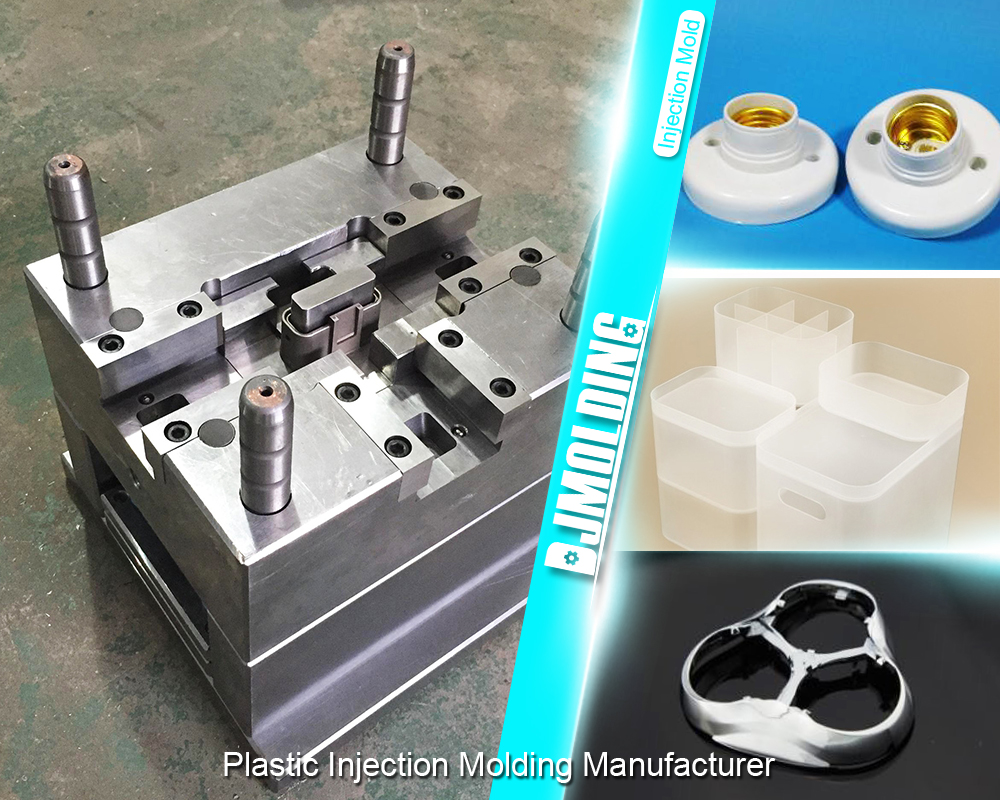

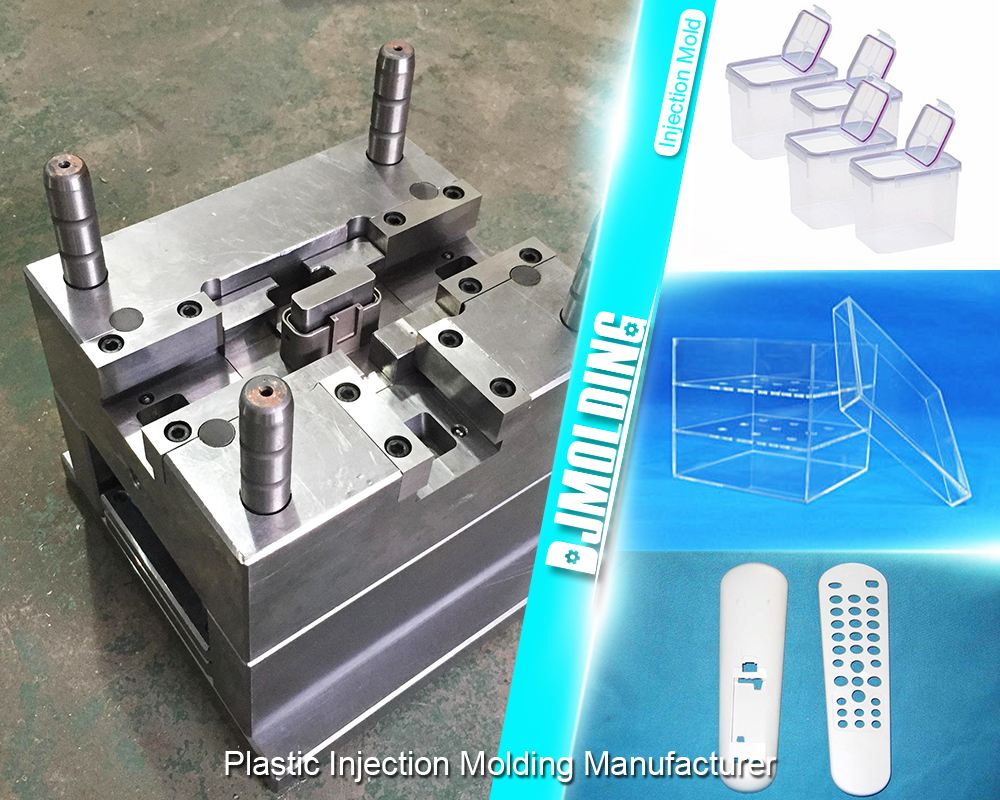

Ubuciko Bokubumba Umjovo Weplastiki Yeqoqo Elincane: Ukuthuthukisa Ukukhiqiza Ngokunemba

Ubuciko Bokubumba Umjovo Weplastiki Yeqoqo Elincane: Ukuthuthukisa Ukukhiqiza Ngokunemba

Ukubumba ngomjovo weplastiki kuvele njengendlela yokuguqula umdlalo endaweni yanamuhla yokukhiqiza esheshayo. Ukuhlanganisa ukunemba nokusebenza kahle kwenza ukukhiqizwa okukhulu kwezingxenye zepulasitiki eziyinkimbinkimbi. Le ndatshana idingida ubunkimbinkimbi bokubumba umjovo wepulasitiki, igqamisa ukubaluleka kwayo, izinzuzo zayo, kanye nokusetshenziswa kwayo kuzo zonke izimboni ezihlukahlukene.

Ukuqonda Ukubunjwa Kwemijovo Yepulasitiki Yeqoqo Elincane

Uhlolojikelele lwencazelo kanye nenqubo

Ukubumba umjovo wepulasitiki kuyinqubo yokukhiqiza ebandakanya ukujova ipulasitiki encibilikisiwe endaweni yokubumba ukuze kwakhe izimo eziyinkimbinkimbi nezinembayo. Lesi sigaba sichaza izinyathelo zenqubo ewumongo, kusukela ekukhethweni kwezinto ezibonakalayo kuya ekusebenziseni izingxenye ezibalulekile ezifana nokubunjwa, amayunithi omjovo, namasistimu okubamba.

Izinhlobo Zepulasitiki Ezisetshenziswa

Impumelelo yokubumba umjovo wepulasitiki incike ekusebenziseni izinhlobo ezahlukene zamapulasitiki eziklanyelwe izinhlelo ezithile. Lapha, sihlola amapulasitiki asetshenziswa kakhulu, okuhlanganisa ama-thermoplastic kanye nama-polymers we-thermosetting. Ngokuqonda izici zabo eziyingqayizivele nezakhiwo, abakhiqizi bangakwazi ukuthuthukisa inqubo yokubumba ukuze kube nemiphumela ephakeme.

Izinzuzo Eziyinhloko Zokubumba Umjovo Wepulasitiki

Ukubumba umjovo wepulasitiki kunikeza izinzuzo eziningi kunezinye izindlela zokukhiqiza. Lesi sigaba sicubungula ukusebenza kahle kwezindleko, ukuguquguquka komklamo, ukusebenza kahle kokukhiqiza okuphezulu, nokulawulwa kwekhwalithi okungaguquki. Izibonelo zomhlaba wangempela kanye nezindaba zempumelelo ziphinde zibonise umthelela oguquguqukayo wokubumba umjovo wepulasitiki ezimbonini ezihlukahlukene.

Inqubo yokubumba ngomjovo wePlastiki

Isikhunta Design and Ukulungiselela

Ukwakhiwa kwesikhunta kuyisici esibalulekile ukufakelwa kwegesi epulasitiki. Sixoxa ngokubaluleka kokuklama isikhunta ukuze sisebenze kahle, siqine, futhi sikhiqize kahle. Ukwengeza, sithinta izinto ezihlukahlukene zokubunjwa kanye nezakhiwo zazo ukuze siqinisekise ukukhethwa kwenketho efanelekayo yephrojekthi ngayinye.

Isigaba sokujova

Isigaba somjovo sibandakanya ukuncibilika kwempahla yepulasitiki, ukuyicindezela, nokuyijova emgodini wokukhunta. Lapha, sinikeza incazelo enemininingwane yalesi sigaba, sigcizelela ukubaluleka kokunemba nokulawula. Abakhiqizi bahlola izinga lokushisa, ingcindezi, nesikhathi sokupholisa ukuze bathole ikhwalithi yomkhiqizo.

Ukupholisa kanye Nokuqinisa

Isigaba sokupholisa sidlala indima ebalulekile enqubweni yokubumba umjovo wepulasitiki. Sihlola amasu okupholisa ukuze siqinisekise ukuqina okufanele kwepulasitiki, sithuthukise ubuqotho besakhiwo kanye nokunciphisa amaphutha. Ochwepheshe baxoxa ngamasu afana nokulawula izinga lokushisa kwesikhunta, ukupholisa okuvumelanayo, nezindlela zokupholisa ngokushesha.

Ukukhipha kanye nokuqeda

Isikhunta siyawukhipha umkhiqizo ngemva kokuqina. Lesi sigaba sichaza inqubo yokukhipha futhi sigqamisa imisebenzi yesibili njengokunquma, ukupholisha, nokuqedwa kwendawo. Ngokubhekana nalokhu kuthintwa kokugcina, abakhiqizi bangathuthukisa ubuhle bomkhiqizo, ukusebenza, kanye nokuthengiseka.

Izicelo zokubunjwa komjovo wePlastiki

- Imikhiqizo yabathengi: Abakhiqizi basebenzisa kakhulu ukubumba komjovo wepulasitiki ukukhiqiza izimpahla zabathengi. Abakhiqizi basebenzisa le ndlela yokwenza izinto zasekhishini, izinto zasendlini, amathoyizi, nezinto zikagesi. Ukuhlukahluka kokubumba komjovo wepulasitiki kuvumela ukudalwa kwemiklamo eyinkimbinkimbi, imibala egqamile, nemikhiqizo eqinile ethuthukisa impilo yethu yansuku zonke.

- Imboni Yezimoto: Imboni yezimoto incike kakhulu ekubunjweni komjovo wepulasitiki ukukhiqiza izingxenye ezahlukahlukene. Kusukela ekulungiseni kwangaphakathi namaphaneli edeshibhodi kuya ezingxenyeni zangaphandle ezifana nobhampa nama-grille, ukubumba komjovo wepulasitiki kunikeza ukuguquguquka kwedizayini, ukunciphisa isisindo, kanye nokusebenza ngempumelelo kwezindleko. Inika amandla imboni yezimoto ukuthi ifinyelele ukukhanga kobuhle, ukuhlanganiswa kokusebenza, kanye nokusebenza kahle kukaphethiloli.

- Ukunakekelwa Kwezempilo Nezempilo: Ukubumba umjovo wepulasitiki kubalulekile emikhakheni yezokwelapha neyokunakekelwa kwezempilo. Abakhiqizi bayisebenzisela ukwakha izinsiza zezokwelapha, okokusebenza, nezinto ezidlekayo ezinamazinga aqinile ekhwalithi kanye nokuthobela imithetho. Abakhiqizi bakhiqiza izinto ezinjengamasirinji, izixhumi ze-IV, amathuluzi okuhlinza, nezimila besebenzisa izinto ezihambisana ne-biocompatible ukuqinisekisa ukuphepha kwesiguli nokusebenza okunembayo.

- Imboni yokupakisha: Ukubumba umjovo wepulasitiki kuyasiza embonini yokupakisha. Inika amandla ukukhiqizwa kweziqukathi zepulasitiki, amabhodlela, amakepisi, nokuvalwa okusetshenziswa emikhakheni ehlukahlukene njengokudla neziphuzo, ukunakekelwa komuntu siqu, kanye nemithi. Ikhono lokudala izimo ezenziwe ngokwezifiso, osayizi, nezici kwenza ukubumba komjovo wepulasitiki kube ukukhetha okuthandwayo kwezixazululo zokupakisha.

- Izingxenye zikagesi nezikagesi: Ukubumba umjovo wepulasitiki kuzuzisa kakhulu imboni yezogesi. Isiza ukukhiqizwa kwama-casings, izixhumi, amaswishi, nezinye izingxenye eziyinkimbinkimbi ezidingekayo kumishini kagesi namasistimu kagesi. Ukubumba komjovo wepulasitiki kuqinisekisa ukunemba, ukuzinza kobukhulu, nokuvikelwa ezicini zemvelo zemikhiqizo kagesi.

- I-Aerospace nokuvikela: Ukubumba komjovo wePlastiki kuthola izinhlelo zokusebenza emikhakheni ye-aerospace neyokuvikela. Abakhiqizi basebenzisa ukubumba komjovo wepulasitiki ukukhiqiza izingxenye ezingasindi, ezinamandla aphezulu ezihlangabezana nezidingo eziqinile zokusebenza nezokuphepha. Izibonelo zifaka ukufakwa kwangaphakathi, amaphaneli wezinsimbi, abakaki, namasistimu okudonsa umkhathi.

- Izinto Zokwakha Nezokwakha: Ukubumba umjovo wePlastiki kunomthelela embonini yokwakha ngokukhiqiza izinto ezinjengamapayipi, okokufakwayo, ukufakwa kwe-insulation, nezinto zokufulela. Ukuqina, ukumelana nokugqwala, kanye nokuphumelela kwezindleko zemikhiqizo ebunjwe ngomjovo wepulasitiki kuyenza ilungele ukusetshenziswa kokwakhiwa.

- Ezemidlalo Nokuzijabulisa: Ukubumba komjovo wePlastiki kukhiqiza okokusebenza kwezemidlalo, imikhiqizo yokungcebeleka, namagiya angaphandle. Abakhiqizi banezinto ezifana nezigqoko zokuzivikela, izinto zokuzivikela, izingxenye zebhola, nezibambo zemishini abasebenzisa le nqubo. Ukubumba ngomjovo weplastiki ivumela ukudalwa kwemikhiqizo engasindi, engazweli ethuthukisa ukusebenza nokuphepha.

Intuthuko kanye Nezitayela Zesikhathi esizayo

Izindlela Ezintsha Zezobuchwepheshe

- Ukuzenzekelayo: I-Automation iguqule ukubumba komjovo wepulasitiki, yenza lula izinqubo zokukhiqiza kanye nokwenza ngcono ukusebenza kahle. Amasistimu azenzakalelayo angakwazi ukuphatha izinto ezibonakalayo, izinguquko zesikhunta, nokulawula ikhwalithi, ukunciphisa amaphutha omuntu nokwandisa umkhiqizo.

- Ukuphrinta kwe-3D: Ukuhlanganisa ubuchwepheshe bokuphrinta be-3D nokubunjwa komjovo wepulasitiki kuvule amathuba amasha okwenziwa kwe-prototyping okusheshayo nokwenza ngokwezifiso. Izibunzi eziphrintiwe ze-3D nezifakiwe zingasetshenziswa eduze kwesikhunta esivamile, okuvumela ukuphindaphinda okusheshayo kanye nokukhiqizwa kwenqwaba yamaqoqo amancane.

- I-Artificial Intelligence (AI): I-AI idlala indima ebalulekile ekubumbeni umjovo wepulasitiki. Isofthiwe enikwe amandla yi-AI ingahlaziya idatha yenqubo ngesikhathi sangempela, ithuthukise amapharamitha afana nezinga lokushisa, ukucindezela, nesikhathi sokupholisa ukuze uthole ikhwalithi yengxenye ethuthukisiwe. Amasistimu okulungisa asebenzisa amandla e-AI abikezelayo angasiza futhi ukuvimbela isikhathi sokuphumula esingalindelekile futhi ehlise izindleko zokulungisa.

- Ukubumba Okuningi: Ikhono lokusebenzisa izinto eziningi kunqubo yokubumba umjovo owodwa liyakhula. Abakhiqizi bangasebenzisa ukubumba komjovo wepulasitiki ukuze bakhe izingxenye eziyinkimbinkimbi ezinezakhiwo ezibonakalayo ezihlukahlukene, njengokuhlanganisa amapulasitiki aqinile futhi aguquguqukayo. Le nqubo yokukhiqiza ivumela ukulawula okunembayo phezu kwenqubo yokubumba, okwenza kufinyelelwe uhla olubanzi lwezingxenye zemiklamo namajiyometriki. Ukubunjwa kwezinto eziningi kunweba amathuba edizayini futhi kuthuthukise ukusebenza komkhiqizo.

- Ukubumba komjovo omncane: I-Miniaturization iwumkhuba okhulayo kuzo zonke izimboni, futhi ukubumba komjovo omncane kuhambisana nalesi sidingo. Le nqubo ikhiqiza izingxenye ezincane ezinembayo eziphezulu, eziyinkimbinkimbi, ezivula amathuba emikhakheni efana ne-electronics, imishini yezokwelapha, ne-microfluidics.

- Izinto Ezisimeme: Njengoba ukusimama kuba yinto ehamba phambili, imboni ihlola ezinye izinto zokubumba umjovo wepulasitiki. Amapulasitiki angaboli kanye ne-bio-based atholakala emithonjeni evuselelekayo aya ngokuduma. Ukwengeza, ukusebenzisa amapulasitiki agaywe kabusha kunciphisa imfucuza futhi kusekela umnotho oyindilinga.

- I-Smart Manufacturing: Ukuhlanganisa ubuchwepheshe be-Intanethi Yezinto (IoT) ekubunjweni komjovo wepulasitiki kuvumela ukuqapha okuhlakaniphile nokulawulwa kwezinqubo zokukhiqiza. Izinzwa nokuxhumana kunika amandla ukuqoqwa kwedatha yesikhathi sangempela, ukuhlaziya, nokuqapha okukude. Ukusebenzisa amasu azenzakalelayo ekubumbeni umjovo wepulasitiki kuthuthukisa ukulawulwa kwekhwalithi, kunciphisa isikhathi sokuphumula, futhi kuthuthukisa ukusebenza kahle okuphelele. Lezi zinqubo zingabandakanya ukuphatha okuzenzakalelayo, ukususwa kwengxenye yerobhothi, kanye namasistimu okuhlola asemgqeni.

- I-Virtual and Augmented Reality: Ekubunjweni komjovo wepulasitiki, abaklami nonjiniyela basebenzisa ubuchwepheshe obungokoqobo nobungathandwa kwabathelisi esikubona ukuze baqinisekise imiklamo kanye nokuthuthukisa izinqubo. Abakhiqizi bangakwazi ukuhlonza izinkinga ezingaba khona, balungiselele imiklamo, futhi banciphise isikhathi sokuya emakethe ngokudala ama-virtual prototypes futhi balingise inqubo yokubumba.

Le ntuthuko kanye nezitayela zesikhathi esizayo ekubumbeni imijovo yepulasitiki zibumba isimo semboni, zenza ukukhiqizwa kusheshe, kusebenze kahle, futhi kuhambisane nemvelo. Ngokwamukela i-automation, ukusebenzisa ukuphrinta kwe-3D ne-AI, ukuhlola izinto ezintsha, nokusebenzisa izindlela zokukhiqiza ezihlakaniphile, abakhiqizi bangahlala bencintisana futhi bahlangabezane nezidingo eziguqukayo zemakethe. Ukuphishekela okuqhubekayo kokusungula izinto ezintsha kuqinisekisa ukuthi ukubumba komjovo wepulasitiki kuhlala kuhamba phambili ekukhiqizeni kwesimanje.

Isiphetho

Ukubumba umjovo wePlastiki kuyisisekelo sokukhiqiza kwesimanje, okuvumela ukukhiqizwa okuphumelelayo kwezingxenye zepulasitiki eziyinkimbinkimbi. Ukubumba komjovo wepulasitiki kuguqule imikhiqizo ngokushintsha izinyathelo zenqubo eyinhloko, kunikeze izinzuzo ezihlukahlukene, nokuthola izinhlelo zokusebenza kuzo zonke izimboni eziningi. Abakhiqizi bangahlangabezana nezidingo zabathengi ezikhula njalo ngokusebenzisa ukunemba, ukuguquguquka kwedizayini, kanye nokusebenza kahle kwezindleko. Imboni yokubumba umjovo wepulasitiki ilungele ikusasa eligcwele ukuqamba kabusha kanye nesibopho sezemvelo njengoba intuthuko yezobuchwepheshe nemizamo yokusimama iqhubeka nokuyibumba. Simema abafundi ukuthi bahlole kabanzi futhi bathole amathuba angenamkhawulo anikezwa ukubunjwa komjovo wepulasitiki.

Ukuze uthole okuningi mayelana iqoqo elincane lomjovo wepulasitiki,ungavakashela i-Djmolding at https://www.djmolding.com/injection-mould-manufacturing/ ukuze uthole olunye ulwazi.