I-Low Volume Molding Molding - Isevisi Yokukhiqiza Ivolumu Ephansi

Usetshenziswa Kanjani Ukubumba Umjovo Wevolumu Ephansi(Isevisi Yokukhiqiza Ivolumu Ephansi)

Sebenzisa ukukhiqiza okudingekayo ukuze unciphise izindleko zokukhiqiza futhi unciphise ukuguquguquka kwesidingo

Kungakhathaliseki ukuthi uklama idivayisi yezokwelapha esindisa impilo noma indiza endiza kakhulu, ukutshala imali engu-$100,000 noma ngaphezulu—ngokuvamile engaphezulu kakhulu—kumathuluzi ensimbi enevolumu ephezulu kuwubungozi bezezimali obuhambisana nokuthuthela emkhiqizweni omkhulu. Okwandisa ubungozi yizinyanga zesikhathi sokungenzi lutho njengoba ulinda ithuluzi lakho lensimbi ukuthi lilungele lapho ungase uphindaphinde ingxenye yedizayini noma ukhiqize imikhiqizo eyenza imali engenayo. Kukhona indlela engcono: ukukhiqiza ngokufunwa.

Kuyini Ukukhiqiza Okufunwa Nguwe(ukubumba umjovo wevolumu ephansi)?

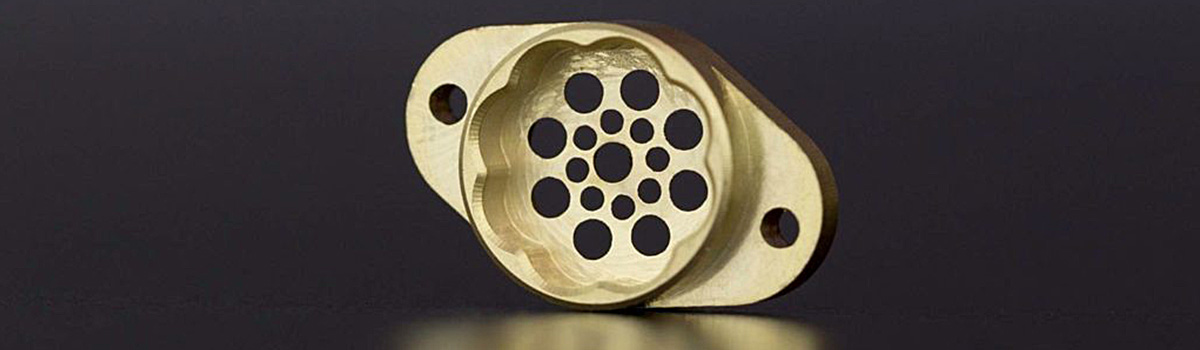

Kwa-DJmolding, umnikelo wethu wokukhiqiza ofunekayo, wevolumu ephansi ngomjovo wokubumba—osebenzisa amathuluzi e-aluminium—uyindlela esheshayo, engabizi kakhulu yokukhiqiza amakhulu ezinkulungwane zezingxenye ezibunjiwe ezisetshenziswa ekugcineni.

Sebenzisa le nqubo njengendlela yokukhiqiza eyinhloko yemikhiqizo yakho. Ukukhiqiza okudingeka kakhulu nakho kuyindlela enhle kakhulu yokusuka ku-prototyping uye ekukhiqizeni ivolumu ephansi yezingxenye ezibunjiwe. I-DJmolding empeleni ingumhlinzeki wokukhiqiza wesevisi ephelele. Ukugijima kwevolumu ephansi kungakusiza futhi ukuthi uqinisekise ingxenye yedizayini futhi uphathe i-inventory overhead ngokukhiqizwa kwezingxenye kuphela lapho isidingo siyala. Ngaphezu kwalokho, ngisho noma udinga ekugcineni ushintshele ekukhiqizeni ngobuningi bezingxenye zepulasitiki, usengasebenzisa amathuluzi ethu e-aluminium angabizi njengebhuloho ngaphambi kokuzibophezela ezindlekweni ezinkulu ngokusetshenziswa kwensimbi. Okokugcina, le ndlela efunwa kakhulu iphinde ithuthukise uchungechunge lwakho lokuhlinzeka, ilwenze libe nekhono ekulawuleni ukuntengantenga kwesidingo.

Biza Izici Ezibalulekile-kuya-kwikhwalithi

Uma usebenzisa inketho yethu yokukhiqiza okufunayo, uzokwazi ukukhombisa engxenyeni yakho ukudizayina ubukhulu obubaluleke kakhulu emsebenzini wengxenye. Ngokubiza lezi zici ezibucayi-kuya-kwikhwalithi (CTQ) kumodeli yakho ye-3D CAD, ungaqiniseka ukuthi izingxenye ezi-odiwe ziyahambisana nemodeli. Ngaphezu kwalokho, lokho kusho ukuthi ngesikhathi esilandelayo lapho u-oda lezo zingxenye, singalandela lezo zinyathelo ezinembile ukuze sikhiqize izingxenye ezingaguquki, eziphindaphindwayo ezinamathela ekucacisweni kwakho kwe-CTQ.

Ukuhlola kuyizingcezu ezibalulekile zale nqubo ye-CTQ. Ngokufanelekile, ithimba lethu lonjiniyela bezinhlelo zokusebenza lizobuyekeza imodeli yakho futhi likuthumelele i-imeyili Isitatimende Sokuhlolwa Somsebenzi (ISOW), esikwazisa ukuthi noma yiziphi izici ozifakile zinezinkinga zokubekezelela nokubumbeka. Uma sesithumele i-ISOW, sikhiqiza futhi sihlole i-oda lakho.

Uma sesiqedile ukuthuthukiswa kwenqubo yokubumba, okuqinisekisa ukuthi sinenqubo engaguquki nephindaphindekayo yokukhiqiza izingxenye zekhwalithi, sizohlola amashothi amathathu okuqala ethuluzi, sisebenzisa umshini wokulinganisa ozenzakalelayo we-Coordinate-measuring (CMM), futhi sikunikeze ezintathu. -ingxenye Umbiko Wokuhlolwa Kwesiqephu Sokuqala (i-FAI), kanye Nombiko Wamandla Enqubo.

Zuza ukuguquguquka kochungechunge lokuhlinzekwa kwempahla kusuka kusevisi yokubumba umjovo wevolumu ephansi ye-DJ

Kulezi zinsuku, njengoba sonke siqhubeka nokuzulazula ubhubhane lomhlaba wonke, ukucatshangelwa kwe-supply chain kubalulekile. Indlela yokukhiqiza okudingeka kakhulu ingakusiza ukuthi udale uchungechunge lokuhlinzeka ngezinto ezilula ngokuthi:

* Ukuthola izingxenye ngokufunwa ngaphandle kwanoma iyiphi I-Minimum Order Quantity (MOQ)

* Ukwehliswa kwezindleko ze-inventory kanye nezindleko zendawo yokugcina impahla ngokufunwa ngokufunwa

* Ukuphatha ukwenyuka kokuntengantenga kwesidingo ngaphandle kokubuyela emuva

* Ukunciphisa ubungozi bokubambezeleka kwemikhumbi yasekhaya neyasemhlabeni jikelele

* Ukunciphisa isikhathi sokuphumula kanye nokunciphisa ingozi yokuphela kwesitokwe lapho amathuluzi amakhulu elungiswa

I-Low-Volume Production ka-DJmolding

Lena isevisi ekhethekile enikeza izingxenye ezigcwele zekhwalithi yokukhiqiza kodwa ngamavolumu ngokuvamile anomkhawulo wezingcezu eziyi-10,000 noma ngaphansi, kuye ngenqubo esetshenzisiwe. Ukubumba kwethu kwevolumu ephansi, okubuye kubizwe ngokuthi ama-run amafushane, kuyagadwa futhi kuyalawulwa ukuze uqiniseke ngazo zonke izici zokuklama nokwakha isikhunta. Lolu hlobo lokukhiqiza lulungele amabhizinisi amancane naphakathi nendawo noma ukukhiqizwa kwamaqoqo amancane.

Ukukhiqiza umthamo ophansi kuyinkambu entsha embonini yokukhiqiza emayelana nokukhipha izingxenye, imikhiqizo, nezinto zokwakha kubantu besithathu.

Lokhu kuvumela inkampani yakho ukuthi igxile kakhulu esicini sokukhiqiza kuyilapho amabhizinisi amancane ephethe ukuklama nokufaka uphawu kwemikhiqizo. Lo mkhuba okhulayo uzodlanga kuzo zonke izimboni njengoba osomabhizinisi abancane bebheke ukukhulisa ibhizinisi labo ngokuthumelela ezinye izinkampani nokugcina izindleko ziphansi.

I-DJmolding's Small Volume Injection Molding

Abantu abaningi bezwa amagama “iShayina” kanye “nokubumba” emshweni ofanayo bese becabanga okubi kakhulu. Bacabanga ngemikhiqizo eshibhile, esezingeni eliphansi eyenziwe kusetshenziswa izindlela zokukhiqiza ezisezingeni eliphansi ezibeka impilo yabasebenzi engcupheni.

Kodwa lokho akunjalo ngaso sonke isikhathi.

I-DJmolding evela e-China inomlando omude wokukhiqiza izimpahla zekhwalithi ezizothunyelwa ngaphandle. Eqinisweni, eminye yemikhiqizo eyenziwe kahle kakhulu emhlabeni ivela eChina! Futhi uma kukhulunywa ngokubumba umjovo wepulasitiki, iChina empeleni ingelinye lamazwe athuthuke kakhulu emhlabeni.

Ukubumba umjovo kuyindlela ethandwayo yokwenza izingxenye zepulasitiki namadivayisi. I-DJmolding ingumkhiqizi omuhle wokuthola isikhunta somjovo wevolumu ephansi ngoba izindleko zabasebenzi zincane kakhulu kunase-United States noma eYurophu. I-DJmolding inenani elincane le-oda (MOQs) yezingcezu eziyi-1,000 kuphela kanye nezikhathi zokuhola zibe mfushane njengamaviki angu-3-4. Lokhu kungaba usizo kakhulu ezinkampanini ezincane ezifuna ukuqalisa ngomugqa wazo womkhiqizo kodwa ezingafuni ukutshala imali eningi ekusetshenzisweni kwamathuluzi nasezindlekweni zokukhiqiza kusengaphambili.

Ngakho wazi kanjani uma usebenzisana nomhlinzeki onokwethenjelwa? Udinga ukubheka imininingwane

Inani Eliphansi Le-oda (MOQ) – Umphakeli othembekile ngeke akucele i-oda elikhulu ngaphambi kokuthi abe nethuba lokuhlangana nawe noma abone umkhiqizo wakho. Kunalokho, sizofuna ukwenza isiqiniseko sokuthi uzimisele ngephrojekthi yakho ngaphambi kokuchitha isikhathi esiningi noma imali kuyo.

Isikhathi Sokuhola - Abahlinzeki abangcono kakhulu bazoba nezikhathi zokuhola ngokushesha ukuze bakwazi ukuletha umkhiqizo wakho ngokushesha ngangokunokwenzeka (futhi bahlangabezane nezindinganiso zekhwalithi).

Ukubumba umjovo kuyinqubo yokukhiqiza edumile yemikhiqizo yepulasitiki ekhiqiza ngobuningi, kodwa kuthiwani uma udinga inani elincane lezingxenye zephrojekthi yakho? Yilapho ukubumba komjovo wevolumu ephansi kungena khona. Kuyindlela engabizi kakhulu yokukhiqiza iqoqo elincane lezingxenye zepulasitiki ngaphandle kokuphula ibhange. Kulokhu okuthunyelwe kwebhulogi, sizongena ezinzuzweni nasekusetshenzisweni komjovo wevolumu ephansi, ukuthi ihluke kanjani ekubunjweni komjovo wevolumu ephezulu, nokuthi ingazuzisa kanjani ibhizinisi lakho.

Ukuqonda Ukubunjwa komjovo wevolumu ephansi

Ukubumba komjovo wevolumu ephansi kuyinqubo yokukhiqiza evumela ukukhiqiza amanani amancane ezingxenye zepulasitiki. Kuyisixazululo esisebenzayo nesingabizi ezinkampanini ezidinga ukukhiqizwa okuncane noma ezinesabelomali esilinganiselwe.

- Inqubo yokubunjwa komjovo wevolumu ephansi iqala ngokudala isikhunta. Ngokuvamile, abakhiqizi benza isikhunta ngensimbi noma i-aluminium futhi bayiklame ukuze kuzuzwe ukuma okufunayo kwengxenye yepulasitiki. Ngesikhathi sokubumba umjovo, abakhiqizi babamba ndawonye izingxenye ezimbili zesikhunta: umgodi kanye nomgogodla.

- Ngaphambi kokubunjwa komjovo, izinto zepulasitiki ziyashiswa futhi zincibilike ekamelweni elihlukile. Abakhiqizi bajova ipulasitiki esikhunjeni ngaphansi kwengcindezi ephezulu uma isifinyelele izinga lokushisa elifunekayo. Ipulasitiki igcwalisa umgodi bese ithatha isimo sesikhunta.

- Ngemva kokuba ipulasitiki ipholile futhi yaqina, abakhiqizi bavula isikhunta futhi bakhiphe ingxenye eqediwe. Isikhathi somjikelezo sokubumba umjovo wevolumu ephansi sifushane, sivumela ukukhiqizwa okusheshayo kunezinye izinqubo zokukhiqiza.

- Ukubunjwa komjovo wevolumu ephansi kunikeza izinzuzo ezimbalwa. Okokuqala, izokwenza ukuthi kukhiqizwe izingxenye eziyinkimbinkimbi neziyinkimbinkimbi ngokunemba okuphezulu nokuphindaphindeka. Izimboni ezidinga izingxenye eziyinkimbinkimbi, njengezimoto, zikagesi, nemishini yezokwelapha, zingaba yinzuzo ukukhetha le nketho.

- Ukwengeza, ukubumba komjovo wevolumu ephansi kunikeza ukonga kwezindleko uma kuqhathaniswa nezindlela zokukhiqiza zevolumu ephezulu. Njengoba ukutshalwa kwezimali kokuqala kokusetshenziswa kwamathuluzi kuphansi, kufinyeleleka kakhudlwana emabhizinisini amancane noma kwabaqalayo. Iphinde inikeze amandla isikhathi esisheshayo sokuya emakethe, njengoba isikhathi sokuhola sokusebenzisa amathuluzi sisifushane.

- Enye inzuzo yokubumba komjovo wevolumu ephansi ukuguquguquka kwayo. Ivumela ukuguqulwa kwedizayini nokuphindaphinda ngaphandle kokufaka izindleko ezibalulekile ezengeziwe. Kungakho izinguquko zedizayini ezilindelwe phakathi nezigaba zakuqala zizuzisa kakhulu ukuthuthukiswa komkhiqizo kanye ne-prototyping.

- Naphezu kwezinzuzo zako, ukubumba komjovo wevolumu ephansi kunemikhawulo ethile. Njengoba igama liphakamisa, ayifanele ukukhiqizwa kwevolumu ephezulu. Izindleko ngengxenye ngayinye zingaba phezulu kunezindlela zokukhiqiza ngobuningi ngenxa yezindleko eziphakeme zamathuluzi nokusetha. Ngakho-ke, ifaneleka kakhulu ekugijimeni kokukhiqiza okuncane kuya kokuphakathi.

- Ukukhethwa kwezinto ezibonakalayo nakho kuyacatshangelwa ekubunjweni komjovo wevolumu ephansi. Izinketho zezinto ezilinganiselwe ziyatholakala uma kuqhathaniswa nezinqubo zokukhiqiza umthamo ophezulu. Kodwa-ke, izinto eziningi ze-thermoplastic, ezihlanganisa i-ABS, i-polycarbonate, inayiloni, ne-polypropylene, zisengasetshenziswa.

- Ukusebenza nomkhiqizi wokubumba umjovo onolwazi nonolwazi kubalulekile ekukhiqizeni umthamo ophansi. Bangaqondisa ukukhethwa kwempahla, ukwakheka kwesikhunta, kanye nokwenza ngcono inqubo ukuze kuqinisekiswe imiphumela engcono kakhulu.

Izinzuzo zokubunjwa komjovo wevolumu ephansi

Ukubumba umjovo wevolumu ephansi kunikeza izinzuzo ezimbalwa ezinkampanini ezinezidingo zokukhiqiza ezincane kuya eziphakathi. Ezinye zezinzuzo ezibalulekile zalolu hlelo lokukhiqiza zihlanganisa:

Ukukhiqiza okungabizi kakhulu

- Ukutshalwa kwezimali kokuqala okuphansi kumathuluzi uma kuqhathaniswa nezindlela zokukhiqiza zevolumu ephezulu.Kufinyeleleka emabhizinisini amancane noma eziqalisweni.

- Isikhathi sokuya emakethe esisheshayo ngenxa yesikhathi esifushane sokuhola sokusetshenziswa kwamathuluzi, ukwehlisa izindleko zokukhiqiza zizonke.

Izingxenye eziyinkimbinkimbi nezinembayo

- Inqubo ivumela ukukhiqizwa kwezingxenye eziyinkimbinkimbi neziyinkimbinkimbi ngokunemba okuphezulu nokuphindaphinda. Ilungele izimboni ezifana nezimoto, zikagesi, nemishini yezokwelapha edinga izingxenye eziyinkimbinkimbi.

- Inqubo ivumela ukubekezelelana okuqinile kanye nokufakwa kwemininingwane emihle ekwakhiweni.

Ukuvumelana nezimo

- Inqubo ivumela ukuguqulwa kwedizayini okulula nokuphindaphinda ngaphandle kwezindleko ezibalulekile ezengeziwe.

- Izuzisa kakhulu ekuthuthukisweni komkhiqizo kanye ne-prototyping, lapho ukulungiswa kwedizayini nokucolisiswa kusezingeni phakathi nezigaba zokuqala.

Ukuguquguquka kwezinto

- Inqubo ihlinzeka ngezinto ezahlukahlukene ze-thermoplastic, okuhlanganisa i-ABS, i-polycarbonate, inayiloni, ne-polypropylene.

- Ihlangabezana nezidingo ezithile kanye nezakhiwo ezifiselekayo zomkhiqizo wokugcina.

Imijikelezo yokukhiqiza esheshayo

- Inqubo iziqhayisa izikhathi zomjikelezo omfushane, ovumela ukukhiqizwa okusheshayo kunezinye izinqubo zokukhiqiza.

- Iwusizo ekuhlangabezaneni neminqamulajuqu eqinile yephrojekthi noma ekuphenduleni isidingo semakethe ngokushesha.

- Yandisa ukukhiqiza futhi inikeza izikhathi zokushintsha ngokushesha.

Ukwehliswa kwemfucuza kanye nomthelela emvelweni

- Inqubo inciphisa udoti wezinto ezibonakalayo ngokusebenzisa kuphela inani elidingekayo lepulasitiki.

- Inqubo inciphisa ukusetshenziswa kwamandla kanye nokukhishwa kwegesi uma kuqhathaniswa nezindlela zokukhiqiza zevolumu ephezulu.

- Inketho yokukhiqiza evumelana nemvelo.

Ikhwalithi nokuvumelana

- Inqubo iqinisekisa izingxenye zekhwalithi ephezulu ezinobukhulu obungaguquki kanye nezakhiwo.

- Le nqubo ihlinzeka ngokulawula okuhle kakhulu kwezinga lokushisa, ingcindezi, neziguquguqukayo zokupholisa.

- Ithembekile ezimbonini lapho ukusebenza komkhiqizo nokuthembeka kuyizinto ezibalulekile.

Ukwenza ngokwezifiso nokwenza kube ngokwakho

- Inqubo inikeza ithuba lokwenza ngokwezifiso kanye nokwenza kube ngokwakho imikhiqizo.

- Ukukhiqizwa kwezingxenye eziyingqayizivele eziklanyelwe izidingo ezithile zamakhasimende.

- Inqubo ithuthukisa ukuhlukaniswa komkhiqizo nokwaneliseka kwamakhasimende.

Ukunciphisa ubungozi kanye nokuhlolwa kwemakethe

- Inqubo iyinketho enengcuphe ephansi yokuthuthukiswa komkhiqizo omusha noma ukuhlolwa kwemakethe.

- Inqubo ikhiqiza izingxenye ezilinganiselwe zokuhlola, ukuqinisekiswa, kanye nempendulo yemakethe.

- Inciphisa ubungozi bokutshala izimali ngenani elikhulu lezingxenye ezingase zidinge ukuguqulwa noma zingahlangabezani nezidingo zemakethe.

Ivolumu Ephansi vs. Ukubunjwa komjovo wevolumu ephezulu

Ungajwayelanisa ukubumba komjovo, inqubo yokukhiqiza eguquguqukayo, ukuze ivumelane nezidingo ezahlukahlukene zokukhiqiza. Izinhlobonhlobo ezimbili ezijwayelekile zokubumba umjovo umthamo ophansi kanye nevolumu ephezulu. Ake siqhathanise lezi zindlela ezimbili futhi sihlole umehluko wazo:

Ukubunjwa komjovo wevolumu ephansi

- Ifanele izinkampani ezinezidingo zokukhiqiza ezincane kuya kweziphakathi.

- Inikeza ukukhiqiza okubiza izindleko, okwenza kufinyeleleke emabhizinisini amancane noma aqalayo.

- Inqubo idinga ukutshalwa kwezimali kokuqala okuphansi kumathuluzi uma kuqhathaniswa nokukhiqizwa kwevolumu ephezulu.

- Ivumela isikhathi esisheshayo sokuya emakethe ngenxa yesikhathi sokuhola esifushane samathuluzi, ukwehlisa izindleko zokukhiqiza zizonke.

- Inqubo ivumela ukukhiqizwa kwezingxenye eziyinkimbinkimbi neziyinkimbinkimbi ngokunemba okuphezulu nokuphindaphinda.

- Inikeza ukuguquguquka kwedizayini, okuvumela ukuguqulwa kwedizayini okulula nokuphindaphinda ngaphandle kwezindleko ezibalulekile ezengeziwe.

- Isekela ukuguquguquka kwezinto ezibonakalayo, ihlinzeka ngezinhlobonhlobo zezinto zokwakha ze-thermoplastic ukuhlangabezana nezidingo ezithile.

- Ihlinzeka ngemijikelezo yokukhiqiza esheshayo uma kuqhathaniswa nezinye izinqubo zokukhiqiza, okunomthelela ekwandeni kokukhiqiza kanye nezikhathi ezimfushane zokushintsha.

- Yehlisa imfucuza yezinto ezibonakalayo ngokusebenzisa kuphela inani elidingekayo lepulasitiki, inciphisa umthelela wendawo.

- Ukuqinisekisa izingxenye zekhwalithi ephezulu ezinobukhulu nezakhiwo ezingaguquki kubalulekile ezimbonini lapho ukusebenza komkhiqizo nokuthembeka kubaluleke kakhulu.

- Inikeza izinketho zokwenza ngendlela oyifisayo nokwenza kube ngokwakho, okuvumela ukukhiqizwa kwezingxenye ezihlukile eziklanyelwe izidingo ezithile zekhasimende.

- Inciphisa ubungozi ngesikhathi sokuthuthukiswa komkhiqizo omusha kanye nokuhlolwa kwemakethe, okuvumela izinkampani ukuthi zikhiqize ingxenye elinganiselwe yezingxenye ukuze ziqinisekiswe futhi ziphendule ngaphambi kokuzibophezela ekukhiqizeni ngokugcwele.

I-High Volume Injection Molding

- Ifanele izinkampani ezinezidingo ezinkulu zokukhiqiza.

- Umthamo wokukhiqiza ophezulu ubandakanya ukutshalwa kwezimali okuthe xaxa kokuqala ekusetshenzisweni kwamathuluzi nokubunjwa.

- Idinga izikhathi zokuhola ezinde zokusetshenziswa kwamathuluzi, okungase kunwebe isikhathi sokumaketha.

- Ihlinzeka ngezinzuzo zezindleko ngenxa yezomnotho zesikali, njengoba umthamo ophezulu usakaza izindleko ezingashintshi kumayunithi amakhulu.

- Le nqubo yenza kube lula ukukhiqizwa kwezingxenye ezinkulu ngesikhathi esifushane.

- Ilungele izimboni ezinemikhiqizo edingeka kakhulu kanye nokuba khona kwemakethe okuqinisekisiwe.

- Ingase inikeze ububanzi obuncane bezinketho zezinto ezibonakalayo uma kuqhathaniswa nokubunjwa komjovo wevolumu ephansi.

- Idinga ukuhlela okucophelelayo kanye nokubikezela ukuze kuthuthukiswe ukusebenza kahle kokukhiqiza futhi kuncishiswe imfucuza.

- Inqubo isekela ukulawulwa kwekhwalithi okungaguquguquki kanye nokubambelela encazelweni kuyo yonke inqubo yokukhiqiza ivolumu ephezulu.

- Inikeza ukuguquguquka kwedizayini okulinganiselwe, njengoba izinguquko zedizayini zingase zibe nezindleko ezingeziwe.

Izicelo zokubunjwa komjovo wevolumu ephansi

Ukubumba komjovo wevolumu ephansi kuyinqubo yokukhiqiza eguquguqukayo ethola izinhlelo zokusebenza kuzo zonke izimboni ezahlukahlukene. Ikhono layo lokuhlinzeka ngokukhiqiza okungabizi kakhulu, ukuguquguquka komklamo, nezinketho zokwenza ngokwezifiso kuyenza ifanelekele izinhlelo zokusebenza eziningi. Ake sihlole ezinye izinhlelo zokusebenza ezijwayelekile zokubumba umjovo wevolumu ephansi:

Industry Automotive

- Ukukhiqizwa kwezingxenye eziyinkimbinkimbi nezinembayo zengaphakathi lezimoto, ingaphandle, nezinhlelo zokusebenza ezingaphansi kwe-hood.

- Ukwenziwa kwamaphaneli edeshibhodi yangokwezifiso, izingcezu zokunquma, amafindo, namaswishi.

- I-Prototyping kanye nokukhiqizwa kwezingxenye zezimoto ezikhethekile ezinempahla ethile.

- Ukwakhiwa kwama-air vents, imigudu, nezixhumi zamasistimu e-HVAC yemoto.

Imboni Yezogesi Nezogesi

- Ukukhiqizwa kwezingxenye eziyinkimbinkimbi zama-electronics abathengi njengama-smartphones, amaphilisi, namakhompyutha aphathekayo.

- Ukwenziwa kwezixhumi, izindlu, nezindawo ezivalekile zamadivayisi kagesi.

- Ukwenza ngendlela oyifisayo amakhiphedi, izinkinobho, namaswishi anezinhlobonhlobo nemibala.

- Ukukhiqizwa kwezixhumi zikagesi nezisekelo zemishini yezimboni.

- I-Prototyping kanye nokukhiqizwa kwamadivayisi we-microelectromechanical systems (MEMS).

Imboni Yezokwelapha Nezempilo

- Ukukhiqiza izingxenye zedivayisi yezokwelapha njengemiphongolo yesirinji, izixhumi ze-IV, namathuluzi okuhlinza.

- Ukukhiqizwa kwezingxenye ezingokwezifiso zemishini yezokwelapha kanye nemishini yokuxilonga.

- I-Prototyping kanye nokukhiqizwa kwezingxenye ze-biocompatible zokufakelwa kwezokwelapha kanye ne-prosthetics.

- Ukukhiqizwa kwemishini yokulethwa kwezidakamizwa nezingxenye zokupakisha.

- Ukukhiqiza imikhiqizo yamazinyo efana namathreyi angokwezifiso, ama-orthodontic aligner, neziqondiso zokuhlinza.

Impahla yabathengi

- Ukwenza ngokwezifiso imikhiqizo yabathengi njengamathoyizi, izinto zasendlini, nezinto zokunakekela komuntu siqu.

- Ukukhiqizwa kwemiklamo eyingqayizivele yokupakisha enezici zokufaka uphawu.

- Ukukhiqizwa kokuphumayo kwezinga elincane kusebenzisa imikhiqizo elinganiselwe noma izimakethe ze-niche.

- Ukukhiqizwa kwezingxenye eziyinkimbinkimbi nezihlobisa zezinto zokuhlobisa ikhaya.

- Ukudalwa kwemikhiqizo yokukhangisa eyenziwe ngokwezifiso kanye nezipho.

Izinsiza Zezimboni

- I-Prototyping kanye nokukhiqizwa kwezingxenye ezikhethekile zemishini yezimboni nemishini.

- Ukwenziwa kwezingxenye zamathuluzi, amajigi, nezinto ezilungiswayo.

- Ukwenza ngokwezifiso izingxenye zemishini yezimboni ukuze kuhlangatshezwane nezidingo ezithile.

- Ukukhiqizwa kwezingxenye ezihlala isikhathi eside nezisebenza kakhulu zezinhlelo zokusebenza ezinzima.

- Ukwakhiwa kwezembozo zokuvikela, onogada, nezikhwelo zemishini.

Ezemidlalo Nokuzijabulisa

- Ukukhiqizwa kwezingxenye zemishini njengezibambo, izibambo, namagiya okuvikela.

- Ukwenziwa kwezingxenye zangokwezifiso zamabhayisikili, ama-kayak, nezinye izinto zemidlalo.

- Ukwakhiwa kwezingxenye ezikhethekile zemishini yokufaneleka.

- I-Prototyping kanye nokukhiqizwa kwezingxenye zemikhiqizo yokuzijabulisa yangaphandle.

Izimboni Ezizuza Ekubumbeni Umjovo Wevolumu Ephansi

Ukubumba umjovo wevolumu ephansi kunikeza izinzuzo ezibalulekile ezimbonini ezimbalwa, okufaka phakathi imishini yezokwelapha, i-aerospace, izimoto, izinto zikagesi, izimpahla zabathengi, okokusebenza kwezimboni, i-prototyping, imikhiqizo ekhethekile, nezingxenye ezishintshayo. Le nqubo yokukhiqiza ehlukahlukene isiza ukukhiqizwa okungabizi kakhulu kwenani elincane, okuvumela ukwenziwa ngokwezifiso, ukuqamba okusha, kanye nokuthuthukiswa komkhiqizo okuphumelelayo.

- Amadivayisi Ezokwelapha:Ukubumba komjovo wevolumu ephansi kulungele ukukhiqiza imishini yezokwelapha eyenziwe ngokwezifiso kanye nezingxenye ezinemininingwane enembile. Ivumela ukukhiqizwa okungabizi kakhulu kwenani elincane, okwenza abakhiqizi bezokwelapha bahlangabezane nezidingo zesiguli ezihlukahlukene.

- I-Aerospace:Imboni ye-aerospace idinga izingxenye eziyinkimbinkimbi ezinokunemba okuphezulu namazinga aqinile ekhwalithi. Ukubumba umjovo wevolumu ephansi kuvumela ukukhiqizwa kwezinto ezingasindi, ezihlala isikhathi eside, ukunciphisa isisindo kanye nokwenza ngcono ukusebenza kahle kukaphethiloli endizeni.

- Izithuthi:Ukubumba umjovo wevolumu ephansi kubalulekile ekwenzeni i-prototyping nokukhiqiza izingxenye zezimoto ezikhethekile. Ivumela abakhiqizi ukuthi baphindaphinde ngokushesha futhi bacwenge imiklamo, baqinisekise ukusebenza okuseqophelweni eliphezulu kanye nokusebenza ngaphambi kokukhiqiza ngezinga eligcwele.

- I-elekhoni:Imboni yezogesi izuza ekubunjweni komjovo wevolumu ephansi ukuze ikhiqize izingxenye eziyinkimbinkimbi, njengezixhumi nama-casings. Le nqubo yenza kube lula ukukhiqizwa kwamaqoqo amancane, okuhambisana nemvelo esheshayo yokukhiqiza izinto zikagesi.

- Izimpahla zabathengi: Ukubumba umjovo wevolumu ephansi kunenzuzo ekudaleni izimpahla zabathengi ezenziwe ngokwezifiso ezinemiklamo eyingqayizivele nezici. Inika amandla ukukhiqizwa okusheshayo kwamanani amancane, yenza kube lula ukuhlolwa kwemakethe nokwenza ngokwezifiso ukuhlangabezana nezintandokazi zabathengi.

- Izisetshenziswa zezimboni: Ukubumba komjovo wevolumu ephansi kukhiqiza izingxenye zemishini yezimboni, njengamagiya, ama-valve, nezindlu. Le nqubo ivumela ukukhiqizwa okungabizi kakhulu kwenani elincane, ukuhlangabezana nezidingo ezithile zezicelo zezimboni.

- I-Prototyping kanye Nokuthuthukiswa Komkhiqizo: Izinkampani zisebenzisa kakhulu ukubumba komjovo wevolumu ephansi ezigabeni ze-prototyping nezigaba zokuthuthukiswa komkhiqizo. Ihlinzeka ngendlela engabizi kakhulu yokukhiqiza ama-prototypes asebenzayo, okuvumela ukuqinisekiswa kwedizayini, ukuhlola, nokucwengwa ngaphambi kokukhiqizwa ngobuningi.

- Imikhiqizo Ekhethekile: Izimboni eziningi ze-niche zidinga izingxenye ezikhethekile ezingakhiqizwa ngobuningi. Ukubumba umjovo wevolumu ephansi kunikeza isisombululo esisebenzayo sokudala lezi zingxenye eziyingqayizivele ngempumelelo, ezihlangabezana nezidingo ezithile zemakethe.

- Izindawo Zokubekwa esikhundleni:Ukubumba umjovo wevolumu ephansi kunenzuzo ekwenzeni izingxenye ezishintshayo zezimboni ezihlukahlukene. Ivumela ukukhiqizwa okufunekayo kwenani elincane, iqinisekisa ukuhlinzekwa okuqhubekayo kwezingxenye ezibalulekile ngaphandle kokudinga i-inventory enkulu.

Izinhlobo Zezinto Ezisetshenziswa Ekubumbeni Umjovo Wevolumu Ephansi

Ukubumba umjovo wevolumu ephansi kusebenzisa izinto ezahlukahlukene ukuze kuhlangatshezwane nezidingo ezahlukahlukene zokukhiqiza.

- Thermoplastics: I-Thermoplastics yizinto ezisetshenziswa kakhulu ekubunjweni komjovo wevolumu ephansi. Angancibilika, apholiswe, futhi aphinde ancibilike izikhathi eziningi ngaphandle kokushintsha kakhulu izakhiwo zawo. Izibonelo ze-thermoplastics zifaka i-polyethylene (PE), i-polypropylene (PP), i-polystyrene (PS), ne-polycarbonate (PC).

- Ama-Elastomers:Ama-Elastomers, aziwa nangokuthi izinto ezifana nerabha, akhiqiza izingxenye eziguquguqukayo ekubunjweni komjovo wevolumu ephansi. Banikeza ukuqina okuhle kakhulu, ukuqina, nokumelana nomthelela. Ama-elastomer ajwayelekile afaka i-silicone, i-polyurethane (PU), nama-thermoplastic elastomers (TPE).

- Ipulasitiki yobunjiniyela:Amapulasitiki obunjiniyela ayizinto ezisebenza kahle kakhulu ezibonisa izakhiwo ezihlukile zemishini, ezishisayo, namakhemikhali. Izimboni ziwasebenzisela kakhulu izingxenye zawo eziqinile neziqinile. Amanye amapulasitiki obunjiniyela asetshenziswa kakhulu ekubunjweni komjovo wevolumu ephansi yi-acrylonitrile butadiene styrene (ABS), inayiloni (PA), i-polyethylene terephthalate (PET), ne-polyoxymethylene (POM).

- Izinto ze-Biodegradable and Sustainable: Ngokugcizelela okukhulayo kokusimama, ukubumba komjovo wevolumu ephansi kusebenzisa izinto ezibolayo neziqhubekayo. Lezi zinto zingathathwa ezinsizeni ezivuselelekayo futhi zinikeze izinzuzo zemvelo. Izibonelo zifaka i-polylactic acid (PLA), i-bio-based polyethylene (PE), kanye ne-bio-based polypropylene (PP).

- Ama-Metal and Ceramic Powders: Ngokungeziwe kumapulasitiki, ukubumba komjovo wevolumu ephansi kungahlanganisa izimpushana zensimbi ne-ceramic ukukhiqiza izingxenye zensimbi noma ze-ceramic. Inqubo, eyaziwa ngokuthi i-metal injection molding (MIM) noma i-ceramic injection molding (CIM), ihlanganisa ukuxuba izimpushana nesibophelelo bese uzijova ezibunjeni. Ngemuva kwalokho, izingxenye zikhishwa futhi zifakwe emanzini ukuze zifeze izici zazo zokugcina.

- Izinto Ezihlanganisiwe:Izinto ezihlanganisiwe zihlanganisa izinto ezahlukene ukuze kuzuzwe izakhiwo ezifiselekayo. Izinto ezixutshiwe zingathuthukisa amandla, ukuqina, noma ukumelana nokushisa ekubumbeni komjovo wevolumu ephansi. Izibonelo zifaka ama-polymers aqiniswe nge-carbon fiber-reinforced (CFRP), ama-polymers aqiniswe ngengilazi (GFRP), kanye nama-polymer agcwele amaminerali.

- Irabha Yerabha Ye-Silicone (LSR): I-LSR iwumsebenzi okhethekile wokukhiqiza izingxenye eziguquguqukayo, ezimelana nokushisa, nezihambisana ne-biocompatible. Ifaneleka kakhulu izinhlelo zokusebenza ezidinga izindawo ezinhle kakhulu zokuvala, njengasezimbonini zezokwelapha nezezimoto.

Indlela Ukubumba Umjovo Womthamo Ophansi Osebenza Ngayo

Ukubumba komjovo wevolumu ephansi kuyinqubo yokukhiqiza ezuzisa izimboni ezihlukahlukene futhi ivumela ukukhiqiza amanani amancane ezingxenye ezingokwezifiso. Kubandakanya ukuklanywa nokwakhiwa kwesikhunta kanye nokulungiswa kwempahla esuke incibilikiswa futhi ifakwe emgodini wesikhunta ngaphansi kwengcindezi ephezulu.

- I-Mold Design:Inqubo iqala ngokuklama nokwenza isikhunta esihambisana nengxenye yejiyomethri oyifunayo. Isikhunta siqukethe izingxenye ezimbili, umgodi kanye nomgogodla, okwenza ukuma kwengxenye yokugcina lapho kuhlanganiswe ndawonye.

- Ukulungiselela Material: Impahla ekhethiwe, ngokuvamile esesimweni samapellets, ilayishwa ku-hopper futhi ifakwe emshinini wokubumba umjovo. Khona-ke amagobolondo ayashisisa futhi ancibilike ancibilike.

- Umjovo:Impahla encibilikisiwe ijova emgodini wesikhunta ngaphansi kwengcindezi ephezulu kusetshenziswa isikulufu esiphindaphindayo noma i-plunger. Lokhu kucindezela kuqinisekisa ukuthi impahla igcwalisa yonke imininingwane eyinkimbinkimbi yesikhunta futhi igcina isimo sayo ngesikhathi sokuqina.

- Ukupholisa kanye Nokuqinisa:Ngemuva kokugcwalisa umgodi wokubumba, izinto ezincibilikisiwe zivunyelwe ukupholisa futhi ziqinise ngaphakathi kwesikhunta. Iziteshi zokupholisa ezihlanganiswe kusikhunta zichitha ukushisa futhi zisheshise inqubo yokuqinisa.

- Ukuvula Nokukhishwa Kwesikhunta:Isikhunta sivuleka uma impahla isiqine ngokwanele, ihlukanise izingxenye ezimbili. Izikhonkwane zejector noma amapuleti aphusha ingxenye iphume emgodini wokukhunta, ingene emgqonyeni weqoqo, noma ingene ebhandeni lokuthutha.

- Ukuqedela:Ingxenye ekhishiwe ingase ibe nezinqubo ezihlukene ukuze kufinyelelwe isiphetho esifiselekayo sobuso kanye nokunemba kobukhulu. Le misebenzi ingase ihlanganise ukuphungula okubalulekile okudlulele, ukususa ifleshi noma ama-burrs, kanye nokwenza imisebenzi yesibili njengomshini noma ukupenda.

- Phinda inqubo:Isikhunta siyavaleka, futhi umjikelezo uyaphinda ukuze ukhiqize ingxenye elandelayo. Ukubunjwa komjovo wevolumu ephansi kuvumela ukuphindaphinda okuningi kanye nokulungiswa kwesikhunta nenqubo, okuvumela ukuguquguquka ekuthuthukisweni kokukhiqiza nokwakheka.

- Ikhwalithi yokulawula:Izinyathelo zokulawula ikhwalithi zisetshenziswa kuyo yonke inqubo ukuze kuqinisekiswe ukuthi izingxenye ezikhiqiziwe ziyahlangabezana nokucaciswa okudingekayo. Le misebenzi ingase ibandakanye ukuhlolwa okuvamile, ukukalwa kobukhulu, nokuhlolwa kokusebenza.

- Ukungafinyeleli:Ukubumba komjovo wevolumu ephansi ngokuyinhloko kugxile ekukhiqizeni amanani amancane, kodwa kungase futhi kusebenze njengesitebhisi sokukhiqiza ngezinga elikhulu.Izinkampani zingakwazi ukuthuthukisa inqubo ngamavolumu aphezulu uma isidingo sikhuphuka ngokusebenzisa imishini emikhulu noma isikhunta esiningi.

Izinhlobo Zemishini Yokubumba Umjovo Wevolumu Ephansi

Imishini ehlukahlukene yokubumba umjovo wevolumu ephansi iyatholakala futhi yakhelwe ukubhekelela izidingo ezihlukene zokukhiqiza. Izinto ezifana nempahla esetshenzisiwe, inkimbinkimbi yokukhiqiza ingxenye, nokunemba okufunayo nokusebenza kahle kunquma ukukhetha komshini. Ukukhetha uhlobo olufanele lomshini kubalulekile ukuze kuzuzwe imiphumela oyifunayo kanye nokuqinisekisa ukuthi ukhiqiza izindleko ngendlela efanele.

- Imishini Ye-Hydraulic:Imishini yokubumba yomjovo wevolumu ephansi ye-Hydraulic isebenzisa amaphampu asebenza ngogesi ukuze ikhiqize ingcindezi edingekayo yokujova izinto endaweni yokubumba. Bangakwazi ukukhiqiza izingxenye ngokunemba okuphezulu nokuphindaphinda futhi baphathe izinto ezihlukahlukene.

- Imishini kagesi:Imishini yokubumba umjovo wevolumu ephansi kagesi isebenzisa amamotho kagesi esikhundleni samaphampu adonsa amanzi ukushayela inqubo yomjovo. Banikeza ukusebenza kahle okukhulu kwamandla, ukulungiswa okuncishisiwe, nokusebenza okuthule kunemishini esebenza ngamanzi.

- Imishini Ehlanganisiwe:Imishini yokubumba yomjovo wevolumu ephansi yeHybrid ihlanganisa izinzuzo zawo womabili amadivayisi we-hydraulic kanye nogesi. Ahlanganisa amadrayivu e-hydraulic kanye nogesi, athuthukisa ukunemba, ukusebenza kahle kwamandla, kanye namazinga omsindo ancishisiwe.

- Imishini Emile:Imishini yokubumba umjovo wevolumu ephansi emile isebenzisa amandla adonsela phansi ukuze ifake isikhunta, futhi isikhunta sigxunyekwa phezulu. Zilungele ukukhiqiza izingxenye ezinamajiyometri ayinkimbinkimbi futhi zingonga indawo yaphansi ezindaweni zokukhiqiza.

- Imishini Yokubumba Encane:Imishini yokubumba i-Micro-molding low volume injection yenzelwe ngokukhethekile ukukhiqiza izingxenye ezinobukhulu obuncane nokunemba okuphezulu. Basebenzisa amathuluzi akhethekile ukuze bathole imiphumela efiselekayo, okuhlanganisa amayunithi omjovo emincane kanye nezimbotshana zesikhunta.

- Imishini eminingi yokudubula:Imishini yokubumba i-Multi-shot low volume injection isebenzisa amayunithi omjovo amaningi ukukhiqiza izingxenye ezinezinto ezihlukahlukene noma imibala. Leli khono livumela ukudala izingxenye eziyinkimbinkimbi ezinokwakheka okuhlukahlukene kanye nokuqedwa.

- Imishini Yokuhlanza:Abaklami badala imishini yokubumba umjovo wevolumu ephansi ye-cleanroom ukuze isetshenziswe ezindaweni eziyinyumba, njengezindawo zokukhiqiza zezokwelapha noma zemithi. Abakhiqizi bawakha ngezinto ezilula ukuzihlanza, ukuhlanzeka, nokuhlanganisa izici ukuze kuncishiswe ukungcola.

Izinto Ezithinta Ukubunjwa Komjovo Wevolumu Ephansi

Izici eziningana zithonya umphumela nokusebenza kahle kokubunjwa komjovo wevolumu ephansi. Ukucabangela lezi zici nokuthuthukisa isici ngasinye senqubo kusiza ukuqinisekisa ukukhiqizwa kokubumba komjovo wevolumu ephansi.

- Ukucatshangelwa kwedizayini:Idizayini yengxenye idlala indima ebalulekile ekubumbeni umjovo wevolumu ephansi. Izinto ezinjengokuqina kodonga, ama-engeli asalungiswa, nokuba khona kwama-undercuts kuthinta ukubumbeka kwengxenye kanye nekhwalithi iyonke. Izici eziklanywe kahle nge-geometry efanele zingasiza ekufinyeleleni imiphumela engcono.

- Ukukhetha Okubalulekile:Ukukhethwa kwempahla yokubumba umjovo wevolumu ephansi kubalulekile. Izinto ezihlukile zinezici ezihlukile, njengezimpawu zokuncibilika kokuncibilika, amazinga okuncipha, nokuzwela kwezinga lokushisa. Izinto ezifanele ezihlangabezane nezidingo zokusebenza kanye nobuhle obufunwayo bubalulekile ekubumbeni ngempumelelo.

- I-Mold Design kanye Nokwakha:Ukuklanywa nokwakhiwa kwesikhunta kuthinta ngqo ikhwalithi kanye nokuba nokwenzeka kokubunjwa komjovo wevolumu ephansi. Ukuze kuqinisekiswe ukugcwaliswa okufanele kwengxenye, ukupholisa, nokukhishwa, umuntu kumelwe acabangele ngokucophelela isikhunta, imigudu yokupholisa, i-venting, nesistimu yokufaka isango.

- Amapharamitha okucubungula:Ukuze uthole ukubumba komjovo wevolumu ephansi, umuntu kufanele alungiselele amapharamitha enqubo ambalwa, okuhlanganisa isivinini somjovo, izinga lokushisa, ukucindezela, nesikhathi sokupholisa. Ukuthola ibhalansi efanele yale mingcele kubalulekile ukuze kuzuzwe ingxenye yekhwalithi ephezulu, ukunciphisa amaphutha, nokuqinisekisa ukukhiqizwa okungaguquki.

- Ikhwalithi yokulawula:Ukusebenzisa izinyathelo zokulawula ikhwalithi kuyo yonke inqubo yokubumba umjovo wevolumu ephansi kubalulekile. Ukuhlola okuvamile, ukuhlola ubukhulu, nokuhlola ukusebenza kusiza ukuhlonza nokubhekana nanoma yiziphi izinkinga noma amaphutha kusenesikhathi, ukuqinisekisa ukuthi izingxenye ezikhiqiziwe ziyahlangabezana nokucaciswa okudingekayo.

- Ukugcinwa Kwamathuluzi Nezisetshenziswa:Ukugcinwa njalo nokugcinwa komshini wokubumba umjovo kanye nezibunjwa kuyadingeka ekukhiqizeni okungaguquki nokusebenza kahle. Ukuhlanzwa ngendlela efanele, ukugcotshwa, nokuhlolwa kwezinto zokusebenza nezisikhunta kusiza ukuvimbela ukuwohloka, ukunciphisa isikhathi sokuphumula, nokuqinisekisa ukuphila isikhathi eside kwamathuluzi.

- Ivolumu Yokukhiqiza:Noma abakhiqizi baklama ukubumba komjovo wevolumu ephansi ngamanani amancane, umthamo wokukhiqiza usengathonya izici ezifana nezindleko ngengxenye ngayinye, isikhathi sokuhola, nezinketho zamathuluzi. Ukuqonda umthamo wokukhiqiza olindelweyo kubalulekile ekuthuthukiseni inqubo nokukhetha isu lokukhiqiza elifanele.

- Izindleko zokucatshangelwa: Izindleko zokubumba umjovo wevolumu ephansi zibandakanya izici ezahlukahlukene, okubandakanya izindleko zempahla, izindleko zokwenziwa kwesikhunta, izindleko zokusethwa komshini nokusebenza, kanye nezindleko zangemuva kokucubungula. Ukulinganisa ukuphumelela kwezindleko nekhwalithi oyifunayo kanye nokusebenza kwezingxenye kubalulekile ekukhiqizeni umthamo ophansi ngempumelelo.

Ukucatshangelwa Kwedizayini Yokubumba Umjovo Wevolumu Ephansi

Ukuklama izingxenye zokubumba umjovo wevolumu ephansi kudinga ukucatshangelwa ngokucophelela kwezici ezihlukahlukene. Lokhu kubandakanya:

Wall Ubukhulu

- Ukugcina udonga olungaguquki futhi olufanele lubalulekile

- Izindonga eziwugqinsi zingaholela ezikhathini zokupholisa ezinde kanye nokungqubuzana okungenzeka.

- Izindonga ezizacile zingase zibe nomphumela ongemuhle wengxenye.

- Ukuklama ngokuqina kodonga olufanayo kuqinisekisa ukugeleza kwezinto ezifanele kanye nekhwalithi yengxenye efanelekile.

Ama-engeli Asalungiswa

- Ukufaka ama-engeli asalungiswa ekwakhiweni kubalulekile ukuze kube lula ukukhipha ingxenye

- Ama-engeli asalungiswa avumela ukususwa okushelelayo kwengxenye ngaphandle kokudala umonakalo.

- Ama-engeli asalungiswa anele asiza ukuvimbela ukunamathela kanye nokwenza lula ukukhiqizwa okuphumelelayo.

Ama-Undercuts kanye Nezenzo Eziseceleni

- Ukunciphisa ama-undercuts kanye nezenzo eziseceleni kuyancomeka

- Ama-undercuts enza ukukhipha kube yinselele futhi kungadinga imiklamo eyinkimbinkimbi yesikhunta noma imisebenzi yesibili.

- Ukwenza ingxenye yejometri ibe lula nokugwema izici eziyinkimbinkimbi kuthuthukisa ukubumba futhi kunciphisa izindleko.

Ukubekwa kwesango

- Ukubekwa kwesango ngendlela efanele kubalulekile ukuze kugeleze kahle impahla kanye nokunciphisa amaphutha

- Indawo yesango ithinta ukubukeka kwengxenye, amandla, kanye ne-warpage.

- Ukubeka amasango ezindaweni ezifanele kuthuthukisa ingxenye yekhwalithi nobuhle.

Ulayini Wokuhlukanisa kanye Nendawo Yokuhlukanisa

- Ukuchaza umugqa wokuhlukanisa ofanelekile kanye nobuso kuyadingeka ekwakhiweni kwesikhunta nokuhlanganisa

- Ulayini wokuhlukanisa ohlanzekile futhi ochazwe kahle usiza ukwakhiwa kwesikhunta futhi unciphise ubungozi bokulimala.

Izimbambo Nabaphathi

- Ukuhlanganisa izimbambo nabaphathi kuthuthukisa ubuqotho besakhiwo nokusebenza

- Izimbambo zinikeza amandla nokuqina ezingxenyeni ezincane.

- Abaphathi basebenza njengamaphoyinti okunamathiselwe noma okufakwayo kokusebenza kwesibili.

I-Surface Finish kanye Nokwakheka

- Uma kucatshangelwa isiphetho esifunwayo sendawo nokuthungwa kubalulekile

- Ukwelashwa kwesikhunta noma ukuthungwa kwe-cavity kungafinyelela izindawo ezibushelelezi noma ezithungwe.

- Ukukhetha okufanele kanye nokuxhumana kwezidingo zokuqedwa kwendawo kunomthelela kubuhle obufiselekayo kanye nokusebenza.

Ukubekezelelana Nokunemba Kobukhulu

- Ukucacisa ukubekezelelana okufanele kanye nokunemba kobukhulu kubalulekile

- Ukuqonda amakhono omjovo wevolumu ephansi kubalulekile.

Ngokucabangela lezi zici zokuklama, abakhiqizi bangakwazi ukuthuthukisa ukubumba komjovo wevolumu ephansi, okuholela ezingxenyeni zekhwalithi ephezulu, ukukhiqizwa okuphumelelayo, nokusebenza kahle kwezindleko.

Ukulawulwa Kwekhwalithi Ekubumbeni Umjovo Wevolumu Ephansi

Ukulawulwa kwekhwalithi kubalulekile ekubunjweni komjovo wevolumu ephansi ukuze kuqinisekiswe ukukhiqizwa kwezingxenye zekhwalithi ephezulu ezihlangabezana nokucaciswa okudingekayo. Nazi ezinye izinto ezibalulekile okufanele uzicabangele ukuze ulawule ikhwalithi ngempumelelo ekubumbeni komjovo wevolumu ephansi:

- Ukuhlola Nokuhlola:Ukuhlola okuvamile nokuhlolwa kukho konke ukukhiqiza kusiza ukuhlonza amaphutha noma izinkinga kusenesikhathi. Ukuqinisekisa ukuthi izingxenye ziyahlangabezana nokucaciswa, umuntu kufanele enze ukuhlola kobukhulu, ukuhlola okubonakalayo, nokuhlola ukusebenza.

- Ukuqinisekisa Okubalulekile: Ukuqinisekisa ikhwalithi nokuvumelana kwezinto ezisetshenziswa ekubumbeni umjovo wevolumu ephansi kubalulekile. Ukuqinisekiswa kwezinto kuhilela ukuhlola izinto ezibonakalayo, njengokugeleza kwe-melt, i-viscosity, nombala, ukuze kuqinisekiswe ukuthi zihambisana nokucaciswa okufunayo.

- Ukunakekelwa Kwesikhunta:Ukugcinwa ngendlela efanele kanye nokugcinwa kwesikhunta kubalulekile ekukhiqizeni okungaguquguquki futhi okuseqophelweni eliphezulu. Ukuhlanza njalo, ukugcoba, nokuhlolwa kwesikhunta kusiza ukuvimbela amaphutha, ukunciphisa isikhathi sokuphumula, nokwandisa isikhathi sokuphila kwesikhunta.

- Ukuqapha Inqubo:Ukuqapha okuqhubekayo kwemingcele yenqubo yokubumba umjovo kubalulekile ekugcineni ikhwalithi. Kudingeka ukuqapha okuguquguqukayo okufana nezinga lokushisa, ukucindezela, nesikhathi somjikelezo ukuze kuqinisekiswe ukuthi kungaphakathi kobubanzi obushiwo futhi kutholwe ukuchezuka noma okungavamile.

- Ukulawulwa Kwenqubo Yezibalo (SPC):Ukusebenzisa amasu e-SPC kusiza ukuqapha nokulawula ukuhlukahluka kwenqubo yokukhiqiza. Kubandakanya ukuqoqa nokuhlaziya idatha kusuka kunqubo yokukhiqiza ukuze kuhlonzwe amathrendi, amaphethini, nemithombo engaba khona yokuhlukahluka, okuvumela ukulungiswa okusebenzayo nokuthuthukiswa.

- Izenzo Zokulungisa Nezokuvikela:Ukwenza izenzo zokulungisa nezokuvikela kubalulekile ekusingatheni izinkinga zekhwalithi noma ukungahambisani. Ngemva kokuhlonza amaphutha noma ukuchezuka, ithimba ngokushesha lenza umzamo wokuzilungisa futhi livimbele ukuphindeka kwazo, liqinisekisa ukuthuthuka okuqhubekayo kwinqubo yokukhiqiza.

- Amadokhumenti kanye nokulandelelwa:Ukugcina imibhalo efanele kanye nokulandeleka kwenqubo yokukhiqiza kubalulekile ekulawuleni ikhwalithi. Ukwenza lula ukulandeleka nokuqinisekiswa kwekhwalithi, imingcele yenqubo yokurekhoda, imiphumela yokuhlola, nolwazi olubalulekile, kanye nokulandelela umlando wengxenye ngayinye ekhiqiziwe, kubalulekile.

- Ukuphathwa Kwekhwalithi Yomhlinzeki:Ukuqinisekisa ikhwalithi yezingxenye nezinto ezitholakala kubahlinzeki kubalulekile. Ukusungula izinqubo eziqinile zokuphatha ikhwalithi yabahlinzeki, okuhlanganisa ukufaneleka, ukuhlola, nokuqapha okuqhubekayo, kusiza ukuqinisekisa ukusetshenziswa kokufakwayo kwekhwalithi ephezulu kuphela ekukhiqizeni.

Ngokusebenzisa izinyathelo zokulawula ikhwalithi ezisebenzayo, abakhiqizi bangakhiqiza izingxenye zekhwalithi ephezulu, ezingaguquki, nezithembekile ngokusebenzisa ukubumba komjovo wevolumu ephansi.

Ithuluzi Lokubumba Umjovo Wevolumu Ephansi

Ithuluzi lokubumba umjovo wevolumu ephansi kudinga ukucatshangelwa ngokucophelela kokukhetha impahla yesikhunta, ukwakheka, ukwakhiwa, ukugcinwa, ukulungiswa, ukufakwa, ukuhlolwa, nokugcinwa.

Ukukhethwa Kwezinto Zokubumba

Ukukhetha i-mold material efanelekile kubalulekile ekubumbeni umjovo wevolumu ephansi. Cabangela izici ezifana nokuqina, ukumelana nokushisa, nokuhambisana uma ukhetha into ethile. Izinto ezijwayelekile zokubumba zifaka ama-alloys ensimbi, ama-alloys e-aluminium, nezinto eziyinhlanganisela.

Design Design

Ukudizayina isikhunta sokubumba umjovo wevolumu ephansi kudinga ukucatshangelwa ngokucophelela kwezinto ezifana nengxenye yejometri, isistimu yokufaka isango, iziteshi zokupholisa, nendlela yokukhipha.

- Ijiyomethri yengxenye efanelekile isiza ukugcwaliswa okufanele, ukupholisa, nokukhipha ingxenye.

- Isistimu yokungena eklanywe kahle iqinisekisa ukuhamba kahle kwezinto futhi inciphisa amaphutha.

- Iziteshi zokupholisa eziklanywe kahle zisiza ukulawula izikhathi zomjikelezo nokuqinisekisa ikhwalithi yengxenye engaguquki.

- I-ejection mechanism ephumelelayo ivumela ukususwa kalula kwengxenye esikhunjeni.

Ukwakhiwa Kwesikhunta

Yenza ukwakhiwa kwesikhunta ngokunemba nokunaka imininingwane.

- Abenzi bamathuluzi abanekhono basebenzisa imishini, i-CNC milling, kanye namasu e-EDM (Electrical Discharge Machining) ukuze benze izingxenye zesikhunta.

- Ukuhlanganiswa ngokucophelela nokuqondanisa kwezingxenye zesikhunta kubalulekile ekusebenzeni okuhle kanye nengxenye yekhwalithi.

Ukugcinwa Nokulungiswa Kwesikhunta

Ukugcinwa njalo kanye nokulungiswa ngesikhathi kwesikhunta kubalulekile ukuze kuqinisekiswe ukuphila kwabo isikhathi eside nokusebenza okungaguquki.

- Ama-opharetha kufanele ahlanze njalo, agcobe, ahlole ukuze avimbele izinkinga futhi athuthukise ukukhiqizwa.

- Ukulungiswa ngokushesha kwanoma yimuphi umonakalo noma ukuguga kwezingxenye zesikhunta kusiza ukugwema amaphutha nokuphazamiseka kokukhiqiza.

Ukufakwa Kwesikhunta Nezingxenye Ezishintshashintshayo

Ukusebenzisa isikhunta kanye nezingxenye ezishintshayo kuvumela ukuguquguquka kanye nempumelelo yezindleko ekubunjweni komjovo wevolumu ephansi.

- Ama-opharetha angashintsha noma ashintshe okokufaka ukuze alungise izinguquko zedizayini noma ezinye izidingo—ukuhlukahluka kwengxenye.

- Izingxenye ezishintshekayo zinika amandla ukushintshwa kwesikhunta okusheshayo, ukunciphisa isikhathi sokuphumula nokwandisa ukusebenza kahle kokukhiqiza.

Ukuhlolwa Kwesikhunta Nokuqinisekisa

Ukuhlolwa okuphelele nokuqinisekiswa kwesikhunta kubalulekile ngaphambi kokuqala ukukhiqiza.

- Senza ukuhlola kwesikhunta ukuze silungiselele amapharamitha enqubo, siqinisekise ingxenye yekhwalithi, futhi sihlonze ukulungiswa okudingekayo.

- Singase senze ukuhlaziya ukugeleza kwesikhunta kanye nokulingisa ikhompyutha ukuze sibikezele futhi sithuthukise inqubo yokubumba.

Ukugcinwa Nokulondolozwa Kwesikhunta

Ukugcinwa okufanele kanye nezinqubo zokulondoloza kubalulekile ukugcina ikhwalithi nokusebenza lapho isikhunta singasetshenziswa.

- Isikhunta kufanele sigcinwe endaweni elawulwayo ukuze kuvikelwe umonakalo osuka ekushintshashintsheni kwezinga lokushisa, umswakama nokungcola.

- Ngisho nangezikhathi zokungasebenzisi, abaqhubi kufanele bahlole njalo futhi banakekele.

Amasu Angabizi Wokubumba Umjovo Wevolumu Ephansi

Ukwamukela amasu angabizi kakhulu wokubumba umjovo wevolumu ephansi kudinga indlela ephelele ehlanganisa ukuklama kwesikhunta, ukukhethwa kwempahla, ukuthuthukiswa kwenqubo, ukuzenzekelayo, kanye nokubambisana kwabahlinzeki. Ngokusebenzisa la masu, izinkampani zingakwazi ukuzuza imiphumela yekhwalithi ephezulu kuyilapho zinciphisa izindleko futhi zandise ukusebenza kahle emisebenzini yazo yokukhiqiza ivolumu ephansi.

- Idizayini yesikhunta esebenzayo:Ukuklama kahle isikhunta sokubumba umjovo wevolumu ephansi kunganciphisa kakhulu izindleko. Ukwenza lula ukwakheka kwesikhunta nokunciphisa inani lemigodi kungehlisa izindleko zamathuluzi futhi kunciphise isikhathi sokukhiqiza.

- Ukukhetha okubalulekile:Ukukhetha impahla efanelekile kubalulekile ekubumbeni umjovo wevolumu ephansi ngendlela engabizi kakhulu. Ukukhetha ama-resin angabizi kakhulu noma ukuhlola ezinye izinto ezihlangabezana nezicaciso ezidingekayo kungaholela ekongeni kwezindleko ezinkulu ngaphandle kokubeka engcupheni ikhwalithi.

- Okuzenzakalelayo kanye namarobhothi:Ukusebenzisa i-automation kanye namarobhothi ekubumbeni umjovo kungathuthukisa ukusebenza kahle futhi kunciphise izindleko zabasebenzi. Amasistimu azenzakalelayo angakwazi ukusingatha imisebenzi ephindaphindwayo, anciphise amaphutha, futhi andise umkhiqizo wokukhiqiza, awenze alungele ukukhiqizwa kwevolumu ephansi.

- Ukuthuthukisa inqubo:Ukulungisa kahle inqubo yokubumba umjovo kungaholela ekongeni kwezindleko. Ukuhlaziya nokuthuthukisa amapharamitha afana nezinga lokushisa, ingcindezi, nezikhathi zomjikelezo kunganciphisa udoti wezinto ezibonakalayo, kuthuthukise ingxenye yekhwalithi, futhi kwandise umkhiqizo.

- Ukukhiqiza okudingekayo:Ukwamukela ukukhiqizwa okufunayo kuvumela ukuguquguquka okwengeziwe kanye nokusebenza kahle kwezindleko ekubunjweni komjovo wevolumu ephansi. Ngokukhiqiza izingxenye kuphela lapho kudingekile, izinkampani zingagwema izindleko ze-inventory eyeqile futhi zinciphise ubungozi bokuphelelwa yisikhathi.

- Ezinye izindlela zamathuluzi:Ukuhlola ezinye izinketho zamathuluzi, njengokubunjwa okuphrintiwe kwe-3D noma ukusebenzisa amathuluzi athambile, kungabiza kakhulu ekukhiqizweni kwevolumu ephansi. Lezi zindlela ezihlukile ngokuvamile zinezindleko zangaphambili eziphansi kanye nezikhathi zokuhola ezimfushane kunesikhunta sensimbi esivamile.

- Ubambiswano lwabahlinzeki:Ukusebenzisana eduze nabahlinzeki bokubumba umjovo abathembekile nabanolwazi kungasiza ukwandisa izindleko. Abahlinzeki abanolwazi ekukhiqizeni umthamo ophansi banganikeza imininingwane ebalulekile, baphakamise izindlela zokonga, futhi banikeze amanani ancintisanayo ezintweni zokwakha namathuluzi.

- Ukuthuthukisa ngemuva kokucubungula:Ukwenza lula imisebenzi yangemva kokucubungula, njengokunquma, ukuhlanganisa, nokuqeda, kunganciphisa izindleko. Ukutshala imali kumishini nezindlela ezisebenza ngemuva kokucubungula kunganciphisa izidingo zabasebenzi futhi kunciphise nezindleko zokusebenza kwesibili.

Izinzuzo Zokusebenzisa Ukuphrinta Kwe-3D Kokubumba Umjovo Wevolumu Ephansi

Ukusebenzisa ukuphrinta kwe-3D ukubumba umjovo wevolumu ephansi kunikeza izinzuzo ezimbalwa. Inika amandla i-prototyping esheshayo, ivumela ukuphindaphinda okusheshayo kanye namaphutha omklamo ancishisiwe. Ukuphrinta kwe-3D kunciphisa ukukhiqizwa kukadoti futhi kusiza ukunciphisa ubungozi ngokuvumela ukuhlola nokuqinisekisa ngaphambi kokuzibophezela ekukhiqizeni ngezinga eligcwele.

- I-prototyping esheshayo: Ukuphrinta kwe-3D kunikeza inzuzo ye-prototyping esheshayo, okuvumela abaklami ukuthi baphindaphinde futhi bacwenge imiklamo yemikhiqizo yabo ngokushesha. Le ndlela yenza izinkampani zikwazi ukuletha imikhiqizo emakethe ngokushesha futhi zigweme amaphutha edizayini abizayo.

- Amathuluzi angabizi kakhulu:Ukuphrinta kwe-3D kungaba enye indlela engabizi kakhulu yamathuluzi okubumba umjovo wevolumu ephansi. Ngokusebenzisa isikhunta esiphrintiwe nge-3D noma izinto ezifakwayo, izinkampani zingonga ezindlekweni zangaphambili zokubunjwa kwensimbi yendabuko, ikakhulukazi ukukhiqiza okuncane.

- Ukuvumelana nezimo zedizayini: Ukuphrinta kwe-3D kuvumela imiklamo eyinkimbinkimbi futhi eyinkimbinkimbi okungenzeka ingenzeki ngezindlela zendabuko zokumaka. Lokhu kuvumelana nezimo kwenza ukukhiqizwa kwezingxenye ezenziwe ngezifiso neziyingqayizivele, ezibhekelela izidingo ezithile zamakhasimende.

- Izikhathi zokuhola ezincishisiwe: Ngokusebenzisa ukuphrinta kwe-3D, abakhiqizi banganciphisa kakhulu izikhathi zokuhola uma kuqhathaniswa nezindlela zokukhiqiza ezivamile. Ukungabikho kwamathuluzi kanye nekhono lokukhiqiza izingxenye lapho kudingeka khona kusheshisa inqubo yokukhiqiza, okuvumela ukulethwa kwamakhasimende ngokushesha.

- Izinhlobonhlobo zezinto:Ukuphrinta kwe-3D kunikeza inhlobonhlobo yezinto zokwakha, kufaka phakathi ama-thermoplastics, ama-resin, nama-composites. Lokhu kuguquguquka kwezinto kuvumela ukukhiqiza izingxenye ezinezakhiwo ezihlukene, ezihlinzekela izidingo ezithile zokusebenza nezobuhle.

- Ukuncishiswa kukadoti:Ukuphrinta kwe-3D kuyinqubo yokukhiqiza okungeziwe, okusho ukuthi kusebenzisa kuphela izinto ezidingekayo ukuze kwakhiwe ingxenye, okuholela ekukhiqizeni udoti okuncane. Ukunciphisa izindleko zempahla nakho kusiza ekukhuthazeni imizamo yokusimama.

- Ukunciphisa ubungozi: Ukusebenzisa ukuphrinta kwe-3D ekubumbeni komjovo wevolumu ephansi kuvumela izinkampani ukuthi zehlise ubungozi obuhambisana nokutshala imali kumathuluzi abizayo emiklamo engaqinisekisiwe noma isidingo semakethe esingaqinisekile. Izovumela ukuhlola imakethe ngamavolumu amancane okukhiqiza ngaphambi kokuzibophezela ekukhiqizeni ngezinga eligcwele.

- Ibhuloho eliya ekukhiqizeni:Ukuphrinta kwe-3D kungasebenza njengebhuloho ekukhiqizeni, okuvumela izinkampani ukuthi ziqinisekise ngokushesha imiklamo yazo futhi zihlole ukusebenza kwezingxenye ngaphambi kokutshala amathuluzi abizayo okubumba umjovo. Ukuhlonza amaphutha edizayini kusenesikhathi kungonga izindleko ngokuhamba kwesikhathi.

Ukusimama Kokubumba Komjovo Wevolumu Ephansi

Ukubumba umjovo wevolumu ephansi kungaba inketho yokukhiqiza esimeme uma kukhulunywa ngemikhuba eqaphela imvelo.

- Ukusebenza kahle kwezinto:Ukubumba umjovo wevolumu ephansi kukhuthaza ukusebenza kahle kwezinto ngokukhiqiza izingxenye ezidingekayo kuphela, ukunciphisa ukukhiqizwa kwemfucuza. Le ndlela isiza ukunciphisa umthelela wemvelo ohambisana nokusetshenziswa kwezinto ezibonakalayo ngokweqile.

- Ukongiwa kwamandla:Uma kuqhathaniswa nezindlela zokukhiqiza zevolumu ephezulu, ukubumba komjovo wevolumu ephansi kudla amandla amancane ngenxa yokugijima kokukhiqiza okufushane kanye nokunciphisa isikhathi sokusebenza komshini. Ngokwenza lokhu, singakwazi ukonga amandla futhi sinciphise ukukhishwa kwamagesi abamba ukushisa.

- Ukuncishiswa kukadoti:Ukubumba komjovo wevolumu ephansi kuvumela ubuningi bokukhiqiza obunembile, kunciphisa isidingo se-inventory eyeqile kanye nokunciphisa imfucuza. Izinkampani zinganciphisa ukuphehlwa kukadoti kanye nezindleko zokulahla ngokuthuthukisa ukuhlelwa kokukhiqiza kanye nesidingo sokubikezela.

- Amathuba okugaya kabusha:Ukubumba komjovo wevolumu ephansi kuvame ukusebenzisa izinto ezigaywa kabusha ezifana ne-thermoplastics. Singaphinda sisebenzise izinto ezisetshenziswayo futhi sinciphise ukuthembela ezinsizeni ezingakaze zibonwe ngokuhlanganisa izinqubo zokuphinda zisetshenziswe enqubweni yokukhiqiza. Ukuhlanganisa izinqubo zokugaya kabusha ohlelweni lokukhiqiza kuvumela ukusetshenziswa kabusha kwezinto futhi kunciphisa ukuthembela ezinsizeni ezimsulwa.

- Izinketho zempahla eqhubekayo:Izinkampani zingabeka eqhulwini ukusebenzisa izinto ezisimeme futhi ezinobungani bemvelo ekubunjweni komjovo wevolumu ephansi. Amapulasitiki asekelwe ku-bio, izinto ezigaywe kabusha, kanye nezinsalela ezibolayo zinikeza ezinye izindlela ezisebenzayo ezinciphisa umthelela wendawo futhi zikhuthaze umnotho oyindilinga.

- Ukukhiqizwa kwendawo:Ukubumba komjovo wevolumu ephansi kuvumela ukukhiqizwa kwendawo, ukunciphisa amabanga ezokuthutha kanye nokukhishwa kwekhabhoni okuhlobene. Ngokukhiqiza eduze nemakethe yokugcina, izinkampani zingakwazi ukunciphisa indawo yemvelo yochungechunge lwazo lokuhlinzeka.

- Idizayini yokusimama:Ukubunjwa komjovo wevolumu ephansi kuvumela umuntu ukuthi afake imigomo yokuklama esimeme. Ukudizayina izingxenye ezinezakhiwo ezingasindi, amajiyometri athuthukisiwe, kanye nokusetshenziswa kahle kwezinto kungathuthukisa ukusimama kwenqubo yokukhiqiza.

- Ukuhlolwa Komjikelezo Wempilo:Ukwenza ukuhlolwa komjikelezo wempilo wezinqubo zokubumba umjovo wevolumu ephansi kusiza ukuhlonza izindawo zokuthuthukiswa nokuthuthukiswa kokusimama. Ukuhlaziya imithelela yezemvelo esigabeni ngasinye, kusukela ekukhishweni kwezinto ezingavuthiwe kuya ekulahlekeni kokuphela kwempilo, kwenza izinkampani zenze izinqumo ezinolwazi futhi zenze izinqubo ezizinzile.

Imithetho kanye Namazinga Wokubumba Umjovo Wevolumu Ephansi

Ukuhambisana nemithethonqubo kanye namazinga ekubunjweni komjovo wevolumu ephansi kubalulekile ukuze kuqinisekiswe ukuphepha komkhiqizo, isibopho sendawo ezungezile, ukuphepha kwendawo yokusebenza, kanye nokuhambisana nezidingo zomthetho nezemboni. Izinkampani kufanele zihlale zinolwazi mayelana nemithethonqubo namazinga asebenzayo futhi ziwahlanganise nezinqubo zazo zokukhiqiza.

- Amazinga okuphepha komkhiqizo:Ukubumba komjovo wevolumu ephansi kufanele kuhambisane namazinga afanele okuphepha komkhiqizo ukuze kuqinisekiswe ukuthi izingxenye ezikhiqiziwe ziyahlangabezana nezidingo zekhwalithi nokuphepha. Lawa mazinga angahluka kuye ngomkhakha, njengezimoto, ezokwelashwa, noma izimpahla zabathengi.

- Imithetho yempahla:Ukulandela imithetho ethile kanye namazinga ekukhetheni nasekusebenziseni izinto zokubumba umjovo wevolumu ephansi kuyadingeka ukuze kuqinisekiswe izinqubo zokukhiqiza ezifanele. Le mithetho ilawula ukwakheka kwezinto, amazinga obuthi, nomthelela wemvelo. Ukuthobela imithetho efana ne-REACH (Ukubhalisa, Ukuhlola, Ukugunyazwa, kanye Nokukhawulelwa Kwamakhemikhali) kubalulekile ukuze kuqinisekiswe ukusetshenziswa kwezinto eziphephile neziqhubekayo.

- Imithetho yezemvelo:Imisebenzi yokubumba umjovo wevolumu ephansi kufanele ihambisane nemithetho yezemvelo ukuze kuncishiswe umthelela wayo kwezemvelo. Le mithetho ibhekana nezindaba ezinjengokukhishwa komoya, ukuphathwa kwamanzi angcolile, ukulahlwa kukadoti, nokusetshenziswa kwamandla. Ukunamathela emikhawulweni efana ne-ISO 14001 (I-Environmental Management Systems) kukhombisa ukuzibophezela ekuzibophezeleni kwezemvelo.

- Amazinga ezempilo nokuphepha emsebenzini:Ukuqinisekisa indawo yokusebenza ephephile kubalulekile ezindaweni zokubumba umjovo wevolumu ephansi. Ukuthobelana namazinga ezempilo nokuphepha emsebenzini, njengemithetho ye-OSHA (Occupational Safety and Health Administration) kusiza ukuvikela abasebenzi ezingozini ezingaba khona ezihlobene nemishini, izinto zokwakha, nezinqubo.

- Amasistimu okuphatha ikhwalithi:Ukusebenzisa izinhlelo zokuphatha ikhwalithi, njenge-ISO 9001, kubalulekile emisebenzini yokubumba umjovo wevolumu ephansi. Lawa masistimu ahlinzeka ngohlaka lokuletha imikhiqizo engaguquki ehlangabezana nezidingo zamakhasimende futhi ethobela imithetho nemigomo esebenzayo.

- Izidingo zokulandeleka nokulebula:Izinyathelo zokulandeleka zingase zidinge ekubunjweni komjovo wevolumu ephansi ukuze kulandelelwe umsuka wezinto ezisetshenziswayo kanye nezingxenye ezisetshenziswa ekukhiqizeni. Izidingo zokulebula, ezifana nokuhlonza umkhiqizo, izinombolo zeqoqo, nezixwayiso zokuphepha, ziqinisekisa ukuxhumana okucacile nokuhambisana nemithetho efanele.

- Ukucatshangelwa kwempahla yobuhlakani:Ukuvikela amalungelo empahla yengqondo kubalulekile ekubumbeni umjovo wevolumu ephansi, ikakhulukazi lapho kukhiqizwa izingxenye zemikhiqizo yobunikazi. Izinkampani kufanele zihloniphe amalungelo obunikazi futhi ziqinisekise ukuthi izinqubo zazo zokukhiqiza aziphuli impahla yengqondo.

- Imithetho yohwebo lwamazwe ngamazwe:Uma uhwebelana namazwe ngamazwe, imisebenzi yokubumba umjovo wevolumu ephansi kufanele ihambisane nemithethonqubo yokuhweba kanye namazinga aqondene namazwe ahililekile. Ukulandela imithetho yempahla edayiswayo kanye nemikhawulo yokungenisa/yokuthekelisa kungase kudingeke ukuze kuqinisekiswe ukuthotshelwa kwezivumelwano zohwebo lwamazwe ngamazwe.

Ukukhetha Umhlinzeki Wesevisi Yokubumba Umjovo Womthamo Ophansi Ongakwesokudla

Uzakwethu onokwethenjelwa nonekhono uzofaka isandla empumelelweni yemizamo yakho yokukhiqiza umthamo ophansi.

- Ubuchwepheshe nolwazi:Bheka umhlinzeki wesevisi onguchwepheshe bokubumba umjovo wevolumu ephansi, onolwazi nolwazi lokuphatha amaphrojekthi esikali esifanayo nobunkimbinkimbi. Umhlinzeki onerekhodi eliqinisekisiwe anganikeza imininingwane ebalulekile, izinqubo ezisebenza kahle, nemiphumela yekhwalithi ephezulu.

- Amandla okwenza ngokwezifiso: Hlola ikhono lomhlinzeki lokuhlinzeka ngezixazululo ezenziwe ngokwezifiso ezihambisana nezidingo zephrojekthi yakho. Bheka ukuguquguquka kwazo ekuhlanganiseni ukuguqulwa kwedizayini, izinketho zezinto ezibonakalayo, kanye namavolumu okukhiqiza ukuze uqinisekise indlela ehambisanayo.

- Ukuqinisekisa ikhwalithi:Qinisekisa ukuthi umhlinzeki wesevisi unezinqubo eziqinile zokuqinisekisa ikhwalithi. Ukuze siqinisekise ukwethembeka nokuvumelana kwezingxenye, sinamathela kumazinga nezitifiketi zezimboni (ezifana ne-ISO 9001) futhi senza ukuhlola nokuhlola okuphelele.

- Amandla okukhiqiza nokulinganisa:Linganisa ikhono lomhlinzeki wesevisi kanye nobukhulu ukuze uhlangabezane nezidingo zakho zokukhiqiza zevolumu ephansi. Kufanele bakwazi ukuphatha amavolumu akho okukhiqiza owafisayo, noma amancane noma anosayizi omaphakathi, futhi akhuphule uma kudingeka.

- Ubuchwepheshe nemishini:Hlola amakhono omhlinzeki wezobuchwepheshe kanye nempahla yesimanjemanje abayisebenzisayo. Imishini yokubumba yomjovo ethuthukisiwe nobuchwepheshe buthuthukisa ukusebenza kahle kwenqubo, ukungaguquguquki kwengxenye, nemijikelezo yokukhiqiza esheshayo.

- Ubuchwepheshe bezinto ezibonakalayo:Cabangela ubuchwepheshe bomhlinzeki wesevisi ekusebenzeni ngezinhlobonhlobo zezinto ezilungele ukubumba umjovo wevolumu ephansi. Kufanele bazi ama-resin ahlukene kanye nezakhiwo zawo futhi bakwazi ukuphakamisa izinketho zezinto ezibonakalayo ezihlangabezana nezidingo zephrojekthi yakho.

- Amasevisi engeziwe:Linganisa izinsizakalo ezengeziwe ezihlinzekwa umhlinzeki, ezifana nokucubungula ngemva kokucubungula, ukuhlanganisa, nokuqeda. Amasevisi engezwe inani angenza lula inqubo yakho yokukhiqiza, anciphise ukuxaka kwezinto, futhi anikeze isixazululo esiphelele kusukela ekuqaleni kuze kube sekupheleni.

- Ukuphatha ukuhlinzeka:Hlola amakhono omhlinzeki wokuphatha uchungechunge lokuhlinzeka, okuhlanganisa izinto zokwakha nezingxenye. Iketango lokuhlinzeka elilawulwa kahle liqinisekisa ukutholakala kwezinto ngesikhathi, linciphisa ukubambezeleka kokukhiqiza, futhi lenze izindleko zisebenze kahle.

- Ukwesekwa kwamakhasimende nokuxhumana:Cabangela ukwesekwa kwamakhasimende kanye nezinga lokuxhumana lomhlinzeki wesevisi. Ukuxhumana okunembayo nokuphendulayo, izibuyekezo ezijwayelekile zephrojekthi, kanye nendlela yokusebenzisana kubalulekile ukuze kube nobudlelwano obuphumelelayo.

- Ukusebenza kwezindleko:Nakuba izindleko kungafanele kube ukuphela kwesici esinqumayo, ukuhlola ukwakheka kwamanani omhlinzeki kanye nokusebenza kahle kwezindleko kubalulekile. Qhathanisa izingcaphuno, hlola inani lemali, futhi uqinisekise ukubamba obala mayelana nanoma yiziphi izinkokhelo noma izinkokhiso ezengeziwe.

Izinselelo Ezivamile Ekubumbeni Umjovo Wevolumu Ephansi

Ukubhekana nalezi zinselele ekubumbeni umjovo wevolumu ephansi kudinga ukuqonda okuphelele kwezidingo zephrojekthi, ukubambisana eduze nabahlinzeki nabalingani, kanye nokuthuthukiswa okuqhubekayo kwezinqubo.

- Izindleko zamathuluzi:Ukubumba komjovo wevolumu ephansi kuvame ukubandakanya ukuqhutshwa kokukhiqiza okuncane, okwenza izindleko zamathuluzi zangaphambili zibe inselele enkulu. Ukuklama nokukhiqiza isikhunta kungaba phezulu ngokulinganayo ingxenye ngayinye kunokukhiqizwa kwevolumu ephezulu, okudinga ukuhlaziywa kwezindleko ngokucophelela nokwenza kahle.

- Ubunkimbinkimbi bedizayini:Ukukhiqizwa kwevolumu ephansi kungase kuhlanganise imiklamo eyinkimbinkimbi futhi eyinkimbinkimbi. Inselele isekuqinisekiseni ukuthi indlela ingenzeka ekubumbeni umjovo nokuthi isikhunta singakhiqiza kabusha ngokunembile ijometri efiswayo. Ukuguqulwa kwedizayini nokuphindaphinda kungase kudingeke ukuze kuzuzwe imiphumela emihle.

- Ukukhetha okubalulekile:Ukukhetha izinto ezifanele zokubumba umjovo wevolumu ephansi kungaba inselele. Kufanele sicabangele izindleko, ukusebenza, ukuqina, nokutholakala. Ukuthola ibhalansi phakathi kwezakhiwo zezinto ezibonakalayo kanye nezidingo zephrojekthi kubalulekile ukuze kuzuzwe ikhwalithi kanye nokusebenza okufunayo.

- Ingxenye yekhwalithi engashintshi:Ukugcina ingxenye yekhwalithi engashintshi kukho konke ukukhiqizwa kwevolumu ephansi kungaba inselele. Ukwehluka kumapharamitha wenqubo, ukuguga kwesikhunta, nezici zempahla kungase kube nomthelela wobukhulu bengxenye, ukuqedwa kwendawo, kanye nezakhiwo zemishini. Izinyathelo eziqinile zokulawula ikhwalithi nokuqapha okuqhubekayo kuyadingeka ukuze kuncishiswe ukuhlukahluka.

- Izikhathi zokuhola:Ukubumba komjovo wevolumu ephansi ngokuvamile kudinga izikhathi zokuhola ezimfushane kunokukhiqizwa kwevolumu ephezulu. Ukuhlela okusebenzayo nokuxhumana kubalulekile ukuze kuthuthukiswe amashejuli okukhiqiza, ukunciphisa isikhathi sokuphumula, nokuqinisekisa ukulethwa kwezingxenye ngesikhathi. Ukuxhumana okuphumelelayo nabahlinzeki kanye nozakwethu kubalulekile ukuze kuhlangatshezwane nezikhathi eziqinile.

- Imikhawulo ye-scalability:Izinqubo zokubumba umjovo wevolumu ephansi zingase zibe nemingcele uma kuziwa ekulinganiseni. Ukushintsha ukusuka kuvolumu ephansi ukuya ekukhiqizweni kwevolumu ephezulu kungadinga amathuluzi, okokusebenza, kanye nokulungiswa kwenqubo. Ukulindela izinselele zokukhula nokuhlelela izidingo zokukhiqiza zesikhathi esizayo kubalulekile.

- Izindleko ngengxenye ngayinye:Izindleko ngengxenye ngayinye ekubunjweni komjovo wevolumu ephansi zivame ukuba phezulu uma kuqhathaniswa nokukhiqizwa kwevolumu ephezulu ngoba sisakaza izindleko zamathuluzi phezu kwezingcezu ezincane. Ukulinganisa ukucatshangelwa kwezindleko ngenkathi kugcinwa amazinga ekhwalithi kanye nokuhlangabezana nezidingo zephrojekthi kubalulekile.

- Ingozi yokuphelelwa yisikhathi:Ukukhiqizwa kwevolumu ephansi kuvame ukuhlinzekela izimakethe ze-niche noma okuhlukile kwemikhiqizo ethile. Ingozi yokuthi izingxenye zingasasebenzi noma zishintshe zifuneke zingadala izinselele. Ukuhlaziywa kwemakethe okucophelelayo, ukubikezela kwesidingo, namasu okuphatha i-inventory kuyadingeka ukuze kuncishiswe ubungozi bokuphelelwa yisikhathi.

Ikusasa Lokubumba Umjovo Wevolumu Ephansi

Ikusasa lokubumba umjovo wevolumu ephansi liqhakazile, ngamathuba amasha avela ekuthuthukisweni kwe-automation, ukukhiqiza okungeziwe, izinto ezisimeme nezinqubo, ukwenza ngokwezifiso, kanye nedijithali. Abakhiqizi abamukela lezi zindlela futhi batshale imali kubuchwepheshe obusha nezinqubo bazobekwa kahle ukuze baphumelele emakethe ethuthuka ngokushesha.

- Okuzenzakalelayo Nezimboni 4.0:Ukubumba komjovo wevolumu ephansi kukulungele ukuzuza kubuchwepheshe be-automation kanye ne-Industrial 4.0 obufana namarobhothi, ubuhlakani bokwenziwa, kanye ne-IoT. Ukuzenzakalela kungasiza ekunciphiseni izikhathi zokuhola, kuthuthukise ukungaguquguquki kwekhwalithi, futhi kwandise ukukhiqiza kuyilapho kunciphisa izindleko zabasebenzi.

- Izinqubo Zokukhiqiza Okungeziwe kanye Nengxubevange: Ukuze kuthuthukiswe amakhono okukhiqizwa kwevolumu ephansi, ukukhiqiza okungeziwe kanye nezinqubo ezihlanganisiwe, njengokuhlanganisa ukuphrinta kwe-3D nokubunjwa komjovo, kungaqashwa. Lobu buchwepheshe bunganika amandla i-prototyping esheshayo, inkululeko enkulu yokuklama, kanye nekhwalithi yengxenye ethuthukisiwe.

- Izinto Ezisimeme Nezinqubo:Ukusimama kuwukugxila okwandayo kwemisebenzi yokukhiqiza. Ikusasa lokubumba umjovo wevolumu ephansi lilele ekwamukeleni izinto ezisimeme nezinqubo. Izinto ezibolayo nezivuselelekayo zinganciphisa umthelela wendawo, kuyilapho amasu okucubungula eco-friendly anganciphisa ukumosha nokusetshenziswa kwamandla.

- Ukwenza ngokwezifiso kanye nokwenza kube ngokwakho:Isidingo sabathengi sokwenza ngokwezifiso kanye nokwenza kube ngokwakho sishayela ukuqamba okusha ekubumbeni komjovo wevolumu ephansi. Isoftware ethuthukisiwe nobuchwepheshe bokuzenzakalela bungavumela ukwenziwa ngokwezifiso kwenqwaba yezingxenye ezinezindleko eziphansi zamathuluzi, kuvule amathuba amasha ezimakethe ze-niche.

- Ukwenza Idijithali Nokuxhumana:Ukwenza idijithali nokuxhumana kuyikusasa lokubumba komjovo wevolumu ephansi. Abakhiqizi bangathuthukisa ukukhiqiza, bathuthukise ikhwalithi, futhi bathuthukise ukubonakala kwe-supply chain ngokusebenzisa ukuhlaziya idatha nezinkundla ezisekelwe emafini. Lobu buchwepheshe bungaphinda bunike amandla ukuqapha okukude nokugcinwa kokuqagela.

Isiphetho

Ukubunjwa komjovo wevolumu ephansi kunikeza izinzuzo ezibalulekile zokugijima kokukhiqiza okuncane. Ubuchwepheshe bokuphrinta be-3D buvumela ukwenza i-prototyping ngokushesha, amathuluzi angabizi kakhulu, kanye nokuguquguquka komklamo. Ivumela amabhizinisi ukuthi anciphise izikhathi zokuhola, akhethe ohlwini olubanzi lwezinto, anciphise udoti, futhi anciphise ubungozi. Ngokwamukela lezi zinzuzo, amabhizinisi amancane angakwazi ukuthuthukisa izinqubo zawo zokukhiqiza, ahlangabezane nezidingo zamakhasimende, futhi alondoloze umkhawulo wokuncintisana emakethe. Ukubumba komjovo wevolumu ephansi kunikeza isixazululo esisebenza kahle, esingabizi esinikeza amandla ukukhiqizwa okuncane ukuze kuchume endaweni yanamuhla yokukhiqiza.