Ukulungisa Isikhunta sokujova

Ukulungisa Nokulungiswa Kwesikhunta

Silungisa zonke isikhunta esenziwe yithi noma abanye abakhiqizi zingakapheli izinsuku ezi-5.

Imishini yamathuluzi

Ukuze kukhiqizwe futhi kusetshenziswe isikhunta i-DJmolding isebenzisa ngaphandle kwemishini evamile efana nezinsimbi, imishini yokugaya eyindilinga neyisicaba, imishini yokugaya kanye nemishini yokugaya kanye nezikhungo zokukhiqiza imishini.

Kusebenza kanjani ukulungisa isikhunta

Senza isikhunta kunoma yimuphi umkhiqizi. Ingabe unaso isikhunta esiphahlazekile? Sihlola umonakalo, siklame isixazululo esizothinta kancane ukuphila kwesikhunta, bese siqala ukusebenza. Ukulungisa okungadingeki kangako kuqedwa phakathi nezinsuku ezi-5. Kodwa-ke, singakwazi ukulungisa isikhunta ngokushesha okukhulu, isibonelo ngempelasonto uma umonakalo wesikhunta udala isikhathi sokukhiqiza. Xhumana nathi, sizothola isixazululo.

Ukulungiswa kwendawo yokuthungwa kwesikhunta yithimba lethu lapha e-DJmoldng kuzokuqinisekisa ukufana okuhle kakhulu.

Izingcweti zethu ezinolwazi kanye nochwepheshe bazobuyisela noma iyiphi iphethini eyonakele. Konke ukulungiswa kwesikhunta kuhlukile noma kungaba:

*Weld ekulungiseni umonakalo omkhulu noma izinguquko zobunjiniyela.

*Ukulungisa ukugqwala nokucwebezela

*Ukwakheka kwe-scuff kusuka kokusalungiswa okuncane

*Ukulungiswa kwesakhiwo

*Izinsimbi zomugqa wokuhlukanisa noma ama-ding

Uma i-welding idingeka, landela amathiphu angezansi ukuze ulungise kahle:

Weld ngento efanayo isikhunta esenziwa ngayo; ie P-20, S-7, H-13 noma insimbi engagqwali. Uma into efanayo ingasetshenziswa, i-weld ingase ibambe ngenani elihlukile ishiye umugqa wofakazi eduze kwe-weld lapho kulungiswa ukuthungwa.

Isikhunta kufanele sishiswe kahle ngaphambi kokushisela. Uma ingashisi ngendlela efanele, ingabangela ukuthi i-weld iphole ngokushesha. Uma lokhu kwenzeka, ngisho nalapho kusetshenziswa into efanayo, kuzobangela ukuthi i-weld igxile ngezinga elihlukile okungabe sekudinga ukushisa kwengcindezi ukuze kujwayeleke insimbi ukuze ithole i-etch engaguquki ukuze uthole umphumela ongcono kakhulu wokulungisa.

Ngokuthuthuka kwemboni ye-laser texturing sithuthukise inqubo yokulungisa i-laser kwa-DJmoldng engasetshenziswa kunoma iyiphi isikhunta noma ngabe yenziwe nge-laser noma ifakwe amakhemikhali ukulungisa izindawo ezilimele. Ngale nqubo singakwazi ukulungisa nge-laser indawo futhi sihlangane nokuthungwa okukhona sisusa noma yikuphi ukonakala okubonakalayo ukubuyisela ithuluzi lakho esimweni esisha.

Isikhunta esiguquliwe

Silungiselela idatha ngokwethu, i-CAD / CAM, futhi siphakamisa indlela engcono kakhulu yokulungisa.

Ukugcinwa Kwesikhunta

Sisebenzisa ikhemistri yethu ukuhlanza izingxenye ezivalekile futhi ngenxa yethoni ye-crane yethu singakwazi ukusevisa ukubunjwa okungafika kumathani angama-20.

Ukulungiswa Kwesikhunta Esilimele

Sikala izimo ezilimele futhi sibuyisela isimo sokuqala.

Idatha ye-2D/3D engekho

Ingabe idatha yesikhunta sakho ilahlekile? Singasiza. Siyakwazi ukulinganisa nokucubungula izingxenye ezithile ukuze silungise isikhunta.

Ukunemba okuphezulu

Senza ama-oda akho ngezinqubo ezijwayelekile ngokunemba okuphezulu. Amakhono ethu ayanda ngawo wonke ama-oda njengomhlinzeki wesevisi kulo mkhakha okhethekile. Sisebenzisa ubuchwepheshe besimanje bokushisela ngokwengxenye obuzenzakalelayo njengokushisela i-plasma, i-E-welding kanye ne-laser-welding. Imishini ye-CNC ezenzakalelayo ngokugcwele isebenza ngokusekelwa kwekhompyutha nangokunemba okukhulu.

Eminye imisebenzi

Ngaphezu kokukhiqiza, ukulungisa kanye nokuguqula isikhunta somjovo nokwenza imishini ye-semi-automatic yezimboni zezimoto, ezenza imithi nezobuchwepheshe, siphinde sinikeze nezinye izinsizakalo ezihambisanayo.

Designing

Sikuklama futhi sikwakhela ifomu ohlelweni lwesofthiwe ye-3D.

prototyping

Silungisa ithuluzi lenhloso eyodwa kusofthiwe ye-3D ukuze ukwazi ukuyizama ngokwenza ngaphambi kokusebenzisa uchungechunge.

I-Laser Welding

Silungisa ngokucophelela isikhunta sakho esiphahlazekile. Akukho ukucindezeleka kwangaphakathi kunsimbi ngesikhathi sokushisela.

Ubunjiniyela be-Precision and Machining

Sisebenza ngokunemba kwe-0.01 mm. Ochwepheshe bethu abanolwazi basebenza nemishini ye-NC, osinki nabasiki bezintambo.

Ukukhiqizwa kanye Nomklamo Wokulawula Nokulinganisa Amajigi

Ukuhlola nokulinganisa amajigi kwenza kube lula ukuhlola ukubunjwa kwakho okuqediwe. Sinakekela ukuklama nokukhiqiza.

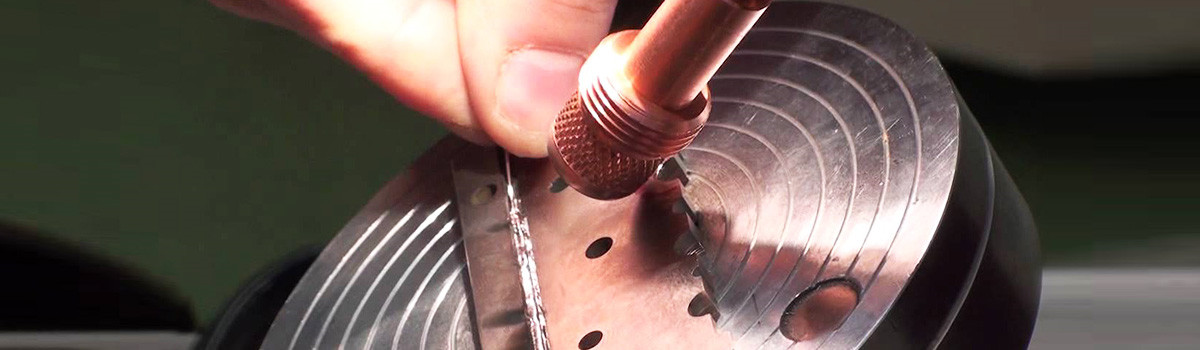

I-Copper Eyenziwe Ngokwezifiso noma Ama-Electrode E-Graphite

Sikhiqiza ama-electrode ethusi ne-graphite adingekayo ukuze kusetshenziswe imishini ye-EDM (i-cavity siking).

Ikhwalithi ekholisayo

Kungakhathaliseki ukuthi ukulungiswa, izinguquko zephrofayela noma ukukhiqizwa okusha - sizokukholisa ngezixazululo ezintsha zezidingo zakho ngazinye. Sikunikeza izixazululo ezenziwe ngokwezifiso nezisekelwe kwizidingo ezinomphumela wekhwalithi ephezulu nohlala isikhathi eside ozokukholisa ekusetshenzisweni kwansuku zonke ekukhiqizeni kwakho.

I-oda ngalinye lihlukile

Amakhasimende ethu alindele imikhiqizo yekhwalithi, uchwepheshe kanye nokwethembeka. Sisungula ubudlelwano besikhathi eside.