On Demand Manufacturing Service

Revolutionizing Industry: The Power of On-Demand Manufacturing Services

In today’s fast-paced world, the demand for efficiency and flexibility in manufacturing has surged. Enter on-demand manufacturing services, a revolutionary approach reshaping traditional production paradigms. This article dives deep into the concept, advantages, applications, and prospects of on-demand manufacturing services, shedding light on how they transform industries worldwide.

Understanding the Basics: What Is On-Demand Manufacturing?

In today’s rapidly evolving business landscape, on-demand manufacturing has emerged as a game-changing solution for companies seeking flexibility, efficiency, and cost-effectiveness in their production processes. But what exactly is on-demand manufacturing?

At its core, on-demand manufacturing is a production strategy that emphasizes creating products in response to customer orders, unlike traditional mass production, where goods are produced in anticipation of future demand. This approach allows businesses to minimize inventory, reduce lead times, and adapt quickly to market changes.

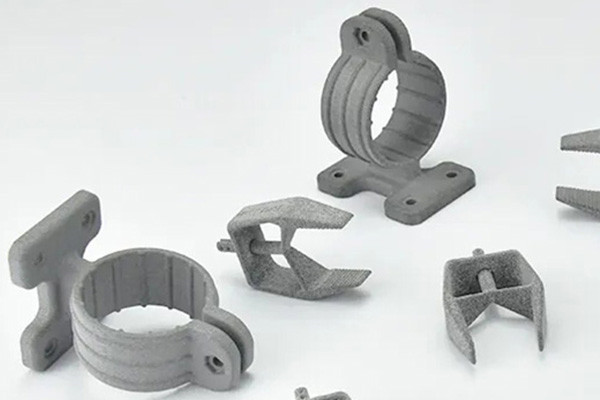

One key aspect of on-demand manufacturing is the use of advanced technologies such as 3D printing and computer numerical control (CNC) machining. These technologies enable rapidly and precisely producing customized or low-volume parts without expensive tooling or molds. As a result, manufacturers can produce small batches of products economically, making on-demand manufacturing particularly advantageous for niche markets and specialized applications.

One of the primary benefits of on-demand manufacturing is its ability to streamline the supply chain. With traditional manufacturing models, companies must forecast demand accurately, leading to the production of large quantities of goods that may or may not be sold. On-demand manufacturing, however, allows businesses to produce items only when there is a confirmed order, reducing the risk of excess inventory and associated costs.

Moreover, on-demand manufacturing promotes sustainability by minimizing waste. Traditional manufacturing often leads to overproduction, resulting in surplus inventory that may eventually be discarded. On-demand manufacturing reduces this waste by producing goods only as needed, contributing to a more environmentally friendly and resource-efficient production process.

Another aspect worth noting is the increased speed of production associated with on-demand manufacturing. Traditional manufacturing processes can involve lengthy lead times, especially with overseas production. On-demand manufacturing allows faster turnaround times, enabling companies to respond promptly to market demands and changing customer preferences.

The Evolution of Manufacturing: Traditional vs. On-Demand Models

The manufacturing industry has undergone a profound transformation in recent years, driven by technological advancements and changing consumer demands. Two prominent models that highlight this evolution are traditional manufacturing and on-demand manufacturing. Let’s delve into the key differences and advantages of these contrasting approaches.

Traditional Manufacturing: A Legacy Approach

Traditional manufacturing has long been the backbone of industrial production. This model involves mass production, where large quantities of goods are produced in anticipation of future demand. The process typically relies on economies of scale to minimize production costs per unit by manufacturing in bulk.

One of the primary characteristics of traditional manufacturing is the use of fixed production lines and molds. This approach requires significant upfront investments in tooling and setup, making it more suitable for large production runs. While traditional manufacturing has effectively met the demands of a mass market, it comes with challenges such as long lead times, excess inventory, and limited flexibility in adapting to changing market dynamics.

On-Demand Manufacturing: The Agile Alternative

On the other hand, on-demand manufacturing represents a paradigm shift towards a more agile and responsive production model. This approach prioritizes the creation of goods in response to actual customer orders, eliminating the need for extensive forecasting and large inventory stockpiles.

Key to on-demand manufacturing is the integration of advanced technologies like 3D printing, CNC machining, and digital manufacturing. These technologies enable the cost-effective production of small batches or even individualized items without expensive tooling. The result is a more flexible and sustainable manufacturing process that aligns closely with the principles of a circular economy.

Advantages of On-Demand Manufacturing:

- Reduced Inventory Costs: On-demand manufacturing minimizes the need to maintain extensive inventories, reducing storage costs and the risk of obsolete products.

- Customization and Personalization: On-demand manufacturing allows for the production of customized and personalized products, catering to individual customer preferences.

- Faster Turnaround Times: Advanced technologies in on-demand manufacturing enable speedier production cycles, reducing lead times and enhancing responsiveness to market changes.

- Environmental Sustainability: On-demand manufacturing contributes to sustainability efforts by minimizing waste and resource consumption by producing goods only as needed.

Choosing the Right Model for the Future

While traditional manufacturing has a proven track record and remains relevant for specific industries, on-demand manufacturing is gaining prominence as companies seek greater flexibility, cost-efficiency, and environmental sustainability. The choice between these models ultimately depends on market demand, product complexity, and the need for customization.

Key Players in On-Demand Manufacturing: Exploring Industry Leaders

In the dynamic realm of on-demand manufacturing, several key players have risen to prominence, driving innovation and shaping the industry landscape. These companies have demonstrated a commitment to flexibility, technological prowess, and customer satisfaction. Let’s explore some of the notable leaders in on-demand manufacturing.

Protolabs:

Protolabs is a global leader in on-demand manufacturing, offering various services, including 3D printing, CNC machining, and injection molding. With a focus on rapid prototyping and low-volume production, Protolabs empowers businesses to bring products to market faster while maintaining high-quality standards.

Xometry:

Xometry is a digital marketplace connecting businesses with a manufacturing partner network. Offering a wide array of manufacturing services, such as CNC machining, 3D printing, and sheet metal fabrication, Xometry provides a one-stop solution for on-demand manufacturing needs. The platform’s algorithm-driven approach ensures efficient sourcing and production.

Fast Radius:

Fast Radius combines advanced manufacturing technologies with a digital platform to offer on-demand production services. Specializing in additive manufacturing and injection molding, Fast Radius caters to aerospace and healthcare industries. The company’s commitment to innovation has positioned it as a key player in the on-demand manufacturing space.

Fictiv:

Fictiv operates as a digital manufacturing platform, connecting customers with a curated network of manufacturing partners. The platform facilitates the production of precision parts through services such as CNC machining and 3D printing. Fictiv’s transparent and data-driven approach has garnered attention in the on-demand manufacturing ecosystem.

Stratasys:

Stratasys is a pioneer in 3D printing technology and has significantly shaped the on-demand manufacturing landscape. Stratasys focuses on additive manufacturing solutions, enabling businesses to create complex prototypes and end-use parts efficiently. The company’s diverse range of 3D printing technologies caters to various industries.

Streamlining Production Processes: How On-Demand Services Work

In the dynamic market demands and technological advancements era, on-demand services have emerged as a key driver in streamlining business production processes. These services, particularly in manufacturing, revolutionize the traditional approach to production. Explore how on-demand services work and contribute to efficient and flexible production.

- Digital Platforms and Connectivity:

On-demand manufacturing services often operate through digital platforms that connect businesses with a network of manufacturing partners. These platforms serve as a centralized hub where companies can submit designs, specify production requirements, and seamlessly collaborate with manufacturers. The digital nature of these platforms facilitates real-time communication and data exchange, enhancing transparency and efficiency.

- Instant Quoting and Quotation Approval:

One hallmark of on-demand services is the ability to receive instant quotes for manufacturing projects. Businesses can input their project specifications through advanced algorithms and automated systems, and the platform rapidly generates cost estimates. Accelerating the quotation process and facilitating prompt decision-making enable businesses to move forward with approved quotes, expediting their progression swiftly.

- Diverse Manufacturing Technologies:

On-demand services leverage various manufacturing technologies, such as 3D printing, CNC machining, and injection molding. This versatility enables businesses to choose the most suitable production method based on material requirements, part complexity, and desired quantities. The flexibility in technology selection is a key aspect of on-demand services, allowing for tailored solutions to meet specific project needs.

- Rapid Prototyping and Iterative Design:

On-demand services empower businesses to embrace rapid prototyping and iterative design processes. With quick turnaround times, manufacturers can produce prototypes promptly, allowing designers and engineers to test and refine their concepts rapidly. This iterative approach accelerates the product development cycle and facilitates faster time-to-market.

- Agile Production and Low-Volume Runs:

Traditional manufacturing often requires large production runs to justify tooling and setup costs. On-demand services, however, excel in agile production, making it economically viable to produce low-volume runs. Particularly advantageous scenarios exist for businesses entering niche markets, offering customization, or responding to unpredictable shifts in demand.

Customization Unleashed: Tailoring Products to Consumer Needs

In the age of mass production, a new paradigm is reshaping the consumer landscape – customization unleashed. This transformative approach to manufacturing goes beyond the one-size-fits-all mentality, allowing businesses to tailor products to individual consumers’ unique needs and preferences. Let’s explore how customization is being unleashed and its impact on the market.

- Personalized Design and Configuration:

Customization begins at the design phase, where consumers can actively participate in shaping the products they purchase. From selecting colors and materials to specifying features and functionalities, customers can create a product that aligns perfectly with their tastes and requirements. This level of personalization fosters a stronger connection between consumers and the products they buy.

- Mass Customization Technologies:

Advancements in technology, particularly in digital manufacturing and 3D printing, have paved the way for mass customization. These technologies enable businesses to efficiently produce customized products at scale, breaking away from the constraints of traditional mass production. Computer-aided design (CAD) and automated manufacturing processes allow cost-effective customization without sacrificing quality.

- Flexible Manufacturing Processes:

Customization unleashed is made possible by flexible manufacturing processes that can accommodate variations in design and specifications. Unlike rigid assembly lines geared toward mass production, flexible manufacturing easily adapts to changing consumer preferences. This agility of output is a key factor in meeting the demands of an increasingly diverse and discerning market.

- Enhanced Customer Experience:

The ability to customize products enhances the overall customer experience. Consumers appreciate the opportunity to express their individuality through the products they purchase. These actions foster brand loyalty and create a sense of ownership and satisfaction among customers who feel that their preferences are valued and acknowledged.

- Niche Markets and Specialized Offerings:

Customization enables businesses to tap into niche markets by offering specialized and tailored products. Whether it’s personalized apparel, custom-designed furniture, or unique gadgets, companies can cater to specific segments of the market that demand individualized solutions. This approach allows for exploring untapped markets and provides a competitive edge in today’s diverse consumer landscape.

Redefining Inventory Management: Just-in-Time Manufacturing

In today’s competitive business landscape, companies constantly seek ways to optimize their operations and improve efficiency. A revolutionary approach gaining traction in the manufacturing sector is Just-in-Time (JIT) manufacturing. This article explores the key aspects of JIT and its transformative impact on traditional inventory management practices.

The Essence of Just-in-Time Manufacturing:

Just-in-time manufacturing is a strategic philosophy centered on producing goods precisely when needed. Unlike traditional inventory management, which often involves maintaining substantial stockpiles, JIT aims to synchronize production with demand. This approach ensures that raw materials arrive exactly when required and finished products are completed in time for delivery.

Advantages of JIT Manufacturing:

Reduced Carrying Costs:

JIT minimizes the need for extensive inventories, significantly lowering carrying costs associated with storing excess materials or finished goods. It enables companies to allocate capital more efficiently.

Minimized Waste:

By producing goods in response to current demand, JIT helps minimize waste associated with obsolete or unsold inventory. This leaner approach is environmentally friendly and aligns with sustainability goals.

Flexibility and Responsiveness:

JIT allows manufacturers to adapt swiftly to changes in customer preferences or market conditions. This flexibility is particularly advantageous in industries with dynamic demand patterns.

Implementation Challenges and Considerations:

Reliance on Accurate Forecasting:

Successful JIT implementation hinges on accurate demand forecasting. Companies must invest in robust forecasting methods to anticipate market trends and fluctuations.

Supplier Relationships:

Establishing reliable relationships with suppliers is critical. JIT relies on a seamless flow of materials, necessitating trust and coordination between manufacturers and suppliers.

Lean Manufacturing Principles:

JIT is most effective when combined with lean manufacturing principles. Efficient production processes and continuous improvement efforts are essential for maximizing the benefits of JIT.

Cost Efficiency and Resource Optimization: The Economic Edge

In today’s fiercely competitive business environment, achieving an economic edge is paramount for sustained success. This article explores the transformative impact of cost efficiency and resource optimization on businesses, shedding light on strategies that provide a decisive economic edge.

Cost Efficiency Strategies:

Streamlined Operations:

Streamlining operations is a fundamental step toward achieving cost efficiency. Businesses can reduce operational costs while enhancing overall productivity by identifying and eliminating inefficiencies in processes.

Technology Integration:

Embracing technology is key to achieving cost efficiency. Automation, data analytics, and advanced software solutions streamline workflows and contribute to significant cost savings by minimizing errors and improving efficiency.

Supply Chain Management:

Efficient supply chain management is critical for controlling costs. Businesses can create a lean and cost-effective supply chain by optimizing inventory levels, negotiating favorable contracts, and utilizing real-time tracking technologies.

Resource Optimization Strategies:

Talent Management:

Maximizing the potential of human resources is central to resource optimization. Investing in employee training, fostering a positive work culture, and aligning skills with organizational needs enhance productivity and efficiency.

Energy and Environmental Considerations:

Resource optimization extends to sustainable practices. Implementing energy-efficient technologies, adopting eco-friendly processes, and minimizing waste reduces environmental impact and leads to significant cost savings.

Flexible Work Models:

Embracing flexible work models enhances resource optimization. Remote work and flexible schedules improve employee satisfaction and optimize resources by reducing the need for physical office space and related expenses.

The Economic Edge Realized:

Competitive Advantage:

Businesses that prioritize cost efficiency and resource optimization gain a competitive advantage. This advantage enables them to offer competitive pricing, improve profit margins, and invest in innovation to stay ahead in the market.

Adaptability in a Changing Landscape:

Economic uncertainties require businesses to be adaptable. Those with efficient operations and optimized resources are better equipped to navigate challenges and seize opportunities in a rapidly changing business landscape.

Long-Term Sustainability:

Cost efficiency and resource optimization contribute to long-term sustainability. Businesses that strategically manage costs and resources weather economic downturns more effectively and position themselves for sustained success over time.

Scalability at Its Finest: Meeting Fluctuating Demands

In today’s dynamic business landscape, adaptability is key to staying ahead. One of the revolutionary trends driving this adaptability is the rise of on-demand manufacturing services. This innovative approach offers businesses the flexibility and scalability to meet fluctuating demands seamlessly.

The Power of Scalability

At the core of on-demand manufacturing services is the concept of scalability. It refers to the ability of a manufacturing process to adapt and adjust production levels in response to changing demand. In essence, businesses can scale up or down without the constraints of traditional production methods, allowing them to optimize costs and maintain competitiveness.

Meeting Fluctuating Demands with Precision

Fluctuating demands in the market are a constant challenge for businesses. On-demand manufacturing services provide an effective solution by allowing companies to respond promptly to spikes in demand without requiring extensive lead times. This responsiveness is crucial in industries where trends evolve rapidly, enabling businesses to capitalize on emerging opportunities and precisely meet customer expectations.

Efficiency and Cost Optimization

By embracing on-demand manufacturing, businesses can streamline their operations and reduce overhead costs associated with maintaining extensive inventories. With the ability to adjust production levels as needed, companies can avoid overstocking and minimize the risk of unsold goods. This lean approach not only improves efficiency but also enhances overall cost optimization.

Adapting to Market Dynamics

In a world where market dynamics are constantly changing, the adaptability offered by on-demand manufacturing services is a game-changer. Whether dealing with seasonal trends, sudden spikes in demand, or shifts in consumer preferences, businesses can align their production strategies with real-time market conditions, ensuring they stay agile and responsive.

Sustainability in Manufacturing: On-Demand’s Environmental Impact

In the era of heightened environmental awareness, businesses are increasingly turning to on-demand manufacturing services for their flexibility and positive impact on sustainability. This article explores how these services contribute to a more eco-friendly approach to production.

Reducing Waste through Precise Production

One of the key benefits of on-demand manufacturing services is their ability to reduce waste significantly. Traditional manufacturing often involves large production runs, leading to excess inventory and unsold goods. On-demand services, however, enable companies to produce items in response to real-time demand, minimizing the need for overproduction and the subsequent disposal of surplus stock.

Energy-Efficient Operations

On-demand manufacturing services are designed for efficiency in terms of production volume and energy consumption. By tailoring production to immediate requirements, companies can operate more energy-efficiently, avoiding the energy-intensive processes associated with prolonged production runs. These practices benefit the environment and contribute to cost savings for businesses.

Sustainable Materials and Practices

Many on-demand manufacturing services prioritize the use of sustainable materials and eco-friendly practices. This commitment to environmental responsibility extends beyond the production phase and encompasses the entire supply chain. Companies utilizing on-demand services can choose materials with lower environmental impact, contributing to a more sustainable and socially responsible approach to manufacturing.

Optimizing Transportation and Logistics

On-demand manufacturing reduces the need for extensive warehousing, leading to a more streamlined and sustainable logistics chain. With products manufactured on demand and shipped directly to consumers or retailers, the environmental impact of transportation is minimized. This leaner supply chain reduces carbon emissions and enhances overall operational efficiency.

Accessibility and Global Reach: Breaking Geographical Barriers

In an era where businesses are reaching across borders, on-demand manufacturing services have emerged as a transformative solution, breaking geographical barriers and providing unprecedented accessibility on a global scale.

Accessible Production for All

Traditional manufacturing often faces limitations based on location, with companies constrained by the availability of production facilities in specific regions. On-demand manufacturing services, however, transcend these limitations, offering accessibility to production facilities worldwide. This democratization of production allows businesses, regardless of their geographic location, to tap into a global network of manufacturing capabilities.

Reducing Lead Times and Expanding Market Reach

One of the key advantages of on-demand manufacturing services is the ability to reduce lead times drastically. International production and shipping can extend product wait times in traditional manufacturing setups. With on-demand services, businesses can produce goods closer to their end-users, cutting down on shipping times and expanding their market reach efficiently.

Customization Without Borders

Geographical constraints often limit the customization options available to businesses. On-demand manufacturing services change this dynamic by providing a platform for customization without borders. Companies can collaborate with manufacturers globally, leveraging specialized skills and expertise to create unique, tailored products that cater to diverse markets and customer preferences.

Streamlining Supply Chains Across Continents

On-demand manufacturing services facilitate the creation of lean and efficient supply chains across continents. With the ability to produce goods on a per-order basis, businesses can reduce the need for extensive warehousing and inventory management. This streamlined supply chain optimizes costs and enhances businesses’ overall agility in responding to market demands.

Fostering Innovation through Global Collaboration

The accessibility provided by on-demand manufacturing services fosters global collaboration and innovation. Businesses can tap into a diverse pool of talent, expertise, and ideas, driving creativity and pushing the possible boundaries. This interconnected approach to manufacturing accelerates innovation, ultimately benefitting industries on a global scale.

Accelerating Innovation: Speed-to-Market Advantage

In the fast-paced landscape of modern business, the ability to bring innovative products to market quickly is a defining factor for success. On-demand manufacturing services have emerged as a catalyst for accelerating innovation, providing businesses a significant speed-to-market advantage.

Rapid Prototyping for Swift Iteration

On-demand manufacturing services offer rapid prototyping capabilities, allowing businesses to iterate and refine their product designs quickly. Traditional manufacturing methods often involve lengthy lead times for prototyping, causing delays in the development process. With on-demand services, companies can swiftly test and modify prototypes, enabling a more agile and iterative approach to product development.

Reducing Time from Design to Production

The conventional journey from the design phase to actual production can be time-consuming. On-demand manufacturing services streamline this process by minimizing the time gap between design finalization and production commencement. This reduction in lead time is crucial for businesses aiming to respond swiftly to market trends, changing consumer preferences, and emerging opportunities.

Flexibility in Production Schedules

The flexibility inherent in on-demand manufacturing services allows businesses to promptly adapt production schedules to meet market demands. Instead of adhering to fixed production cycles, companies can adjust output levels based on real-time requirements. This agility is a game-changer, enabling businesses to capitalize on trends and get ahead of competitors whose traditional production timelines may bind.

Meeting Dynamic Market Demands

Market demands can be unpredictable and subject to rapid fluctuations. On-demand manufacturing services empower businesses to respond dynamically to these changes. Whether facing unexpected surges in demand or shifting consumer preferences, companies leveraging on-demand services can adjust production volumes quickly, ensuring they stay ahead in the ever-evolving marketplace.

Fostering a Culture of Innovation

The speed-to-market advantage provided by on-demand manufacturing services goes beyond mere efficiency—it fosters a culture of innovation within organizations. Knowing that ideas can be transformed into tangible products rapidly encourages teams to think creatively and push the boundaries of what is possible, ultimately driving sustained innovation.

On-Demand Manufacturing in Healthcare: Precision and Personalization

On-demand manufacturing services have ushered in a new era for the healthcare industry, transforming how medical devices, prosthetics, and personalized treatments are created. This innovative approach, focusing on precision and personalization, has opened avenues for unprecedented advancements in patient care.

Customization for Patient-Centric Solutions

The hallmark of on-demand manufacturing in healthcare lies in its ability to offer tailored solutions. From customized prosthetics to patient-specific medical devices, this technology ensures that healthcare products precisely meet individual needs. For instance, 3D printing enables the creation of anatomically accurate models, facilitating surgical planning and enhancing treatment precision.

Accelerating Prototyping and Production

The traditional manufacturing process often involves lengthy prototyping stages. However, on-demand services drastically reduce this timeline. Healthcare professionals can swiftly create prototypes and iterate designs, expediting the development of medical devices. This speed-to-market advantage means quicker access to innovative solutions for patients.

Cost-Effective Solutions and Reduced Waste

On-demand manufacturing services optimize resource utilization, reducing material wastage and minimizing production costs. Customized production helps avoid the expenses associated with mass production, ensuring that resources are utilized efficiently. This cost-effectiveness can translate to more affordable healthcare solutions for patients in need.

Meeting Specific Medical Demands

Healthcare needs often vary significantly from one patient to another. On-demand manufacturing enables the production of specialized equipment and devices tailored to unique medical conditions. This customization empowers healthcare providers to address specific patient requirements, enhancing treatment efficacy and patient outcomes.

Innovative Pharmaceutical Applications

Beyond devices, on-demand manufacturing has revolutionized pharmaceuticals. Personalized medicine, where treatments are tailored to individual genetic profiles, has become feasible. This technology facilitates the creation of custom medication dosages and formulations, maximizing therapeutic benefits while minimizing side effects.

Adapting to Dynamic Healthcare Landscapes

The flexibility of on-demand manufacturing aligns perfectly with the ever-evolving healthcare landscape. Possibilities for rapid responses to emergencies, such as the urgent need for medical equipment during pandemics, become feasible. This adaptability ensures that healthcare providers can swiftly address emerging challenges.

Automotive Industry’s Transformation: On-Demand’s Impact

The automotive industry is undergoing a seismic shift, with on-demand manufacturing services emerging as game-changers. This evolution is not only altering production paradigms but also reshaping consumer experiences and industry dynamics.

What are On-Demand Manufacturing Services?

On-demand manufacturing services entail the production of goods in response to real-time demand, avoiding traditional mass production models. Leveraging advanced technologies like 3D printing and CNC machining, these services offer:

- Customization: Tailoring products to individual specifications.

- Flexibility: Swift adjustments in production volume and product variations.

- Efficiency: Streamlined processes, reducing inventory overheads.

Impact on Automotive Production

Redefined Supply Chains:

- Just-in-Time Manufacturing: Components are produced as needed, reducing excess inventory.

- Localization: Production closer to consumption hubs for quicker delivery.

Customization and Personalization:

- Unique Features: On-demand services allow for tailored car components and accessories.

- Customer-Centric Approach: Meeting diverse preferences enhances brand loyalty.

Accelerated Innovation:

- Rapid Prototyping: Quick iterations enable faster testing and implementation of new designs.

- Reduced Time-to-Market: Speedy production of new models or upgraded parts.

Transforming Consumer Experiences

Empowering Consumer Choice:

- Tailored Solutions: Customers can personalize their vehicles, from aesthetics to performance.

- Faster Delivery: Reduced wait times for customized orders.

Enhanced Quality and Reliability:

- Precision Manufacturing: On-demand services often employ advanced technologies, ensuring high-quality components.

- Reduced Defects: Improved production control leads to fewer manufacturing flaws.

Industry Dynamics and Sustainability

Cost Efficiency:

- Lower Overheads: On-demand manufacturing minimizes inventory costs and excess production.

- Economies of Scale: Efficient use of resources for smaller batches.

Sustainable Practices:

- Waste Reduction: Precise production reduces material wastage.

- Energy Efficiency: Localized production lowers transportation-related carbon emissions.

Future Implications and Conclusion

On-demand manufacturing services are poised to continue revolutionizing the automotive industry. The potential future implications include:

- Shift in Business Models: Companies may focus more on service-oriented models than product sales.

- Collaborative Ecosystems: Partnerships across sectors to enhance on-demand capabilities.

- Regulatory Adaptations: Regulations may evolve to accommodate this dynamic production model.

Fashion and Design: Rapid Prototyping and Iteration

In the fast-paced world of fashion and design, staying ahead of trends and meeting consumer demands requires agility and innovation. One of the key tools revolutionizing the industry is on-demand manufacturing services, enabling rapid prototyping and iteration. Let’s explore how these services are reshaping the fashion and design landscape.

The Rise of On-Demand Manufacturing Services

- On-demand manufacturing services have emerged as a game-changer in the fashion industry, allowing designers to transform their visions into tangible products swiftly.

- These services encompass a spectrum of technologies, from 3D printing to CNC machining, facilitating quick and precise production of prototypes and final products.

Rapid Prototyping: Transforming Ideas into Reality

- Traditionally, creating prototypes was a time-consuming and costly affair, often causing delays in the design process. On-demand manufacturing services have revolutionized this by offering rapid prototyping capabilities.

- Designers can now swiftly translate their concepts into physical models, allowing for quicker design visualization, testing, and refinement.

- This agility accelerates the design cycle, fostering creativity and enabling designers to experiment with various iterations without significant time or financial investments.

Iterative Design: Enhancing Creativity and Functionality

- The iterative design process has become more efficient with on-demand manufacturing services. Designers can quickly produce multiple iterations, allowing experimentation with materials, forms, and functionalities.

- This iterative approach fosters innovation by encouraging designers to explore and refine unconventional ideas based on immediate feedback.

- The ability to swiftly iterate designs enhances creativity and ensures that the final product aligns closely with market needs and consumer preferences.

Reduced Waste and Sustainable Practices

- On-demand manufacturing promotes sustainability by minimizing waste. With the ability to produce items as needed, there’s a significant reduction in excess inventory and unsold products.

- Additionally, these services often utilize eco-friendly materials and efficient production methods, contributing to a more sustainable fashion and design ecosystem.

The Future Outlook

- As technology advances, on-demand manufacturing services will become even more sophisticated, offering greater customization and faster production times.

- Collaboration between designers and manufacturing services will further streamline processes, fostering a symbiotic relationship that fuels innovation and creativity.

Electronics and Technology: Adapting to Market Dynamics

The rapid evolution of the electronics and technology industry demands adaptability and agility. In this context, on-demand manufacturing services have emerged as a pivotal solution, reshaping the production landscape and meeting the market’s dynamic needs.

Understanding On-Demand Manufacturing Services

On-demand manufacturing refers to a flexible production model that enables companies to create products in response to real-time demand. It harnesses technology to streamline production, allowing quicker turnaround times and reduced inventory overheads.

Flexibility in Product Development

In the realm of electronics and technology, the need for constant innovation is paramount. On-demand manufacturing empowers companies to iterate and refine their products swiftly, accommodating design, feature, or specification changes in response to market feedback.

Meeting Changing Consumer Preferences

Consumer preferences in electronics and technology fluctuate rapidly. With on-demand manufacturing, businesses can swiftly pivot to produce gadgets and devices that align with the latest trends, ensuring they remain competitive and relevant.

Reducing Time-to-Market

Time is a critical factor in the technology sector. On-demand manufacturing significantly reduces the time to market for new products. This agility allows companies to seize opportunities promptly, capitalizing on emerging trends and gaining an edge over competitors.

Cost-Efficiency and Scalability

Traditional manufacturing often involves high setup costs and minimum order quantities. On-demand services eliminate these barriers, enabling cost-efficient production even for smaller batches. Moreover, scalability becomes more manageable as companies can ramp up production as demand increases.

Sustainability and Waste Reduction

The electronics industry faces challenges concerning waste and environmental impact. On-demand manufacturing minimizes overproduction and excess inventory by producing solely what is necessary, contributing to a more sustainable approach.

Integration of Advanced Technologies

The convergence of on-demand manufacturing with advanced technologies like AI, IoT, and 3D printing further revolutionizes the sector. These technologies enhance precision, customization, and efficiency, fostering continuous innovation.

Challenges and Pitfalls: Addressing Limitations of On-Demand Services

On-demand manufacturing services have reshaped traditional production models, offering flexibility and efficiency. Yet, navigating their challenges is crucial for sustained success in this dynamic landscape.

Supply Chain Disruptions

Managing supply chain disruptions is one of the primary hurdles in on-demand manufacturing. Dependencies on timely access to raw materials and components can cause bottlenecks, impacting production schedules.

Quality Control Consistency

Maintaining consistent quality levels across diverse production cycles remains a challenge. Ensuring stringent quality checks and adherence to standards in an on-demand setting is vital to product excellence.

Cost Management Dynamics

Balancing costs in response to fluctuating demands poses a significant challenge. Adapting inventory levels, optimizing production capacities, and managing overheads without compromising profitability is a delicate balance.

Technology Integration Challenges

The integration of new technologies for scaling operations often presents hurdles. Harmonizing diverse systems and ensuring compatibility with existing infrastructure can be complex and time-consuming.

Security and Intellectual Property Risks

The digital nature of on-demand services raises concerns about data security and intellectual property protection. Safeguarding proprietary information throughout the manufacturing process is imperative.

Meeting Customer Expectations

The pressure to deliver faster without compromising quality poses a constant challenge. Reducing lead times while meeting diverse customer requirements necessitates precise planning and execution.

Sustainability Concerns

Aligning on-demand manufacturing with sustainable practices presents a growing challenge. Balancing quick turnarounds with eco-friendly materials and processes is essential for long-term viability.

Security and Intellectual Property: Safeguarding Designs and Data

Securing designs and intellectual property (IP) is paramount in the realm of on-demand manufacturing services. Protecting sensitive data and innovative designs ensures the integrity of products and prevents unauthorized use or replication.

Data Security Measures

- Encryption Protocols: Implementing robust encryption safeguards data during transmission and storage, preventing unauthorized access.

- Access Control: Limiting access to sensitive information through authentication protocols and user permissions adds layers of protection.

Protecting Design Integrity

- Digital Rights Management (DRM): Utilizing DRM tools safeguards designs by controlling their use preventing unauthorized duplication or modification.

- Watermarking and Tracing: Embedding unique identifiers or watermarks in designs enables traceability, aiding in identifying the source of any unauthorized use.

Challenges and Solutions

- Cyber Threats: Constant vigilance against cyber threats necessitates regular security audits and updates to fortify systems.

- Collaboration Risks: Secure collaboration platforms and robust contracts mitigate risks associated with sharing designs across multiple parties.

Legal Safeguards

- Patents and Trademarks: Registering designs and trademarks offers legal protection, enabling legal recourse in case of infringement.

- Non-Disclosure Agreements (NDAs): Implementing NDAs with employees and partners ensures confidentiality, outlining consequences for unauthorized information sharing.

Technology as a Shield

- Blockchain for Traceability: Utilizing blockchain technology enables immutable records of design ownership and transactions, bolstering IP protection.

- AI-Powered Monitoring: AI algorithms can monitor data access patterns, swiftly detecting anomalies or potential breaches.

Balancing Innovation and Protection

- Agile Response to Threats: Staying updated with the latest security measures while fostering innovation maintains a delicate balance between protection and progress.

- Education and Awareness: Training employees on security best practices and the significance of IP protection fosters a culture of vigilance.

Regulatory Compliance: Navigating Legal Frameworks

The burgeoning realm of on-demand manufacturing services has revolutionized the production landscape, offering unparalleled flexibility and efficiency. However, amid this dynamic landscape, understanding and adhering to regulatory compliance and legal frameworks are pivotal for businesses venturing into this domain.

Understanding Regulatory Compliance

Regulatory compliance within on-demand manufacturing encompasses a multifaceted spectrum, including environmental regulations, quality standards, and industry-specific protocols. Navigating this labyrinth necessitates a comprehensive grasp of regional, national, and international statutes.

Quality Assurance Protocols

Ensuring adherence to stringent quality standards remains a cornerstone of on-demand manufacturing. Companies must comply with ISO certifications, material sourcing regulations, and product safety standards to uphold quality benchmarks and guarantee customer satisfaction.

Environmental Sustainability Imperatives

In a world increasingly focused on sustainability, on-demand manufacturing services must align with eco-friendly practices. Compliance with environmental regulations, waste management protocols, and sustainable sourcing methodologies has become non-negotiable.

Intellectual Property Protection

Safeguarding intellectual property (IP) rights is critical in on-demand manufacturing. Firms must navigate patent laws, trademark protections, and copyright regulations to shield their innovations and designs from infringement.

Supply Chain Transparency and Ethical Practices

Transparency across the supply chain is pivotal. Compliance involves ethical sourcing, fair labor practices, and visibility into every production stage, ensuring adherence to labor laws and ethical standards.

Global Trade Regulations

Navigating international trade laws and tariffs is essential for companies engaged in on-demand manufacturing across borders. Understanding import/export regulations and trade agreements aids in avoiding legal pitfalls and optimizing global operations.

The Way Forward

Amidst the intricate regulatory compliance and legal frameworks, on-demand manufacturing services can thrive by prioritizing proactive strategies. Collaborating with legal experts, investing in robust compliance protocols, and fostering a culture of adherence to ethical and legal standards can pave the way for sustained success in this ever-evolving landscape.

Future Trends: The Next Frontier of On-Demand Manufacturing

On-demand manufacturing services are at the forefront of transforming traditional production models. As we look to the future, several emerging trends promise to revolutionize the landscape, offering unprecedented flexibility and efficiency in the manufacturing sector.

Customization Redefined

On-demand manufacturing is fueling a customization revolution. Consumers now seek personalized products, and manufacturers adapt to this demand by offering customizable solutions. From bespoke apparel to tailor-made electronic devices, the future of manufacturing lies in the ability to produce customized items at scale swiftly.

Rapid Prototyping and Innovation

With on-demand manufacturing, prototyping, and product development are becoming quicker and more iterative. This trend enables companies to bring ideas to life swiftly, test prototypes, gather feedback, and iterate designs in real-time. Consequently, innovation cycles are shortening, fostering a culture of constant evolution and improvement.

Sustainability and Reduced Waste

On-demand manufacturing significantly reduces excess inventory and waste by producing items only as needed. This lean approach minimizes environmental impact, curtailing overproduction and reducing the need for large-scale warehousing. Additionally, utilizing eco-friendly materials and optimized production processes further contribute to sustainability.

Decentralized Production Hubs

The future of on-demand manufacturing may witness the proliferation of localized production hubs. These hubs will be strategically positioned closer to consumer markets, minimizing shipping times and costs. Such decentralization could also create jobs within local communities, driving economic growth.

Digitalization and Industry 4.0 Integration

Integrating on-demand manufacturing with Industry 4.0 technologies is pivotal for its evolution. IoT-enabled smart factories, AI-driven production optimization, and blockchain-enabled supply chain traceability will further streamline manufacturing processes, enhancing efficiency and quality.

Dynamic Supply Chains

On-demand manufacturing is reshaping supply chain dynamics by making them more adaptable and responsive. The ability to quickly adjust production based on real-time demand fluctuations ensures better inventory management and reduces the risks associated with market uncertainties.

Embracing the Shift: Strategies for Adopting On-Demand Services

In today’s rapidly evolving market landscape, on-demand manufacturing services have emerged as a game-changer, revolutionizing traditional production models. Businesses across industries increasingly turn to on-demand manufacturing to streamline operations, reduce costs, and meet ever-changing consumer demands.

Understanding On-Demand Manufacturing Services

On-demand manufacturing services entail a flexible production approach where products are created only when a specific demand exists. This departure from conventional mass production allows companies to minimize inventory costs and respond swiftly to market fluctuations. From 3D printing to CNC machining, these services offer various production possibilities tailored to diverse business needs.

Flexibility: Catering to Dynamic Market Demands

One of the paramount advantages of on-demand manufacturing is its ability to accommodate market volatility. Fluctuating consumer preferences and seasonal demands can pose challenges for traditional manufacturing models. However, on-demand services empower businesses to swiftly adjust production volumes and product variations, ensuring responsiveness and adaptability.

Cost-Efficiency and Reduced Risk

Traditional manufacturing often involves significant upfront investments in inventory and tooling. On-demand manufacturing mitigates these risks by minimizing the need for surplus inventory. This leaner approach reduces storage costs and minimizes the financial impact of unsold inventory, optimizing resource allocation and enhancing overall cost-efficiency.

Enhanced Customization and Innovation

Embracing on-demand manufacturing unlocks a realm of customization possibilities. Businesses can tailor products to meet specific customer needs, fostering customer loyalty and satisfaction. Furthermore, this flexibility enables a culture of innovation, allowing companies to experiment with new designs and functionalities without the constraints of mass production.

Implementing On-Demand Services: Key Strategies

- Adopting Agile Processes: Embrace agile methodologies to adapt to changing demands swiftly. Establish seamless communication channels between design, production, and marketing teams to ensure a responsive workflow.

- Technology Integration: Invest in cutting-edge technologies such as AI-driven manufacturing tools and advanced analytics to optimize production processes and forecast demand accurately.

- Strategic Partnerships: Collaborate with on-demand manufacturing service providers who align with your business goals and offer the expertise needed to navigate this evolving landscape.

- Iterative Approach: Start with pilot projects to test the waters before scaling up. Evaluate feedback and iterate processes to fine-tune operations and maximize efficiency.

Conclusion

On-demand manufacturing services are the catalysts for a new era in manufacturing, heralding agility, precision, and sustainability. Their ability to customize, optimize resources, and expedite production has reshaped industries. As technology advances and businesses increasingly pivot towards flexibility and efficiency, on-demand services will continue to play a pivotal role, driving innovation and redefining the essence of manufacturing processes. The journey has only begun, promising an exciting future where customization, speed, and sustainability converge to shape how we create and consume products.