Icala eNdiya

Faka Isikhunta sika-DJmolidng Kusevisi Yokubumba Umjovo Wezinkampani ZaseNdiya

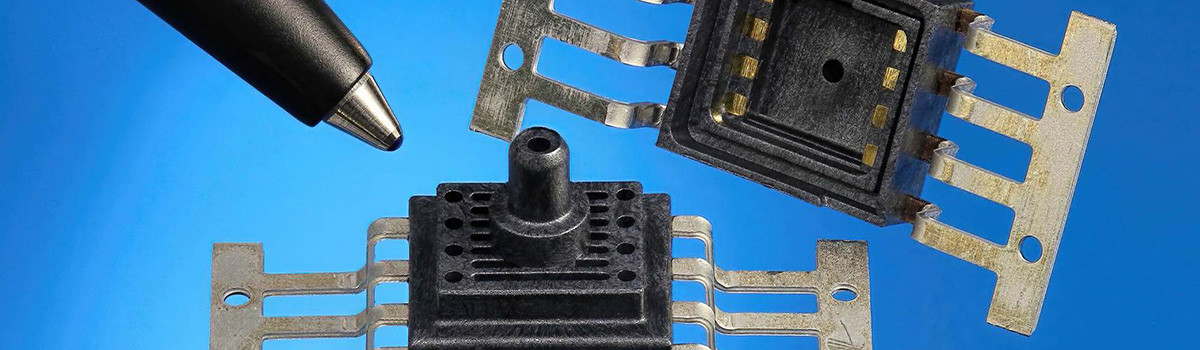

Faka isikhunta ngokuvamile kuwuhlobo lwesikhunta esenza amantongomane, izingxenye zensimbi noma izingxenye zepulasitiki eziqinile ezifakwe ngaphakathi kwemigodi yokubumba umjovo.

I-DJmolding ihlinzeka ngensizakalo yokubumba umjovo we-mlod emakethe yase-India, futhi sikhiqiza izingxenye eziningi zepulasitiki zokubumba ezimbonini ezihlukene, ikakhulukazi abakhiqizi bezinto zikagesi zasendlini. Abanye abakhiqizi bezinto zikagesi zasendlini zaseNdiya bathenga izingxenye zepulasitiki zokubumba isikhathi eside befomu elithi DJmolding. Sinobambiswano oluhle kakhulu nalezi zinkampani zaseNdiya.

Faka ukubumba komjovo wamantongomane: impahla yamantongomane ingaba insimbi engagqwali, ithusi, ithusi nensimbi, ngokuvamile amantongomane ethusi avame ukusetshenziswa. Ithusi kulula ukulikhanda, elisiza amantongomane namapulasitiki ukuthi kuhlangane kangcono. Ukubekezelelwa kwe-nut bores yangaphakathi kufanele kulawulwe ngaphakathi kuka-0.02mm, ngaphandle kwalokho kubangele ukukhanya uma ukubekezelelana okungaphezu kuka-0.02mm. Ekufakeni isikhunta, udinga ukuhlanganisa amantongomane uwafake izikhonkwane ukuze ahlolwe. Uma ilingana phakathi kwamantongomane namaphini, kungaba nzima ukukhipha ingxenye bese udala amamaki okukhipha noma izinkinga zokunamathela. Uma ingalingani kahle, ingadala i-flash.

Faka izingxenye zensimbi zokubumba umjovo:

Izingxenye zensimbi zingaba insimbi engagqwali, i-aluminium, ithusi, insimbi ... njll. Ukubekezelelwa kwezingxenye zensimbi kufanele kulawulwe ngaphakathi kuka-0.02mm, ngaphandle kwalokho kunzima ukuvala impahla futhi kulula ukuba ne-flash. I-acreage yezingxenye zensimbi ayikwazi ukuklanywa ibe nkulu kakhulu.

Uma i-acreage yokugcwalisa yezingxenye zensimbi inkulu kakhulu, kungaba nzima kakhulu ukuzuza umjovo ngokugcwele njengomehluko omkhulu wokushisa phakathi kwezingxenye zensimbi. Ukuma kwezingxenye zensimbi kuvame ukuklanywa endaweni njengoba umgodi unganyakazi, okusiza ukugwema umphumela we-flash kusuka kuzingxenye zensimbi ezixegayo uma zinyakaza(uma kwenzeka kakhulu, kungalimaza isikhunta). Ezimweni ezithile, izikhundla zezingxenye zensimbi zingaklanywa kuphela endaweni ephakathi noma ohlangothini lomkhiqizo.

Faka ukubumba komjovo wepulasitiki oqinile:

Ngokuvamile khetha amapulasitiki aqinile anephuzu eliphezulu lokuncibilika, njenge-PEEK, PA66+30GF, PP+30GF, PA12+30GF, PPS….etc. Ukubekezelela la mapulasitiki aqinile kufanele kube okunembile. Amaphutha afana nokushwabana, ukubola, nokuguqulwa akukwazi ukuba khona endaweni yokuvala. Ekufakeni isikhunta, ipulasitiki eqinile kufanele ifakwe ngaphakathi kwesikhunta ukuze ihlolwe, futhi ishiywe i-0.05-0.1mm icindezela ngaphambili eduze kwendawo yokuvala ukuze kufinyelelwe ukuvaleka okungcono.

Ingxenye yepulasitiki eqinile akufanele yakhelwe i-acreage enkulu kakhulu, okuzodala umehluko wezinga lokushisa futhi kwenze kube nzima ukugcwalisa okokusebenza ngomjovo. Ngokuvamile yenza ingxenye yepulasitiki eqinile igxile ohlangothini lwesigxobo, ngoba umgodi awunyakazi, ukugwema ukukhanya noma ukulimaza isikhunta ekunyakazeni kwesikhunta. Ezimweni ezithile, izikhundla zezingxenye zensimbi zingaklanywa kuphela endaweni ephakathi noma ohlangothini lomkhiqizo.

Yakha amaphuzu abalulekile

I-1.Design shrinkage yemikhiqizo efakwe amantongomane, kuyilapho kungekho sidingo sokuklama ukuncipha kwemikhiqizo enezingxenye zensimbi kanye nokufakwa kwepulasitiki kanzima. Ezindaweni ezidinga ukubekezelelana okuqinile, lungisa ukubekezelela usayizi wemikhiqizo kube yi-median.

2.Ngokujwayelekile sebenzisa isisekelo sesikhunta esinesango lephinikhodi elijwayelekile ekwakhiweni kwesikhunta, futhi kumjovo wesibili, faka izingxenye ezifakayo emgodini ngangokunokwenzeka. Esimweni sokwenza okufakiwe kulungiswe emgodini, cabanga ukuthi ungayenza kanjani ingxenye esele kumgogodla ngemuva kokubunjwa komjovo, ngale ndlela, ingxenye ingakhishwa. Ngokuvamile engeza amabhlogo anwebekayo endaweni kanye neglue enwebekayo ukuze ingxenye ihlale kumongo. Ibanga phakathi kwamabhulokhi anwebekayo kanye neglue alikwazi ukuba likhulu kakhulu, ngaphandle kwalokho amandla okunwebeka azobangela ukuwohloka kwezingxenye zepulasitiki eziqinile noma zensimbi. Ibanga ngokuvamile liklanywa phakathi kuka-2mm, futhi likhuphule ngokufanelekile inani lamabhulokhi anwebekayo kanye neglue enwebekayo lapho izinsimbi noma ipulasitiki eqinile ine-acre enkulu uma kuqhathaniswa.

3.Ubukhulu bezinto ezibonakalayo bungcono kakhulu phakathi kuka-1.3-1.8mm(cishe u-1.5mm bungcono kakhulu), uma kungenjalo, kudingeka uhlole imidwebo yomkhiqizo futhi uphakamise ukuthi ikhasimende liyiguqule. Uma ugqinsi lwempahla luzacile kuno-1.3mm, kunzima ukugcwaliswa kwempahla, kuyilapho ukujiya kwempahla kushubile kuno-1.8mm, ukushwabana kulula ukwenzeka ekukhiqizeni.

4.Ukugawula kubaluleke kakhulu esikhunjeni. Ibhalansi yokugcwaliswa kwezinto ezibonakalayo endaweni yesango kufanele kucatshangelwe ngokugcwele.Lapho izinto zigijima endaweni lapho izingxenye zensimbi noma zepulasitiki eziqinile zilungiswa, isivinini sokugcwalisa izinto kanye nokucindezela kuzokwehla ngenxa yokuthi ukufakwa kokumelana nokuhluka kokushisa.

5.Ngohlelo lwe-mold ejector, Ibhalansi yokukhipha kufanele icatshangelwe noma ukuguqulwa kuzokwenzeka ngemva kokukhishwa. Ukuze izingxenye azikwazi ukukhishwa kubhalansi, kudingeka ucabange ukugoqa ukuze kuthuthukiswe inkinga yebhalansi ekwakhiweni kwesakhiwo.

6.Ukuqinisekisa ukufaneleka kokubukeka kwezingxenye ngemva kokukhishwa ekubunjweni komjovo, idivayisi ye-ejector kufanele ibe isigaxa sepulasitiki esiqinile esifakwe ne-ABS noma i-PMMA. Uma isikhunta sivalekile, klama amaslayidi endaweni kaningi ngangokunokwenzeka, ngoba amaslayidi asemgqeni enza kube lula ukufaka isikhunta.

7.Ukuqinisekisa amandla okuvala i-SA(isibonelelo somthungo), ngomkhiqizo owenziwe ngomjovo ophindwe kabili, ububanzi be-sealing SA kufanele okungenani bube ngu-0.8mm. Okomjovo wesibili kuyipulasitiki eqinile, ububanzi be-sealing SA kufanele okungenani bube ngu-1.0mm, ngaphandle kwalokho, kudingeka basikisele ikhasimende ukuthi liguqule umkhiqizo.

I-8.Ekuklanyweni kwesikhunta, kufanele sicabangele imishini yokubumba umjovo ukuze ikhiqize ukuze sibone ukuthi ithatha luphi uhlobo lomshini, oqondile noma ovundlile. Kuphakanyiswa ukuthi ungaklami izimbobo eziningi kakhulu, ikakhulukazi isikhunta esinezigijimi ezibandayo njengoba imigodi eminingi yenza umgijimi abe isikhathi eside, amoshe impahla futhi kuyingozi ukuzuza umjovo osebenza kahle kakhulu. Ukufanisa umshini wokubumba umjovo, kufanele sicabangele ukuthi ingabe ihlangene futhi inengqondo yini ezinhlelweni zomkhiqizo.Imikhiqizo kufanele ilungiswe ukuze kuqinisekiswe ukuthi imikhiqizo isesimweni esifanayo ngaso sonke isikhathi lapho ifakwa esikhunjeni. Enye indlela isistimu yokusabela yomklamo ukuze ixwayise uma ingxenye ingekho endaweni efanele ngaphambi kokuvalwa kwesikhunta, okusiza ukumisa ukuvala isikhunta. Ngale ndlela, izingxenye zisesimweni esifanayo esikhunjeni, okuphakamisa amazinga afanelekayo kanye nokusebenza kahle kokukhiqiza ekubumbeni umjovo.

9.Ukwesekwa kwensimbi kufanele kuklanywe njengoba indawo yomjovo wesikhunta ithwala ingcindezi enkulu ekujozweni (kufanele ibe nkulu ngo-5-10 mm kunaleyo yengxenye yokuma nosayizi). Akumele kushiywe igebe phakathi kwezingxenye ezizungeze indawo yokubumba ngaphezulu, ngaphandle kwalokho ingxenye izobe ingasekho esimweni ngemva komjovo wesibili. Izingxenye ezingenayo i-SA(seam allowance) zizodinga ukunaka kakhulu lesi sici.

10.Uhambo lwasemoyeni lulula kalula Uhambo lomoya lwenzeka kalula ekubunjweni komjovo, ngakho-ke kufanele ucabangele ngokugcwele ukuphuma ekuklameni isikhunta. Kuwo wonke ama-engeli angaboniyo kanye nezindawo zolayini wamanzi webanga elide, kufanele bakhe izimbobo zokuphuma engxenyeni yepulasitiki eqinile njengoba kuba nzima kakhulu ukugcwalisa okubalulekile ngama-engeli angaboni.

11.Ukuqinisekisa ukuthi izinto ezijovwe kanye nokugxilwa okufanelekile kugcwaliswe ngokugcwele, enye indlela iwukuklama ama-undercuts emakhoneni engxenye ukuze uthuthukise umphumela wokunamathela bese wenza izingxenye zibambelele ngokuqinile.

12.Endaweni yokuvala kanye nendawo yomugqa wokuhlukanisa, akufanele sisuse umgodi kanye nomgogodla, ngoba imigqa yokuhlanganisa esikhunjeni kanye nokusalungiswa kokudilizwa kuzodala ukukhanya ekulinganeni kwesikhunta. Zama ukudiliza nge-LISS-OFF.

Izinhlobo zamaphoyinti esango zokufaka isikhunta

Iphoyinti lesango lokufaka isikhunta lingaklanywa ukuqondisa isango levalvu ye-sprue eshisayo, isango lephinikhodi le-sprue elishisayo, isango lephoyinti lokukhonjwa, isango elincane, isango lomphetho...njll.

Isango le-valve ye-sprue elishisayo: i-liquidity enhle, indawo yokukhetha eguquguqukayo, iphoyinti lesango elincane. Amasudi okukhiqizwa okukhulu kanye nemikhiqizo enodonga oluwugqinsi. Ingasiza ekongeni okubalulekile, akukho ukumosha impahla yesango, isikhathi esifushane sokuhola, kanye nekhwalithi ephezulu. Okuwukuphela kwesici ukulandelelwa kwesango okuncane.

Isango lephinikhodi le-sprue elishisayo: i-liquidity enhle, ukukhetha isikhundla esivumelana nezimo, iphoyinti lesango elincane. Amasudi okukhiqizwa okukhulu kanye nemikhiqizo enodonga oluwugqinsi. Ingasiza ekongeni okubalulekile, akukho ukumosha impahla yesango, isikhathi esifushane sokuhola, kanye nekhwalithi ephezulu. Kodwa kukhona okungalungile, okufana nempahla engu-0.1mm eshiywe eduze kwephoyinti lesango, futhi kulula ukuyibhanqa. Kudingeka wenze ama-grooves ukumboza izinto ezingakwesokunxele eduze kwendawo yesango.

Isango lokuphina: isikhundla sokukhetha okuguquguqukayo, i-liquidity ebuthakathaka, ibanga lomgijimi omude, iphoyinti lesango elincane. Amasudi okukhiqiza amaqoqo amancane. Imfucuza eyengeziwe ezungeze indawo yesango. Kudingeka izingalo eziwumshini ukuze ubambe iphoyinti lesango ekukhiqizeni. Isikhathi eside sokuhola. Isici siyinto engu-0.1-0.2mm eshiywe eduze kwephoyinti lesango, idinga imisele yokuvala into engakwesokunxele eduze kwendawo yesango.

Isango elingaphansi: ingaklanywa ezimbanjeni ezingaphakathi, umgogodla, izindonga ezisemaceleni, nezikhonkwane ze-ejector. Ingakhetha indawo yesango ngokuguquguqukayo, isango lokuthela lihlukanisa ingxenye ngokuzenzakalelayo, umkhondo wokungena kancane. Amaphutha: kulula ukukhipha impahla eduze kwendawo yesango, kulula ukubangela izimpawu zokoma endaweni yokungena, idinga ukusula izinto ngesandla, ukulahlekelwa okukhulu kokucindezela kusukela endaweni yesango kusuka emigodini.

Isango lomngcele: ipulasitiki encibilikisiwe igeleza esangweni, inikezwe ngokulinganayo, inciphise ukucindezeleka; nciphisa amathuba okungena komoya emgodini, gwema ukubangela imivimbo namabhamuza. Amaphutha: isango lokuthulula alikwazi ukuhlukana nengxenye ngokuzenzakalelayo, izimpawu ze-sprue ezisele emaphethelweni engxenye, zidinga amathuluzi okucubungula ukuthululwa kwesango eliyisicaba. Isango le-Edge lingasiza umjovo wesilinganiso nokubamba ingcindezi, futhi lilungele ukubamba ingcindezi kanye nokudla, ngale ndlela, lingcono ukuthuthukisa imigqa yomoya, izimpawu zokugeleza…njll.

Ukucubungula nokufaka isikhunta sokufaka

1.Ngaphambi kokucubungula, sebenzisa ubuchwepheshe bokucubungula isikhunta. Khetha imishini yokucubungula enembayo ephezulu, umshini onesivinini esikhulu, umshini wokusika kancane we-NC wire, isibuko se-EDM(umshini wokukhipha ugesi) njll.

2.Dizayina 0.05-0.1mm kwesokunxele endaweni yokucindezela ngaphambilini.

3.Qaphela izidingo zokunemba ekucubunguleni isisekelo sesikhunta, hlola ukubekezelelana ngemuva kokuthola isisekelo sesikhunta futhi ungasisebenzisi uma ukubekezelelana kungafaneleki.

4.Beka amantongomane, izingxenye zensimbi kanye nezingxenye zepulasitiki eziqinile ngaphakathi kwesikhunta ukuze kufakwe isikhunta. Uma uthola izinkinga ekufakweni kwesikhunta, hlola amantongomane, izingxenye zensimbi, izingxenye zepulasitiki eziqinile kanye nezibunji ukuze ubone ukuthi iyiphi engalungile. Cacisa ingxenye ngokomdwebo kangangokunokwenzeka, okusiza ukulandelela idatha esikhathini esizayo.

5.Ayikwazi ukusebenzisa igrinder ukufaka isikhunta. Phendukela emishinini yokulungisa lapho ukufaka isikhunta kungalungile.

6.Yenza ukuhlolwa kwesenzo ngaphambi kwecala, gwema ukuphuthelwa ukuhlanganisa nokuhlanganisa okuyiphutha. Ukuhlangana ngephutha kuzodala ukulimala kwesisekelo sesikhunta.

Ukuhlolwa kwesikhunta sokufaka isikhunta

1.Ekuhlolweni kwesikhunta, umuntu udinga ukwazi ngokucacile mayelana nokulandelana kokuvula, ukuvala nokukhipha isikhunta. Qonda izici zesakhiwo kanye nezakhiwo zezingxenye zensimbi nezingxenye zepulasitiki eziqinile.

2.Yazi ngokucacile mayelana nenani lamasampula elidingwa yikhasimende, lungiselela amantongomane anele, izingxenye zensimbi namapulasitiki aqinile, ngoba idinga amasampula amaningi ekuhlolweni kwesikhunta.

3.Qaphela ukuthi ingakwazi yini ukuhlola isikhunta ngaphandle kokufaka amantongomane, izingxenye zensimbi noma amapulasitiki aqinile. Uma faka amantongomane, izingxenye zensimbi namapulasitiki aqinile kungahlanganiswanga esikhunjeni, ingxenye ingaba namaphutha njengokunamathela esikhunjeni noma isibhamu esifushane.

4. Ezimweni eziningi, kudingeka ulungise ipuleti le-waterline ekubunjeni, kodwa ngezinye izikhathi alikwazi ukulungisa ipuleti lomugqa wamanzi kwezinye isikhunta sokufaka ngokusekelwe esakhiweni sazo, noma okubi nakakhulu, isikhunta sibambeke kakhulu futhi sidinga ukuguqulwa, noma isikhunta sonakaliswa ukuvula.

5.Izinkinga zingase zenzeke ekuhlolweni kwesikhunta, njengokushutha okufushane, ukuhamba emoyeni, ukukhanya, noma ukunamathela esikhunjeni. Uma izinkinga zingaqinisekiswa emshinini wokubumba umjovo, kungcono ukuzixazulula.

I-DJmolding inesipiliyoni sokubumba iminyaka engaphezu kwe-10+, uma unombuzo, sicela usithinte.