukunemba nokunemba ekukhiqizeni izingxenye eziyinkimbinkimbi neziyinkimbinkimbi. Imishini elawulwa ikhompuyutha nesofthiwe ethuthukisiwe inika amandla ukubekezelelana okuqinile okuphindaphindwayo nokunemba okuphezulu.

- I-Versatility Injection molding iyinqubo eguquguqukayo engakhiqiza izinhlobonhlobo zezingxenye zepulasitiki ezinobukhulu obuhlukahlukene, ubujamo, kanye nobunkimbinkimbi. Inqubo ingasetshenziswa ukwenza yonke into kusuka ezingxenyeni ezincane ezinemininingwane eyinkimbinkimbi kuya kumanani amakhulu ngamajiyometri ayinkimbinkimbi.

- I-Material Flexibility Umjovo wokubumba ungasebenzisa inhlobonhlobo yezinto zepulasitiki, okuhlanganisa i-thermoplastics, ama-thermosets, nama-elastomer. Lokhu kuvumela ukukhiqiza izingxenye ezinezakhiwo ezihlukahlukene zemishini, ezishisayo, namakhemikhali.

- I-Low Waste Production Umjovo wokubumba inqubo yokukhiqiza imfucuza encane njengoba idala imfucuza encane ngesikhathi sokukhiqiza. Noma iyiphi impahla eyeqile ingabuyekezwa kalula futhi isetshenziswe kabusha ekukhiqizeni, okuyenza ibe inqubo yokukhiqiza evumelana nemvelo.

- Izindleko Ezincishisiwe Zabasebenzi Izinga eliphezulu lokuzishintshashintsha ekubumbeni umjovo linciphisa isidingo sezinqubo ezidinga abasebenzi abaningi, linciphise kakhulu izindleko zabasebenzi. Lokhu futhi kunciphisa ingozi yephutha lomuntu, ukuthuthukisa ikhwalithi nokuqina komkhiqizo wokugcina.

- Ukusebenza Okuncishisiwe Kwangemva Kokukhiqiza Ukubumba komjovo kukhiqiza izingxenye ezinemba okuphezulu nokungaguquguquki, kunciphisa isidingo semisebenzi yangemva kokukhiqiza efana nokusikwa, ukubhola, noma ukugaya. Lokhu kunciphisa isikhathi sokukhiqiza kanye nezindleko zomkhiqizo wokugcina.

- Ukubumbana nokubumba komjovo wekhwalithi kukhiqiza izingxenye ezinezinga eliphezulu lokungaguquguquki kanye nekhwalithi. Ubuchwepheshe obuthuthukisiwe nemishini elawulwa ngekhompuyutha iqinisekisa ukuthi yonke imininingwane iyafana ngokuma, usayizi, kanye nekhwalithi.

- Ukubunjwa komjovo wokuvumelana nezimo kunikeza izinga eliphezulu lokuguquguquka komklamo, njengoba kuvumela ukukhiqiza izingxenye ezinamajiyometri ayinkimbinkimbi, ama-undercuts, kanye nemininingwane eyinkimbinkimbi. Lokhu kuzokwenza abaklami bakwazi ukudala izingcezu ezinobunjwa obuhlukile nemisebenzi engeke yenziwe kusetshenziswa ezinye izinqubo zokukhiqiza.

- Okungabizi kakhulu kokubumba kwe-High-Volume Production Injection kuyinqubo engabizi kakhulu yokukhiqiza izingxenye zepulasitiki. Izindleko zokuqala zamathuluzi zingaba phezulu, kodwa izindleko zengxenye ngayinye ziyehla njengoba umthamo wokukhiqiza ukhula. Lokhu kwenza kube inqubo ekahle yokukhiqiza izingxenye ezinkulu zezingxenye.

Ukubumba umjovo wePlastiki kunikeza izinzuzo eziningi, okwenza kube ukukhetha okudumile kokukhiqiza izingxenye zepulasitiki. Ukusebenza kwayo okuphezulu, ukunemba, ukuguquguquka, ukuguquguquka kwezinto ezibonakalayo, ukukhiqizwa kwemfucuza ephansi, ukunciphisa izindleko zabasebenzi, nokungaguquguquki kanye nekhwalithi kwenza kube inqubo efanelekile yezinhlelo zokusebenza ezihlukahlukene. Ikhono lokukhiqiza izingxenye eziyinkimbinkimbi neziyinkimbinkimbi ezinokuguquguquka kwedizayini ephezulu kanye nezindleko eziphumelelayo zokukhiqiza umthamo ophezulu kwenza kube inqubo yokukhiqiza efunwa kakhulu.

Ububi bePlastiki Umjovo Molding

Ukubumba umjovo wepulasitiki kuyinqubo yokukhiqiza esetshenziswa kabanzi ebandakanya ukujova ipulasitiki encibilikisiwe endaweni yokubumba ukuze kukhiqizwe izingxenye eziningi zepulasitiki nemikhiqizo. Nakuba ukubumba umjovo wepulasitiki kunezinzuzo eziningi, kubuye kube nokubi. Nazi ezinye zezinkinga ezinkulu zokubumba umjovo wepulasitiki:

- Izindleko eziphezulu zamathuluzi: Izindleko zokuklama nokukhiqiza isikhunta sokubumba umjovo wepulasitiki zingaba phezulu kakhulu. Lokhu kungenxa yokuthi isikhunta sidinga ukwenziwa ngezinto ezisezingeni eliphezulu futhi sifakwe ngomshini ngokunembile ukuze kwakhiwe ingxenye oyifunayo. Ukwengeza, izindleko zokudizayina kanye nokukhiqiza isikhunta zingase zenqabele ukukhiqizwa kwezinga elincane, okwenza ukubumba komjovo wepulasitiki kungabi namali ekukhiqizeni umthamo ophansi.

- Izikhathi zokuhola ezinde: Inqubo yokuklama nokukhiqiza isikhunta sokubumba umjovo wepulasitiki ingathatha isikhathi eside, okungabambezela ukukhiqizwa kwezingxenye zepulasitiki. Lokhu kungaba inkinga ikakhulukazi kumabhizinisi adinga ukuphendula ngokushesha ezinguqukweni ezifunwa yimakethe noma athuthukise ngokushesha imikhiqizo emisha.

- Ukuvumelana nezimo okulinganiselwe: Uma isikhunta sesiklanywe futhi sakhiqizwa, kuba lula futhi kushibhile ukushintsha umklamo noma ukuguqula inqubo yokukhiqiza. Lokhu kungakhawulela ukuguquguquka kokubumba komjovo wepulasitiki futhi kukwenze kungalungeli kakhulu ukukhiqiza imikhiqizo yangokwezifiso noma yohlobo olulodwa.

- Ukukhathazeka ngemvelo: Ukubumba umjovo wepulasitiki kuncike enanini elikhulu lepulasitiki, elingase libe nomthelela ongemuhle kwezemvelo. Imfucuza yepulasitiki iyinkinga enkulu yezemvelo, futhi ukubumba umjovo wepulasitiki kungaba nomthelela kule nkinga. Ukwengeza, inqubo yokukhiqiza imikhiqizo yepulasitiki idinga ukusetshenziswa kwamandla nezinsiza zemvelo, ezingase zibe nomthelela omubi emvelweni.

- Amazinga aphezulu e-Scrap: Ukubumba umjovo wepulasitiki kungakhiqiza izinto ezilahliwe ezibalulekile, ezingabiza ukulahla noma ukugaywa kabusha. Ukwengeza, ukukhiqizwa kwezinto ezilahliwe kungakhuphula izindleko zokukhiqiza zizonke futhi kunciphise ukusebenza kahle kwenqubo yokukhiqiza.

- Izinketho zezinto ezibonakalayo ezinomkhawulo: Ukubumba komjovo wepulasitiki kusetshenziswa ngokuyinhloko ukukhiqiza izingxenye nemikhiqizo evela kuzinto ze-thermoplastic, ezinezakhiwo ezilinganiselwe uma ziqhathaniswa nezinye izinto ezifana nezinsimbi noma izitsha zobumba. Lokhu kungenza ukubumba komjovo wepulasitiki kungafaneleki ezinhlelweni ezidinga amandla aphezulu, ukumelana nezinga lokushisa, noma ezinye izakhiwo ezithuthukile.

Imikhawulo yokubunjwa komjovo wePlastiki

Ngenkathi ukubumba komjovo wepulasitiki kunikeza izinzuzo eziningi, ukulinganiselwa okuthile kuhlotshaniswa nenqubo. Nansi eminye imikhawulo yokubumba umjovo wepulasitiki:

Izindleko Eziphezulu Zokuqala Zokusebenzisa: Izindleko zokuqala zokuklama nokukhiqiza isikhunta zinganyuswa. Isikhunta sidinga ukunemba futhi siqine ukuze simelane nenqubo yokubumba yomjovo ephindaphindiwe, futhi lokhu kungadinga ukutshalwa kwezimali okukhulu kwangaphambili, ikakhulukazi isikhunta esiyinkimbinkimbi noma esikhulu.

Isikhathi Sokuhola: Isikhathi sokuhola sokwenza isikhunta singaba sibalulekile, kusukela emasontweni kuya ezinyangeni, kuye ngobunkimbinkimbi nobukhulu besikhunta. Lokhu kungabangela ukubambezeleka emugqeni wesikhathi wokukhiqiza, ikakhulukazi kumaphrojekthi azwela isikhathi.

Izithiyo Zokuklama: Ukubumba komjovo kunemikhawulo ethile yokuklama okufanele icatshangelwe. Isibonelo, ukufeza ubukhulu bodonga obufanayo kuyo yonke ingxenye kubalulekile ukuze kuqinisekiswe ukugcwaliswa nokupholisa okufanele. Ukwengeza, ama-engeli asalungiswa ayadingeka ezindaweni eziqondile ukuze kunikwe amandla ukukhishwa kalula esibunjeni.

Imikhawulo Yosayizi Wengxenye: Ukubumba komjovo kulungele kakhulu ukukhiqiza izingxenye ezincane kuya ezimaphakathi. Izingxenye ezinkulu zingase zidinge izinto eziyisipesheli kanye nesikhunta esikhudlwana, okunezela ezindleko nokuba yinkimbinkimbi.

Ukukhethwa Kwezinto Ezibalulekile: Nakuba ukubunjwa komjovo kuvumela inhlobonhlobo yezinto zepulasitiki, ukukhetha kwezinto kusanqunyelwe uma kuqhathaniswa nezinye izinqubo zokukhiqiza. Izinto ezincibilika kakhulu noma izici zokugeleza ezingezinhle zingase zingakulungeli ukubumba umjovo.

I-Surface Finish: Inqubo yokubumba umjovo ingase ibangele imigqa elukiwe ebonakalayo noma imigqa yokuhlukanisa phezu kwengxenye. Ukuthola isiphetho sekhwalithi ephezulu kungaba yinselele, futhi ezinye izindlela, njengokupholisha noma ukunameka, zingadingeka.

Ama-Undercuts Alinganiselwe: Ama-undercuts yizici noma imininingwane engxenyeni evimbela ukuba isuswe kalula esibunjeni. Ama-undercuts angenza kube nzima inqubo yokukhipha futhi adinge izici ezengeziwe zesikhunta noma imisebenzi yesibili ukuze kuzuzwe ingxenye yejiyomethri oyifunayo.

Izinketho Zokulungisa Okulinganiselwe: Uma isikhunta sonakalisiwe noma sidinga ukuguqulwa, kungase kubize futhi kudle isikhathi ukulungisa noma ukushintsha isikhunta esikhona. Ngezinye izikhathi, kungase kudingeke ukuba kwenziwe isikhunta esisha, okuholela ezindlekweni ezengeziwe nokubambezeleka.

Ngaphandle kwalokhu kulinganiselwa, ukubumba umjovo wepulasitiki kuseyinqubo yokukhiqiza eguquguqukayo futhi esetshenziswa kabanzi ukukhiqiza izingxenye zepulasitiki. Ngokucubungula ngokucophelela le mikhawulo ngesikhathi sokuklama kanye nezigaba zokuhlela ukukhiqiza, kungenzeka ukunciphisa umthelela wazo futhi kusetshenziswe ngempumelelo izinzuzo zokubumba umjovo.

Izicelo zokubunjwa komjovo wePlastiki

Ukubumba umjovo wepulasitiki kuyinqubo yokukhiqiza eguquguqukayo engakhiqiza izingxenye eziningi zepulasitiki. Nazi ezinye zezicelo zokubumba umjovo wepulasitiki:

- Imikhiqizo Yabathengi: Ukubumba komjovo kusetshenziswa kabanzi ukukhiqiza imikhiqizo ehlukahlukene, njengamathoyizi, i-kitchenware, nezinto zikagesi. Inqubo ingakhiqiza izingxenye zekhwalithi ephezulu ezinamajiyometri ayinkimbinkimbi kanye nobukhulu obunembile, iyenze ibe ilungele imikhiqizo edinga ukubekezelelana okuqinile kanye nokwakheka okuyinkimbinkimbi.

- Izingxenye Zezimoto: Izingxenye eziningi zepulasitiki zemoto, njengezingxenye zedeshibhodi, izibambo zeminyango, nokukhanyisa, zikhiqizwa kusetshenziswa ukubumba komjovo. Inqubo ivumela amavolumu aphezulu okukhiqiza kanye nekhwalithi engashintshi, okwenza kube inketho engabizi kakhulu kubakhiqizi bezimoto.

- Amadivayisi Ezokwelapha: Ukubumba komjovo kuvame ukusetshenziselwa ukukhiqiza imishini yezokwelapha, njengamasirinji, ama-inhalers, nemishini yokuxilonga. Inqubo ingakhiqiza izingxenye ngokunemba okuphezulu nokuvumelana, iqinisekisa ikhwalithi nokuthembeka kwamadivayisi.

- Ukupakisha: Ukubumba komjovo kusetshenziswa kakhulu ukukhiqiza amaphakheji epulasitiki, njengeziqukathi, izivalo, namakepisi. Inqubo ingaba nezingxenye ezinobukhulu obungaguquki kanye nokuqedwa kwekhwalithi ephezulu, okuyenza ilungele ukupakishwa ngokubukeka okukhangayo nokulingana okuvikelekile.

- I-Aerospace kanye Nokuvikela: Ukubumba komjovo kukhiqiza izingxenye ezihlukahlukene ze-aerospace nezokuvikela, njengendawo yangaphakathi yendiza, izibani, nezinhlelo zokuxhumana. Inqubo ingaba nezingxenye ezinezinto ezingasindi, eziqinile, ezizenza zifaneleke izinhlelo zokusebenza ezidinga izilinganiso eziphezulu zamandla nesisindo.

- Ukwakhiwa: Ukubumba umjovo kungakhiqiza izinto zokwakha ezihlukahlukene, njengamathayela epulasitiki, ukufulela, nokuseceleni. Inqubo ingaba nezingxenye ezinobukhulu obungaguquki kanye nokuqedwa kwekhwalithi ephezulu, okwenza kube inketho ekhangayo ezinkampanini zokwakha.

- Ezemidlalo Nokuzijabulisa: Ukubumba komjovo kusetshenziswa kakhulu ekukhiqizeni izinto zezemidlalo, njengamakilabhu egalofu, amarakhethi ethenisi, nezingxenye zamabhayisikili. Inqubo ingakhiqiza izingxenye ezinezinto ezingasindi kanye namajiyometri anembile, iqinisekisa ukusebenza nokuqina kwezisetshenziswa.

Sekukonke, ukubumba komjovo wepulasitiki kuyinqubo yokukhiqiza eguquguqukayo futhi esetshenziswa kabanzi engakhiqiza izingxenye zepulasitiki ezisezingeni eliphakeme zokusetshenziswa okuhlukahlukene. Inqubo ingalungiswa ukuze ihlangabezane nezidingo ezithile zokuklama nokukhiqiza, okuyenza ibe inketho ekhangayo kubakhiqizi bezimboni eziningi.

Imboni Yezimoto kanye Nokubunjwa komjovo wePlastiki

Imboni yezimoto ingumsebenzisi obalulekile wobuchwepheshe bokubumba umjovo wepulasitiki. Inqubo yokubumba umjovo wepulasitiki iguqule ukukhiqizwa kwezingxenye zezimoto kanye nezingxenye, okwenza kube nokwenzeka ukukhiqiza izimo eziyinkimbinkimbi ngokunemba okuphezulu nokunemba. Nazi ezinye zezindlela zokubumba umjovo wepulasitiki osetshenziswa embonini yezimoto:

- Izingxenye zangaphakathi: Ukubumba umjovo wepulasitiki kukhiqiza izici eziningi zangaphakathi, ezihlanganisa izingxenye zedeshibhodi, amaphaneli eminyango, izingcezu zokunquma, nokunye. Lezi zingxenye zingaklanywa zibe nokwakheka nokuthungwa okuyinkimbinkimbi futhi zenziwe ngendlela oyifisayo ukuze zihambisane nesitayela nezidingo zokusebenza zemodeli ngayinye yemoto.

- Izingxenye zangaphandle: Ukubumba komjovo wePlastiki nakho kusetshenziselwa ukukhiqiza izici zangaphandle ezihlukahlukene, kuhlanganise nobhampa, ama-grille, izibuko eziseceleni, nokunye. Lezi zingxenye zingaklanywa ukuthi zimelane nezimo zezulu ezimbi futhi zenziwe ngemibala eminingi kanye nokuqedwa.

- Izingxenye ezingaphansi kwe-hood: Ukubumba komjovo wepulasitiki kukhiqiza izici eziningi ezingaphansi kwe-hood, okuhlanganisa amakhava enjini, amasistimu okungenisa umoya, nezingxenye zesistimu yokupholisa. Lezi zingxenye zidinga izinga lokushisa eliphezulu nokumelana namakhemikhali, okungafinyelelwa ngezinto ze-thermoplastic.

- Izingxenye zikagesi neze-elekthronikhi: Ukubumba komjovo wepulasitiki kukhiqiza izingxenye ezihlukene zikagesi neze-elekthronikhi, okuhlanganisa izixhumi, izindlu, nezinzwa. Lezi zingxenye zidinga ukunemba okuphezulu nokuthembeka, okungafinyelelwa ngokunemba nokuvumelana kokubunjwa komjovo wepulasitiki.

- I-Lightweighting: Ukubumba umjovo wepulasitiki kuvame ukusetshenziselwa ukukhiqiza izingxenye ezingasindi ezisiza ukunciphisa isisindo sisonke semoto, ukuthuthukisa ukusebenza kahle kukaphethiloli kanye nokunciphisa ukungcola. I-Lightweighting nayo ingathuthukisa ukuphathwa nokusebenza kwemoto.

Imboni Yezokwelapha kanye Nokubunjwa Kwemijovo Yepulasitiki

Ukubumba umjovo wepulasitiki kusetshenziswa kabanzi embonini yezokwelapha ukukhiqiza izinhlobonhlobo zemishini yezokwelapha kanye nezingxenye. Inqubo yokubumba umjovo wepulasitiki ivumela ukukhiqizwa kobunjwa obuyinkimbinkimbi ngokunemba okuphezulu nokunemba, okwenza kube indlela ekahle yokukhiqiza yezinhlelo eziningi zezokwelapha. Nazi ezinye zezindlela zokubumba umjovo wepulasitiki osetshenziswa embonini yezokwelapha:

- Imishini yezokwelapha: Ukubumba umjovo wepulasitiki kukhiqiza amathuluzi ezokwelapha ahlukahlukene, okuhlanganisa amathuluzi okuhlinza, amathuluzi okuxilonga, amasistimu okulethwa kwezidakamizwa, njll. Lawa madivayisi ngokuvamile adinga ukunemba okuphezulu nokunemba, futhi ukubumba komjovo wepulasitiki kungahlangabezana nalezi zidingo.

- Izimila: Ukubumba komjovo wePlastiki nakho kusetshenziselwa ukukhiqiza izinhlobo ezihlukahlukene zokufakelwa, okuhlanganisa ukushintshwa kwamalungu, ukufakwa kwamazinyo, nokunye. Lezi zimila zingaklanywa ukuze zihambisane nesimo somzimba wesiguli futhi zikhiqizwe ngezinto ezihambisana ne-biocompatible.

- Imishini yaselabhorethri: Ukubumba umjovo wepulasitiki kukhiqiza amapayipi, ama-microplates, namashubhu okuhlola. Lezi zingxenye zidinga ukunemba okuphezulu nokunemba ukuze kuqinisekiswe imiphumela ethembekile.

- Ukupakisha: Ukubumba komjovo wepulasitiki kusetshenziselwa ukukhiqiza ukupakishwa kwemishini yezokwelapha, okuhlanganisa amasistimu okuvimbela amagciwane kanye nokupakisha ngokwezifiso kwemikhiqizo ngayinye. Lezi zixazululo zokupakisha zingasiza ukugcina ubunyumba nobuqotho bedivayisi yezokwelapha.

- Imishini esetshenziswa kanye: Ukubumba umjovo wepulasitiki kuvame ukukhiqiza izinto ezisetshenziswa kanye njengemijovo, izinaliti, nama-catheter. Lawa madivaysi angenziwa ngevolumu ephezulu ngenani eliphansi futhi angasiza ekuvimbeleni ukusabalala kwezifo ezindaweni zokunakekelwa kwempilo.

Imikhiqizo Yabathengi kanye Nokubunjwa komjovo wePlastiki

Ukubumba komjovo wePlastiki kusetshenziswa kakhulu ekukhiqizeni imikhiqizo yabathengi ngenxa yokuguquguquka kwayo, ukusebenza kahle, nokusebenza kahle kwezindleko. Inqubo yokubumba umjovo wepulasitiki ivumela ukukhiqizwa kobunjwa obuyinkimbinkimbi ngokunemba okuphezulu nokunemba, okwenza kube indlela ekahle yokukhiqiza yezicelo eziningi zabathengi. Nazi ezinye zezindlela zokubumba umjovo wepulasitiki osetshenziswa ngazo ekukhiqizeni imikhiqizo yabathengi:

- Amathoyizi: Ukubumba komjovo wePlastiki kukhiqiza amathoyizi anhlobonhlobo, kusukela emifanekisweni emincane kuya kumasethingi amakhulu okudlala. Inqubo ivumela ukudala imiklamo eyinkimbinkimbi nemininingwane nokwenza amathoyizi ngemibala ehlukahlukene kanye nezinto zokwakha.

- Izimpahla zasendlini: Ukubumba umjovo wepulasitiki kukhiqiza izimpahla zasendlini ezihlukahlukene, okuhlanganisa izitsha zasekhishini, izitsha zokugcina impahla, nezinto zokuhlanza. Le mikhiqizo ingaklanywa ukuthi iqine, ingasindi, futhi ibe lula ukuyisebenzisa.

- Ezogesi: Ukubumba komjovo wepulasitiki kukhiqiza izinto eziningi zikagesi, okuhlanganisa izindlu zamakhompiyutha, amakesi ezingcingo, namashaja. Ukunemba nokunemba kwenqubo kuqinisekisa ukuthi lezi zingxenye zenziwa ngezinga eliphezulu lokungaguquguquki nokuthembeka.

- Imikhiqizo yokunakekelwa komuntu siqu: Ukubumba umjovo wepulasitiki kukhiqiza imikhiqizo yokunakekela eyingqayizivele, ehlanganisa izixubho, izinsingo, nezixubho. Le mikhiqizo idinga ukunemba okuphezulu nokunemba ukuze kuqinisekiswe ukusetshenziswa kalula nokuphepha.

- Izinsiza zezimoto: Ukubumba komjovo wepulasitiki kukhiqiza izinsiza zezimoto, okuhlanganisa izingxenye zedeshibhodi, izibambi zenkomishi, nokunye. Lezi zingxenye zingaklanywa ukuthi zibe lula, ziqine, futhi zimelane nokuguga kokusetshenziswa kwansuku zonke.

Ukucatshangelwa Kwemvelo Ekubunjweni komjovo wePlastiki

Ukubumba umjovo wePlastiki kuyinqubo yokukhiqiza esetshenziswa kakhulu kodwa kunemiphumela ephawulekayo yemvelo. Nazi ezinye zezinto ezicatshangelwayo zemvelo ekubunjweni komjovo wepulasitiki:

- Ukukhethwa kwempahla: Ukukhethwa kwezinto zepulasitiki ezisetshenziswa ekubumbeni umjovo kungaba nomthelela omkhulu emvelweni. Ezinye izinto ziyabola noma zigaywe kabusha, kanti ezinye azikwazi ukubola. Ukusebenzisa izinto ezibolayo noma ezigaywa kabusha kungasiza ukunciphisa umthelela wemvelo wokubumba umjovo wepulasitiki.

- Ukusetshenziswa kwamandla: Ukubumba umjovo wepulasitiki kudinga amandla abalulekile ukuncibilikisa ipulasitiki bese uyijova esibunjeni. Imishini nezinqubo ezonga amandla, njengemishini kagesi nezinhlelo ezivaliwe, zinganciphisa ukusetshenziswa kwamandla kanye nomthelela emvelweni.

- Ukulawulwa kukadoti: Ukubumba umjovo wepulasitiki kukhiqiza imfucuza ngezinto ezisetshenziswa ngokweqile, izingxenye ezinokukhubazeka, nokupakishwa. Izinqubo ezifanele zokulawula imfucuza, njengokugaywa kabusha kanye nokusebenzisa kabusha udoti, kungasiza ekwehliseni umthelela wemvelo wokubumba umjovo wepulasitiki.

- Ukusetshenziswa kwamakhemikhali: Amanye amakhemikhali ekubunjweni komjovo wepulasitiki, njengama-ejenti akhulula isikhunta nezincibilikisi zokuhlanza, angalimaza imvelo. Ukusebenzisa ezinye izindlela ezihambisana nemvelo noma ukunciphisa ukusetshenziswa kwalawa makhemikhali kungasiza ekunciphiseni umthelela wendawo.

- Ukucatshangelwa kokuphela kwempilo: Imikhiqizo yepulasitiki ekhiqizwa ngokubumba umjovo ngokuvamile igcina isendaweni yokulahla imfucumfucu, okungathatha amakhulu eminyaka ukwehlisa izinga. Ukudizayina imikhiqizo yokuthi iphinde isetshenziswe kabusha noma i-biodegradability inganciphisa umthelela wemvelo wokubumba umjovo wepulasitiki.

Ikusasa Lokubumba Umjovo Wepulasitiki

Ikusasa lokubumba umjovo wepulasitiki libukeka lithembisa, njengoba intuthuko kwezobuchwepheshe nezinto zokwakha kulindeleke ukuthi yenze inqubo isebenze kahle, ingabizi kakhulu, futhi iqhubeke. Nawa amanye amathrendi nokuthuthuka okungenzeka kulolonge ikusasa lokubunjwa komjovo wepulasitiki:

- Ukukhiqiza okungeziwe: Ukukhiqiza okungeziwe, okwaziwa nangokuthi ukuphrinta kwe-3D, ubuchwepheshe obusafufusa obunamandla okuguqula ukubumba komjovo wepulasitiki. Ngokusebenzisa ukuphrinta kwe-3D ukuze benze isikhunta, abakhiqizi banganciphisa kakhulu isikhathi nezindleko ezihambisana namasu okudala okwenza isikhunta.

- Ukukhiqiza okuhlakaniphile: Ukukhiqiza okuhlakaniphile, okubandakanya ukuzenzekelayo, ukuhlaziya idatha, nokufunda ngomshini, kulindeleke ukuthi kuguqule ukubumba komjovo wepulasitiki. Abakhiqizi bangathuthukisa ukusebenza kahle, banciphise ukumosha, futhi bakhulise ukukhiqiza ngokusebenzisa izinzwa nokuhlaziya idatha ukuze bathuthukise izinqubo.

- Izinto ezisimeme: Izinto ezisimeme, ezifana ne-bioplastics kanye namapulasitiki agaywe kabusha, ziya ngokuya ziduma embonini yokubumba imijovo yepulasitiki. Lezi zinsiza zinikeza izinzuzo zemvelo futhi zingasiza abakhiqizi ukuthi bahlangabezane nezinhloso zokusimama.

- Ukubumba okuncane: Ukubumba okuncane, okubandakanya ukukhiqiza izingxenye ezincane ngokunemba okuphezulu, kuba bucayi kakhulu ezimbonini ezifana nokunakekelwa kwezempilo kanye ne-electronics. Intuthuko kwezobuchwepheshe nezinto zokwakha kulindeleke ukuthi yenze ukubumba okuncane kufinyeleleke futhi kungabizi kakhulu.

- Ukwenza ngokwezifiso: Njengoba abathengi befuna imikhiqizo yomuntu siqu, ukubumba komjovo wepulasitiki kulindeleke ukuthi kuguquguquke futhi kube ngokwezifiso. Ukuthuthuka kwezobuchwepheshe, njengempendulo yesikhathi sangempela nokufunda komshini, kuzokwenza abakhiqizi bakwazi ukukhiqiza imikhiqizo yangokwezifiso ngokushesha nangempumelelo.

Isiphetho:

Ukubumba umjovo wePlastiki kuyinqubo yokukhiqiza eguquguqukayo futhi ephumelelayo eguqule ukukhiqizwa kwemikhiqizo eminingi. Kusukela kumishini yezokwelapha kuya ezingxenyeni zezimoto, ukubumba komjovo wepulasitiki kunikeza izinzuzo eziningi kunezinye izinqubo zokukhiqiza, okuhlanganisa amanani aphezulu okukhiqiza, ukuguquguquka kokuklama, kanye nokusebenza kahle kwezindleko. Ngokuthuthuka okuqhubekayo kwezobuchwepheshe nezinto zokwakha, ikusasa lokubumba umjovo wepulasitiki libukeka liqhakazile, futhi le nqubo cishe izodlala indima ebaluleke nakakhulu embonini yokukhiqiza eminyakeni ezayo.