Faka Ukubumba Umjovo

Faka ukubumba komjovo kuyinqubo yokukhiqiza esetshenziswa kabanzi ekukhiqizeni izingxenye zepulasitiki eziyinkimbinkimbi ezinezingxenye ezishumekiwe. Le nqubo ihlanganisa ukufaka izingxenye zensimbi noma zepulasitiki endaweni yokubumba ngaphambi kwenqubo yokubumba umjovo. Impahla encibilikisiwe ibe isigeleza izungeze into efakiwe, idale isibopho esiqinile phakathi kwezinto ezimbili. Faka ukubumba komjovo kunikeza izinzuzo ezimbalwa, okufaka ukuguquguquka kwedizayini okuthuthukisiwe, isikhathi esincishisiwe sokuhlanganisa, nokusebenza kwengxenye okuthuthukisiwe. Lo mhlahlandlela ophelele uzohlola amasu ahlukene, izinzuzo, kanye nokusetshenziswa kokubumba komjovo wokufaka.

Kuyini Ukubumba Umjovo Wokufaka?

Ukubumba umjovo kuyinqubo yokukhiqiza esetshenziselwa ukwakha izingxenye nemikhiqizo ehlukahlukene. Faka ukubumba komjovo wuhlobo lokubumba lomjovo oluvumela ukufakwa kwezinto esezike zaba khona, noma ukufakwa, esibunjeni ngaphambi kokuba inqubo yokubumba iqale. Le nqubo ivumela ukwakhiwa kwezingxenye ezidinga izici ezithile izindlela zokubumba zendabuko ezingakwazi ukuzifeza.

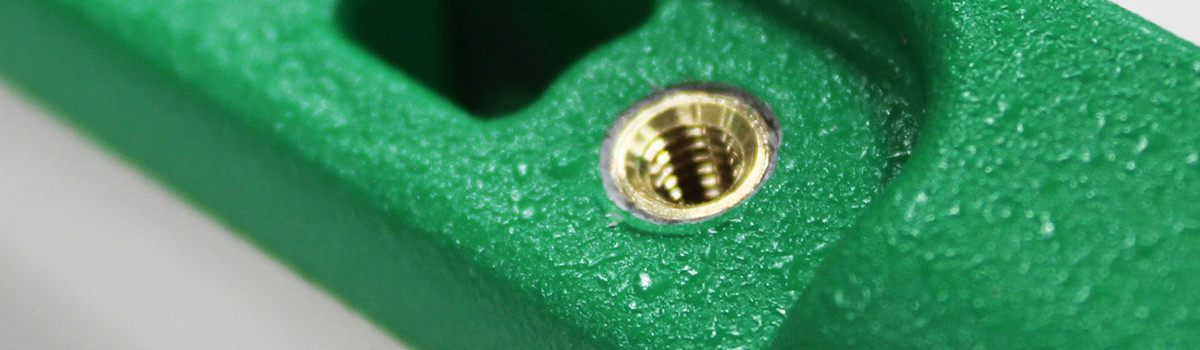

Faka ukubumba komjovo kusebenza ngokubeka okokufaka okwakhiwe ngaphambilini endaweni yokubumba ngaphambi kokuthi inqubo yokubumba iqale. Okufakiwe kungaqukatha izinto ezihlukahlukene, okuhlanganisa insimbi, ipulasitiki, nezitsha zobumba. Inqubo yokubumba iqala njengenjwayelo, kufakwe ipulasitiki encibilikisiwe embotsheni yesikhunta. Njengoba ipulasitiki iphola futhi iqina, ihlangana nokufaka, idale ingxenye eyodwa, ehlanganisiwe.

Kunezinzuzo eziningana zokusebenzisa ukubumba umjovo wokufaka. Enye yezinzuzo eziyinhloko zale nqubo ukuthi ivumela ukudalwa kwezingxenye ezinezici ezithile ezingakwazi ukufeza izindlela zendabuko zokubumba umjovo. Isibonelo, ukufaka ukubumba komjovo kungasetshenziswa uma umsebenzi udinga ukufaka okunentambo noma ingxenye yensimbi ukuze kuqiniswe. Le nqubo iphinde ivumele ukwakhiwa kwezingxenye ezinenhlanganisela yezinto, njengengxenye yepulasitiki enokufakwa kwensimbi.

Enye inzuzo yokubumba umjovo wokufaka ukonga isikhathi nemali. Esikhundleni sokuhlanganisa izingxenye eziningi, ukufaka ukubumba komjovo kwakha ucezu olulodwa, oluhlanganisiwe. Ngokwenza kanjalo, izinkampani zinganciphisa isikhathi nezindleko ezidingekayo zokuhlanganisa.

Faka ukubumba komjovo nakho kuyasiza ekudaleni izingxenye eziyinkimbinkimbi. Ngenxa yokuthi okufakwayo kungafakwa endaweni yokubumba ngaphambi kokuba inqubo yokubumba iqale, kungenzeka ukukhiqiza izingxenye ezinamajiyometri ayinkimbinkimbi nezici okungaba nzima ukuzifeza ngokusebenzisa izindlela ezijwayelekile zokubumba umjovo.

Isebenza Kanjani I-Injection Molding Molding?

Kuwuhlobo lwenqubo yokubumba umjovo evumela ukufakwa kwezingxenye ezakhiwe kusengaphambili, noma ukufakwa, esikhunjeni ngaphambi kokuba inqubo yokubumba iqale. Le nqubo ivumela ukudala izingcezu ezinezici ezithile izindlela zokubumba umjovo zendabuko ezingakwazi ukuzifinyelela futhi ziwusizo ikakhulukazi ekudaleni izingxenye eziyinkimbinkimbi. Lapha sizoxoxa ngendlela yokufaka umsebenzi wokubumba umjovo.

Inqubo yokubumba umjovo wokufaka ibandakanya lezi zinyathelo ezilandelayo:

- Faka Indawo:Isinyathelo sokuqala enqubweni yokubumba umjovo wokufaka ukubeka into efakwe ngaphambilini endaweni yokubumba. Abakhiqizi bangakhiqiza lesi sithako ngezinto ezihlukahlukene, njengensimbi, ipulasitiki, noma izitsha zobumba.

- I-Mold Clamping:Isikhunta siyavalwa futhi sivalwe ngokuboshiwe lapho okufakiwe sekusendaweni. Umgomo uwukugcina ukufakwa endaweni ngesikhathi sokubumba.

- Umjovo we-Molten Plastic:Inqubo yokubumba umjovo ijova ipulasitiki encibilikisiwe endaweni yokubumba. Abakhiqizi bavamise ukushisisa ipulasitiki ibe izinga lokushisa eliphakathi kuka-200 no-300 degrees Celsius, beyinquma ngokusekelwe kupulasitiki othize osetshenzisiwe.

- Ukupholisa kanye Nokuqinisa: Njengoba ipulasitiki iphola futhi iqina, ihlangana nokufaka, idale ingxenye eyodwa, ehlanganisiwe. Isikhathi sokupholisa nokuqiniswa sincike kupulasitiki othize osetshenzisiwe kanye nobunzima bokukhiqiza ucezu.

- Ukuvula Nokukhishwa Kwesikhunta: Uma ingxenye isipholile futhi iqinile, opharetha uvula isikhunta futhi akhiphe into. Khona-ke ucezu lungaqedwa futhi lulungiselelwe ukusetshenziswa.

Kunezinzuzo eziningana zokusebenzisa ukubumba umjovo wokufaka. Ezinye zalezi zinzuzo zihlanganisa:

- Ikhono lokudala izingxenye ezinezici ezithile ezingakwazi ukufeza izindlela ezijwayelekile zokubumba umjovo

- Ama-elementi angenziwa njengesiqeshana esisodwa, esihlanganisiwe, okuholela ekunciphiseni kwesikhathi sokuhlanganisa kanye nezindleko

- Ikhono lokudala izingxenye eziyinkimbinkimbi ezinamajiyometri ayinkimbinkimbi nezici

- Amandla okusebenzisa izinto ezahlukahlukene, kufaka phakathi insimbi, ipulasitiki, kanye ne-ceramics

- Ukubumba umjovo kuyinqubo esebenza kahle kakhulu futhi ephindaphindwayo engakhiqiza izingxenye ezinkulu zezingxenye ngokunemba okuphezulu nokunemba.

Izinhlobo Zokufaka Ezisetshenziswa Ekubumbeni Umjovo

Abakhiqizi bangasebenzisa izinto ezihlukahlukene, kuhlanganise insimbi, ipulasitiki, nezitsha zobumba, ukuze bafake izinto ezifakiwe. Lokhu kufaka kunika amandla ukudalwa kwezingxenye ezinezici ezithile izindlela zokubumba ezijwayelekile ezingakwazi ukuzifeza. Lapha sizoxoxa ngezinhlobo ezahlukene zokufaka ezisetshenziswa ekubumbeni umjovo.

- Izinsimbi Zensimbi:Ukufakwa kwensimbi kuvame ukusetshenziswa ekubunjweni komjovo ukuze kunikeze amandla engeziwe nokuzinza ezingxenyeni zepulasitiki. Ngokuvamile zenziwa ngethusi, insimbi, noma i-aluminium futhi zingacutshungulwa noma zingafundiwe, kuye ngohlelo lokusebenza. Abakhiqizi bangasebenzisa okokufaka kwensimbi ukuze benze izingxenye ezinejometri eyinkimbinkimbi nezici ezidinga amandla aphezulu nokuqina.

- Izinto zePlastiki: Ukufakwa kwepulasitiki kuvame ukusetshenziswa ekubumbeni umjovo ukusekela nokuqinisa izingxenye zepulasitiki. Ngokuvamile zenziwa ngezinto ezisetshenziswayo zenayiloni, i-ABS, noma i-polycarbonate futhi zingakha izingcezu ezinezici ezithile ezifana nokuxhuma okufinyeleleka kalula noma izimbobo ezinentambo. Abakhiqizi bayakwazisa ukufaka kwepulasitiki ngekhono labo lokunikeza izixazululo ezingasindi, ezingabizi kakhulu kanye nokubumba kalula kube izimo nosayizi abahlukahlukene.

- I-Ceramic Insert: Ukufakwa kwe-Ceramic kusetshenziselwa ukubumba umjovo ukudala izingxenye ezidinga amandla aphezulu nokumelana nokuguga. Ngokuvamile zenziwa ngezinto ezifana ne-zirconia noma i-alumina futhi zingasetshenziswa ukukhiqiza izingxenye zezimboni zezimoto, i-aerospace, kanye nezokwelapha. Izithako ze-Ceramic zimelana kakhulu nezinga lokushisa eliphezulu, ukugqwala, nokuhuzuka, okuzenza zilungele izindawo ezinokhahlo.

- Okufakiwe Okuhlanganisiwe: Abakhiqizi bahlanganisa izinto ezimbili noma ngaphezulu, njengensimbi nepulasitiki, futhi bazibumbe ukuze bakhe ukufakwa okuyinhlanganisela, okuholela engxenyeni eyodwa, ehlanganisiwe. Abakhiqizi bangasebenzisa okufakwayo okuhlanganisiwe ukuze bakhe izingcezu ezinezici ezithile ezingeke zifinyelelwe nezindlela ezijwayelekile zokubumba umjovo. Ngaphezu kwalokho, bangakwazi ukwenza ngendlela oyifisayo lokhu okufakwayo ukuze kuhlangatshezwane nezidingo ezihlukile zezinhlelo zokusebenza ezithile.

- Okufakiwe Okuqinisiwe: Ngesikhathi sokubumba umjovo, abakhiqizi babumba bafaka engxenyeni yepulasitiki, okuholela kulokho okwaziwa ngokuthi ukufakwa okubunjwe ngokweqile. Le nqubo ihlanganisa ukwenza ishothi lokuqala lepulasitiki elizungeze okokufaka bese ubeka okwesibili phezu kweshothi yokuqala ukuze udale ingxenye eyodwa, ehlanganisiwe. Abakhi bavame ukusebenzisa izinto ezifakwa ezibunjwe ngokweqile ukuze bakhe izingcezu ezihlanganisa izinto, njengokufaka into efakwa ensimbi engxenyeni yepulasitiki.

I-Metal Insert vs. I-Plastic Insert

Inqubo ihilela ukusebenzisa izingxenye ezakhiwe kusengaphambili, noma izinto ezifakwayo, ezifakwe esikhunjeni ngaphambi kokuba inqubo yokubumba umjovo wepulasitiki iqale. Abakhiqizi bangakwazi ukufaka izinto ngezinto ezihlukahlukene, okuhlanganisa insimbi nepulasitiki, futhi uhlobo ngalunye lunikeza izinzuzo zalo eziyingqayizivele kanye nokubi. Lesi sihloko sizoqhathanisa ukufakwa kwensimbi nepulasitiki futhi sikusize uthole inketho engcono kakhulu yohlelo lwakho lokusebenza.

Izinsimbi Zensimbi

Abakhiqizi bavamise ukusebenzisa izinto ezifakwa ensimbi ekubumbeni ngenxa yamandla abo aphezulu nokuqina. Ngokuvamile zenziwa ngethusi, insimbi, noma i-aluminium futhi zingafakwa intambo noma zingafundiwe, kuye ngohlelo lokusebenza. Ukufakwa kwensimbi kuvame ukusetshenziswa ekubunjweni komjovo ukuze kunikeze amandla engeziwe nokuzinza ezingxenyeni zepulasitiki.

Izinzuzo Metal Insert

- Amandla aphezulu nokuqina

- Ukumelana nokugqoka nokudabuka

- Inganikeza ukusebenza okwengeziwe ngokusebenzisa intambo

- Ilungele izingxenye ezinezidingo eziphezulu zokucindezeleka noma ezithwala umthwalo

Ukungalungi Kokufakwa Kwensimbi

- Izindleko eziphakeme kunokufakwa kwepulasitiki

- Kuyinselele enkulu ukubumba kunokufakwa kwepulasitiki

- Kunzima, okungase kube ukukhathazeka ezinhlelweni ezithile

Plastic Insert

Ukufakwa kwepulasitiki kudumile ekubumbeni ngenxa yokuguquguquka kwazo kanye nokusebenza kahle kwezindleko. Ngokuvamile abakhi bazenza ngezinto ezifana nenayiloni, i-ABS, noma i-polycarbonate, futhi bangakwazi ukuzibumba zibe izimo nosayizi abahlukahlukene. Okufakwayo kwepulastiki kunesisindo esincane futhi kungakha izingxenye ezinezici ezithile, njengokuxhuma kwe-snap-fit noma izimbobo ezinentambo.

Izinzuzo zokufakwa kwePlastiki

- Kuqiza kahle

- Okulula

- Ibunjwe kalula ibe yizinhlobonhlobo zomumo nosayizi

- Ilungele izingxenye ezinengcindezi ephansi noma izidingo zokuthwala umthwalo

Ububi bePlastiki Ifaka

- Ihlala isikhathi eside kunokufakwa kwensimbi

- Ayilungele izingxenye ezinengcindezi ephezulu noma izidingo ezithwala umthwalo

- Kungase kube lula ukuguga futhi kudabuke ngokuhamba kwesikhathi

Ungakhetha Nini Izinsimbi Zensimbi

Izinsimbi zensimbi zihamba phambili ezingxenyeni ezidinga amandla aphezulu nokuqina, njengoba zimelana nokuguga futhi zinikeza ukusebenza okwengeziwe kokucutshungulwa. Izinsimbi zensimbi nazo zilungele imisebenzi enezidingo eziphezulu zokucindezeleka noma ezithwala umthwalo. Kodwa-ke, zibiza kakhulu kunokufakwa kwepulasitiki futhi kungase kube nzima kakhulu ukubumba.

Izinhlelo zokusebenza ezingase zidinge ukufakwa kwensimbi zihlanganisa

- Izingxenye zezimoto kanye ne-aerospace

- Amadivayisi ezokwelapha

- Imishini yezimboni

- Ama-electronics abathengi

Ungakhetha Nini Izithako Zepulasitiki

Ukufakwa kwepulasitiki kuyabiza futhi kuguquguquka ezingxenyeni ezinengcindezi ephansi noma izidingo ezithwalayo. Babonisa izici ezingasindi; abakhiqizi bangawabumba abe yizimo nobukhulu obuhlukahlukene. Ukufakwa kwepulastiki nakho kulungele izindawo ezidinga izici ezithile ezifana nokuxhuma kwe-snap-fit noma izimbobo ezinentambo. Kodwa-ke, zingadinga ukuthi zifaneleke kakhulu ngemininingwane enezimfuneko eziphezulu zokucindezeleka noma ezithwala umthwalo.

Izicelo ezingase zidinge ukufakwa kwepulasitiki kufakwe

- Izimpahla zabathengi

- Izinto zasendlini

- Amathoyizi nemidlalo

- Electronics

Izinzuzo Zokubumba Umjovo Wokufaka

Faka ukubumba komjovo kuyinqubo yokukhiqiza edumile ehlanganisa izingxenye ezakhiwe kusengaphambili noma izinto ezifakwa esikhunjeni ngaphambi kokuba inqubo yokubumba yomjovo wepulasitiki iqale. Le nqubo inikeza izinzuzo eziningi phezu kwezindlela zokubumba zendabuko, okwenza kube ukukhetha okudumile kwezinhlelo zokusebenza ezihlukahlukene. Lesi sihloko sizoxoxa ngezinye zezinzuzo eziyinhloko zokufaka ukubunjwa komjovo.

- Kuqiza kahle: Faka ukubumba komjovo kungaba yisixazululo sokukhiqiza esingabizi kakhulu ngoba siqeda isidingo sokuhlangana kwangemuva kokubumba kwezingxenye ezihlukene. Ngokuhlanganisa ukufakwa ngesikhathi sokubunjwa, abakhiqizi banganciphisa izindleko zabasebenzi kanye nokuhlanganisa ngenkathi bekhulisa ukusebenza kahle kokukhiqiza.

- Amandla engxenye athuthukisiwe: Faka ukubumba komjovo kungathuthukisa amandla nokuqina kwezingxenye ngokusebenzisa izinto ezihlukene ezindaweni ezahlukene zesiqephu. Lesi sici singaba yinzuzo ikakhulukazi ezinhlelweni zokusebenza ezidinga imininingwane yokubekezelela izimfuno eziphezulu zestress noma ezithwalayo.

- Ukwandisa ukuguquguquka kwedizayini: Faka ukubumba komjovo kunikeza ukuguquguquka okukhulu komklamo, njengoba kwakha izingxenye eziyinkimbinkimbi ezinezici eziningi nemisebenzi. Le nqubo ifaneleka kahle imiklamo eyinkimbinkimbi kanye nejometri, okwenza kube ukukhetha okuhle kwemininingwane enjalo.

- Ukuvumelana nokunemba: Faka ukubumba komjovo kunikeza ukuvumelana okuhle kakhulu nokunemba ekukhiqizeni okuyingxenye. Sibeka kahle okufakwayo esenziwe ngaphambilini esikhunjeni, siqinisekisa ukubekwa kwazo ngokwezidingo zengxenye ngayinye. Ngenxa yalokho, sifinyelela ubukhulu obufanayo kanye nokulawulwa kwekhwalithi okukhethekile ezingcezu ezikhiqiziwe.

- Isikhathi somjikelezo esincishisiwe: Faka ukubumba komjovo kunganciphisa isikhathi somjikelezo ngokuhlanganisa izinyathelo eziningi zibe yinqubo eyodwa. Le ndlela ingonga isikhathi futhi ithuthukise ukukhiqiza, ikakhulukazi uma usebenzelana nokugijima kokukhiqiza kwevolumu ephezulu.

- Izinhlobonhlobo zezinto: Faka ukubumba komjovo kungasetshenziswa ngezinto ezahlukahlukene, kufaka phakathi ipulasitiki, insimbi, ne-ceramic. Abakhiqizi manje bangakhetha okokusebenza okufaneleka kakhulu kwanoma yiluphi uhlelo lokusebenza ngokucabangela amandla, ukuqina, kanye nezindleko.

- Izinzuzo zemvelo: Faka ukubumba komjovo kunganikeza izinzuzo zemvelo ngokunciphisa udoti nokunciphisa ukusetshenziswa kwezinto. Ngoba sibeka ngokunembile okokufaka esikhunjeni, sithola imfucuza yezinto ezibonakalayo kunezindlela zokubumba ezivamile. Ukwenza lokhu kungaholela ekwehleni komthelela kwezemvelo kanye nokwehliswa kwezindleko zokukhiqiza.

Ukucatshangelwa Kwedizayini Yokufaka Ukubumba

Faka ukubumba kuyinqubo yokukhiqiza edumile ebandakanya ukuhlanganiswa kokufakwayo okwenziwe kusengaphambili kunqubo yokubumba umjovo wepulasitiki. Le nqubo ihlinzeka ngezinzuzo eziningi, okuhlanganisa amandla engxenye athuthukisiwe, izindleko zokuhlanganisa ezincishisiwe, nokwenyuka kokuguquguquka komklamo. Kodwa-ke, ukuklama izingxenye zokufaka ukubumba kudinga ukucatshangelwa ngokucophelela kwezici eziningana ukuze kuqinisekiswe ukukhiqizwa okuphumelelayo nokusebenza kahle. Lesi sihloko sizoxoxa ngezinye zezinto ezibalulekile zokucatshangelwa kwesakhiwo sokufaka ukubumba.

- Faka Indawo: Ukubekwa kokufakwa ngaphakathi kwesikhunta kubalulekile empumelelweni yenqubo yokubumba yokufaka. Ukufakwa kufanele kumiswe ngokunembile ngaphakathi kwesikhunta ukuze kuqinisekiswe ukuthi impahla yepulasitiki ihlanganisa ngokugcwele ngesikhathi sokubumba. Abaklami kufanele futhi baqinisekise ukuthi okufakiwe akuphazamisi ukuhamba kwezinto zepulasitiki noma kubangele izinkinga zomugqa wokuhlukanisa.

- Ukuhambisana Kwezinto: Ukukhethwa kwezinto zokufakwayo kanye nezinto zepulasitiki kubalulekile empumelelweni yenqubo yokubumba yokufaka. Izinto ezisetshenziswayo kumele zihambisane ukuze kuvinjwe izinkinga zebhondi noma ukungezwani kwezinto. Abaklami kufanele bacabangele ngokucophelela izici ezibonakalayo, njengendawo yokuncibilika, ukuncipha, kanye ne-coefficient yokunwetshwa kwe-thermal, ukuze baqinisekise ukubumba okufakiwe okuphumelelayo.

- Ingxenye yeJiyomethri: Ijiyomethri yengxenye ingenye ukucatshangelwa okubalulekile ekubumbeni kokufaka. Idizayini kufanele ivumele ukugcwaliswa okufanele kanye nokupakishwa kwempahla yepulasitiki ezungeze okufakiwe ukuze kuqinisekiswe ukuthi ihlanganisa ngokugcwele. Ijiyomethri yengxenye kufanele futhi ivumele umoya owanele kanye nokupholisa ukuze kuvinjelwe noma yiziphi izinkinga ezihambisana nokungqubuzana, ukushwabana, noma amamaki okucwila.

- Ama-engeli asalungiswa kanye nama-Undercuts: Ukuba khona kwama-engeli asalungiswa kanye nama-undercuts kungathinta ukubumbeka kwengxenye ekubumbeni kokufaka. Abaqambi kufanele bacabangele ngokucophelela ukubekwa kanye nejiyomethri yama-engeli asalungiswa kanye ne-undercuts ukuze baqinisekise ukuthi bangasusa kalula okufakiwe esikhunjeni ngaphandle kokudala umonakalo engxenyeni noma isikhunta.

- Ukucatshangelwa kwamathuluzi: Amathuluzi adingekayo ekubumbeni kokufaka kungaba yinkimbinkimbi kunezindlela zokubumba ezivamile. Abaklami kufanele bacabangele ngokucophelela idizayini yesikhunta, okuhlanganisa ukubekwa nejiyomethri yokufakwayo, indawo yokungena nokukhipha umoya, nanoma yiziphi izenzo ezidingekayo eziseceleni. Ukwengeza, ithuluzi kufanele likwazi ukugcina ukubekezelelana okuqinile ukuze kuqinisekiswe ukufakwa okufanele kokufakwayo futhi kuvimbele noma yiziphi izinkinga ngengxenye yekhwalithi.

Izinto Ezisetshenziswa Ekubumbeni Umjovo Wokufaka

Faka ukubumba komjovo kuyinqubo ekhetheke kakhulu ekhiqiza izingxenye eziyinkimbinkimbi ngokunembile nangokungaguquguquki. Le nqubo ibandakanya ukusebenzisa izici esezakhiwe ngaphambili ezibizwa ngokuthi ama-insert, afakwa esibunjeni ngaphambi kokubumba komjovo. Lokhu kufaka kungenziwa ngezinto ezihlukahlukene, ngayinye enezakhiwo eziyingqayizivele kanye nezinzuzo. Lapha sizoxoxa ngezinto ezivame kakhulu ezisetshenziswa ekufakeni umjovo wokubumba kanye nezinzuzo zazo.

Metals

Ukubumba komjovo kusebenzisa kakhulu izinto ezifakwayo ezenziwe ngezinsimbi ezifana nensimbi, i-aluminium, nethusi. Lezi zinto zinikeza amandla amahle kakhulu nokuqina, okuzenza zilungele izingxenye ezidinga ukuguga okuphezulu nokungagugi. Ngaphezu kwalokho, izinsimbi ezifakwayo zingamelana namazinga okushisa aphezulu, zizenze zifaneleke ukusetshenziswa ezinsizeni ezinzima njengezimboni ze-aerospace nezimboni zezimoto. Ezinye zezinzuzo ezithile zokusebenzisa izinsimbi zensimbi ekubumbeni umjovo zihlanganisa:

- Amandla aphezulu nokuqina

- Ukumelana nokushisa okuhle kakhulu

- Ukumelene nokushisa

- Ikhono lokumelana nokucindezela okukhulu nokucindezeleka

Plastics

Ukufakwa kwepulasitiki nakho kuvame ukusetshenziswa ekubumbeni umjovo, ngezinto ezifana ne-PEEK, PTFE, kanye ne-UHMW okuyizinketho ezidumile. Lezi zinto zinikeza izinga eliphezulu lokumelana nokushisa, ukumelana namakhemikhali, kanye nezakhiwo eziphansi zokungqubuzana. Lezi zingxenye zifaneleka kahle ukuthi zisetshenziswe kumishini yezokwelapha kanye nokukhiqizwa kwe-semiconductor ngenxa yokunemba kwazo okuphezulu nokuhlanzeka, okuyizinto ezibalulekile kulezo zinhlelo zokusebenza. Ezinye zezinzuzo ezithile zokusebenzisa ukufaka ipulasitiki ekubumbeni umjovo zifaka:

- Ukumelana namakhemikhali aphezulu

- Ukumelana nokushisa okuhle kakhulu

- Izici zokungqubuzana okuphansi

- Kulula ukwenza umshini nokuma

Ceramics

Ekubumbeni umjovo, izinto ezifakwa nge-ceramic zithola ukusetshenziswa ngenxa yamandla azo aphezulu, ubulukhuni, nokumelana nokuguga. Lezi zinto zilungele ukusetshenziswa ezinhlelweni lapho ingxenye idinga ukumelana namazinga okushisa aphezulu noma izindawo ezinokhahlo. Ngaphezu kwalokho, ukufakwa kwe-ceramic kunikeza ukuzinza okuhle kakhulu kwe-dimensional, okubenza bafanelekele izinhlelo zokusebenza zobunjiniyela obunembayo. Ezinye zezinzuzo ezithile zokusebenzisa ukufaka i-ceramic ekubumbeni umjovo zifaka:

- Amandla aphezulu nobulukhuni

- Ukumelana nokugqoka okuhle kakhulu

- Ukushisa okukhulu okushisa

- Ukuzinza kobukhulu

Izingqungquthela

Izinto ezihlanganisiwe, ezifana ne-carbon fibre noma i-fiberglass, zisetshenziswa ekubumbeni umjovo ngesilinganiso sazo esikhulu samandla nesisindo. Izimboni ze-aerospace nezezimoto zivame ukusebenzisa lezi zinto lapho ukunciphisa isisindo kubaluleke kakhulu. Okufakiwe okuyinhlanganisela kunikeza ukuqina okukhulu namandla, okuwenza alungele izinjini zomoya kanye nezicelo zemishini yezemidlalo esebenza kahle. Ezinye zezinzuzo ezithile zokusebenzisa izinto ezihlanganisiwe ekubumbeni umjovo zihlanganisa:

- Isilinganiso esiphakeme samandla kuya kwesisindo

- Ukuqina okuphezulu namandla

- Ukumelana nomthelela omuhle

- I-coefficient ye-expansion ephansi yokushisa

Rubber

Izinto zenjoloba, njenge-silicone noma i-neoprene, zisetshenziselwa ukubumba umjovo ngenxa yokuguquguquka kwazo kanye nezakhiwo zokuvala. Lezi zinto zivame ukusetshenziswa ezimbonini zezokwelapha nezezimoto lapho ukubekwa uphawu kanye ne-cushioning kubalulekile. Ukufakwa kwenjoloba kunikeza ukumelana okuhle kakhulu namakhemikhali namazinga okushisa aphezulu, okuwenza alungele ukusetshenziswa ezindaweni ezinokhahlo. Ezinye zezinzuzo ezithile zokusebenzisa ukufaka irabha ekubunjweni komjovo zifaka:

- Izakhiwo ezinhle zokuvala uphawu

- Ukuguquguquka okuphezulu

- Ukumelana namakhemikhali nokushisa

- Ukudlidliza okuhle

Foam

Izinto zegwebu, njenge-polyurethane noma i-polystyrene, zisetshenziswa ekubunjweni komjovo ngenxa yezakhiwo zazo ezingasindi futhi ezimunca ukushaqeka. Lezi zinto zivame ukusetshenziswa ezimbonini zokupakisha nezezimoto lapho ukugcinwa kanye nokumelana nomthelela kubalulekile. Ukufakwa kwegwebu kunikeza ukwahlukanisa okuphezulu, okuwenza alungele izinhlelo zokusebenza ezizwelayo kukushisa. Ezinye zezinzuzo ezithile zokusebenzisa ukufakwa kwegwebu ekubumbeni umjovo zifaka:

- Ilula futhi iyavumelana nezimo

- Ukumuncwa okuhle kakhulu

- Izici ezinhle ze-insulation

- Ikhono layo lokubumba libe yizimo eziyinkimbinkimbi

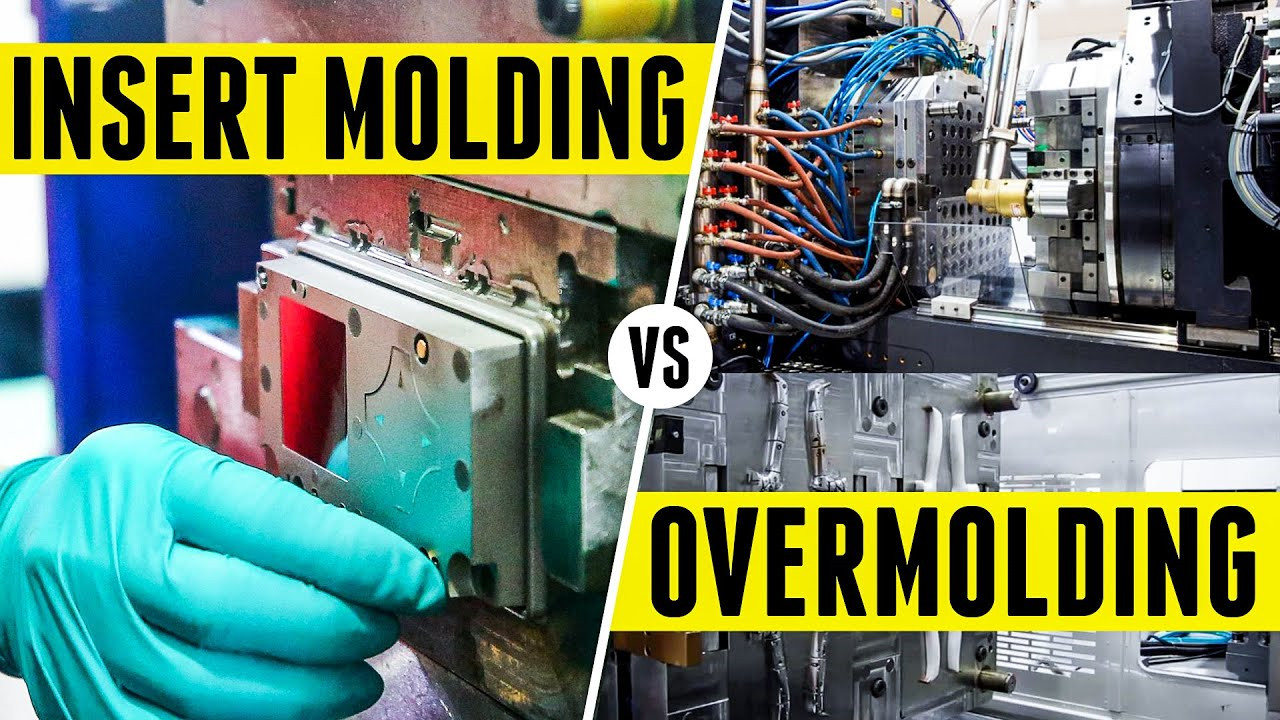

Faka Ukubunjwa vs. Overmolding: Uyini Umehluko?

Faka ukubumba kanye nokunqwabelana ngokweqile yizinqubo ezimbili ezivame ukusetshenziswa ekubumbeni umjovo ezibandakanya izinto eziningi. Nakuba lezi zinqubo zingase zibonakale zifana, zinokuhluka okuthile okuyisisekelo. Lapha sizoxoxa ngomehluko phakathi kokubunjwa kokufaka nokubunjwa ngokweqile.

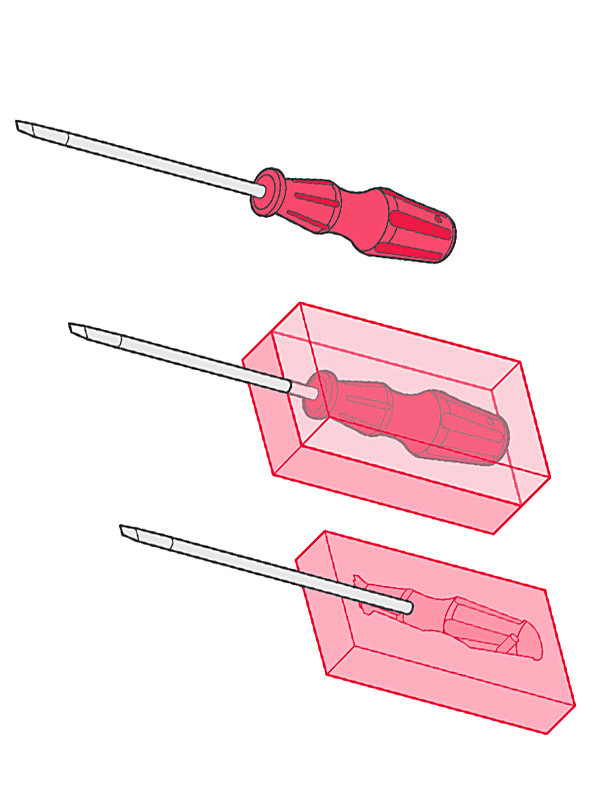

Faka Ukubumba

Faka ukubumba kuyinqubo ebandakanya ukufakwa kwezingxenye ezakhiwe ngaphambili, ezaziwa ngokuthi zifakwa, esikhunjeni ngaphambi kokuba inqubo yokubumba yomjovo yenzeke. Izinto zepulasitiki zibe sezijovwa nxazonke zokufaka, zenze umkhiqizo ophelile ohlanganisa izakhiwo zokufaka kanye nezinto zepulasitiki. Le nqubo ivamise ukusetshenziswa embonini yezimoto, yezokwelapha, neye-aerospace ukuze kwakhiwe izingxenye ezinezinga eliphezulu lokunemba.

Izinzuzo zokufaka ukubumba

- Ukunemba okuphezulu nokunemba

- Amandla engxenye athuthukisiwe nokuqina

- Isikhathi sokuhlanganisa esincishisiwe nezindleko

- Ikhono lokuhlanganisa izinto ezinezakhiwo ezahlukene

Okweqile

I-overmolding iyinqubo ebandakanya ukubumba umjovo wento yesibili phezu kwengxenye ekhona ngaphambili. Abakhiqizi basebenzisa le nqubo ukuze bakhe izibambo zokuthinta ezithambile, izibambo, neminye imikhiqizo yabathengi. Izinto ezibunjwe ngokweqile ngokuvamile zithambile futhi zifana nerabha, zinikeza ukubamba okuthuthukisiwe nokunethezeka. Ngokuya ngobunkimbinkimbi bengxenye, singenza ukubumba ngokweqile ngenqubo yokushutha okukodwa noma okubili.

Izinzuzo zokubumba ngokweqile

- I-ergonomics ethuthukisiwe ne-aesthetics

- Ukubamba okuthuthukisiwe nokunethezeka

- Isikhathi sokuhlanganisa esincishisiwe nezindleko

- Ikhono lokuhlanganisa izinto ezinezakhiwo ezahlukene

Umehluko phakathi kokubumba okufakiwe nokubunjwa ngokweqile

- Ukufaka ukubumba kuhilela ukufakwa kwezingxenye ezakhiwe ngaphambili, kuyilapho ukugoqa ngokweqile kuhlanganisa ukubunjwa komjovo wento yesibili phezu kwengxenye ekhona ngaphambili.

- Sisebenzisa ukubumba okufakiwe ukuze sidale izingcezu ezinezinga eliphezulu lokunemba, kuyilapho sisebenzisa ukubumba okungaphezulu ukuze sithuthukise i-ergonomics nobuhle bomkhiqizo.

- Faka ukubumba kuhlanganisa ukuhlanganisa izinto ezinezici ezihlukene, kuyilapho ukubumba ngokweqile kuhilela ukusebenzisa into ethambile, efana nerabha engxenyeni ebunjwe kakhulu.

- Ukubumba okufakiwe kuvame ukusetshenziswa embonini yezimoto, yezokwelapha, neye-aerospace, kuyilapho ukubumba ngokweqile kuvame ukusetshenziswa emikhiqizweni yabathengi njengamathuluzi, izinto zikagesi, nezinto zokunakekela umuntu.

Amasu Okufaka Indawo

Faka ukubumba kuyinqubo lapho izingxenye ezenziwe ngaphambilini, noma izinto ezifakiwe, zifakwa esikhunjeni ngaphambi kokuba inqubo yokubumba yomjovo yenzeke. Izinto zepulasitiki zijovwa nxazonke zokufaka ukuze kwakhiwe umkhiqizo oqediwe. Ukubeka izinto ezifakiwe kubalulekile empumelelweni yenqubo yokubumba yokufaka. Lapha sizoxoxa ngamanye amasu okufaka ukufakwa.

- Ukubekwa mathupha: Umsebenzisi ubeka ngesandla okokufaka esikhunjeni kule nqubo. Abakhiqizi bavamise ukusebenzisa le ndlela ezingxenyeni ezincane noma eziqondile ezidinga ukufakwa okumbalwa kuphela. Kodwa-ke, kungase kudle isikhathi futhi kusebenze kanzima, futhi kunengozi enkulu yephutha ngenxa yokubeka ngesandla.

- Ukubekwa okuzenzakalelayo: Kule nqubo, okufakwayo kufakwa esikhunjeni kusetshenziswa isistimu yekhompyutha, njengerobhothi noma umshini wokukhetha nendawo. Le nqubo iyashesha futhi inembe kakhulu kunokubekwa mathupha, okuyenza ifanelekele ukugijima okukhulu kokukhiqiza noma izingxenye eziyinkimbinkimbi. Kodwa-ke, kudinga ukutshalwa kwezimali kokuqala kumishini futhi kungase kudinge ukonga kakhulu ekukhiqizeni okuncane.

- Faka i-molding over-molding: Sibeka okufakwayo engxenyeni yesibili, ehlanganiswe ngokweqile bese siyibeka ekubunjweni okuyinhloko. Abakhiqizi bavamise ukusebenzisa le nqubo ngezimangalo ezinejometri eyinkimbinkimbi noma izindawo okunzima ukuzifinyelela. Ingakwazi futhi ukuhlanganisa izinto ezinezici ezihlukene, ezifana nokufakwa kwepulasitiki okuqinile ngezinto ezibunjiwe ezithambile.

- I-Adhesive-backed inserts:Kule nqubo, sigcoba ngaphambili okufakiwe ngokusekela okunamathelayo, okusivumela ukuthi sikubeke esikhunjeni ngaphandle kokudinga ukubekwa okwenziwa ngesandla noma okuzenzakalelayo. I-adhesive backing iyancibilika ngesikhathi sokubunjwa komjovo, ibophe okokufaka ezintweni zepulasitiki. Le nqubo ivame ukusetshenziselwa izingxenye ezincane, ezilula futhi inganciphisa isikhathi sokukhiqiza kanye nezindleko.

- Okufakiwe okunemicu: Kule nqubo, ukufakwa okufakwe intambo kufakwa esikhunjeni futhi kusetshenziselwa ukwakha izintambo kumkhiqizo oqediwe. Abakhiqizi bavamise ukusebenzisa le ndlela ekukhiqizeni imikhiqizo edinga ukufakwa isikulufu noma ibhawudi, njengezinto zikagesi noma izingxenye zezimoto.

Izinhlobo Zemishini Yokubumba Yokufaka Umjovo

Enye yezingxenye ezibalulekile zenqubo yokubumba umjovo umshini wokubumba umjovo. Le mishini iza ngezinhlobo ezahlukene, ngamunye unezici ezihlukile kanye nezinzuzo. Lapha sizobheka izinhlobo ezahlukene zemishini yokubumba umjovo.

Okokuqala, ake sichaze ukuthi uyini umshini wokubumba umjovo wokufaka. Umshini wokubumba umjovo owufaka uwumshini wokubumba umjovo ovumela ukufakwa kwezingxenye ezakhiwe kusengaphambili, njengokufakwa kwensimbi noma kwepulasitiki, esikhunjeni ngaphambi kokujova okubalulekile kwepulasitiki. Ngaleli khono, kuba nokwenzeka ukwenza izingxenye eziyinkimbinkimbi ezidinga izici ezengeziwe ezifana nezimbobo ezinentambo noma izisekelo zensimbi.

Nazi izinhlobo ezahlukene zemishini yokubumba yokufaka umjovo:

- Imishini yokubumba umjovo oqondile:Le mishini inomklamo wokuma mpo, lapho ikhweza khona isikhunta sibheke phezulu. Zilungele ukufaka ukubunjwa ngoba zivumela ukufakwa kalula kwe-insert ku-mold kusuka phezulu. Lolu hlobo lomshini luphinde luthathe indawo encane yaphansi futhi lufaneleka kangcono ukugijima kokukhiqiza okuncane.

- Imishini yokubumba evundlile yomjovo:Le mishini inomklamo wokuma okuyisicaba, lapho ikhweza khona isikhunta sivundlile. Banikeza ukufaneleka okungcono kakhulu kokusebenza kokukhiqiza okukhudlwana, futhi abakhiqizi ngokuvamile bawasebenzisela ukukhiqiza izingxenye ezibaluleke kakhulu. Ngemishini enezingqimba, okufakiwe kungalayishwa ukusuka ohlangothini, okwenza kube inselele kakhulu ukuqinisekisa ukuqondanisa okufanele.

- Imishini yokubumba i-Rotary table injection:Le mishini inetafula elijikelezayo elivumela ukubunjwa okuningi ukuthi kufakwe futhi kujikelezwe kuyunithi yomjovo ukuze kukhiqizwe. Lolu hlobo lomshini lulungele ukufaka ukubunjwa ngoba luzokwenza ukuthi ukufakwa okuhlukahlukene ku-mold, kudala izingxenye eziyinkimbinkimbi.

- Imishini yokubumba umjovo weShuttle: Le mishini ine-shuttle ehambisa isikhunta emuva naphambili phakathi kweyunithi yomjovo nendawo yokubumba. Zifaneleka kakhulu ekugijimeni kokukhiqiza okuncane futhi zilungele ukufaka ukubumba ngoba zivumela ukulayisha kalula nokulayishwa kwezinto ezifakiwe.

Amapharamitha Okucubungula Wokufaka Ukubumba

Umkhiqizo ovelayo unamandla amakhulu nokuqina uma kuqhathaniswa nokubunjwa komjovo wendabuko. Imingcele yenqubo yokubumba yokufaka ibalulekile ekuzuzeni imiphumela yekhwalithi ephezulu nengaguquguquki. Lapha sizobheka amapharamitha enqubo yokufaka ukubumba.

- Ukukhetha Okubalulekile: Ukukhetha impahla kuyipharamitha yenqubo ebalulekile yokubunjwa kokufaka. Impahla yepulasitiki kufanele ihambisane nempahla yokufaka kanye nesicelo. Ukuhambisana kuqinisekisa ukuthi okufakiwe kanye nezinto zepulasitiki kunamathela kahle, okuholela kumkhiqizo oqinile futhi ohlala njalo.

- Ukushisa: Izinga lokushisa lidlala indima ebalulekile enqubweni yokubumba yokufaka. Kumelwe sibeke izinga lokushisa lesikhunta ngendlela efanele ukuze siqinisekise ukuthi izinto zepulasitiki zigeleza ngokulinganayo futhi zigcwalise umgodi ngaphandle kwama-voids noma ukuguqulwa. Kufanele futhi sicabangele izinga lokushisa lokufaka ukuze siqinisekise ukuthi izinto zepulasitiki zinamathela kahle ekufakeni ngaphandle kokudala umonakalo oshisayo.

- Ingcindezi Yomjovo: Ukucindezela komjovo kungenye ipharamitha ebalulekile yokubunjwa kokufaka. Kumelwe simise ukushuba kwesimo ngendlela efanele ukuze siqinisekise ukuthi sijova izinto zepulasitiki ngendlela efanayo futhi ngokushesha endaweni yesikhunta. Ukucindezela okuphezulu komjovo kungabangela ukuguqulwa kokufakwayo noma isikhunta, kuyilapho ukucindezela okuphansi komjovo kungaholela ekugcwalisweni okungaphelele kwe-mold cavity.

- Isivinini sokujova: Ijubane lomjovo liphinde libe yipharamitha ebalulekile yokufaka ukubumba. Kumelwe sibeke isilinganiso ngendlela efanele ukuze siqinisekise ukuthi izinto zepulasitiki zigcwalisa ngokulinganayo isikhunta ngaphandle kwe-voids noma ukuguqulwa. Isivinini somjovo ophezulu singaholela esiphithiphithini ezintweni zepulasitiki, okuholela ekulimaleni komkhiqizo ophelile.

- Isikhathi Sokupholisa: Isikhathi sokupholisa siyadingeka ukuze impahla yepulasitiki iqine futhi yakhe umumo wokugcina womkhiqizo. Kumelwe simise kahle isikhathi sokupholisa ukuze siqinisekise ukuthi sifinyelela umumo nosayizi esiwufunayo womkhiqizo osuphelile. Isikhathi esifushane sokupholisa singaholela ekushintshashintsheni noma ekuncipheni, kuyilapho isikhathi eside sokupholisa singaholela ezikhathini zomjikelezo omude kanye nokuncipha kokukhiqiza.

- Isikhathi Sokukhipha: Sidinga isikhathi sokukhipha ukuze sikhiphe umkhiqizo oqediwe esikhunjeni. Kumelwe simise kahle isikhathi sokukhipha ukuze sisuse umkhiqizo osuphelile ngaphandle kokudala umonakalo noma ukuwohloka. Isikhathi esifushane sokukhipha singaholela ekukhishweni okungaphelele noma ekulimaleni komkhiqizo, kuyilapho isikhathi eside sokukhipha singaholela ezikhathini zomjikelezo omude kanye nokuncipha kokukhiqiza.

Ukukhubazeka Okujwayelekile Kokufaka Kokubumba nokuthi Ungakugwema Kanjani

Faka ukubumba kuyinqubo yokukhiqiza edumile ebandakanya ukubeka izinto esezike zakhiwe ngaphambili, njengokufakwa kwensimbi noma kwepulasitiki, esikhunjeni ngaphambi kokujova izinto zepulasitiki. Le nqubo iholela emikhiqizweni emikhulu futhi ehlala isikhathi eside kunokwakheka komjovo ojwayelekile. Kodwa-ke, njenganoma iyiphi inqubo yokukhiqiza, ukufaka ukubumba kungaba namaphutha athinta ikhwalithi nokuvumelana komkhiqizo wokugcina. Lapha sizobhekisisa iziphambeko zokubumba ezivamile zokufaka nokuthi ungazigwema kanjani.

Flash: I-flash iphutha elenzeka lapho impahla yepulasitiki eyeqile ivuza esikhunjeni futhi yakhe ungqimba oluncane ebusweni bomkhiqizo oqediwe. Lesi sici singathinta ukubukeka nokusebenza komkhiqizo. Ukuze ugweme i-flash, ungathatha izinyathelo ezilandelayo:

- Yehlisa umfutho womjovo

- Khulisa amandla okubamba isikhunta

- Sebenzisa i-ejenti yokukhulula isikhunta

- Khulisa isikhathi sokupholisa

Ishothi emfushane: Ukudubula okufushane kuyisici esenzeka lapho izinto zepulasitiki zingagcwalisi isikhunta, okuholela ekukhiqizeni okungaphelele noma okungaphansi. Ukuze ugweme ukudubula okufushane, ungathatha izinyathelo ezilandelayo:

- Khulisa umfutho womjovo

- Khulisa ijubane lomjovo

- Khulisa izinga lokushisa lempahla

- Khulisa izinga lokushisa lesikhunta

Ikhasi lempi: I-Warpage iyisici lapho umkhiqizo oqediwe ukhubazekile noma usontekile ngenxa yokupholisa okungalingani noma ukushwabana. Ukuze ugweme i-Warpage, ungathatha izinyathelo ezilandelayo:

- Khulisa izinga lokushisa lesikhunta

- Khulisa isikhathi sokupholisa

- Khulisa ingcindezi yokupakisha

- Sebenzisa isistimu yokupholisa elinganiselayo

Sink Marks: Ama-sink marks ama-depressions noma ama-indent ayenzeka ebusweni bomkhiqizo oqediwe ngenxa yokupholisa okungalingani noma ukushwabana. Ukuze ugweme ama-sink marks, ungathatha izinyathelo ezilandelayo:

- Khulisa izinga lokushisa lesikhunta

- Khulisa isikhathi sokupholisa

- Khulisa ingcindezi yokupakisha

- Sebenzisa izindonga ezinkulu noma izimbambo ukuze uqinise umkhiqizo

I-Delamination: I-Delamination iyisici esenzeka lapho izinto zepulasitiki nezinto ezifakiwe zingahlangani kahle, okuholela ekuhlukaneni noma ekuxebukeni. Ukuze ugweme i-delamination, ungathatha izinyathelo ezilandelayo:

- Sebenzisa i-plastic material ehambisanayo bese ufaka ikani

- Khulisa ingcindezi yomjovo kanye nesivinini

- Khulisa izinga lokushisa lokufaka

- Khulisa izinga lokushisa lesikhunta

I-Post-Molding Operations Yokufaka Ukubumba

Kodwa-ke, ngemva kokuqeda inqubo yokubumba yokufaka, kufanele senze imisebenzi eminingana yokubumba ukuze siqinisekise ukuthi umkhiqizo wokugcina uhlangabezana nokucaciswa okufunayo. Lapha sizobhekisisa imisebenzi yangemuva kokubumba yokubumba yokufaka.

- Ukunciphisa:I-Deflashing yinqubo esusa noma yiziphi izinto ezidingekayo, njenge-flash noma ama-burrs, emkhiqizweni oqediwe. Le nqubo ingenziwa ngesandla noma ngokuzenzakalelayo, kuye ngobukhulu nobunkimbinkimbi bomkhiqizo.

- Ukunquma:Ukunquma kuyinqubo esusa noma iyiphi impahla eyengeziwe noma ama-protrusions emkhiqizweni osuphelile. Le nqubo ingenziwa ngokusebenzisa amathuluzi okusika ahlukahlukene noma izindlela, kuye ngokuma nobukhulu bomkhiqizo.

- Ukuhlanza: Ukuhlanza kuyinqubo esusa noma yikuphi ukungcola, udoti, noma ukungcola emkhiqizweni osuphelile. Le nqubo ingenziwa kusetshenziswa ama-ejenti ahlukahlukene okuhlanza noma izindlela, kuye ngokuthi uhlobo lwempahla esetshenziselwa inqubo yokufaka.

- Umhlangano:Ukuhlanganisa kuyinqubo ehlanganisa ukuhlanganisa izingxenye eziningi ukuze kwakhe umkhiqizo oqediwe. Le nqubo ingenziwa kusetshenziswa izindlela ezihlukahlukene, njenge-welding ye-ultrasonic, isitembu esishisayo, noma i-adhesive bonding, kuye ngokuthi hlobo luni lwempahla kanye nomkhiqizo wokugcina oyifunayo.

- Ukuhlola: Ukuhlola kuyinqubo eqinisekisa ukuthi umkhiqizo oqediwe uhlangabezana nezicaciso ezifiselekayo kanye namazinga ekhwalithi. Le nqubo ingabandakanya ukuhlolwa okuhlukahlukene, okufana nokuhlolwa kwemishini, kagesi, noma okubonakalayo, kuye ngohlobo lomkhiqizo nokusetshenziswa kwawo okuhlosiwe.

Ngaphezu kwalokhu kusebenza kokubumba, kunezici ezimbalwa okufanele zicatshangelwe lapho uklama inqubo yokubumba yokufaka ezonciphisa isidingo sezinqubo zokubumba. Lokhu kubandakanya:

- Ukukhetha izinto ezifanele zokufaka kanye nengxenye ebunjiwe

- Ukuqinisekisa ukuthi okufakiwe kubekwe ngendlela efanele futhi kubanjwe endaweni ngesikhathi sokubumba

- Ukulungisa amapharamitha wokubumba, afana nezinga lokushisa nokucindezela, ukuze kuncishiswe amaphutha nezinto ezidingekayo

- Ukusebenzisa isikhunta sekhwalithi ephezulu kanye nemishini yokuqinisekisa ukuvumelana nokunemba kumkhiqizo oqediwe

Izicelo Zokubumba Umjovo Wokufaka

Faka ukubumba komjovo kuyinqubo yokukhiqiza enemisebenzi eminingi esetshenziswa ezimbonini eziningi ukukhiqiza izingxenye ezisezingeni eliphezulu, eziyinkimbinkimbi ezinamandla amakhulu nokuqina. Lapha sizobhekisisa izinhlelo zokusebenza zokubumba umjovo kanye nezinzuzo zako ezimbonini ezahlukene.

- Imboni Yezimoto:Imboni yezimoto ingomunye wabasebenzisi ababaluleke kakhulu bokufaka umjovo wokubumba. Ithola ukusetshenziswa ekukhiqizeni izingxenye ezihlukahlukene, okuhlanganisa izindlu zama-airbag, amabhande ezihlalo, nezingxenye zenjini. Inqubo ivumela ukubumba okunembile nokunembile kwezingxenye ezingamelana nezimo ezinzima zokusetshenziswa kwezimoto.

- Imboni Yezogesi:Imboni yezogesi iphinde ithembele kakhulu ekufakeni umjovo wokubumba ukuze ikhiqize izingxenye zamadivayisi afana nama-smartphones, amakhompyutha aphathekayo, nezinye izinto zikagesi. Inqubo ithola ukusetshenziswa ekudaleni izinto ezifana nezixhumi, amaswishi, nezindlu zezingxenye ze-elekthronikhi. Le nqubo isebenza kahle kakhulu futhi ingakhiqiza izingxenye eziningi ngokushesha futhi ngendlela engabizi kakhulu.

- Imboni yezokwelapha: Imboni yezokwelapha nayo izuza kakhulu ngokufaka ukubumba komjovo. Inqubo ithola ukusetshenziswa ekukhiqizeni izingxenye ezihlukahlukene, okuhlanganisa amathuluzi okuhlinza, amadivaysi okulethwa kwezidakamizwa, nezifakelo zezokwelapha. Le ndlela ivumela ukubumba okunembile kwezinto ezingamelana nobunzima bokusetshenziswa kwezokwelapha futhi ivumela ukukhiqizwa kwenani elikhulu.

- Imboni ye-Aerospace: Imboni ye-aerospace ingenye imboni esebenzisa ukubumba komjovo wokufaka kakhulu. Inqubo ithola ukusetshenziswa ekukhiqizeni izingxenye ezifana nemigudu yomoya, abakaki, nezindlu zezingxenye zendiza. Inqubo ivumela ukwakhiwa kwezingxenye ezinamandla amakhulu ezingamelana nokucindezeleka okuphezulu kanye nezinga lokushisa elidlulele lokusetshenziswa kwe-aerospace.

- Imboni Yezimpahla Zabathengi: Imboni yezimpahla zabathengi isebenzisa ukubumba komjovo wokufaka kakhulu ukukhiqiza imikhiqizo eminingi efana namathoyizi, izinto zasendlini, nemishini yezemidlalo. Inqubo ivumela ukwakhiwa kwezingxenye zekhwalithi ephezulu, ezihlala isikhathi eside, ezingasindi, nezibukeka kahle.

Ngaphezu kwalezi zimboni, ukufaka umjovo ukubumba kuyasetshenziswa kwezinye izinhlelo zokusebenza eziningi, okuhlanganisa:

- Imboni yokupakisha: ukukhiqiza amakepisi, ukuvalwa, nezinye izingxenye zokupakisha

- Imboni yezokwakha: ukukhiqiza amapayipi, okokufaka, nezinye izakhi zokwakha

- Imboni Yezempi: ukukhiqiza izingxenye zezimoto zempi nemishini

Izicelo Zemboni Yezimoto

Imboni yezimoto ingomunye wabasebenzisi ababaluleke kakhulu bokubumba umjovo wepulasitiki, njengoba kuyindlela engabizi futhi ephumelelayo yokwenza izingxenye zemoto eziyinkimbinkimbi. Lapha sizobheka kabanzi ukusetshenziswa okuhlukahlukene komjovo wepulasitiki embonini yezimoto.

- Izingxenye Zangaphakathi: Ingaphakathi lemoto liqukethe izingxenye zepulasitiki ezimbalwa ezibalulekile kubo bonke ubuhle nokusebenza kwemoto. Lezi zingxenye zihlanganisa ideshibhodi, izicabha, ama-air conditioning, nama-steering wheel components. Ukubunjwa komjovo kuvumela ukukhiqizwa kwalezi zingxenye ngevolumu ephezulu ngokushesha nangezindleko eziphumelelayo kuyilapho kugcinwa izinga eliphezulu lokunemba.

- Izingxenye Zangaphandle: Ingaphandle lemoto liqukethe izingxenye zepulasitiki ezimbalwa, okuhlanganisa amakhava obhampa, amalambu ahlanganisayo, nama-taillight assembles. Ukubumba umjovo kukhiqiza lezi zingxenye ezingeni eliphezulu lokunemba, okuqinisekisa ukuthi zihlangabezana nezindinganiso eziqinile zokuphepha kanye nekhwalithi edingekayo embonini yezimoto.

- Izingxenye Zenjini: Ukubumba komjovo nakho kuthola ukusetshenziswa ekukhiqizeni izingxenye zenjini ezimbalwa, okuhlanganisa ukuphindaphindeka kokungenisa umoya, amakhava enjini, nezihlungi zikawoyela. Kufanele sikhiqize lezi zingxenye ukuze zibekezelelane namazinga aqinile, futhi ukubumba komjovo kuvumela ukukhiqizwa kwezithako zekhwalithi ephezulu ezihlangabezana nalezi zidingo.

- Izingxenye zikagesi: Izingxenye zikagesi emotweni, njengezixhumi, amaswishi, nezindlu zezinzwa, nazo zikhiqizwa kusetshenziswa ukubumba komjovo. Lezi zingxenye kufanele ziqine futhi zimelane nezimo zokusebenza ezinzima, futhi ukubumba umjovo kuvumela ukukhiqiza izithako zekhwalithi ephezulu ezingamelana nalezi zimo.

- Izingxenye ze-HVAC:Ukubumba komjovo kukhiqiza izingxenye ezimbalwa ezisetshenziswa kusistimu ye-HVAC yemoto, okuhlanganisa namapayipi omoya kanye namapayipi. Lezi zingxenye kufanele zenzelwe ukubekezelelana okunembayo ukuze kuqinisekiswe ukugeleza komoya okufanele kanye nokungena komoya emotweni.

Ngaphezu kwalezi zinhlelo zokusebenza, abakhiqizi basebenzisa i-injection molding ukuze bakhiqize ezinye izingxenye zezimoto ezimbalwa, ezihlanganisa uphethiloli, amabhuleki, namasistimu amisiwe.

Izinzuzo zokusebenzisa ukubumba umjovo embonini yezimoto ziningi, okuhlanganisa:

- Ukusebenza Okuphezulu:Ukubumba umjovo kuvumela ukukhiqiza ngokushesha izingxenye zekhwalithi ephezulu ngamavolumu amakhulu, ukunciphisa izikhathi zokukhiqiza nezindleko.

- hle:Ukubumba komjovo kuvumela ukwakhiwa kwezingxenye ngokunemba okuphezulu nokungaguquguquki, okuqinisekisa ukuthi zihlangabezana nezindinganiso eziqinile zekhwalithi.

- Ukwenza ngokwezifiso: Ukubumba komjovo kuvumela ukukhiqizwa kobunjwa obuyinkimbinkimbi nemiklamo, okuvumela abakhiqizi ukuthi benze izinto ngendlela oyifisayo ukuze zihlangabezane nezidingo ezithile zokuklama.

Izicelo Zemboni Yezokwelapha

Imboni yezokwelapha iyinkundla lapho ukunemba nokuthembeka kubaluleke kakhulu, okwenza ukubumba komjovo wepulasitiki kube inqubo efanelekile yokukhiqiza yokukhiqiza izingxenye zezokwelapha. Lapha sizobhekisisa ukusetshenziswa okuhlukahlukene komjovo wepulasitiki embonini yezokwelapha.

- Izinsimbi Zokuhlinza: Ukubumba umjovo kukhiqiza amathuluzi amaningi okuhlinza, okuhlanganisa ama-forcep, ama-clamp, nama-scalpel. Abakhiqizi kufanele benze lezi zingxenye ukuze zibekezelelane ngokuqinile namazinga ukuze kuqinisekiswe ukunemba okuphezulu nokunemba.

- Amadivayisi Ezokwelapha:Abakhiqizi baphinde basebenzise ukubumba komjovo ukuze bakhiqize izinto zezokwelapha, njengama-catheter kanye nezingxenye zokuphefumula. Ukuqinisekisa ukuphepha nokwethenjwa kweziguli, abakhiqizi kufanele benze lezi zingxenye ngokuvumelana nezindinganiso eziqinile.

- Izingxenye zokuxilonga: Abakhiqizi basebenzisa ukubumba komjovo ukukhiqiza izingxenye ezimbalwa ezisetshenziswa emishinini yokuxilonga, njengamapayipi, amasirinji, namashubhu okuhlola. Lezi zingxenye kufanele zenzelwe ukubekezelelana okunembile ukuze kuqinisekiswe imiphumela yokuhlolwa enembile.

- Okufakiwe: Ukubumba umjovo kukhiqiza ukupakishwa kwemikhiqizo yezokwelapha, njengamathileyi angenalutho, iziqukathi, nezinto zokupakisha. Lezi zingxenye kufanele zenziwe ngezindinganiso eziqinile ukuze kuqinisekiswe ubunyumba nokuphepha kwemikhiqizo yezokwelapha.

- Izingxenye Zamazinyo: Ukubumba umjovo kukhiqiza izingxenye eziningi zamazinyo, okuhlanganisa abaqaphi bomlomo, amathreyi, nezingcezu ze-orthodontic. Lezi zingxenye kufanele zenzelwe ukubekezelelana okunembayo ukuze kuqinisekiswe ukufaneleka nokunethezeka okufanele kwesiguli.

Ngaphezu kwalezi zinhlelo zokusebenza, abakhiqizi basebenzisa ukubumba komjovo ukuze bakhiqize ezinye izakhi zezokwelapha ezimbalwa, ezihlanganisa izitho zokwenziwa, izinsiza-kuzwa, nemishini yaselabhorethri.

Izinzuzo zokusebenzisa ukubumba umjovo embonini yezokwelapha ziningi, okuhlanganisa:

- Ukunemba okuphezulu:Ukubumba komjovo kuvumela ukukhiqiza izingxenye ezinamazinga aphezulu okunemba nokungaguquguquki, okuqinisekisa ukuthi zihlangabezana nezindinganiso eziqinile zekhwalithi.

- Ukwenza ngokwezifiso:Ukubumba komjovo kuvumela ukukhiqizwa kobunjwa obuyinkimbinkimbi nemiklamo, okuvumela abakhiqizi ukuthi benze izinto ngendlela oyifisayo ukuze zihlangabezane nezidingo ezithile zokuklama.

- Kuqiza kahle: Ukubumba umjovo kuyinqubo yokukhiqiza engabizi kakhulu ekhiqiza izingxenye zekhwalithi ephezulu ngamavolumu amakhulu, ukunciphisa izikhathi zokukhiqiza nezindleko.

Izicelo Zemboni Yezogesi

Imboni ye-elekthronikhi iyinkambu ethembele kakhulu ezinqubweni zokukhiqiza ezinembayo nezisebenzayo. Ukubumba umjovo wepulasitiki kuyinqubo ekahle yokukhiqiza izingxenye ze-elekthronikhi ngenxa yokunemba kwayo, ukuguquguquka, kanye nesivinini. Lapha sizobheka kabanzi ukusetshenziswa okuhlukahlukene komjovo wepulasitiki embonini ye-elekthronikhi.

- Izixhumanisi: Ukubumba umjovo kukhiqiza izinhlobonhlobo zezixhumi ezisetshenziswa embonini ye-elekthronikhi, okuhlanganisa izixhumi ze-USB, izixhumi ze-HDMI, namajekhi alalelwayo. Lezi zingxenye kufanele zenzelwe ukubekezelelana okunembayo ukuze kuqinisekiswe ukusebenza okufanele nokuhambisana.

- Izindlu Nezindawo Ezivalekile: Ukubumba umjovo kukhiqiza izindlu kanye nezivalo zemishini kagesi, okuhlanganisa omakhalekhukhwini, amakhompyutha aphathekayo, nezinye izinto zikagesi zabathengi. Abakhiqizi kufanele benze lezi zingxenye ukuze zibe nemininingwane eqondile ukuze baqinisekise ukufaneleka nokusebenza okufanele.

- Ukushintshwa: Ukubumba umjovo kukhiqiza izinhlobo ezimbalwa zezilawuli ezisetshenziswa emishinini kagesi, okuhlanganisa ukushintshwa kwe-rocker, ukushintshwa kwezinkinobho ezicindezelayo, nokushintshwa kwamaslayidi. Lezi zingxenye kufanele zenzelwe ukubekezelelana okunembile ukuze kuqinisekiswe ukusebenza okuthembekile.

- Izingxenye ze-LED:Ukubumba komjovo kukhiqiza izakhi ezimbalwa ezisetshenziswa ekukhanyeni kwe-LED, okuhlanganisa amalensi, izibonisi, nama-diffuser. Abakhiqizi kufanele benze lezi zingxenye ukuze zicacise kahle ukuze kuqinisekiswe ukusatshalaliswa kokukhanya okufanele nokusebenza kahle.

- Izingxenye Zokuhlinzeka Ngamandla: Ukubumba komjovo kukhiqiza izingxenye ezimbalwa ezisetshenziswa kumayunithi okunikezwa kwamandla, okuhlanganisa amasokhethi, amapulaki, nezixhumi zekhebula. Lezi zingxenye kufanele zenzelwe ukubekezelelana okunembile ukuze kuqinisekiswe ukusebenza okuphephile nokuthembekile.

Ngokungeziwe kulezi zinhlelo zokusebenza, abakhiqizi basebenzisa i-injection molding ukukhiqiza ezinye izingxenye ze-elekthronikhi ezimbalwa, ezihlanganisa amakhibhodi, amagundane ekhompyutha, nezilawuli kude.

Izinzuzo zokusebenzisa ukubumba umjovo embonini ye-elekthronikhi ziningi, kufaka phakathi:

- Ukunemba okuphezulu: Ukubumba komjovo kuvumela ukukhiqiza izingxenye ezinamazinga aphezulu okunemba nokungaguquguquki, okuqinisekisa ukuthi zihlangabezana nezindinganiso eziqinile zekhwalithi.

- Ukwenza ngokwezifiso: Ukubumba komjovo kuvumela ukukhiqizwa kobunjwa obuyinkimbinkimbi nemiklamo, okuvumela abakhiqizi ukuthi benze izinto ngendlela oyifisayo ukuze zihlangabezane nezidingo ezithile zokuklama.

- Isivinini:Ukubumba umjovo kuyinqubo yokukhiqiza esheshayo nephumelelayo evumela ukukhiqiza izingxenye zekhwalithi ephezulu ngamavolumu amakhulu, ukunciphisa izikhathi zokukhiqiza nezindleko.

Izicelo Zemboni Yezindiza

Imboni ye-aerospace iwumkhakha odinga izinga eliphezulu lokunemba, ukunemba, nokuqina kuzo zonke izingxenye zayo. Ukubumba umjovo wepulasitiki embonini ye-aerospace sekuvame kakhulu ngenxa yekhono layo lokukhiqiza amajiyometri ayinkimbinkimbi, ukunciphisa isisindo, kanye nokuthuthukisa ubuqotho besakhiwo. Lapha sizobheka kabanzi ukusetshenziswa okuhlukahlukene komjovo wepulasitiki embonini ye-aerospace.

- Izingxenye Zangaphakathi: Ukubumba umjovo kukhiqiza uhla lwezingxenye zangaphakathi zendiza, okuhlanganisa izihlalo ezingemuva, amatafula ethreyi, namakhompathimenti angaphezulu. Lezi zingxenye kufanele zibe lula futhi ziqine, zikwazi ukumelana nokucindezeleka okukhulu nokuguga.

- Izingxenye Zesakhiwo: Ukubumba umjovo kukhiqiza izingxenye zesakhiwo sendiza, okuhlanganisa amaphiko, ama-fairing, nezigaba ze-fuselage. Lezi zingxenye kufanele zibe lula, ziqine, futhi ziqine ukuze kuqinisekiswe ukuphepha nokusebenza kahle kwendiza.

- Izingxenye Zenjini:Ukubumba komjovo kukhiqiza izingxenye ezimbalwa zezinjini zezindiza, okuhlanganisa ama-turbine blades, imibhobho kaphethiloli, nezindlu. Lezi zingxenye kufanele zenzelwe ukucaciswa okunembayo ukuze zimelane namazinga okushisa aphezulu, izingcindezi, nezingcindezi.

- Izingxenye zikagesi: Ukubumba umjovo kukhiqiza izingxenye zikagesi zendiza, okuhlanganisa izixhumi, amaswishi, namahhanisi ezintambo. Lezi zingxenye kufanele zenzelwe ukubekezelelana okunembayo ukuze kuqinisekiswe ukusebenza okufanele nokwethembeka.

- Izingxenye Zamathuluzi:Ukubumba komjovo kukhiqiza izingxenye zamathuluzi endiza, okuhlanganisa amaphaneli okulawula kanye nezindlu zamathuluzi. Lezi zingxenye kufanele ziqine futhi zimelane namazinga okushisa aphezulu, ukucindezela, nokudlidliza.

Ngaphezu kwalezi zinhlelo zokusebenza, abakhiqizi basebenzisa ukubumba komjovo ukuze bakhiqize ezinye izingxenye ezimbalwa zemboni ye-aerospace, okuhlanganisa abakaki, izinsimbi, nama-gaskets.

Izinzuzo zokusebenzisa ukubumba umjovo embonini ye-aerospace ziningi, okuhlanganisa:

- Ukunciphisa Isisindo: Ukubumba umjovo kuvumela ukukhiqizwa kwezingxenye ezingasindi ezinciphisa isisindo sendiza, okuholela ekusetshenzisweni kukaphethiloli okuphansi kanye nokusebenza kahle okwandisiwe.

- hle:Ukubumba umjovo kuvumela ukukhiqiza izingxenye ezinemba okuphezulu nokungaguquguquki, okuqinisekisa ukuthi zihlangabezana nezindinganiso eziqinile zekhwalithi.

- Ukwenza ngokwezifiso:Ukubumba komjovo kuvumela ukukhiqizwa kobunjwa obuyinkimbinkimbi nemiklamo, okuvumela abakhiqizi ukuthi benze izinto ngendlela oyifisayo ukuze zihlangabezane nezidingo ezithile zokuklama.

- Ukuqina: Ii-njection molding ikhiqiza izingxenye ezihlala isikhathi eside futhi ezikwazi ukumelana namazinga aphezulu okucindezeleka, izinga lokushisa, nokucindezela, okuqinisekisa ukuphepha nokwethembeka kwendiza.

Izicelo Zemboni Yezimpahla Zabathengi

Imboni yezimpahla zabathengi ingomunye wemikhakha ebaluleke kakhulu emnothweni womhlaba. Izimpahla zabathengi ziyimikhiqizo esetshenziswa abantu nsuku zonke, okuhlanganisa izinto zasendlini, izinto zikagesi, amathoyizi, nemikhiqizo yokunakekela abantu. Ukubumba komjovo wepulasitiki embonini yezimpahla zabathengi sekuye kwaduma kakhulu ngenxa yekhono layo lokukhiqiza izingxenye zekhwalithi ephezulu ngokunemba nokunemba. Lapha sizobheka kabanzi ukusetshenziswa okuhlukahlukene komjovo wepulasitiki embonini yezimpahla zabathengi.

- Okufakiwe: Ukubumba umjovo kusetshenziswa kakhulu ekukhiqizeni izinto zokupakisha zezimpahla zabathengi, okuhlanganisa ukupakisha ukudla, amabhodlela eziphuzo, neziqukathi zezimonyo. Ukubumba umjovo kuvumela ukukhiqizwa kobunjwa obuyinkimbinkimbi nemiklamo, ukuqinisekisa ukuthi izinto zokupakisha ziyasebenza futhi zibukeka kahle.

- Izinto Zasekhaya: Ukubumba umjovo kukhiqiza izinhlobonhlobo zezinto zasendlini, okuhlanganisa izitsha zasekhishini, iziqukathi zokugcina, nezinto zokuhlanza. Lezi zinto kufanele ziqine, zibe lula, futhi zimelane nokusetshenziswa kwansuku zonke.

- Amathoyizi: Ukubumba umjovo kukhiqiza amathoyizi ahlukahlukene, okuhlanganisa izibalo zesenzo, onodoli, nemidlalo yebhodi. Lawa mathoyizi kufanele enziwe abe nemininingwane eqondile ukuqinisekisa ukuthi aphephile futhi ahlala isikhathi eside.

- Imikhiqizo Yokunakekela Umuntu: Ukubumba umjovo kukhiqiza imikhiqizo yokunakekelwa eyingqayizivele, okuhlanganisa izixubho, ama-razor, namabhodlela e-shampoo. Le mikhiqizo kufanele ibe yinhle ngobuhle, isebenze, futhi imelane nokusetshenziswa njalo.

- I-elekhoni: Ukubumba komjovo kukhiqiza izingxenye ezimbalwa zemishini kagesi, okuhlanganisa amakesi, izinkinobho, nezixhumi. Lezi zingxenye kufanele zihlale isikhathi eside, zilula, futhi zimelane namazinga okushisa aphezulu nezingcindezi.

Ngokungeziwe kulezi zinhlelo zokusebenza, abakhiqizi basebenzisa ukubumba komjovo ukukhiqiza ezinye izingxenye ezimbalwa zemboni yezimpahla zabathengi, okuhlanganisa izingxenye zezimoto, izinto zezokwelapha, nemishini yezimboni.

Izinzuzo zokusebenzisa ukubumba umjovo embonini yezimpahla zabathengi ziningi, okuhlanganisa:

- Kuqiza kahle:Ukubumba umjovo kuvumela ukukhiqiza izingxenye zekhwalithi ephezulu ngenani eliphansi kunezinye izinqubo zokukhiqiza.

- Ukwenza ngokwezifiso: Iukubumba kwe-njection kuvumela ukudala izakhi ezinobunjwa obuyinkimbinkimbi nemiklamo, okuvumela abakhiqizi ukuthi benze ngendlela oyifisayo izici ukuze bahlangabezane nezidingo ezithile zokuklama.

- hle: Ukubumba umjovo kunemininingwane enembe kakhulu futhi engaguquki ehlangabezana nezindinganiso eziqinile zekhwalithi.

- ukuqina: Ukubumba komjovo kwenza izingxenye ziqine futhi zikwazi ukumelana namazinga aphezulu okucindezeleka, izinga lokushisa, nokucindezela, okuqinisekisa ukuphepha nokwethembeka kwemikhiqizo.

Amathrendi Azayo Ekubumbeni Umjovo Wokufaka

Njengoba ubuchwepheshe buthuthuka kanye nezimfuno zabathengi zishintsha, imboni yokubumba umjovo wokufaka ihlale ishintsha. Abakhiqizi bahlale befuna izindlela zokuthuthukisa ukusebenza kahle, ukunciphisa izindleko, nokukhiqiza imikhiqizo yekhwalithi ephezulu. Lapha sizobheka amathrendi athile esikhathi esizayo ekufakeni ukubumba komjovo.

- Ukuzenzekelayo: I-Automation iya ngokuya iduma embonini yokukhiqiza, futhi ukufaka ukubumba komjovo nakho. Amasistimu azenzakalelayo anganciphisa izindleko zabasebenzi, akhuphule isivinini sokukhiqiza, futhi athuthukise ukulawulwa kwekhwalithi.

- Ukusimama: Ngokukhula kokukhathazeka kwemvelo, abakhiqizi bafuna izindlela zokunciphisa udoti nokuthuthukisa ukusimama. Ukusebenzisa izinto ezigaywe kabusha kanye nokuklama imikhiqizo engagaywa kabusha kalula noma isetshenziswe kabusha kuyizindlela ezimbalwa nje abakhiqizi abalungisa ngayo le nkinga.

- Ukuphrinta kwe-3D: Ezinye izici zokubumba umjovo wokufaka sezivele zisebenzisa ukuphrinta kwe-3D, kodwa kunamandla okuba zivame kakhulu esikhathini esizayo. Ikhono lokudala ngokushesha ama-prototypes nokukhiqiza izingxenye ezenziwe ngezifiso kuyinzuzo eyodwa nje yokuphrinta kwe-3D.

- Izinto Ezithuthukile: Abacwaningi nabakhiqizi bakha izinto ezintsha ezikwazi ukumelana namazinga okushisa ahlukahlukene, izingcindezi nezingcindezi.

- I-Smart Manufacturing:Ukukhiqiza okuhlakaniphile kuhilela ukusebenzisa ubuchwepheshe ukuqoqa nokuhlaziya idatha ngesikhathi sangempela, okuvumela ukwenziwa kwezinqumo okusheshayo nokukhiqiza okunempumelelo kakhudlwana. Lobu buchwepheshe bungathuthukisa ukulawulwa kwekhwalithi, bunciphise isikhathi sokuphumula, futhi bukhulise ukukhiqiza.

Isiphetho

Faka ukubumba komjovo kuyinqubo yokukhiqiza eguquguqukayo futhi engabizi evumela ukwakhiwa kwezingxenye eziyinkimbinkimbi ezinezingxenye ezishumekiwe. Izinzuzo zayo ngaphezu kwezindlela zokuhlanganisa ezivamile ziyenza idume ezimbonini ezihlukahlukene, okuhlanganisa ezezimoto, ezokwelashwa, eze-electronics, i-aerospace, kanye nezimpahla zabathengi. Ngokuqonda amasu ahlukene, izinto zokwakha, nokucatshangelwa kwedizayini okuhilelekile ekubumbeni umjovo, abakhiqizi bangakwazi ukuthuthukisa izinqubo zabo zokukhiqiza futhi balethe imikhiqizo yekhwalithi ephezulu kumakhasimende abo. Njengoba ubuchwepheshe buthuthuka, singalindela ukubona izinhlelo zokusebenza ezintsha zokubumba umjovo wokufaka.