Kuyini ukubumba komjovo wepulasitiki

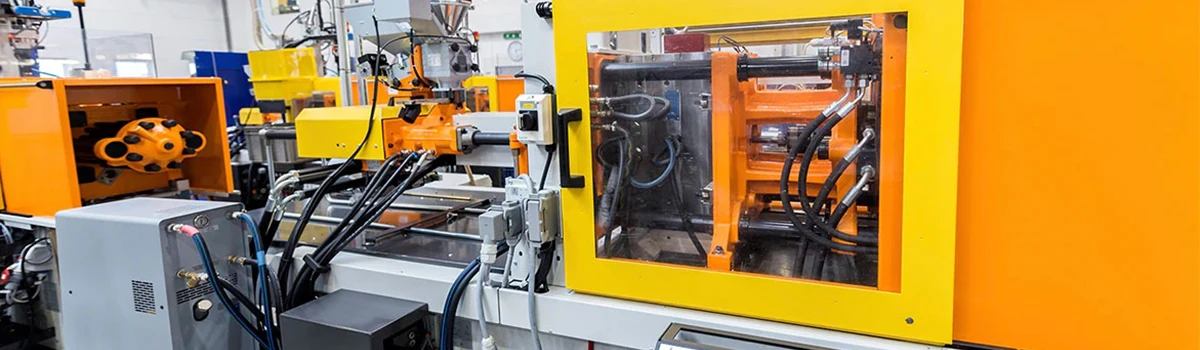

Ukubumba komjovo we-Thermoplastic kuyindlela yokwenza izingxenye zevolumu ephezulu ngezinto zepulasitiki. Ngenxa yokuthembeka nokuguquguquka kwezinketho zokuklama, ukubumba umjovo kusetshenziswa ezimbonini eziningi, okuhlanganisa: ukupakisha, umthengi & electronics, izimoto, ezokwelapha, nokunye okuningi.

Ukubumba umjovo kungenye yezinqubo zokukhiqiza ezisetshenziswa kakhulu emhlabeni. Ama-Thermoplastic ama-polymer athambisayo futhi ageleze lapho kufudumala, futhi aqine njengoba epholile.

Izicelo

Ukubumba umjovo kuyindlela evamile yesimanje yokukhiqiza izingxenye zepulasitiki; ilungele ukukhiqiza imiqulu ephezulu yento efanayo. Ukubumba umjovo kusetshenziselwa ukudala izinto eziningi, okuhlanganisa ama-wire spools, ukupakisha, izigqoko zamabhodlela, izingxenye zezimoto kanye nezingxenye, ama-consoles amageyimu, ama-pocket Combs, izinsimbi zomculo, izihlalo namatafula amancane, iziqukathi zokugcina, izingxenye zemishini, neminye imikhiqizo eminingi yepulasitiki.

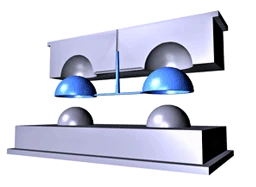

Isikhunta design

Ngemuva kokuthi umkhiqizo uklanywe nge-Software efana nephakheji ye-CAD, isikhunta senziwa ngensimbi, ngokuvamile insimbi noma i-aluminium, futhi yenziwe ngokunemba ukuze kwakhiwe izici zengxenye oyifunayo. Isikhunta siqukethe izingxenye ezimbili eziyinhloko, isikhunta sokujova (i-A plate) kanye nesikhunta se-ejector (B plate). I-resin yepulasitiki ingena esikhunjeni nge-sprue, noma isango, futhi igelezela emgodini wesikhunta ngamashaneli, noma izigijimi, ezifakwe ebusweni bamapuleti A no-B.

Inqubo yokubumba umjovo

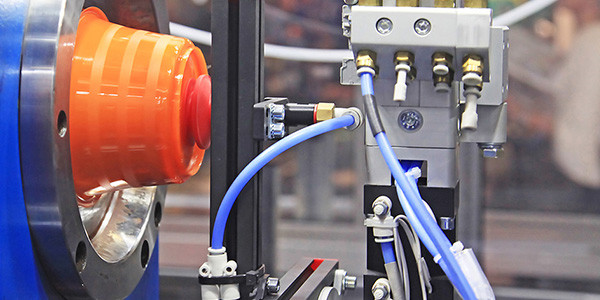

Uma i-thermoplastics ibunjwa, impahla eluhlaza ejwayele ukufakwa ngamapellet idliswa nge-hopper ibe umgqomo oshisayo onesikulufu esiphindaphindayo. Isikulufu siletha impahla eluhlaza phambili, ngevalvu yokuhlola, lapho siqoqa khona ngaphambili kwesikulufu sibe ivolumu eyaziwa ngokuthi ishothi.

Isibhamu yinani le-resin edingekayo ukuze kugcwaliswe umhluzi, umgijimi kanye nemigodi yesikhunta. Lapho impahla eyanele isiqoqiwe, i-material iphoqelelwa ngokucindezela okukhulu kanye nesivinini endaweni eyakha ingxenye.

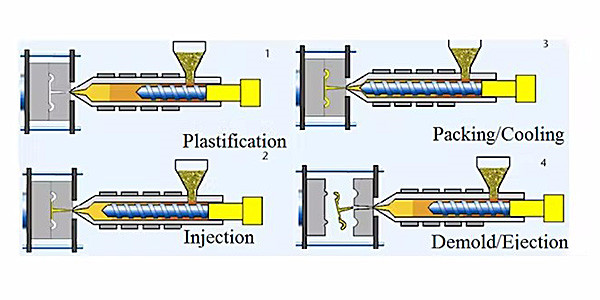

Isebenza Kanjani Ukubumba Umjovo?

Uma ipulasitiki isigcwalise isikhunta okuhlanganisa ama-sprues ayo, abagijimi, amasango, njll., isikhunta sigcinwa ekushiseni okumisiwe ukuze kuvunyelwe ukuqina okufanayo kwezinto zibe yingxenye yomumo. Ukucindezela kokubamba kuyagcinwa ngenkathi kupholisa kokubili ukumisa ukugeleza okubuyela emuva emgqonyeni futhi kunciphise imiphumela enciphayo. Kuleli qophelo, ama-granules epulasitiki amaningi anezelwa ku-hopper ngokulindeleke umjikelezo olandelayo (noma ukudubula). Uma ipholile, i-platen iyavuleka futhi ivumele ingxenye eqediwe ukuthi ikhishwe, futhi isikulufu sidonselwa emuva futhi, okuvumela okubalulekile ukuthi kungene emgqonyeni futhi kuqale inqubo futhi.

Umjikelezo wokubumba umjovo usebenza ngale nqubo eqhubekayo-ukuvala isikhunta, ukondla / ukushisa ama-granules epulasitiki, ukuwacindezela ekubunjeni, ukupholisa kube ingxenye eqinile, ukukhipha ingxenye, nokuvala isikhunta futhi. Lolu hlelo luvumela ukukhiqizwa ngokushesha kwezingxenye zepulasitiki, futhi izingxenye zepulasitiki ezingaphezu kweziyi-10,000 zingenziwa ngosuku lokusebenza kuye ngomklamo, usayizi, kanye nempahla.

Umjikelezo wokubumba umjovo

Umjikelezo wokubumba umjovo mfushane kakhulu, ngokuvamile phakathi kwamasekhondi angu-2 nemizuzu emi-2 ubude. Kunezigaba eziningana:

1.Ukubamba

Ngaphambi kokujova izinto ezibunjweni, ama-halves amabili esikhunta avaliwe, ngokuvikelekile, ngeyunithi yokubopha. Iyunithi yokubamba esebenza nge-hydraulically iphusha izingxenye zesikhunta ndawonye futhi isebenzise amandla anele ukugcina isikhunta sivaliwe ngenkathi okokusebenza kujovwa.

2.Umjovo

Uma isikhunta sivaliwe, isibhamu se-polymer sijova emgodini wesikhunta.

3.Kupholisa

Lapho umgodi ugcwaliswa, kusetshenziswa ingcindezi yokubamba evumela i-polymer eyengeziwe ukuthi ingene emgodini ukuze kunxephezele ukushwabana kwepulasitiki njengoba iphola. Okwamanje, isikulufu siyajika futhi sifake ishothi elandelayo kusikulufu sangaphambili. Lokhu kubangela ukuthi isikulufu sihoxe njengoba kulungiswa isithombe esilandelayo.

4.Ukukhishwa

Lapho ingxenye isipholile ngokwanele, isikhunta siyavuleka, ingxenye iyakhishwa, futhi umjikelezo uqala futhi.

Izinzuzo

1.Ukukhiqiza okusheshayo; 2.Ukuguquguquka komklamo; 3.Ukunemba; 4.Izindleko eziphansi zabasebenzi; 5.Imfucuza ephansi