Konke Odinga Ukukwazi Mayelana Ne-Plastic Injection Molding

Konke Odinga Ukukwazi Mayelana Ne-Plastic Injection Molding

Ukubumba ngomjovo weplastiki iyinqubo yokukhiqiza esetshenziswa kabanzi ukukhiqiza izingxenye zepulasitiki eziyinkimbinkimbi. Lokhu okuthunyelwe kwebhulogi kuzoxoxa ngezisekelo zokubumba umjovo wepulasitiki, umsebenzi wawo, izinhlelo zokusebenza, izinzuzo, kanye nokubi.

Ukubumba komjovo wePlastiki:

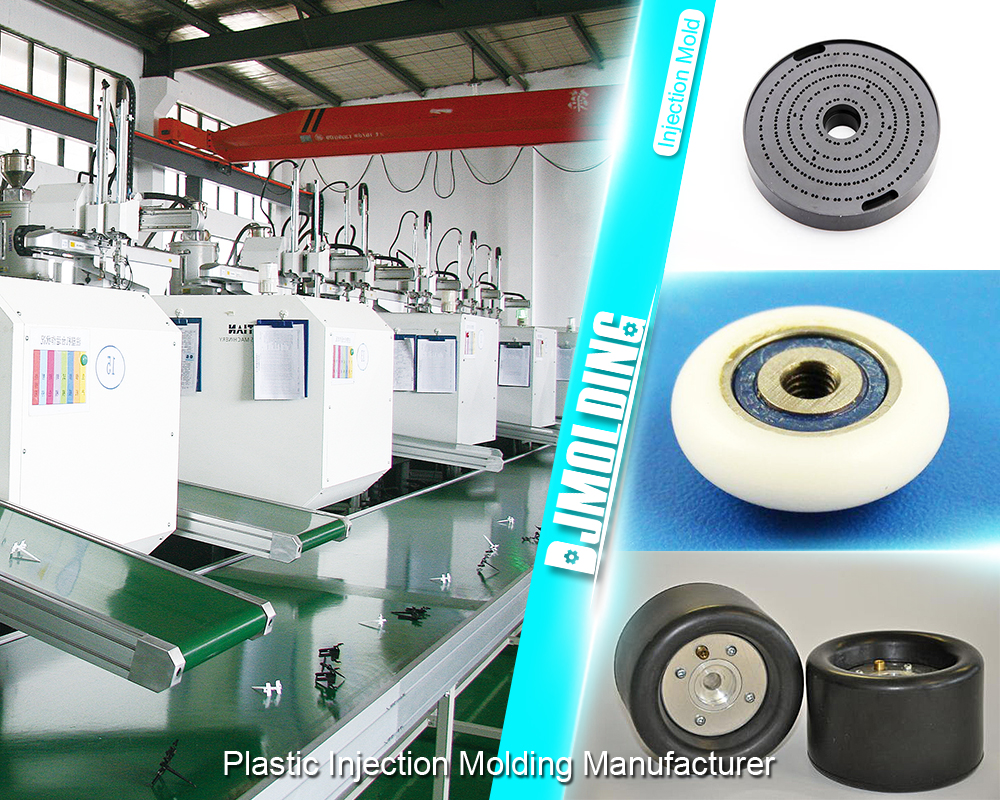

Ukubumba umjovo wePlastiki kungenye yezindlela zokukhiqiza ezaziwa kakhulu zokukhiqiza imikhiqizo yepulasitiki esezingeni eliphakeme ngobuningi. Izimboni ezahlukahlukene, njengezezimoto, zezokwelapha, zokupakisha, nezimpahla zabathengi, zisebenzisa ukubumba umjovo ukwenza imikhiqizo yazo. Le nqubo ihilela ukuncibilikisa ama-pellets epulasitiki bese uwajova esikhunjeni ngaphansi kwengcindezi ephezulu. Khona-ke ipulasitiki iyaphola futhi iqine, yakhe isikhunta. Kulokhu okuthunyelwe kwebhulogi, sizongena emininingwaneni yenqubo yokubumba umjovo wepulasitiki.

Inqubo yokubumba ngomjovo wePlastiki

Ukubumba umjovo wepulasitiki kuyinqubo eyinkimbinkimbi ehlanganisa izinyathelo eziningi. Nazi izinyathelo eziyisisekelo ezihilelekile kwinqubo yokubumba umjovo wepulasitiki:

Design Design

Isinyathelo sokuqala kule nqubo ukuklama isikhunta. Isinyathelo sokuqala kule nqubo ukuthuthukisa isikhunta usebenzisa isofthiwe ye-computer-aid design (CAD), esiza ukwakha imodeli ye-3D yengxenye. Isikhunta senziwe ngokusekelwe kulo mklamo kusetshenziswa insimbi noma i-aluminium.

Ukukhetha Izinto

Isinyathelo esilandelayo ukukhetha okokusebenza kwengxenye. Ama-Thermoplastics, angancibilika futhi akhe kabusha izikhathi eziningi, ayizinto ezisetshenziswa kakhulu ekubumbeni umjovo wepulasitiki. Izinto ezikhethiwe kufanele zifanele ukusetshenziswa okuhlosiwe.

Ukushisisa nokuncibilika

Uma ithimba lokuklama lenze isikhunta futhi likhetha izinto ezifanele, umshini wokubumba umjovo uyashisa futhi uncibilikise ama-pellets epulasitiki. Inqubo yokubumba umjovo ilawula izinga lokushisa ngokucophelela ukuze kuqinisekiswe ngisho nokuncibilika kwezinto.

Injection

Sibe sesifaka ipulasitiki encibilikisiwe emgodini wesikhunta ngaphansi kwengcindezi ephezulu. Ukucindezela kuqinisekisa ukuthi impahla igcwalisa i-niche yonke futhi ithatha isimo sesikhunta.

Ukupholisa kanye nokukhishwa

Ipulasitiki bese ivunyelwa ukuthi iphole futhi iqine, ithatha isimo sesikhunta sesikhunta. Uma ipulasitiki isipholile, umshini wokubumba umjovo uvula isikhunta bese ukhipha ingxenye.

Isetshenziselwa Ukubumba Umjovo Wepulasitiki

I-Plastic injection molding isetshenziswa ezimbonini ezihlukahlukene ukukhiqiza izingxenye ezahlukene. Nazi ezinye zezicelo ezivame kakhulu zokubumba umjovo wepulasitiki:

- Imboni Yezimoto: Izimboni ezahlukahlukene zisebenzisa ukubumba komjovo wepulasitiki ukukhiqiza izakhi ezahlukahlukene, njengamadeshibhodi ezimoto, obhampa, nezinsimbi zangaphakathi.

- Umkhakha wezokwelapha: Ukubumba umjovo wePlastiki kukhiqiza amathuluzi ezokwelapha afana namasirinji, ama-inhalers, nezinsimbi zokuhlinza.

- Imboni yokupakisha: Ukubumba umjovo wepulasitiki kukhiqiza izinto zokupakisha njengezikepisi zamabhodlela, iziqukathi, nokuvalwa.

- Imboni Yezimpahla Zabathengi: Ukubumba umjovo wePlastiki kukhiqiza impahla ehlukahlukene yabathengi, njengamathoyizi, izinto zikagesi, nezinto zikagesi zasendlini.

Izinzuzo Plastic Injection Molding

Ukubumba ngomjovo weplastiki iyinqubo yokukhiqiza esetshenziswa kabanzi enikeza izinzuzo ezimbalwa kunezinye izindlela zokukhiqiza. Le nqubo ihilela ukujova ipulasitiki encibilikisiwe embotsheni yesikhunta, epholisa futhi iqine ukuze yakhe ingxenye yekhwalithi ephezulu. Nazi ezinye zezinzuzo zokubumba umjovo wepulasitiki.

Ukusebenza Okuphezulu

Ukubunjwa komjovo wePlastiki kuyinqubo esebenza kahle kakhulu engakhiqiza ngokushesha izingxenye eziphezulu zezingxenye. Kuyinqubo ezenzakalelayo enamakhulu noma izinkulungwane zezici ngokushesha, okuyenza ifanelekele ukuqhutshwa kokukhiqiza okukhulu. Ukwengeza, inqubo ingathuthukiswa ukuze kuncishiswe isikhathi somjikelezo, kuthuthukiswe ukusebenza kahle.

Ukuvumelana nokunemba

Ukubumba komjovo wepulasitiki kukhiqiza izingxenye ezingaguquki ngosayizi nokuma ngokunemba okuphezulu. I-mold cavity iqinisekisa ukuthi umshini wenza i-elementi ibe nobukhulu obufunekayo nokuthi inqubo iphindaphindeka kakhulu. Ikhwalithi engaguquki ekhiqizwa ukubumba komjovo wepulasitiki ibalulekile ezinhlelweni zokusebenza lapho izilinganiso ezinembile zibalulekile, ukuqinisekisa ukuthi izingxenye ezikhiqizwayo zizoba nekhwalithi engaguquki.

yizinhlobonhlobo

Ukubumba umjovo wepulasitiki kungakhiqiza izingxenye ezinobukhulu obuhlukahlukene kanye nokuma. Abaqambi bangakha isikhunta esinezici ezinejometri eyinkimbinkimbi, njengezingxenye ezinodonga oluncane, okungenzeka kube nzima noma kungenzeki ukukhiqiza usebenzisa ezinye izindlela. Ukwengeza, le nqubo ingasebenzisa izinto ezihlukahlukene zepulasitiki, kuhlanganise nezinsalela zebanga lobunjiniyela, ezingakhethwa ngokusekelwe ezintweni ezifunwayo zengxenye.

Kuqiza kahle

Ukubumba umjovo wePlastiki kuyinqubo engabizi kakhulu yokukhiqiza izingxenye eziphezulu zezingxenye. Izindleko zokuqala zokuklama nokukhiqiza isikhunta zingaba phezulu, kodwa izindleko zengxenye ngayinye ziyehla njengoba umthamo wokukhiqiza ukhula. Ukwengeza, inqubo ingenziwa ngokuzenzakalelayo, enciphisa izindleko zabasebenzi futhi ithuthukise ukusebenza kahle. Udoti omncane wezinto ezibonakalayo usiza futhi ekwehliseni izindleko, njengoba noma iyiphi impahla eyeqile ingabuyekezwa futhi isetshenziswe ekukhiqizeni okuzayo.

Ukulahlwa Kwezinto Ezincane

Ukubumba umjovo wePlastiki kukhiqiza udoti omncane wezinto ezibonakalayo, njengoba noma iyiphi impahla eyeqile ingabuyekezwa futhi isetshenziswe ekukhiqizeni okuzayo. Ukubumba umjovo wePlastiki kusebenza kahle kakhulu kunezinye izindlela zokukhiqiza ngoba kuyancibilika futhi kujove inani elidingekayo lezinto endaweni yesikhunta, kunciphisa imfucuza. Noma iyiphi impahla eyeqile ngokuvamile iyaqoqwa futhi iphinde isetshenziswe, okunciphisa udoti futhi kuthuthukise ukusimama.

Okubi kakhulu okubalulekile

Abakhiqizi basebenzisa kakhulu ukubumba komjovo wepulasitiki ngezinzuzo zakhona kodwa kufanele bacabangele ukonakala okuthile okubalulekile. Lesi sigaba sizoxoxa ngobubi obubaluleke kakhulu bokubumba umjovo wepulasitiki.

Utshalomali Olukhulu Lokuqala

Enye yezinto ezimbi kakhulu zokubumba umjovo wepulasitiki ukutshalwa kwezimali okuphezulu kokuqala okudingekayo ukuze kwakhiwe isikhunta. Ukwakhiwa kwesikhunta kanye nenqubo yokudala kungabiza, ikakhulukazi imiklamo eyinkimbinkimbi noma isikhunta esikhulu. Izindleko zesikhunta zingaba isithiyo ekungeneni kwamabhizinisi amancane noma aqalayo, okwenza kube nzima kubo ukuncintisana nezinkampani ezinkulu ezingakwazi ukukhokhela ukutshalwa kwezimali okuphezulu.

Ukuguquguquka Kwedizayini Okunomkhawulo

Isikhunta sikhawulela ukwakheka kwengxenye, okusho ukuthi ukwenza izinguquko kunqubo kungaba nzima futhi kubize. Ukwenza izinguquko ezivamile esikhunjeni kungaba yingozi enkulu njengoba kudinga isikhathi nemali eyengeziwe ekuguquleni ngakunye. Lo mkhawulo wokuguquguquka kwedizayini ungaba inselele ikakhulukazi emikhiqizweni edinga ukubuyekezwa njalo noma ukwenziwa ngendlela oyifisayo.

Isikhathi sokukhiqiza

Okunye okungalungile kokubunjwa komjovo wepulasitiki ukuthi inqubo ingathatha amasonto ambalwa, kusukela ekuklanyeni kuya ekukhiqizeni. Isikhathi esidingekayo sokwakhiwa nokudalwa kwesikhunta, ukulungiswa kwezinto ezibonakalayo, nokukhiqizwa kungenza kube inselele ukuhlangabezana nezikhathi zokushintsha ngokushesha. Ukushintsha isikhunta kungaba yingozi enkulu ezinkampanini ezidinga izikhathi zokukhiqiza ezisheshayo noma ezibhekane nemijikelezo yempilo emifushane yomkhiqizo.

Impembelelo yemvelo

Inqubo yokubumba umjovo wepulasitiki ingalimaza imvelo. Le nqubo idinga ukusetshenziswa kwezinto zokubasa ezimbiwa phansi ukuze kushiswe futhi kuncibilike ipulasitiki, kube nomthelela ekukhishweni kwesisi esibamba ukushisa. Ukwengeza, le nqubo ingadala imfucuza ngokusetshenziswa kwepulasitiki ngokweqile namandla, kulimaza imvelo.

ISIPHETHO

Sengiphetha, ukubumba umjovo wepulasitiki kuyinqubo yokukhiqiza ethembekile nephumelelayo yokukhiqiza imikhiqizo yepulasitiki ephezulu. Izinzuzo zayo, njengokungaguquguquki, ukunemba, kanye nokusebenza kahle kwezindleko, kuyenza ibe ukukhetha okudumile ezimbonini ezahlukahlukene. Kodwa-ke, imibi yayo, njengokutshalwa kwezimali okuphezulu kokuqala kanye nokuguquguquka okulinganiselwe kwedizayini, kufanele futhi kucatshangelwe. Ukubumba umjovo wepulasitiki kuwubuchwepheshe obubalulekile obuguqule imboni yokukhiqiza. Njengoba ubuchwepheshe buthuthuka, ukubumba komjovo wepulasitiki cishe kuzoqhubeka nokushintshashintsha futhi kuthuthuke, kuba yimpumelelo nakakhulu, kungabizi kakhulu, futhi kuhambisane nemvelo.

Ukuze uthole okuningi mayelana ukufakelwa kwegesi epulasitiki,ungavakashela i-Djmolding at https://www.djmolding.com/ ukuze uthole olunye ulwazi.