Recycled Plastic Injection Molding

Can You Use Recycled Plastics in Plastic Injection Moulding?

If you manufacture your products using the plastic injection moulding process, you may be wondering whether you can use recycled plastics instead. Keep reading to learn more about the benefits of using recycled plastics and why Guangdong China based DJmolding Corporation is the recycled plastic injection-moulding specialist.

What Constitutes Recycled Plastic?

Recycled plastics refer to plastic materials that are repurposed. It can come from other plastic products or waste that results from the plastic injection moulding process. These recycled materials can be of any type or colour, and when you use them to manufacture products via injection moulding, there is no loss in quality.

Some examples of plastics that can be recycled include Polyvinyl Chloride (PVC), polypropylene, and polyethylene.

The process involves melting down plastics and pressing them into specialized moulds that are shaped like your product. Once the plastic has cooled down, the casting is removed, and you are left with your final product.

Recycled plastic injection moulding allows you to mass-produce products with an efficient system that minimises scrap losses, eliminates the need for product finishing after completion, and allows you to use a wide variety of materials.

It doesn’t matter if you need parts that require tensile strength or flexibility – working with a Brisbane based plastic injection moulding company like DJmolding Corporation that specialises in recycled plastics can help you get the job done right.

Benefits of Using Recycled Plastic

There are many benefits to using recycled plastic in the injection moulding process, with the most prominent being the reduced environmental impact. Reusing plastic minimises your company’s overall greenhouse gas emissions and is part of running an environmentally responsible organisation.

Similarly, when we recycle plastic during the manufacturing process, we are also eliminating a lot of the waste that ends up in landfill and our oceans. By recycling plastics we can reduce pollution to both the ground and air.

Statistics suggest consumers in today’s market prefer to shop with brands that are environmentally conscious and who make an effort to recycle their plastics and reduce their waste.

Another benefit to using recycled plastics for injection moulding is that it could save you a significant amount of money in the long run. The cost of quality recycled plastic is about 10% to 15% lower than traditional materials, and it also requires less energy to melt down and mould.

In other words, using recycled plastics can help you control your material expenses as well as the cost of energy required to run your injection moulding process. Incorporating a recycling aspect to your manufacturing process allows you to create a closed-loop, where old parts are recycled and create the materials you need for your new plastic components.

Challenges to Using Recycled Plastics

Although recycling plastic is a great way to save money and help the environment, there are some challenges to using it in manufacturing.

The main issue involves the need to recycle at the machine and with rejected parts or purges. A plastics company will use many different additives during its manufacturing process, so it can be difficult to create an efficient process for capturing plastic that can be recycled.

New technology has made solving these challenges easier, and tools like slow-speed granulators are ideal for reintroducing recycled plastic into the injection moulding process.

Why You Should Work with DJmolding Corporation

As you can see, it’s essential to work with an experienced recycled plastics injection moulding company that can help you incorporate recycling into your processes.

DJmolding is a Guangdong China based plastic injection moulding company that prides itself on helping organisations minimize their environmental footprints by offering options for recycling and other sustainable injection moulding practices.

We have many years of experience in our industry and our experts will do everything they can to help your brand turn recycled plastics into new products.

Contact us today to start using recycled plastics in your manufacturing process!

Plastic injection molding is a popular manufacturing process that involves injecting molten plastic into a mold to create different shapes and objects. However, producing plastic products generates a lot of plastic waste that harms the environment. Recycled plastic injection molding has emerged as an eco-friendly solution that reduces plastic waste and conserves resources. This blog post will explore the benefits and applications of recycled plastic injection molding and how it is transforming the manufacturing industry.

Understanding Recycled Plastic Injection Molding

Recycled plastic injection molding is a manufacturing process that involves melting down recycled plastic material and injecting it into a mold to produce a new product. This process is becoming increasingly popular today as we continue to look for ways to reduce waste and preserve the environment. This blog post will examine recycled plastic injection molding and its benefits and limitations.

Recycled plastic injection molding starts with the collection and sorting of plastic waste. The plastic waste is then cleaned, sorted by type, and shredded into small pieces. The process involves melting down the trim pieces and injecting them into a mold, shaping them into the desired product. The final product is removed from the mold, inspected, and prepared for use.

Recycled plastic injection molding offers several benefits over traditional manufacturing processes. Firstly, it helps to reduce the amount of plastic waste that ends up in landfills and oceans. Using recycled plastic can minimize the environmental impact of plastic production and reduce the need for virgin plastic.

Another benefit of recycled plastic injection molding is its cost-effective manufacturing process. Using recycled plastic can be cheaper than virgin plastic, which can help lower the overall production cost. Reducing manufacturing expenses and increasing profits is a vital consideration for companies.

While recycled plastic injection molding offers many benefits, it has some limitations. One of the main limitations is that the quality of the final product may be lower than that of products made from virgin plastic. Recycled plastic may have impurities or a different molecular structure than virgin plastic, impacting the final product’s properties.

Another limitation is that not all types of plastic allow for recycling. Recycled plastic injection molding can limit the range of products that manufacturers can produce.

Benefits of Recycled Plastic Injection Molding

This process is becoming increasingly popular today as we continue to look for ways to reduce waste and preserve the environment. This blog post will examine the benefits of recycled plastic injection molding.

- Environmental Benefits: Recycled plastic injection molding helps reduce the amount of plastic waste in landfills and oceans. Using recycled plastic can minimize the environmental impact of plastic production and reduce the need for virgin plastic. The Environmental Protection Agency (EPA) states that recycling plastic can conserve up to 80% of the energy manufacturers would have used to produce virgin plastic.

- Cost-Effective Manufacturing: Using recycled plastic can be cheaper than virgin plastic, which can help lower the overall production cost. Reducing manufacturing costs and improving the bottom line are crucial for companies to consider. In addition, recycled plastic injection molding can help to reduce the costs associated with disposing of plastic waste, such as landfill fees.

- Energy Efficiency: Recycled plastic injection molding requires less energy than producing products from virgin plastic. Recycling plastic requires less energy than making new plastic because melting and molding recycled plastic is more straightforward. These energy savings can help reduce a company’s carbon footprint and contribute to a more sustainable future.

- Versatility: Recycled plastic injection molding can produce many products, including automotive parts, toys, packaging, and consumer goods. This versatility makes it a popular choice for many industries and applications.

- Positive Brand Image: Using recycled plastic injection molding can help to improve a company’s brand image and reputation. Consumers are becoming increasingly aware of the environmental impact of plastic production and are more likely to support companies taking steps to reduce their ecological footprint.

Types of Plastic Used in Recycled Injection Molding

While recycling is not feasible for all types of plastic, recycled injection molding can utilize several common types of plastic. In this blog post, we’ll take a closer look at the kinds of plastic used in recycled injection molding.

Polyethylene Terephthalate (PET)

PET is a widely used plastic in the food and beverage industry for packaging products such as water bottles and soft drink containers. PET is highly recyclable and can be used in recycled injection molding to produce a wide range of products.

High-Density Polyethylene (HDPE)

HDPE is a versatile plastic commonly used to manufacture plastic bags, milk jugs, and detergent bottles. HDPE is highly recyclable and can be used in recycled injection molding to produce outdoor furniture and storage containers.

Polypropylene (PP)

PP is a lightweight plastic commonly used in manufacturing food packaging, automotive parts, and medical devices. PP is highly recyclable and can produce various products in recycled injection molding.

Polycarbonate (PC)

PC is a durable plastic used to manufacture electronic components, eyewear, and medical devices. Recycled injection molding can utilize the highly recyclable PC (polycarbonate) to produce safety goggles and cell phone cases.

Acrylonitrile Butadiene Styrene (ABS)

ABS is a solid and durable plastic commonly used in manufacturing toys, automotive parts, and computer components. ABS is highly recyclable and can produce various products in recycled injection molding.

Polystyrene (PS)

PS is a lightweight plastic commonly used in manufacturing food packaging, CD cases, and disposable utensils. PS is highly recyclable and can be used in recycled injection molding to produce office supplies and picture frames.

Recycled Plastic Injection Molding Process

However, with the growing concern for environmental sustainability, manufacturers are seeking ways to reduce waste and utilize recycled materials in their production processes. The industry has seen a rise in the popularity of the recycled plastic injection molding process. Researchers and innovators have developed this process as a solution to tackle the issue of plastic waste.

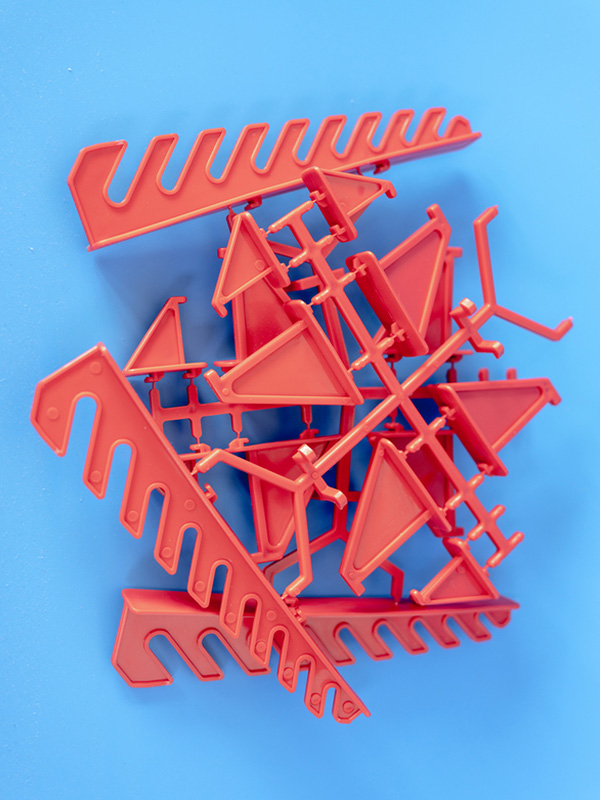

The recycled plastic injection molding process involves the use of recycled plastic materials in the injection molding process. Here are some key aspects of the process:

- Material selection: Recycled plastic materials are carefully selected based on their properties and suitability for the intended product. Different types of recycled plastics can be used, including PET, HDPE, and LDPE.

- Sorting and cleaning: The recycled materials are sorted and cleaned to remove any impurities or contaminants that may affect the quality of the final product. This step is crucial in ensuring the final product meets the required standards.

- Mixing: The recycled materials are combined with virgin plastic to achieve the desired properties and consistency. The amount of recycled material used in the process can vary depending on the product’s requirements.

- Injection molding: An injection molding machine injects the mixed materials into a mold, shaping and cooling them to create the final product. The injection molding process resembles the traditional one but involves managing the recycled material with a few variations.

The use of recycled plastic materials in the injection molding process offers several benefits, including:

- Reduced environmental impact: Using recycled plastic reduces waste and conserves natural resources. Reducing the amount of plastic waste that ends up in landfills or the ocean can positively impact the environment.

- Cost-effective:Recycled plastic materials are often less expensive than virgin materials, making the process more cost-effective. By implementing this solution, manufacturers can lower production expenses and enhance profits.

- High-quality products: Using recycled plastic does not compromise the quality or performance of the final product. Some studies have shown that recycled plastic materials can be as good, if not better, than virgin materials.

- Improved brand reputation: Companies prioritizing sustainability and environmental responsibility can improve their brand reputation and attract eco-conscious customers. Building customer loyalty can lead to increased sales in the long run.

Properties of Recycled Plastic

Recycled plastic is becoming increasingly popular in manufacturing due to its sustainability benefits. Manufacturers produce it by processing and transforming post-consumer or post-industrial plastic waste into a new product. However, not all recycled plastics are created equal, and it is essential to understand their properties before deciding to use them in a product. Here are some fundamental properties of recycled plastic:

- Strength and durability: Recycled plastic can be as strong and durable as virgin plastic, depending on the processing and treatment methods used. In some cases, recycled plastic can even be stronger than virgin plastic due to how it is processed.

- Color variations: Recycled plastic can have variations in color due to the different types of plastic materials mixed. When considering a unique appearance for a product, it’s essential to determine if a consistent color is necessary.

- Consistency: The consistency of recycled plastic can vary depending on the source and processing method used. The final product may suffer in quality and character as a result.

- Chemical properties: Recycled plastic may contain residual chemicals from its previous use, which can affect its properties and make it unsuitable for specific applications. It is essential to ensure that the recycled plastic is free from harmful chemicals before using it in a product.

- Environmental impact: The use of recycled plastic can have a positive effect on the environment by reducing waste and conserving natural resources. However, it is essential to consider the environmental impact of the entire product lifecycle, including production, use, and disposal.

- Cost: Recycled plastic can be less expensive than virgin plastic, making it a cost-effective alternative. However, the price can vary depending on the processing and treatment methods.

Advantages of Using Recycled Plastic in Injection Molding

The world generates millions of tons of plastic waste annually, much of which is in landfills, oceans, and other natural environments. Recycling plastic waste can be an effective way to reduce this pollution and conserve natural resources. The injection molding process utilizes recycled plastic, which provides several advantages over virgin plastic. This article will explore the benefits of using recycled plastic in injection molding.

- Environmental Sustainability: Using recycled plastic in injection molding helps reduce waste and conserve natural resources. By reusing plastic waste instead of creating new plastic from scratch, the amount of plastic waste in landfills or the ocean is reduced. This action benefits the environment and safeguards natural resources for future generations.

- Cost-Effective: Recycled plastic is often less expensive than virgin plastic, making it a cost-effective alternative for manufacturers. Implementing this can lower production expenses and boost profitability. Additionally, using recycled plastic may reduce transportation costs, as it can be sourced locally and does not need to be shipped long distances.

- Consistency and Quality: Recycled plastic can be just as consistent and high-quality as virgin plastic, depending on the processing and treatment methods used. In some cases, recycled plastic can even be stronger than virgin plastic due to how it is processed. Using recycled plastic in injection molding does not mean compromising the quality or consistency of the product.

- Energy Savings: The production of recycled plastic requires less energy than virgin plastic, making it a more energy-efficient option. Reducing greenhouse gas emissions can aid in mitigating the impacts of climate change. Additionally, using recycled plastic can reduce the need for fossil fuels and other non-renewable resources.

- Brand Reputation: Companies prioritizing sustainability and environmental responsibility can improve their brand reputation and attract eco-conscious customers. By doing this, you can establish customer loyalty and boost long-term sales. Consumers are increasingly concerned about the environmental impact of the products they buy, and companies that use recycled plastic in injection molding can benefit from this trend.

- Regulatory Compliance: Using recycled plastic in injection molding can help companies comply with environmental regulations and standards. By following this, you can prevent fines and penalties that may result from non-compliance. Companies can demonstrate their commitment to sustainability and environmental responsibility by using recycled plastic.

Applications of Recycled Plastic Injection Molding

Recycled plastic injection molding is becoming increasingly popular in various industries due to its cost-effectiveness, sustainability, and versatility. Using recycled plastic in injection molding allows companies to create high-quality products while reducing their carbon footprint. Here are some of the applications of recycled plastic injection molding:

- Automotive industry: The automotive sector extensively utilizes recycled plastic injection molding to create interior and exterior components. These include dashboard components, door panels, steering wheel covers, etc. Using recycled plastic in manufacturing these parts can help automakers meet sustainability goals while reducing production costs.

- Packaging industry: Recycled plastic injection molding produces various packaging materials, such as bottles, caps, and containers. Food and beverage, personal care, and cleaning products employ these packaging materials. Using recycled plastic to produce these items can help reduce waste and promote environmental sustainability.

- Electrical and electronics industry: The electrical and electronics sector utilizes recycled plastic injection molding to create various components, including housings, switches, and connectors. Using recycled plastic in these products can help companies meet sustainability goals and reduce production costs.

- Construction industry: The construction industry utilizes recycled plastic injection molding to produce various products, including PVC pipes, fittings, and decking materials. Using recycled plastic in these products can help reduce the environmental impact of construction activities and promote sustainable building practices.

- Healthcare industry: The healthcare industry employs recycled plastic injection molding to create medical devices and equipment. These include syringes, IV components, and blood collection tubes. Using recycled plastic to produce these items can help reduce production costs and promote sustainability in the healthcare industry.

Recycled Plastic Injection Molding Vs. Conventional Injection Molding

There are two primary methods of plastic injection molding: conventional and recycled. While both ways produce plastic parts, the two have significant differences. This post will explore the differences between recycled plastic and traditional injection molding.

Conventional Injection Molding

Conventional injection molding is the traditional method of plastic injection molding. This method involves using virgin plastic, which is new and unused plastic, to create plastic parts. Pure plastic material is melted and injected into the mold to produce the final product. Here are some key features of conventional injection molding:

- It uses a virgin plastic material, which is new and unused plastic.

- It has high-quality plastic parts with excellent surface finishes.

- Requires high amounts of energy to make new plastic material, resulting in increased carbon emissions and environmental impact

- Generates waste through excess material and scrapped parts, contributing to landfill waste

- It has higher production costs due to the cost of virgin plastic material.

Recycled Plastic Injection Molding

Recycled plastic injection molding is a more sustainable alternative to conventional injection molding. This method involves using recycled plastic, which has been previously used and then recycled, to create plastic parts. Here are some key features of recycled plastic injection molding:

- It uses recycled plastic material, which has been previously used and then recycled.

- Produces high-quality plastic parts with good surface finishes

- It requires less energy to make recycled plastic material, resulting in lower carbon emissions and environmental impact.

- Generates less waste by utilizing recycled plastic and reducing excess material and scrapped parts

- Has lower production costs due to the lower price of recycled plastic material

Recycled Plastic Injection Molding vs. Conventional Injection Molding

While both methods produce plastic parts, there are several critical differences between recycled plastic injection molding and conventional injection molding:

- Material: Conventional injection molding uses virgin plastic, while recycled plastic injection molding uses recycled plastic.

- Environmental Impact:Recycled plastic injection molding has a lower environmental impact than conventional injection molding, as it requires less energy and generates less waste.

- Production Costs:Recycled plastic injection molding has lower production costs due to the lower price of recycled plastic material.

- Surface Finish: Conventional injection molding produces plastic parts with a better surface finish than recycled plastic injection molding.

Advantages of Recycled Plastic Injection Molding

Recycled plastic injection molding offers several advantages over conventional injection molding, including:

- Improved Environmental Sustainability: Recycled plastic injection molding is more environmentally sustainable than conventional injection molding, using recycled plastic material and generating less waste.

- Cost Savings: Recycled plastic injection molding has lower production costs than conventional injection molding, making it more cost-effective.

- Lower Energy Consumption: Recycled plastic injection molding requires less energy to produce recycled plastic material, resulting in lower carbon emissions and environmental impact.

- Increased Efficiency: Recycled plastic injection molding generates less waste and excess material, resulting in higher production efficiency.

- Meets Sustainability Goals:Recycled plastic injection molding is an excellent option for companies looking to meet sustainability and environmental goals.

Challenges in Recycled Plastic Injection Molding

Recycled plastic injection molding is an excellent way to reduce waste and promote sustainability. However, some challenges are associated with this manufacturing process, and this post will explore some of the difficulties in recycled plastic injection molding.

Material Inconsistencies

One of the biggest challenges in recycled plastic injection molding is the inconsistency of the recycled plastic material. Recycled plastic is made from various sources and may have different compositions, additives, and colors, which can lead to variations in the quality and appearance of the final product. To overcome this challenge, manufacturers may need to test and adjust the molding process for each batch of recycled plastic material.

Contamination

Other materials or substances, such as dirt, metal, or chemicals, may contaminate recycled plastic, affecting the final product’s quality and performance. To prevent contamination, manufacturers must thoroughly clean and sort the recycled plastic material before using it in molding.

Poor Flowability

Recycled plastic material may need better flowability, meaning it does not flow smoothly and evenly into the mold, which can lead to defects and inconsistencies in the final product. To improve flowability, manufacturers may need to adjust the temperature and pressure settings of the injection molding machine.

Reduced Strength and Durability

Recycled plastic material may have reduced strength and durability compared to virgin plastic material, affecting the final product’s quality and performance. To address this challenge, manufacturers may need to use additives or reinforcement materials to improve the strength and durability of the recycled plastic material.

Limited Availability

Recycled plastic material may not always be readily available or more expensive than virgin plastic, affecting the cost and availability of recycled plastic injection molding. To overcome this challenge, manufacturers may need to explore alternative sources of recycled plastic material or work with suppliers to secure a steady supply.

Factors Affecting Recycled Plastic Injection Molding

Recycled plastic injection molding is an eco-friendly process that has recently gained popularity. This process utilizes recycled plastic materials to create new products, reducing plastic waste in landfills and oceans. However, the success of recycled plastic injection molding depends on several factors that impact the quality and performance of the finished product. This blog post will discuss the key factors affecting recycled plastic injection molding.

- Material Selection: The quality of the recycled plastic material used in injection molding is a crucial factor that determines the outcome of the process. The impurities in the recycled plastic can cause defects in the final product, leading to poor quality and performance. Therefore, high-quality recycled plastic material is essential to ensure the finished product meets the desired specifications.

- Mold Design: The design of the mold used in recycled plastic injection molding is another factor that affects the outcome of the process. A poorly designed mold can cause defects in the final product, leading to waste and increased costs. Manufacturers must prepare the mold accordingly to ensure recycled plastic’s smooth and uniform flow without defects or irregularities.

- Injection Molding Machine: The injection molding machine used in the process plays a significant role in determining the quality and performance of the finished product. Manufacturers must carefully control the machine’s pressure, temperature, and speed to ensure correct melting and injection of the recycled plastic material into the mold. A machine incorrectly calibrated can cause defects in the final product, leading to waste and increased costs.

- Post-Processing: The post-processing steps after injection molding also impact the final product’s quality and performance. Manufacturers must carefully control the cooling time, pressure, and temperature during the post-processing step to ensure the finished product meets the desired specifications. Improper post-processing can cause warping, cracking, or defects in the final product.

Sustainability of Recycled Plastic Injection Molding

Sustainability has recently become vital in manufacturing processes, and recycled plastic injection molding is no exception. This process uses recycled plastic materials to create new products, reducing plastic waste in landfills and oceans. However, the sustainability of recycled plastic injection molding goes beyond just reducing waste. In this blog post, we’ll discuss the sustainability of recycled plastic injection molding.

- Reduced Environmental Impact: Recycled plastic injection molding minimizes the amount of plastic waste in landfills and oceans, reducing the environmental impact of plastic production. Using recycled plastic reduces the need for new plastic production, reducing the manufacturing process’s carbon footprint. Additionally, the process reduces the energy required to produce new plastic products.

- Circular Economy: Recycled plastic injection molding supports the circular economy, where products and materials are reused and recycled instead of discarded. Using recycled plastic reduces the need for virgin plastic production, helping a closed-loop system that reduces waste and conserves resources.

- Energy Efficiency: Recycled plastic injection molding is more energy-efficient than traditional injection molding. The process requires less energy to produce the same amount of products due to the reduced energy needed to melt recycled plastic materials. Additionally, the use of recycled plastic materials reduces the amount of energy required to produce new plastic products.

- Cost-Effective: Recycled plastic injection molding can be cost-effective compared to traditional injection molding. Using recycled plastic can reduce the cost of raw materials, making it an attractive option for businesses. The reduced energy needed to produce recycled plastic products can also reduce manufacturing costs.

- Social Responsibility: Using recycled plastic materials in manufacturing supports social responsibility by reducing the environmental impact of plastic waste on communities and ecosystems. The process can also support job creation in the recycling industry, contributing to local economies.

Recycled Plastic Injection Molding Machinery

Recycled plastic injection molding machinery uses recycled plastic as the raw material instead of virgin plastic resin. Recycling plastic instead of using new plastic saves energy and resources, as it requires less processing energy for recycled plastic. Using recycled plastic injection molding machinery has numerous benefits, including waste reduction. Some of these benefits are:

- Environmental Sustainability: Recycled plastic injection molding machinery helps reduce the amount of plastic waste in landfills or the ocean. By using recycled plastic, companies can help to reduce their carbon footprint and contribute to a more sustainable future.

- Cost Savings: Recycled plastic is typically less expensive than virgin plastic, so using recycled plastic injection molding machinery can help companies save on material costs. Additionally, since recycled plastic requires less energy to process, companies may also see savings on energy costs.

- Improved Brand Image: Consumers are increasingly aware of environmental issues and more likely to support companies prioritizing sustainability. Using recycled plastic injection molding machinery can help companies improve their brand image and attract eco-conscious consumers.

- Regulatory Compliance: Many countries and regions have regulations that require companies to reduce their plastic waste and increase their use of recycled materials. Using recycled plastic injection molding machinery can help companies comply with these regulations and avoid fines or penalties.

In addition to the benefits listed above, recycled plastic injection molding machinery also offers several practical advantages:

- Comparable Quality: Recycled plastic can produce products of equal quality to those made from virgin plastic. Companies can use recycled plastic injection molding machinery without sacrificing product quality.

- Wide Availability:Various suppliers offer a wide availability of recycled plastic, making it easily sourced. With this solution, companies can easily find a dependable source of recycled plastic for their injection molding machines.

- Versatility:Recycled plastic injection molding machines create various products, from consumer goods to industrial parts. This versatility makes it a valuable asset for companies across multiple industries.

Design Considerations for Recycled Plastic Injection Molding

However, designing products for recycled plastic injection molding requires different considerations than designing for traditional injection molding. Here are some key design considerations to keep in mind when planning for recycled plastic injection molding:

- Material Properties: Recycled plastic has different properties than virgin plastic, so choosing a suitable recycled plastic for the application is essential. For example, recycled polypropylene may have other flow characteristics than virgin polypropylene, affecting molding and final products.

- Color and Appearance: Recycled plastic can have variations in color and appearance due to the nature of the recycling process. Considering these variations when designing for recycled plastic injection molding is essential. Consider using darker colors or adding texture to the product to mask any variations in color or appearance.

- Wall Thickness: Recycled plastic may have lower strength and stiffness than virgin plastic, so it’s essential to design for appropriate wall thickness. Thinner walls may be more prone to warping or breaking, while thicker walls can lead to sink marks or longer cycle times.

- Part Design: The part’s design can also affect the feasibility of using recycled plastic injection molding. Parts with complex geometries or tight tolerances may be more challenging to produce with recycled plastic. Simplifying the part design and minimizing the number of features can make it easier to create with recycled plastic.

- Mold Design: The design of the mold can also impact the success of the injection molding process with recycled plastic. Designing the mold should consider any variations in the recycled plastic material and ensure its robustness to withstand the potentially abrasive nature of recycled plastic.

- Material Handling: Recycled plastic can be more susceptible to contamination or degradation than virgin plastic, so handling it carefully throughout manufacturing is vital. Store the material in a clean, dry environment and remove any contaminants before processing.

Recycling of Post-Consumer Plastic Waste

Post-consumer plastic waste is plastic that has served its intended purpose and is no longer needed, such as plastic packaging or single-use plastics. This type of plastic waste has become a major environmental issue, as it often ends up in landfills or the ocean. However, recycling post-consumer plastic waste can help to reduce the environmental impact and create new products. Here are some key points about the recycling of post-consumer plastic waste:

- Sorting and Collection: The first step in recycling post-consumer plastic waste is sorting and collection. To properly recycle plastic, it is necessary to sort the different types of plastic and eliminate any impurities, such as food scraps or non-plastic items. Curbside recycling programs, drop-off centers, or waste-to-energy facilities can facilitate the sorting and collecting of recycled plastic.

- Processing:After sorting and collection, the post-consumer plastic waste undergoes processing to transform it into reusable materials. Recyclers typically shred or melt the plastic and convert it into small pellets or flakes in plastic recycling. Manufacturers can utilize the resulting material as a raw material for manufacturing new products.

- Applications:Various applications, such as building materials, automotive parts, and consumer goods, can incorporate post-consumer plastic waste. Recycled plastic can make many products, including bags, bottles, furniture, and toys.

- Environmental Benefits:Recycling post-consumer plastic waste has numerous environmental benefits. It helps reduce plastic waste in landfills or the ocean, which can harm wildlife and pollute the environment. Recycling conserves resources and reduces the energy needed to produce new plastic products.

- Economic Benefits: Recycling post-consumer plastic waste can also have financial benefits. It creates jobs in the recycling and manufacturing industries and can reduce the cost of raw materials for companies. Additionally, recycling can reduce the cost of waste management and help cities and municipalities save money on landfilling and disposal costs.

- Challenges: Despite the benefits of recycling post-consumer plastic waste, stakeholders must address various challenges. For example, stakeholders must acknowledge that not all types of plastic are recyclable, and they should address the energy-intensive nature of the recycling process. Additionally, recycling rates vary widely across different regions and countries, and there is a need for improved infrastructure and technology to increase recycling rates.

Recycling of Post-Industrial Plastic Waste

Post-industrial plastic waste refers to plastic waste generated during the manufacturing process, such as scrap plastic from injection molding or extrusion. Recycling post-industrial plastic waste can help reduce waste and conserve resources. Here are some key points about the recycling of post-industrial plastic waste:

- Sorting and Collection: The first step in recycling post-industrial plastic waste is sorting and collection. To recycle plastic properly, sorting it by type and removing any impurities like metal or dirt is essential. Sorting and grouping can be done on-site at manufacturing facilities or through third-party recycling companies.

- Processing: After sorting and collecting, stakeholders process post-industrial plastic waste into reusable materials. The usual process includes shredding or grinding the plastic and transforming it into pellets or flakes. Manufacturers can use the resulting raw material to produce new products.

- Applications: Various applications, such as building materials, automotive parts, and consumer goods, can utilize post-industrial plastic waste. Recycled plastic can make many products, including packaging, flooring, and furniture.

- Environmental Benefits: Recycling post-industrial plastic waste has numerous environmental benefits. It helps reduce plastic waste in landfills, which can harm wildlife and pollute the environment. Recycling conserves resources and reduces the energy needed to produce new plastic products.

- Economic Benefits: Recycling post-industrial plastic waste can also have financial benefits. It creates jobs in the recycling and manufacturing industries and can reduce the cost of raw materials for companies. Additionally, recycling can reduce the cost of waste management and help companies save money on disposal costs.

- Challenges:Despite the benefits of recycling post-industrial plastic waste, we must address the challenges. For example, the quality of recycled plastic can vary depending on the source and processing method. Furthermore, recycling can consume a significant amount of energy, and recycling all plastic types may be challenging.

Quality Control in Recycled Plastic Injection Molding

Quality control is essential in any manufacturing process, especially for recycled plastic injection molding. Recycled plastic materials can vary in quality and consistency, impacting the final product. Here are some critical points about quality control in recycled plastic injection molding:

- Material Selection: The first step in quality control is selecting the appropriate recycled plastic material for the manufactured product. Different types of recycled plastic have varying properties, such as stiffness, strength, and heat resistance, which can impact the final product.

- Testing and Validation: The recycled plastic material should be tested and validated before production to ensure it meets the required specifications. One way to determine the quality of a material is by conducting tests on its physical properties, like tensile strength and elongation, as well as it’s chemical properties, like melt flow rate and thermal stability.

- Process Monitoring: To ensure consistency and quality, one should closely monitor the injection molding process during production. To ensure a perfect final product, monitoring injection pressure, temperature, and cooling time is essential. Additionally, inspecting the finished product for any defects is crucial.

- Post-Production Inspection: To meet the required specifications, one should inspect the final product. We need to examine an item’s appearance and analyze its physical and chemical characteristics.

- Record Keeping: Quality control also involves keeping detailed records of the production process and any deviations or issues. This process makes it easier to pinpoint areas that need improvement and maintain consistency in upcoming production runs.

- Continuous Improvement: Quality control is an ongoing process, and it is essential to continually evaluate and improve the process to ensure the highest quality products. The method may include introducing new technologies, enhancing training and education, and integrating input from clients and other parties involved.

Cost-Benefit Analysis of Recycled Plastic Injection Molding

Recycled plastic injection molding has numerous benefits, including reducing waste and conserving resources. However, like any manufacturing process, there are also costs associated with recycled plastic injection molding. Here are some key points about the cost-benefit analysis of recycled plastic injection molding:

- Cost Savings: One of the main benefits of recycled plastic injection molding is cost savings. Using recycled plastic materials can be less expensive than using virgin materials, which can reduce production costs. Additionally, recycling can reduce the cost of waste management and help companies save money on disposal costs.

- Environmental Benefits: Recycling plastic waste has numerous environmental benefits, such as reducing the amount of plastic waste that ends up in landfills and conserving resources. These benefits can have long-term economic benefits, such as reducing the cost of environmental cleanup and mitigating the effects of climate change.

- Quality Considerations: When utilizing recycled plastic materials, one must consider quality considerations. Recycled plastic materials can vary in quality and consistency, impacting the final product. Additional steps, such as testing and validation, may need to be taken in the manufacturing process to ensure consistent quality.

- Market Demand: The demand for environmentally friendly products has increased in recent years, and recycled plastic injection molding can help companies meet this demand. Producing eco-friendly products can help companies stand out and attract environmentally-conscious customers.

- Infrastructure Costs: Implementing a recycled plastic injection molding may require infrastructure upgrades or changes, such as purchasing new equipment or hiring additional staff. In the cost-benefit analysis, one should consider these costs.

- Regulatory Compliance: Regulations regarding waste management and environmental protection can impact the cost-benefit analysis of recycled plastic injection molding. Companies must comply with these regulations, which can require additional resources and expenses.

Regulations and Standards for Recycled Plastic Injection Molding

Recycled plastic injection molding is subject to a range of regulations and standards designed to ensure the safety and quality of the final product. Here are some key points about rules and standards for recycled plastic injection molding:

- Environmental Regulations:Recycled plastic injection molding is subject to many ecological regulations, including waste management and emissions control. These regulations protect the environment and public health by ensuring the safe and responsible management of waste.

- Material Standards:One must follow material standards when using recycled plastic materials in injection molding. These standards ensure the materials are safe and consistent, essential for producing high-quality products.

- Product Standards: One must follow product and material standards in recycled plastic injection molding. These standards ensure that the final product meets particular safety and quality requirements, such as strength, durability, and resistance to heat and chemicals.

- Health and Safety Standards: Recycled plastic injection molding must comply with health and safety standards, such as worker and product safety regulations. The purpose of these standards is to ensure worker and consumer safety and to guarantee the product’s security.

- Certification:Companies can seek accreditation from regulatory bodies or independent organizations to ensure compliance with these regulations and standards. Certification demonstrates that a company has met certain requirements and can help build trust with customers and stakeholders.

- International Standards: Many countries have regulations and standards for recycled plastic injection molding, but international standards apply. For instance, the International Organization for Standardization (ISO) has formulated environmental and quality management measures that companies can implement in recycled plastic injection molding.

Future of Recycled Plastic Injection Molding

Recycled plastic injection molding has recently gained popularity as companies and consumers become more environmentally conscious. As the world continues to face environmental challenges, the future of recycled plastic injection molding looks promising. Here are some key points about the end of this manufacturing process:

- Advancements in Technology: Technology is constantly advancing, and recycled plastic injection molding is no exception. Improvements in machinery and processes are making it easier and more efficient to recycle plastic waste and use it in injection molding. For instance, manufacturers are utilizing 3D printing technology to create new injection molds using recycled plastic materials.

- Increased Demand: As consumers become more environmentally conscious, the demand for recycled plastic products will likely increase. As a result, the need for recycled plastic injection molding will increase, likely spurring further innovation in the industry.

- Circular Economy: The circular economy is an economic model that focuses on recycling and reuse rather than disposal. Recycled plastic injection molding fits well into this model, as it takes waste plastic and turns it into new products. As the circular economy becomes more important, recycled plastic injection molding will play a more significant role in manufacturing.

- Government Support: Governments around the world are recognizing the importance of recycling and are providing support for companies that use recycled plastic in their products. This support can come from funding, tax incentives, and regulatory approval.

- Education and Awareness: Education and awareness campaigns are helping to promote the importance of recycling and the benefits of using recycled plastic materials in injection molding. As more people become aware of the benefits of recycling and the environmental impact of plastic waste, the demand for recycled plastic injection molding will likely increase.

Conclusion

In conclusion, recycled plastic injection molding offers a promising future for sustainable manufacturing. Companies can embrace a more environmentally friendly manufacturing process by taking advantage of technological advancements, increasing demand for eco-friendly products, and government support. Recycled plastic injection molding helps reduce plastic waste and offers a cost-effective and efficient solution for producing high-quality products. Moreover, recycled plastic injection molding provides an opportunity to contribute to the circular economy, which is becoming increasingly important in our society. We can create a more sustainable and efficient manufacturing process by reusing and recycling plastic waste.