Plastic injection molding technology and application

Injection moulding is a technique used for manufacturing various mechanical components. The versatility of this method enables the high quality, low-cost, rapid manufacturing of plastic parts.

What are the most common types of injection molding processes?

Thermoset injection molding

Molding with thermoset materials requires heat or chemical means to cross-link polymer chains.

Overmolding

Overmolding is an injection molding process where one material is molded on top of another.

Gas-assisted injection molding

Inert gas is introduced, at high pressure, into the polymer melt at the end of the injection phase of molding.

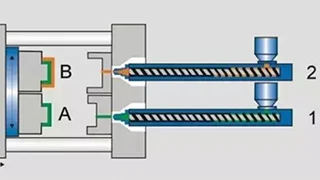

Co-injection & Bi-injection molding

Injection of two different materials using either the same or different injection locations.

Co-injection & Bi-injection molding

Injection of two different materials using either the same or different injection locations.

Powder injection molding (PIM)

Forming technique for producing small components using powders, typically ceramics (CIM) or metals (MIM), and binding agents.

What is plastic injection molding

Thermoplastic injection molding is a method for manufacturing high-volume parts with plastic materials. Due to its reliability and flexibility in design options, injection molding is used in many industries, including: packaging, consumer & electronics, automotive, medical, and many more.

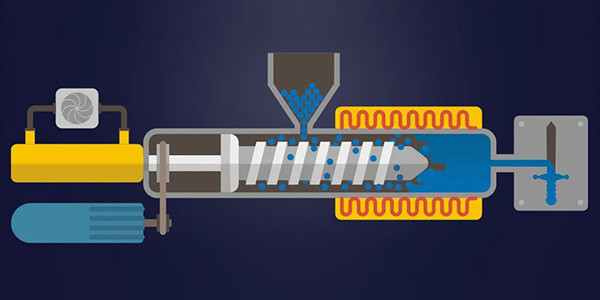

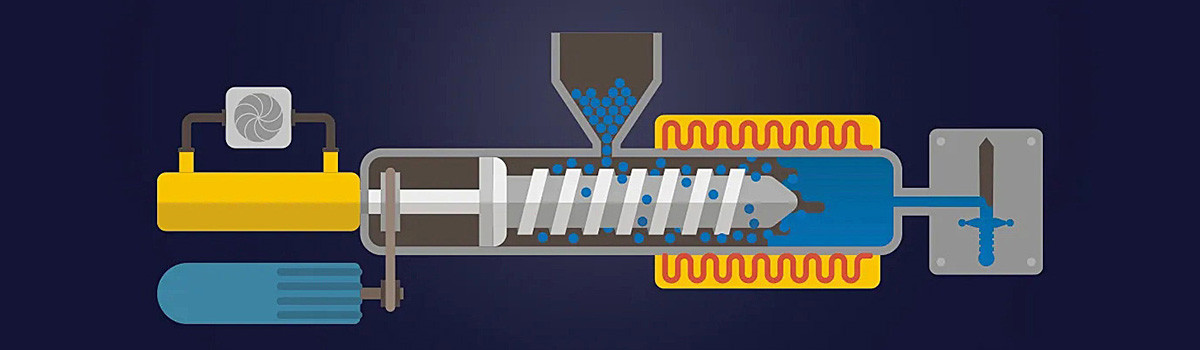

Injection molding is one of the most widely used manufacturing processes in the world. Thermoplastics are polymers that soften and flow when heated, and solidify as they cool.

What is Cushion & why do I need to hold it

Injection Molding has a lot of strange sounding terms. Fill time, back pressure, shot size, cushion. For people new to plastics or injection molding, some of these terms might feel overwhelming or make you feel unprepared. One of the goals of our blog is to help newer processors have the tools they need to succeed. Today we will take a look at cushion. What is it, and why is it important to “hold it?”

Basics of Plastic Injection Molding

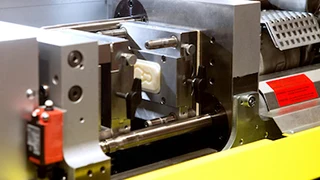

Plastic injection molding is a popular manufacturing technique in which thermoplastic pellets are converted into high volumes of complex parts. The injection molding process is suitable for a variety of plastic materials and is a vital aspect of modern life—phone cases, electronic housings, toys, and even automotive parts would not be possible without it. This article will break down the basics of injection molding, describe how injection molding works, and illustrate how it is different from 3D printing.

New Developments in Plastic Injection Moulding

Plastic injection molding as a manufacturing technique has been around for decades. However, new injection molding trends are propelling this method forward, bringing new and unprecedented advantages to the companies that opt for it.

Find out what the new injection molding trends are for the coming years and how your company can benefit from applying them.

Plastic Injection Molding Key Considerations

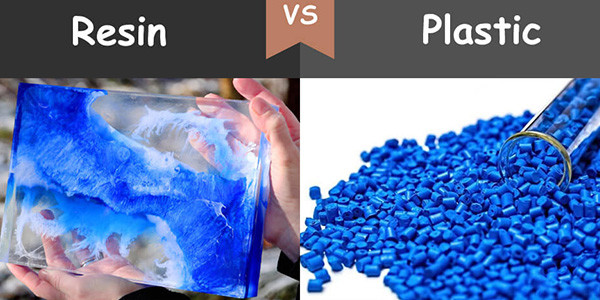

Materials play a significant role in injection molding. A skilled injection molding provider can help you choose a thermoplastic that fits your budget and performance requirements. Because molders often get discounts on the large quantities of thermoplastic grades they purchase, they can pass on those savings to you.

How to Choose The Best Plastic Materials For Plastic Injection Molding

Choosing the right plastic for plastic injection molding can be difficult—there are thousands of options in the market from which to choose, many of which will not work for a given goal. Luckily, an in-depth understanding of the desired material properties and intended application will help narrow the list of potential options into something more manageable.

How to Choose the Best Plastic for Plastic Injection Molding

With hundreds of commodity and engineering resins available on the market today, the material selection process for plastic injection molding jobs can often seem daunting at first.

At DJmolding, we understand the unique benefits and properties of different types of plastics and work closely with clients to find the best fit for their project.

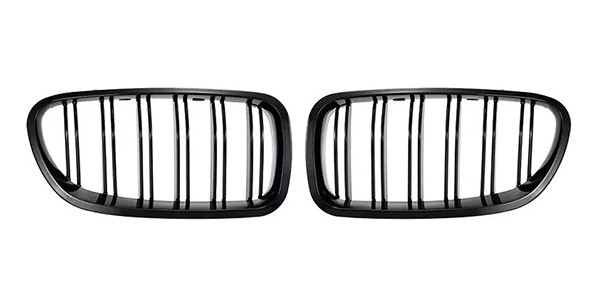

Innovative Injection Molding Solutions For The Automotive Industry

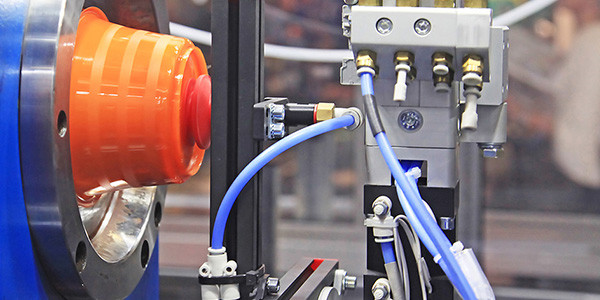

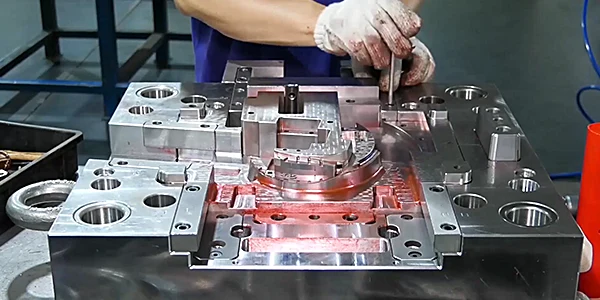

Once the right molds for the products are acquired, the actual part of the multi-step plastic injection molding process is carried out. First, the plastic is melted in special barrels; then the plastic is compressed and injected into the previously prepared molds. This way, precisely manufactured components can be created very quickly. This is why rapid injection molding has become so popular in many industries, including the automotive sector.

How To Pick A Good Injection Molding Company

Are you a plastic parts buyer? Are you struggling to find a partnership with a valuable molder? PMC (Plastic Molded Concepts) is here to help you. We understand identifying a respectable molding company is crucial to your company’s success. It is important to prioritize the process of choosing a good molder. Let’s review a few questions that will assist you in finding a beneficial teammate to support your company’s commitment to quality.

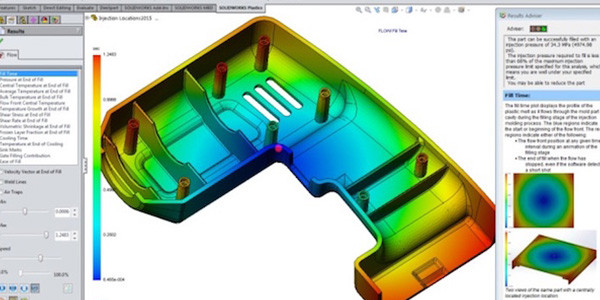

Solutions to Common Molding Defects of Injection Molding

Defects are common when using molds to process plastic injection molding parts, and this largely affects the processing efficiency. The following are common molding defects and solutions for plastic injection mold parts.