5 Common Plastic Resins Used in Injection Molding

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

With hundreds of commodity and engineering resins available on the market today, the material selection process for plastic injection molding jobs can often seem daunting at first.

At DJmolding, we understand the unique benefits and properties of different types of plastics and work closely with clients to find the best fit for their project.

What Are Plastic Resins?

We live in a world surrounded by plastic resins. Due to their several desirable properties, plastic resins can be found in everything from bottles and containers to automotive and medical components and much more. Plastic resins include a large family of materials that each have their own unique properties that make them ideal for different applications. When choosing the right resin for your project, it’s important to understand what each type has to offer.

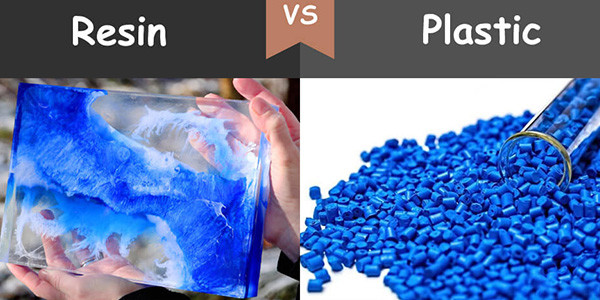

What Is the Difference Between Resin and Plastic?

Resin and plastic are both important compounds, but feature some key differences, including:

*Origin: While resins are naturally occurring in plants, plastics are synthetic and are typically derived from petrochemicals.

*Definition: Plastic is a type of synthetic resin, whereas resins are amorphous compounds that can either be semi-solid or solid.

*Stability and impurities: Plastics are more stable than resin and lack impurities. With resins, impurities cannot be avoided.

*Hardness: Plastic is dense and hard, while resin is typically a gluey and viscous substance.

*Environmental impact: Since resin is natural, it offers a more environmentally friendly alternative to plastic. Plastic degrades slowly and often has toxic additives that can lead to environmental pollution.

Common Applications for Plastic Resin Injection Molding

Plastic injection molding is compatible with a wide range of resin materials. When determining the right resin for your needs, it’s important to understand the needs of your particular application. Common applications for different injection molding resins include:

ABS

Injection-molded ABS is used in a wide variety of applications, including plastic wall plates for electrical outlets, protective headgear, keyboard keys, electronic components, and automotive components such as auto body parts, wheel covers, and dashboards. It is also used for a range of industrial fittings, sports equipment, and consumer goods.

Celson (Acetal)

Because of its low coefficient of friction, injection-molded Celson is ideal for pulley wheels, conveyor belts, gears, and bearings. This material can also be found in various high-performance engineering components, lock systems, firearms, eyeglass frames, and fasteners.

Polypropylene

Injection-molding polypropylene is used in a wide variety of industrial, commercial, and consumer applications. For example, it can be found in power tool bodies, appliances, packaging components, sporting goods, storage containers, and children’s toys.

HIPS

Because HIPS features a higher impact strength, it can be found in appliances, printing equipment, signage, and equipment components. Other common applications include children’s toys and electrical components.

LDPE

Due to its flexibility and resistance to moisture and chemicals, injection-molded LDPE is often used for applications including medical device components, wire and cable insulators, toolboxes, and children’s toys.

Key Factors to Consider When Choosing an Injection Molding Material

Custom plastic parts from DJmolding to ensure you select the right resin for your project, keep in mind the following variables:

*Impact strength — Some applications require more base strength than others, so a resin’s Izod impact strength should be determined from the start.

*Tensile strength — Ultimate tensile strength, or ultimate strength, measures the resin’s resistance to tension and its ability to withstand a given load without pulling apart.

*Flexural modulus of elasticity — This refers to the degree to which a material can be bent without damage and still snap back to its original form.

*Heat deflection — This is especially important for applications that require insulating performance or tolerance for a variety of temperature ranges.

*Water absorption — This is based on the percentage of liquid taken on by a material after 24 hours of immersion.

Custom Material Selection with DJmolding

Djmolding is plastic injection molding manufacturer,manufacturing plastic parts with acrylic (PMMA),acrylonitrile butadiene styrene (ABS),nylon (polyamide, PA),polycarbonate (PC),polyethylene (PE),polyoxymethylene (POM),polypropylene (PP),polystyrene (PS) and so on

Choosing the right material from the start will not only save you time, and money but will also ensure optimal performance and manufacturability. Research your options carefully, and consult with an experienced plastic injection molder to help determine the ideal choice.