Case in Germany:

The Application of Injection Molding in Automotive Parts Production

In Germany, injection molding is one of the most commonly used production processes for plastics. This is rightly so as it offers a viable solution for the mass production of high-quality injection automotive parts from a broad range of polymers. In the automotive industry, where consistency, safety, and quality are of utmost importance, automotive plastic injection molding is an important manufacturing process.

There are several well known auto industry manufacturers from Germany, cooperate with DJmolding, purchase the automotive plastic components from DJmolding injection molding services, including fenders, grilles, bumpers, door panels, floor rails, light housings, and more.

At DJmolding, we offer professional injection molding services, delivering mass-produced plastic car parts to clients in the automotive and other industries. Our services include thermoplastic injection molding, over-molding, insert molding, and mold making. In the latter case, our experts work with German clients to produce high-quality molds for prototyping or large production runs.

DJmolding also works with a wide range of plastic injection materials, including strong, heat resistant, and rigid thermoplastics; flexible, fast curing thermoplastics; and durable, high-temperature rubber plastics. Our professional automotive plastic injection molding services enable our automotive clients to obtain high-quality molded automotive parts that meet their application requirements, especaily for the powerful auto industry countries, just like the Gemany, USA, Japan.

Production Applications for Automotive Injection Molding

In the automotive sector, injection molding is one of the predominant methods manufacturers use to form plastic parts. However, it would be difficult to make a list of plastic components in a car produced using injection molding, so we’ll look at some of the main ones.

1. Components under-the-hood

For the past two decades or so, many under-the-hood components that manufacturers formerly made from metal have been transitioned to plastic. For these applications, robust polymers such as ABS, Nylon, and PET are common. However, manufacturers now make parts such as cylinder head covers and oil pans using injection molding. This method offers lower weights and costs compared to metal parts.

2. Exterior Components

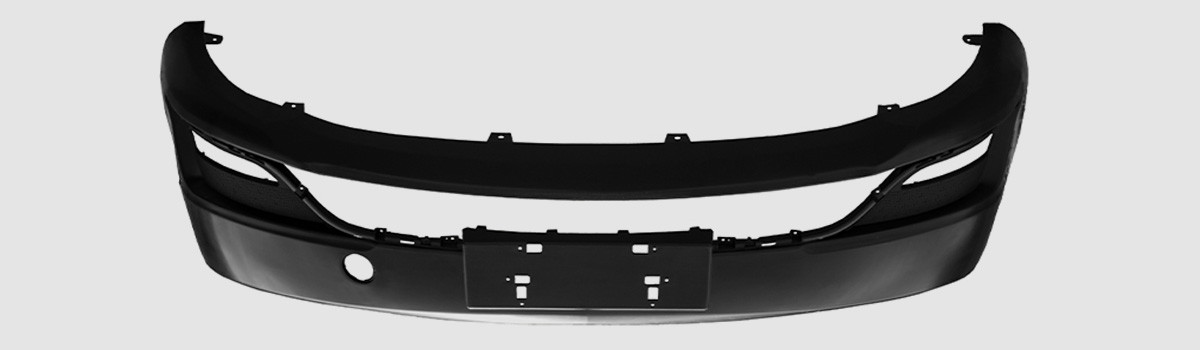

Injection molding is an established process for many exterior automotive components, including fenders, grilles, bumpers, door panels, floor rails, light housings, and more. Splash guards are a fine example for demonstrating the durability of injection molded parts. In addition, the components, which protect the car from road debris and minimize splashing, are often made from rubber or other durable and flexible materials.

3. Interior Components

Manufacturers also produce many automotive interior parts using automotive plastic injection molding. They include instrumentation components, interior surfaces, dashboard faceplates, door handles, glove compartments, air vents, and more. In addition, they also use injection molding for producing decorative plastic elements.

Alternatives to Injection Molding for Low-cost Automotive Prototypes

In many cases, molded plastics serve as an alternative to metals. Formerly, manufacturers make items like brackets, trunk lids, seatbelt modules, and air-bag containers exclusively from metal. Nowadays, injection molding is the preferred production method for these plastics.

On the other hand, manufacturers can sometimes replace molded plastic parts with 3D-printed plastic car parts. This happens especially in prototyping, where there is less need for extreme durability or a smooth surface finish. Many moldable plastics can serve as FDM 3D printer filaments or as SLS 3D printer powders for nylons. Some specialist and high-temp 3D printers can also print reinforced composites for high-strength parts.

For one-off prototypes, especially non-mechanical parts, 3D printing may offer a cost-effective alternative to molding. Due to the absence of tooling costs, production prices are not as high.

In some cases, manufacturers may even use 3D printing for a handful of end-use automotive parts. They may use SLM 3D printing to make fluid handling components like valves (not usually injection molded). However, another option is using SLS 3D printing to make parts like bumpers, trim, and windbreakers, which are sometimes injection molded.

Manufacturers may use additive manufacturing for a much wider range of injection auto parts in the not-too-distant future. This may range from doors and body panels (SLM) to powertrain and drivetrain parts (EBM).

DJmolding is very good at plastic injection molding for automotive components, if you want to start your automotive parts production project, please contact us, we will have a nice corperation.